Patents

Literature

204results about How to "Reliable feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

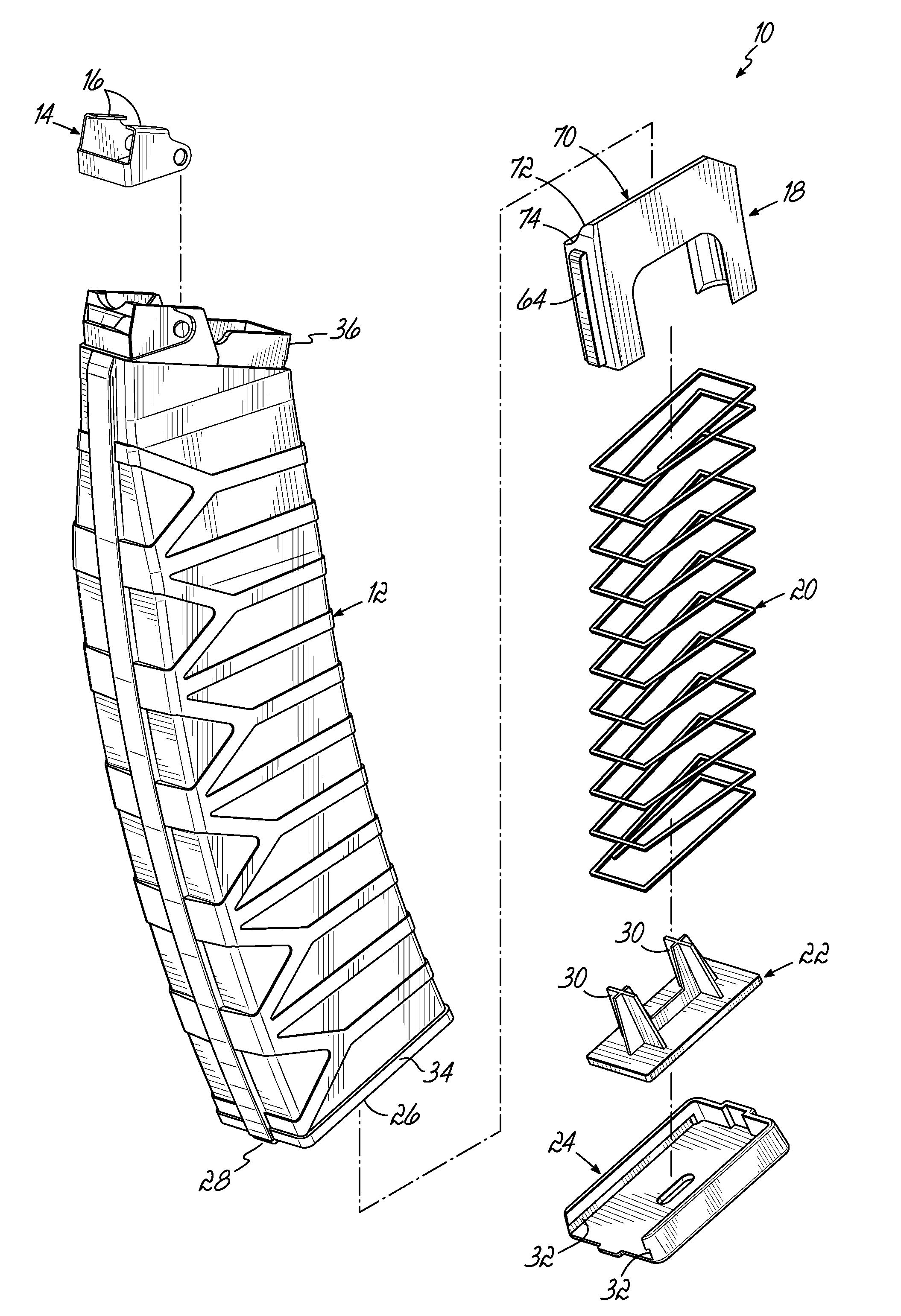

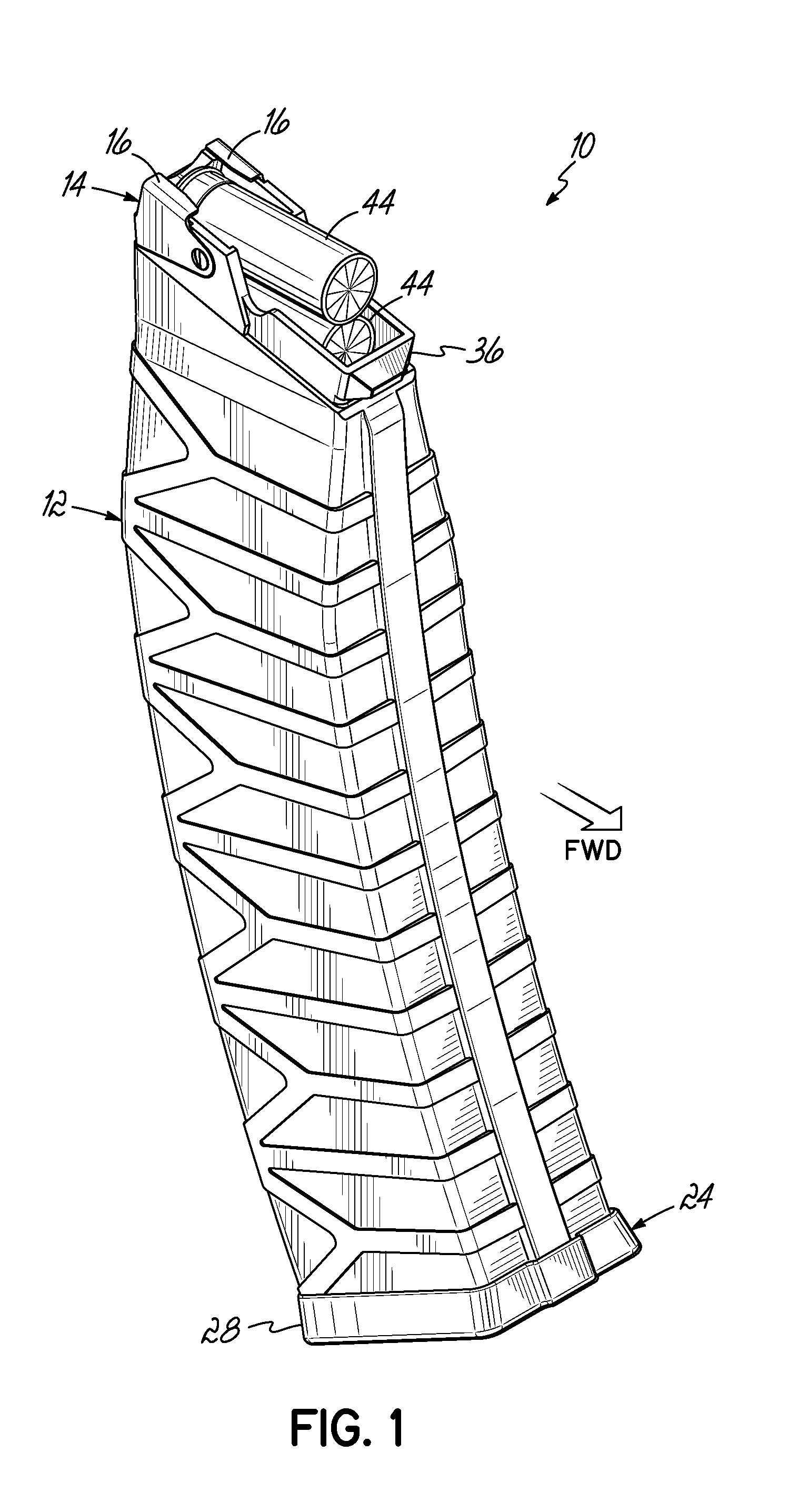

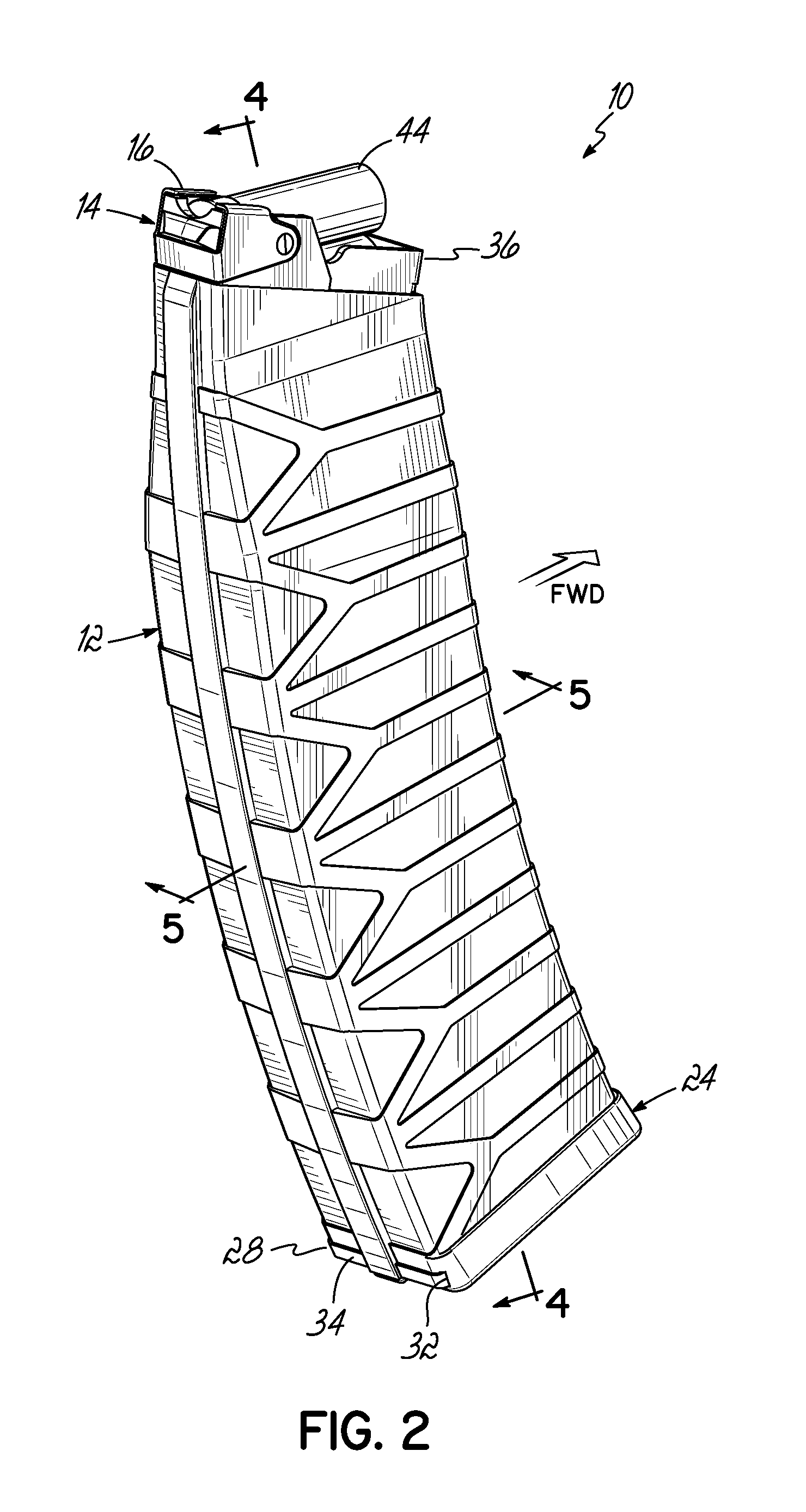

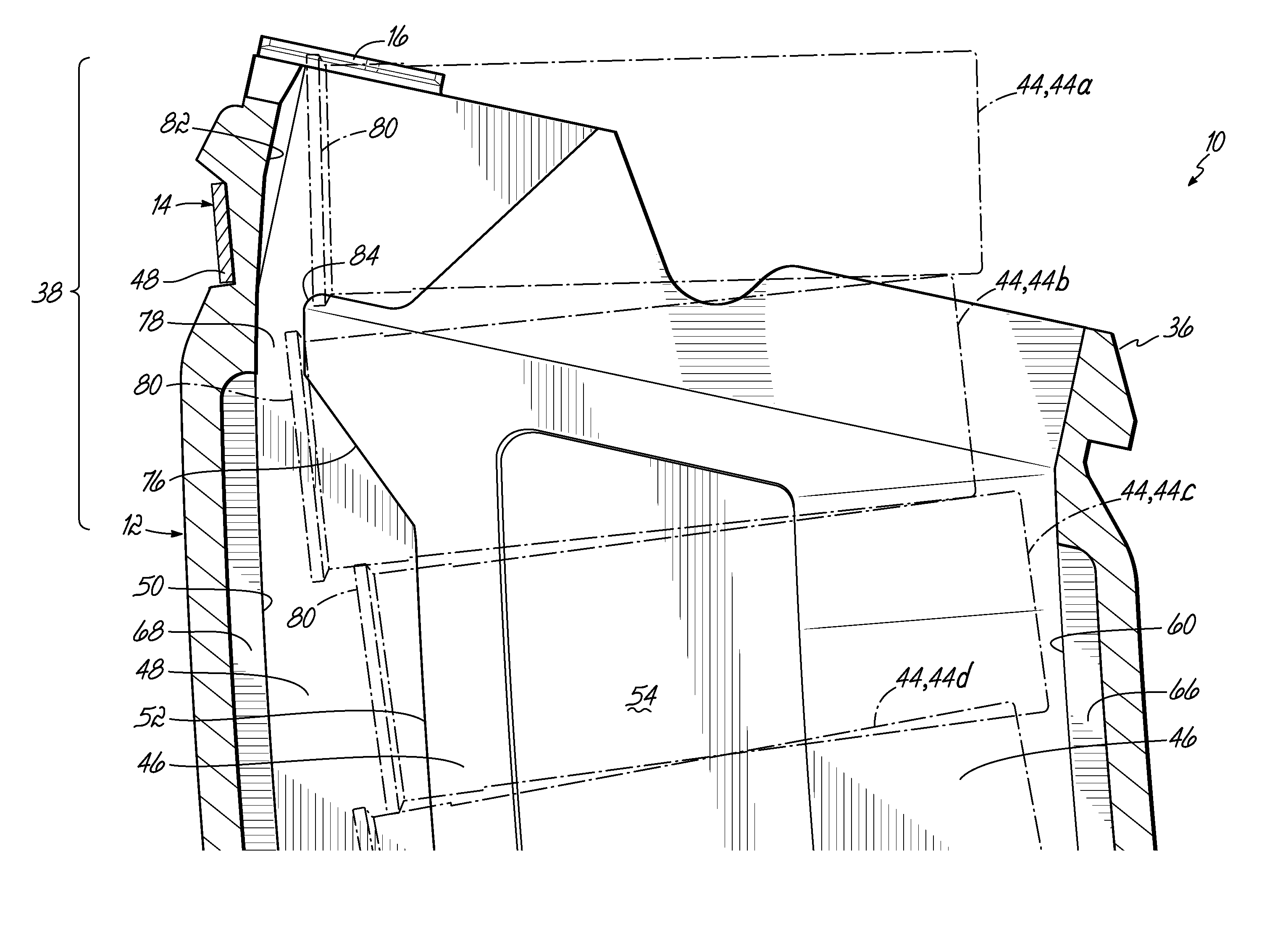

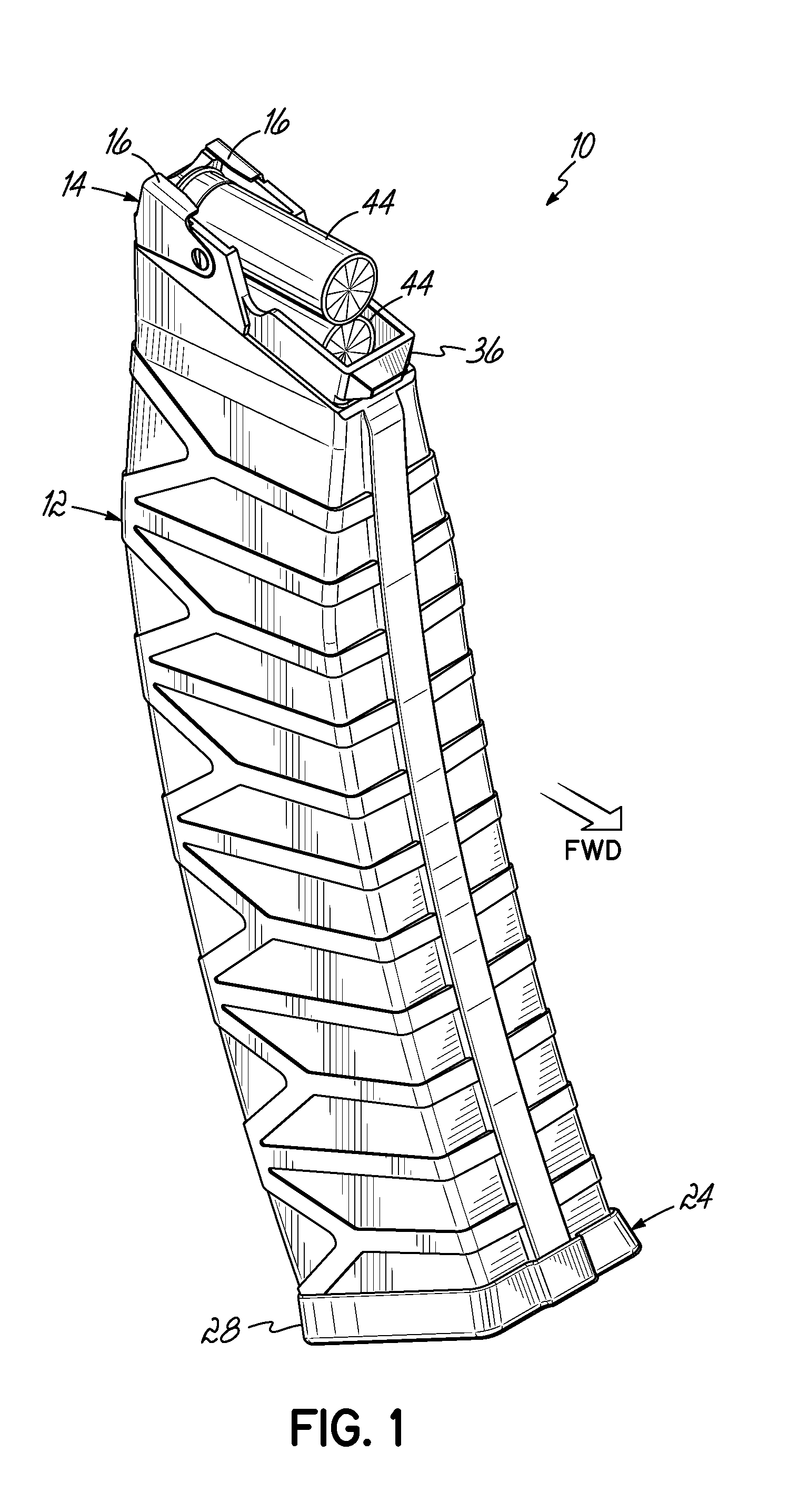

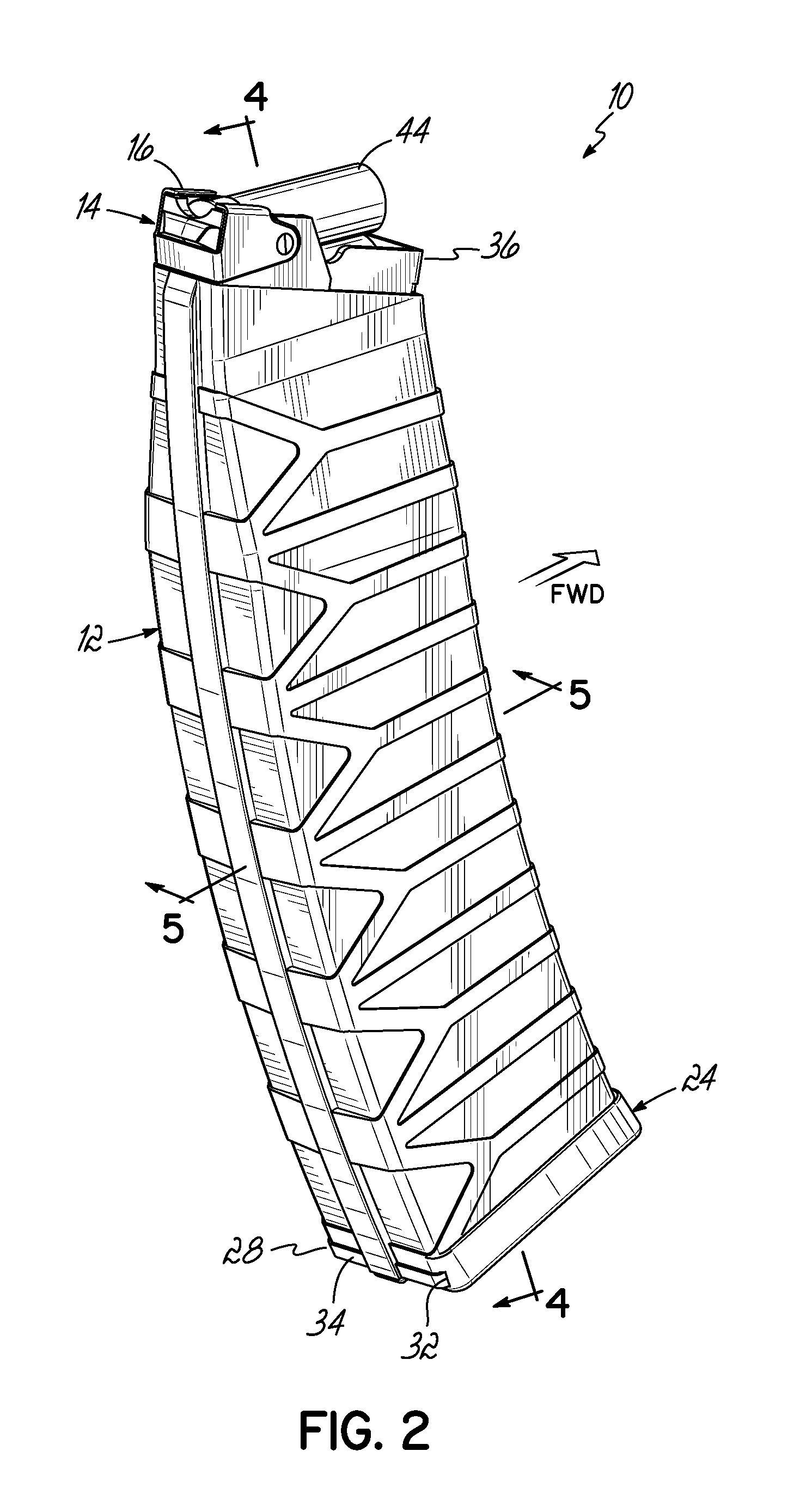

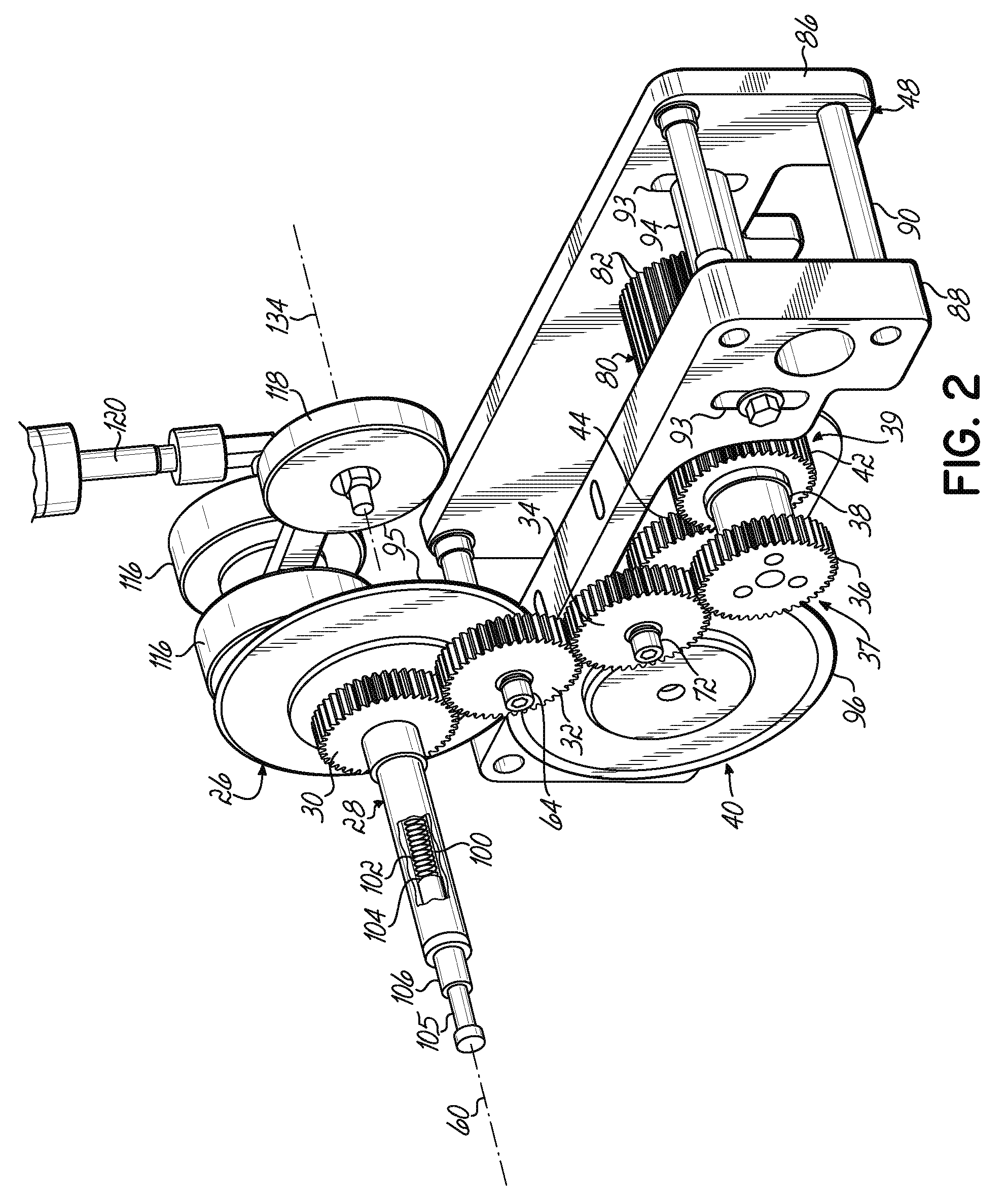

Double Stack Box Magazine for Rimmed Cartridges of Varying Length

ActiveUS20120066950A1Inhibit bindingLoss of feed reliabilityAmmunition loadingAbutmentElectrical and Electronics engineering

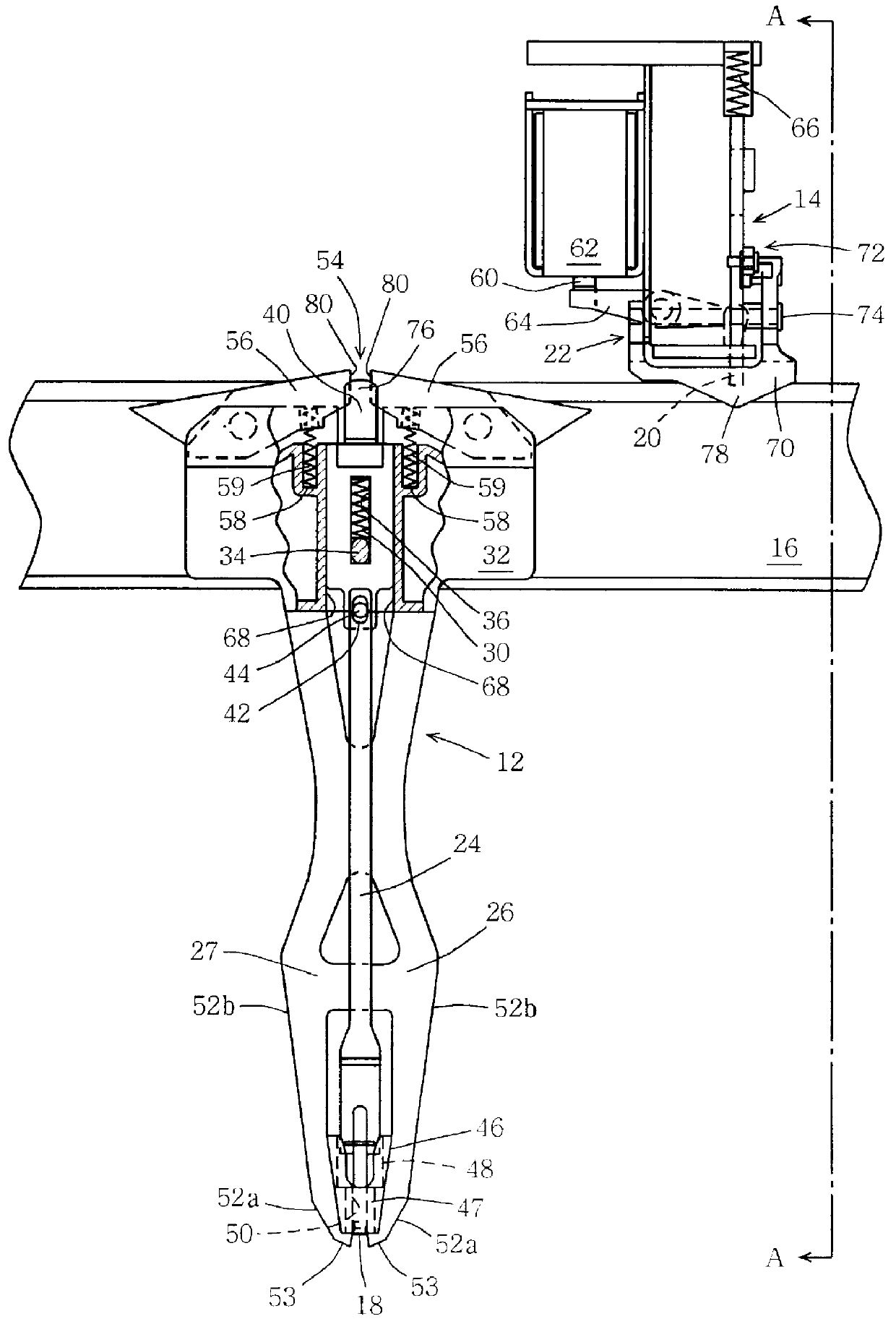

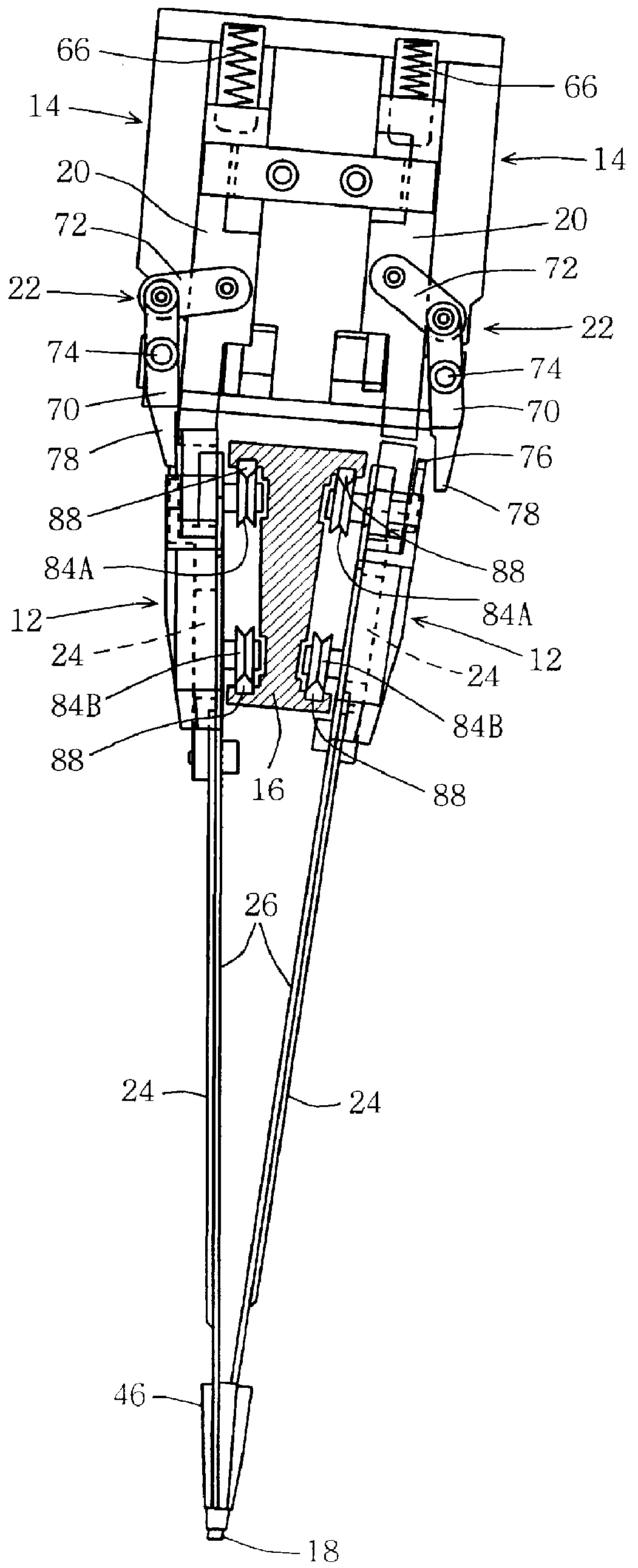

Disclosed is a double stack box magazine for rimmed ammunition cartridges of varied lengths. It includes a housing having a neck portion in which cartridges are arranged in a single column, a double-stack portion in which cartridges are arranged in laterally alternating columns, and a transition portion between the neck portion and the double-stack portion. A pair of rim clearance channels is provided, on opposed interior lateral surfaces of the housing. A first channel portion allows clearance for cartridge rims without respect to forward and rearward position of the cartridges within the housing, which may vary depending on individual cartridge length. A second channel portion in the neck provides an abutment against which laterally opposed areas of a cartridge rim bear to shift the cartridge to a rearward position. A third channel portion provides transition between the first and second channel portions.

