Efficient organic light-emitting diode and manufacturing method thereof

A light-emitting diode, high-efficiency technology, applied in the direction of organic light-emitting device, organic light-emitting device structure, semiconductor/solid-state device manufacturing, etc., can solve the problems of reducing the optical coupling output efficiency of the device, light loss, etc. properties, the effect of improving transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

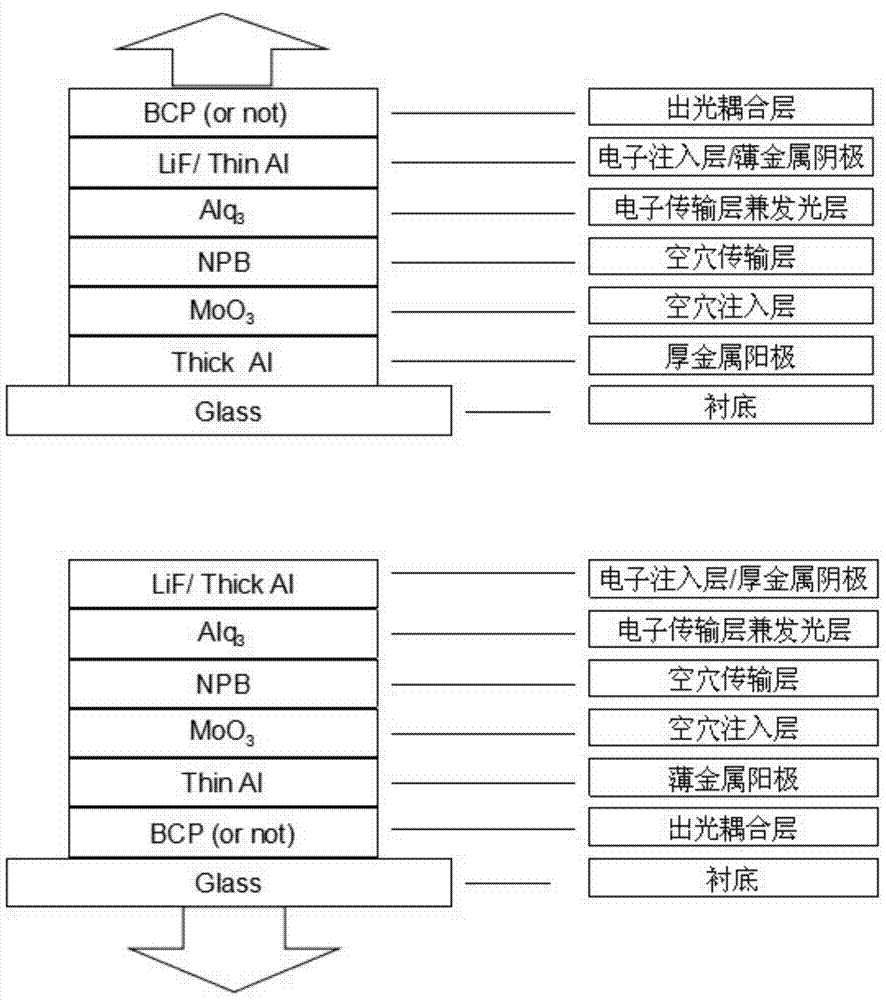

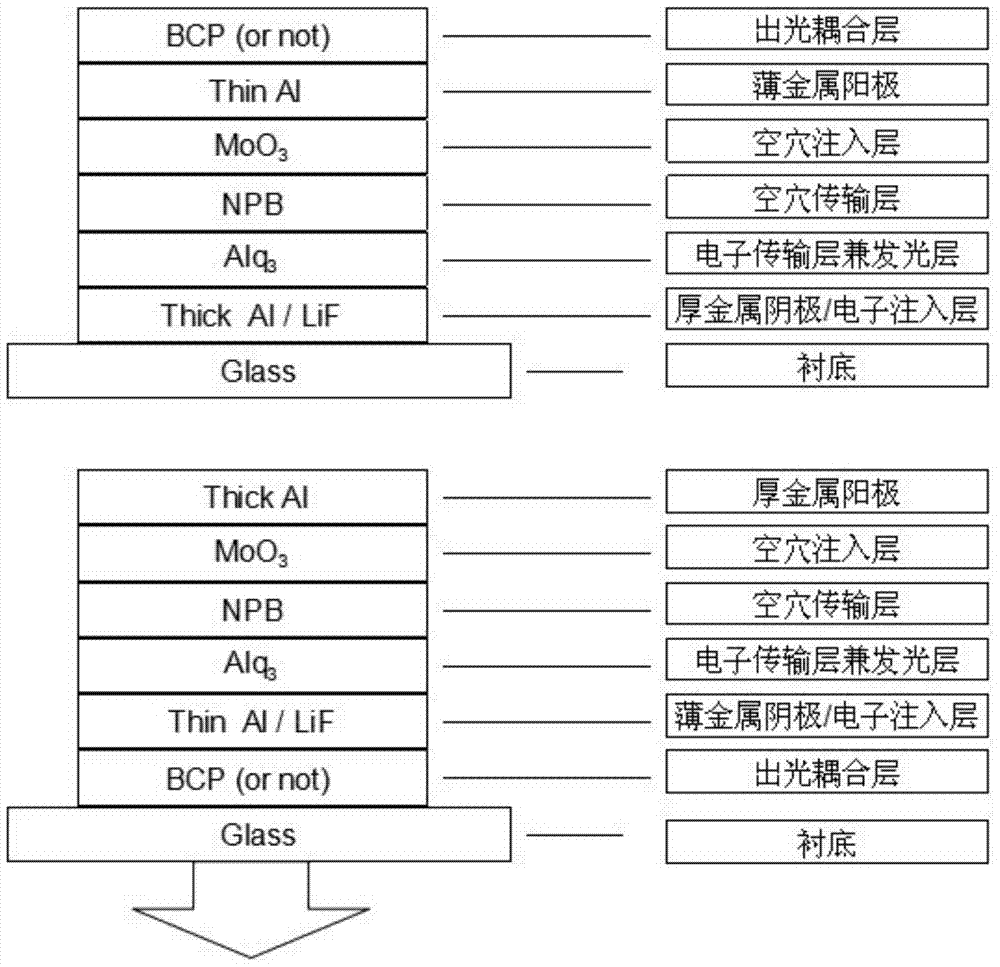

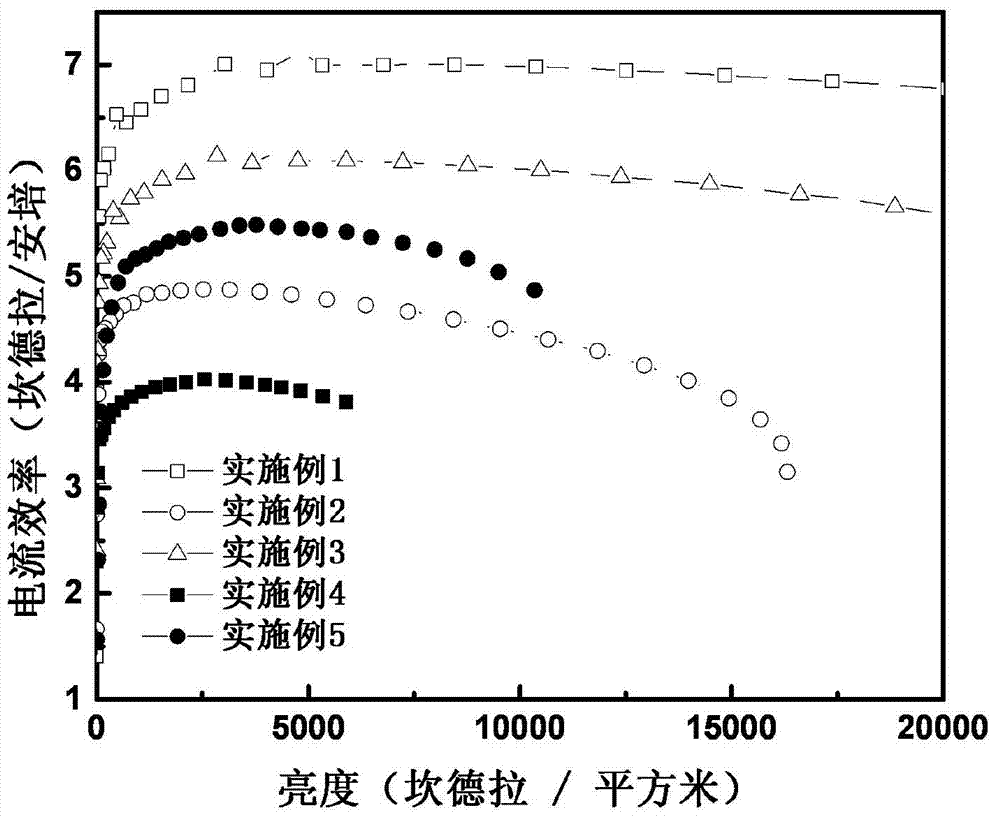

Embodiment 1

[0055] Clean the glass substrate with better flatness, blow it dry with nitrogen, place the glass substrate in a UV oven and treat it with ultraviolet ozone for 5 minutes, and finally put the glass substrate into a vacuum coating system. The organic material is placed in different evaporation sources, and the temperature of each evaporation source can be controlled individually. When the vacuum degree of the vacuum coating system reaches 3×10 -5 When it is below Pascal, first evaporate aluminum with a width of 4 mm and a length of 26 mm on the glass substrate as a thick metal anode. Then, the