Patents

Literature

251results about How to "Pulling smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

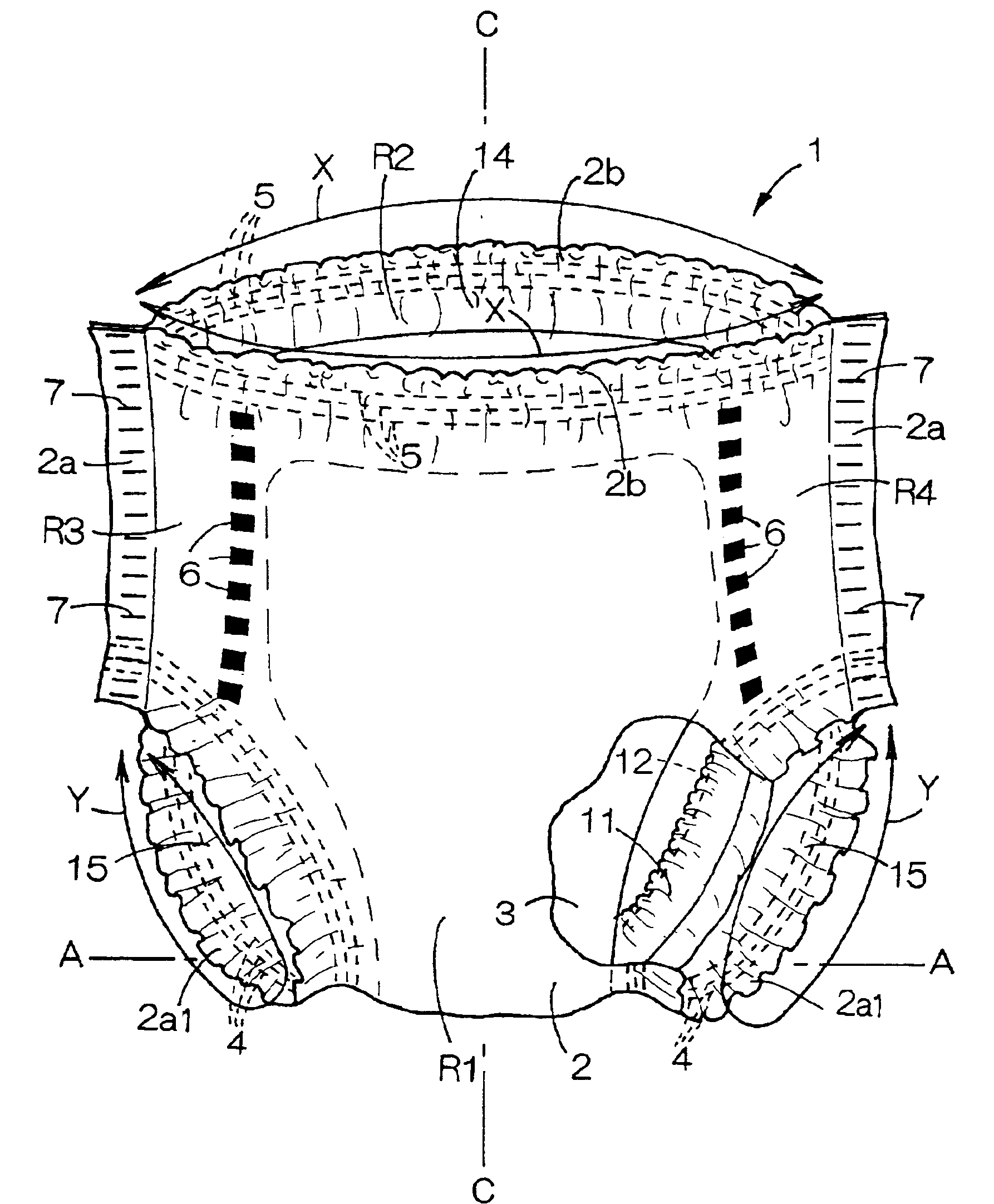

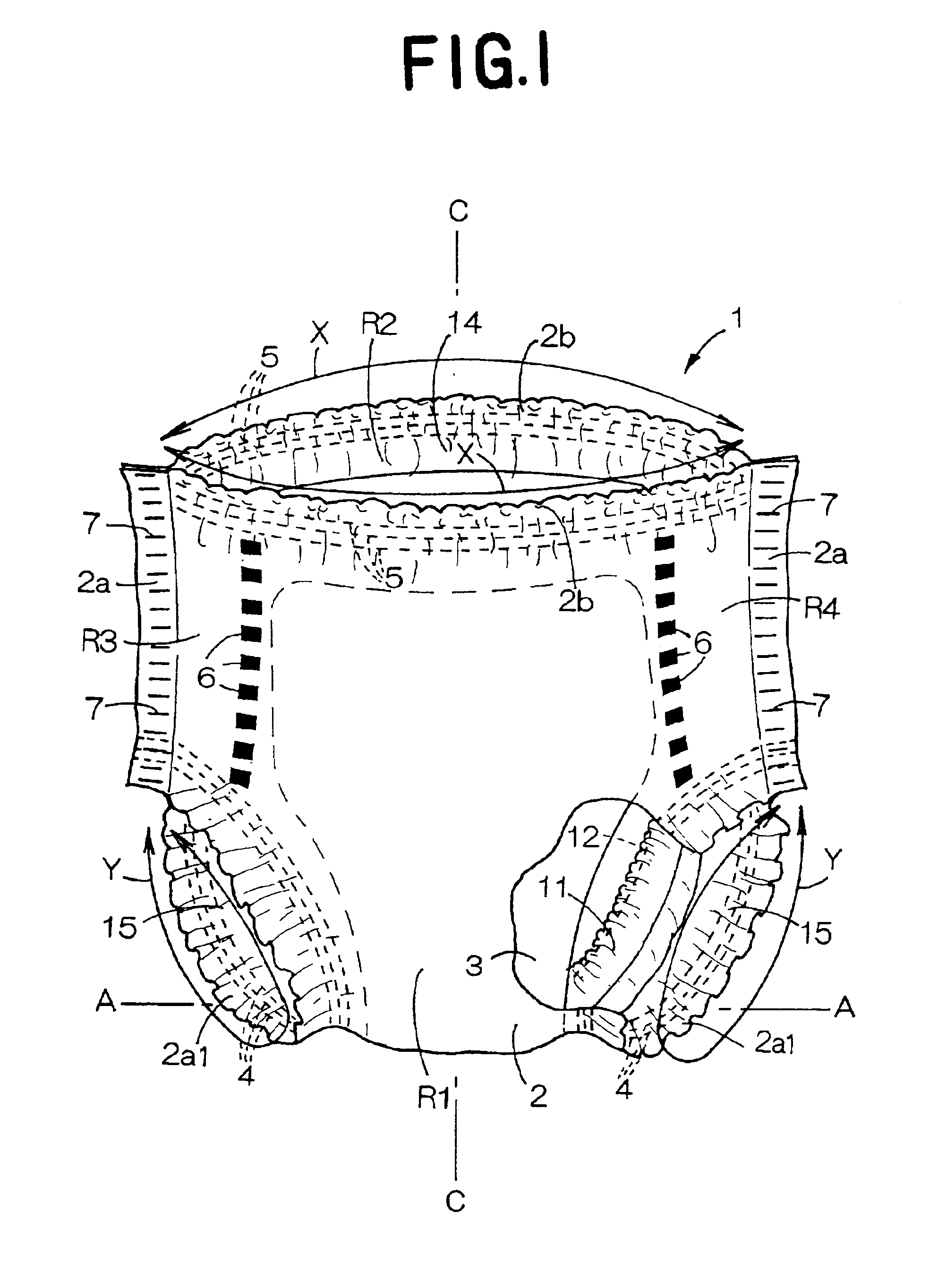

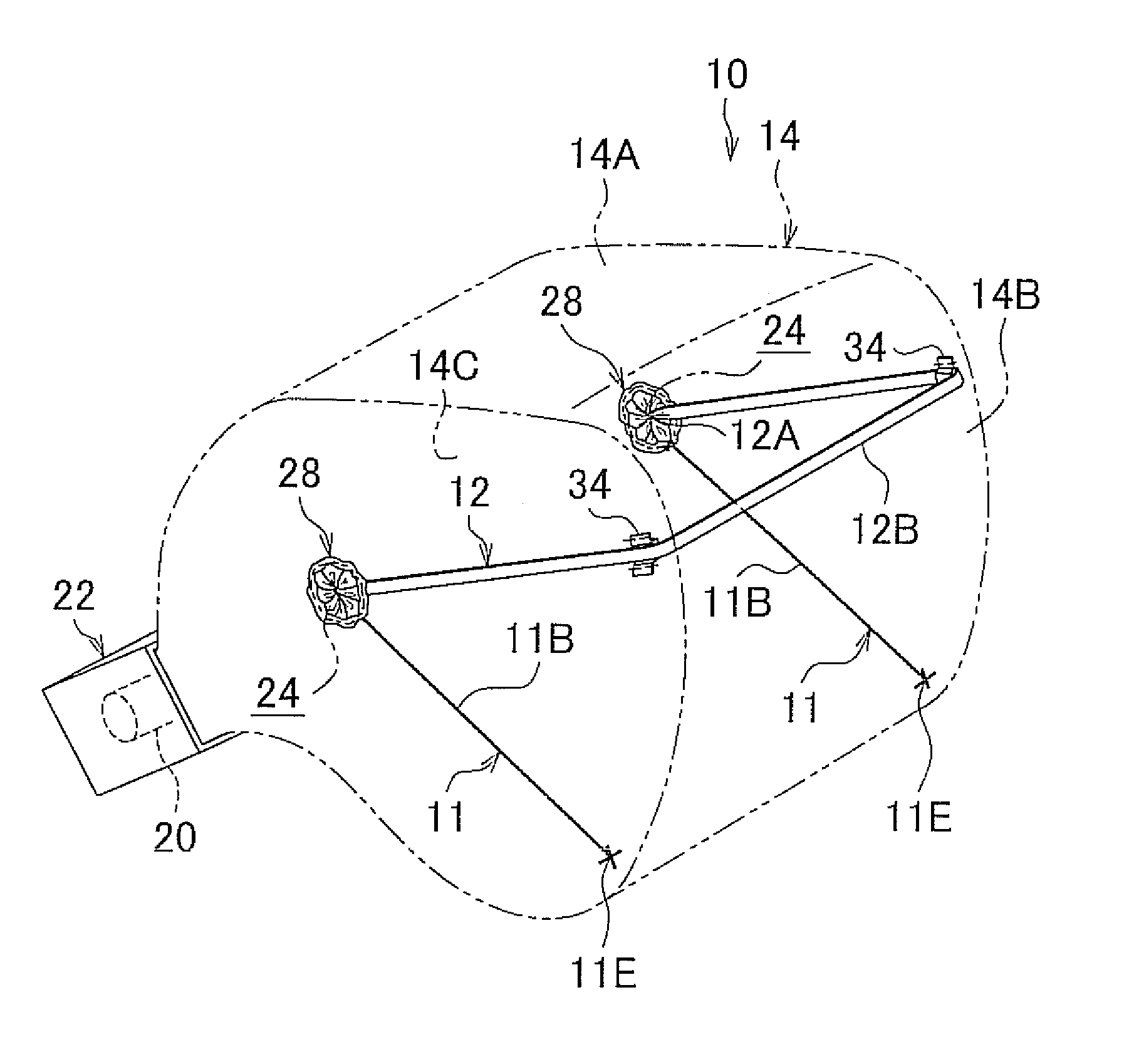

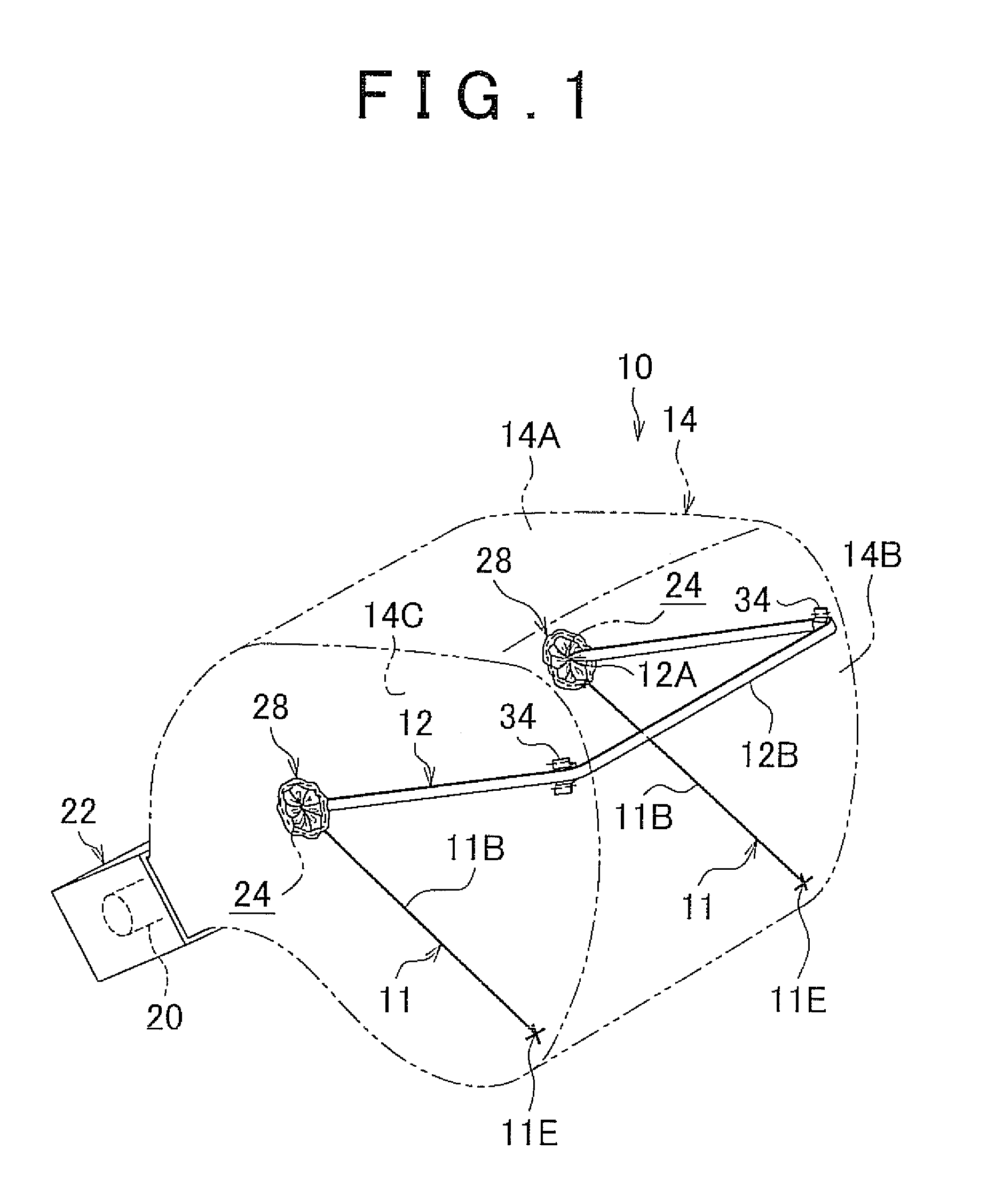

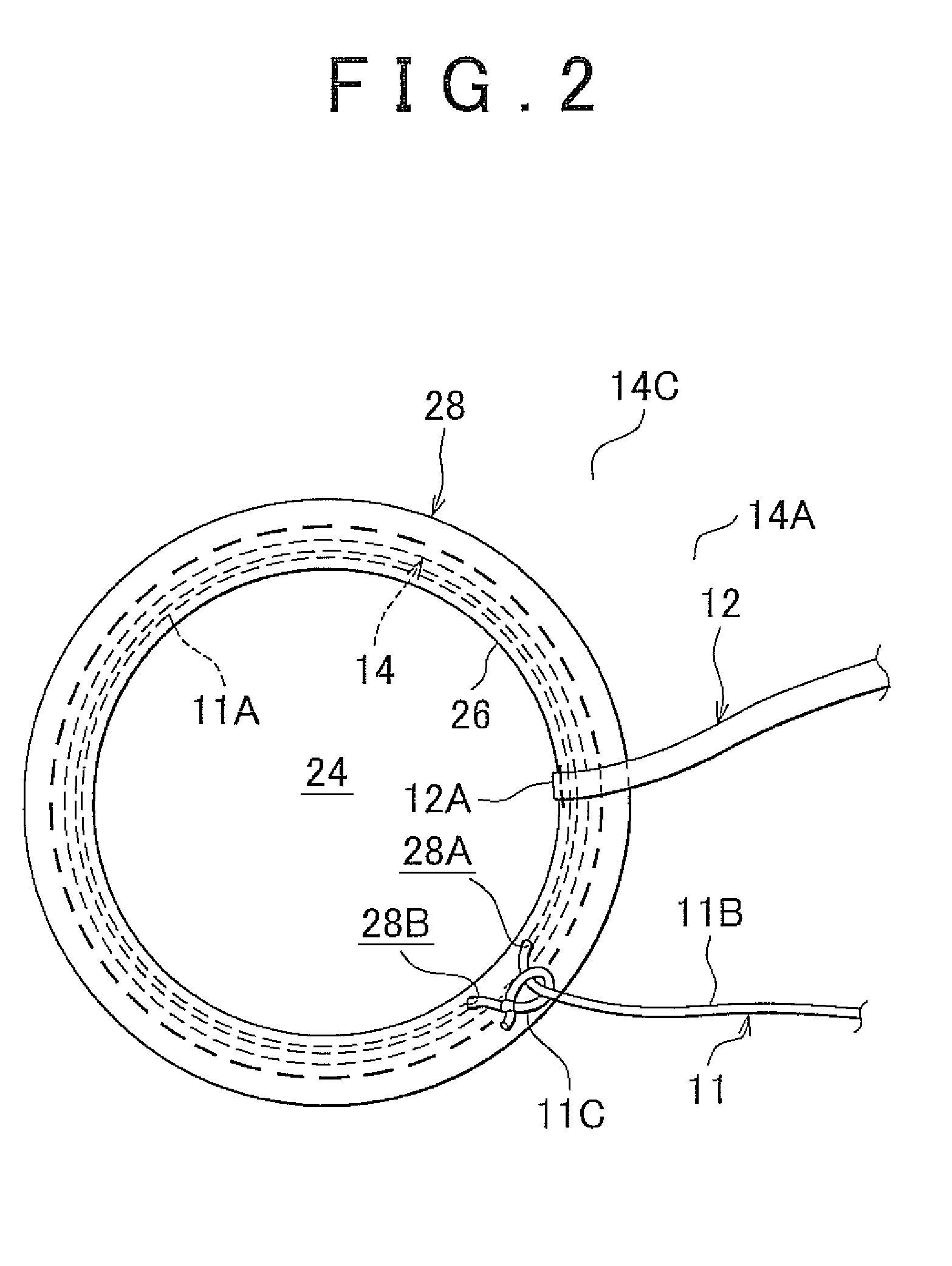

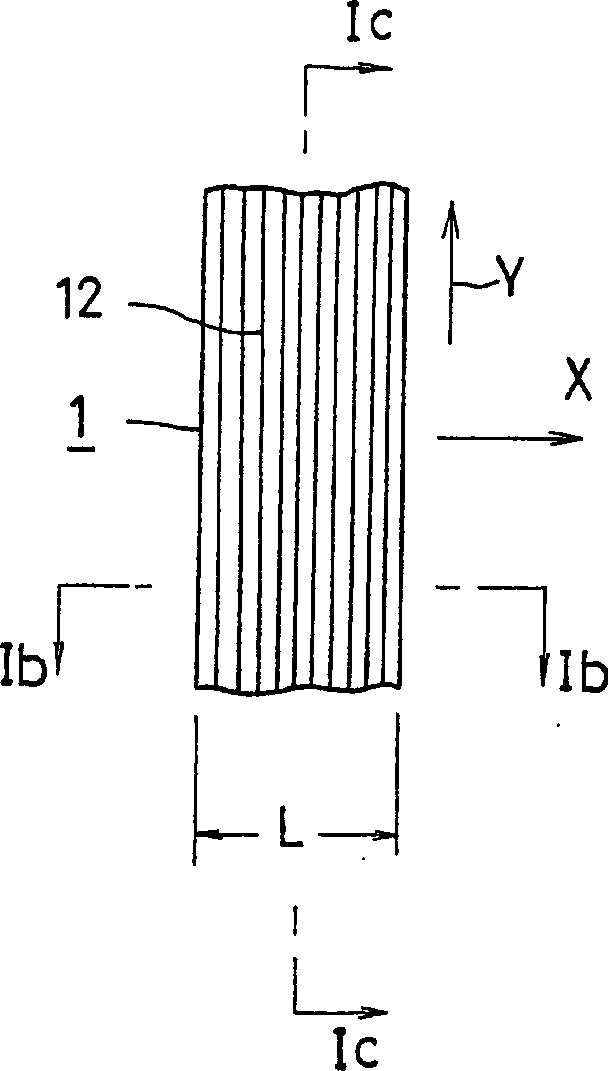

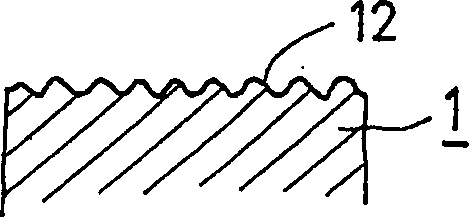

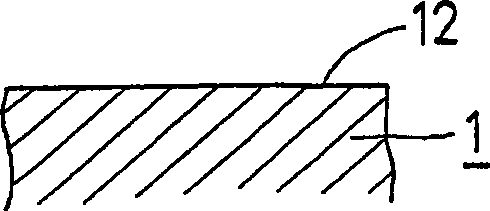

Elastically stretchable disposable pants

Elastically stretchable disposable pants that include first and second lateral waist regions, which are formed in at least a front waist region with substantially inelastic guide zones arranged intermittently in the longitudinal direction. The pants thus constructed can be smoothly pulled up to a desired level at which the pants are properly worn.

