Surface polishing machine of metal zipper

A technology of surface polishing and metal zipper, applied in the field of polishing machines, can solve the problems of high cost, unsatisfactory, unsatisfactory polishing effect, etc., and achieve the effect of many times of polishing, smooth surface and smooth pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

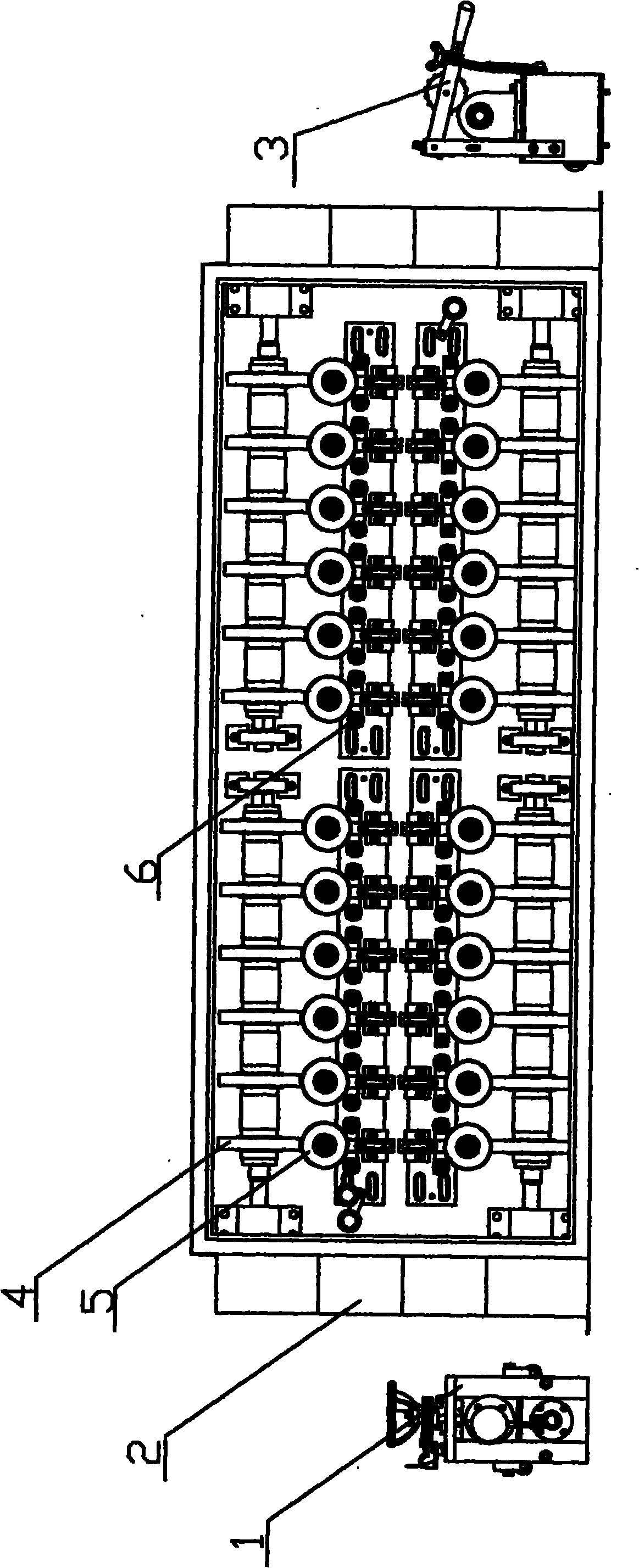

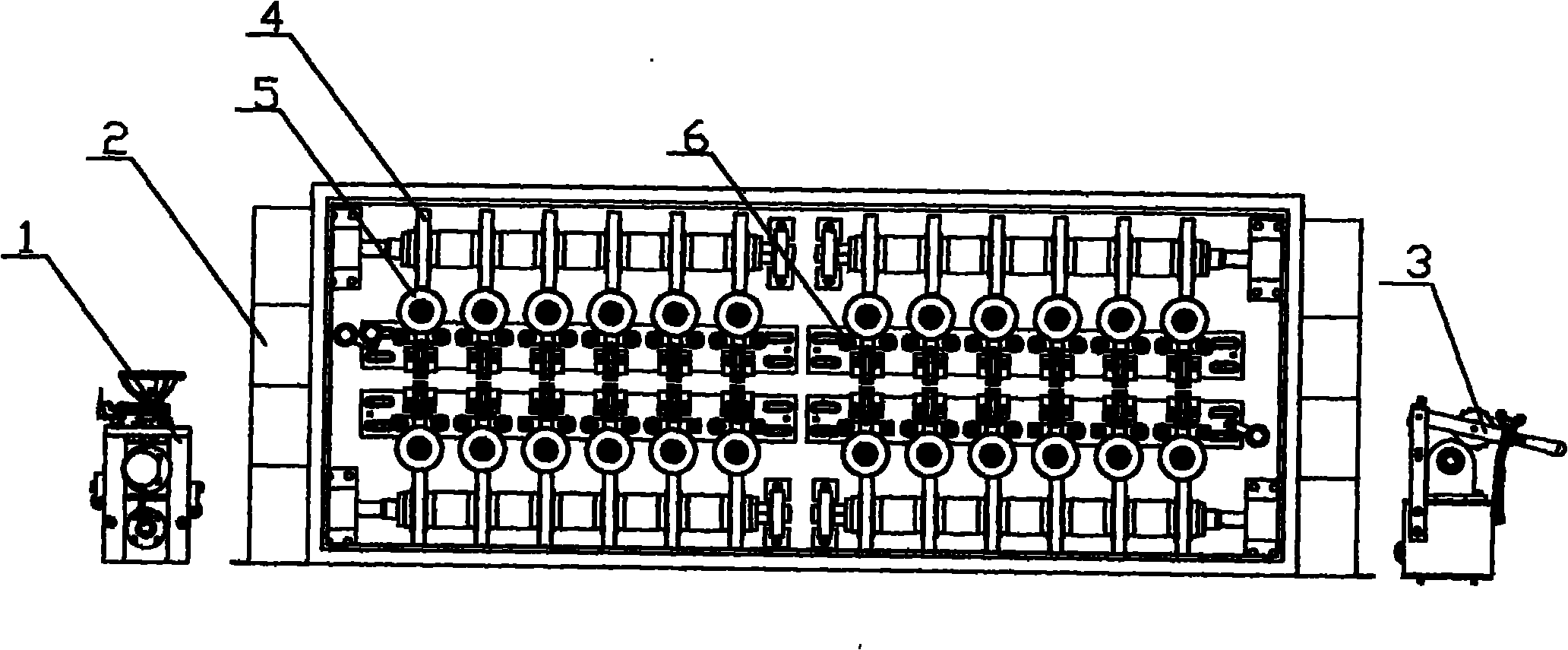

[0011] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] Referring to the accompanying drawings, the present invention consists of a drum pressing mechanism 1, a polishing mechanism 2 arranged behind the drum pressing mechanism 1, and a tape-out mechanism 3 arranged behind the polishing mechanism 2, and is characterized in that: the polishing mechanism 2 is provided with A polishing wheel 4, a polishing supporting wheel 5 is arranged under the polishing wheel 4, and two passing pulleys 6 are arranged under the polishing supporting wheel 5, and the polishing wheel 4, the polishing supporting wheel 5 and the passing pulley 6 constitute a polishing unit.

[0013] It is characterized in that: the polishing wheel 4 is a flap wheel.

[0014] The polishing units are arranged oppositely to form a polishing unit group, and the polishing unit group is at least two groups.

[0015...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com