hole injection layer MoO was sequentially evaporated on the anode 3 , hole transport layer NPB, light emitting layer and electron transport layer Alq 3 , electron injection layer LiF and thin metal cathode Al, where the two electrodes intersect each other to form the light-emitting area of the device, the effective area of the light-emitting area is 16 square millimeters, thick meta...

Embodiment 2

[0057] Clean the glass substrate with better flatness, blow it dry with nitrogen, place the glass substrate in a UV oven and treat it with ultraviolet ozone for 5 minutes, and finally put the glass substrate into a vacuum coating system. When the vacuum degree of the vacuum coating system reaches 3×10-5 When it is below Pascal, first evaporate aluminum with a width of 4 mm and a length of 26 mm on the glass substrate as a thick metal anode. Then, the hole injection layer MoO was sequentially evaporated on the anode 3 , hole transport layer NPB, light emitting layer and electron transport layer Alq 3 , electron injection layer LiF and thin metal cathode Al, where the two electrodes intersect each other to form the light-emitting area of the device, the effective area of the light-emitting area is 16 square millimeters, thick metal anode, hole injection layer, hole transport layer, light-emitting layer The thicknesses of electron transport layer, electron injection layer an...

Embodiment 3

[0059] Clean the glass substrate with better flatness, blow it dry with nitrogen, place the glass substrate in a UV oven and treat it with ultraviolet ozone for 5 minutes, and finally put the glass substrate into a vacuum coating system. When the vacuum degree of the vacuum coating system reaches 3×10 -5 When it is below Pascal, first evaporate aluminum with a width of 4 mm and a length of 26 mm on the glass substrate as a thick metal anode. Then, the hole injection layer MoO was sequentially evaporated on the anode 3 , hole transport layer NPB, light emitting layer and electron transport layer Alq3, electron injection layer LiF, thin metal cathode Al and light coupling layer BCP, where the two electrodes cross each other to form the light emitting area of the device, and the effective area of the light emitting area is 16 mm2, the thicknesses of thick metal anode, hole injection layer, hole transport layer, light-emitting layer and electron transport layer, electron inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com