Owner:UNI CHARM CORP

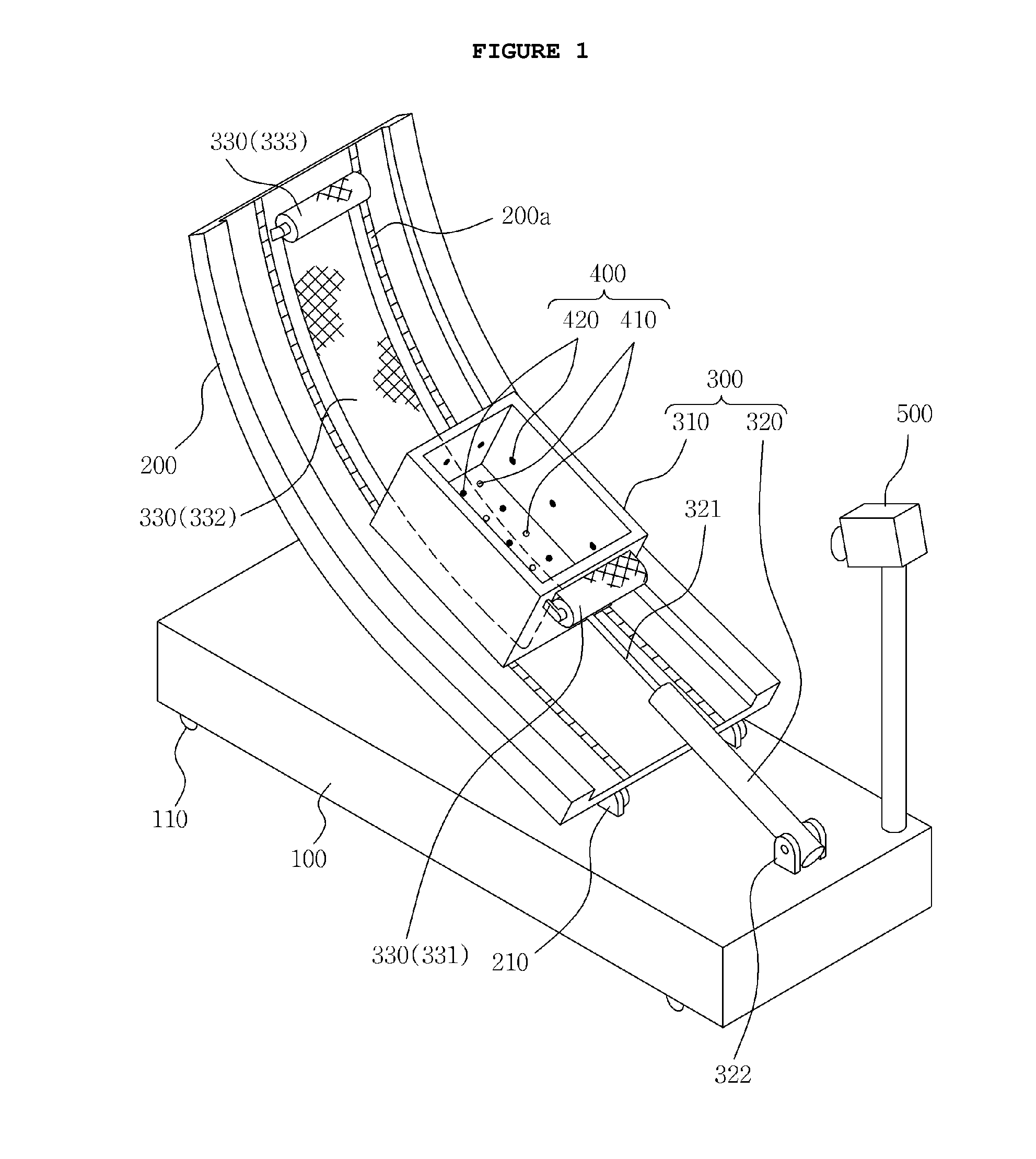

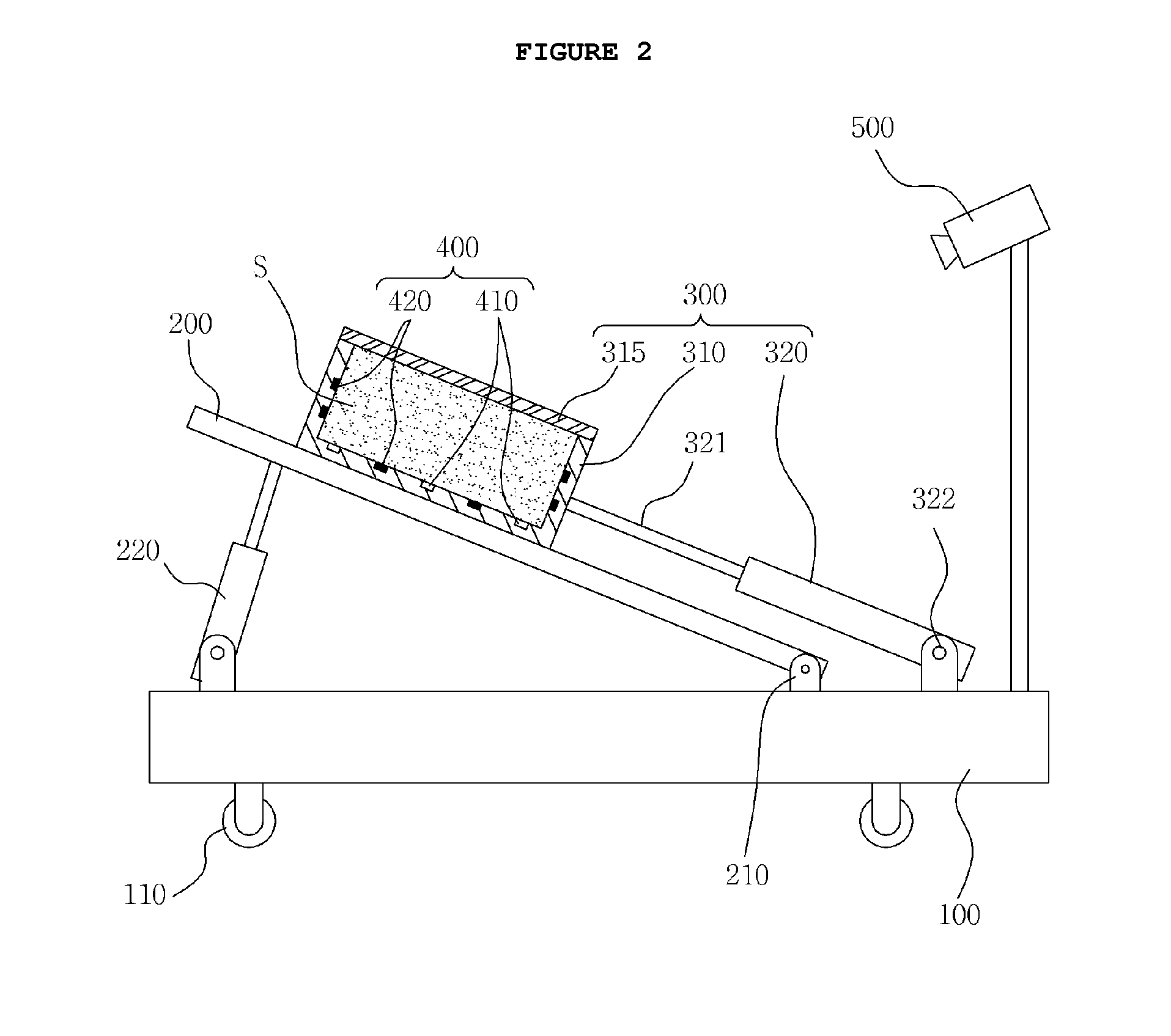

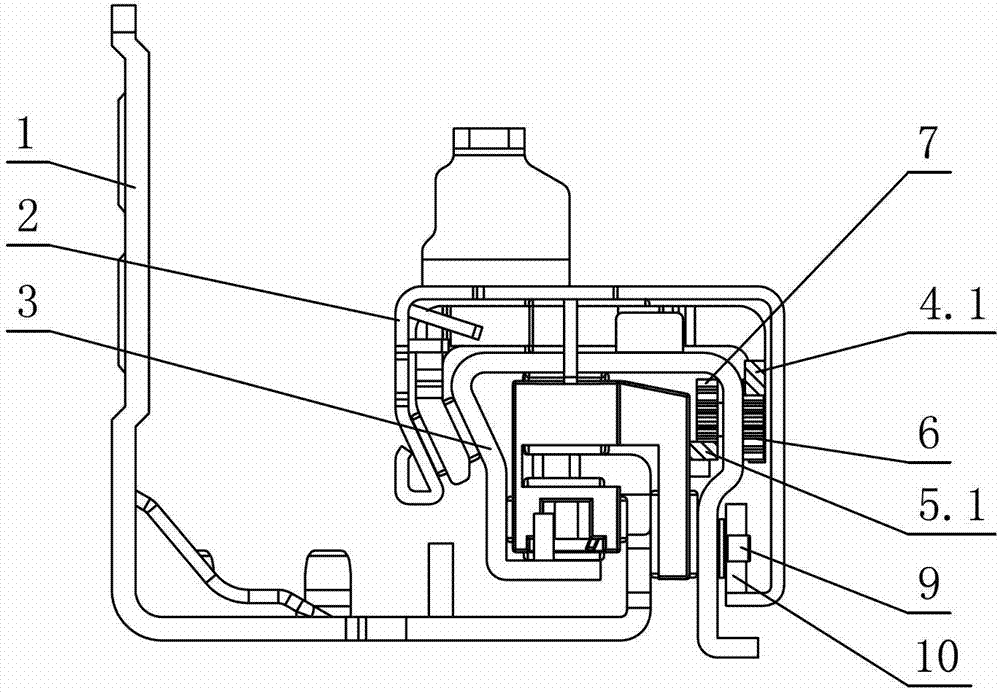

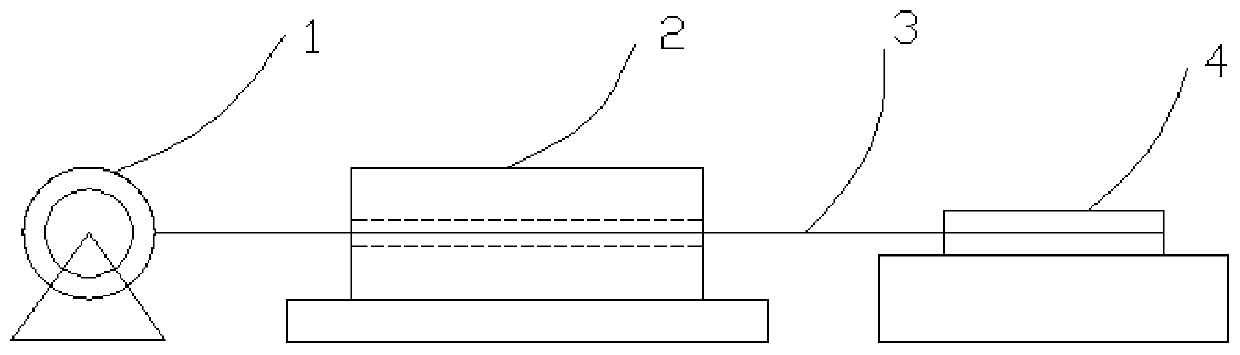

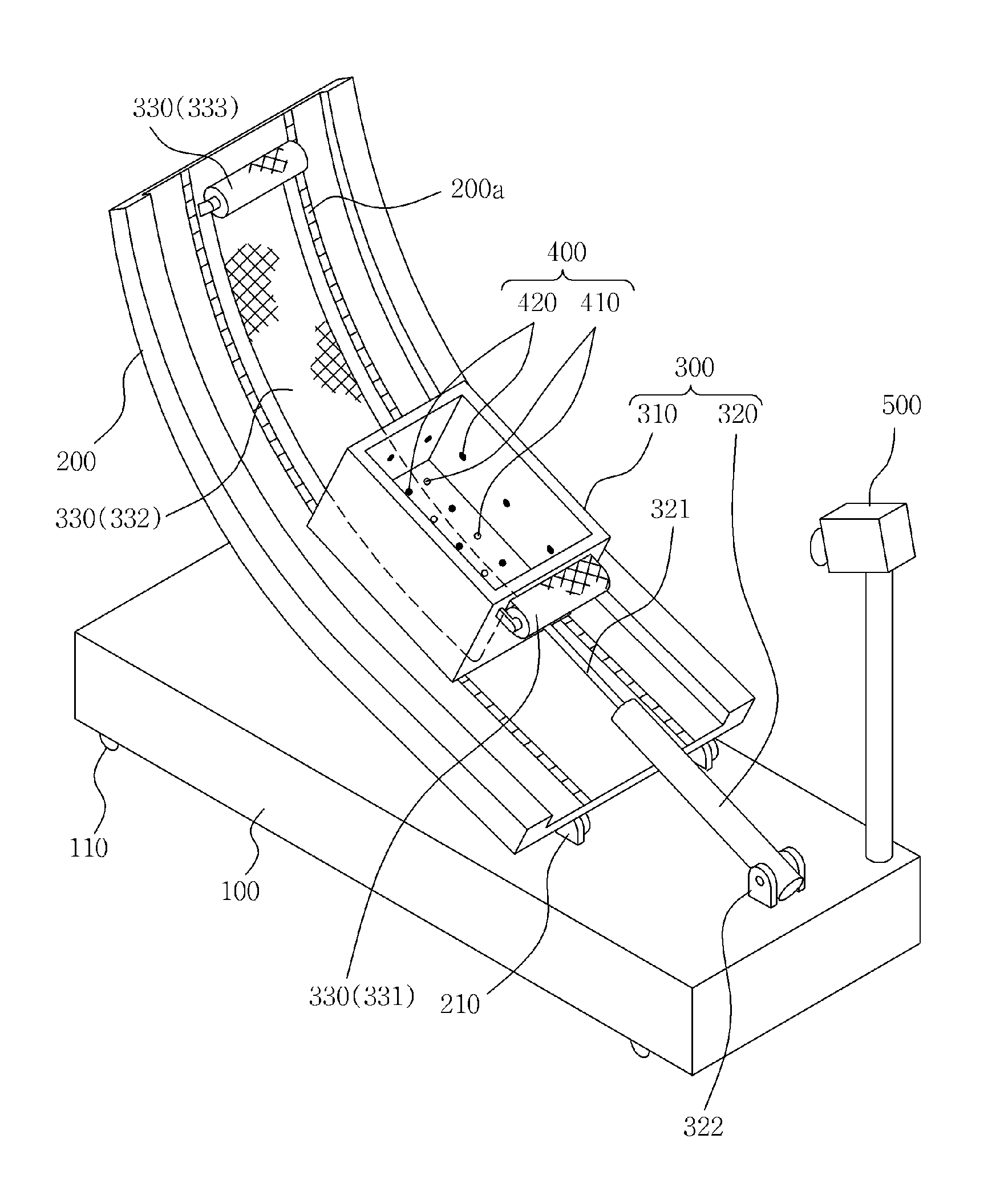

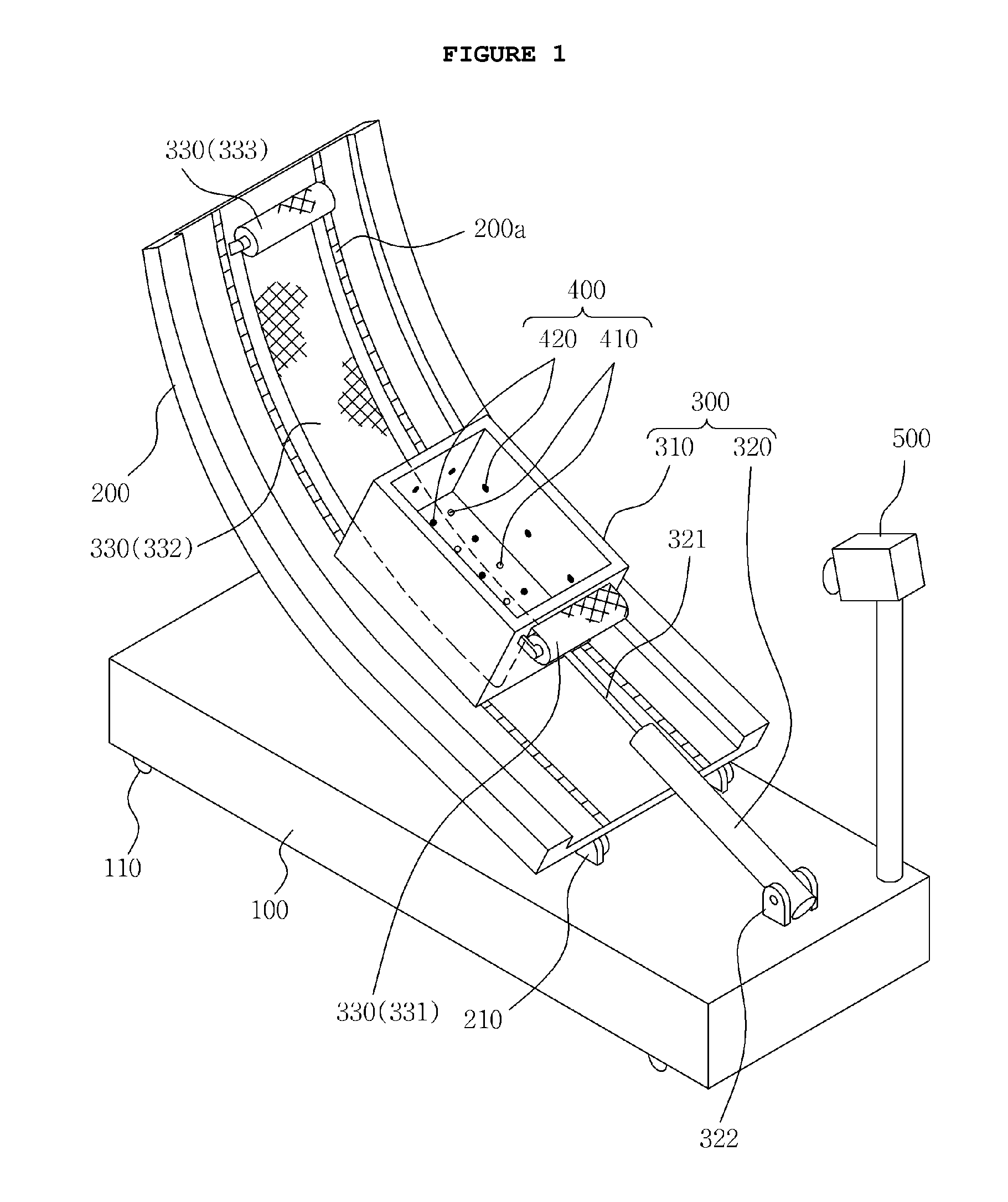

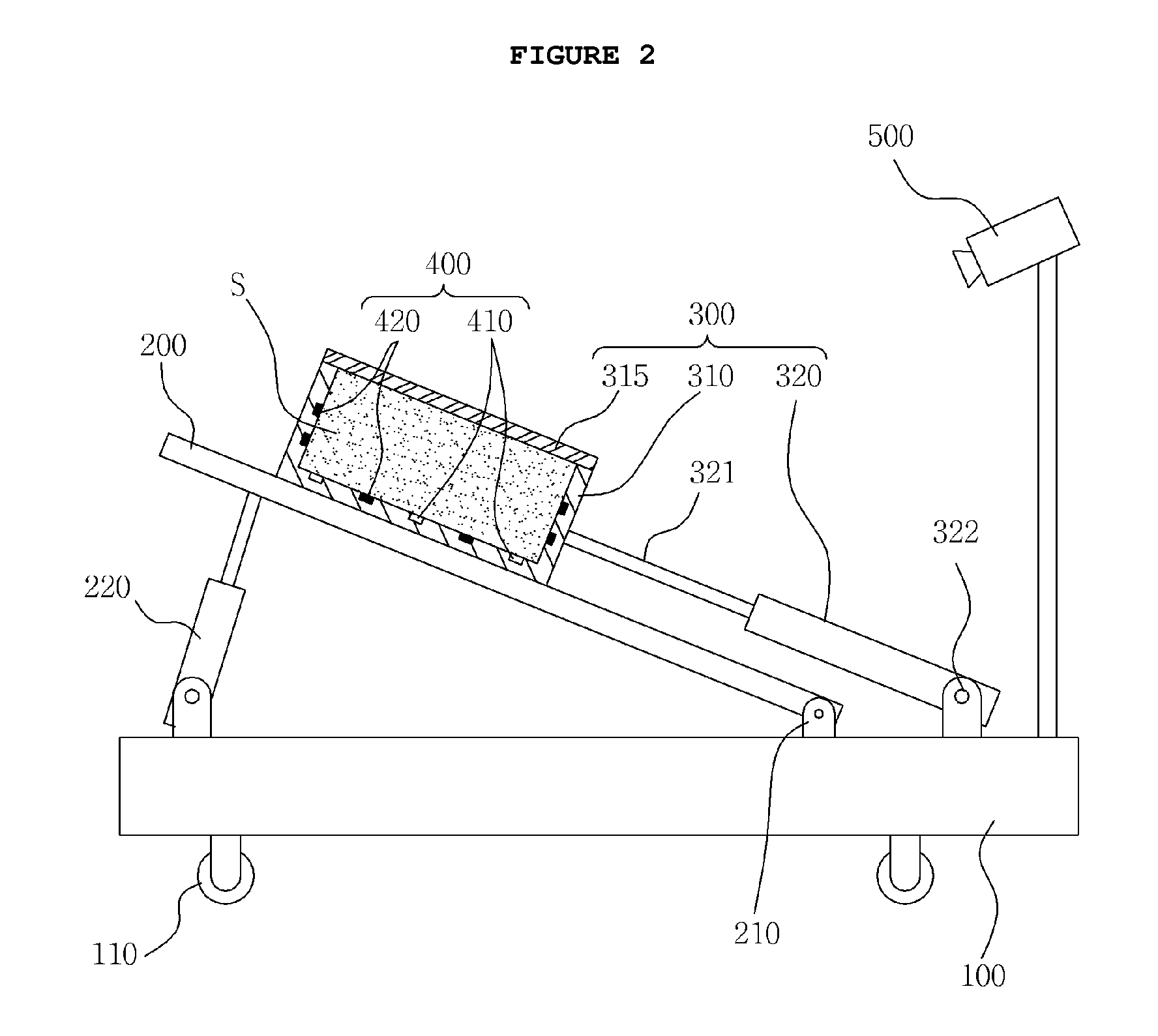

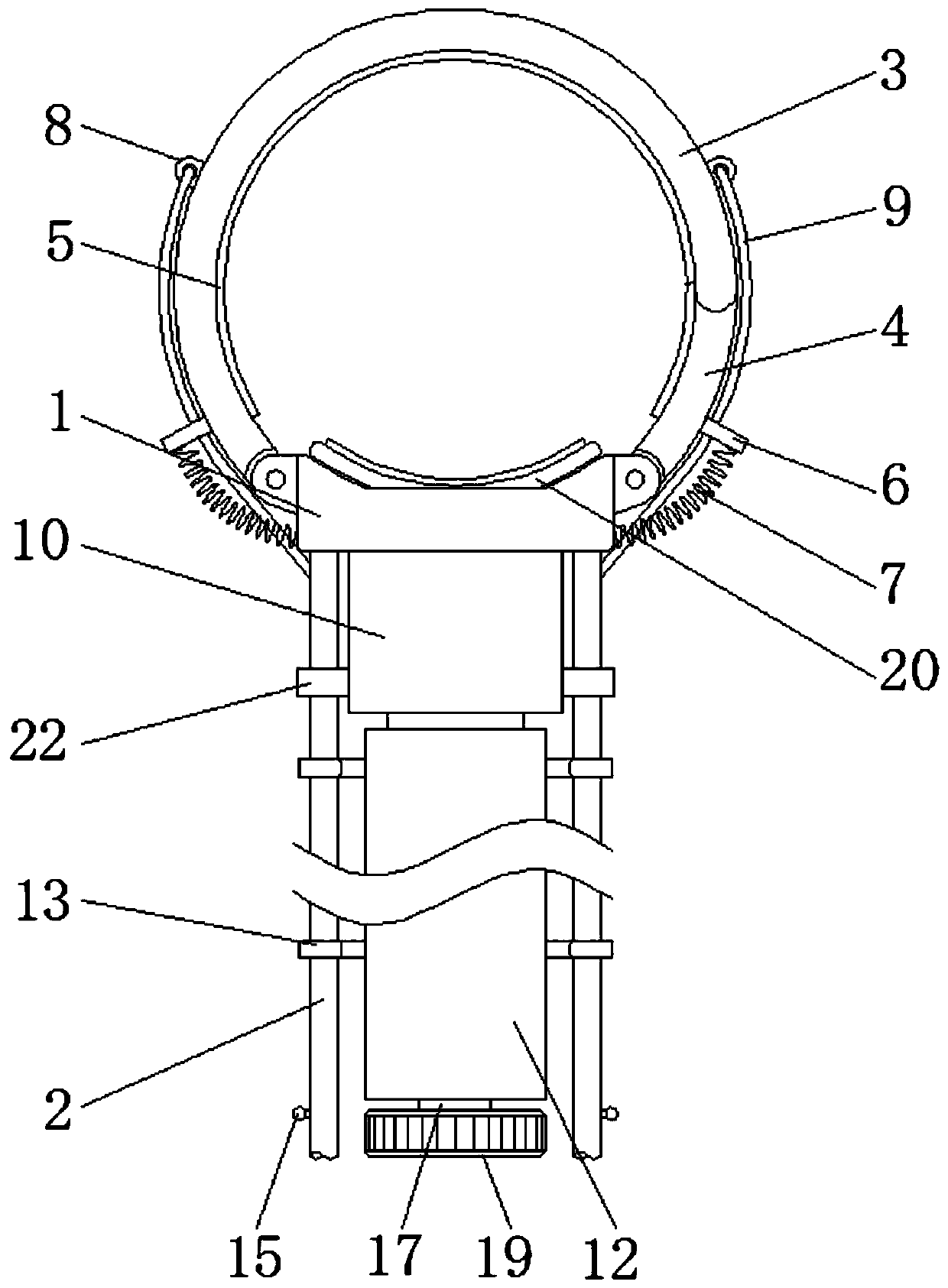

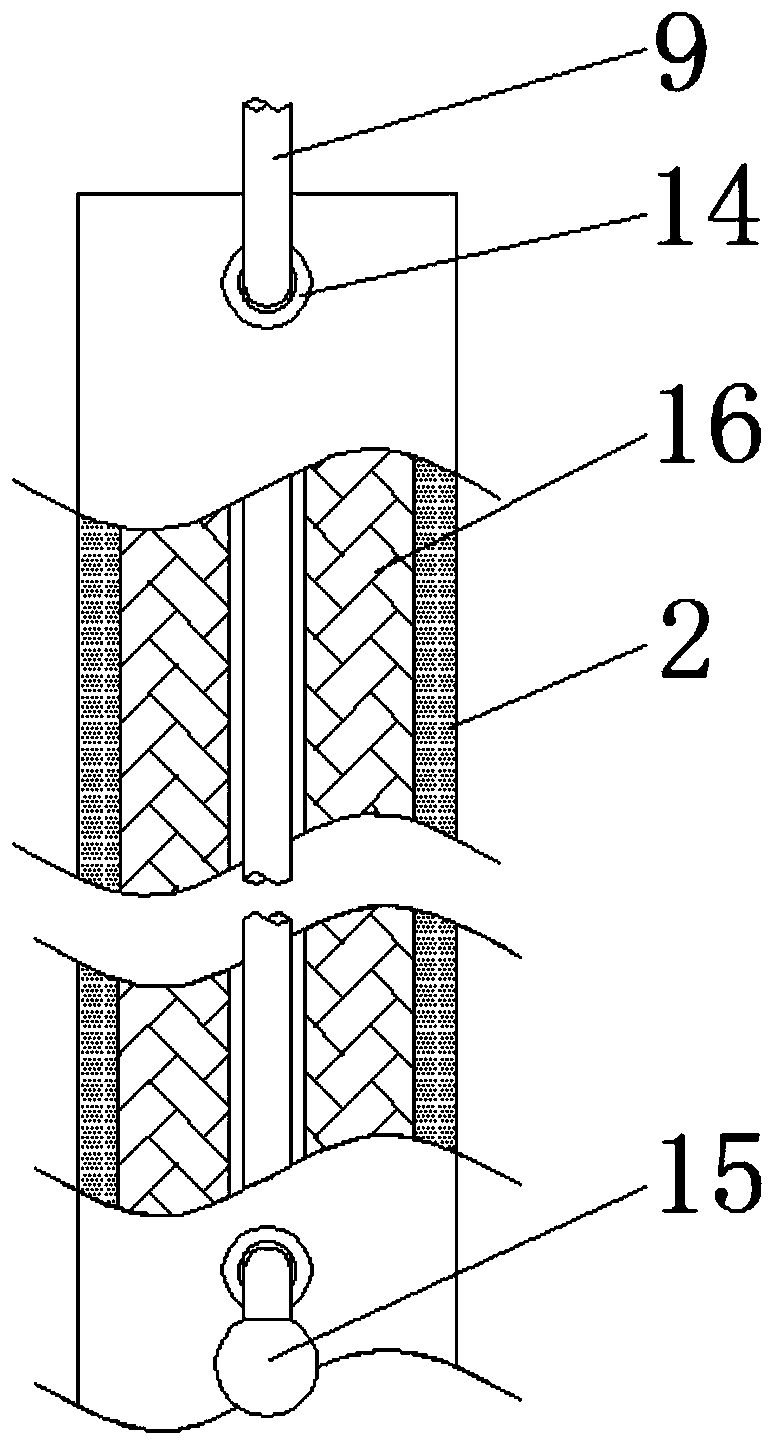

Test apparatus for early landslide detection fully-connected with pore water pressure, surface displacement and shear surface

ActiveUS20160047724A1Reliable test environmentSmoothly pullForce measurementEarth material testingEngineeringFactor of safety

Disclosed herein is a test apparatus for early landslide detection fully-connected with pore water pressure, surface displacement and shear surface. The test apparatus calculates a factor of safety of a slope based on variation in pore water pressure, surface displacement and shear surface of a soil mass, and predicts a change in factor of safety, thus making early landslide detection possible. In the test apparatus, while a container of a slider is moved with a soil mass loaded into the container, shear surface and surface displacement environment is provided, and the shear strength and the shear stress of the soil mass can be calculated based on the pore water pressure and the weight of the soil mass. Thereby, the factor of safety of the soil mass can be calculated, and early landslide detection can be realized by using variation of the factor of safety of the slope.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

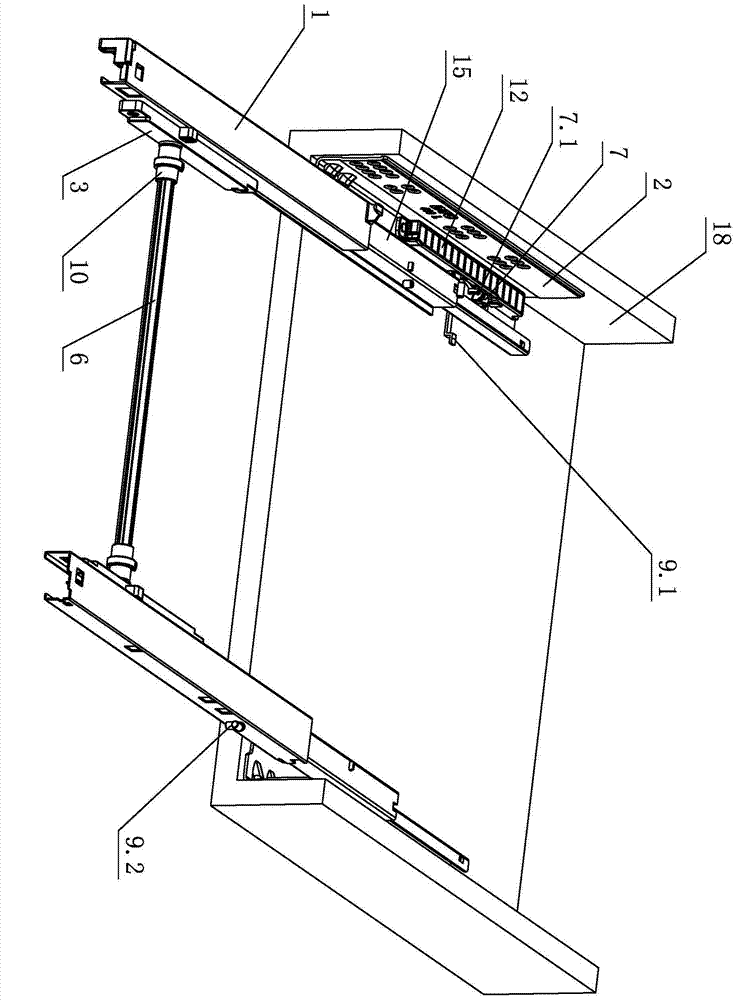

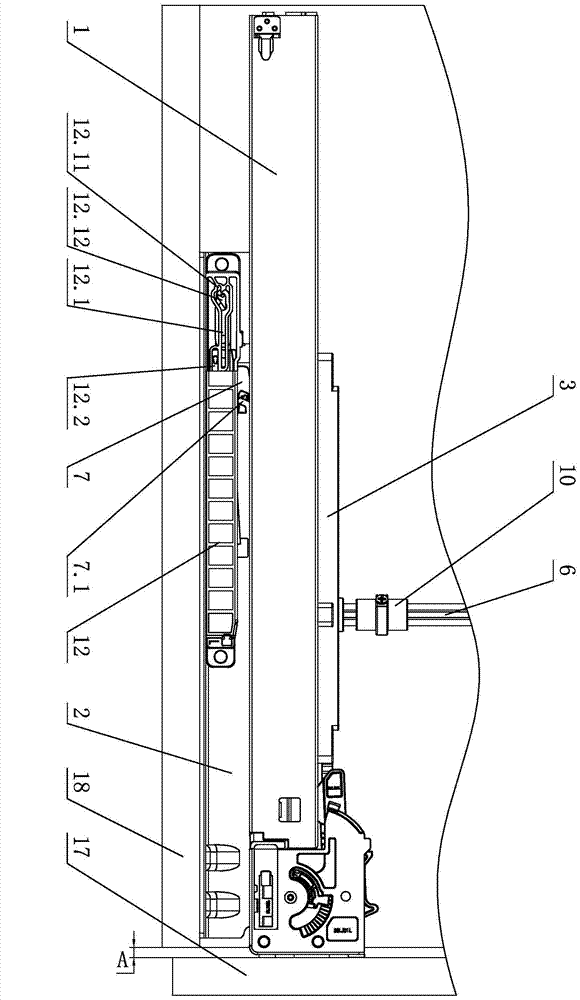

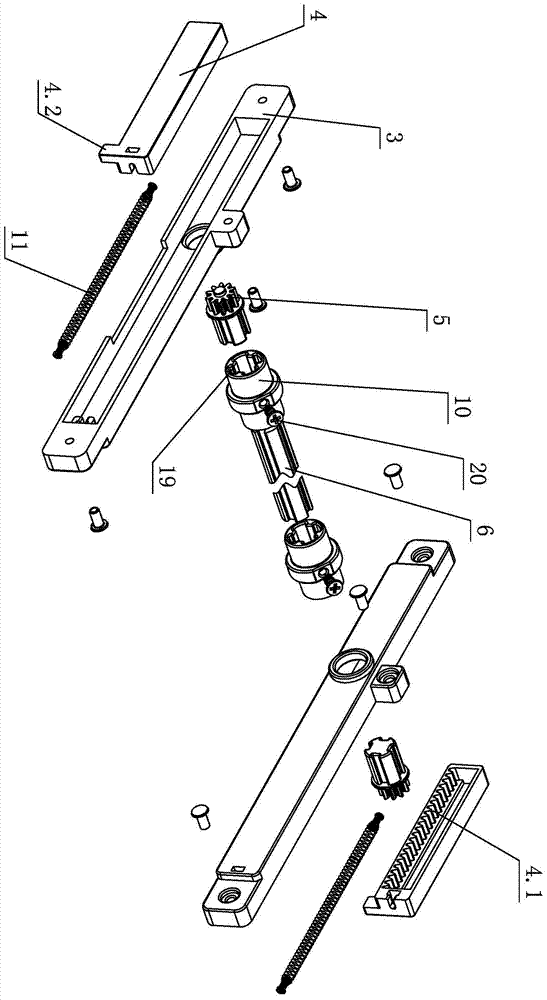

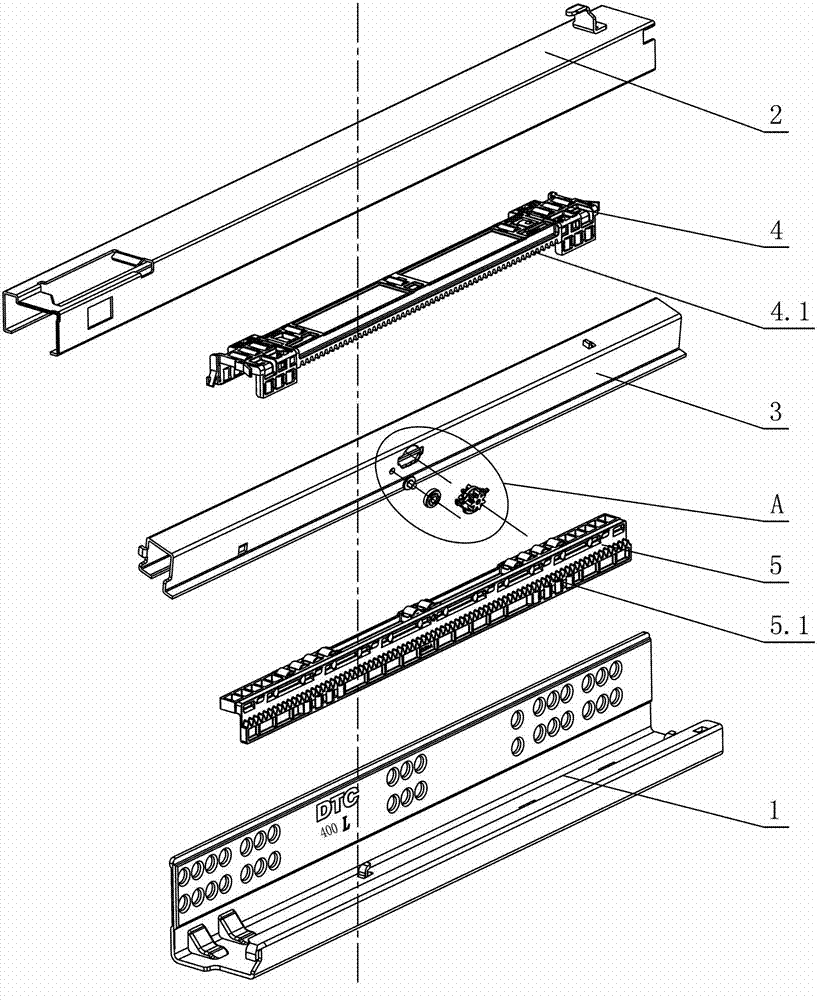

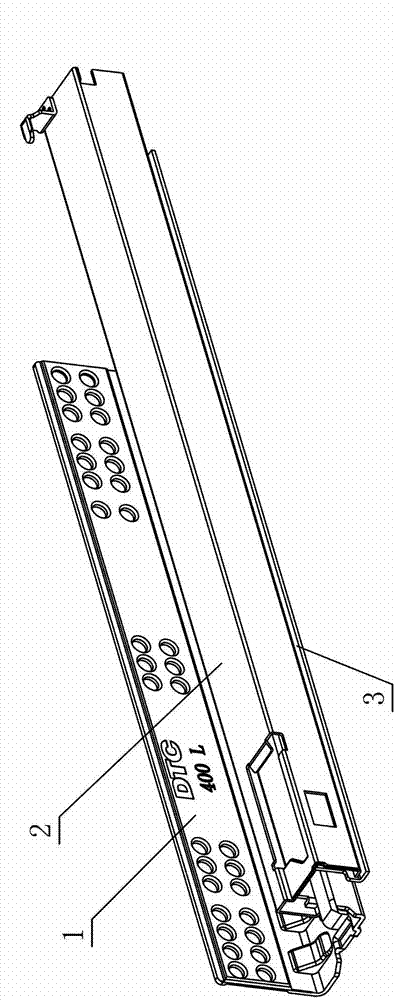

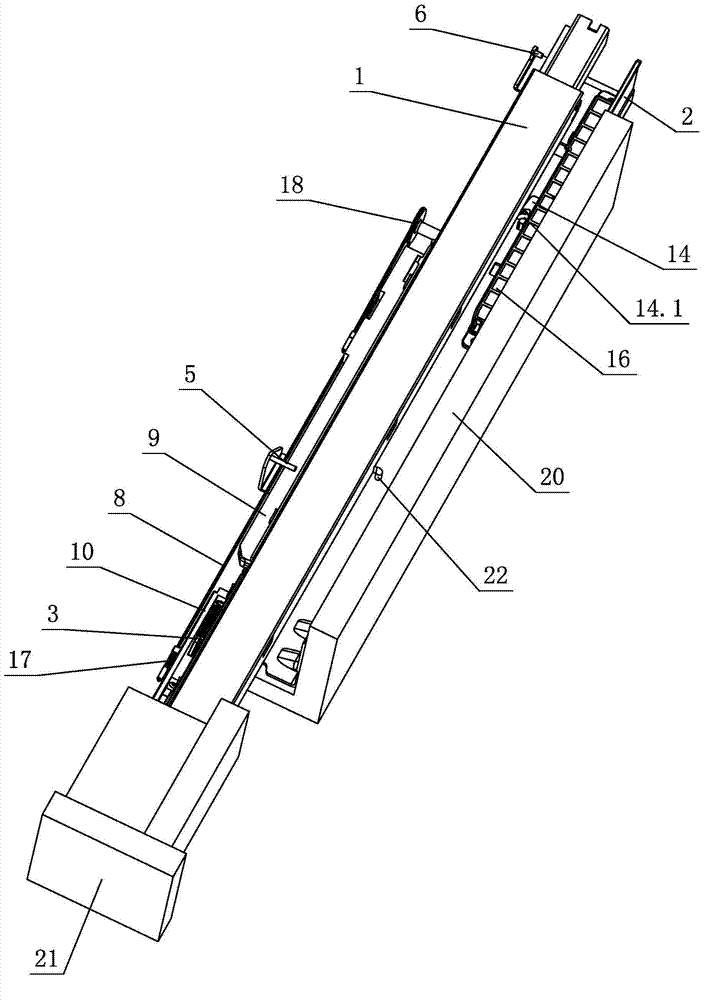

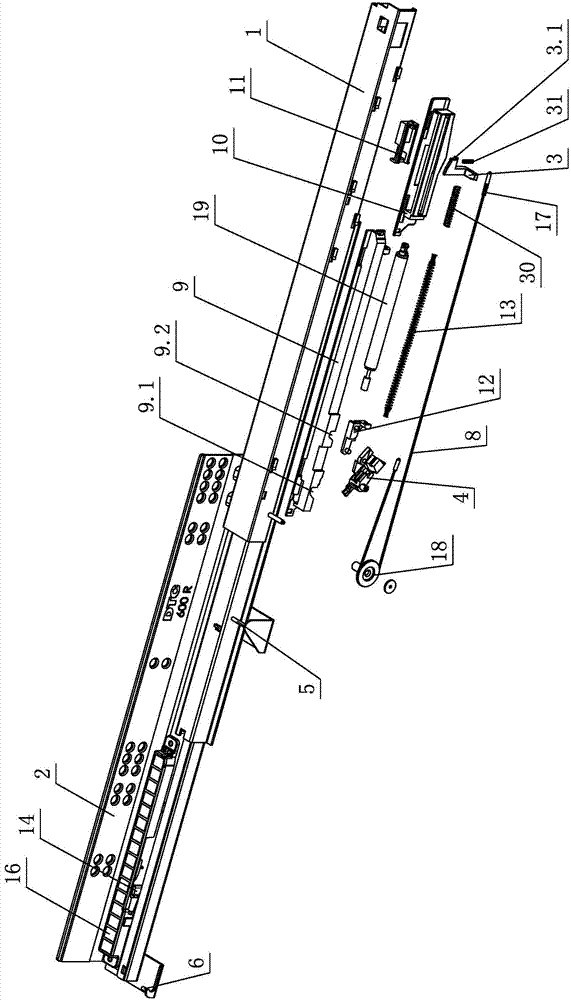

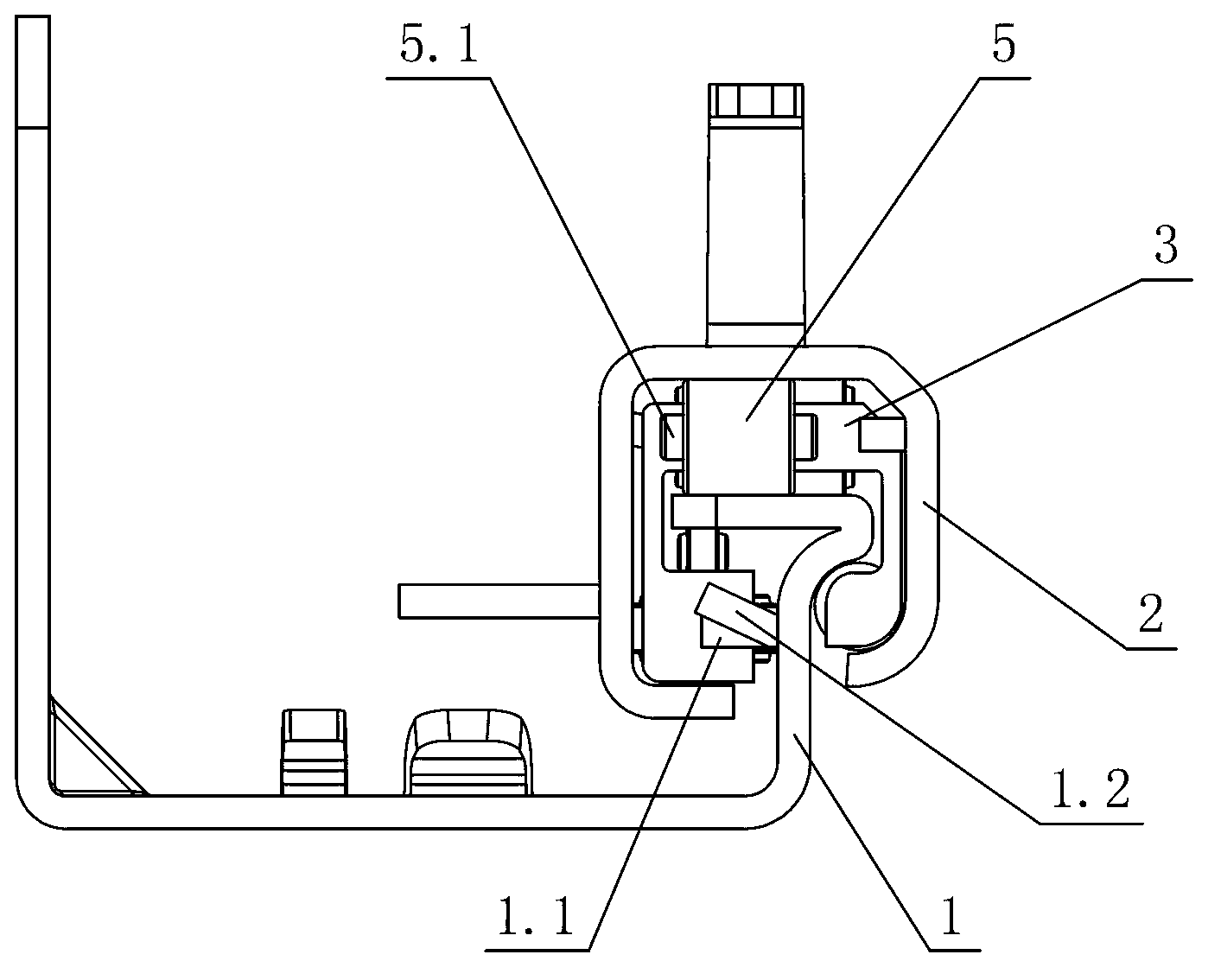

Synchronizing device of drawer sliding rails

A synchronizing device of drawer sliding rails comprises two sets of sliding rail assemblies arranged on a cabinet left side plate and a cabinet right side plate, wherein a drawer is arranged on the sliding rail assemblies and is at least composed of a bottom and a front panel, each sliding rail assembly is at least composed of a movable sliding rail and a fixed sliding rail, a drawer synchronizing device body is arranged on the left movable sliding rail and the right movable sliding rail or the left fixed sliding rail and the right fixed sliding rail and at least comprises a sliding groove base and a sliding block, the sliding block acts on the sliding groove base, racks are arranged on the sliding block, gears mutually meshed with the racks are rotationally arranged on the sliding groove base and correspond to the racks, and the left gear and the right gear are connected through a rotating connecting rod to achieve synchronous opening and closing of the left sliding rail assembly and the right sliding rail assembly; a poking block is arranged on the movable sliding rails or the fixed sliding rails, and a stopping part is arranged on the sliding block and is loaded on the poking block through elasticity of an elastic part at least when a suspending distance A is preserved between the front panel and the cabinet side plates; the sliding block acts on the poking block through the stopping part in at least one segment of travel when the drawer is opened or closed so that the sliding block can slide on the sliding groove base.

