Phase-change material packaging process and phase change heat storage product

A technology of phase change materials and packaging technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of lack of progress in packaging technology, achieve the effects of improving energy utilization, obvious energy saving effects, and reducing supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

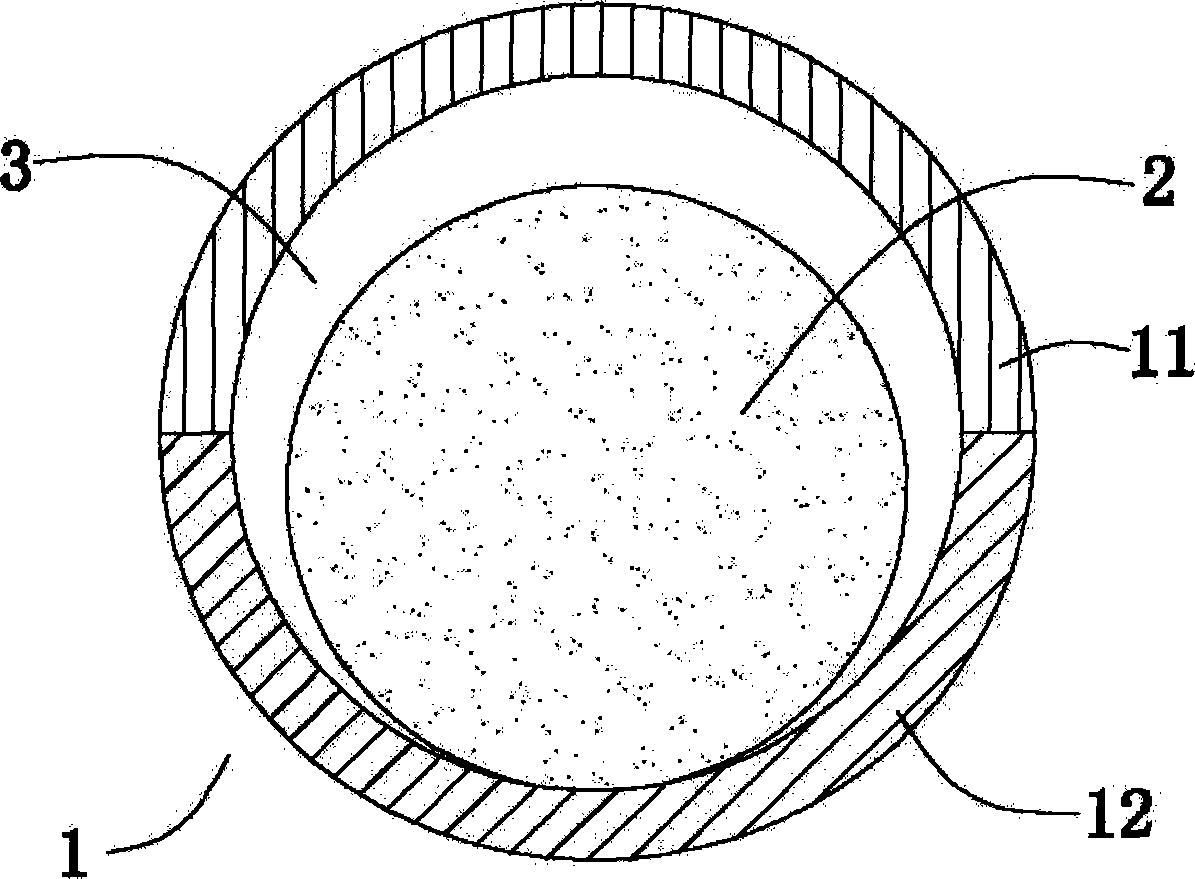

[0034] Example: see figure 1 , a phase change material packaging process provided in this embodiment, which includes the following steps:

[0035] (1) making an upper silica gel hemisphere 11 and a lower silica gel hemisphere 12 compatible with the upper silica gel hemisphere 11;

[0036] (2) Preparing a phase change material, the phase change material is a powdery or granular phase change material. In this embodiment, the phase change material is pressed into a sphere 2 by a thermocompression molding machine. In other embodiments, the phase change material can be wrapped with a film to form a sphere 2; the film is preferably 0.05 to 0.3 mm in thickness. PE film.

[0037] (3) Place the sphere 2 in the lower silica gel hemisphere 12, and then cover the upper silica gel hemisphere 11 on the lower silica gel hemisphere 12;

[0038] (4) Weld and join the joints of the upper silica gel hemisphere 11 and the lower silica gel hemisphere 12 by a hot plate machine to form a complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com