Rotation wire drawing die box and using method thereof

A wire drawing die and rotary die technology, applied in the direction of wire drawing dies, etc., to reduce wear, facilitate plastic deformation, and increase shear stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

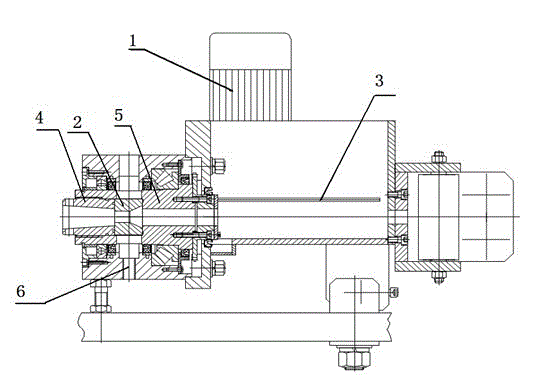

[0013] A kind of rotary drawing die box of the present invention is described in further detail below in conjunction with accompanying drawing:

[0014] In the figure, the rotary wire drawing die box of the present invention is mainly composed of a motor 1, a wire drawing die 2, a drawing powder agitator 3, a top wire 4, a rotating die holder 5 and a cooling water device 6; the motor 1 drives the rotating die holder 5 to rotate , the rotating die base 5 is provided with a wire drawing die 2, a drawing powder agitator 3 and a top wire 4, the wire drawing die 2 is locked and fixed by the top wire 4, and a cooling water device 6 is arranged outside the wire drawing die 2.

[0015] The method of use of the present invention is as follows: start the motor 1, the motor 1 drives the rotating mold base 5 to rotate, the rotating mold base 5 drives the wire drawing die 2 and the drawing powder agitator 3 to rotate, and the wire drawing die rotates around the steel wire axis during the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com