Owner:DAVIDSON MICHAEL J

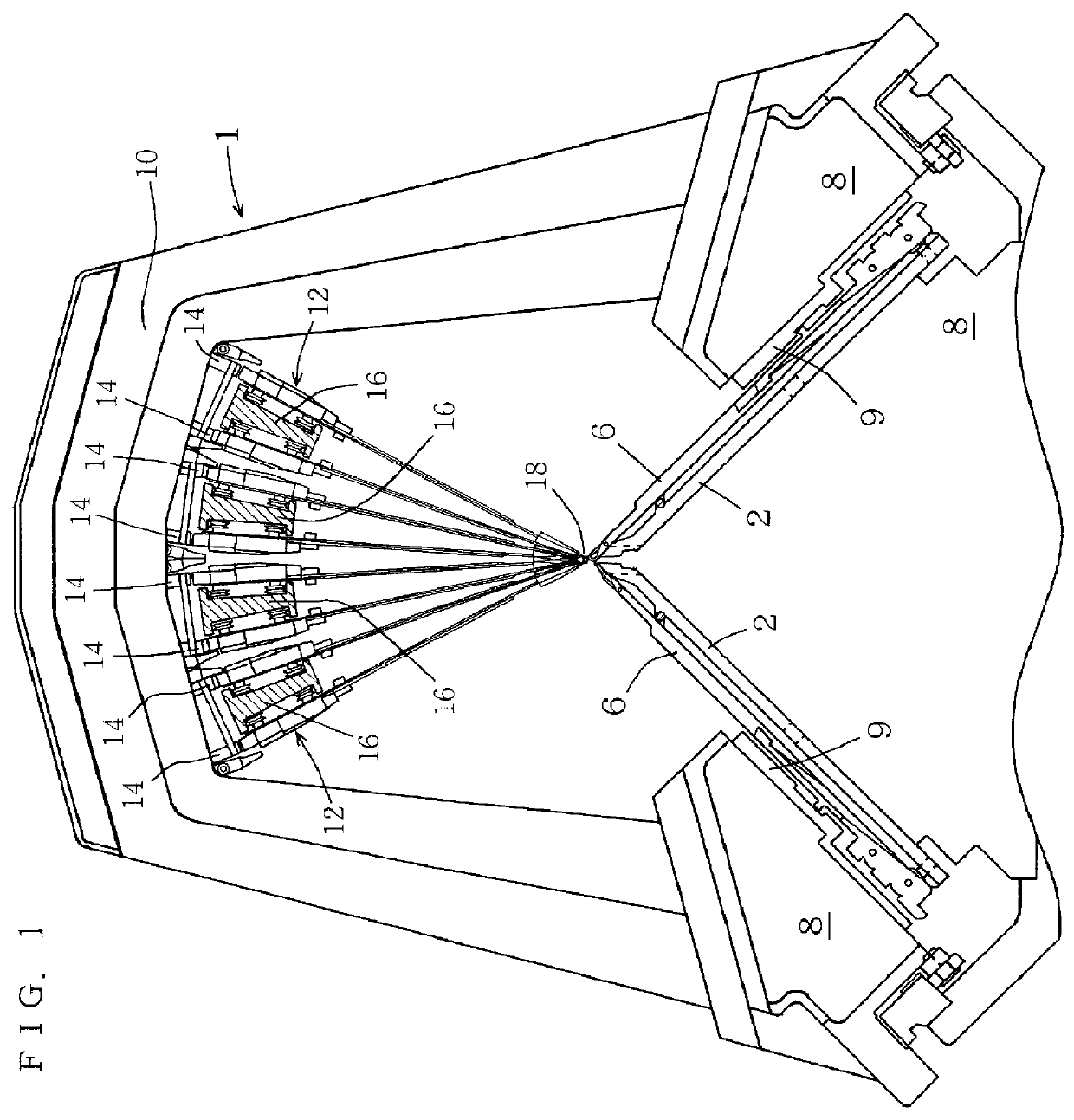

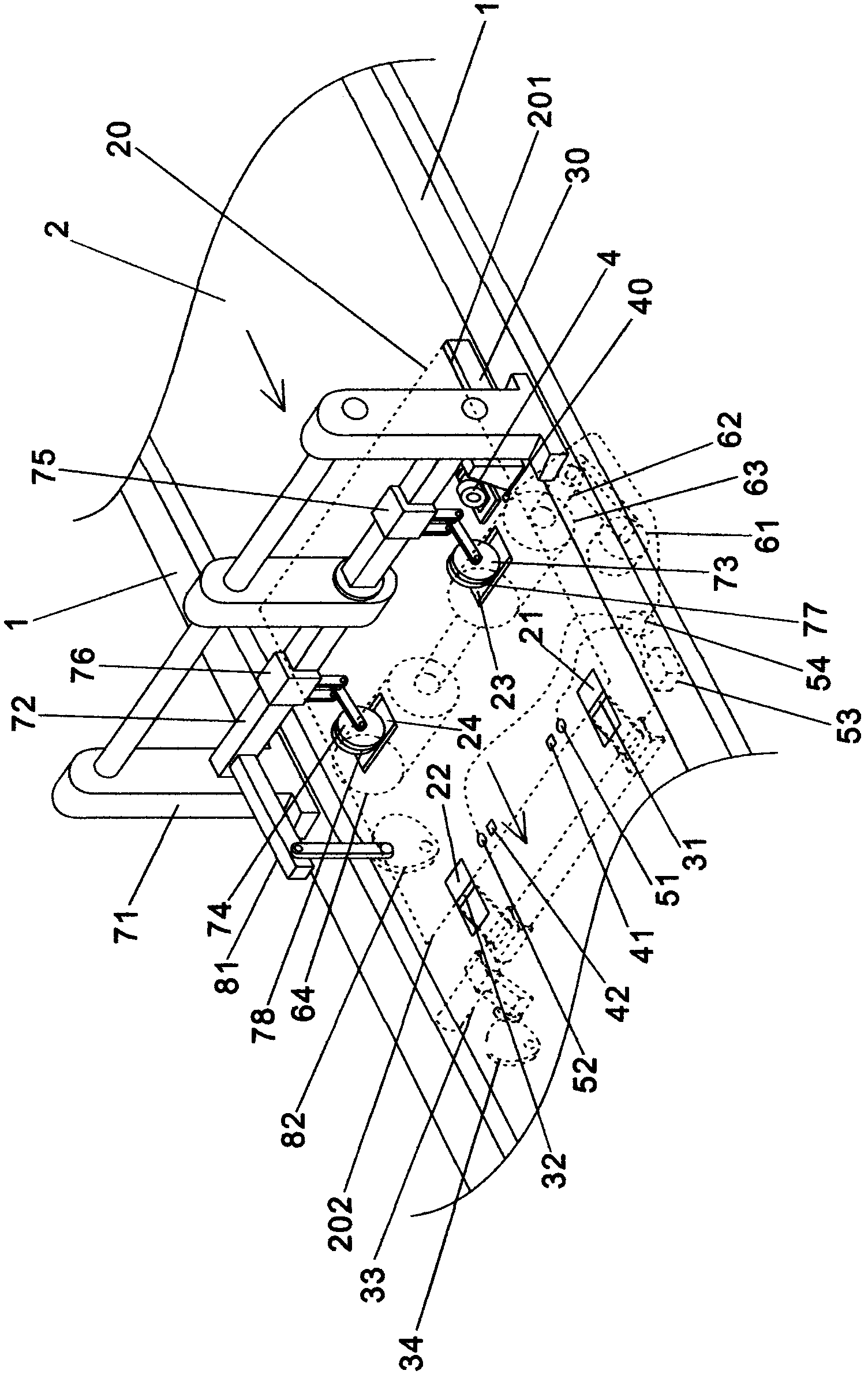

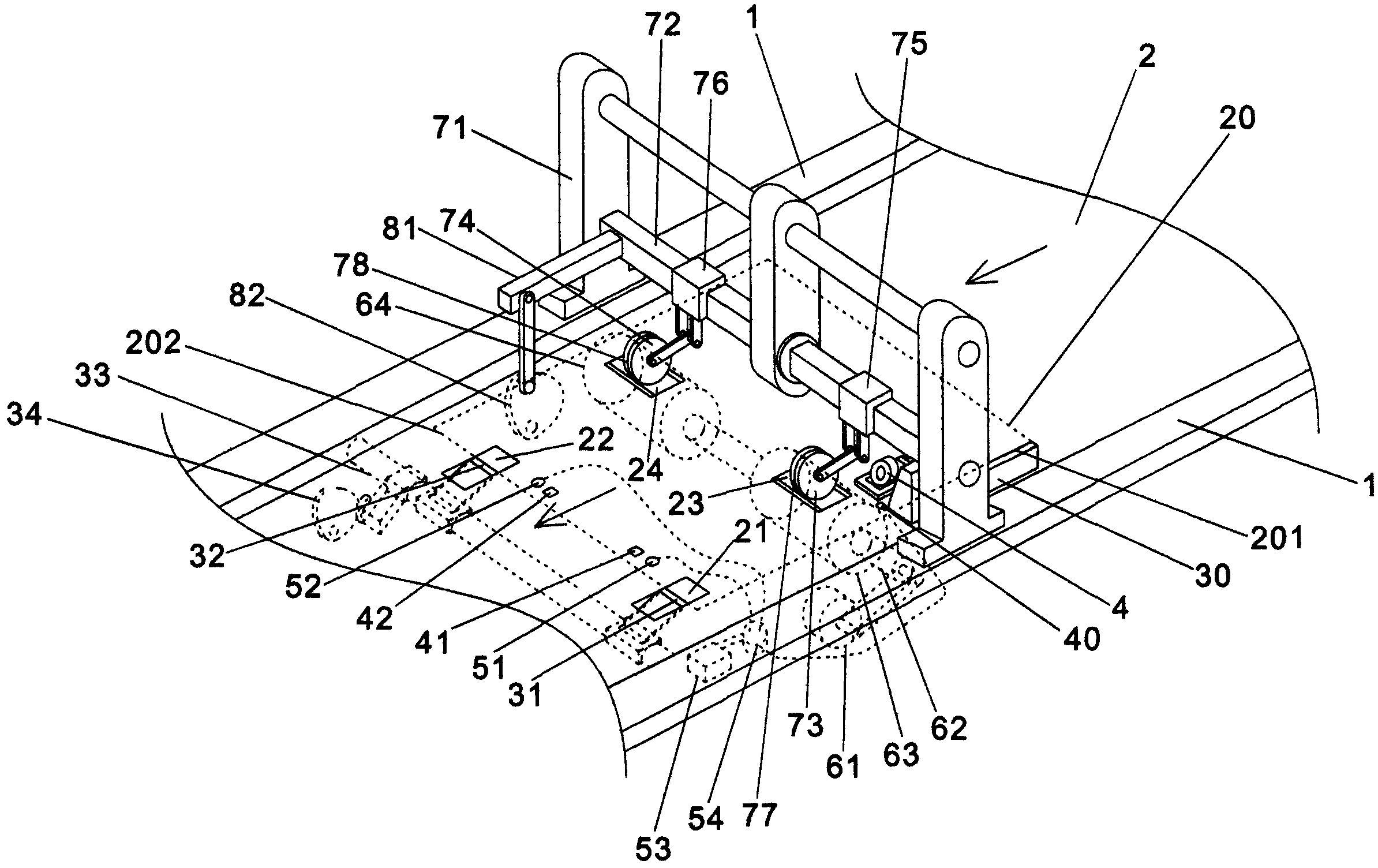

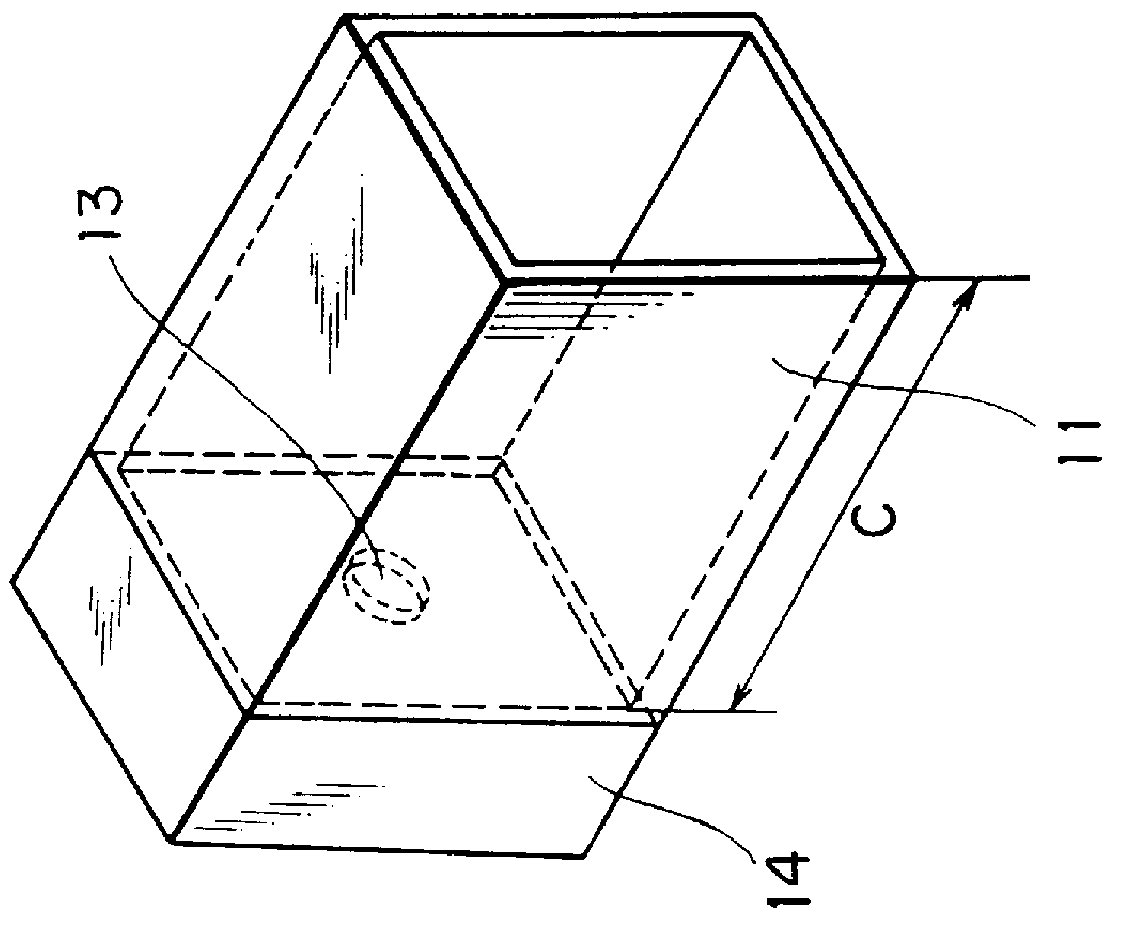

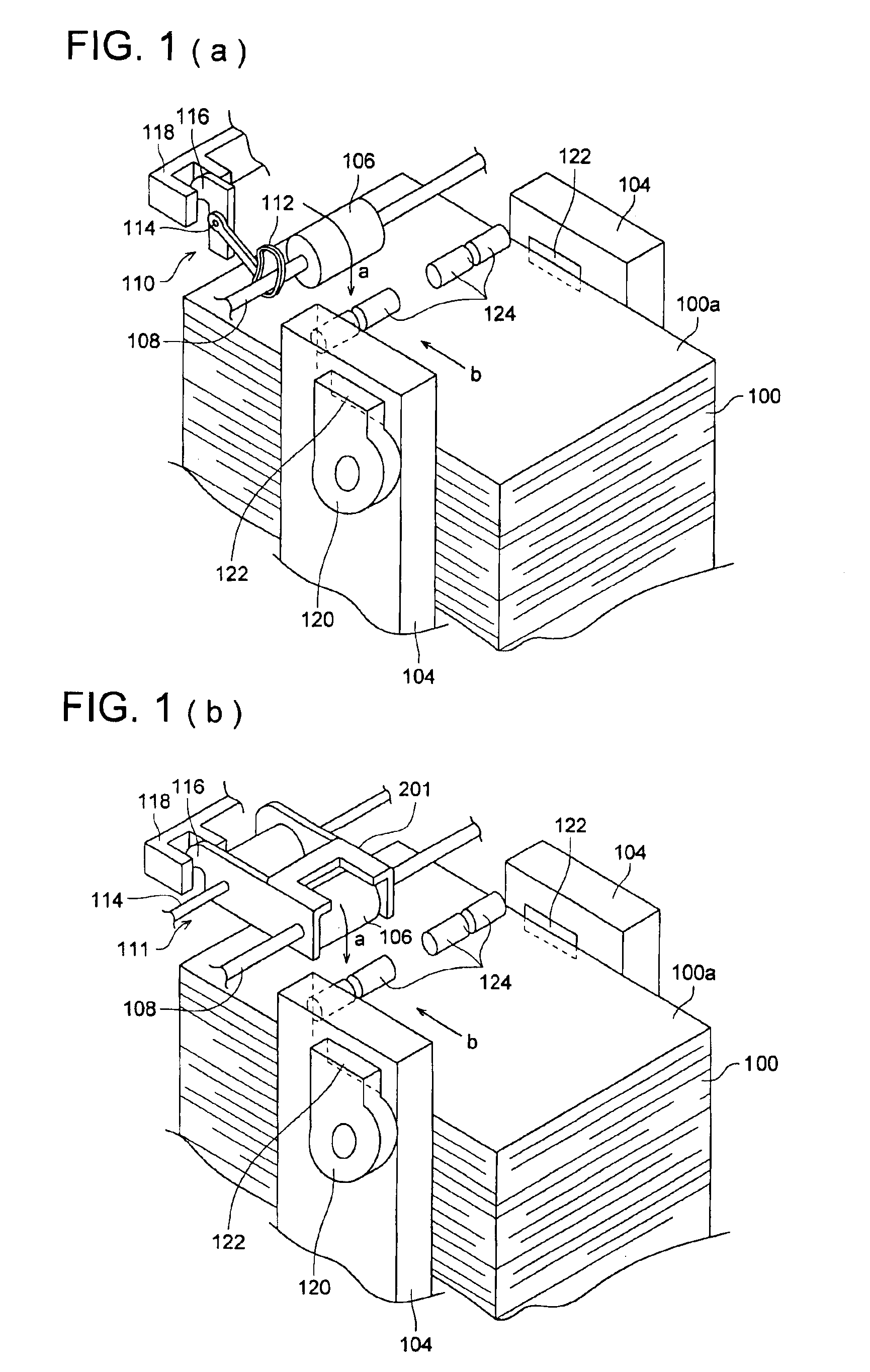

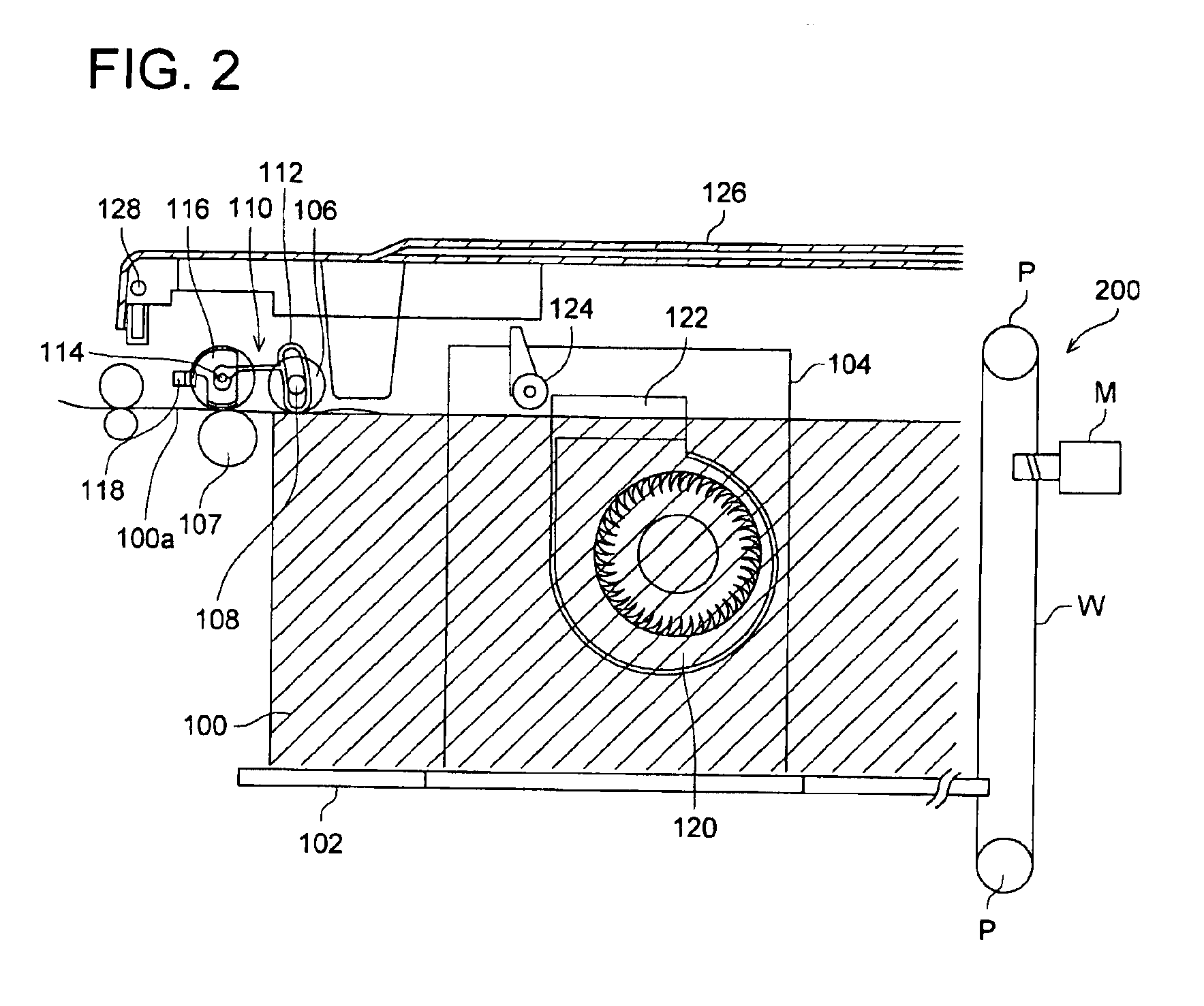

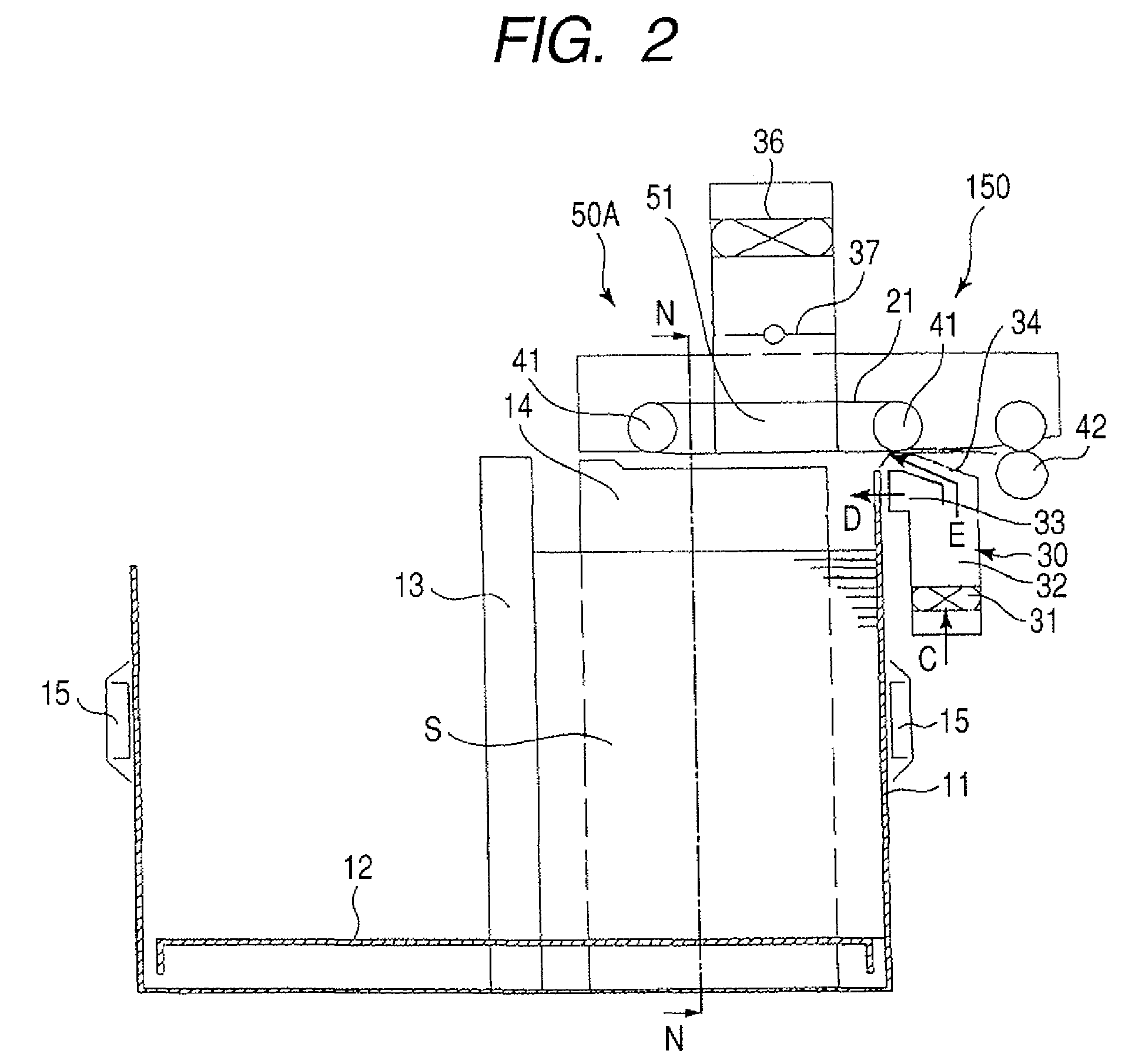

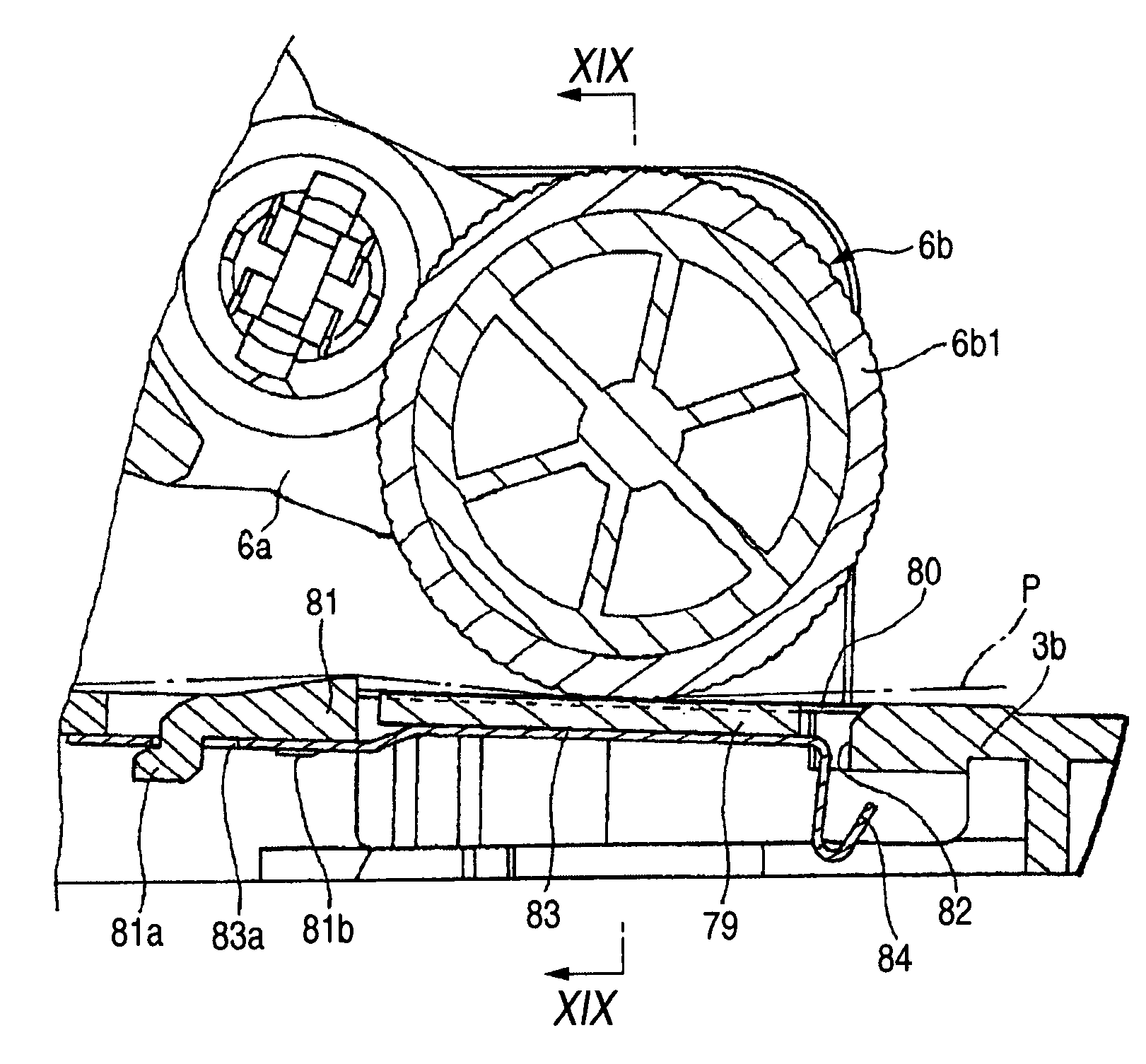

Flat knitting machine having a yarn feeding system

Plural carrier rails are arranged radially relative to a trick gap, and yarn carriers are made to run on the rails. In the yarn carrier, a feeder rod is mounted on a yarn rod guide so that the the rod can slide up and down. The feeder rod is pushed up by a spring coil, and the feeder rod is pushed down by a catching member toward the trick gap.

Owner:SHIMA SEIKI MFG LTD

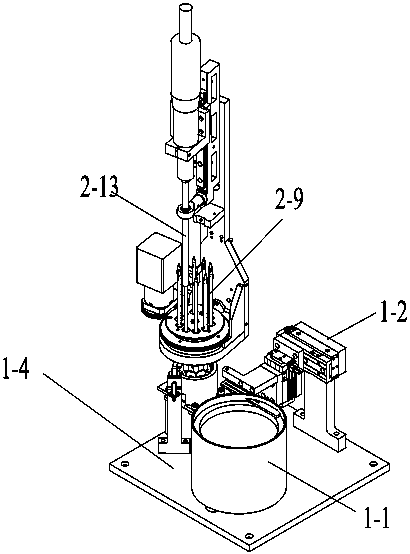

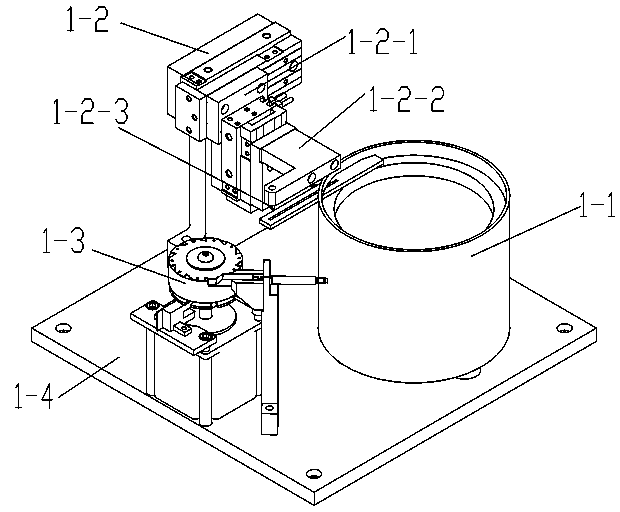

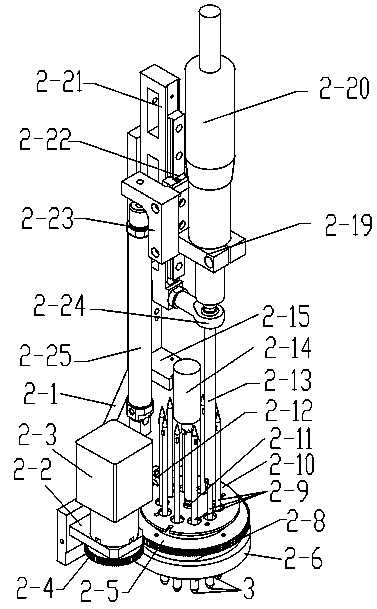

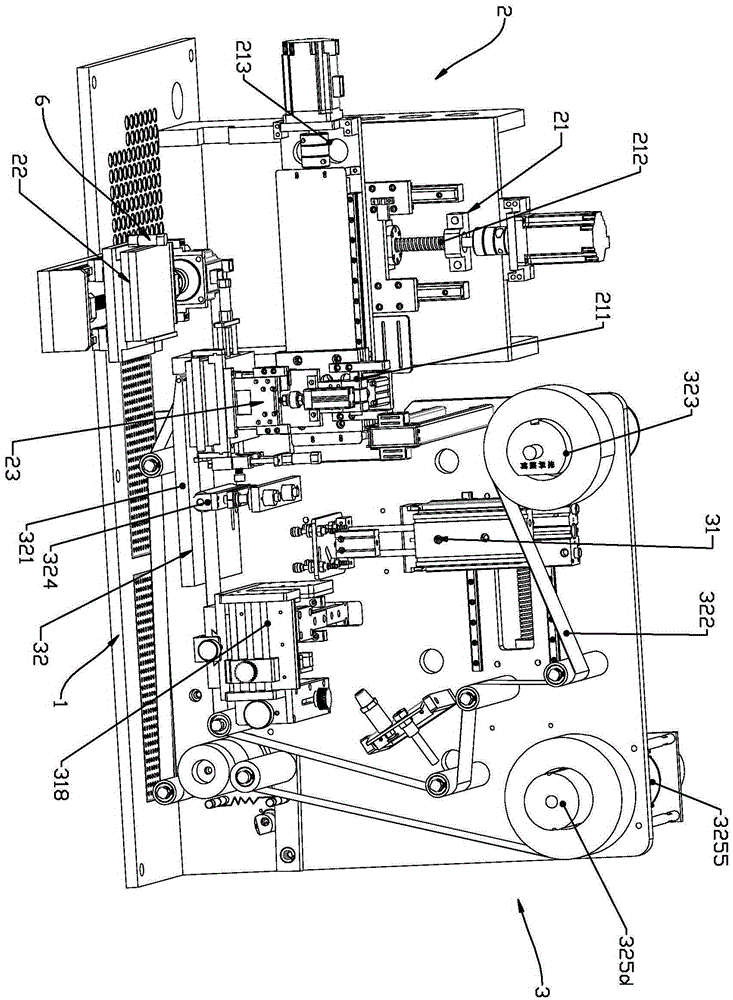

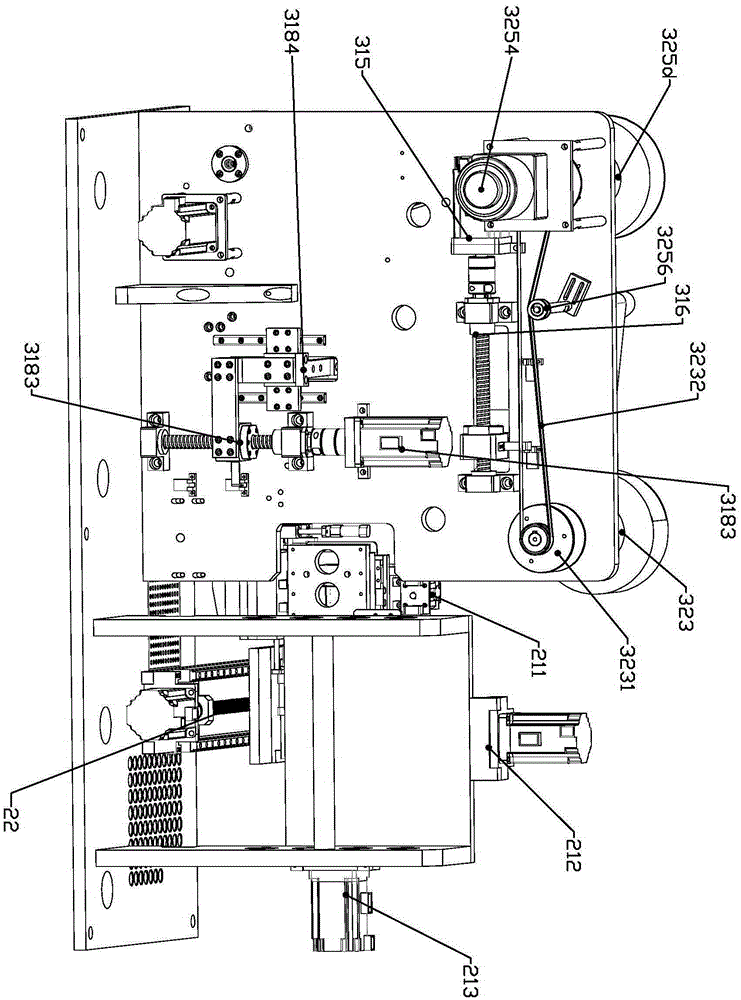

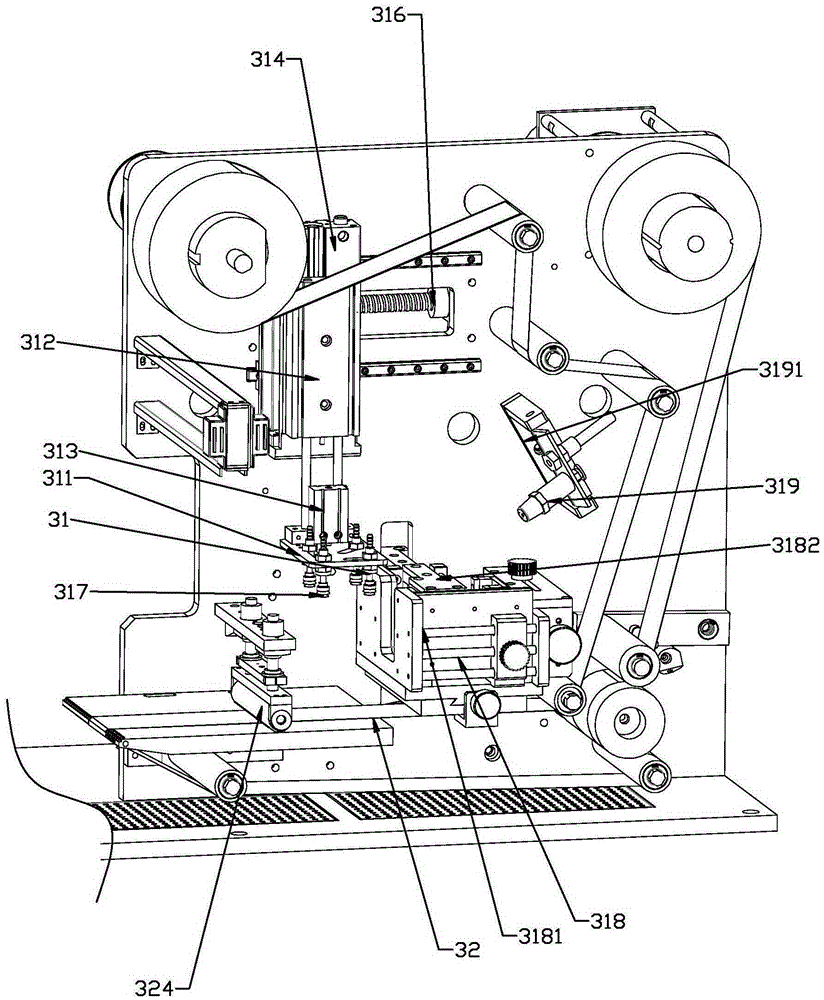

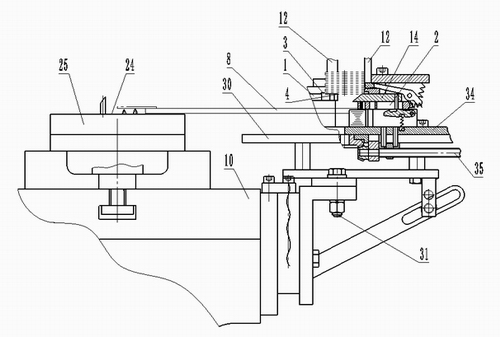

Automatic screwturningmachine

InactiveCN103753201AReliable feedingStable and accurate workMetal working apparatusManipulatorEngineering

The invention discloses an automatic screw turningmachine which comprises a feeding mechanism and a screw turning mechanism. The feeding mechanism comprises a vibration disc, a material taking mechanical hand and a screw storing table, wherein the vibration disc is used for automatically sorting screws and conveying the screws in a directional mode, the material taking mechanical hand is used for attracting the screws and transferring the screws to the screw storing table, the screw storing table is used for storing the screws, the screw turning mechanism comprises at least one screw driver, a general electric screw driver and a first air cylinder, the screw drivers attract the screws through magnetic force, the general electric screw driver drives the screw drivers to rotate, the first air cylinder drives the general electric screw driver to move up and down, the first air cylinder drives the general electric screw driver to move downwards to be clamped with the screw drivers, and then the general electric screw driver drives the screw drivers to automatically turn the screws. According