Owner:伍志勇

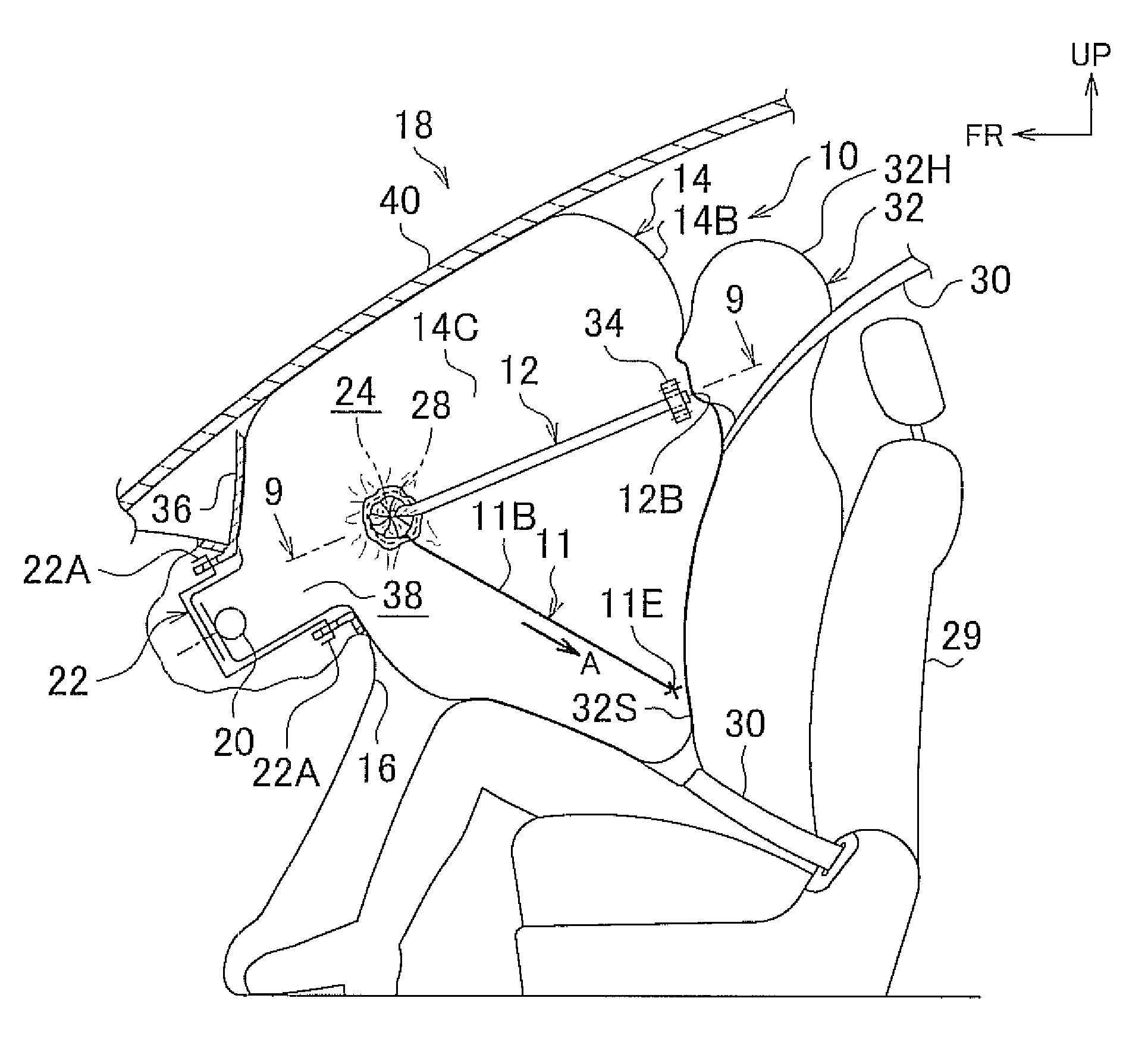

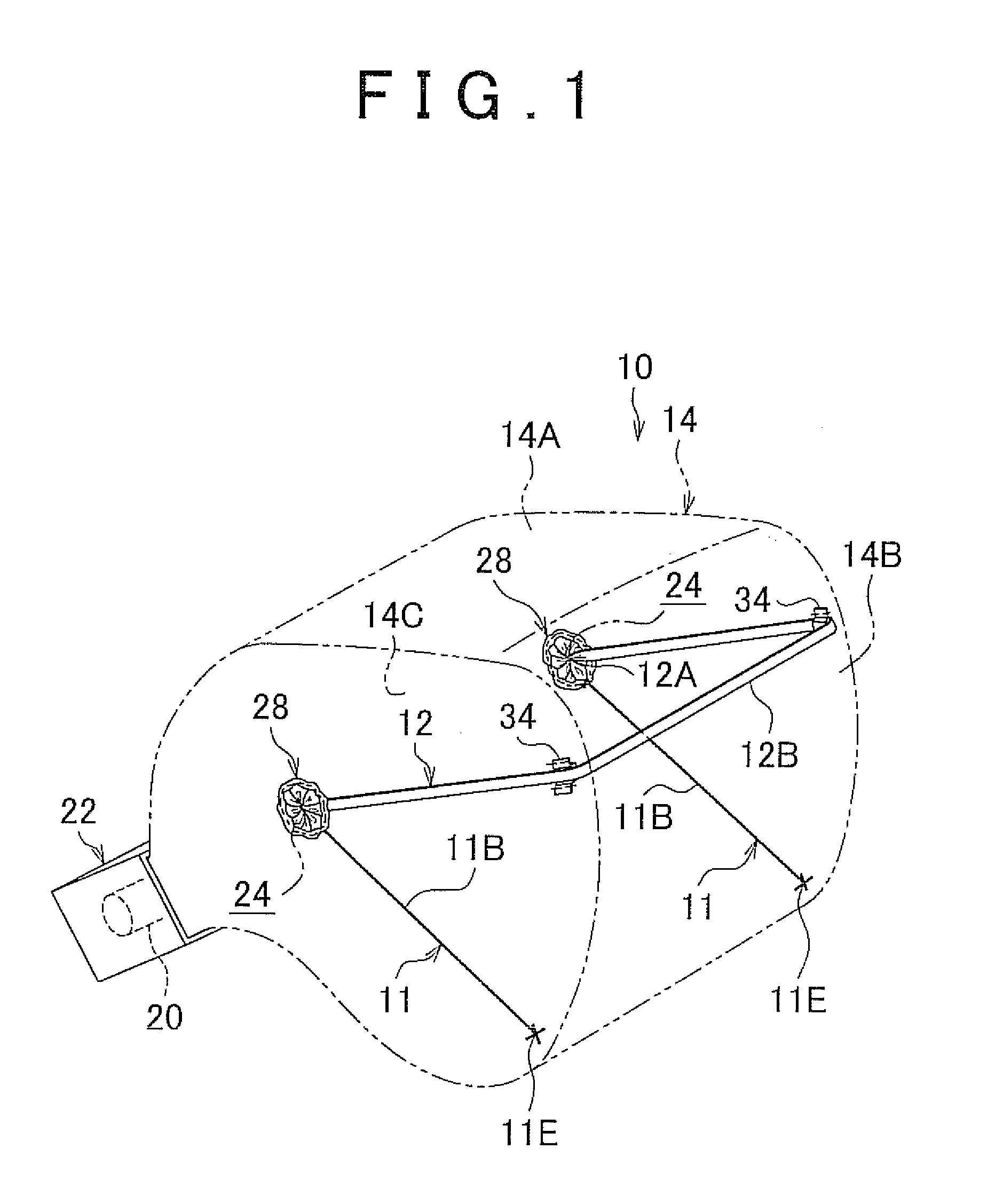

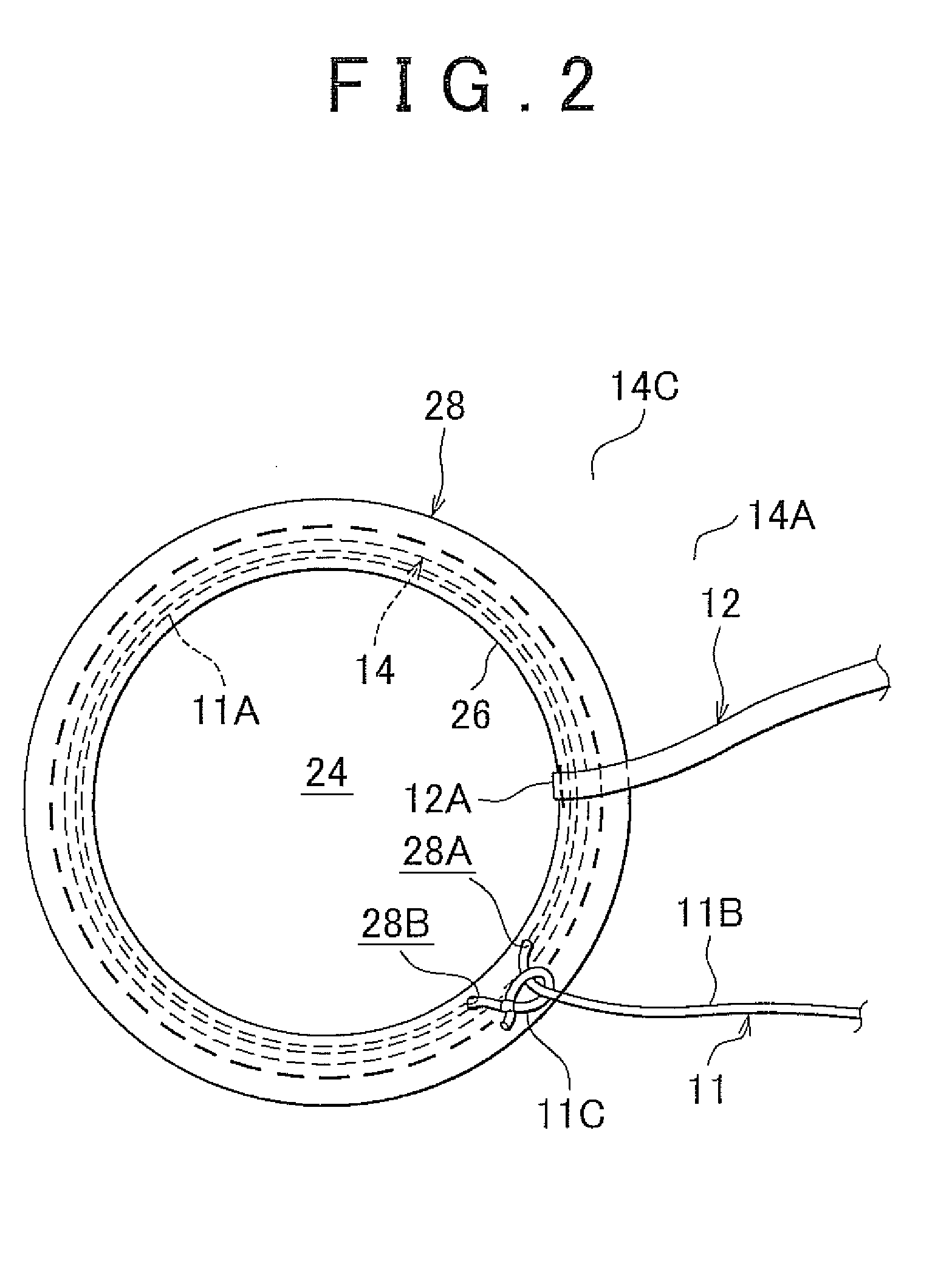

Front passenger seat air bag apparatus

InactiveUS20100052297A1Promote escapeReaction forcePedestrian/occupant safety arrangementBelt safety

Owner:TOYOTA JIDOSHA KK

Front passenger seat air bag apparatus

InactiveUS7959184B2Promote escapeReaction forcePedestrian/occupant safety arrangementEngineeringAirbag

