Drawer slide rail system

A technology for drawers and slide rails, applied in the field of slide rail systems, which can solve the problems of uneven opening and closing of drawers, difficult installation and positioning, and short use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

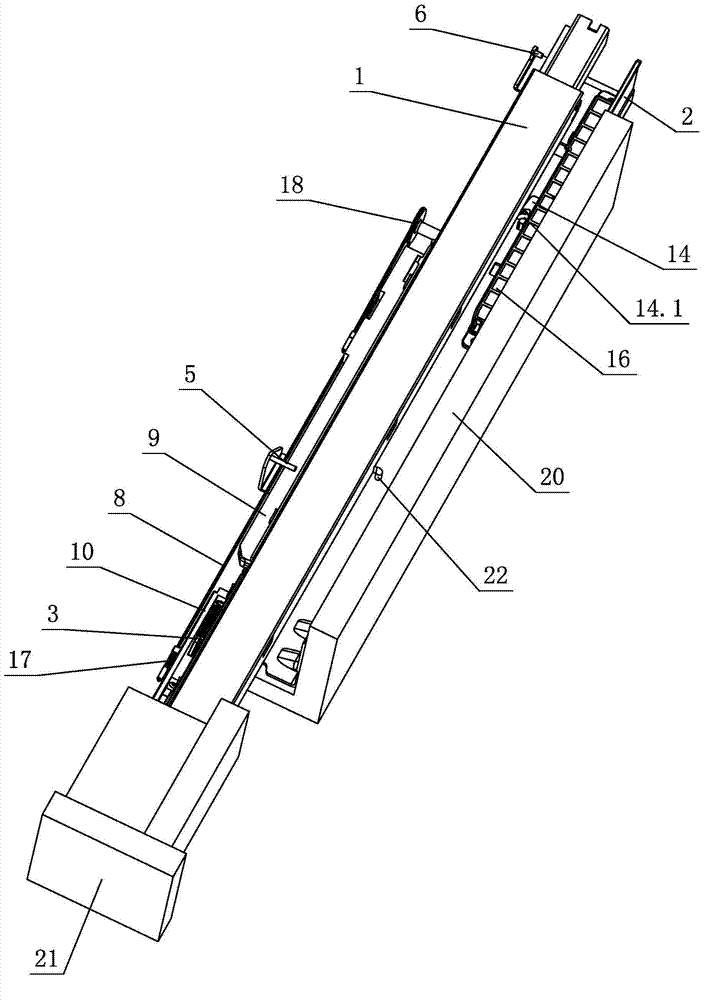

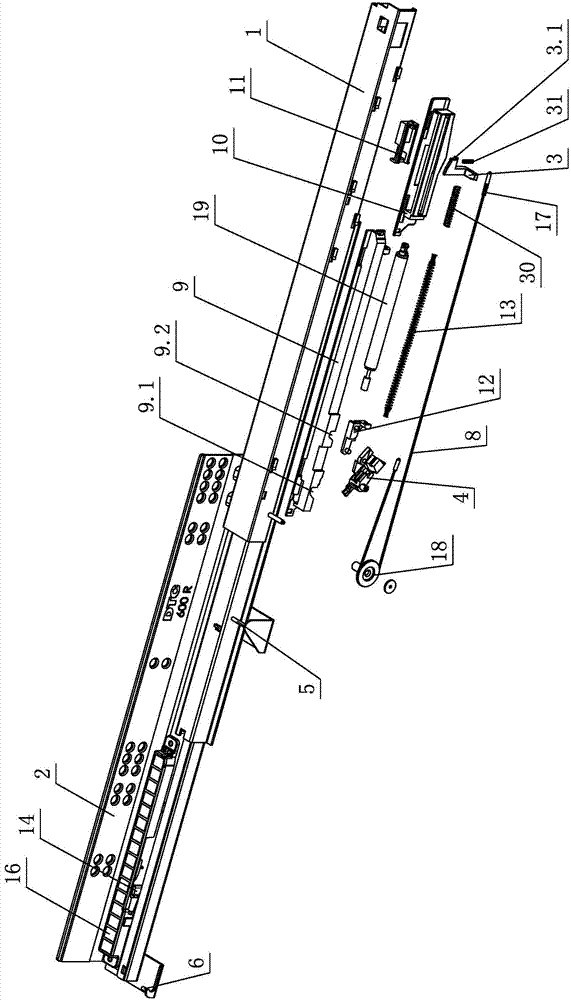

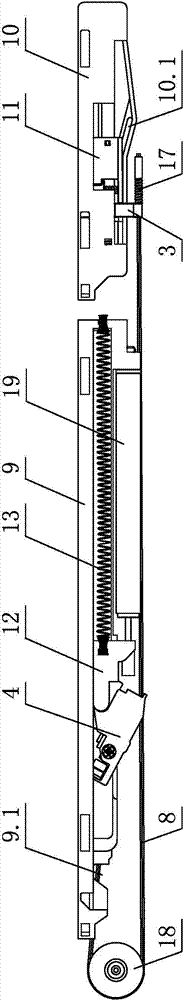

[0029] see figure 1 - Figure 4 , the drawer slide rail system includes a slide rail assembly arranged on the side panel 20 of the cabinet, the slide rail assembly is provided with a drawer, the drawer is at least composed of a bottom plate and a front panel 21, and the slide rail assembly is at least composed of a movable slide rail 1 and a fixed slide rail Rail 2, the moving slide rail 1 or the fixed slide rail 2 is provided with a damping device, and the damping device has at least a certain stroke when the drawer is closed, passing through the elastic pendulum A3 set on it and the front end of the fixed slide rail 2 or the moving slide rail 1 The setting dial A5 touches each other, and drives the sliding pendulum B4 on the damping device through a cable 8, belt or rope, so that the sliding pendulum B4 is locked on the first locking notch 9.1 of the damping device. When the drawer continues to close, the sliding pendulum bolt B4 has at least one section of stroke that touc...

no. 2 example

[0042] see Figure 19 , this embodiment is different from the first embodiment in that:

[0043] The pressing rebound device is arranged on the side panel 20 of the cabinet, and includes an elastic stopper (not shown in the figure), a moving part 14' and a spring (not shown in the figure); the elastic stopper and the moving part 14' are arranged on the sideboard 20 of the cabinet On the other hand, one end of the spring is connected with the elastic stopper, and the other end is connected with the moving part 14'; at least a part of the moving part 14' protrudes out of the side panel 20 of the cabinet, and at least passes through the spring when the drawer is opened and / or closed. The spring is loaded on the front panel 21 to realize the sliding of the moving part 14 ′ on the side panel 20 of the cabinet.

[0044] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com