to the automatic screw turning machine, a magnetic type feeding automatic screw turning device is provided on the basis of traditional automatic nut turning, the screws can be fed at one time by the automatic screw turning machine, and the automatic screw turning machine drives the screw drivers to rotate so as to sequentially conduct screw turning. The automatic screw turning machine is rapid and reliable in feeding, stable and accurate in work, and capable of achieving rapid feeding of the screws of different specifications without replacing the screw drivers.

Owner:THE JIE PRECISION MACHINERY AUTOMATION

Double stack box magazine for rimmed cartridges of varying length

ActiveUS8448364B2Inhibit bindingLoss of feed reliabilityAmmunition loadingAbutmentElectrical and Electronics engineering

Owner:DAVIDSON MICHAEL J

Paper conveying device

InactiveCN102431818AGuaranteed accuracyReliable feedingArticle feedersPaper sheetPulp and paper industry

A paper conveying device comprises a framework, a paper conveying platform, a paper deviation correcting and limiting mechanism, a paper detecting mechanism, a paper absorbing and positioning mechanism and a batch type paper feeding mechanism. The paper deviation correcting and limiting mechanism, the paper detecting mechanism, the paper absorbing and positioning mechanism and the batch type paper feeding mechanism are arranged on the paper conveying platform, the paper deviation correcting and limiting mechanism forms a paper limiting area on the paper conveying platform, the paper detecting mechanism, the paper absorbing and positioning mechanism and the batch type paper feeding mechanism are respectively arranged in the paper limiting area, and the paper detecting mechanism is electrically connected with the paper absorbing and positioning mechanism. The paper conveying device is capable of preventing slanting or deviating of paper by deviation correcting and position limiting of the paper deviation correcting and limiting mechanism and absorbing and positioning of the paper absorbing and positioning mechanism, so that paper can be stably reliably conveyed, accuracy of printing and processing of paper printing and processing equipment and accuracy of printed matter quality detection and code spraying equipment detection are guaranteed.