Owner:TOYOTA JIDOSHA KK

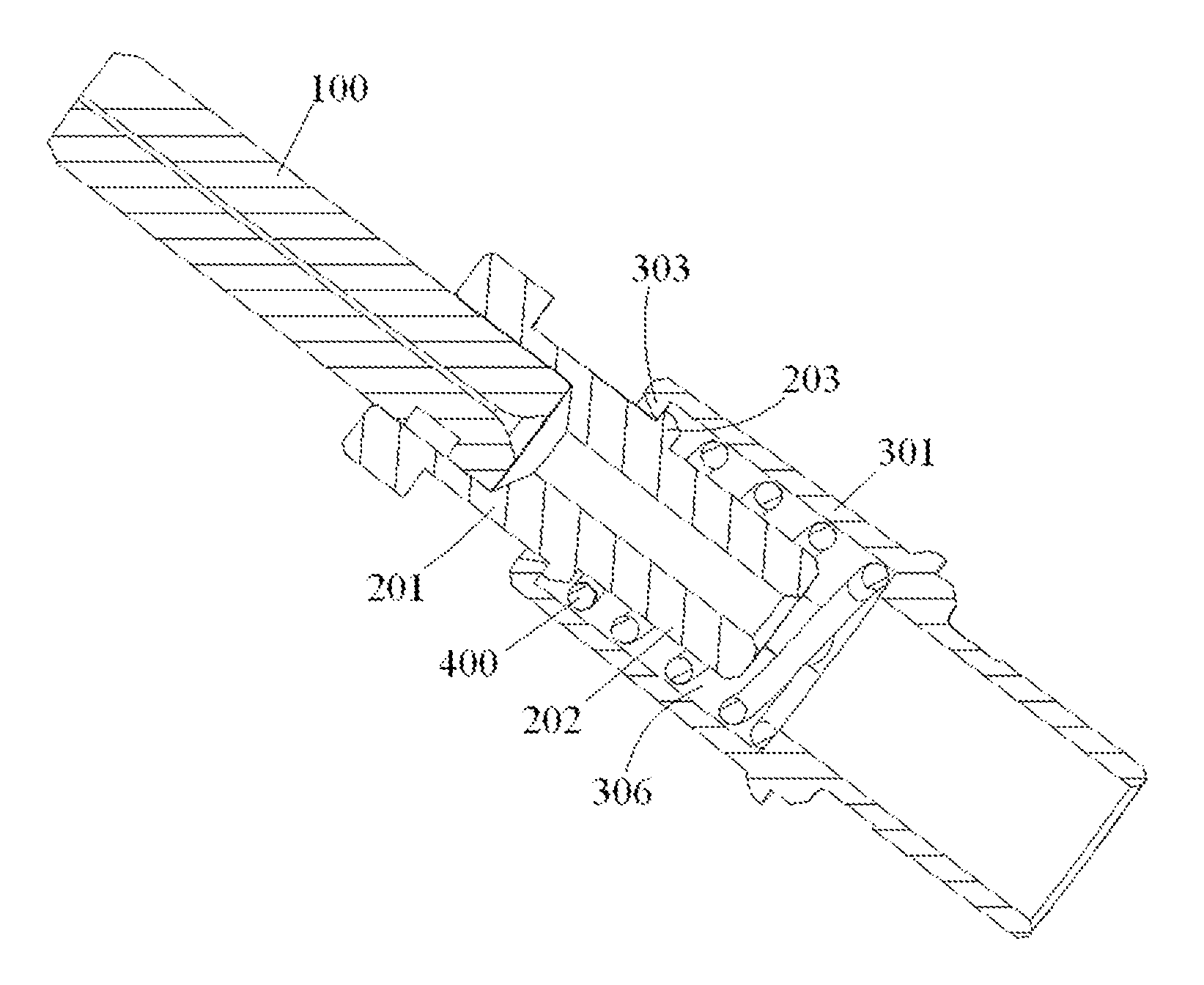

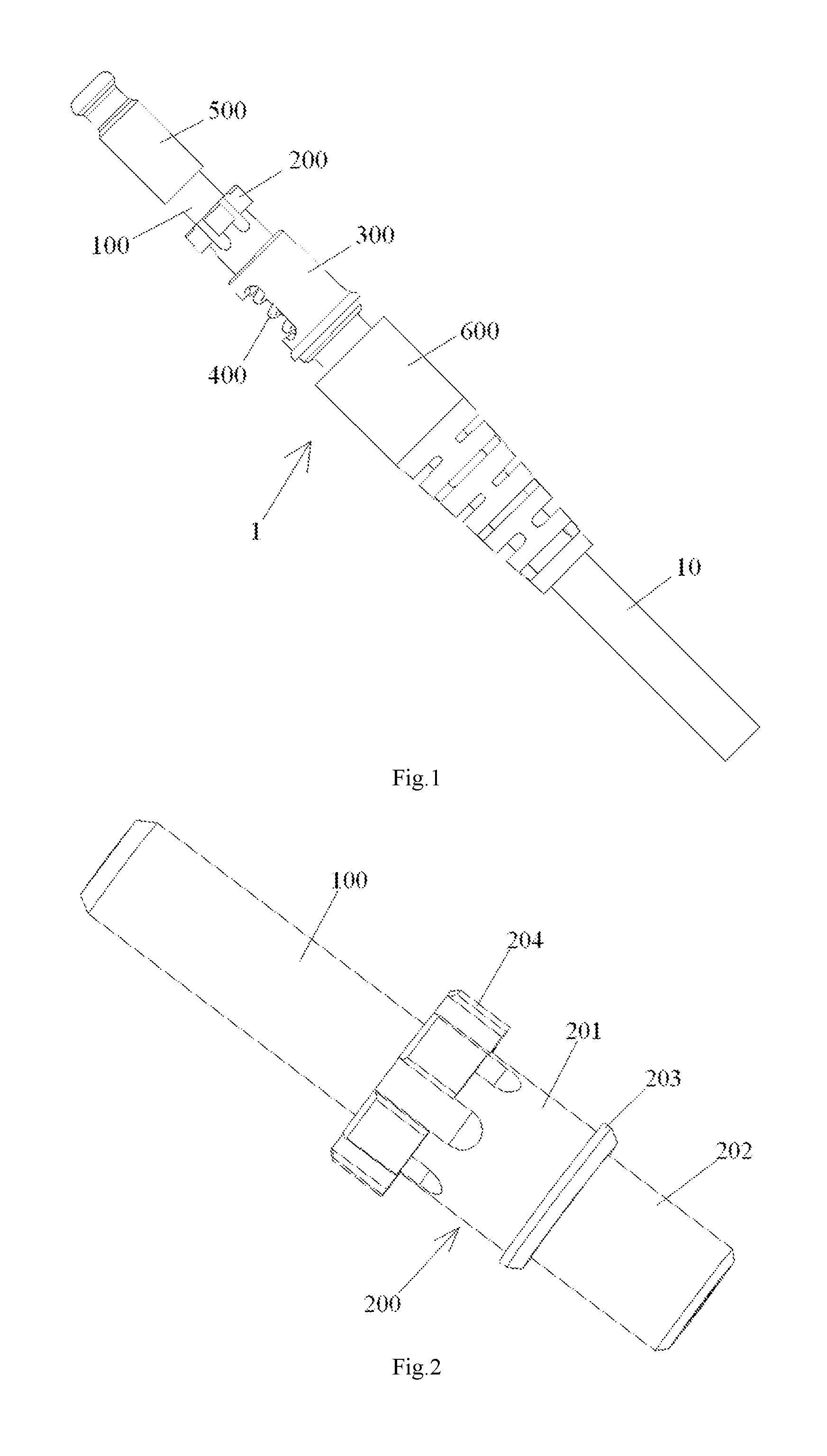

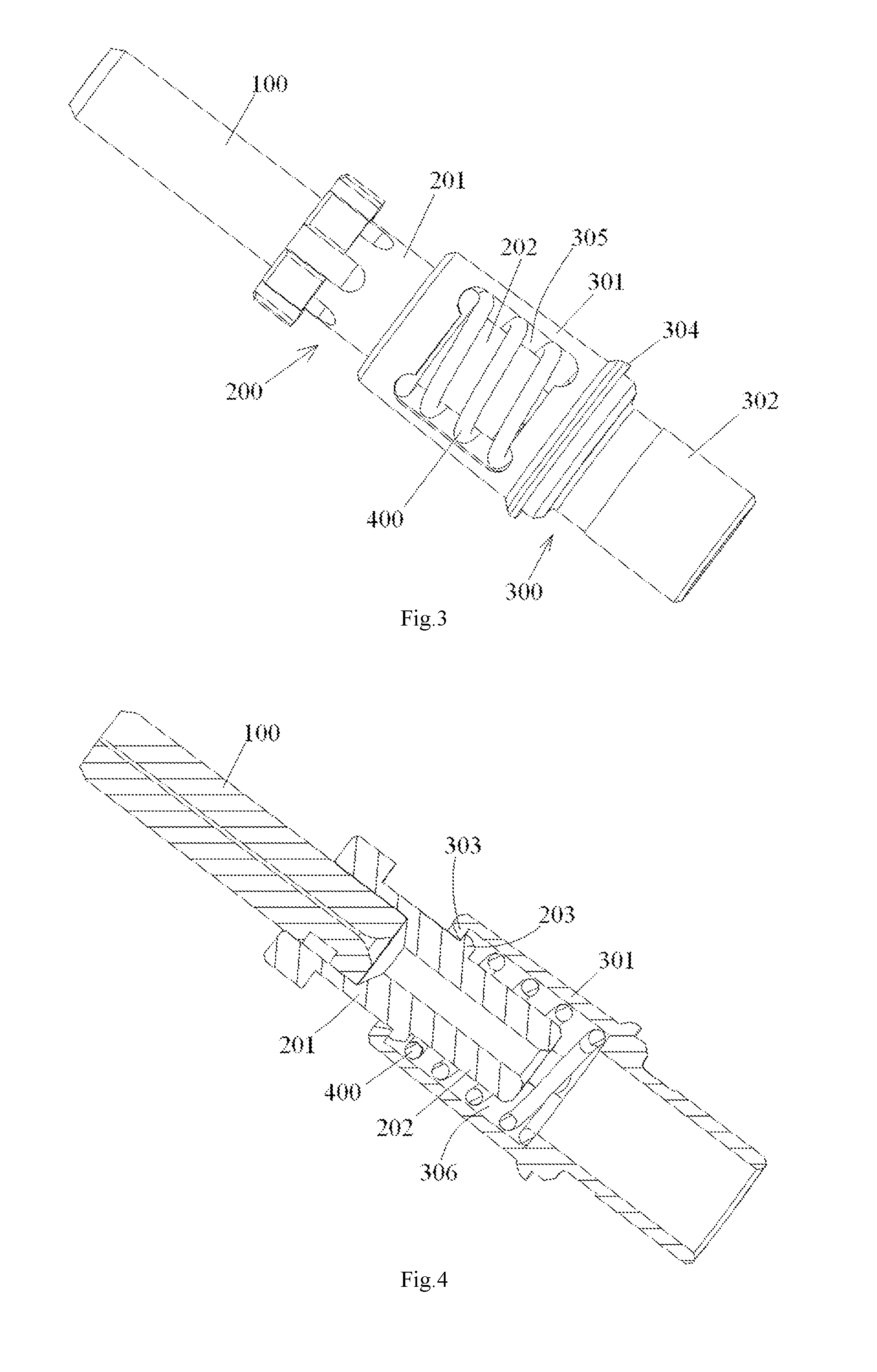

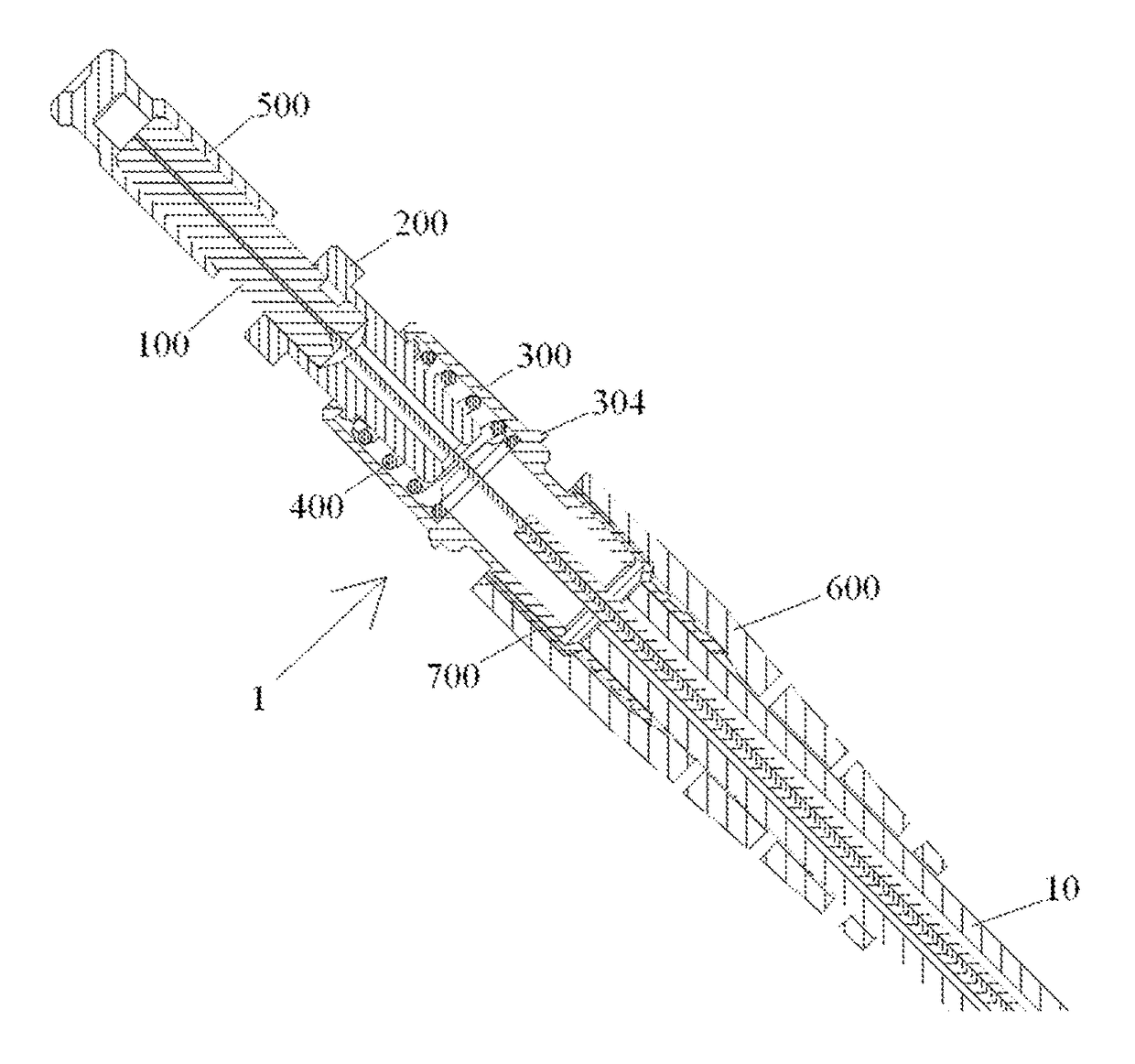

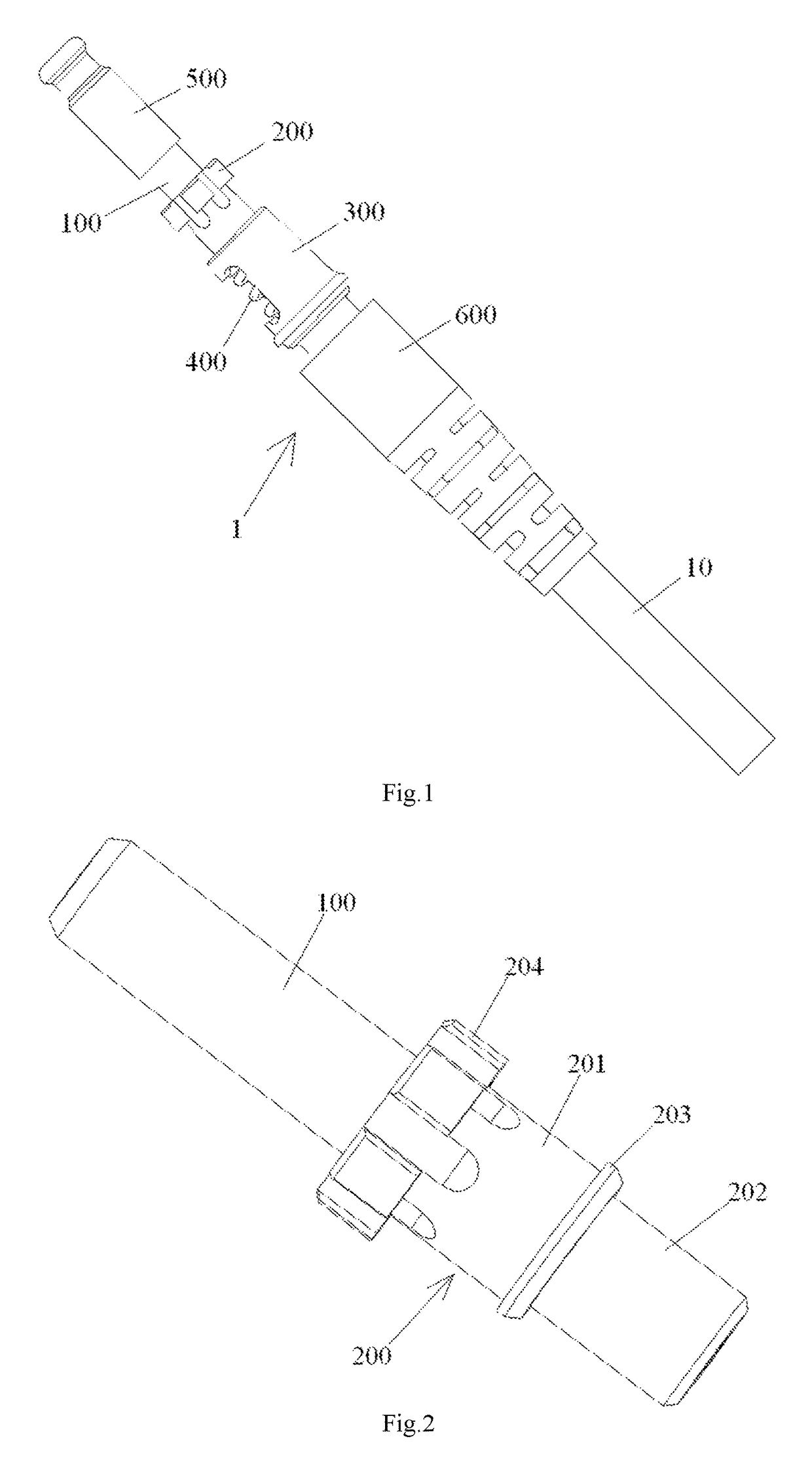

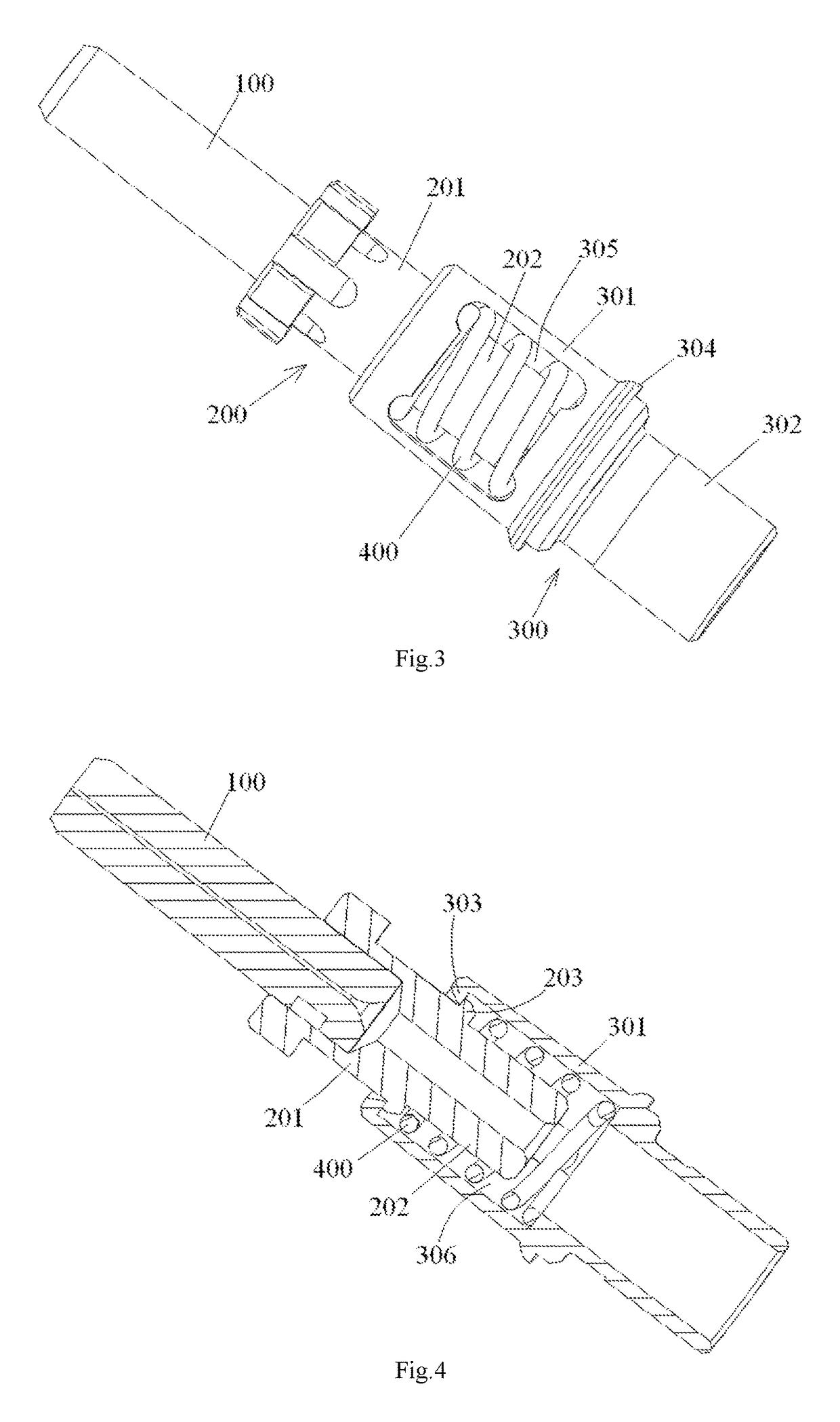

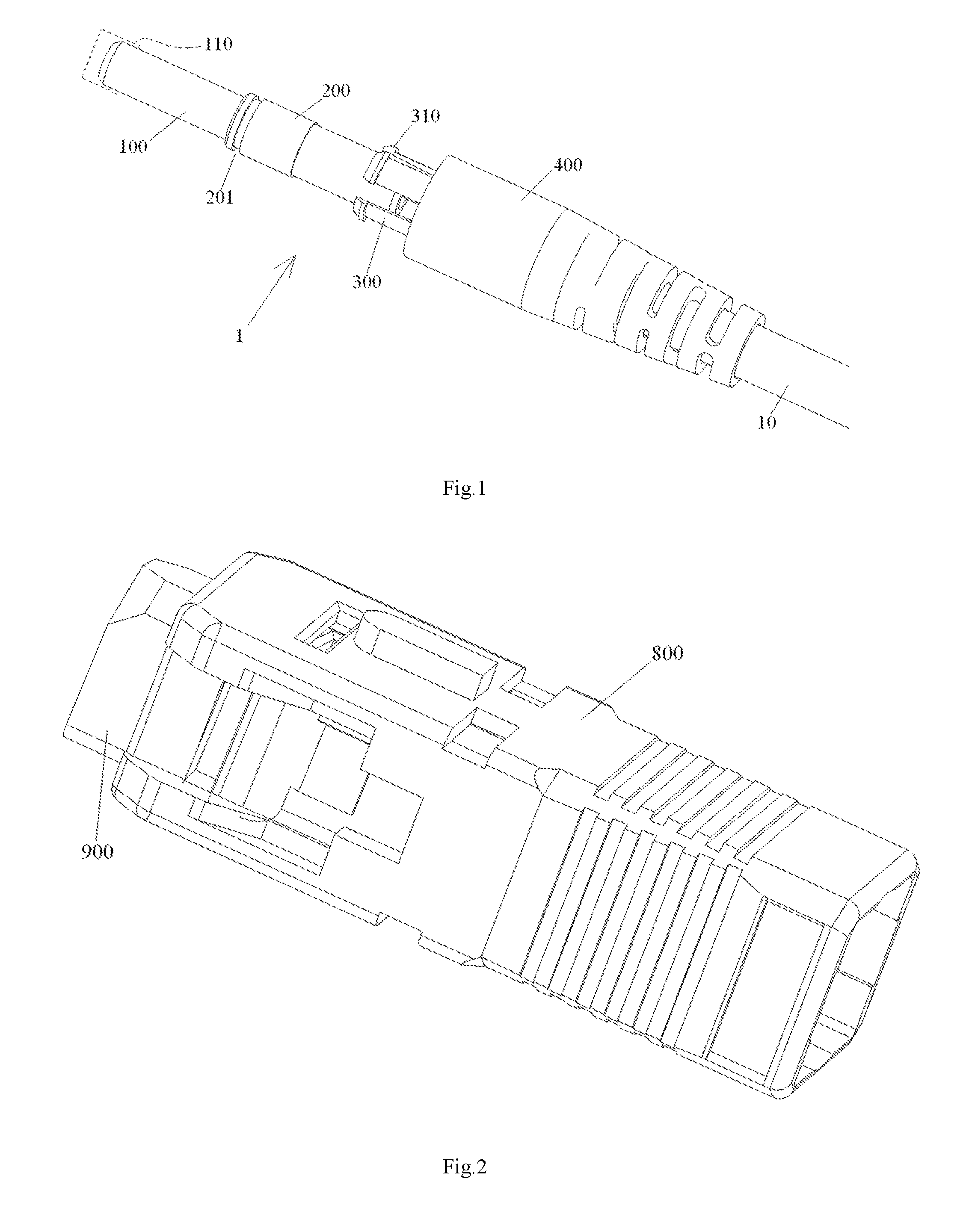

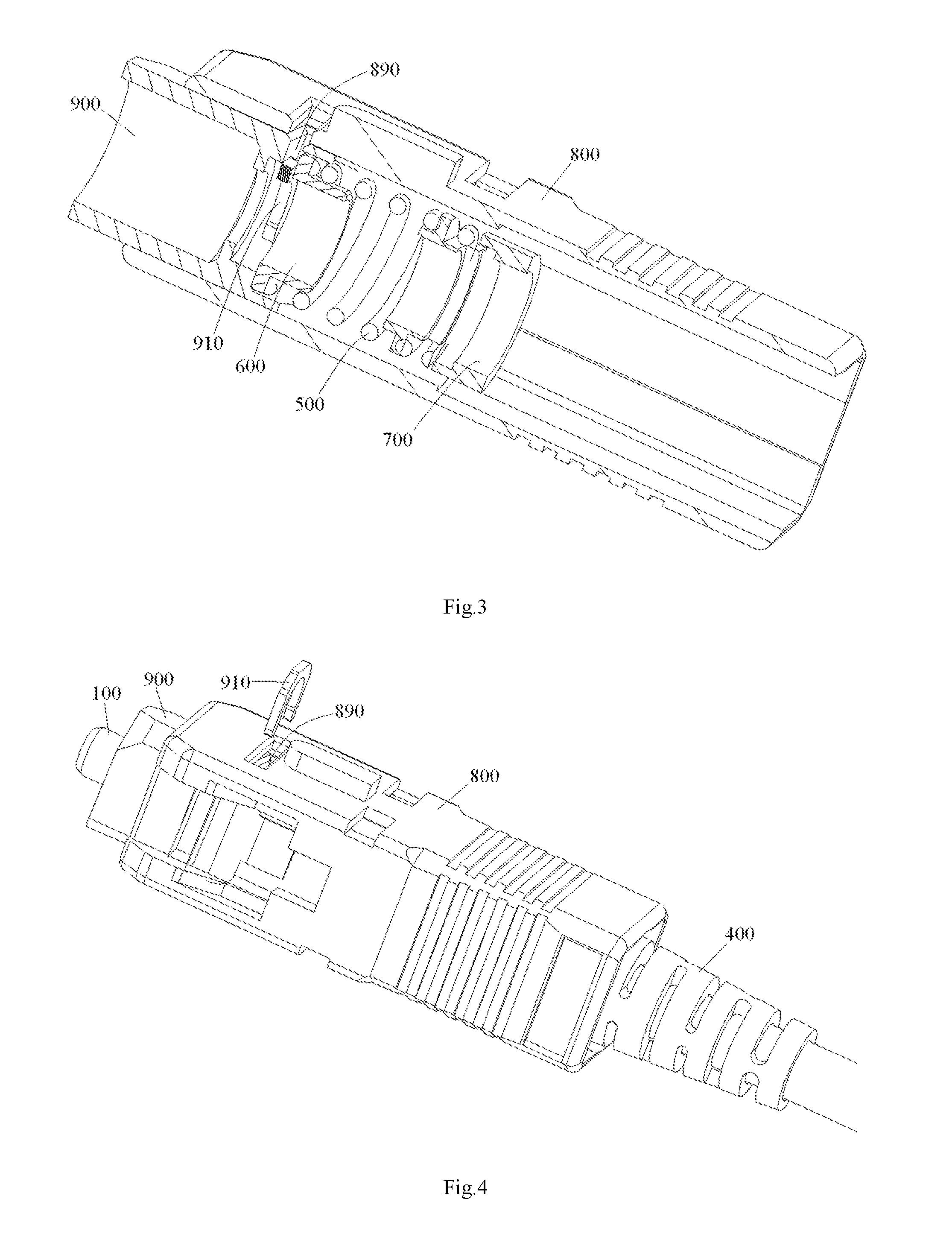

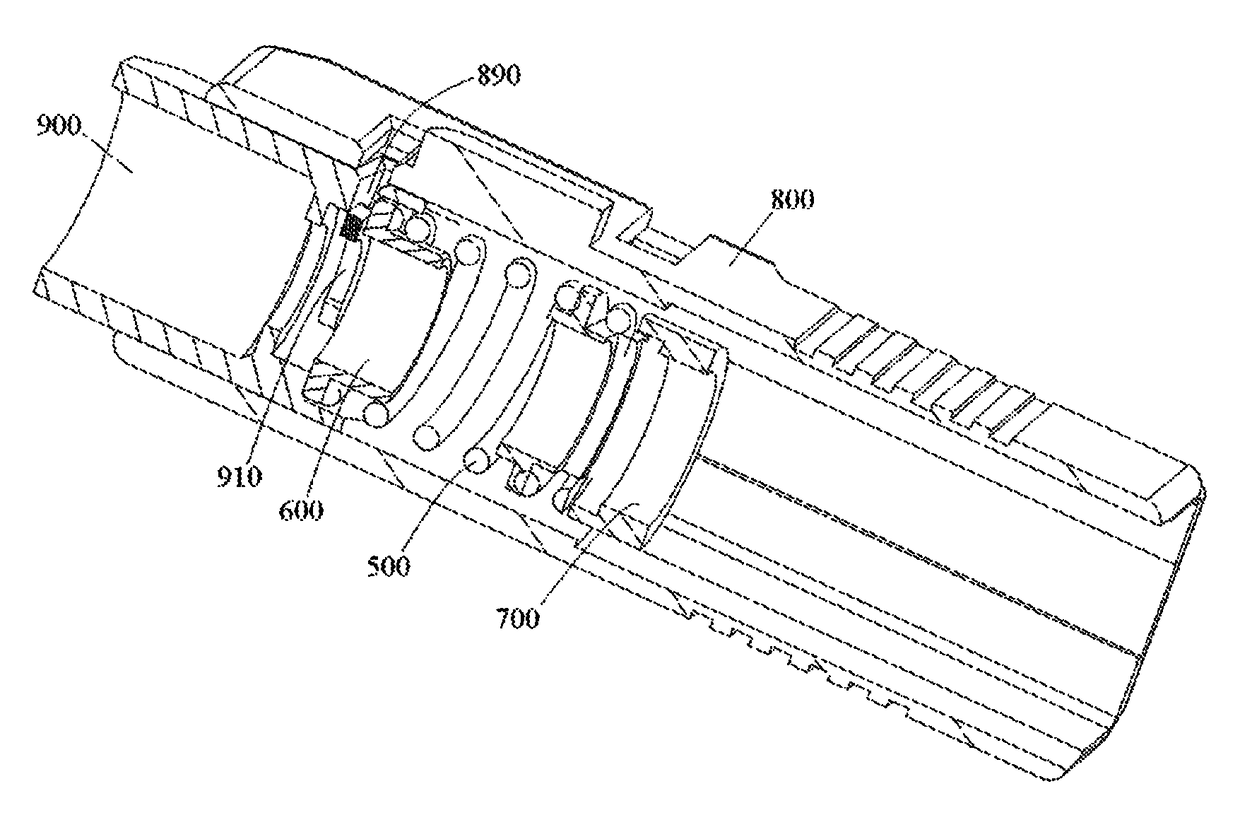

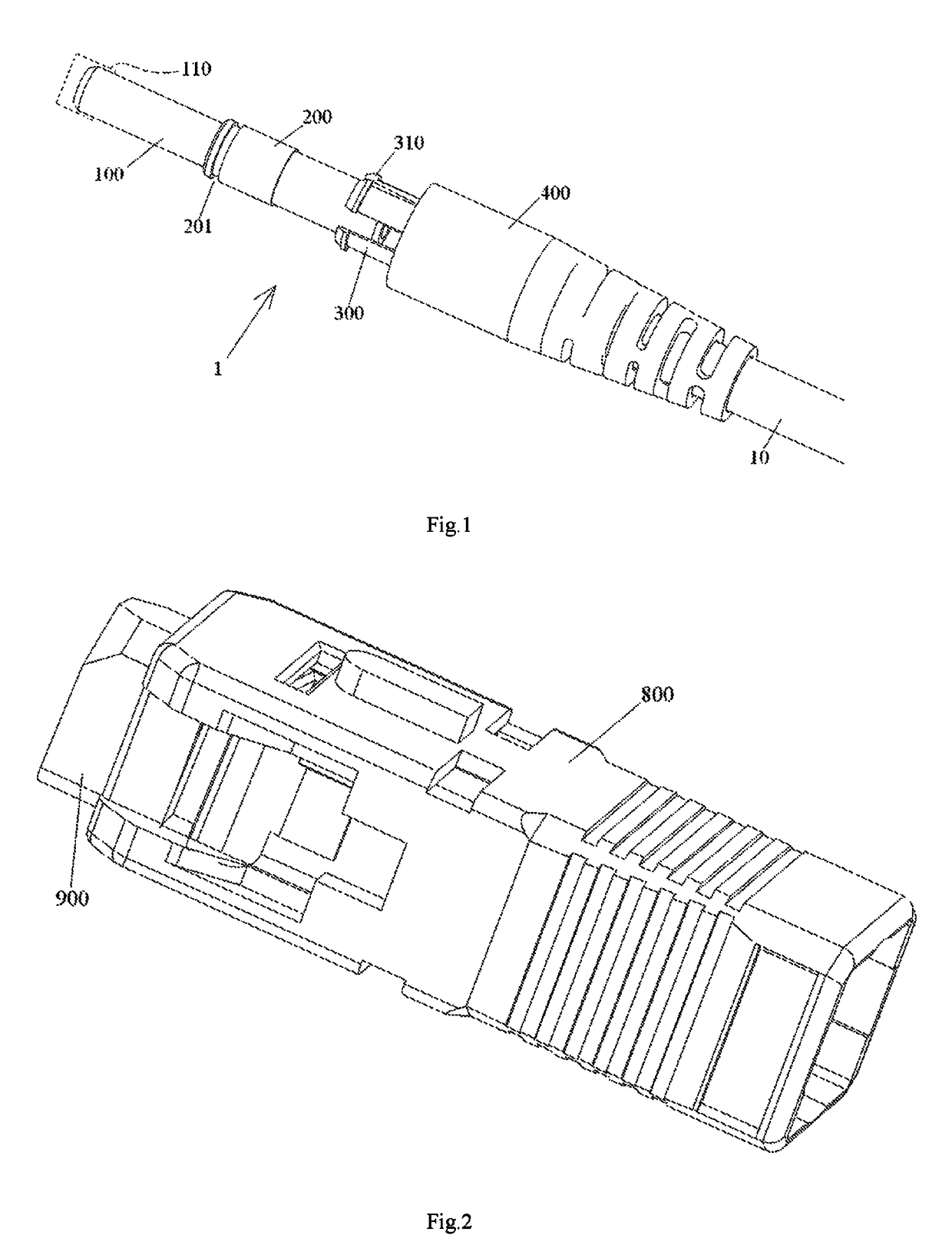

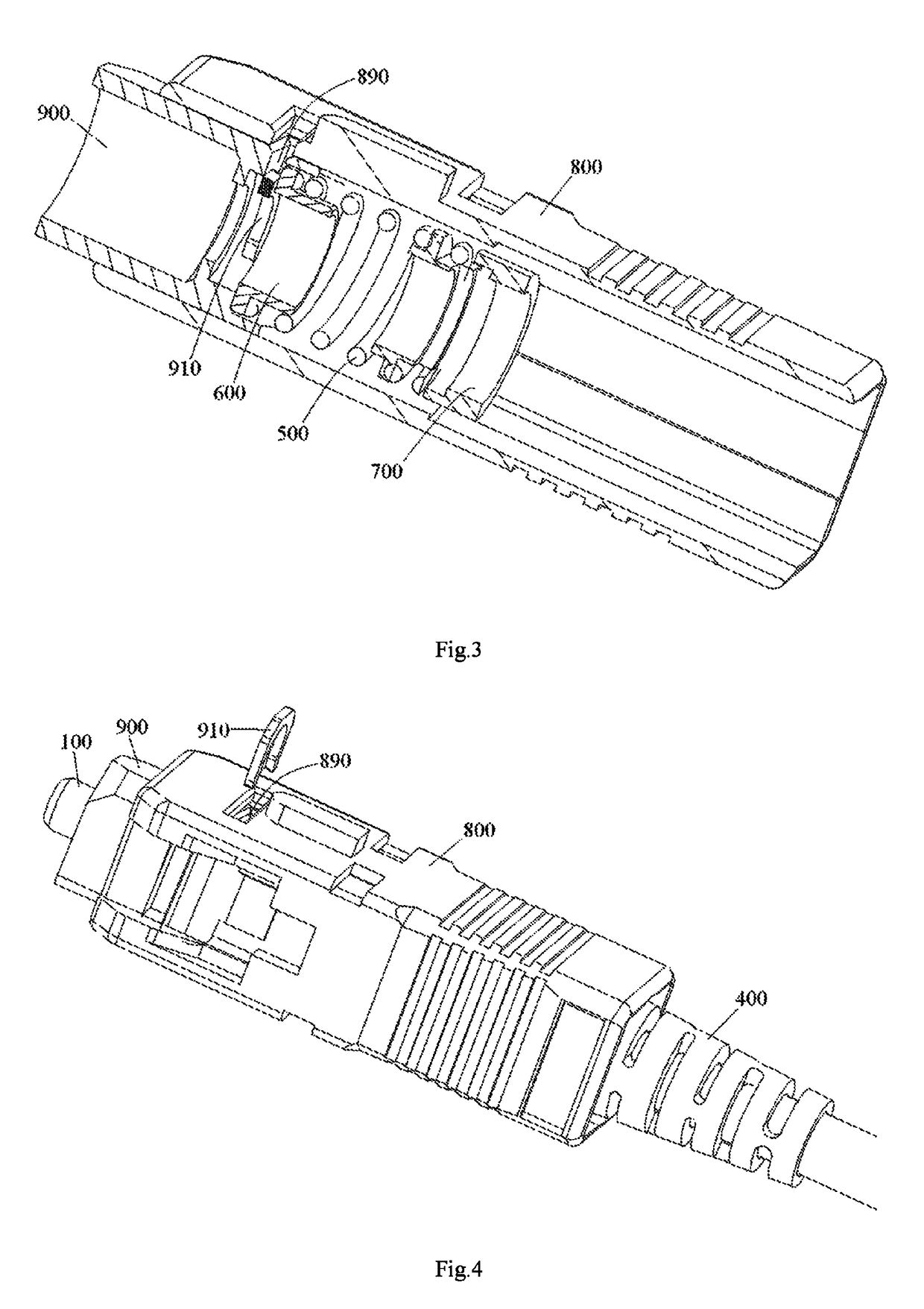

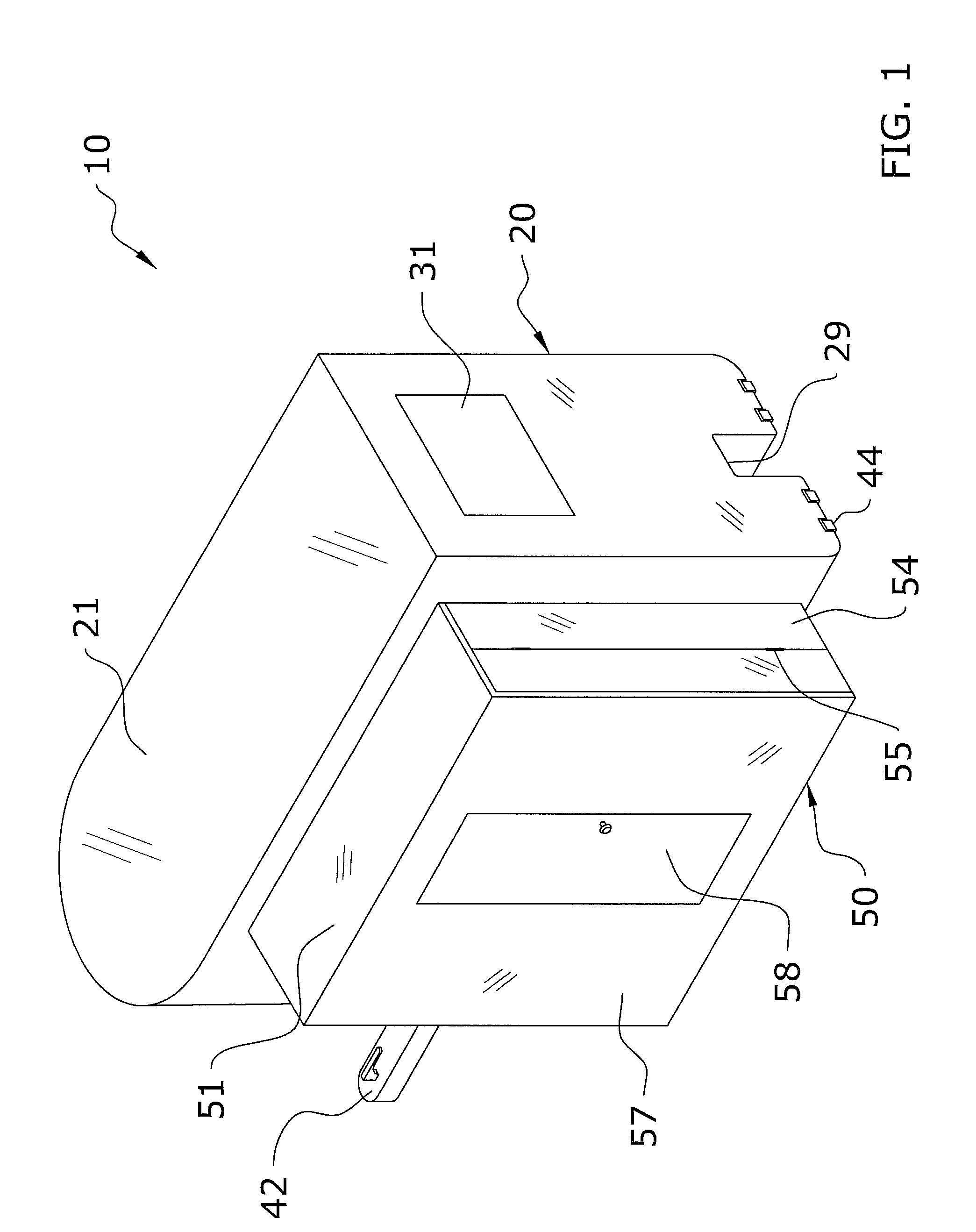

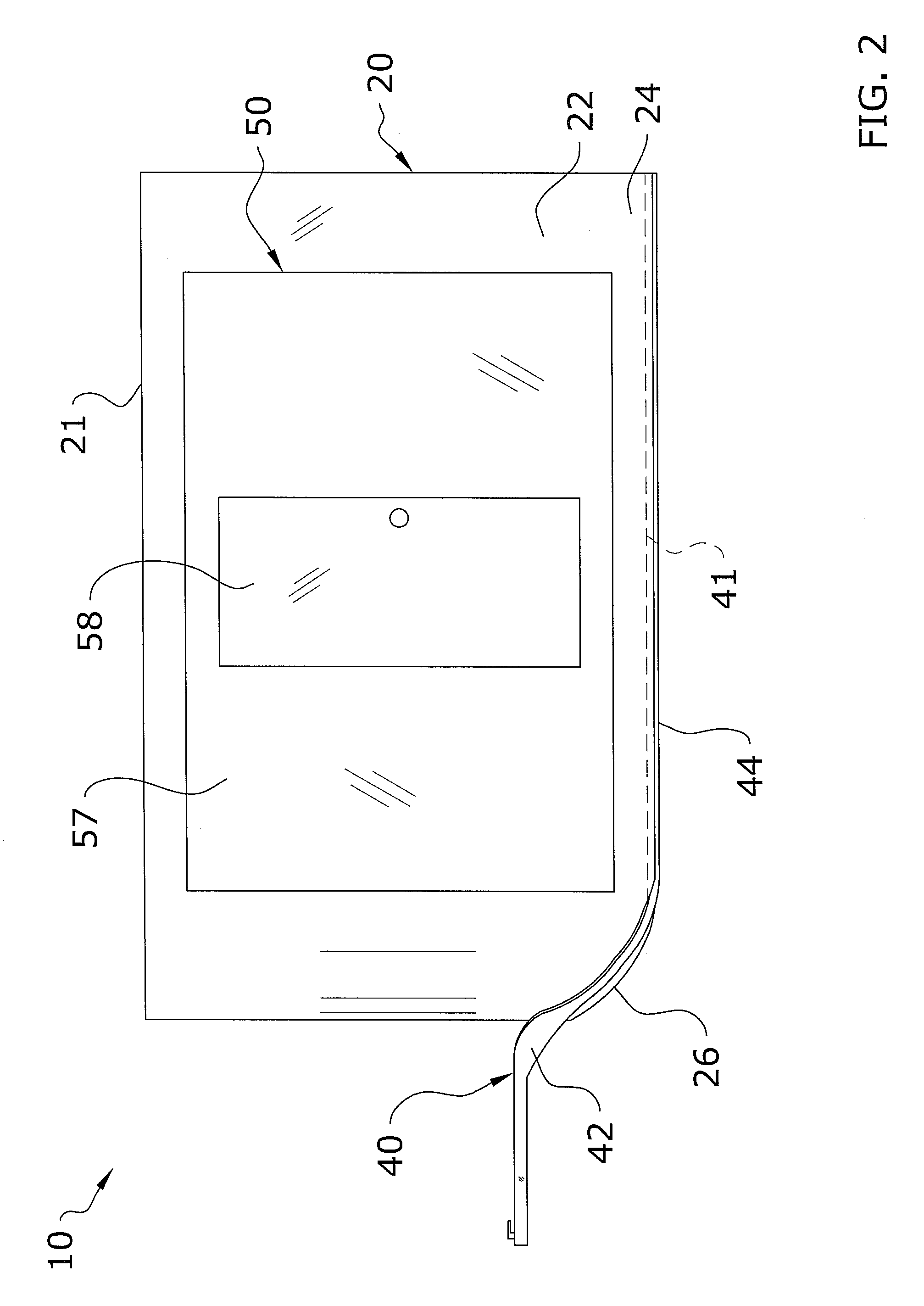

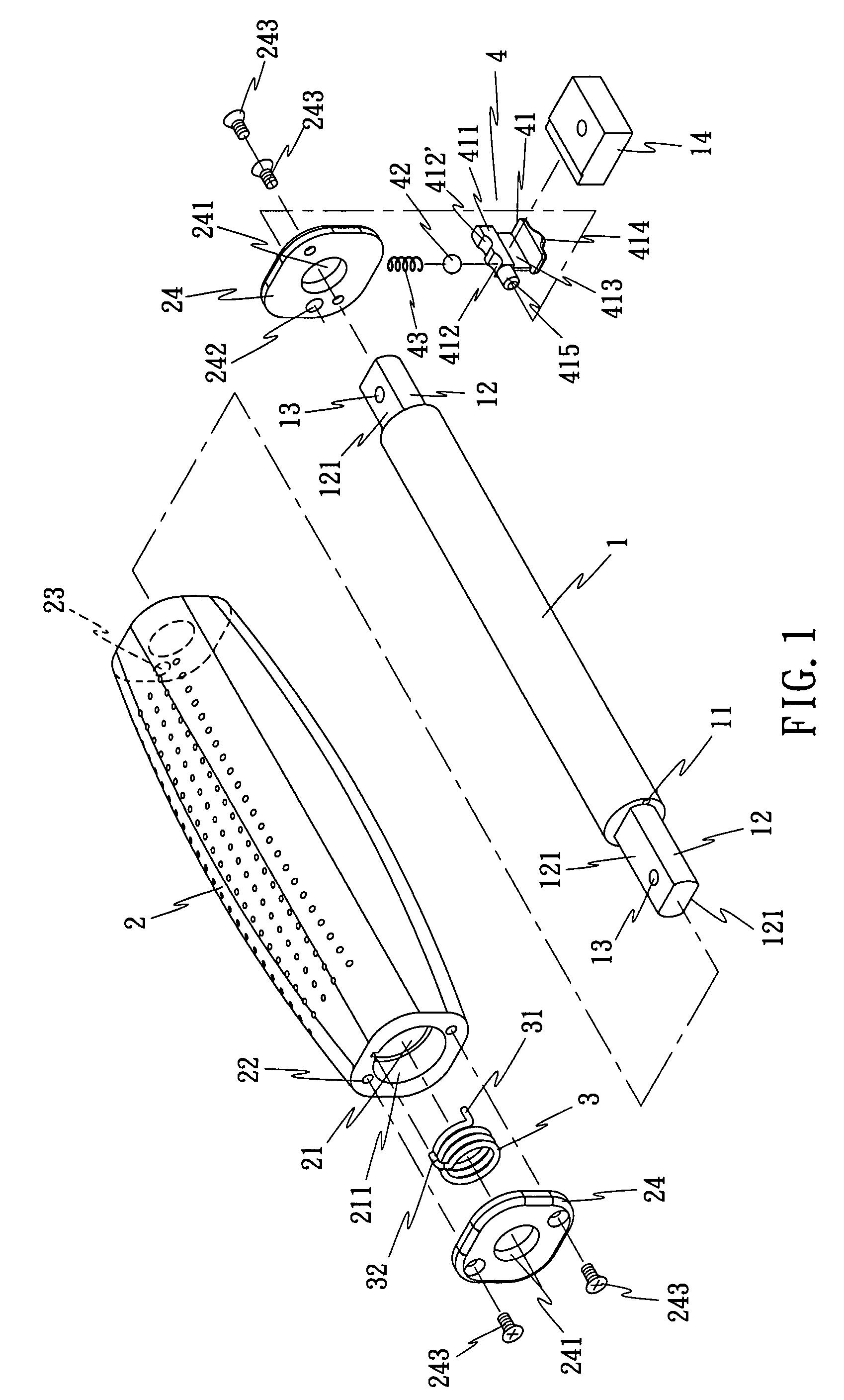

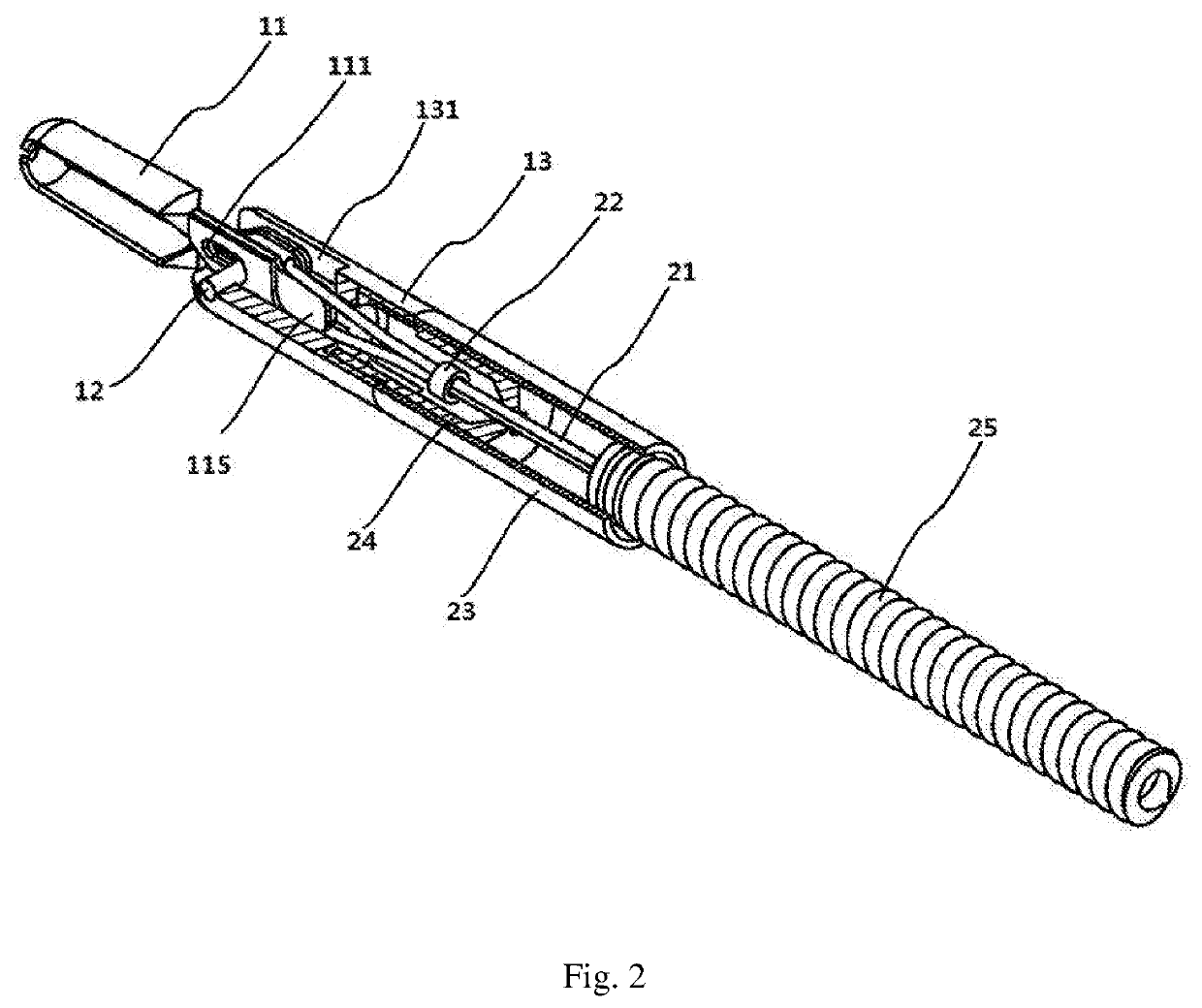

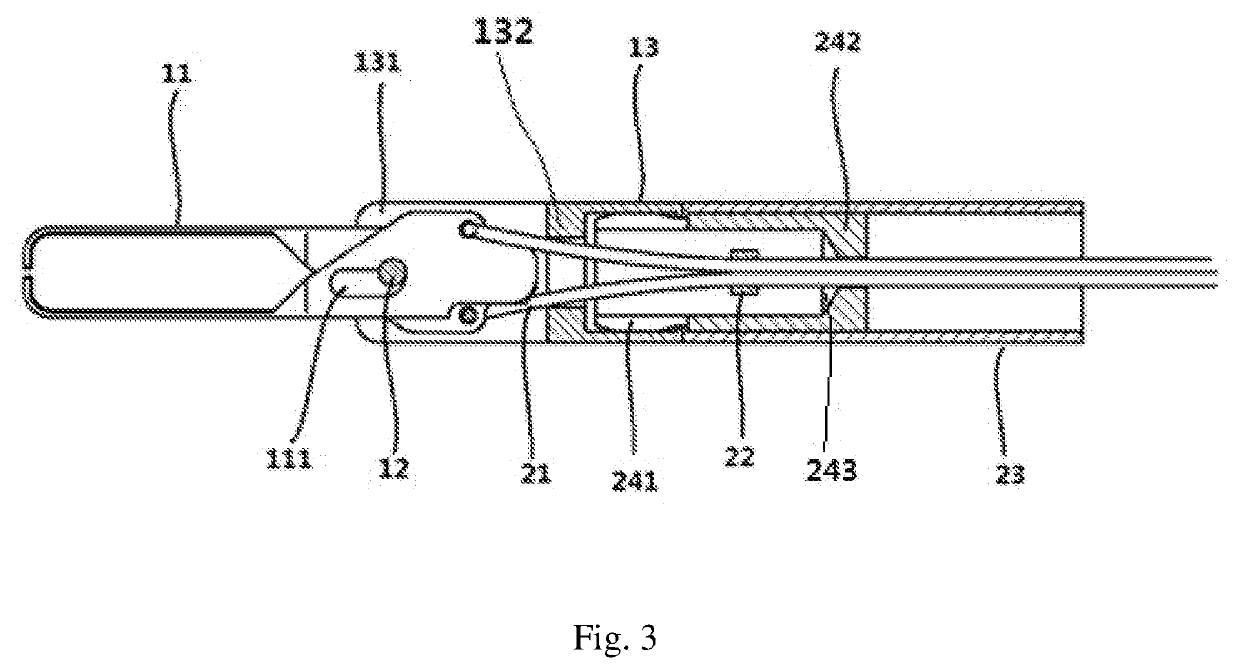

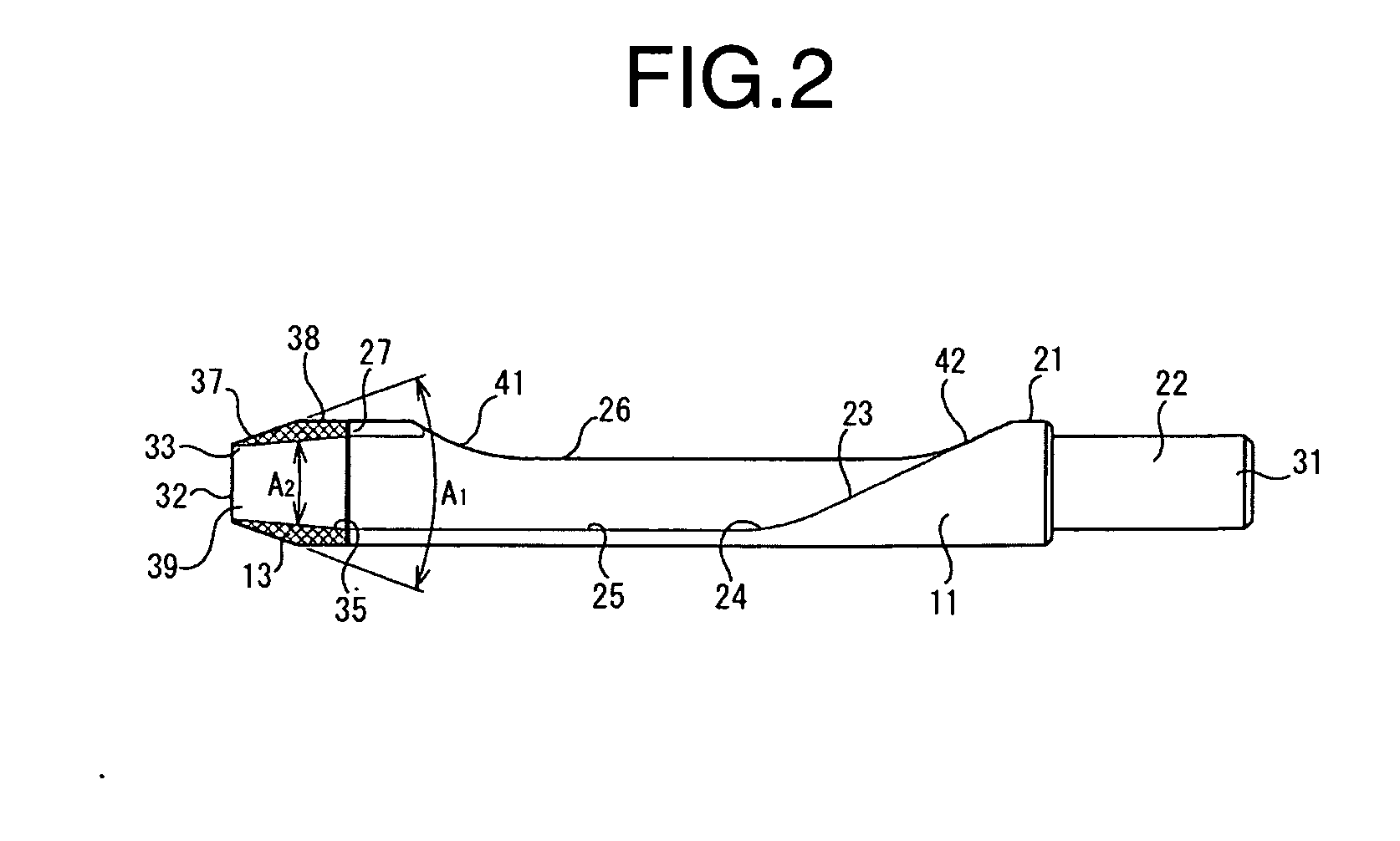

Fiber optic connector and method of assembling the same

ActiveUS20160356963A1Less profile sizeQuick assemblyCoupling light guidesOptical fiber connectorFiber

The present invention discloses a fiber optic connector comprises: a ferrule assembly; a spring seat provided behind the ferrule assembly; and a spring provided between the ferrule assembly and the spring seat. The spring seat has a receiving chamber having an insertion port through which a portion of the ferrule assembly is inserted into the receiving chamber; wherein the ferrule assembly is pre-assembled into the receiving chamber of the spring seat in a way that the ferrule assembly is held to be movably engaged with the spring seat. The spring is fitted and compressed in the receiving chamber. As a result, the ferrule assembly, the spring seat and the spring are pre-assembled into an integral assembly before being inserting into a connector housing. All components of the connector except for the housing may be smoothly pulled through a small long pipe as a whole. After being pulled through the pipe, all components of the connector except for the housing may be easily and quickly inserted into the housing as a whole at one time.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

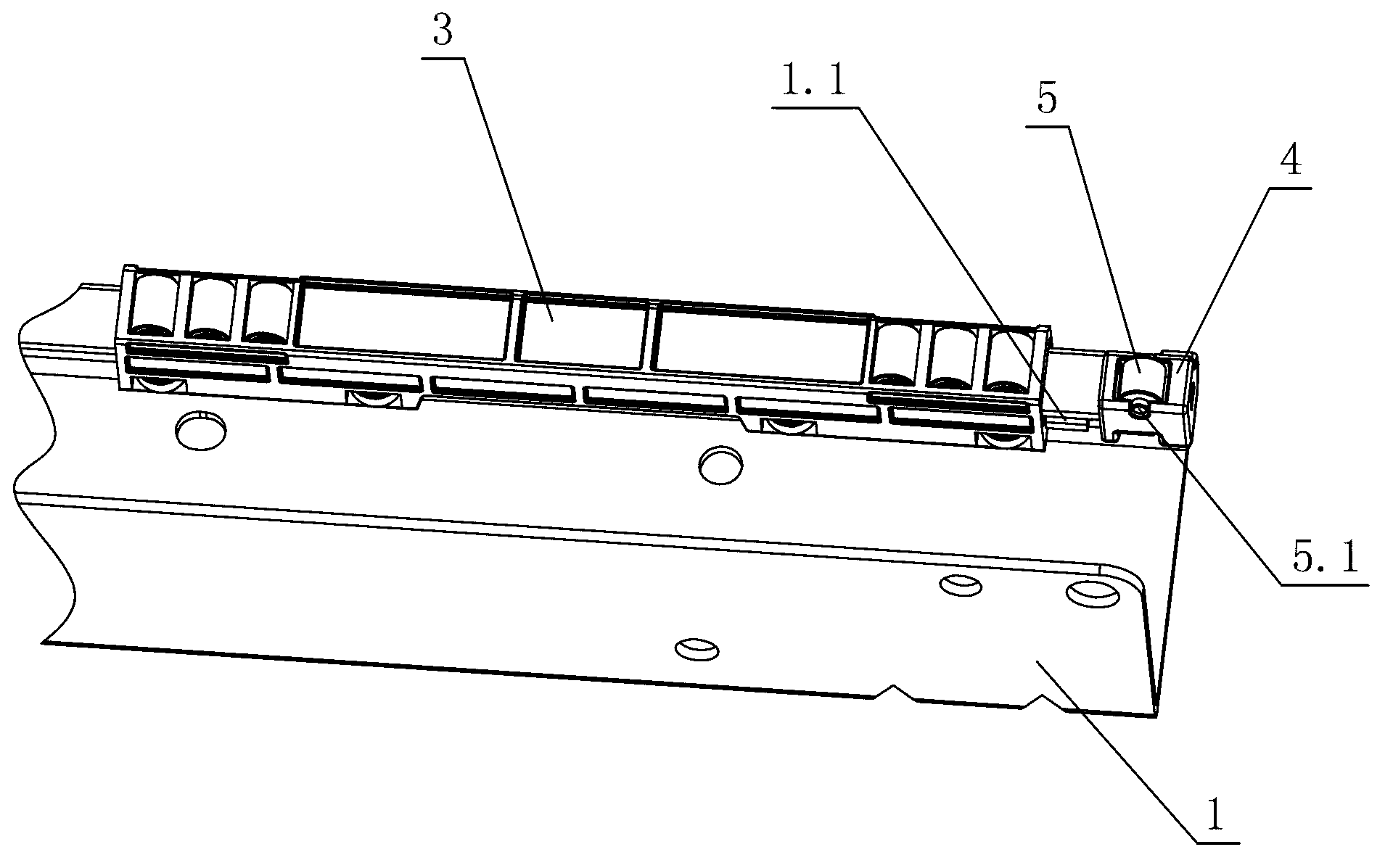

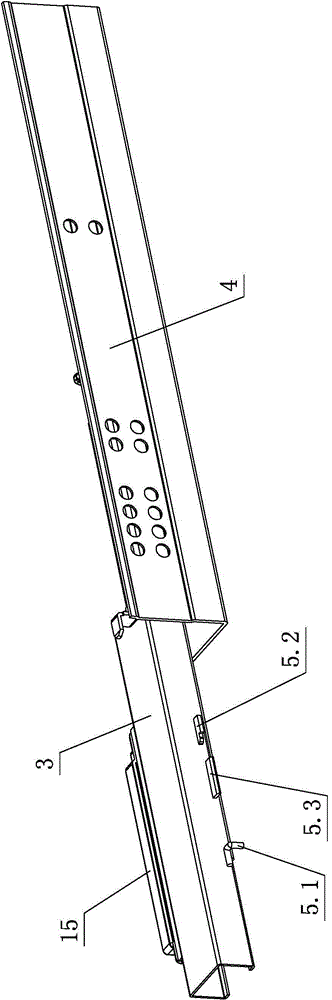

Balancing and stabilizing mechanism of drawer slide rail

A balancing and stabilizing mechanism of a drawer slide rail comprises a fixed slide rail and a movable slide rail which are connected with each other in a sliding way, wherein a middle slide rail is arranged between the fixed slide rail and the movable slide rail; the fixed slide rail, the middle slide rail and the movable slide rail are connected with each other in a sliding way; the middle slide rail is connected with the movable slide rail through a first holding frame in a sliding way; the middle slide rail is connected with the fixed slide rail through a second holding frame in a sliding way; the balancing and stabilizing mechanism is characterized in that a duplex movable gear set is arranged on the middle slide rail; two groups of gears of the duplex movable gear set are respectively engaged with a first rack and a second rack, wherein the first rack is arranged on the first holding frame and the second rack is arranged on the second holding frame, so that the fixed slide rail, the movable slide rail and the middle slide rail slide relative to each other; and the duplex movable gear set is integrally arranged or integrally fixed and then embedded in the middle slide rail after being separately arranged. The balancing and stabilizing mechanism of the drawer slide rail, provided by the invention, has the advantages of convenience and rapidness in mounting and accurate positioning as the duplex movable gear set is integrally fixed after being separately arranged and finally embedded in the middle slide rail; moreover, as a roller arranged on the middle slide rail is connected with the movable slide rail through a pin separately arranged on the middle slide rail in a rolling way, the integral stamping of the pin on the middle slide rail is avoided, the manufacturing process for the middle slide rail is simplified and the production is more convenient.

Owner:伍志勇

Fiber optic connector and method of assembling the same

