Sheet stock blank feeding equipment for punching process

A technology of stamping processing and feeding equipment, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of large running inertia, low stamping frequency, high stamping cost, simple and compact structure, avoid plastic deformation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

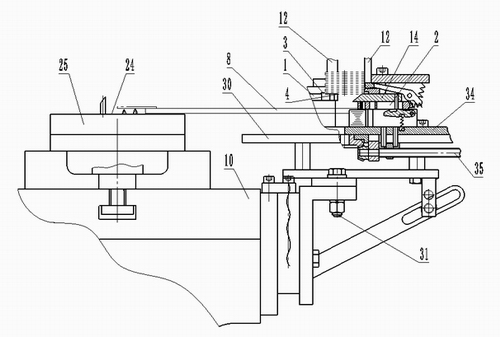

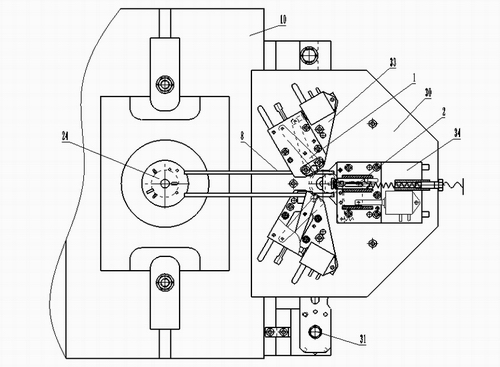

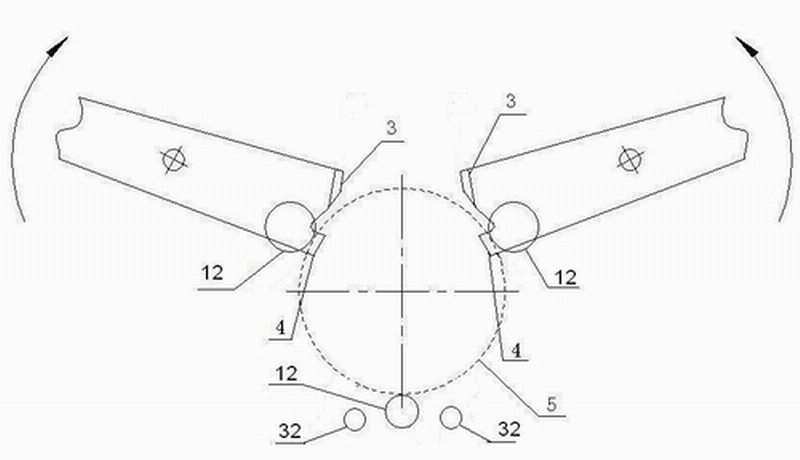

[0029] refer to Figure 1 to Figure 9 , a sheet material blank feeding device for stamping processing, comprising a frame 30, characterized in that: the frame 30 is provided with a feeding platform 8, and above the delivery platform 8 is provided with a The vertical blanking guide frame 12, the lower port of the vertical blanking guide frame 12 is provided with a sheet material blank stack 5 single piece separation device 1, and the feeding end side of the conveying platform 8 is provided with a The elastic hitting mechanism 2 of the single-piece blank 6 that falls on the conveying platform 8 after being toggled, so that the single-piece blank 6 moves along the conveying platform 8 to the punching machine on the other side of the conveying platform 8 Platform 25; the single-piece separating device 1 of the sheet blank stack includes at least one pair of single-piece lateral toggle pendulum blocks 3 located on both sides of the lower end of the sheet blank stack 5, and the sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com