Owner:陈晓滨

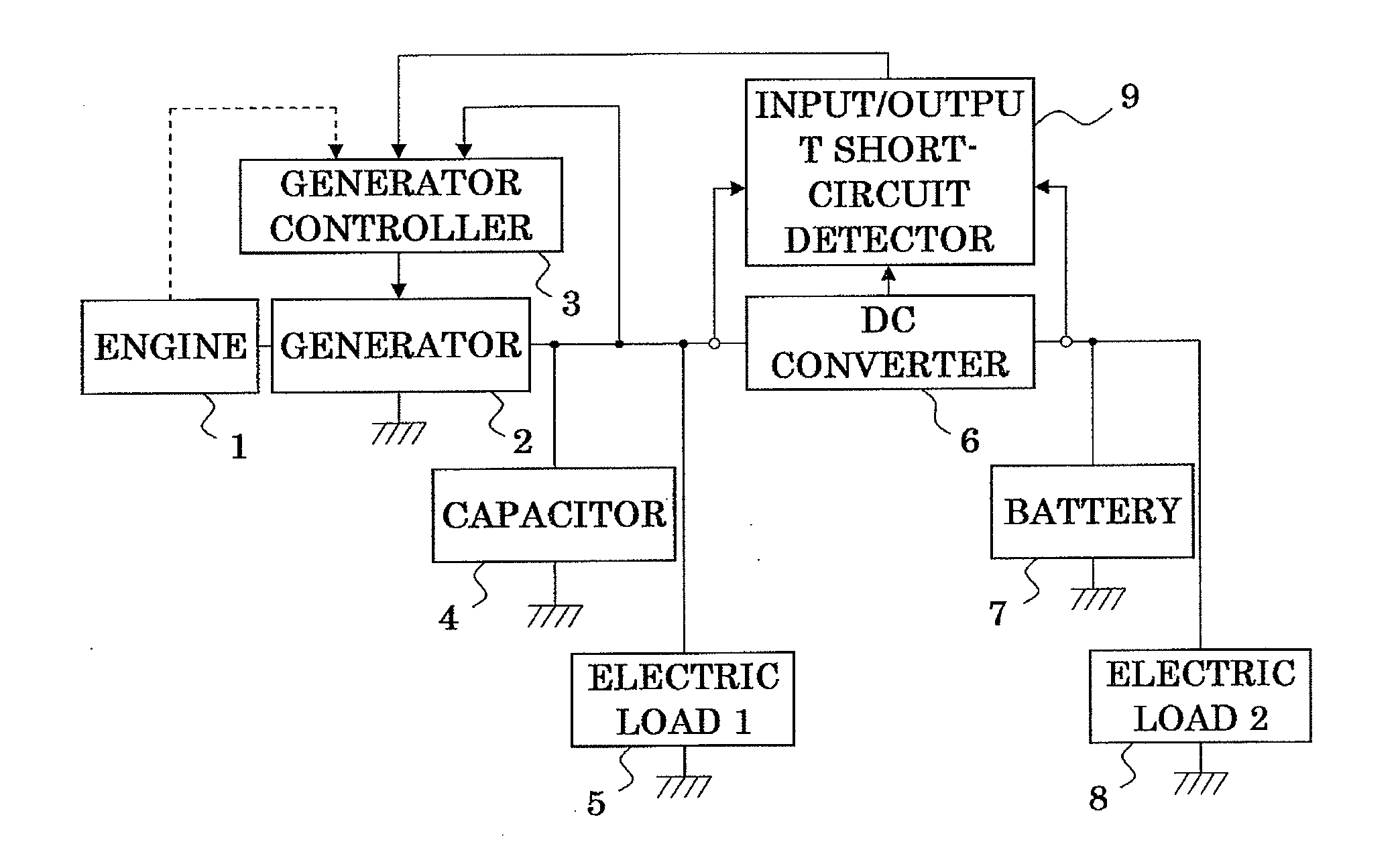

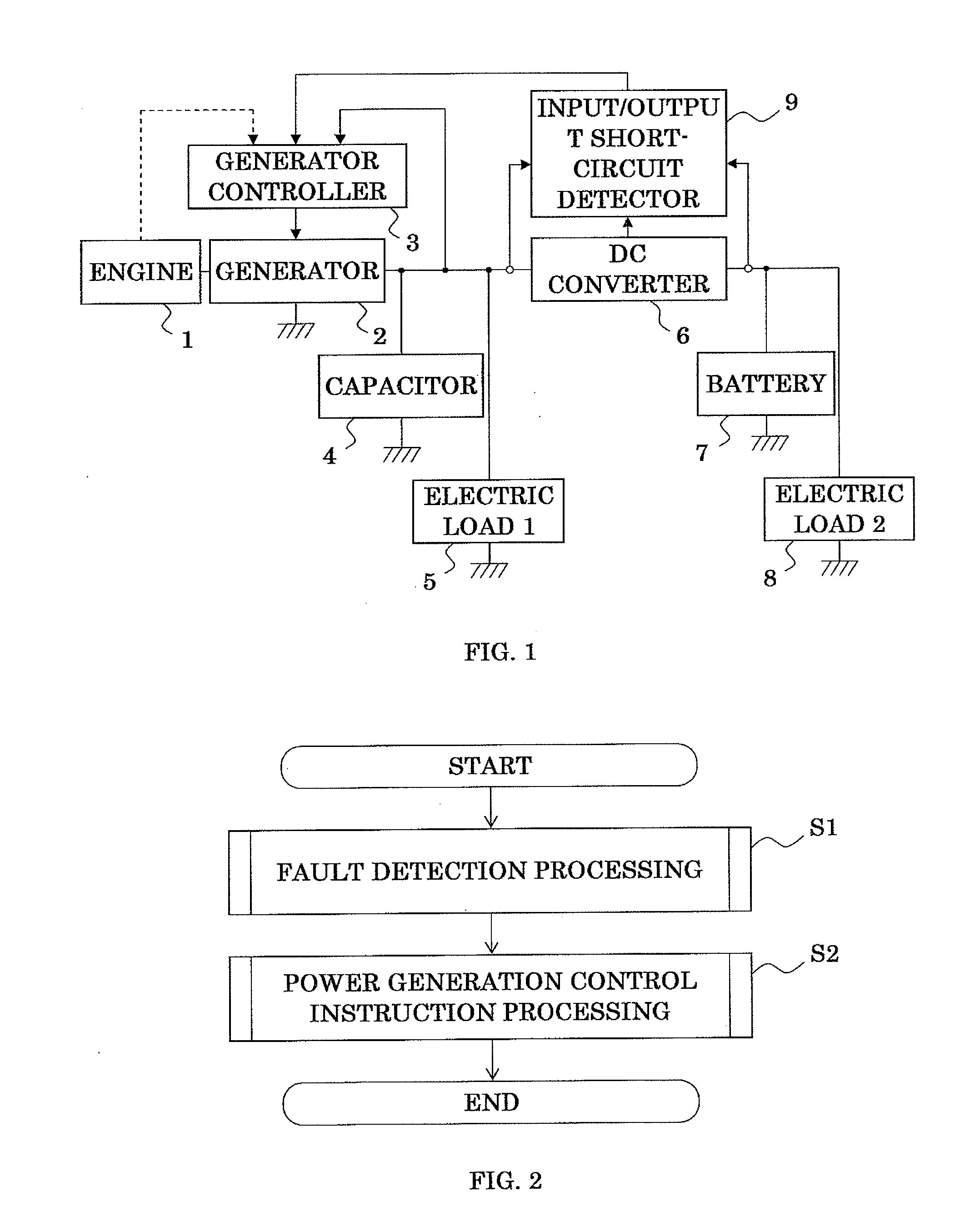

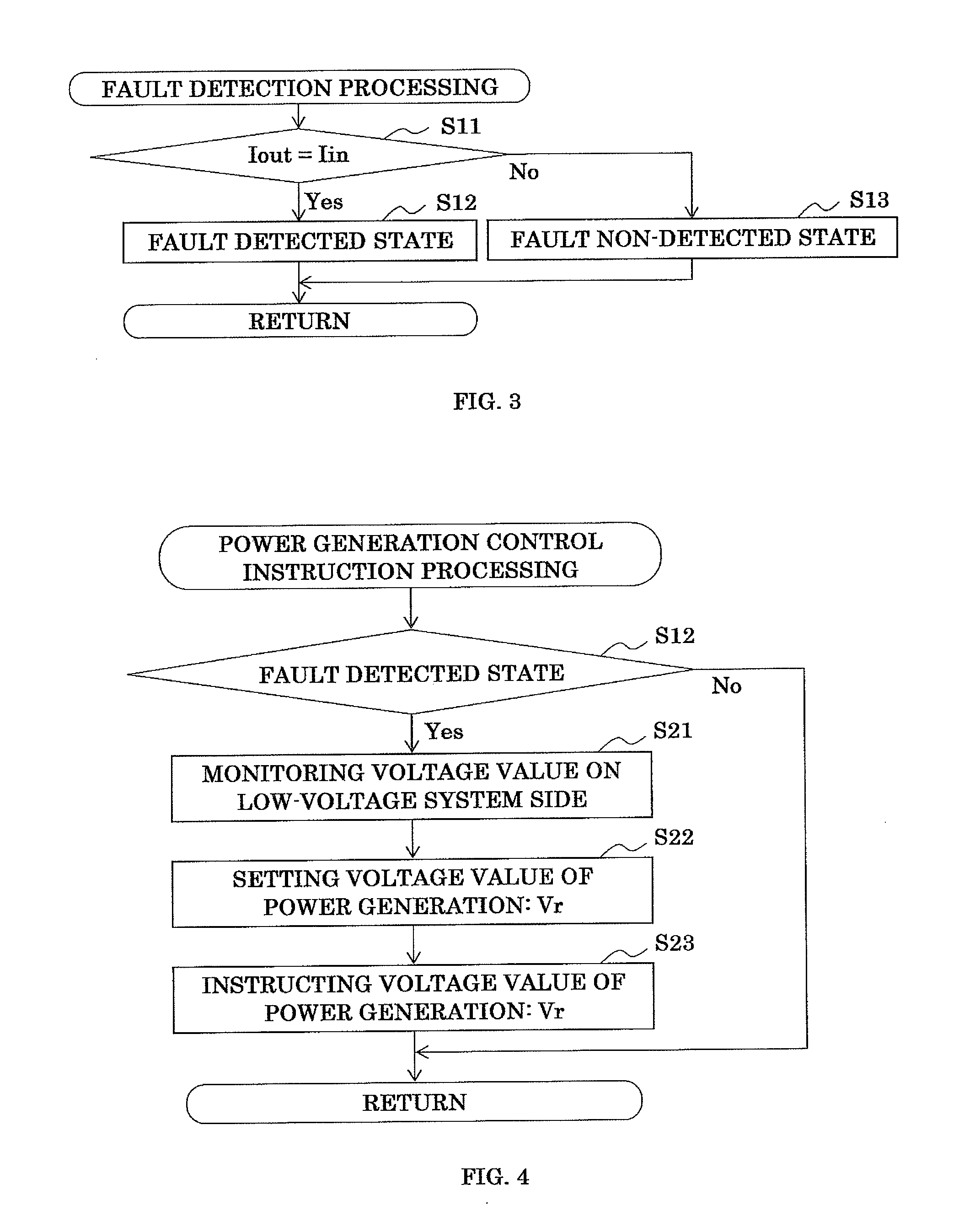

Power supply system

ActiveUS20100289336A1Guaranteed uptimeReliable feedingCircuit monitoring/indicationDifferent batteries chargingElectric power systemElectric power

A power supply system is provided with devices of generating an electric power, controlling an amount of power generation, charging an electric power having been generated, converting an electric power having been generated, charging an electric power having been converted, operating an electric load by an electric power having been converted, and detecting a short-circuit fault of input / output of a DC converter. In the case of detecting an input / output short-circuit fault of the DC converter, from the input / output short-circuit detector to the generator controller, an instruction is given such that the generator is switched to make a power generation at a predetermined constant voltage determined based on a voltage of the circuit arrangement.