The present invention discloses a fiber optic connector comprises: a ferrule assembly; a spring seat provided behind the ferrule assembly; and a spring provided between the ferrule assembly and the spring seat. The spring seat has a receiving chamber having an insertion port through which a portion of the ferrule assembly is inserted into the receiving chamber; wherein the ferrule assembly is pre-assembled into the receiving chamber of the spring seat in a way that the ferrule assembly is held to be movably engaged with the spring seat. The spring is fitted and compressed in the receiving chamber. As a result, the ferrule assembly, the spring seat and the spring are pre-assembled into an integral assembly before being inserting into a connector housing. All components of the connector except for the housing may be smoothly pulled through a small long pipe as a whole. After being pulled through the pipe, all components of the connector except for the housing may be easily and quickly inserted into the housing as a whole at one time.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

High titanium special welding wire steel smelting method

ActiveCN104831014ASolve the problem of nodulation in submerged nozzlesPulling smoothlyManufacturing convertersTitaniumOxygen content

The invention discloses a high titanium special welding wire steel smelting method, the technical process of converter-ladle furnace (LF) refining-150 mm*150 mm small square billet continuous casting is used, the titanium content is stably controlled at 0.14% to 0.19%, on average, 0.16%; carbon content is stably controlled at 0.03-0.08%; the total oxygen content is stably controlled at 0.0030% or less, nozzle clogging problem is successfully solved, the number of furnaces of continuous casting can reach 22, welding wire welding performance is good, splash is greatly reduced, and the demand of a high-end welding wire material can be achieved. The high titanium special welding wire steel smelting method adopts steel manufacture conventional production equipment, and is simple in operation and strong in commonality, casting blank quality is stable, and the production cost is low.

Owner:QINGDAO SPECIAL STEEL CO LTD

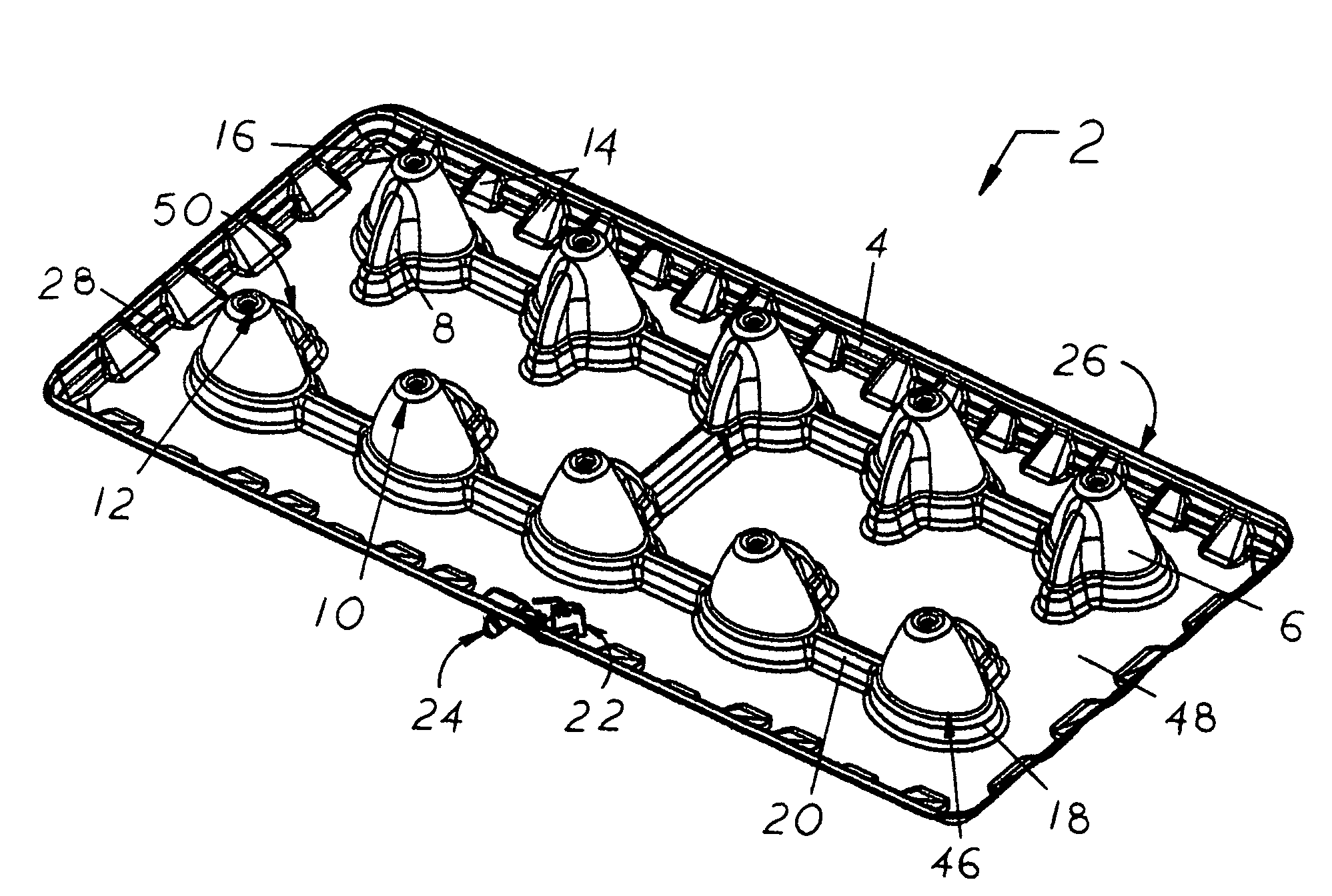

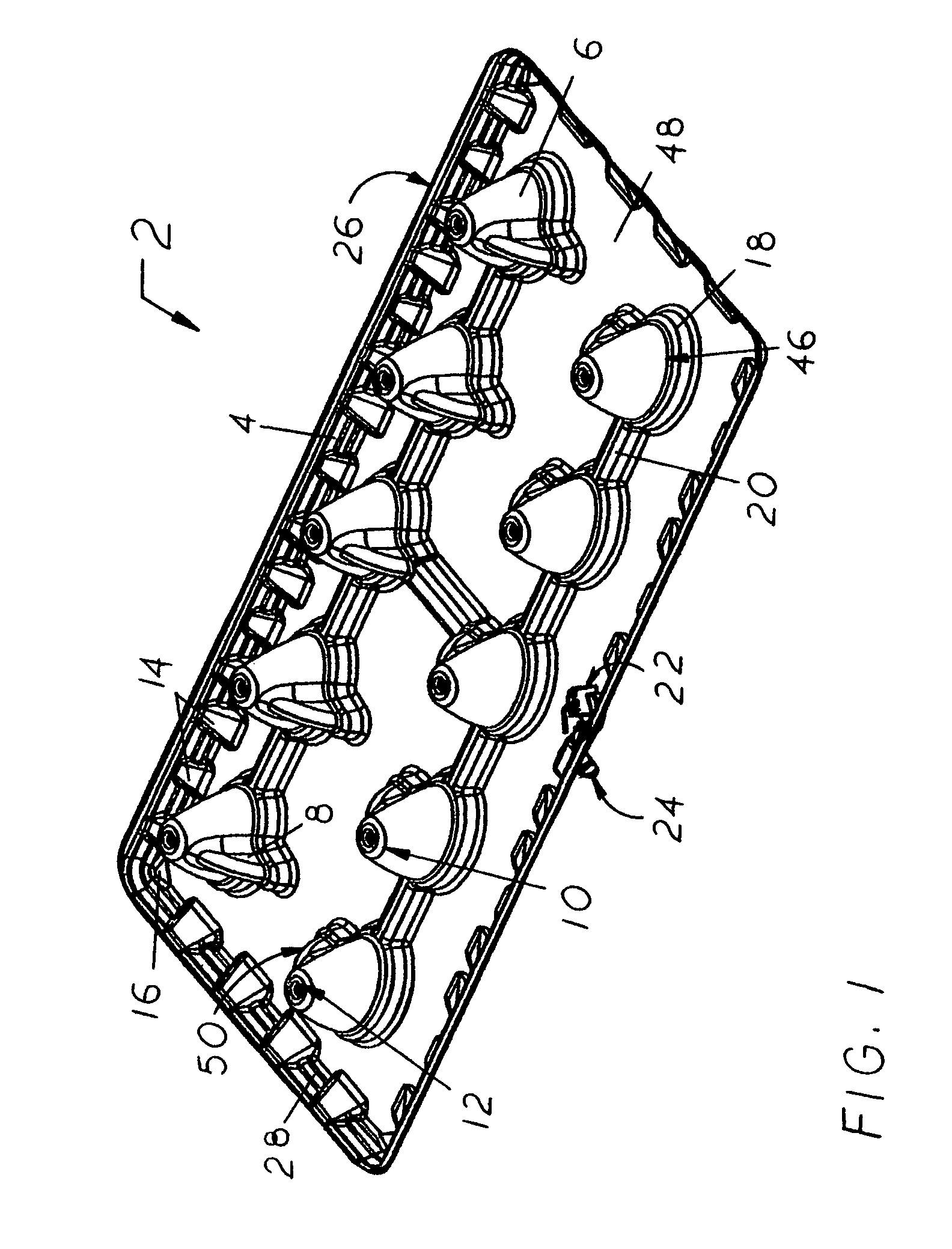

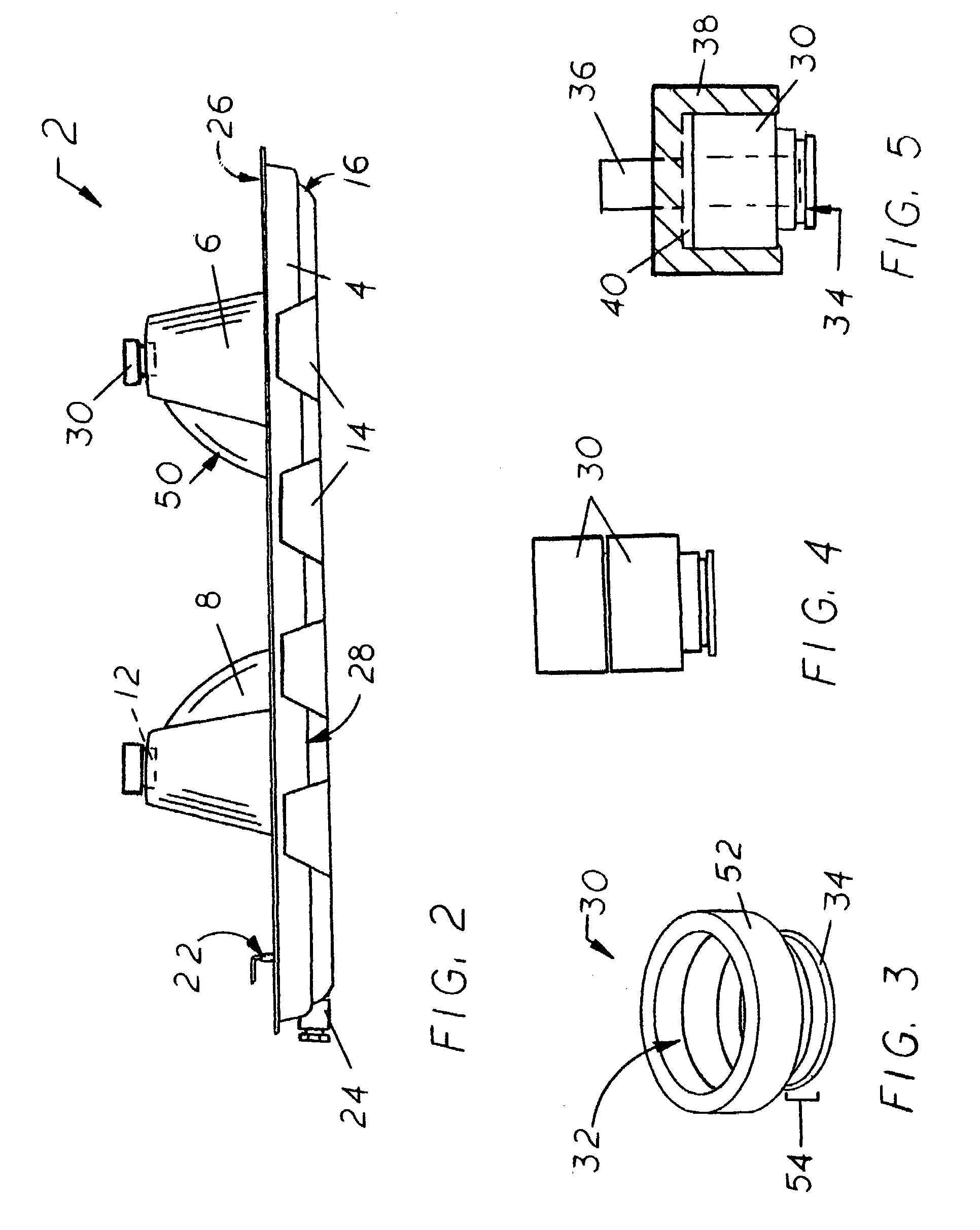

Pan with integrated egg-shaped supports

ActiveUS7673646B1Weight distributionReduce morbidityLighting and heating apparatusCombustion enginesMechanical engineeringWeight distribution

A fluid-collection pan configured for supporting a unit or system responsible for fluid damage risk to its surroundings. Multiple large egg-shaped supports upwardly extend from the pan's bottom surface and are integrated with it. They also each have an arcuate top surface that is transformed into an elliptical base as it meets the pan's bottom surface. Each support also has an upwardly-tapering protrusion with a convexly-shaped top edge that extends centrally from one of the longer sides of the elliptical base toward the support's top surface. The protrusion and the narrow sides of the elliptical base form a substantially triangular shape, which broadens the weight distribution of the supported fluid-causing unit across the pan's bottom surface. The top surface of each support also has a central indentation configured for receipt of a vibration isolator that provides contact with the supported unit. Optional stress-transmitting ribs may extend between adjacent egg-shaped supports.

Owner:RECTORSEAL LLC

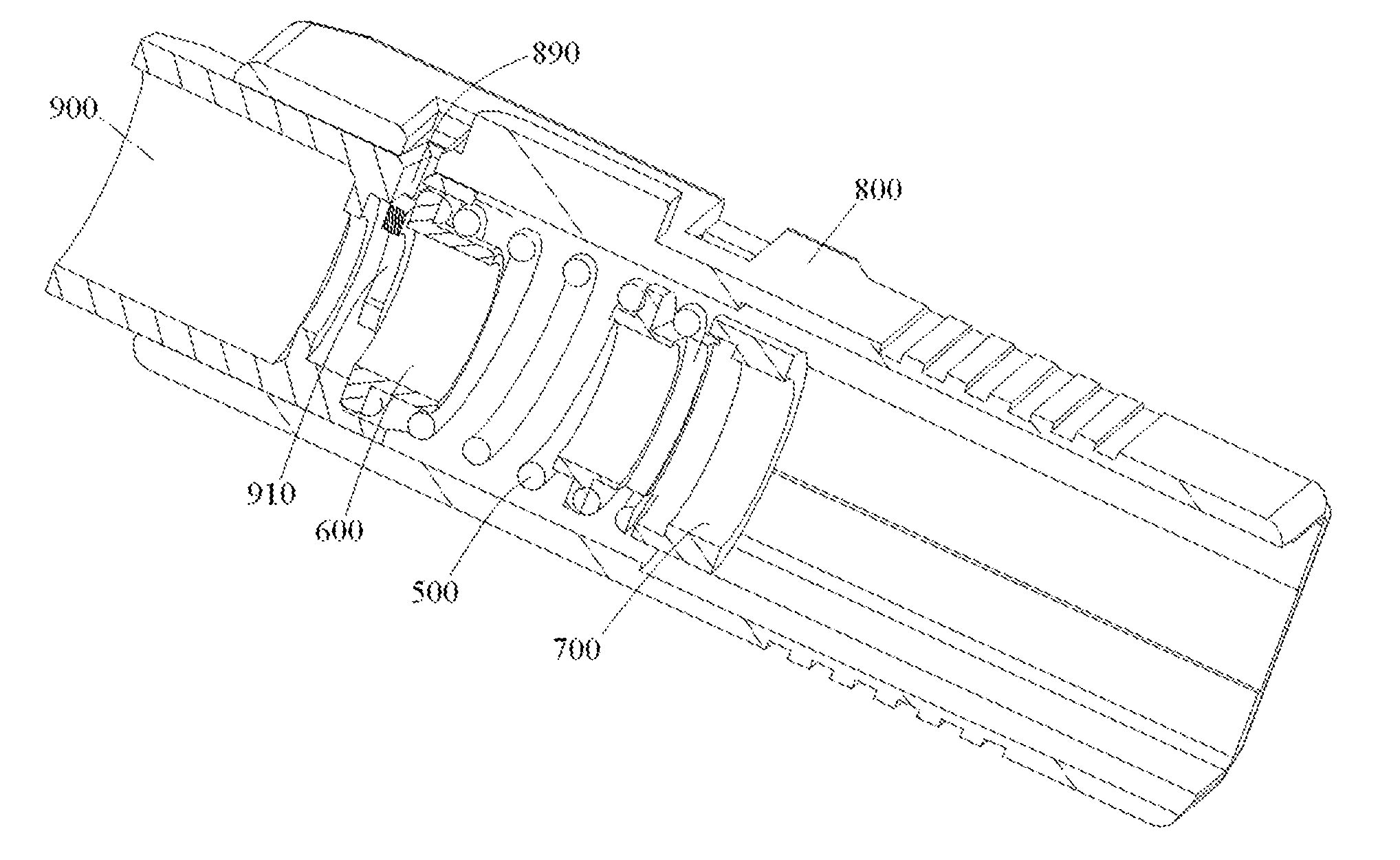

Fiber optic connector and method of assembling the same

The present invention discloses a fiber optic connector comprising a housing, a spring, a ferrule assembly and a crimping seat. Before being inserted into the housing, the ferrule assembly is pre-assembled into the crimping seat in a manner of being movable relative to the crimping seat. The spring is pre-assembled into the housing before the ferrule assembly is inserted into the housing. After the pre-assembled ferrule assembly and crimping seat are inserted into the housing, the crimping seat is snap-fitted in the housing, and the spring pushes the ferrule assembly, so that the ferrule assembly is capable of being moved against the spring relative to the crimping seat. Before inserted into a housing of the fiber optic connector, some components may be pre-assembled together to form an integral assembly having a size less than that of a housing of the fiber optic connector. Accordingly, the integral assembly may be smoothly pulled through a small long pipe. After pulled through the pipe, the integral assembly may be easily and quickly inserted into the housing as a whole at one time.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

