Machining method of nickel and titanium shape memory alloy wire

A technology of memory alloy wire and processing method, which is applied in the field of medical material processing, and can solve problems such as not being suitable for mass production, low efficiency, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

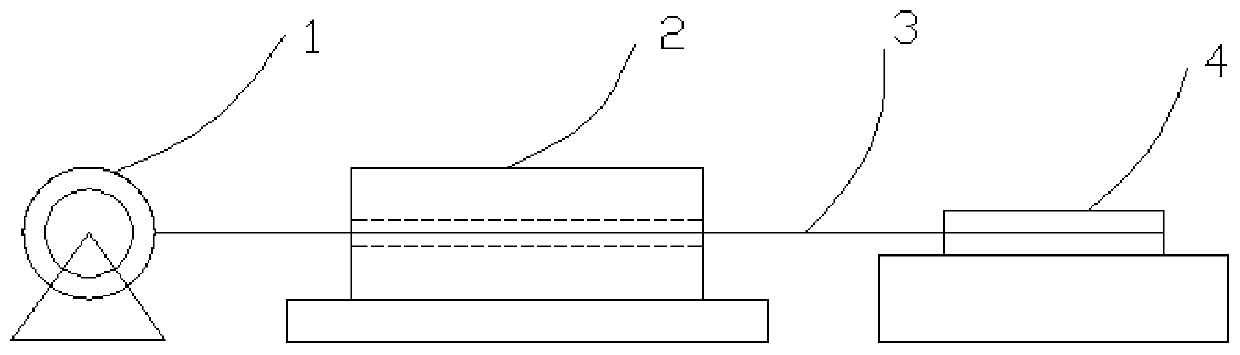

[0024] Grind one end of a nickel-titanium shape memory alloy wire 3 with a diameter of 2.0mm on the pay-off reel 1 into a tapered shape and pass it into a wire drawing die with a single deformation of 22%, and set the annealing temperature of the tubular resistance furnace 2 to 650°C. And stabilized at this temperature, then pass the finished nickel-titanium shape memory alloy wire 3 through the tubular resistance furnace 2, and fix it on the wire drawing machine 4 at the other end, perform online annealing and cold drawing to 1.0mm; Grind one end of the semi-finished 1.0mm nickel-titanium shape memory alloy wire 3 into a tapered shape and put it into a wire drawing die with a single deformation of 22%. Set the annealing temperature of the tubular resistance furnace 2 to 650°C and stabilize it at At this temperature, the finished nickel-titanium shape memory alloy wire 3 passes through the tubular resistance furnace 2, and is fixed on the wire drawing machine 4 at the other end...

specific Embodiment approach 2

[0026] Grind one end of a nickel-titanium shape memory alloy wire 3 with a diameter of 2.0mm on the pay-off reel 1 into a tapered shape and pass it into a wire drawing die with a single deformation of 18%, set the annealing temperature of the tubular resistance furnace 2 to 740°C, And stabilized at this temperature, then pass the finished nickel-titanium shape memory alloy wire 3 through the tubular resistance furnace 2, and fix it on the wire drawing machine 4 at the other end, perform online annealing and cold drawing to 1.0mm; Grind one end of the semi-finished product of the 1.0mm nickel-titanium shape memory alloy wire 3 that has been drawn into a tapered shape and penetrate it into a wire drawing die with a single deformation of 18%. Set the annealing temperature of the tubular resistance furnace 2 to 750°C and stabilize it at At this temperature, the finished nickel-titanium shape memory alloy wire 3 passed through the tubular resistance furnace 2, and fixed on the wire ...

specific Embodiment approach 3

[0028] Grind one end of a nickel-titanium shape memory alloy wire 3 with a diameter of 5.0 mm on the pay-off reel 1 into a tapered shape and pass it into a wire drawing die with a single deformation of 20%, and set the annealing temperature of the tubular resistance furnace 2 to 780°C. And stabilized at this temperature, then the nickel-titanium shape memory alloy wire 3 that has been molded is passed through the tubular resistance furnace 2, and fixed on the wire drawing machine 4 at the other end, for online annealing and cold drawing to 3.0mm; Grind one end of the semi-finished product of the drawn 3.0mm nickel-titanium shape memory alloy wire 3 into a tapered shape and put it into a wire drawing die with a single deformation of 20%, set the annealing temperature of the tubular resistance furnace 2 to 780°C, and stabilize At this temperature, the finished nickel-titanium shape memory alloy wire 3 passed through the tubular resistance furnace 2, and fixed on the wire drawing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com