Owner:MITSUBISHI ELECTRIC CORP

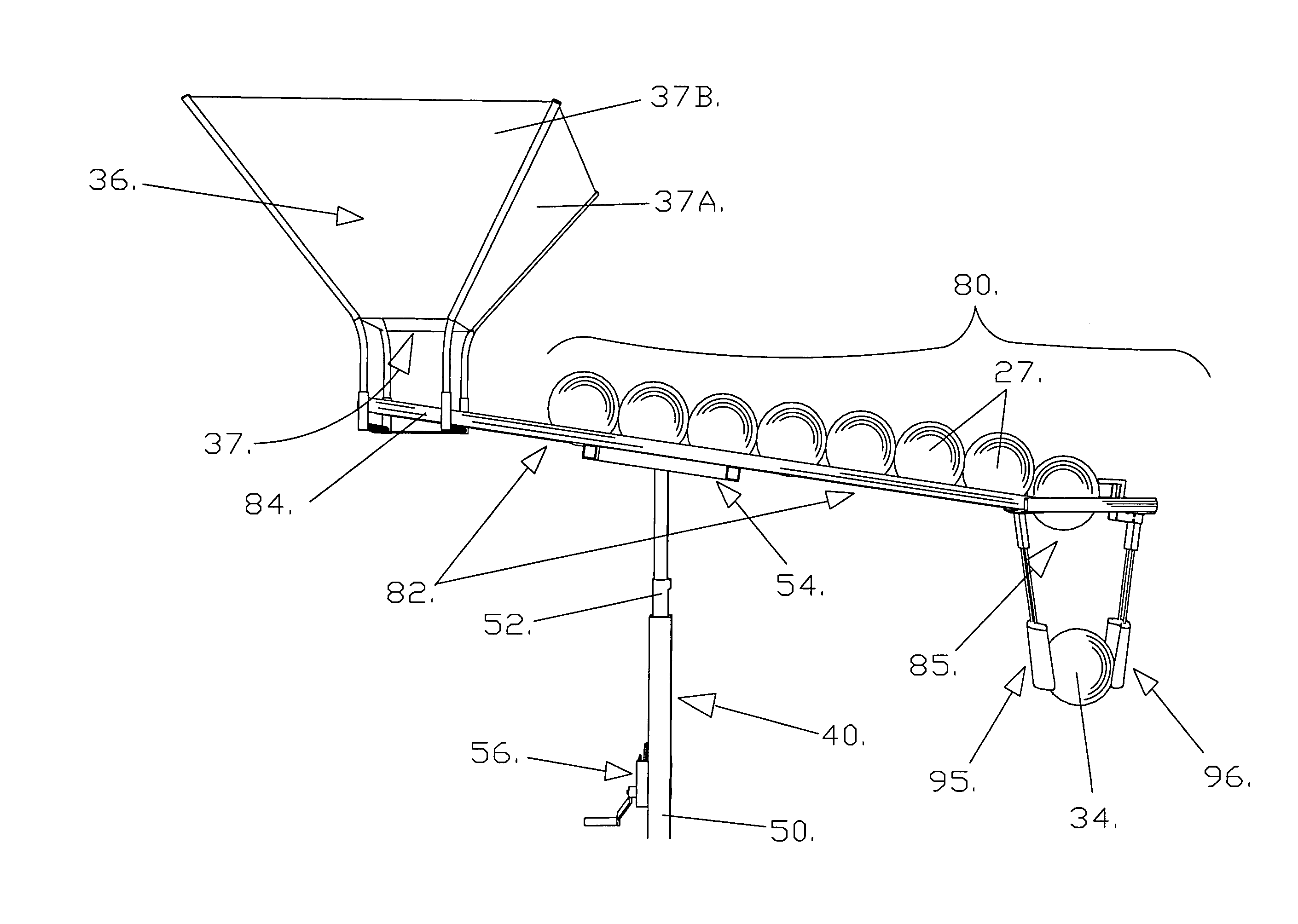

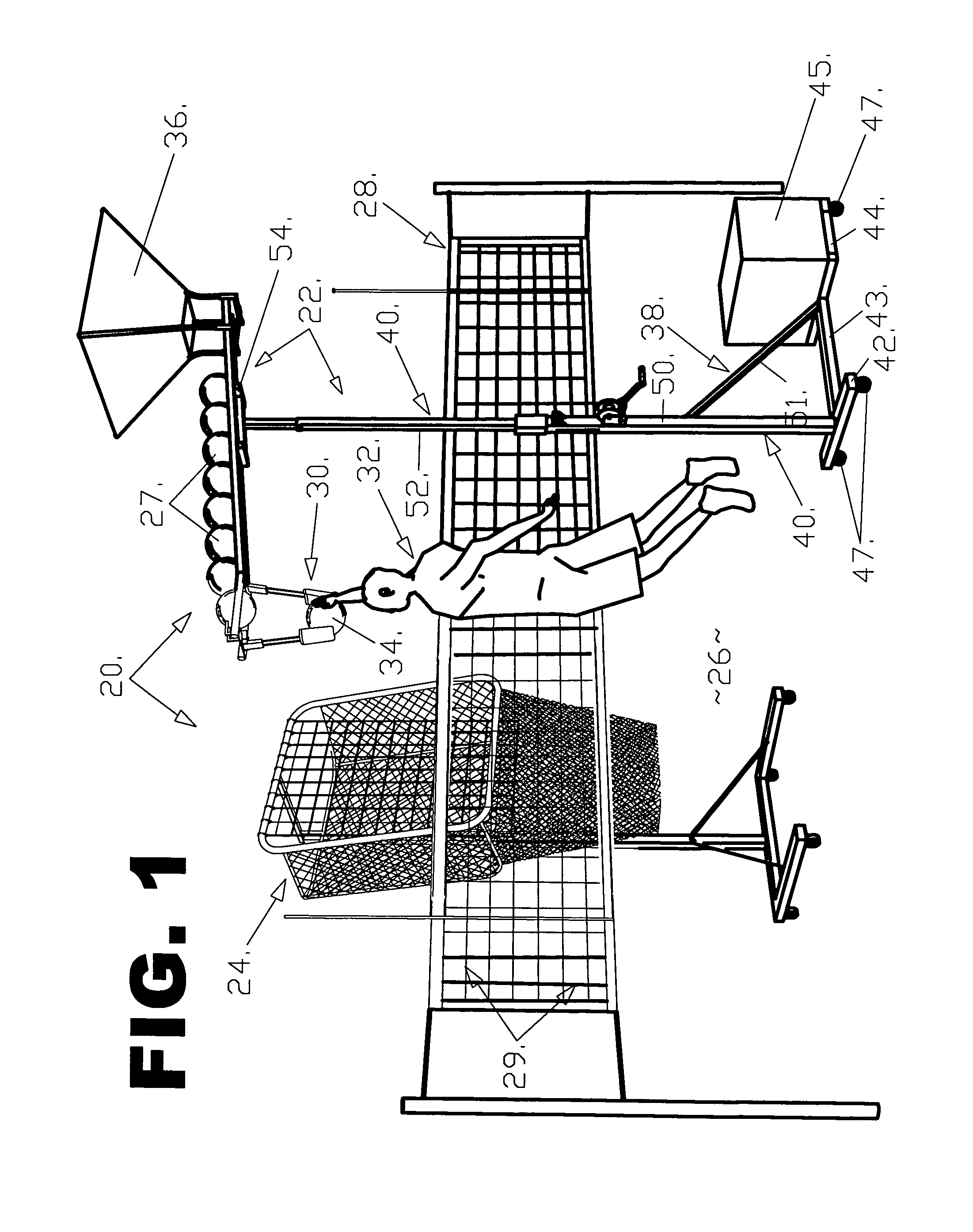

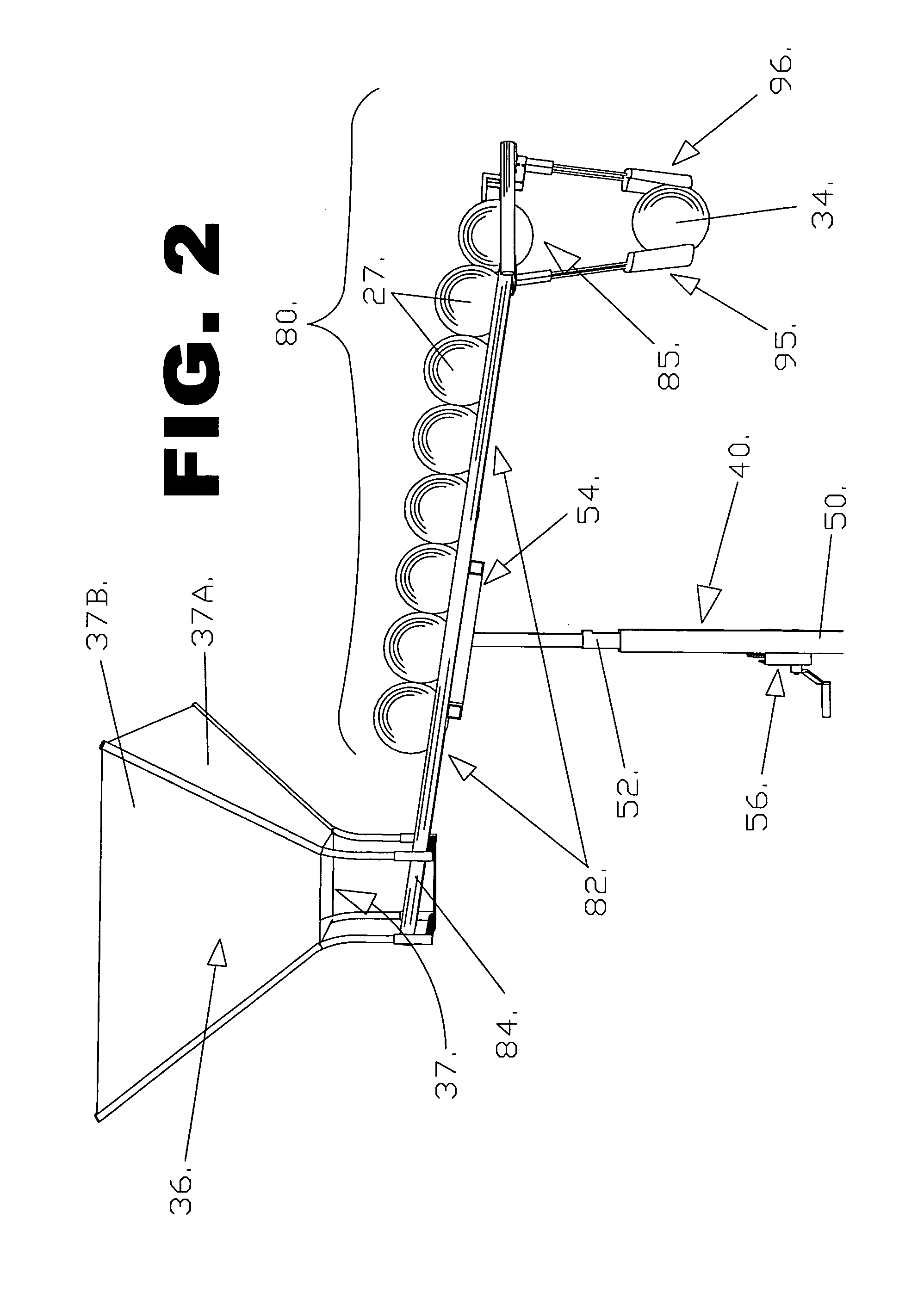

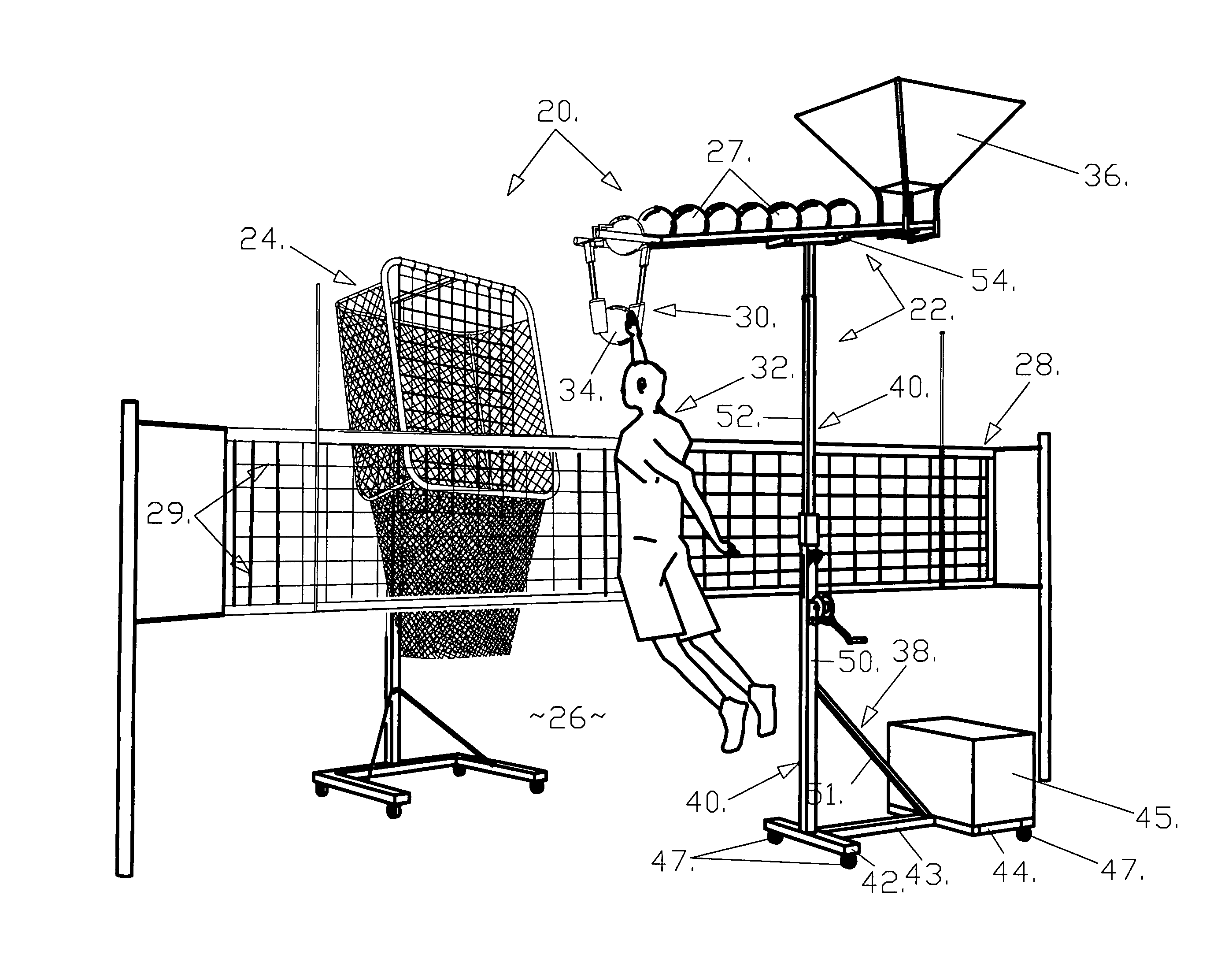

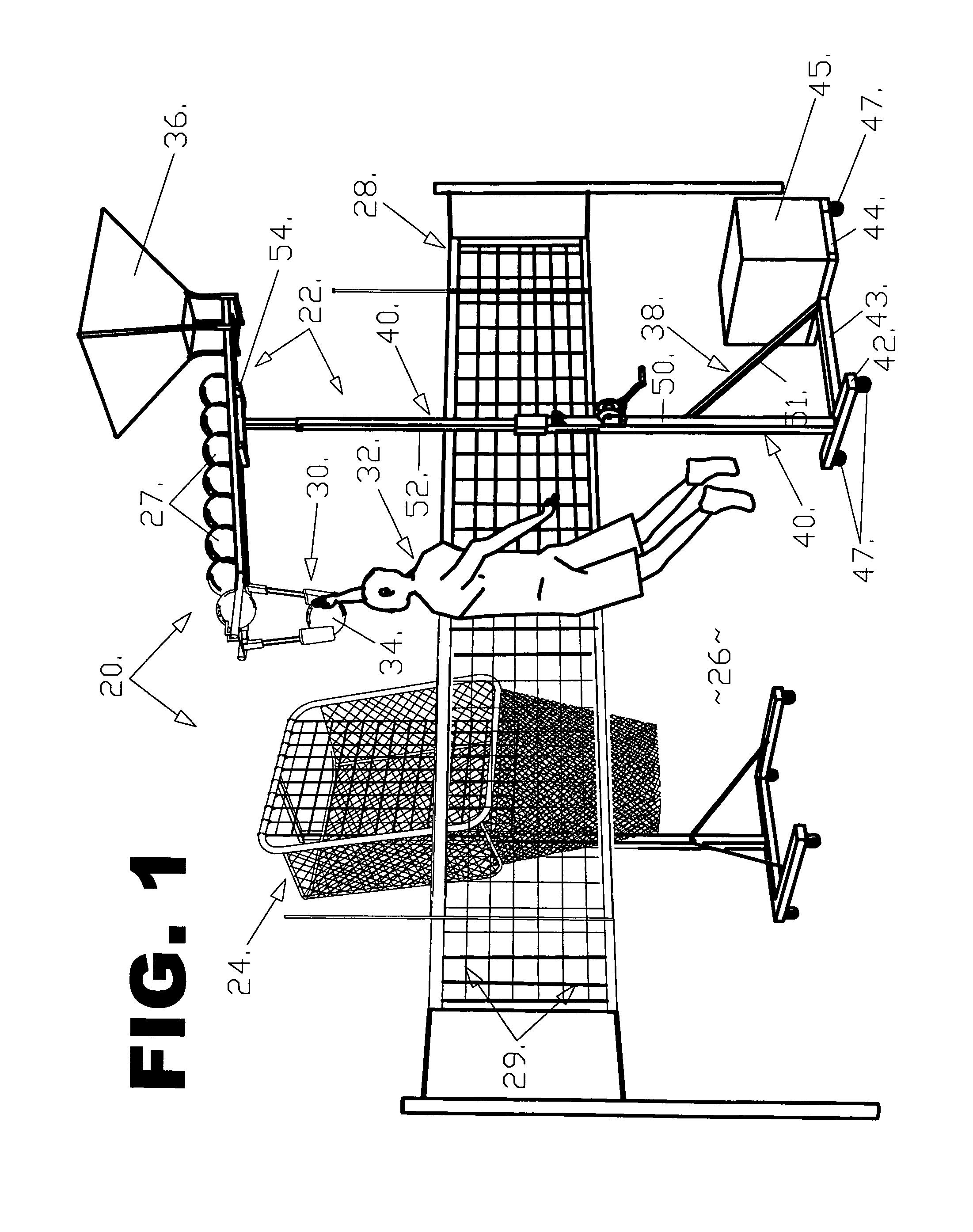

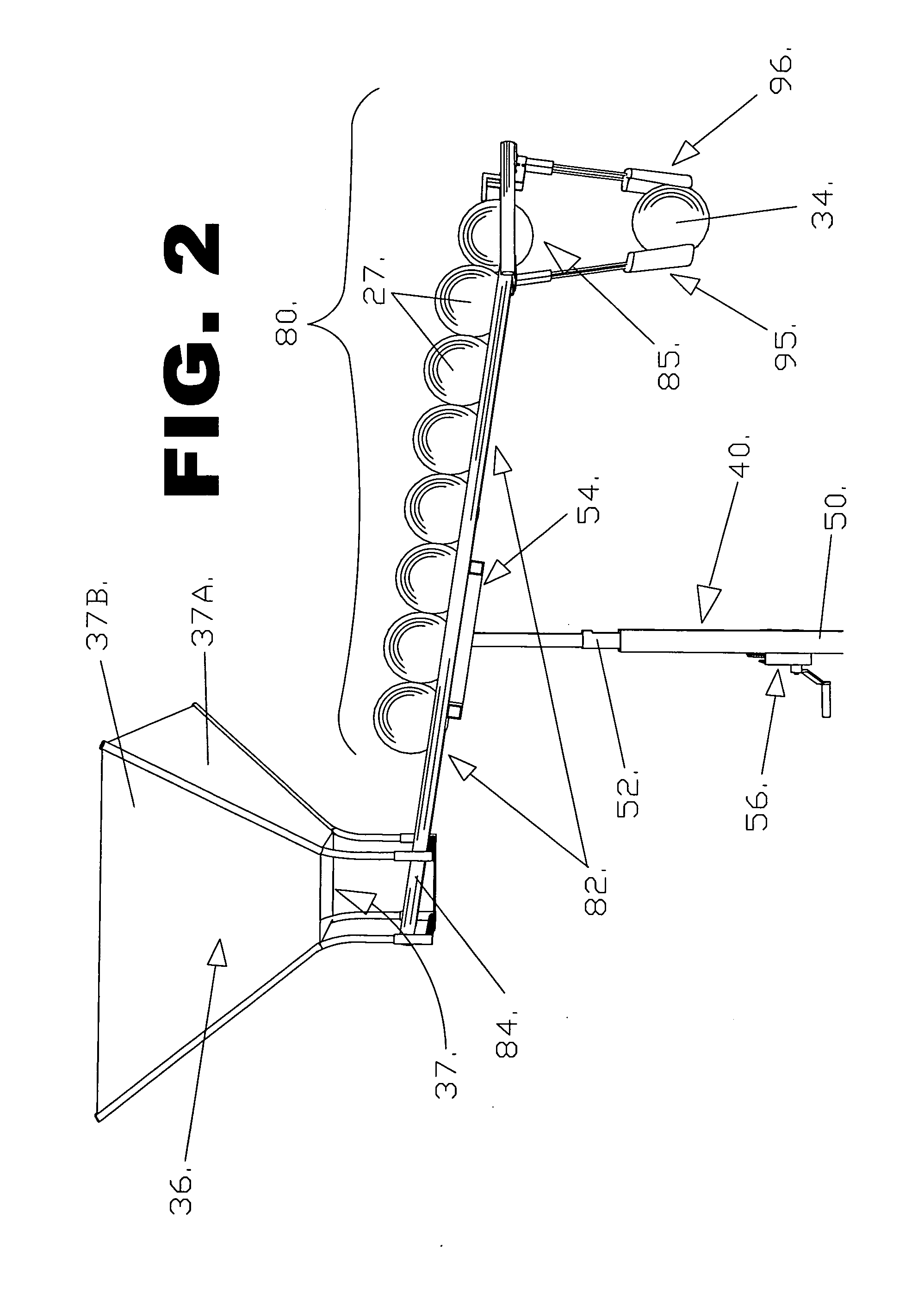

Volleyball spiking training device

A volleyball spike training system comprises a ball holder and an optional net. The training holder comprises a wheeled chassis supporting a vertical stanchion projecting upwardly that supports a hopper and a ball feeding apparatus. The stanchion includes a crank system for vertically adjusting telescoped stanchion segments. Balls dropping from the hopper travel by gravity down an inclined ramp at the top of the frame towards a discharge throat. Balls travelling down the ramp are indexed by a Z-shaped lever that serially separates them. A pair of downwardly projecting hands, one fixed and one pivoted, receive dropping balls and temporarily hold them for shooting. The pivoting hand controls the indexing lever to jam successive balls when the device is loaded. When a ball is shot and removed from between the feed hands, another ball is freed by the indexing lever to automatically drop into a shooting position between the hands.