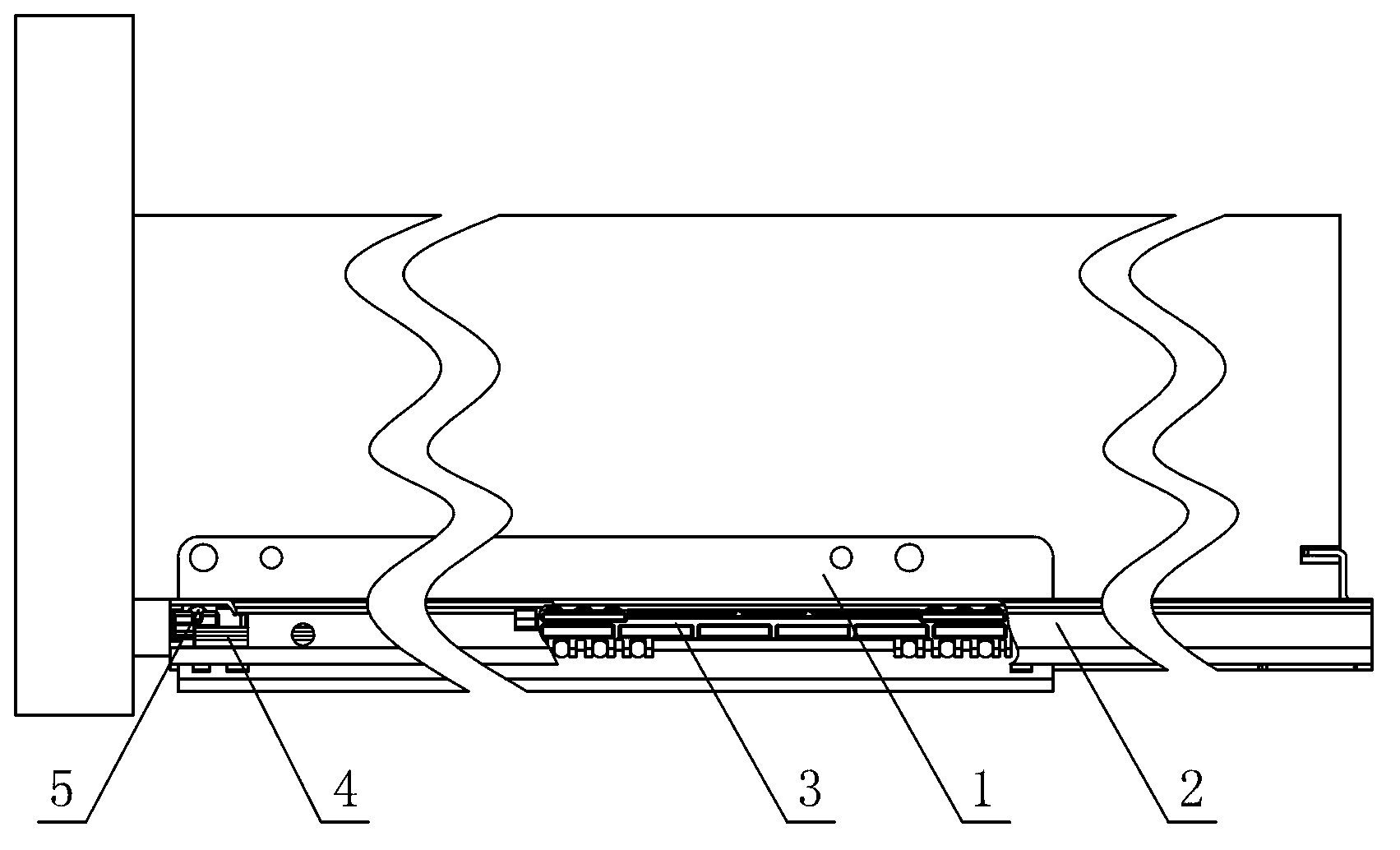

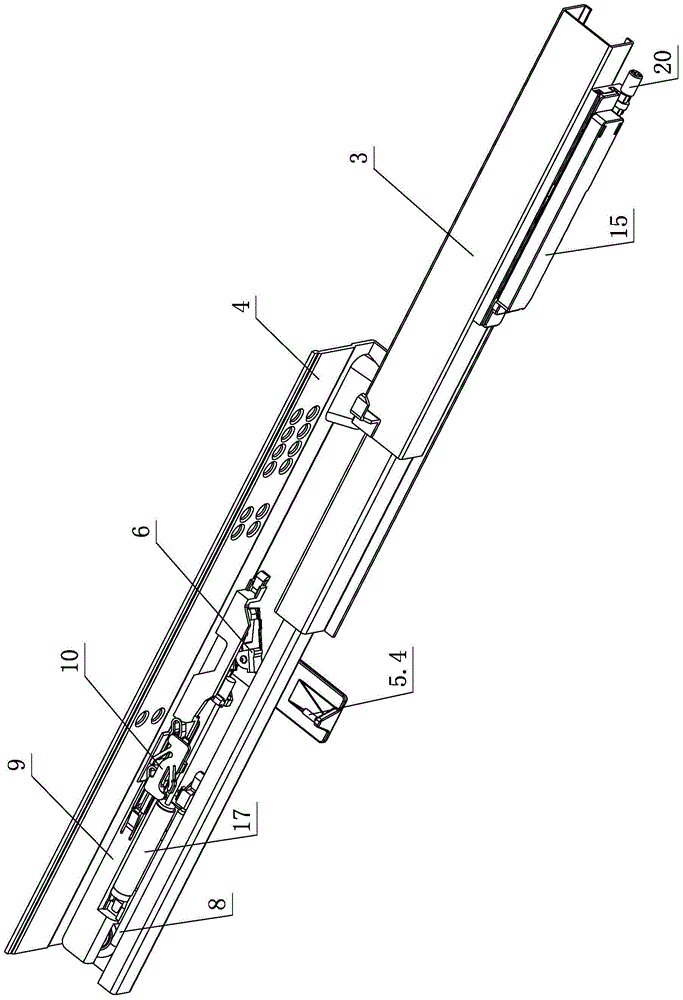

Drawer slide rail system

A drawer slide rail system comprises a slide rail subassembly, wherein the slide rail subassembly is arranged on a side plate of a cabinet and is provided with a drawer; the drawer comprises a bottom plate and a front panel; the slide rail subassembly comprises a movable slide rail and a fixed slide rail; a damping device is arranged on the movable slide rail or the fixed slide rail; when the drawer is closed, the damping device travels by a distance, and an elastic swinging plug A arranged on the damping device touches a shifting nail A arranged at the front end of the fixed slide rail or the movable slide rail; a sliding swinging plug B on the damping device is clamped in a first locking notch in the damping device by a cable, a strap or a rope; when the drawer continues being closed, the sliding swinging plug B touches a shifting nail B arranged at the rear end of the fixed slide rail or the movable slide rail, so that the sliding swinging plug B is released from the first locking notch; and the drawer is automatically closed by a damping spring. A pushing rebounding device is arranged on the movable slide rail, the fixed slide rail or the side plate of the cabinet; when closed, the drawer is automatically stopped at a position which is distant from a pre-stopping position of the side plate of the cabinet by a distance H through an elastic stopping block on the pushing rebounding device, and is positioned by elasticity; and moreover, the drawer is automatically opened by the elastic stopping block.

Owner:伍志勇

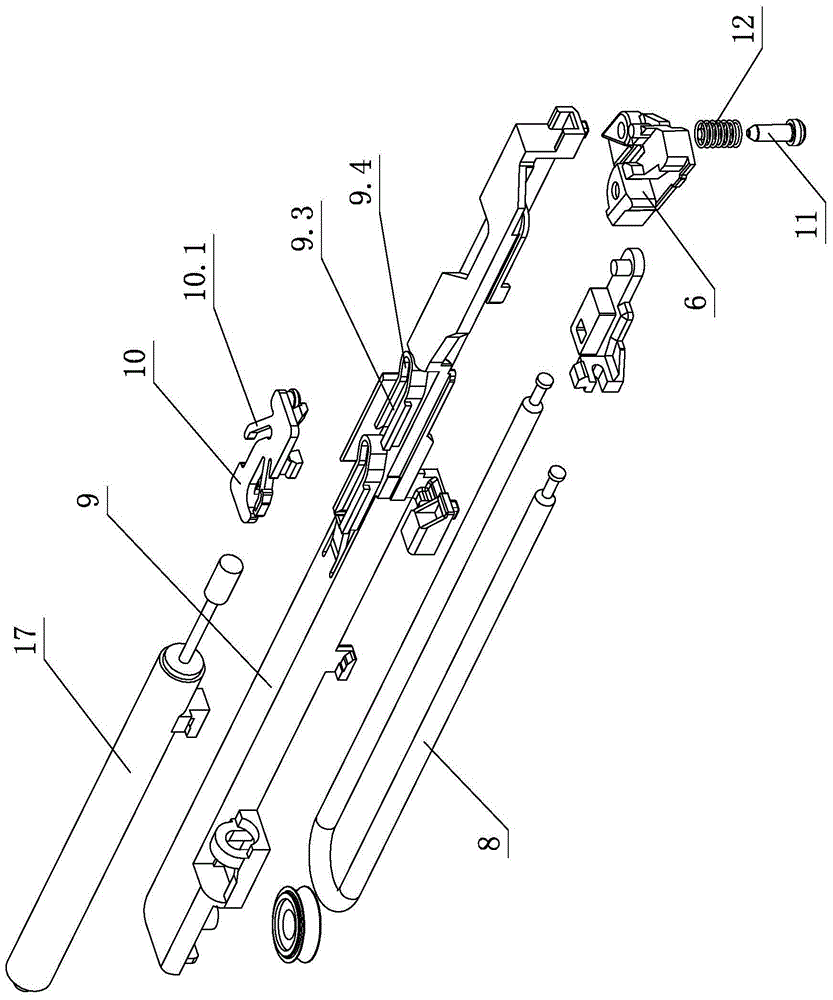

Supporting and limiting mechanism of drawer sliding rail

A supporting and limiting mechanism of a drawer sliding rail comprises at least one fixed sliding rail and at least one movable sliding rail, wherein the fixed sliding rail is in sliding connection with the movable sliding rail through a retainer, the fixed sliding rail is connected with a drawer cabinet body, the movable sliding rail is connected with a drawer base plate or a drawer side plate, the front end of the fixed sliding rail is provided with a supporting and limiting mechanism body, and the movable sliding rail is in sliding connection with the fixed sliding rail through the supporting and limiting mechanism body. The supporting and limiting mechanism body arranged at the front end of the fixed sliding rail comprises at least one rolling wheel seat wrapping the front end of the fixed sliding rail laterally and at least one rolling wheel arranged on the rolling wheel seat and connected with the fixed sliding rail and the movable sliding rail in a rolling mode. When a drawer is drawn out, the fixed sliding rail and the rolling wheel support the movable sliding rail through the retainer, the problem that a gap between the fixed sliding rail and the movable sliding rail is large, the fixed sliding rail and the movable sliding rail cannot be supported mutually, and accordingly sinking and deformation of the front end of the movable sliding rail, collision and friction between the front end and the fixed sliding rail and the like are caused is solved while the weight of the drawer is increased, and accordingly the drawer cannot swing laterally and shake vertically when drawn out and pushed into.

Owner:伍志勇

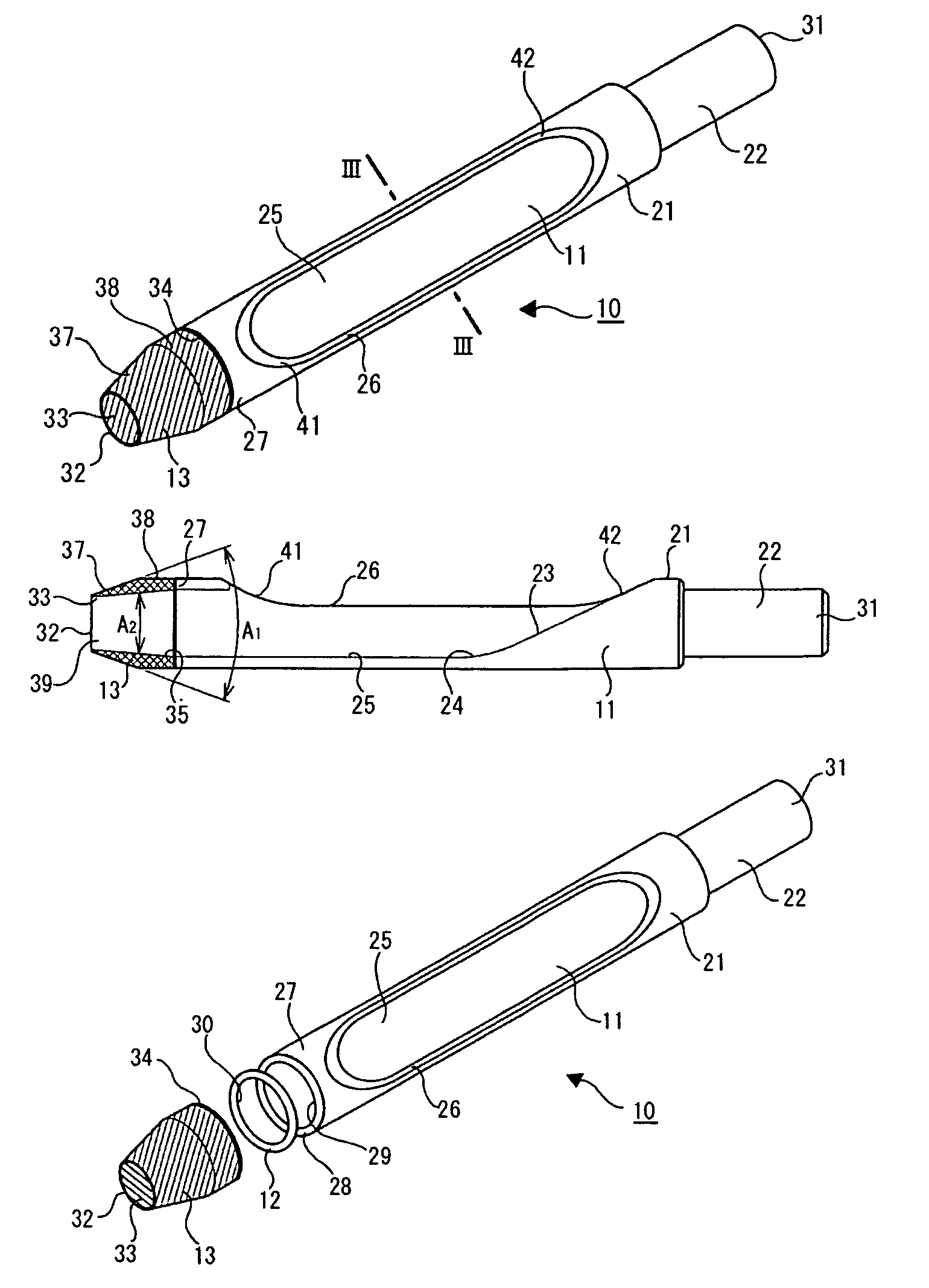

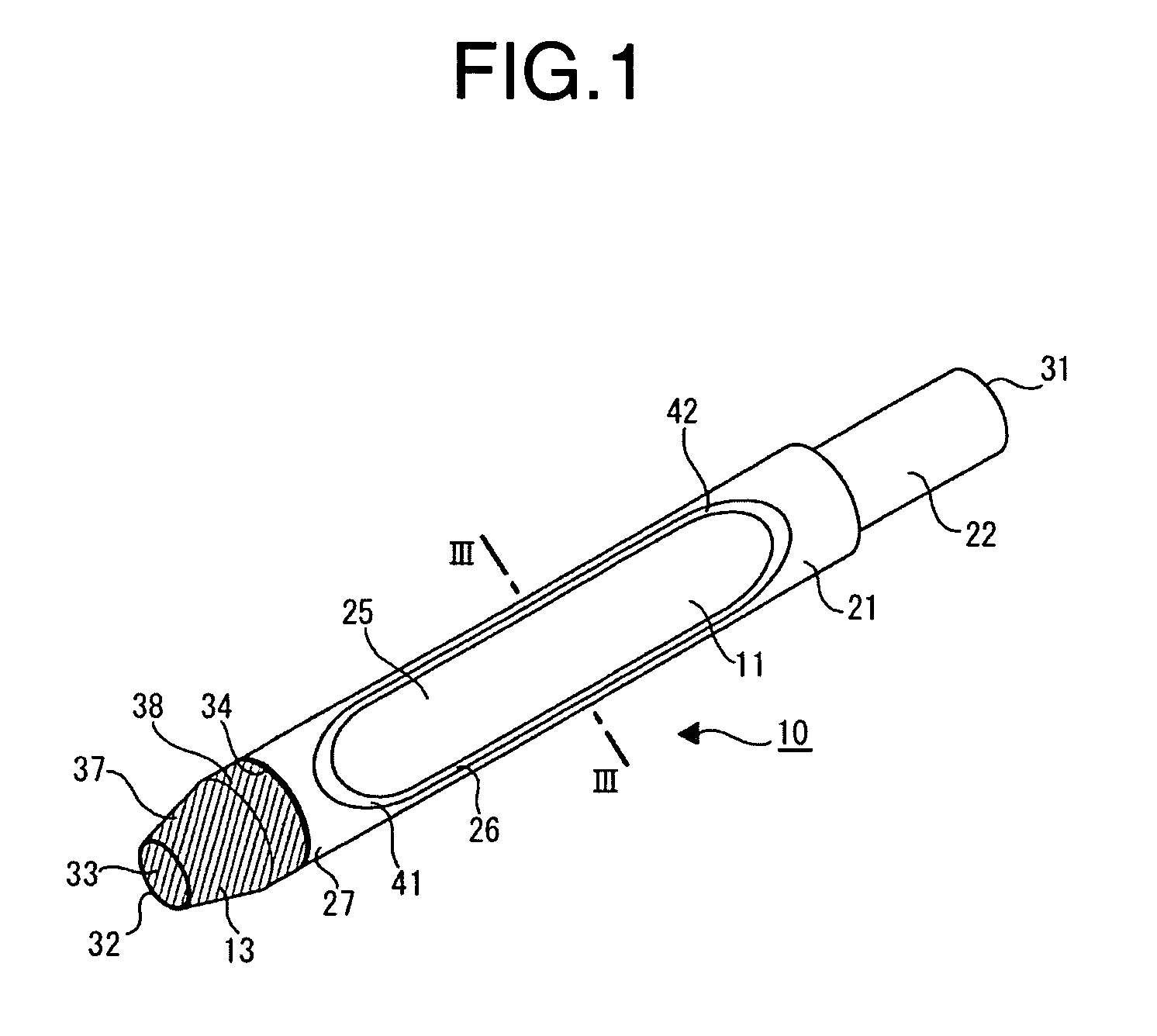

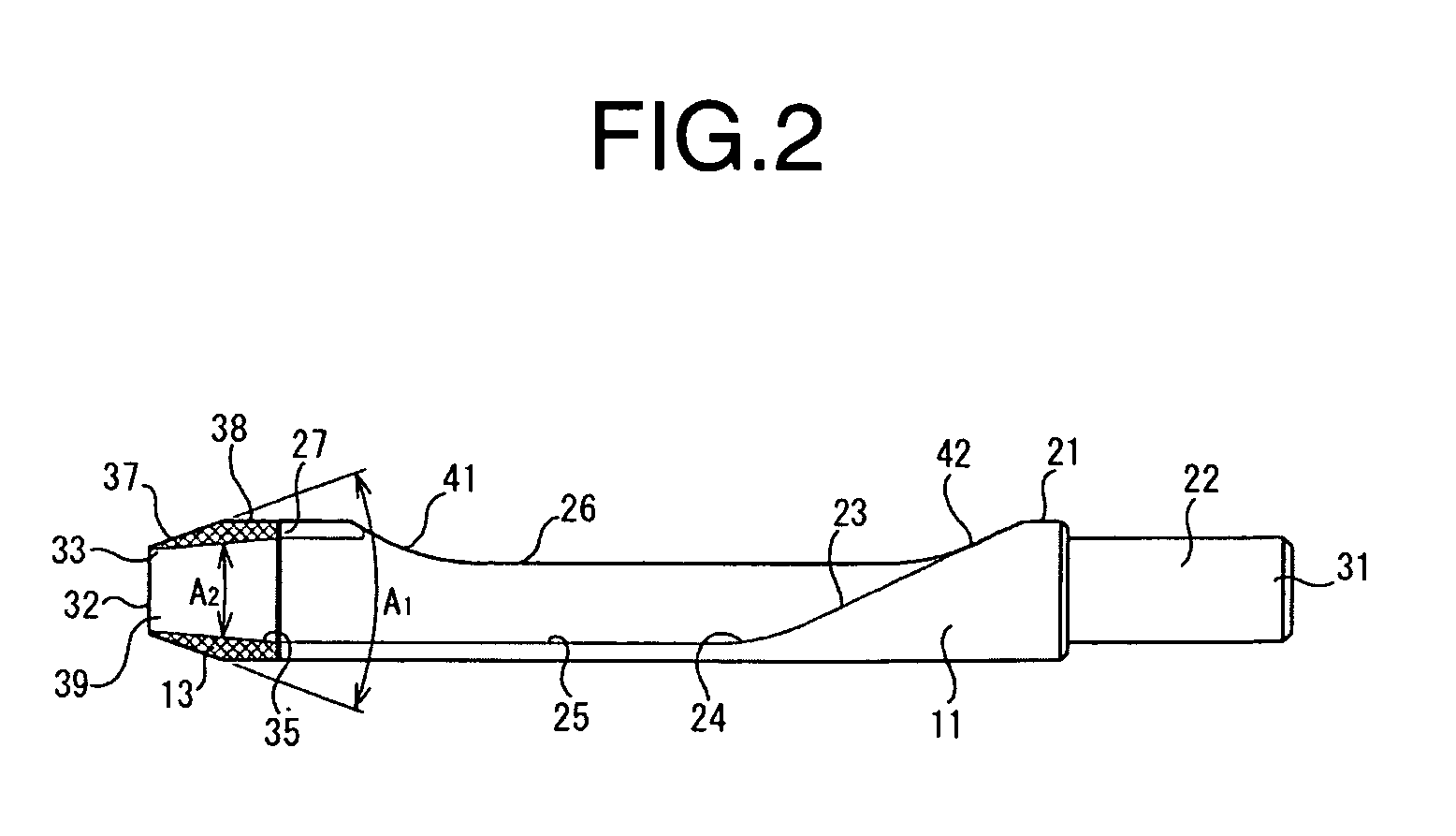

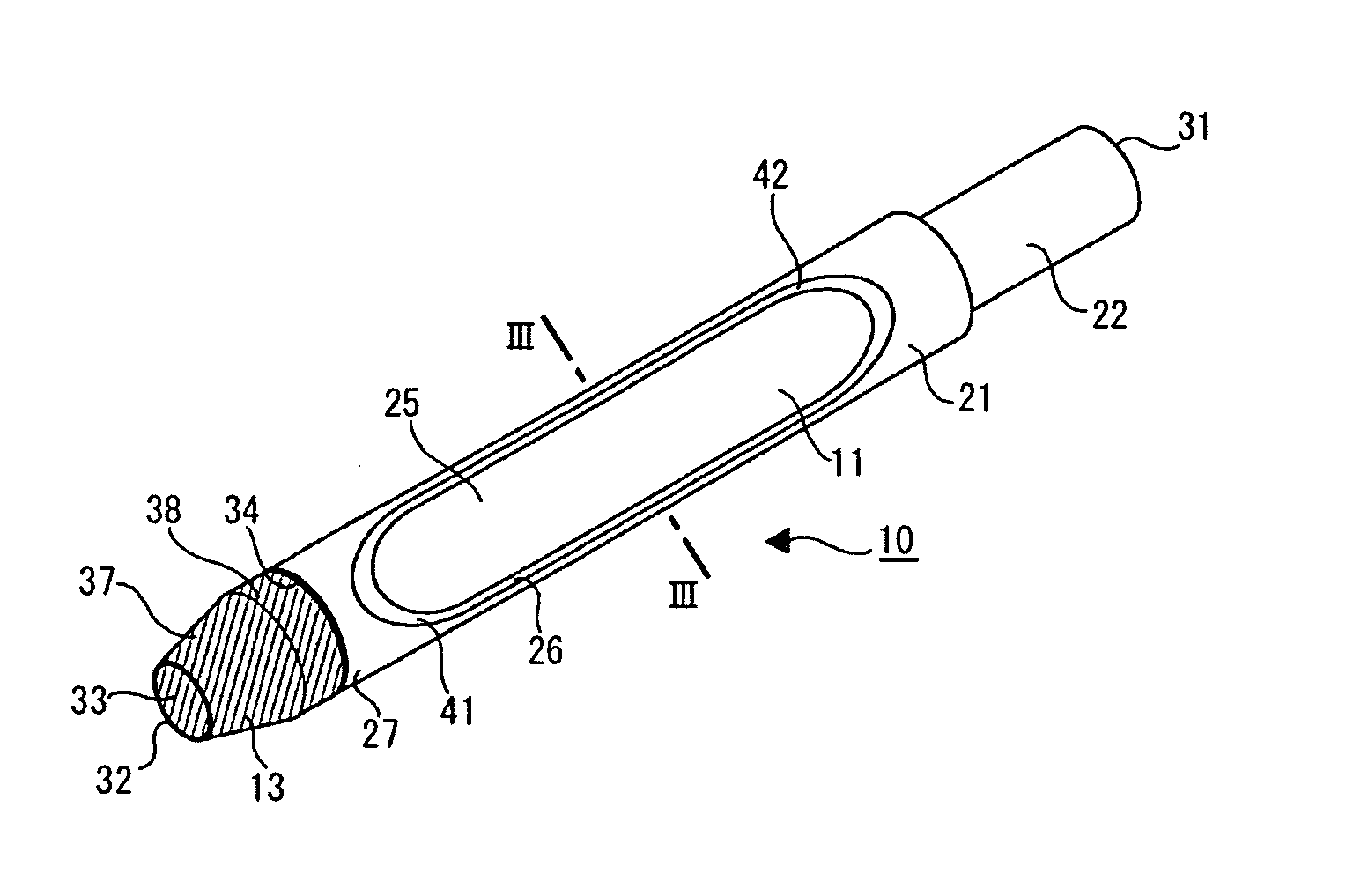

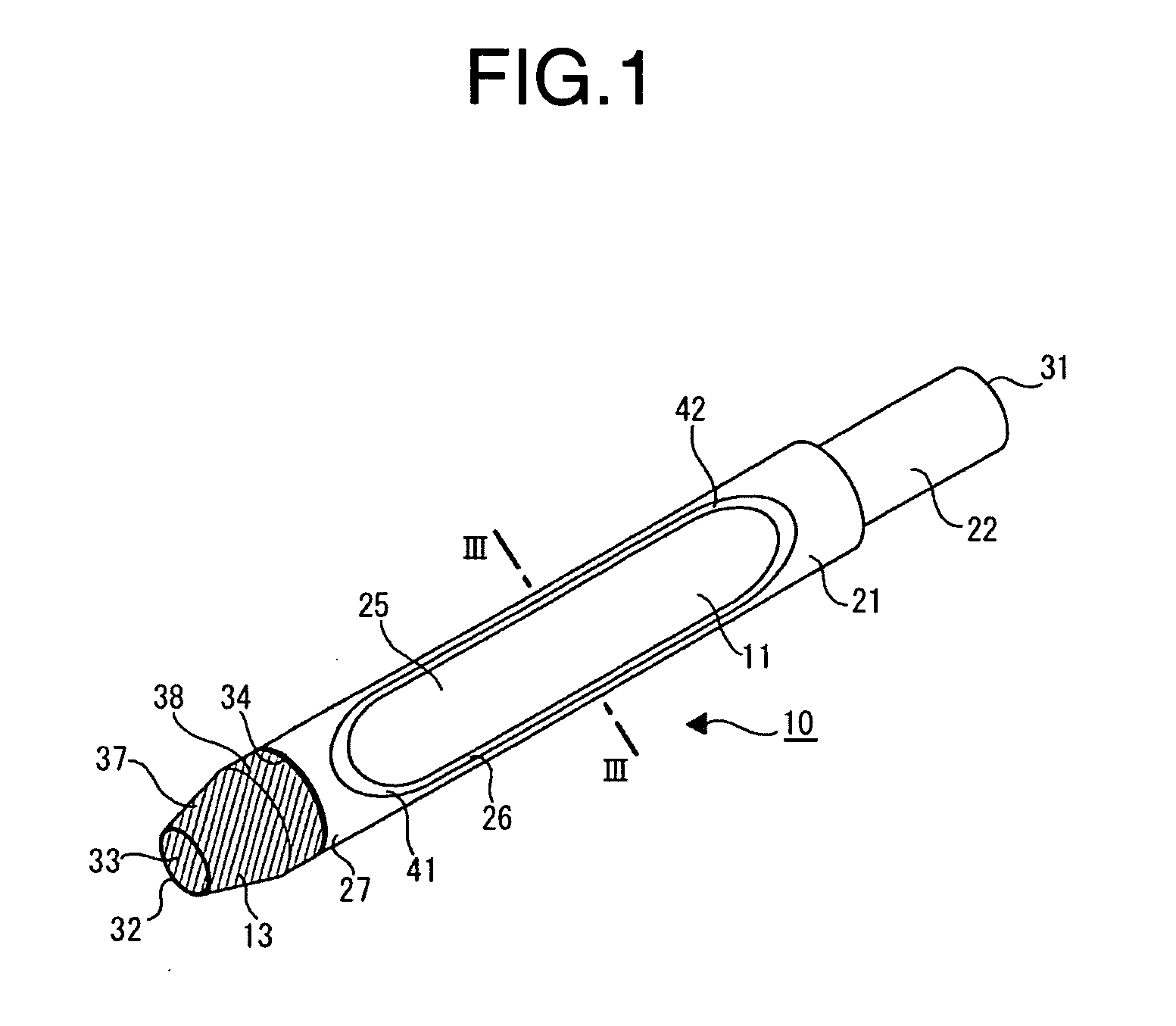

Aeration tine device

InactiveUS6945332B2Guaranteed uptimeImprove controllabilitySoil-working equipmentsDragsHard metalEngineering

A highly durable aeration tine device attached to a soil aerator has a tubular tine member extending cylindrically and a hard metal tip made of a hard metal material and typically made in a frustum shape of a cone, which is in an area contact with the tubular tine member between the surfaces of the tubular tine member and the hard metal tip. Each surface of the tubular tine member and the hard metal tip is extending in a plane perpendicular to the axial direction and can be fabricated easily, and the drive force provided from the soil aerator can be transmitted without loss.

Owner:KASHIWATOOL CORP

Fiber optic connector and method of assembling the same

The present invention discloses a fiber optic connector comprising a housing, a spring, a ferrule assembly and a crimping seat. Before being inserted into the housing, the ferrule assembly is pre-assembled into the crimping seat in a manner of being movable relative to the crimping seat. The spring is pre-assembled into the housing before the ferrule assembly is inserted into the housing. After the pre-assembled ferrule assembly and crimping seat are inserted into the housing, the crimping seat is snap-fitted in the housing, and the spring pushes the ferrule assembly, so that the ferrule assembly is capable of being moved against the spring relative to the crimping seat. Before inserted into a housing of the fiber optic connector, some components may be pre-assembled together to form an integral assembly having a size less than that of a housing of the fiber optic connector. Accordingly, the integral assembly may be smoothly pulled through a small long pipe. After pulled through the pipe, the integral assembly may be easily and quickly inserted into the housing as a whole at one time.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

