Aluminum pipe having excellent surface quality, method and apparatus for manufacturing the aluminum pipe, and photosenstive drum base body

A manufacturing method and a manufacturing device technology, which are applied in the field of photosensitive drum substrates, and can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] Under the following extrusion conditions, for Mn: 1.12% by mass, Si: 0.11% by mass, Fe: 0.39% by mass, Cu: 0.16% by mass, Zn: 0.01% by mass, Mg: 0.02% by mass, other components are aluminum and The billet composed of unavoidable impurities was extruded to obtain an aluminum extruded billet tube (32 mm in outer diameter, 1.5 mm in wall thickness). The surface roughness Ry of the aluminum extruded pipe was 2.5 micrometers in the circumferential direction. Moreover, the average length of the grains on the surface of the extruded aluminum tube in the drawing direction is 200 microns.

[0141] (extrusion condition)

[0142] Extrusion temperature: 520°C

[0143] Extrusion speed: 0.5 m / min

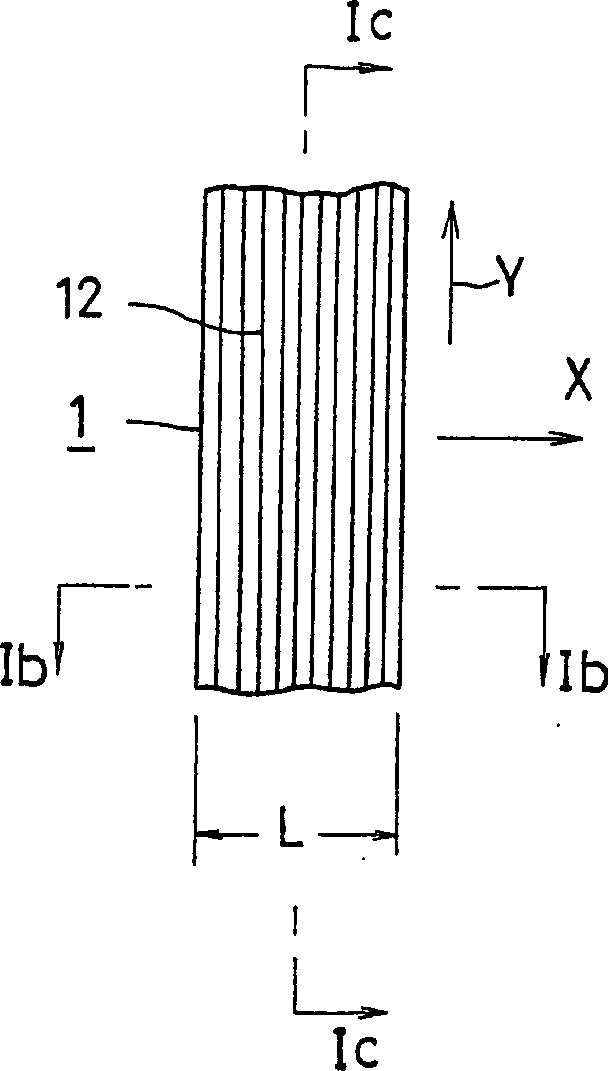

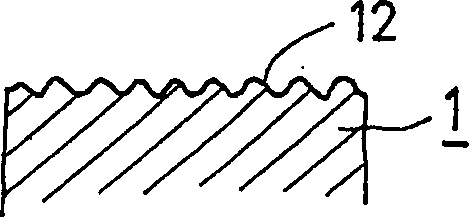

[0144] Extrusion Die: Use Figure 1 and figure 2 The multi-hole split extrusion die is shown. The length L of the sizing belt portion of the die hole in the extrusion direction is 3 mm. The relationship between the centerline average roughness Ra(Y) in the circumferential direction o...

Embodiment 2~7

[0168] Except that the distance Q from the extrusion die discharge position M of the extruder 24 to the cutting position N of the cutting machine 25 and the length R of the extruded tube 4 obtained by cutting are set to the values shown in Table 1, the same as Same as in Example 1, an aluminum tube for a photosensitive drum was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com