Owner:ACU PAC INC

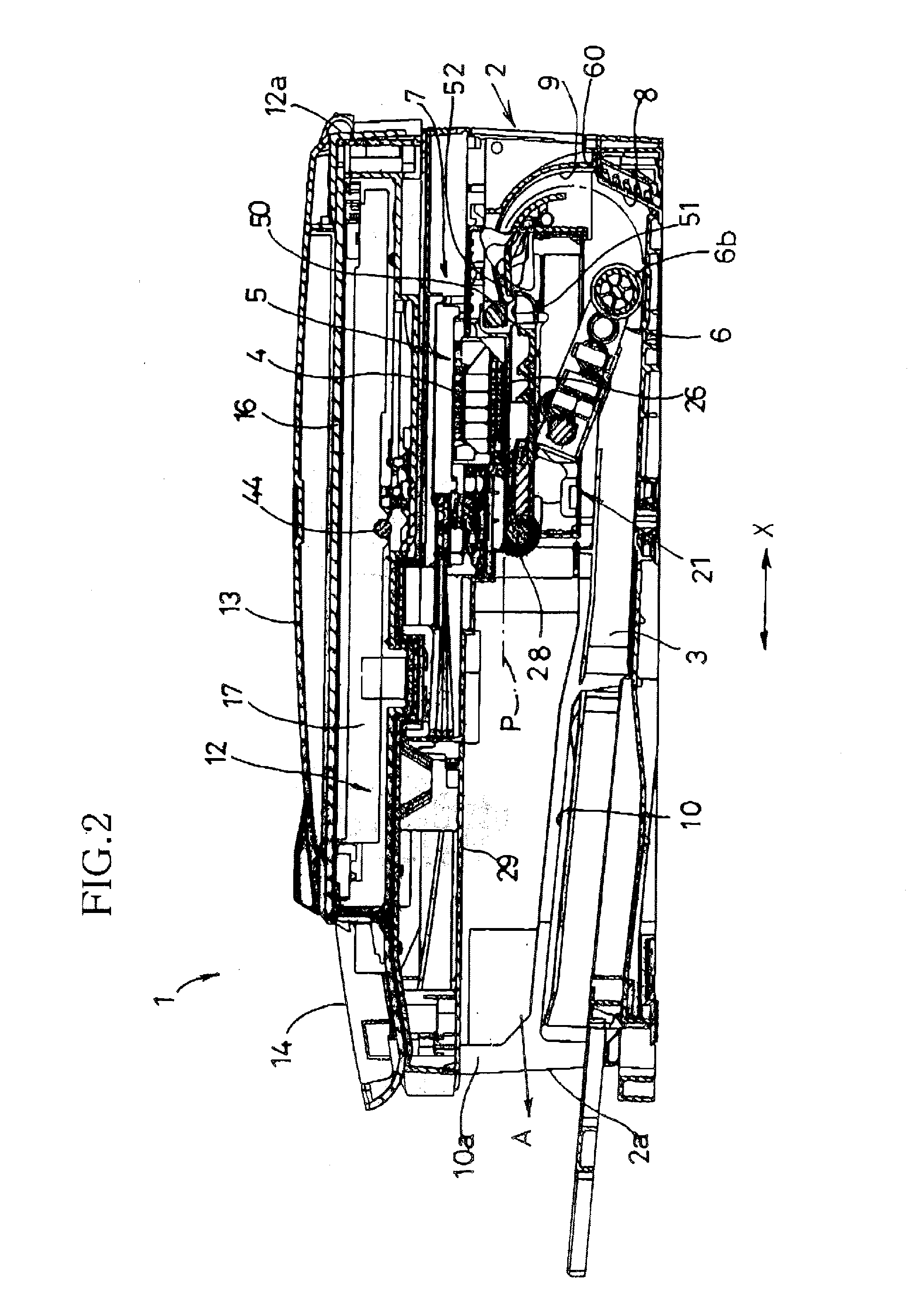

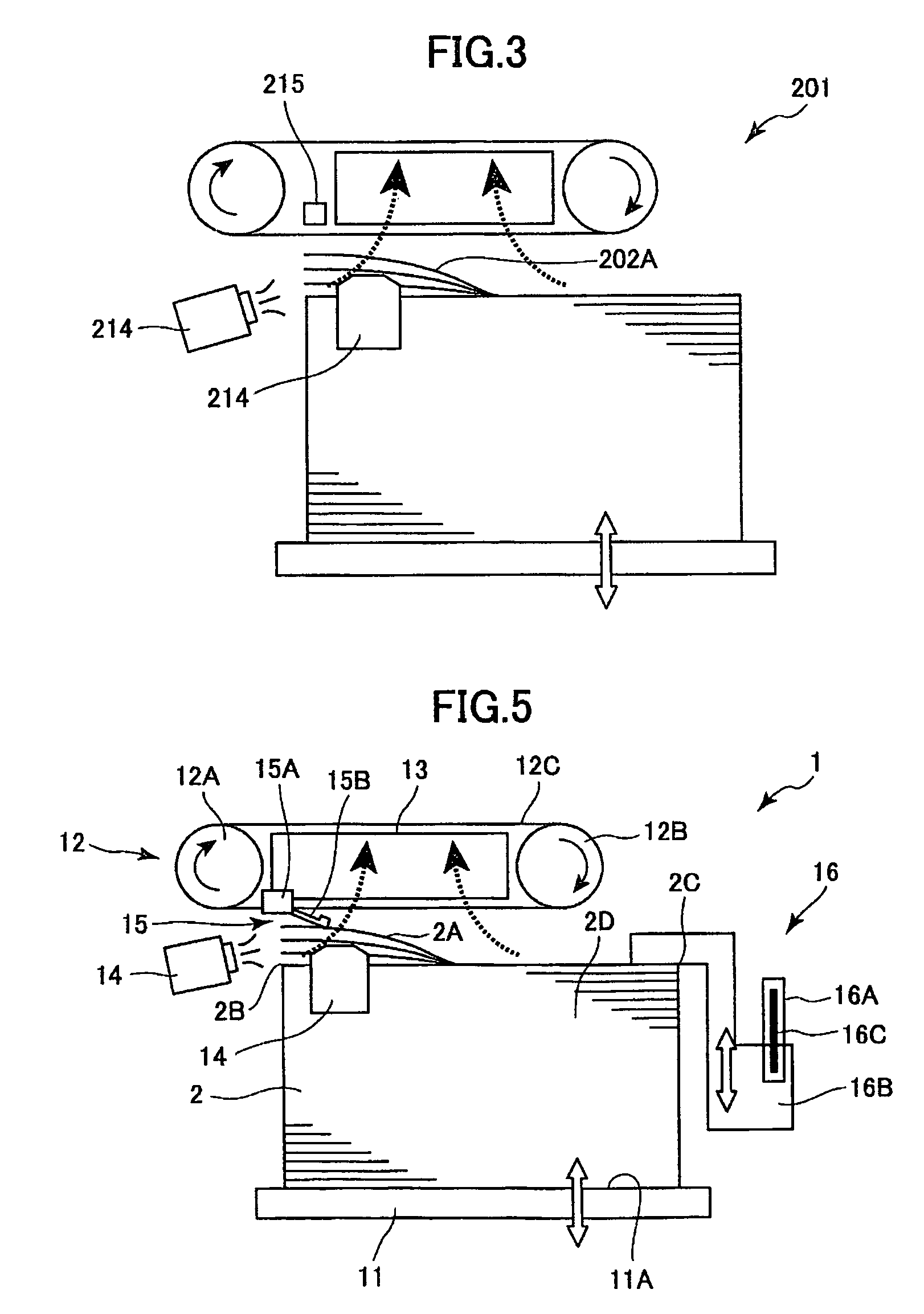

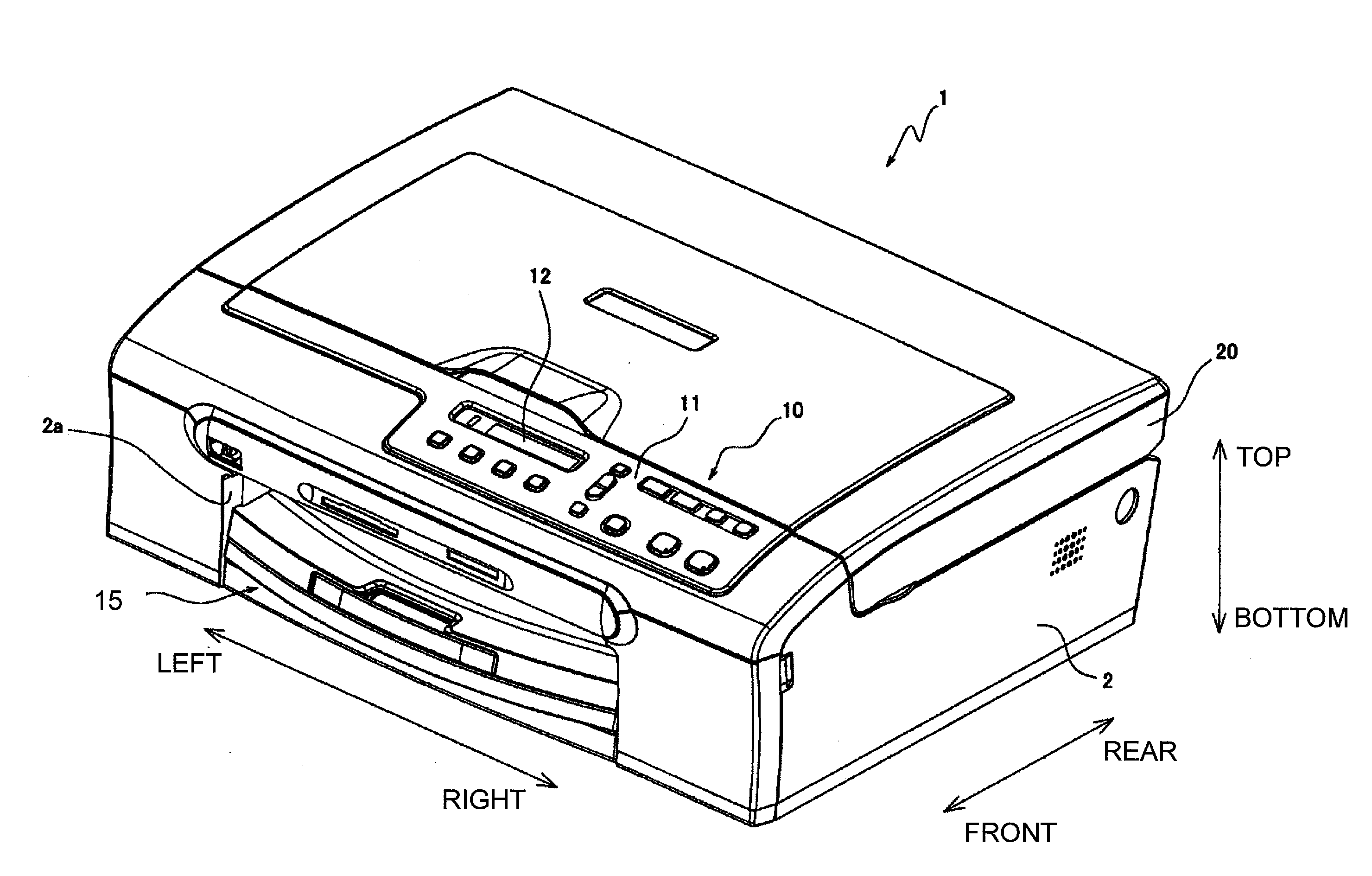

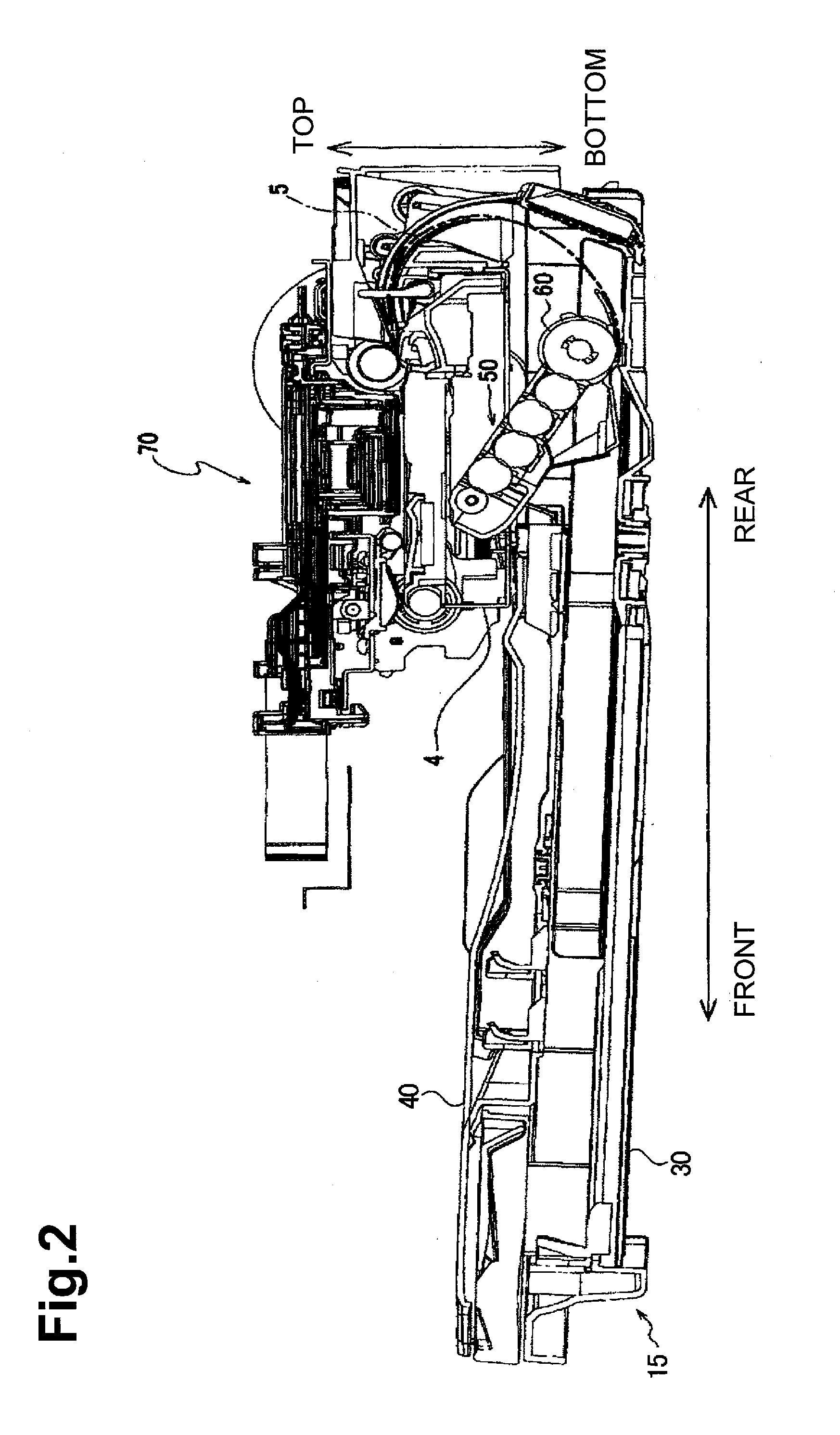

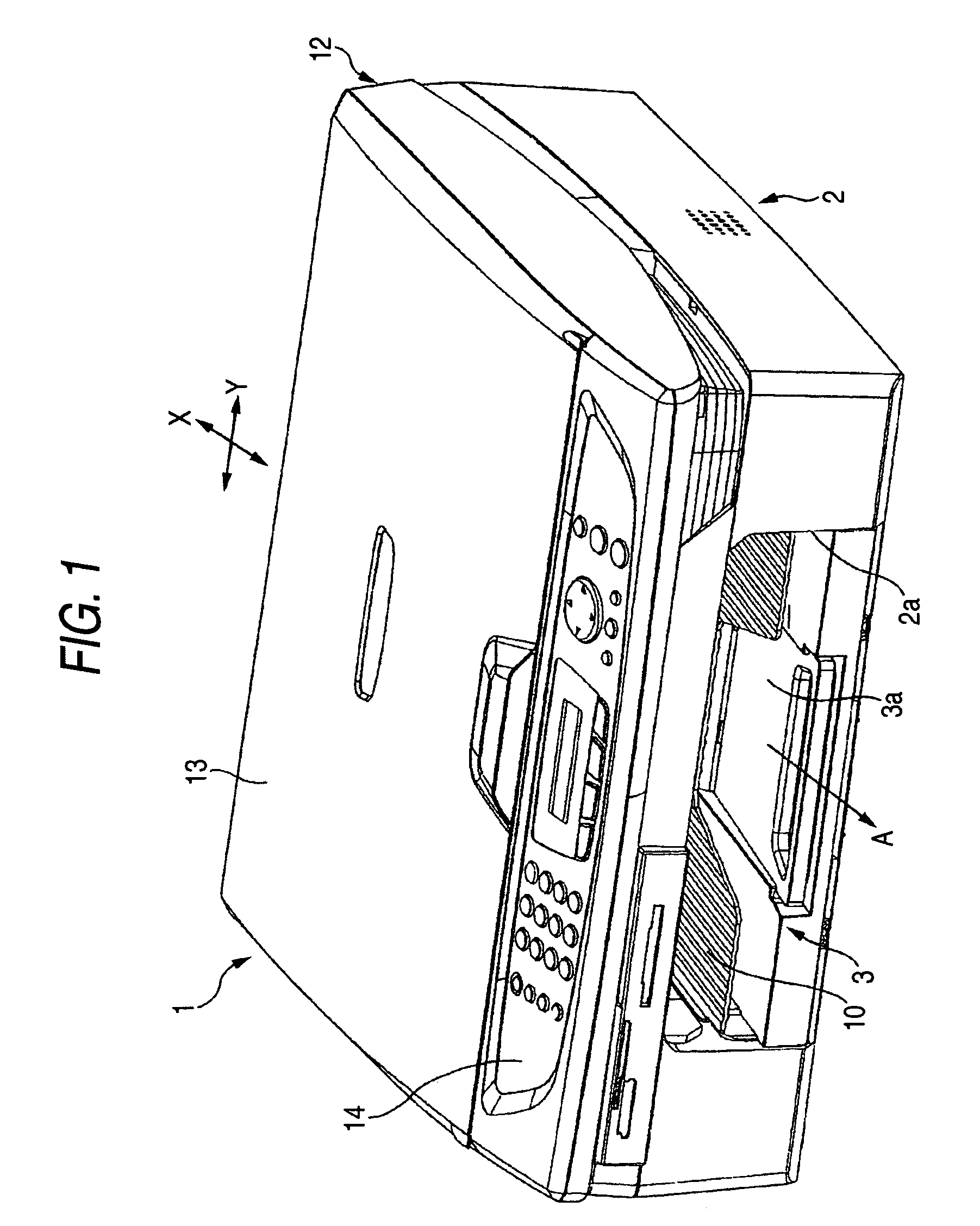

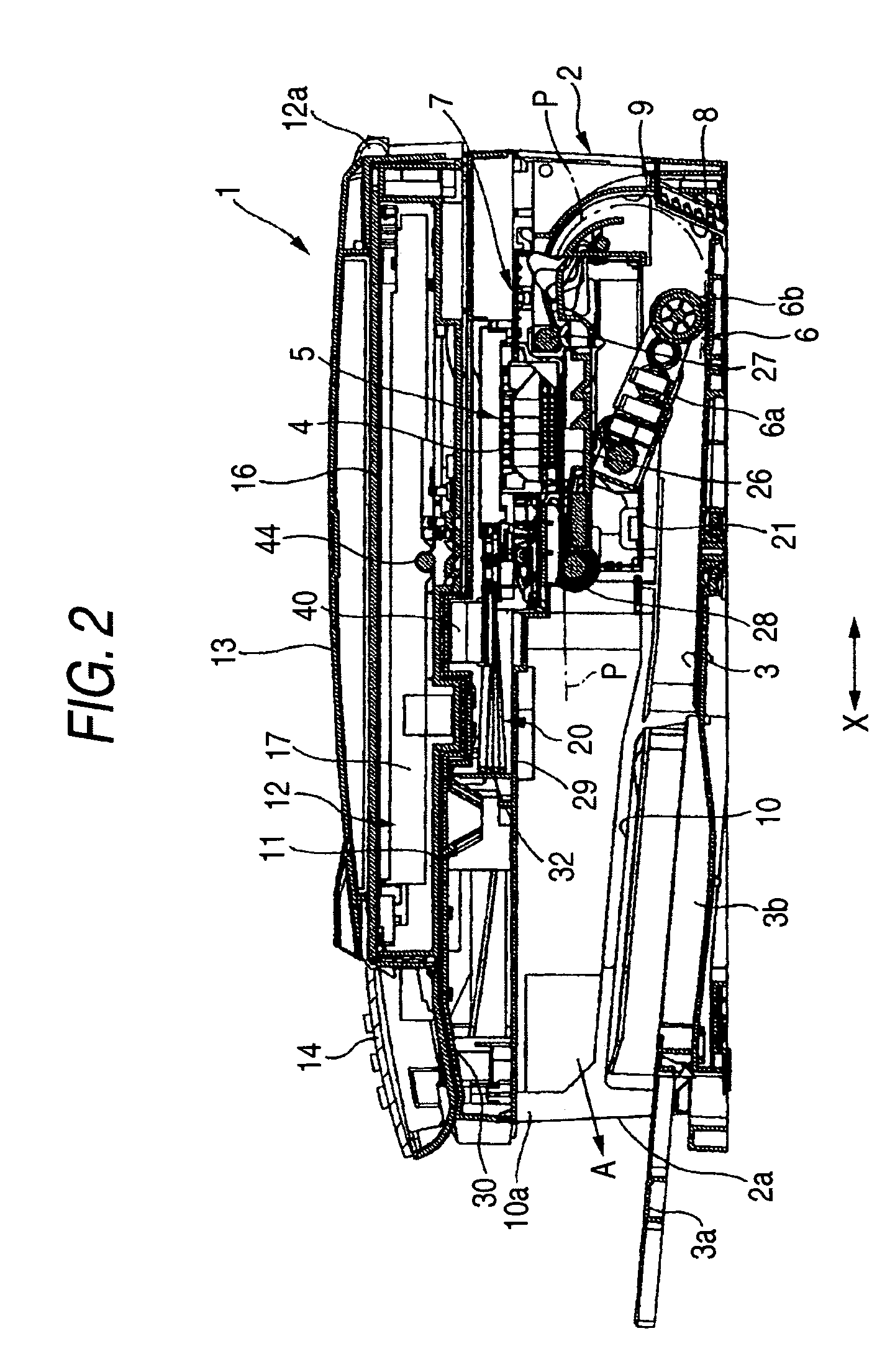

Recording medium feeder and image recording device

InactiveUS20050242485A1Increase coefficient of frictionDifficult to slideArticle separationImage recordingEngineering

A recording medium feeder includes: a tray on which a plurality of recording medium are to be stacked; a feed roller that feeds the recording medium stacked on the tray; a first friction member provided on the tray and having high friction coefficient; and a second friction member provided on the tray at a position opposing the feed roller and having low friction coefficient that is lower than the friction coefficient of the first friction member, wherein the first friction member is configurable to be in one of positions of a protruded position in which a surface of the first friction member is protruded from a surface of the second friction member towards the feed roller and a retracted position in which the surface of the first friction member is arranged to be not higher than the surface of the second friction member.