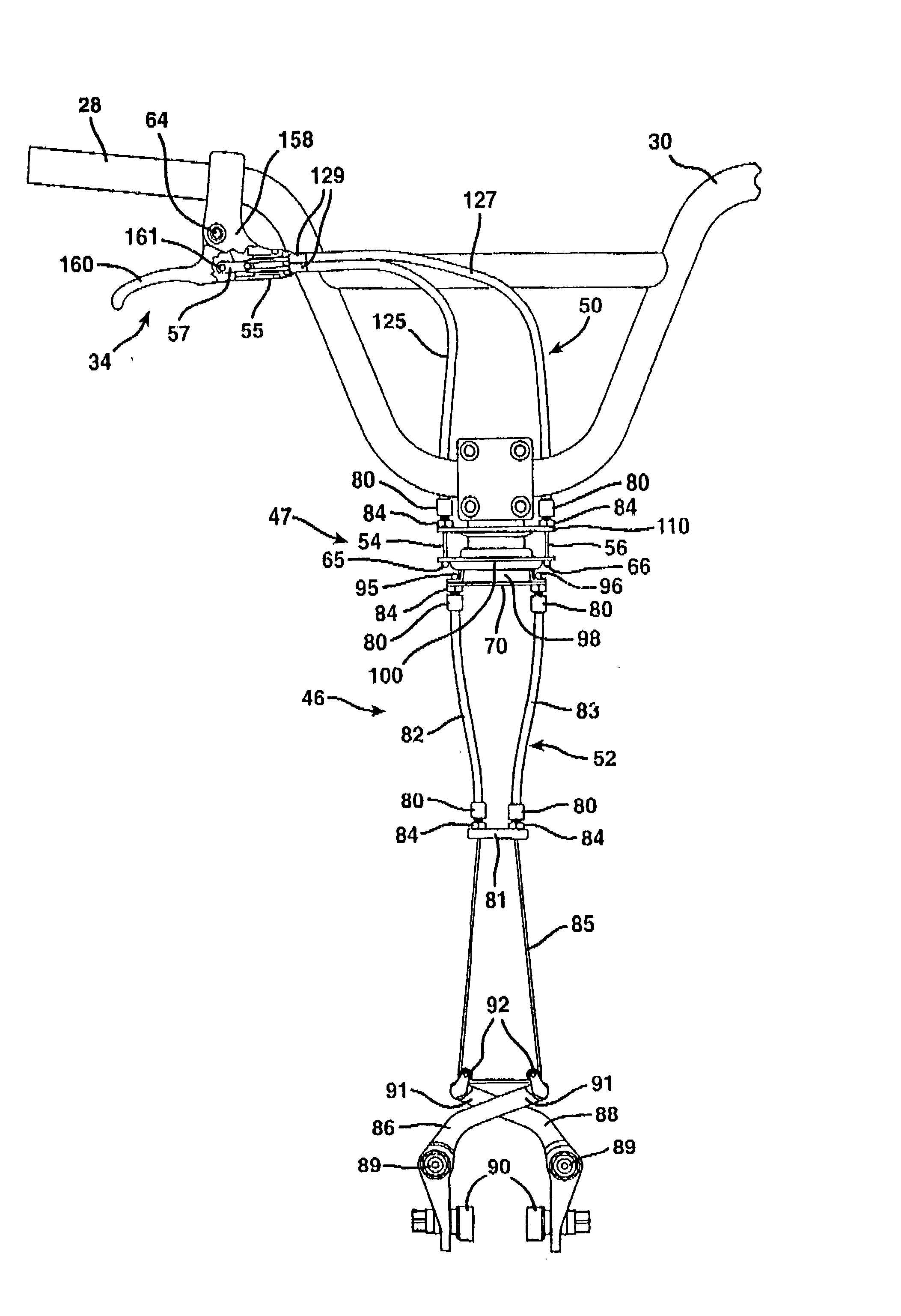

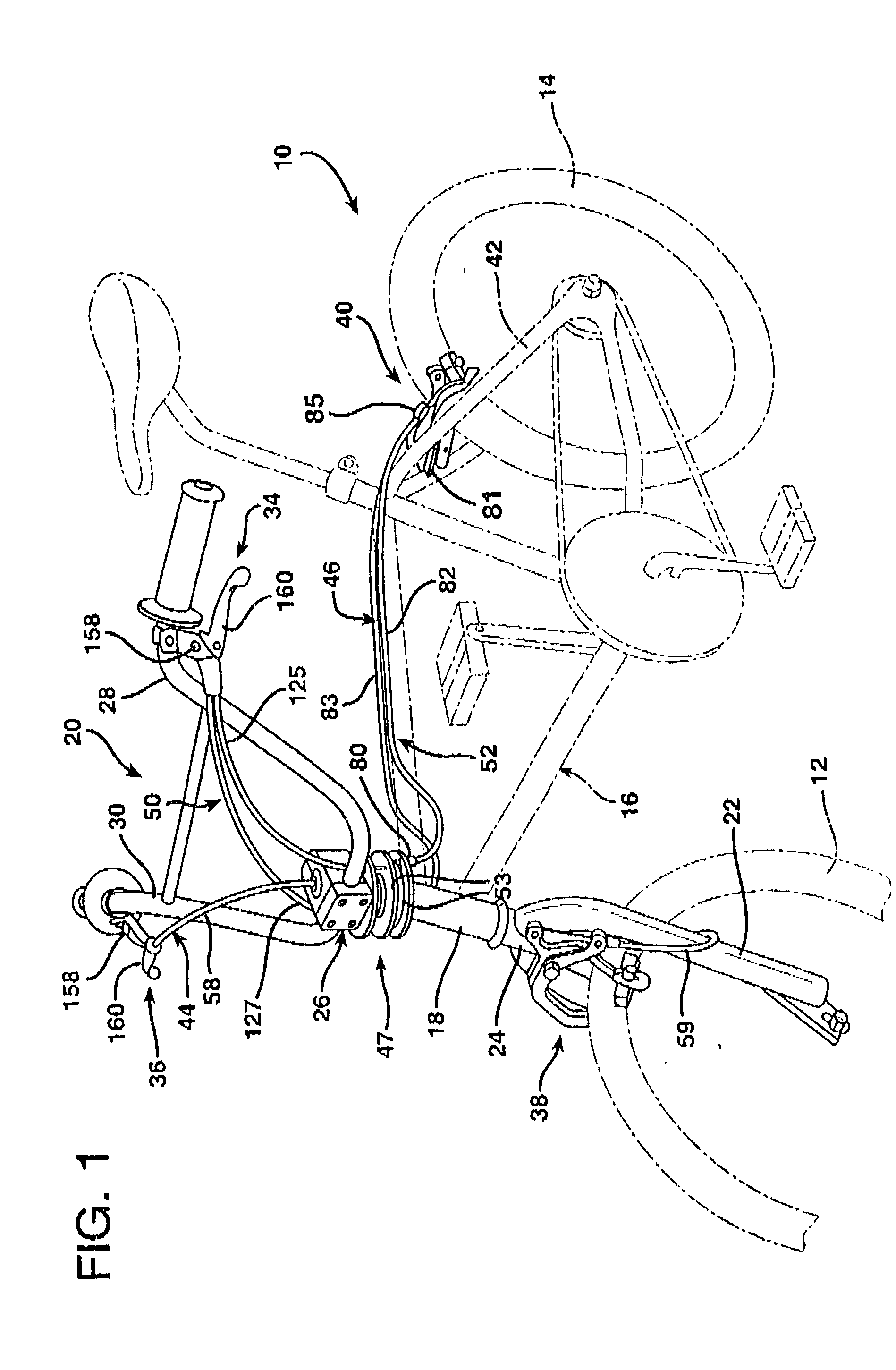

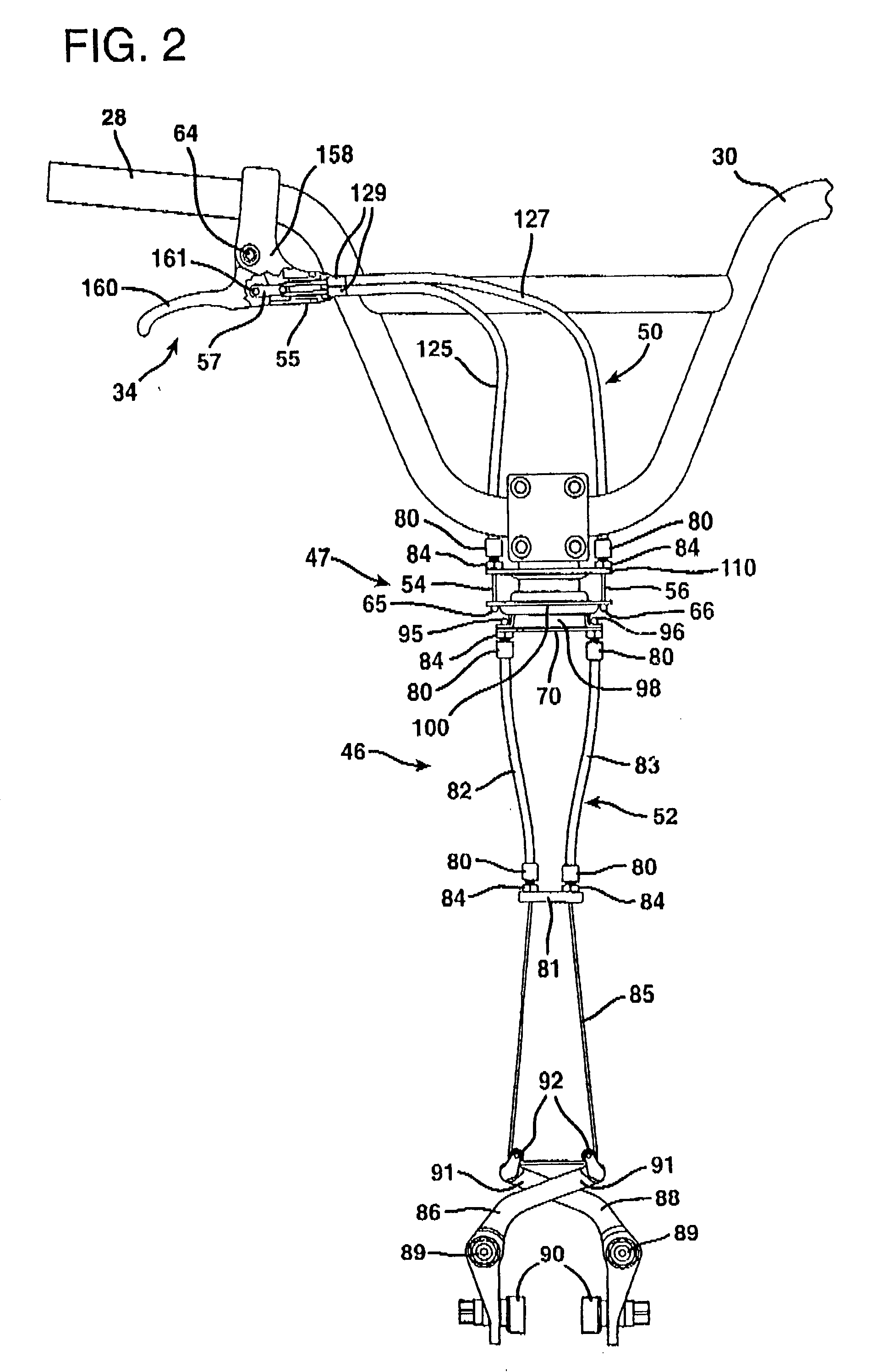

Bicycle cable brake control line

InactiveUS20040112685A1Free rotationPulling smoothlyBraking element arrangementsSteering deviceGyroscopeVehicle frame

A single rear bicycle brake control cable core is employed to operate the rear brake of a freestyle bicycle that employs a rotatable coupling that allows the handlebars, front wheel, and front wheel fork of a bicycle to be rotated through a complete revolution about the axis of the head tube of the bicycle frame. The single brake control cable core is looped about a roller which may be a pulley attached to the cable-engaging end of the handlebar-mounted rear brake lever, so that the point of contact between the control cable loop relative to the brake lever is not fixed. Cable sheaths surround portions of the cable core and are seated in a cable segment connector that in turn is rotatably mounted in a cable coupler attached to a handlebar-mounted brake lever assembly body. The coupler rotates about its own axis to maintain the unsheathed, proximal portions of the loop adjacent the pulley in coplanar alignment with the pulley. The brake lever rotates relative to the brake lever assembly body so as to move the pulley closer to or further from the cable coupler. Because the control cable loop passes about the pulley, tension on the cable brake line allows the gyroscopic system to self-adjust the balance of its bearing unit. Preferably, a toggle link is provided between the cable-engaging end of the brake lever and the cable core loop. The pulley is mounted at the end of the toggle link, remote from the brake lever.

Owner:BEARCORP

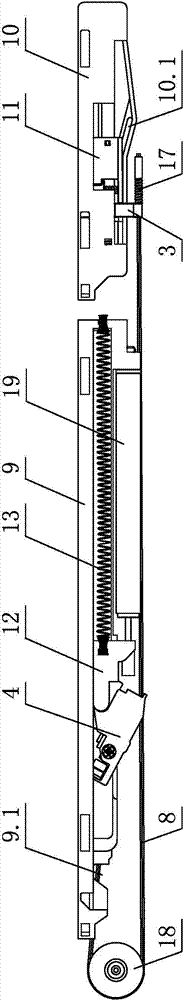

Drawer slide rail which is closed in damping mode and opened in pressing mode

A drawer slide rail which is closed in a damping mode and opened in a pressing mode comprises a slide rail assembly arranged on a cabinet side plate. A drawer is arranged on the slide rail assembly and is at least composed of a bottom plate and a front panel. The slide rail assembly is at least composed of a movable slide rail and a fixed slide rail, and the movable slide rail and the fixed slide rail are both provided with a pressing rebounding device, a damping device, a shifting part A and a shifting part B which interact with one another. Each damping device makes contact with the corresponding shifting part A when the drawer is closed by at least a segment of travel, and the drawer is automatically closed through the acting force of each damping device. The front panel automatically pauses at a pre-pause distance H relative to the cabinet side plate through the pressing rebounding devices when the drawer is automatically closed, the front panel is pressed in the closing direction in the opening process, and the drawer is automatically opened through the acting force of the pressing rebounding devices. Due to the structural improvement, the drawer slide rail has the advantages of being simple and reasonable in structure, safe, reliable, small in size, long in service life, steady and smooth in the pulling process, small in exerted force, convenient to operate, and humanized in design and is high in practicability.

Owner:伍志勇

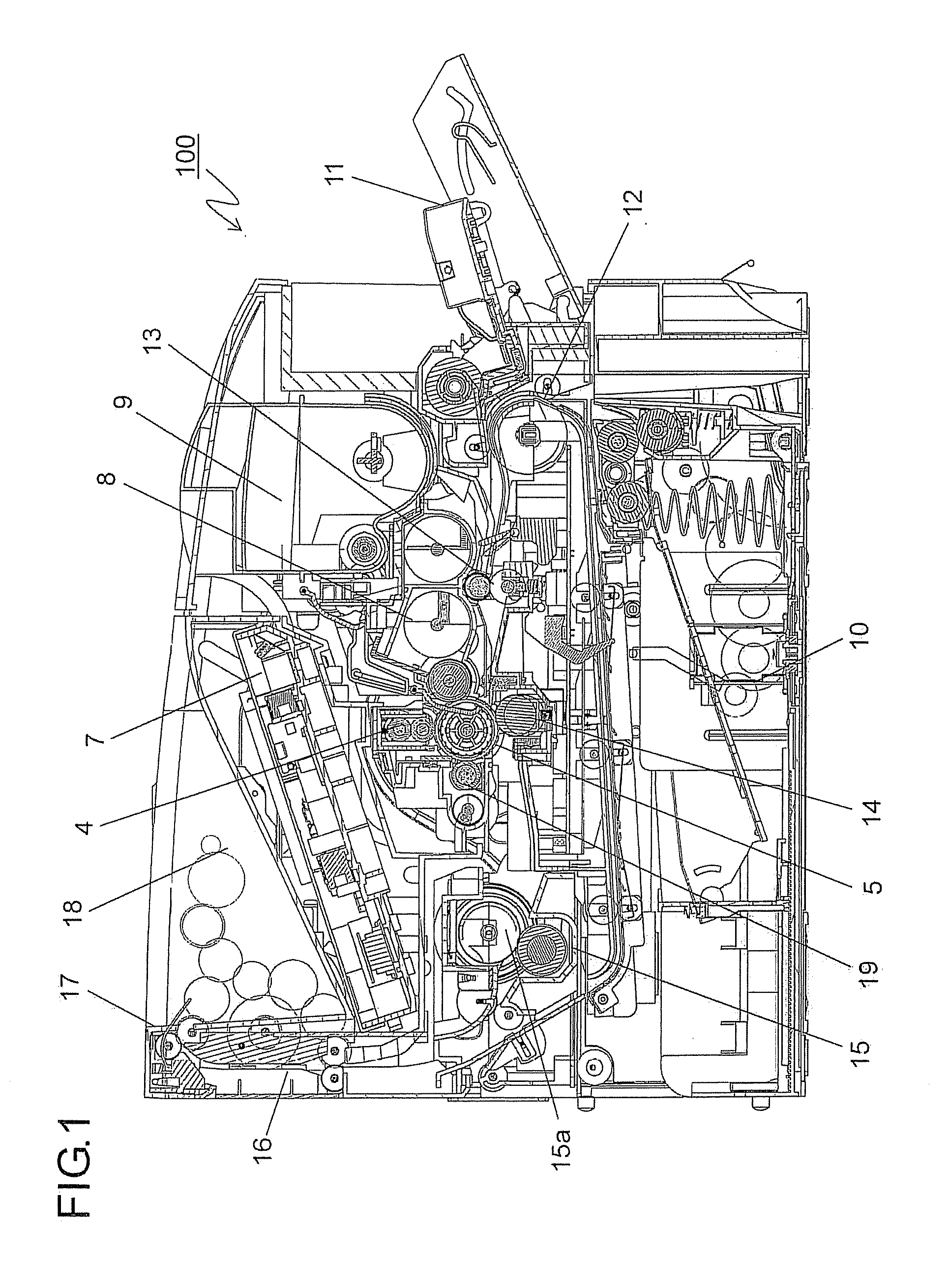

Aluminum pipe having excellent surface quality, method and apparatus for manufacturing the aluminum pipe, and photosenstive drum base body

InactiveCN1819879AEfficient preparationPrevent heat stickingDrawing mandrelsDrawing diesMaterials scienceAluminium

In a manufacturing method in which an aluminum bullet is extruded to obtain an extruded raw pipe 4 and then the extruded raw pipe 4 is subjected to a drawn process, the aluminum extruded raw pipe 4 is cut at a position within 10m from a discharge position M of an extruding die to obtain an aluminum extruded raw pipe 4 with a length of 10m or shorter, and the extruded raw pipe 4 is subjected to a drawing process. With this, an aluminum pipe excellent in surface quality having no surface defect such as white peeling can be manufactured at high manufacturing efficiency.

Owner:RESONAC HOLDINGS CORPORATION

Portable ice fishing shelter

ActiveUS8191564B1Efficiently providePulling smoothlyVehicle with living accommodationProtective buildings/sheltersInterior spaceEngineering

A portable ice fishing shelter for providing an enclosed and expandable structure for ice fishing within. The ice fishing shelter generally includes a rigid primary enclosure having sidewalls, a roof, and a base to form a first interior space, wherein the base forms an inverted U-shaped raised center portion to accommodate a seat within and allow for smoother pulling below. The primary enclosure also has a side opening extending through at least one of the sidewalls for a rigid extendable enclosure. The extendable enclosure includes an open bottom and extends from a perimeter of the side opening and is movably connected thereto. The extendable enclosure is adapted to move between a retracted position during storage or transport and an extended position during use, wherein a second interior space is formed to accommodate one or more angling holes. A tow hitch and glide members may also extend from the primary enclosure.

Owner:LINDHOLM MICHAEL T

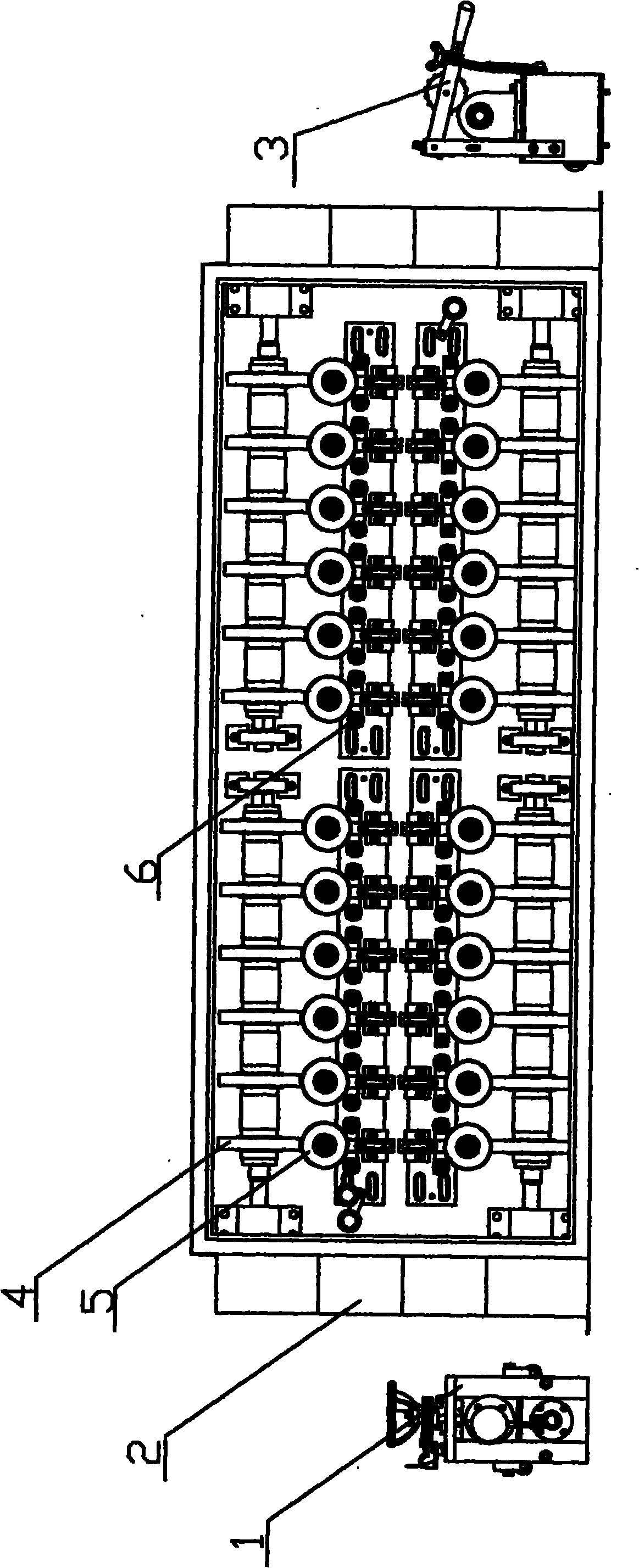

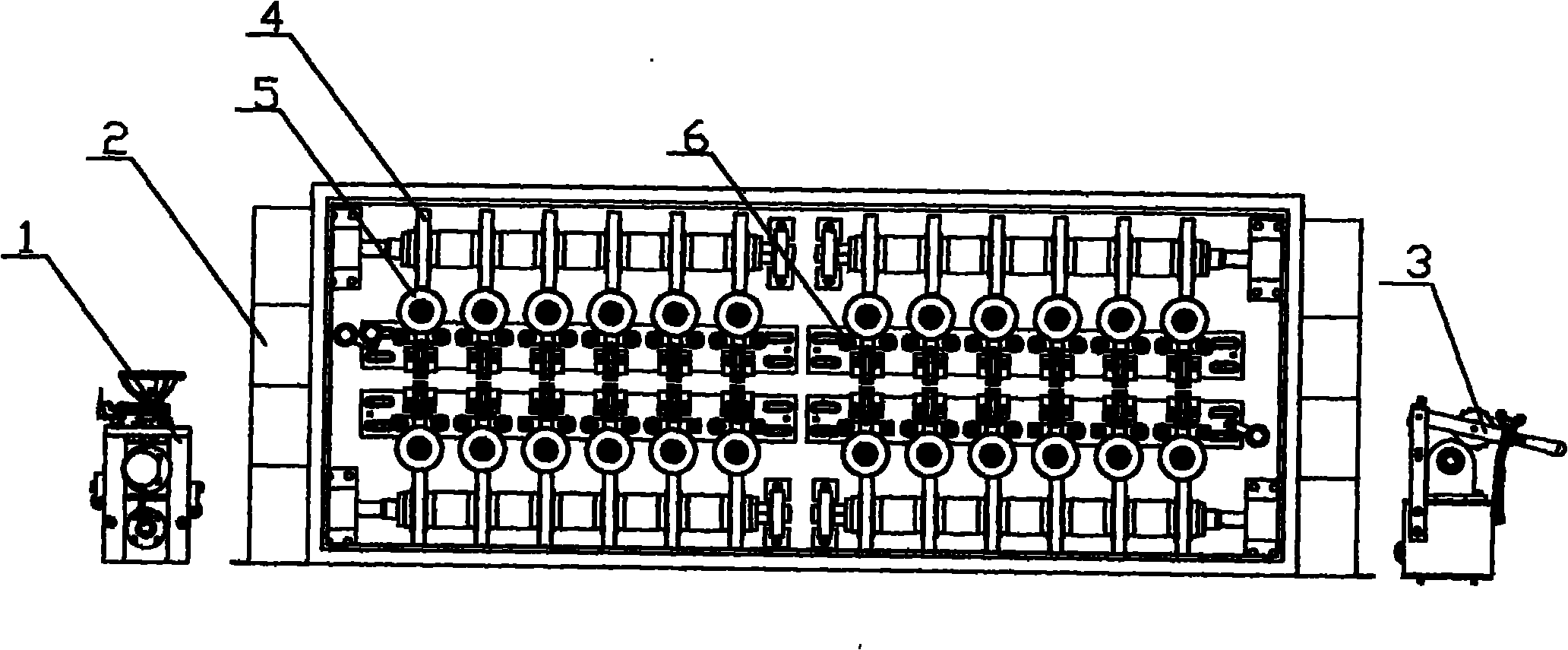

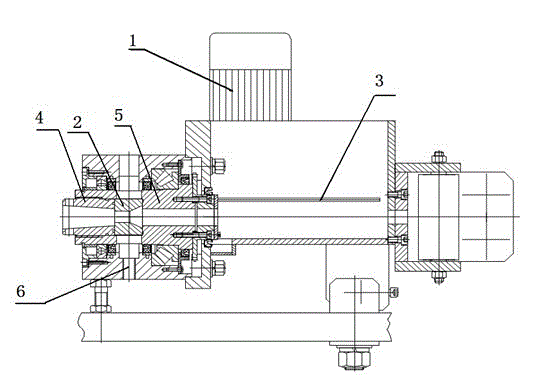

Surface polishing machine of metal zipper

InactiveCN102059639ANot easy to damageReduce the influence of external factorsPolishing machinesEngineeringUnit group

The invention discloses a surface polishing machine of a metal zipper, aiming at providing the surface polishing machine of the metal zipper with good polishing effect. The surface polishing machine of the metal zipper consists of a pressing drum mechanism, a polishing mechanism arranged behind the pressing drum mechanism and a belt discharging mechanism arranged behind the polishing mechanism, and is characterized in that polishing wheels are arranged in the polishing mechanism; polishing supporting wheels are arranged under the polishing wheels; two belt-passing wheels are arranged under the polishing supporting wheels; and the polishing wheels, the polishing supporting wheels and the belt-passing wheels form polishing units. The polishing wheels are flap wheels. The polishing units are arranged oppositely to form at least two the polishing unit groups. The surface polishing machine is mainly used for polishing the surface of the metal zipper of a metal zipper manufacturer so as to improve the quality.

Owner:岳从平

Machining method of nickel and titanium shape memory alloy wire

The invention discloses a machining method of a nickel and titanium shape memory alloy wire. The method comprises the following steps that firstly, one end of the nickel and titanium shape memory alloy wire is milled into a cone shape and penetrates into a wire drawing mold with 0-40% deformation amount; secondly, the nickel and titanium shape memory alloy wire after penetrating the mold penetrates through a pipe type resistance furnace, the temperature is set between 600 DEG C and 800 DEG C, online annealing is carried out, and the wire is drawn to the specific size in a cold manner; and thirdly, the step one and the step two are repeated until the nickel and titanium shape memory alloy wire is drawn to the needed size. In addition, multiple pipe type furnaces and wire drawing machines are connected in series to use, and one-time forming of the nickel and titanium shape memory alloy wire can be achieved. The efficiency and the stability of drawing the nickel and titanium shape memoryalloy wire can effectively improved.

Owner:INNOVATIVE MATERIAL & DEVICES

Rotation wire drawing die box and using method thereof

Owner:GUIZHOU WIRE ROPE

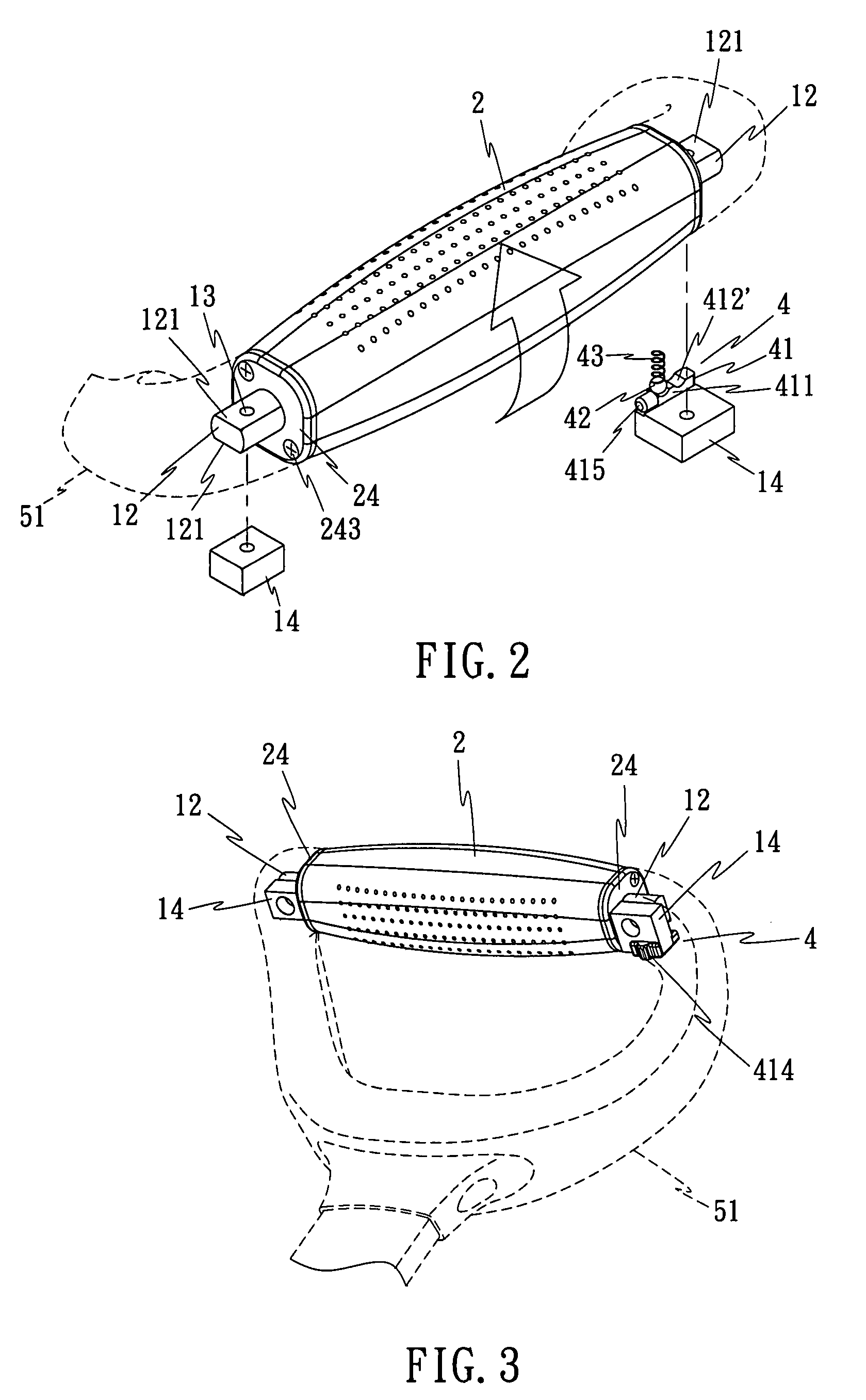

Rotation-controllable rotary grip assembly for luggage handle

A rotation-controllable rotary grip assembly includes a shaft affixed to a retractable handle of a luggage, a barrel-like grip sleeved onto and turntable about the shaft, a spring member sleeved onto one extension rod at one end of the shaft and connected between the shaft and the grip for returning the grip to its former position after a rotary motion of the grip relative to the shaft, and a lock for locking the grip to the shaft to prohibit rotation of the grip relative to the shaft.

Owner:GRP III INT

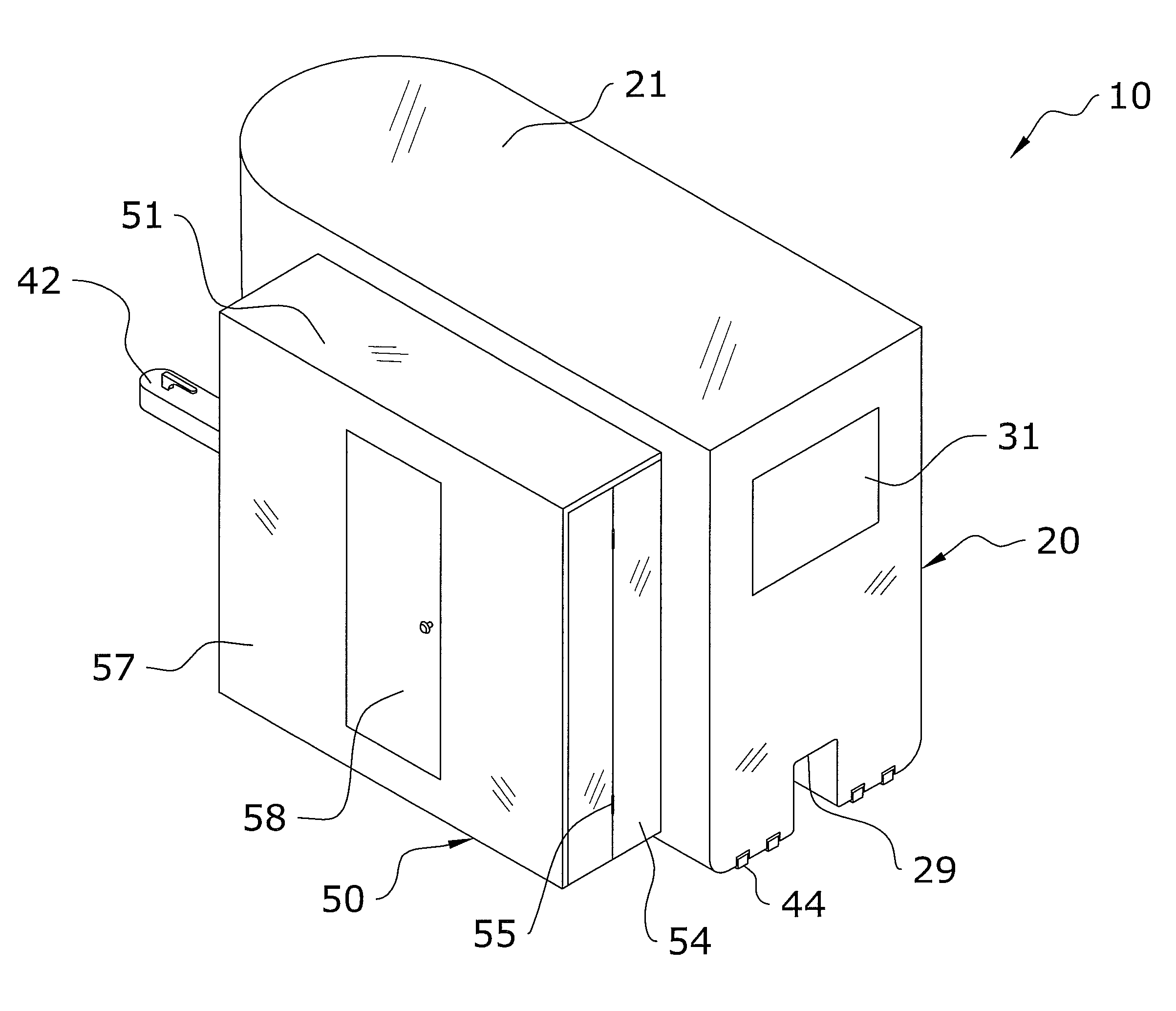

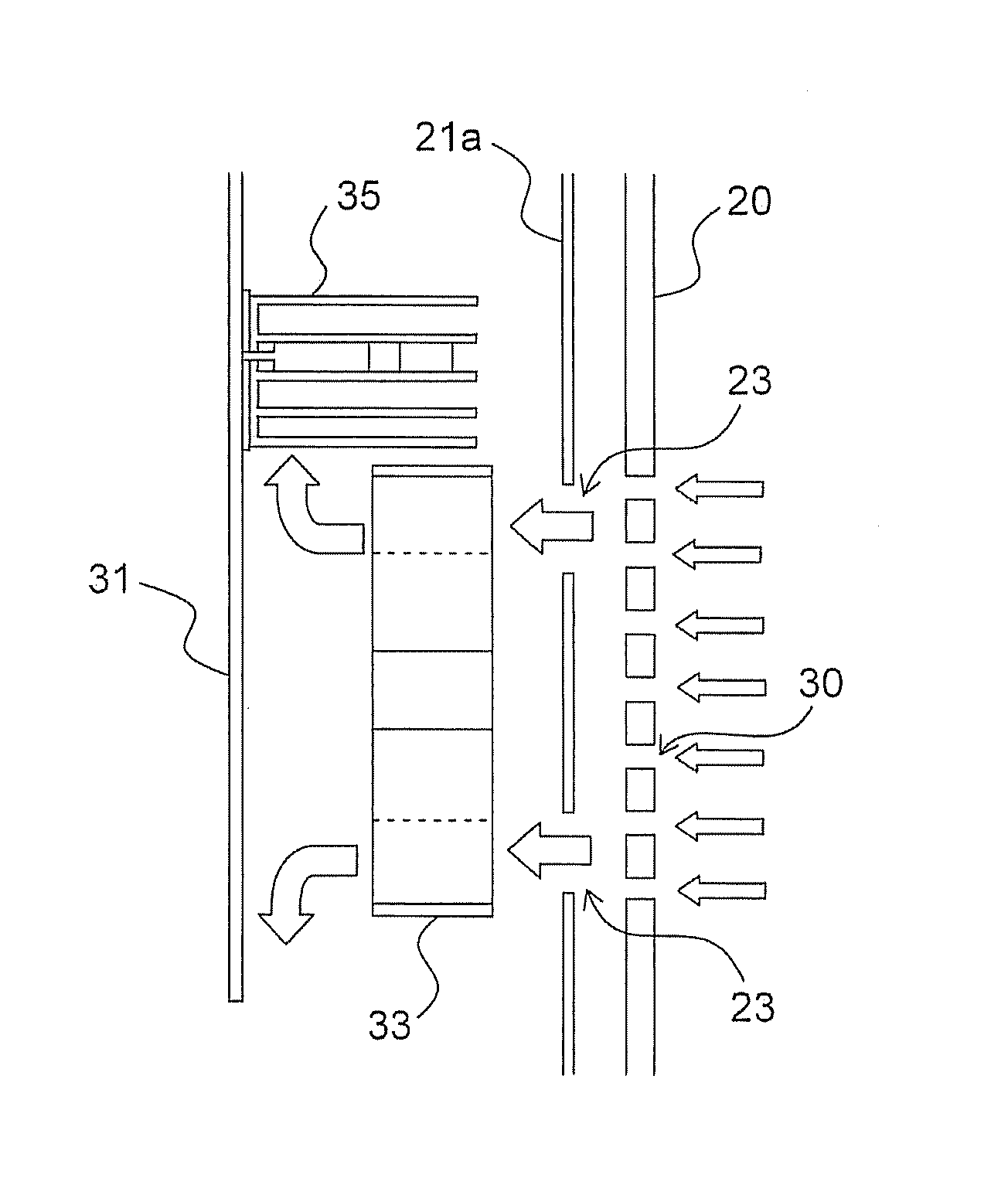

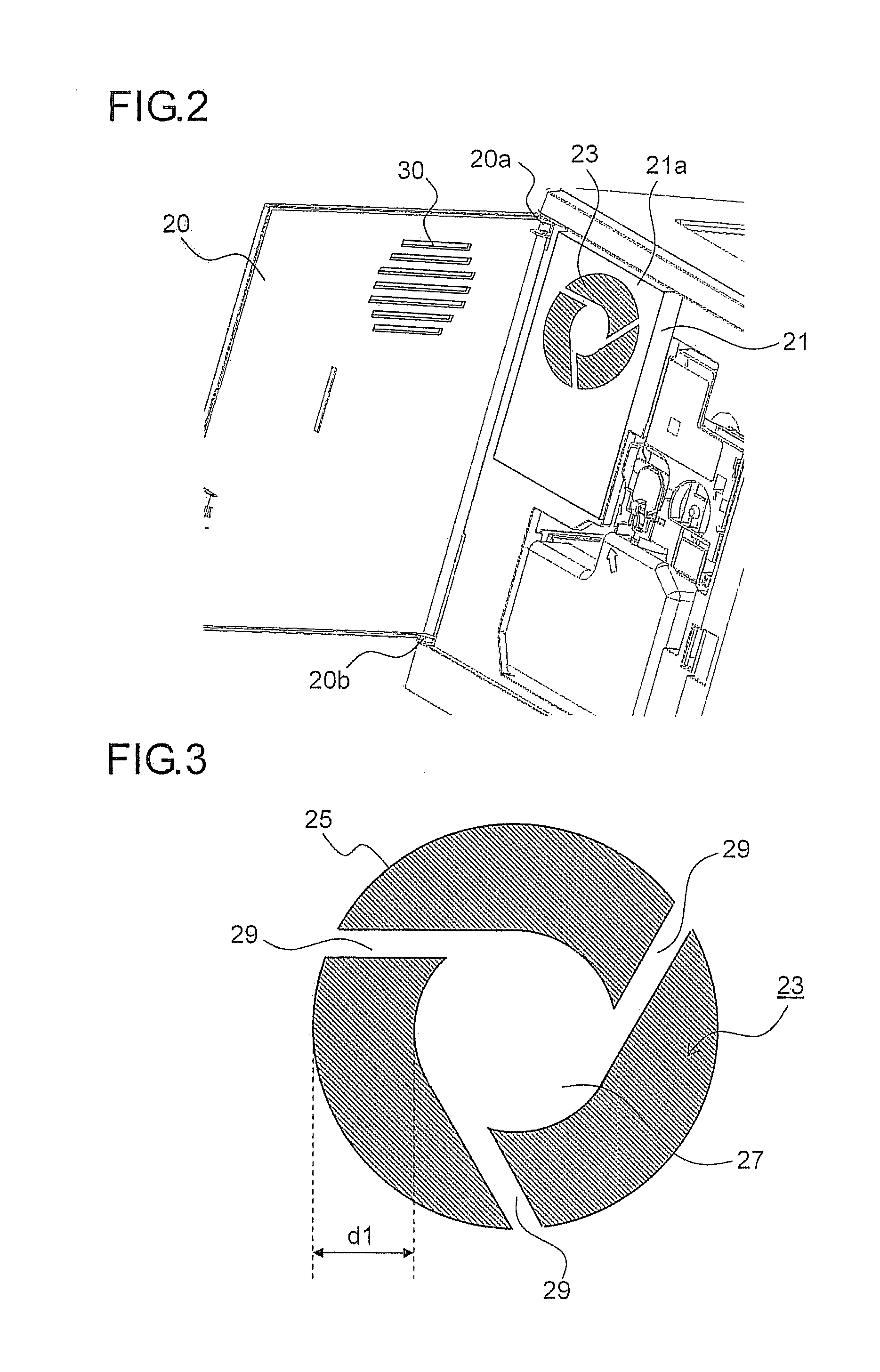

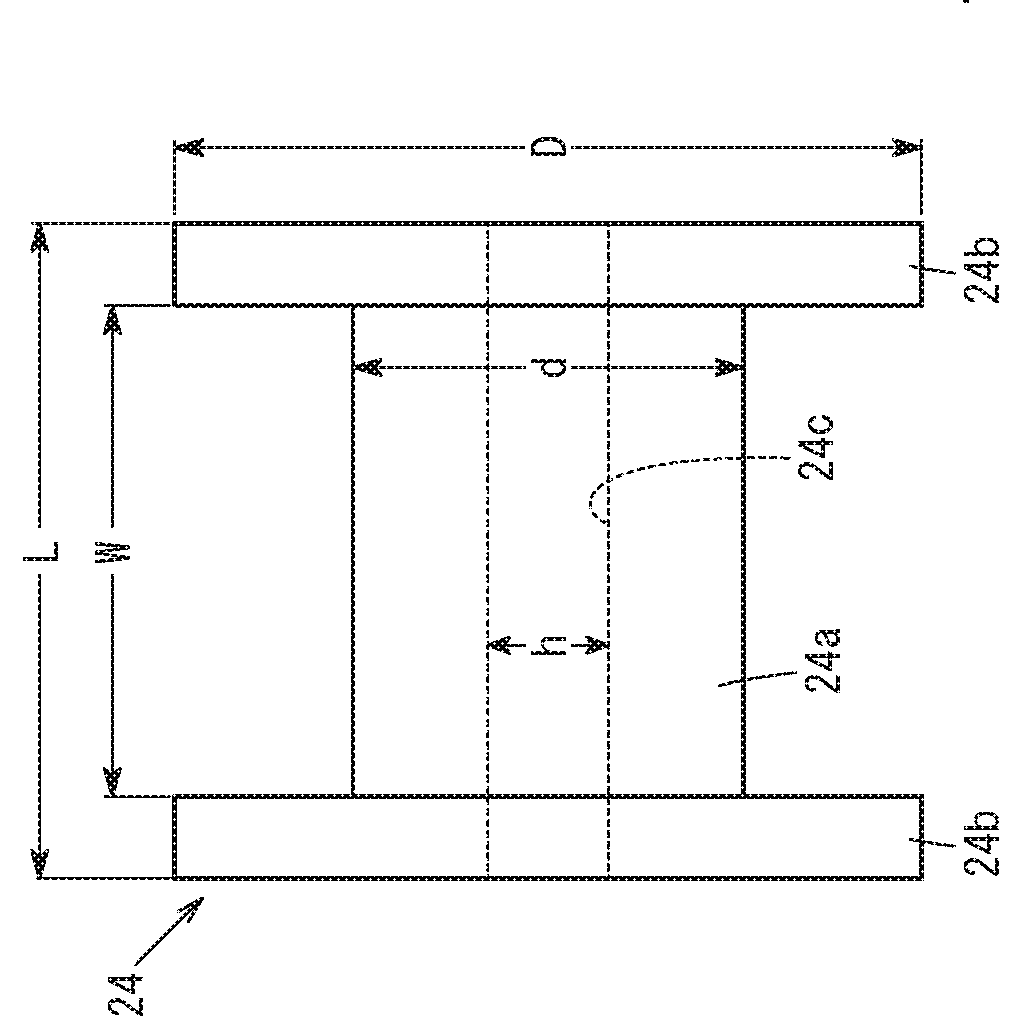

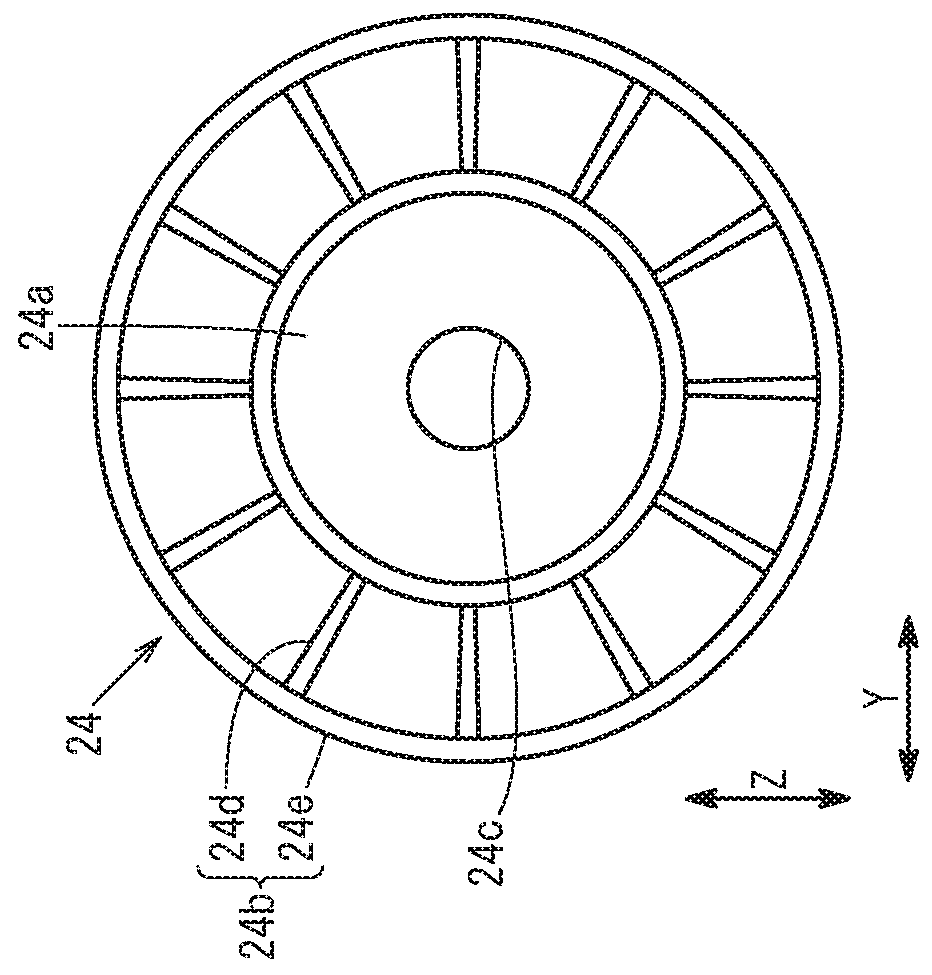

Air intake mechanism of electronic apparatus, and image forming apparatus provided with air intake mechanism

InactiveUS20150003859A1InhibitionCurb occurrence of noise produced by vibration of the inner coverDigital data processing detailsElectrography/magnetographyEngineeringLouver

This air intake mechanism is configured of a first louver (23), a second louver (30), and an axial fan (33). The first louver (23) is an annular opening between an outer circular section (25), which is concentric to the rotating axis (rotation center) of the axial fan (33), and an inner circular section (27), which is concentric to the outer circular section (25). The second louver (30) is configured of a plurality of linear slits (30a), which are parallel to each other. The opening width (d2) of each of the slits (30a) that constitutes the second louver (30) is smaller than the opening width (d1) of the first louver (23).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

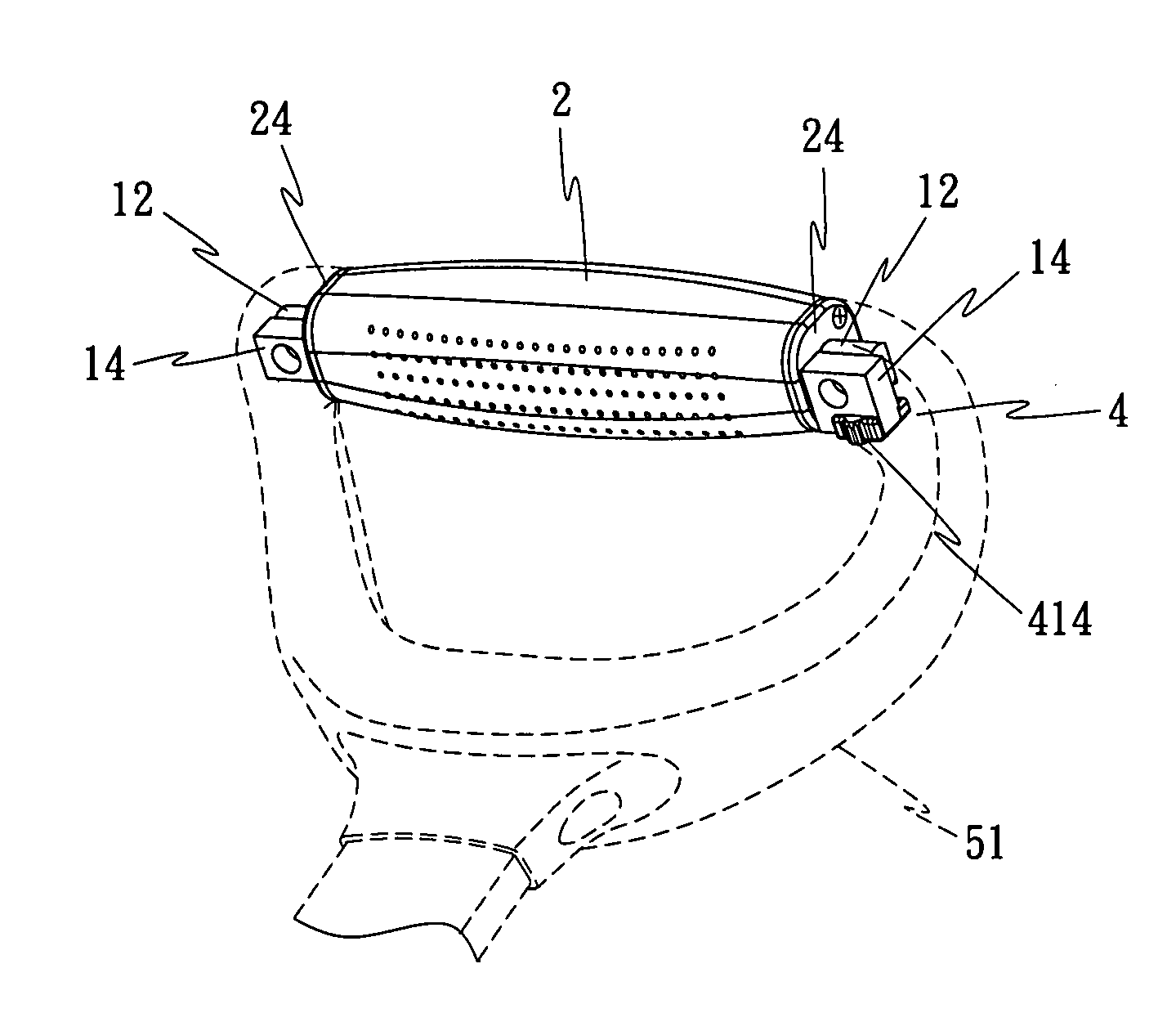

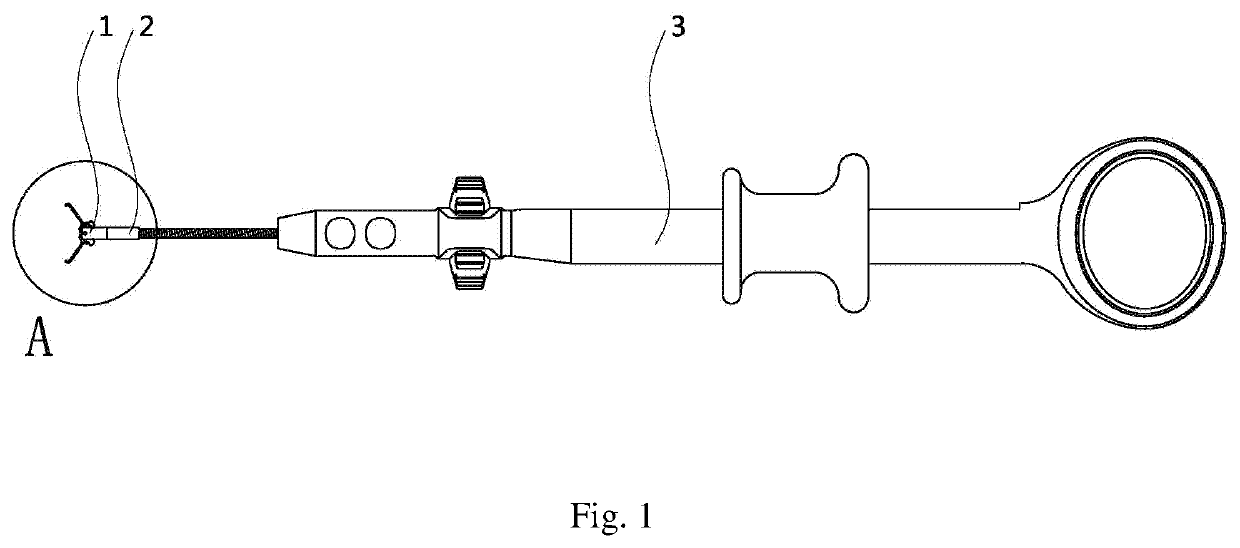

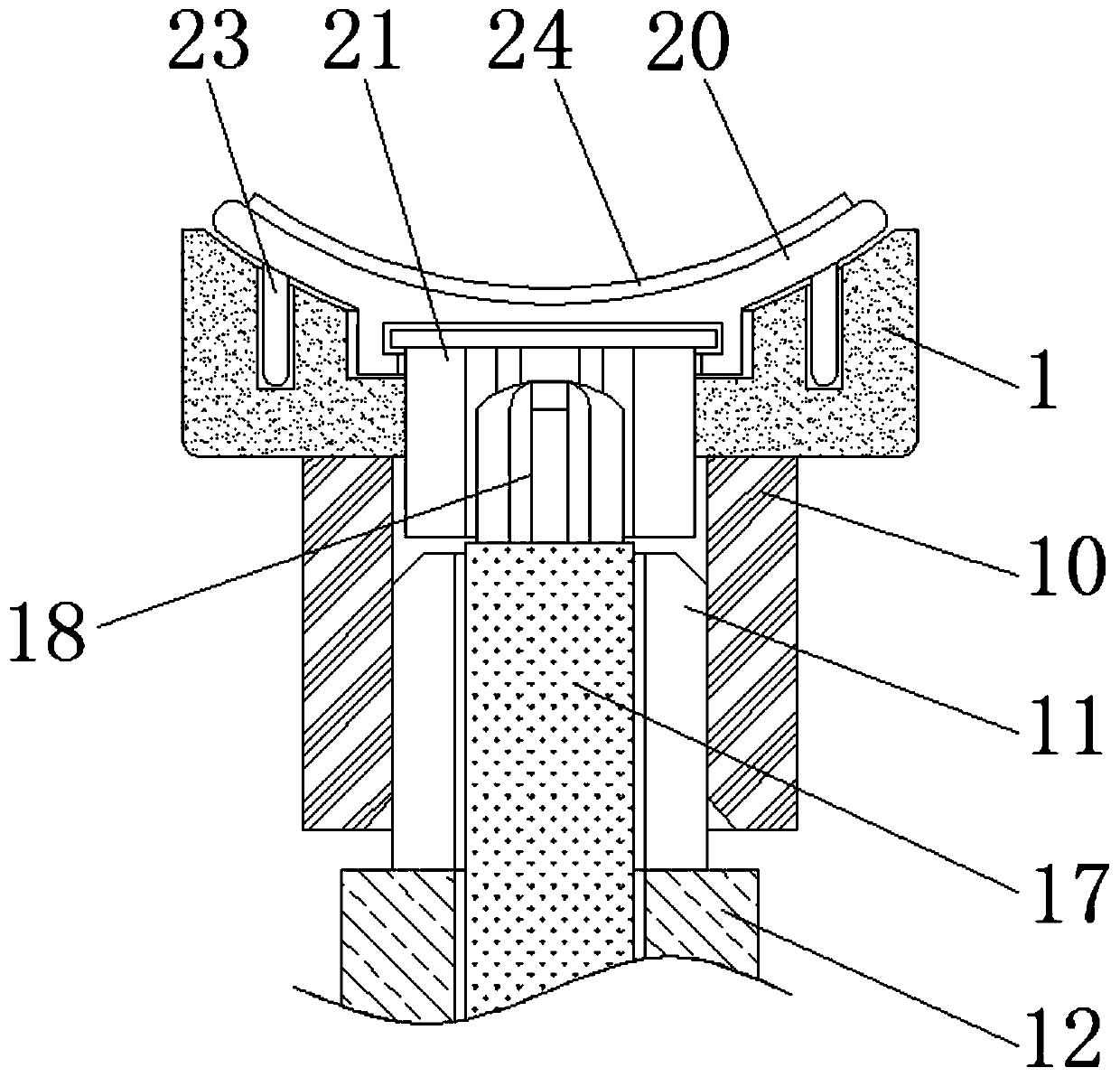

Hemostatic Clip Device

ActiveUS20190336130A1Simple structurePulling smoothlySurgical forcepsWound clampsBiomedical engineeringClip device

The present invention relates to a medical instrument, and particularly relates to a hemostatic clip device. The device includes a clamping component and a holder component. The head portion of the sleeve is provided with open slots for clamping arms to move. The tail ends of the outer side edges of clamping arms each is provided with a recess. A hole, corresponding to the position of the recess of one clamping arm, is formed in the other one. The sleeve is connected with the sleeve holder through inner core. The head end of the double-wire supporting arm is connected with the holes, and the other end is connected with wire rope and passes through the sleeve, the inner core, the sleeve holder and a bourdon tube so as to be connected with an operation handle. The device has the advantages of simple structure, firm clamping, convenient use and the like.

Owner:ALTON SHANGHAI MEDICAL INSTR

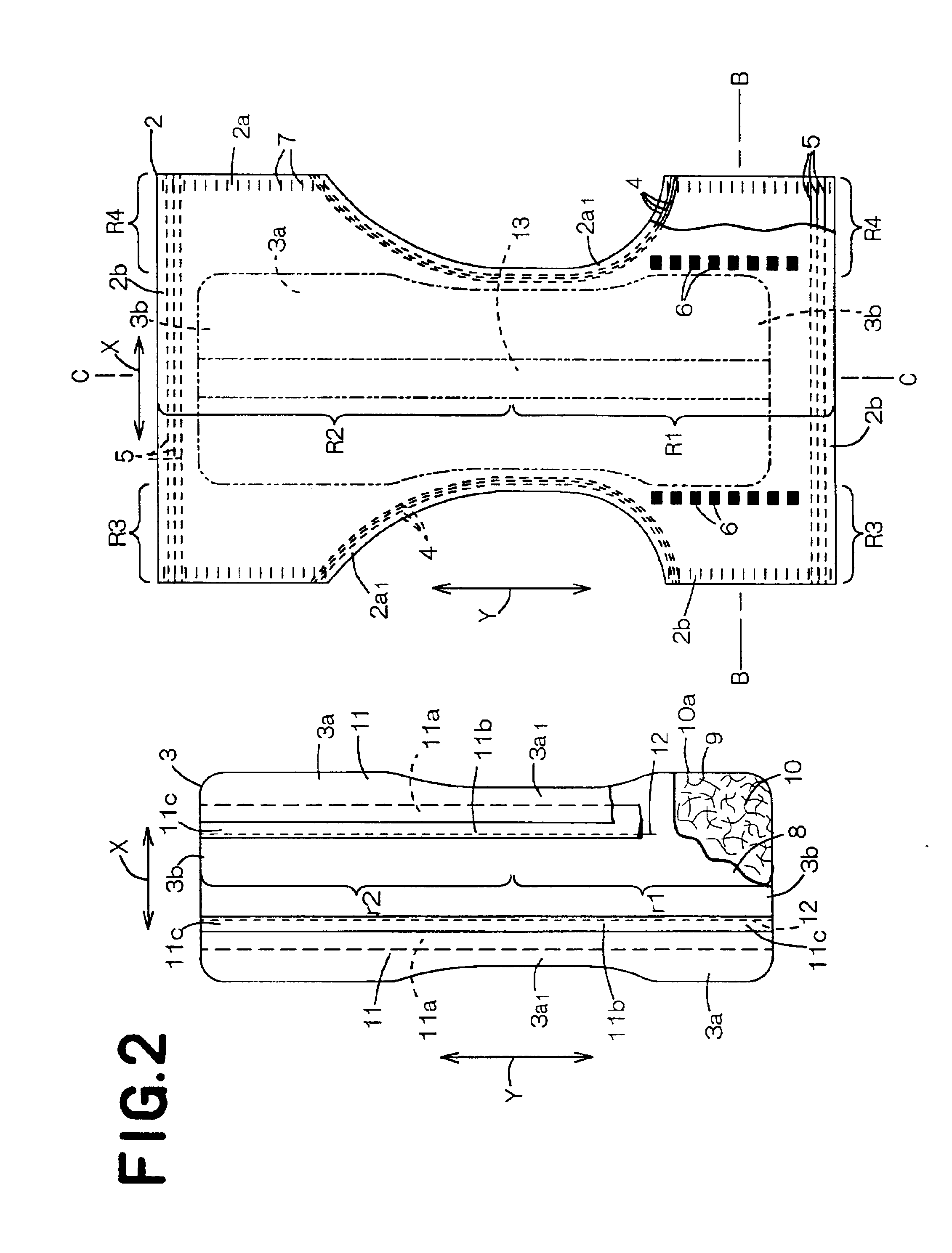

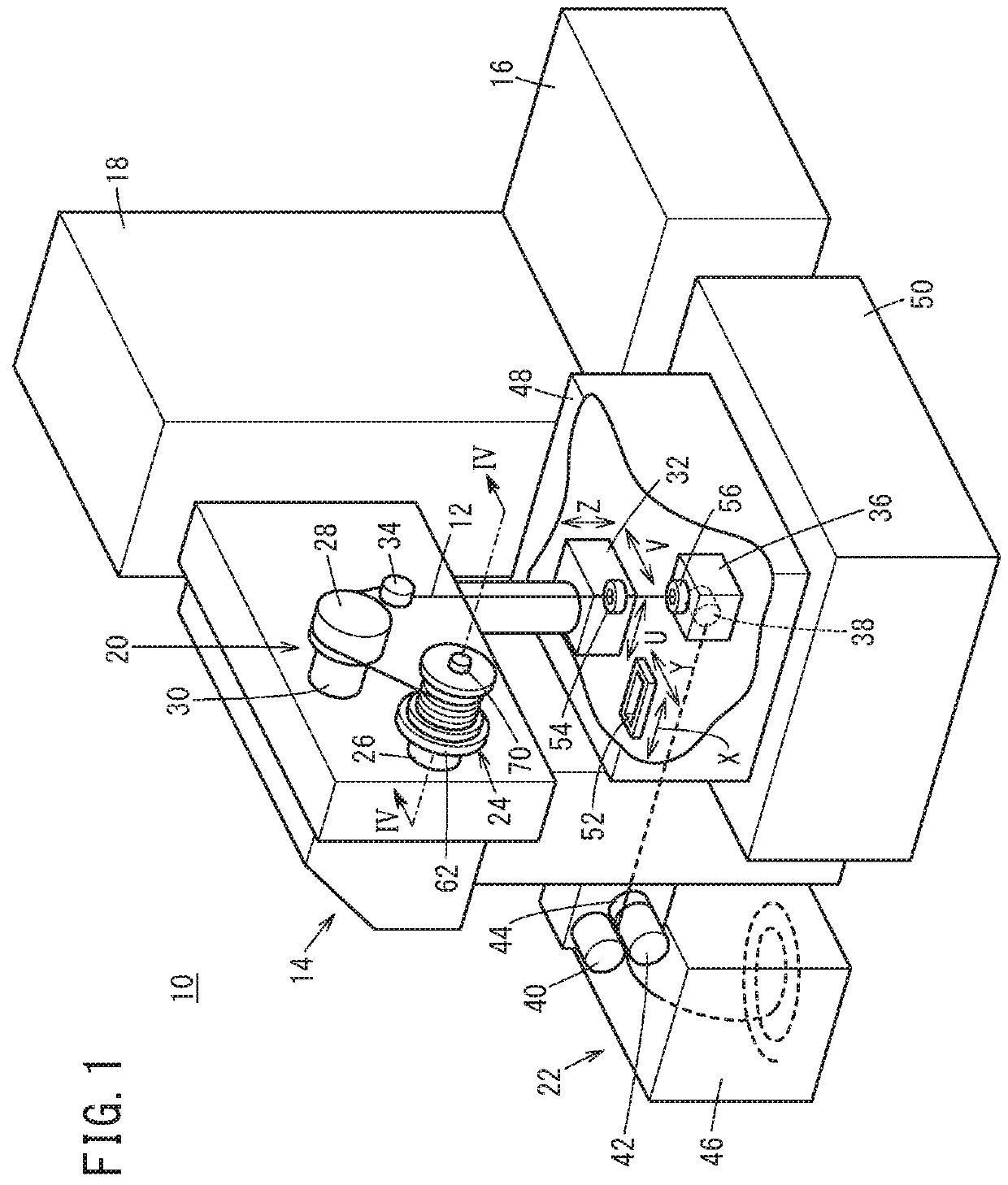

Test apparatus for early landslide detection fully-connected with pore water pressure, surface displacement and shear surface

ActiveUS9488561B2Reliable environmentPrevent leakageEarth material testingFluid pressure measurementShear stressPore water pressure

Disclosed herein is a test apparatus for early landslide detection fully-connected with pore water pressure, surface displacement and shear surface. The test apparatus calculates a factor of safety of a slope based on variation in pore water pressure, surface displacement and shear surface of a soil mass, and predicts a change in factor of safety, thus making early landslide detection possible. In the test apparatus, while a container of a slider is moved with a soil mass loaded into the container, shear surface and surface displacement environment is provided, and the shear strength and the shear stress of the soil mass can be calculated based on the pore water pressure and the weight of the soil mass. Thereby, the factor of safety of the soil mass can be calculated, and early landslide detection can be realized by using variation of the factor of safety of the slope.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

Aeration tine device

InactiveUS20050167126A1Guaranteed uptimeImprove controllabilitySoil-working equipmentsDragsHard metalEngineering

A highly durable aeration tine device attached to a soil aerator has a tubular tine member extending cylindrically and a hard metal tip made of a hard metal material and typically made in a frustum shape of a cone, which is in an area contact with the tubular tine member between the surfaces of the tubular tine member and the hard metal tip. Each surface of the tubular tine member and the hard metal tip is extending in a plane perpendicular to the axial direction and can be fabricated easily, and the drive force provided from the soil aerator can be transmitted without loss.

Owner:KASHIWATOOL CORP

Easy-to-operate branch pulling device for agriculture and forestry

The invention discloses an easy-to-operate branch pulling device for agriculture and forestry, and relates to the technical field of equipment for agriculture and forestry. The easy-to-operate branchpulling device comprises a clamping block and fixing belts, wherein the bottom of the clamping block is fixedly connected with the tops of the fixing belts, and a first clamping hook and a second clamping hook are hinged to the left and right sides of the clamping block through hinges respectively. According to the easy-to-operate branch pulling device for agriculture and forestry, through the arrangement of pulling wires, the first clamping hook and the second clamping hook can be spread out by a certain angle, at this moment, a hanging pipe can be directly utilized for pushing the first clamping hook and the second clamping hook towards branches, and the first clamping hook and the second clamping hook are automatically spread out after being stressed, and can be restored under the elasticity of springs after passing through the branches, so that the branches are automatically covered; through the two clamping hooks which are arranged oppositely, gaps are mutually filled, so that thebranches do not easily fall off; moreover, through the arrangement of a threaded cover, the hanging pipe can be detached, and the easy-to-operate branch pulling device can be directly operated undera tree and is easy and convenient to use.

Owner:太湖县木子峰农业发展有限公司

Fixing structure of wire bobbin and fixing method of the same

In a fixing structure and fixing method of a wire bobbin, the wire bobbin is abutted against the regulating member with the bolt inserted into the insertion hole of the wire bobbin. Then, a nut is inserted into a through hole while being kept inclined so that the axis of the through hole is substantially aligned with the axis of the bolt. Thereafter, the inclination of the nut is returned so that the axis of threaded hole becomes substantially aligned with the axis of the bolt, and then the nut is turned so as to insert part of a tapered portion into the insertion hole.

Owner:FANUC LTD

Method for machining large-caliber ultralong copper coil pipe

ActiveCN109201770ATo achieve annealing requirementsPulling smoothlyDrawing diesFurnace typesIngotCopper coil

The invention discloses a method for machining a large-caliber ultralong copper coil pipe. The method comprises the steps of 1, casting, wherein a copper-base alloy is molten and solidified to form asolid copper ingot; 2, extruding, wherein the copper ingot is extruded into a round pipe blank; 3, rolling, wherein the round pipe blank is rolled into a rolled blank pipe; 4, combined drawing, wherein a movable core mark procedure is adopted for drawing the rolled blank pipe four times, during each drawing, the drawing modular angle is set to be 30 degrees, the movable core mark angle is 22 degrees, after each drawing is completed, the rolled blank pipe is coiled through a coiling machine, when next drawing is carried out, the coiled rolled blank pipe is straightened through an uncoiler, thelast drawing is completed, and the finished pipe is formed; 5, annealing, wherein the finished pipe is annealed through a gas protection pass-type two-frequency annealing furnace in a passing-while-annealing manner, the annealing temperature ranges from 520 DEG C to 550 DEG C, and the passing speed of the finished pipe is smaller than or equal to 2 mm / min; and 6, winding, wherein the annealed finished pipe is wound. According to the method, the large-caliber ultralong copper coil pipe can be machined.

Owner:HEBEI OUTONG NONE FERROUS METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com