Owner:BROTHER KOGYO KK

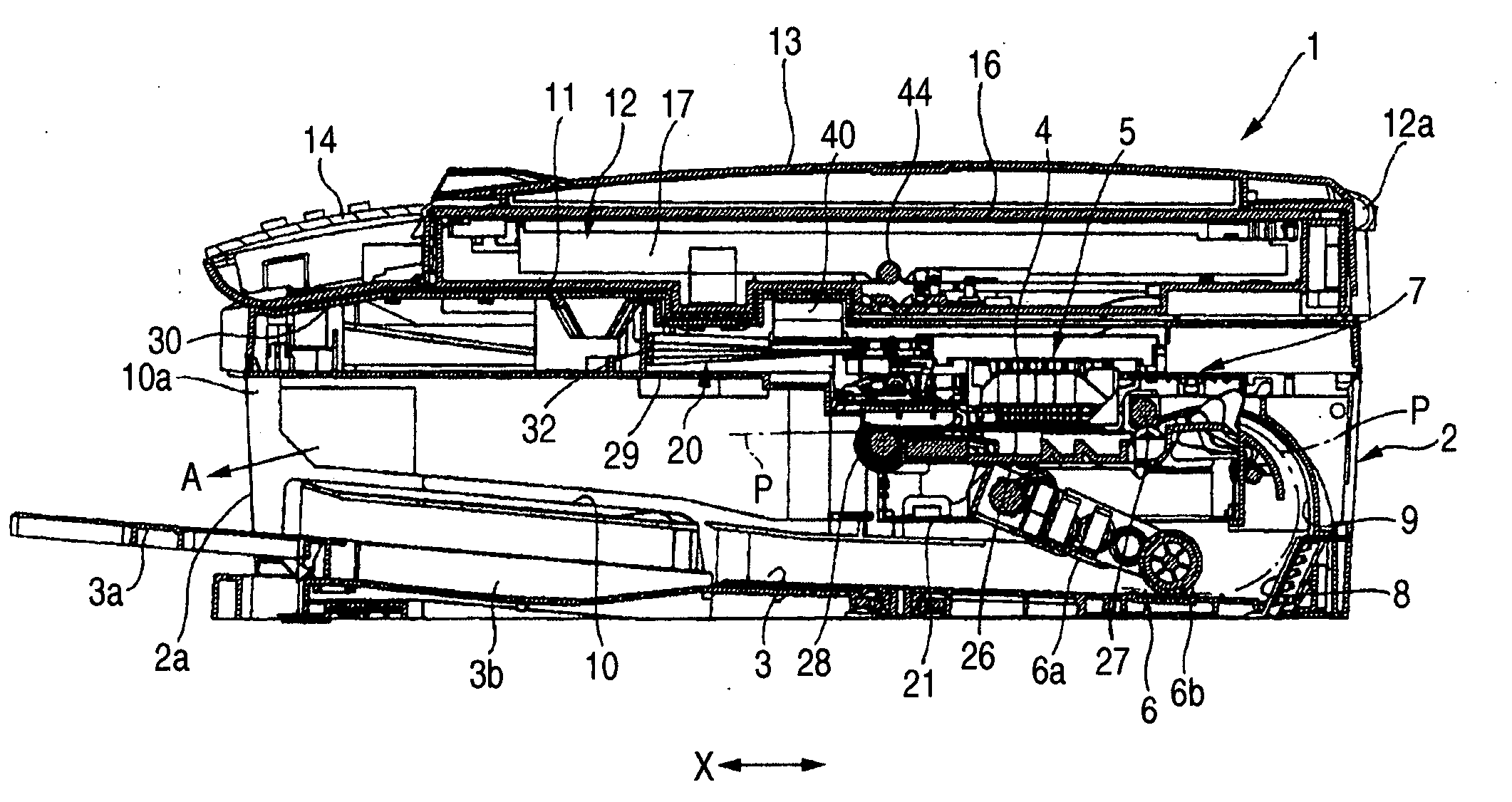

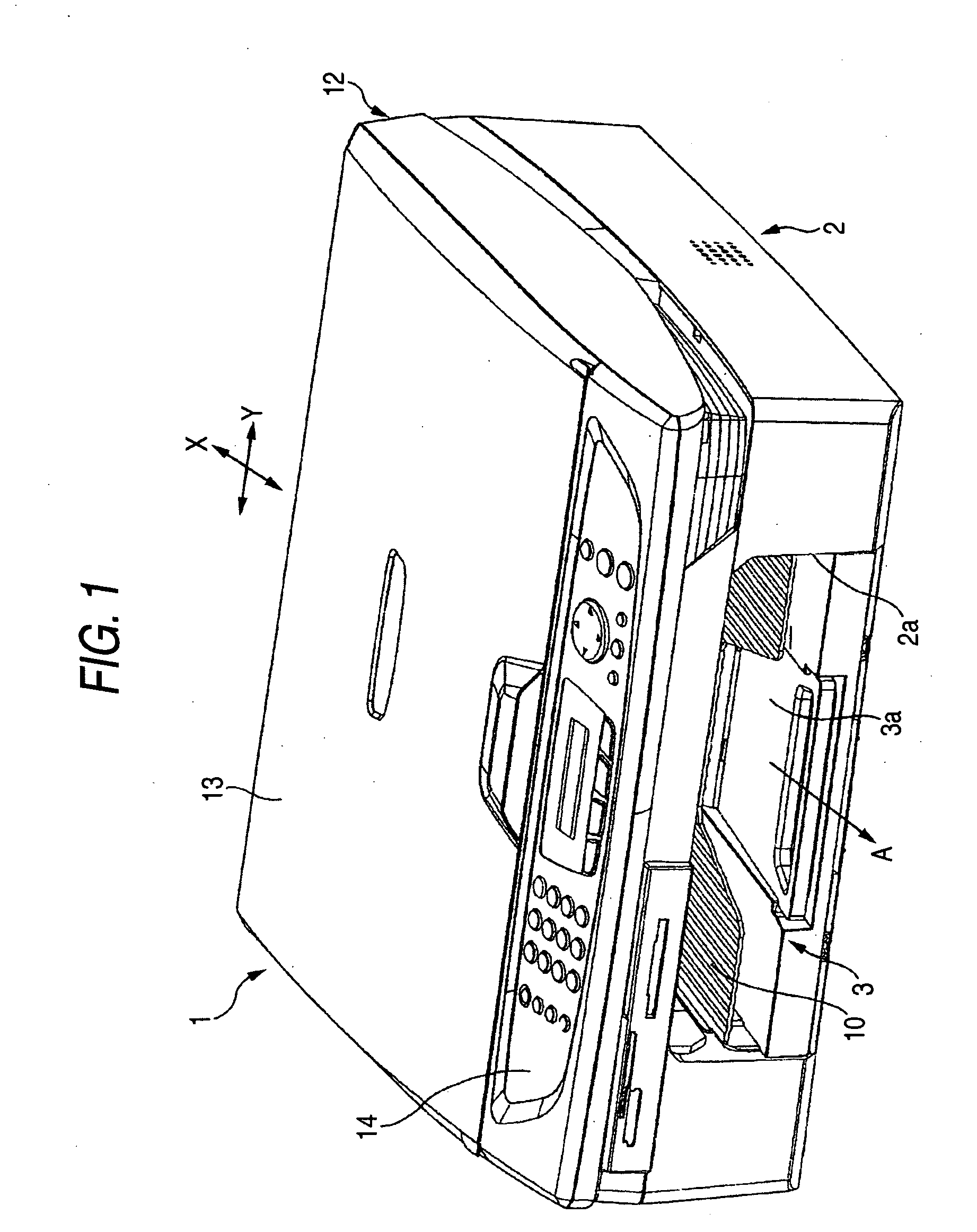

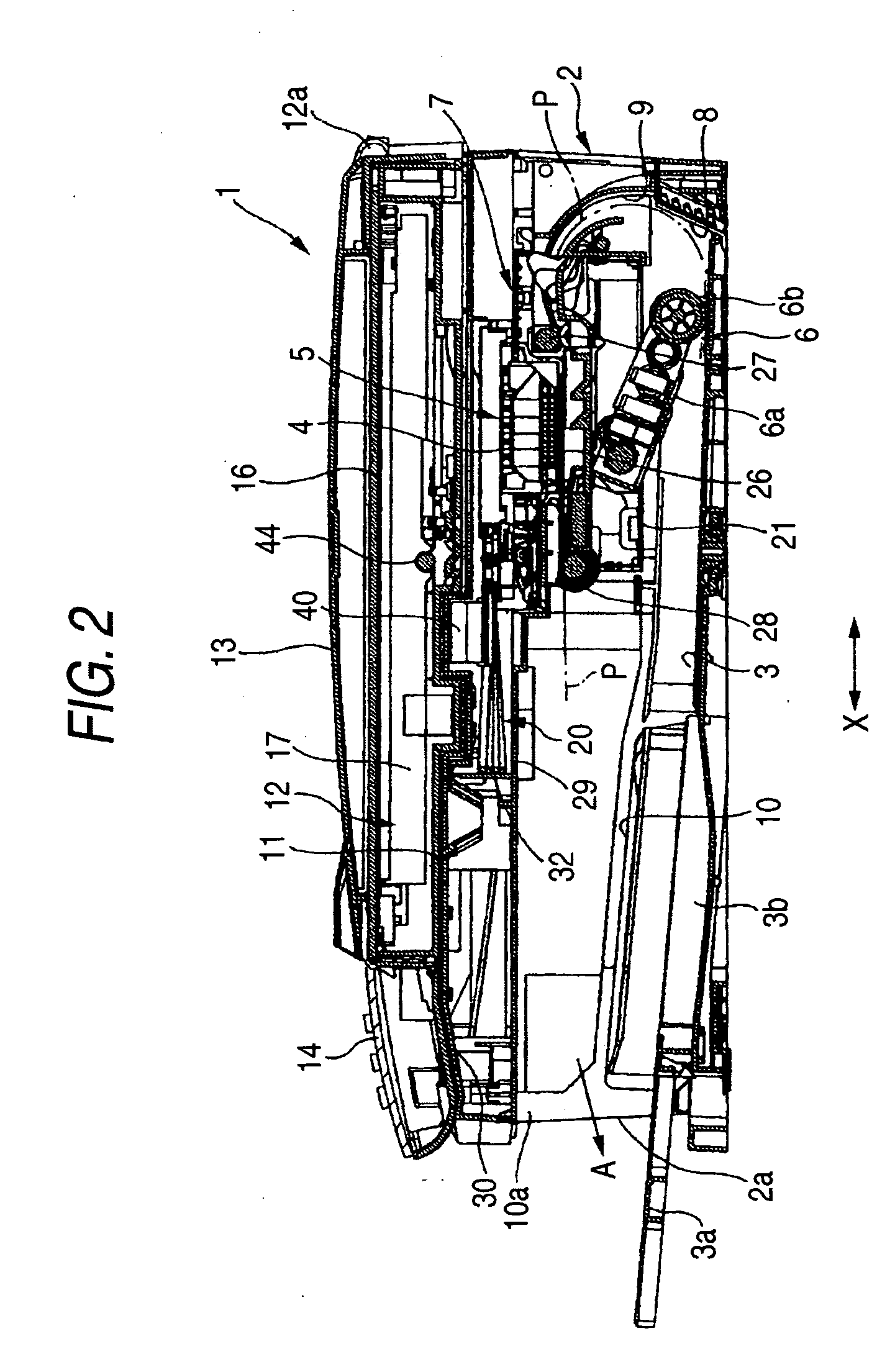

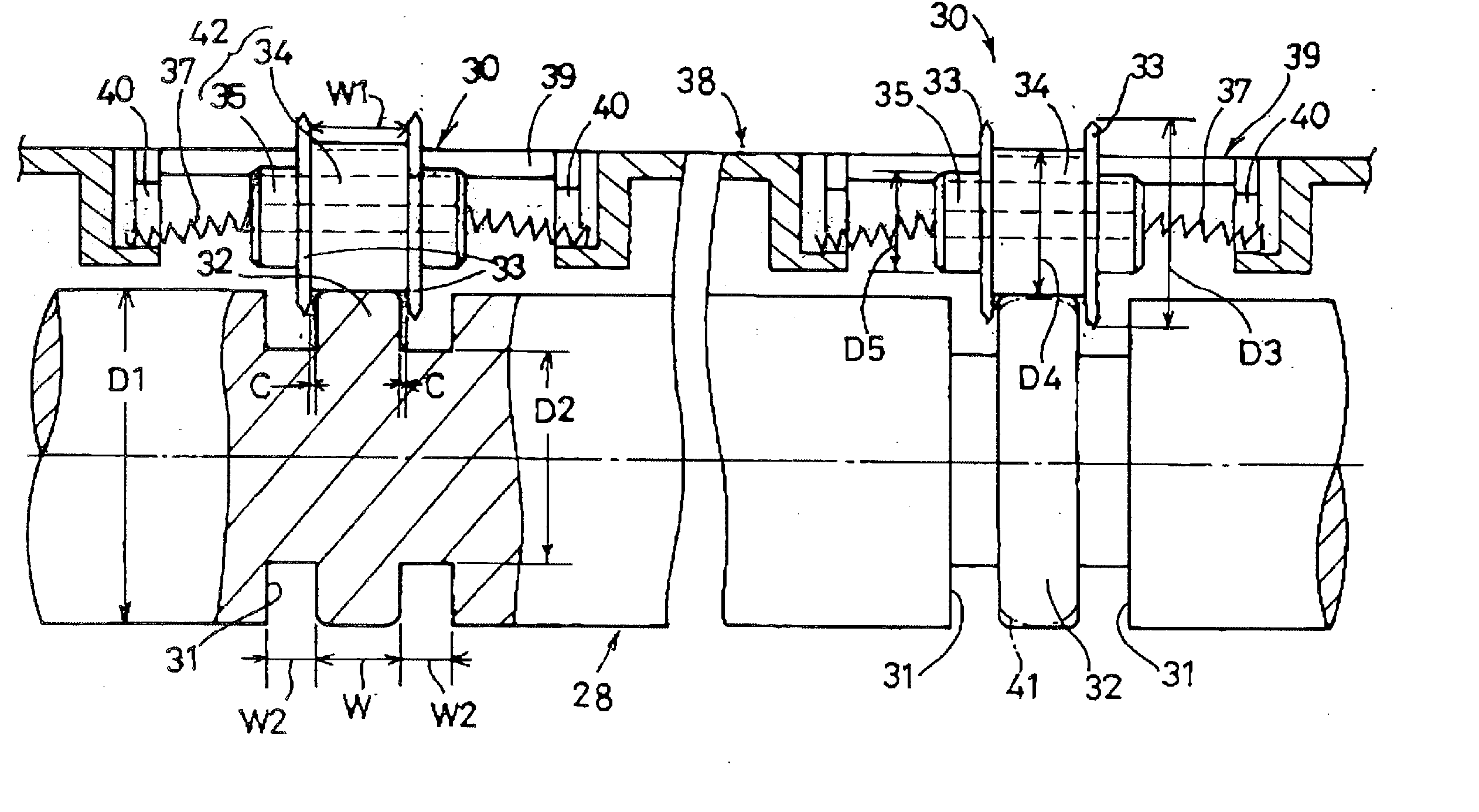

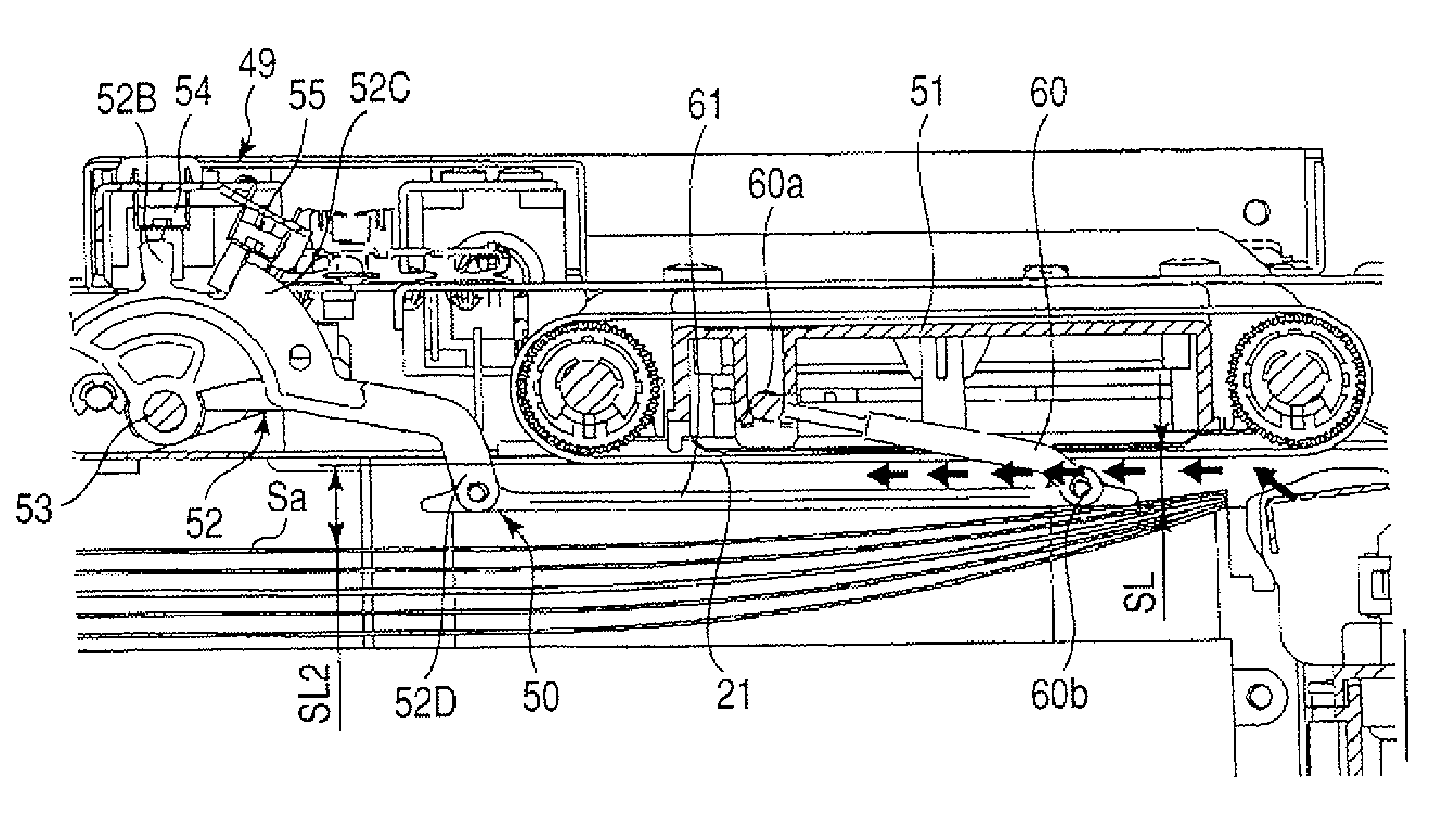

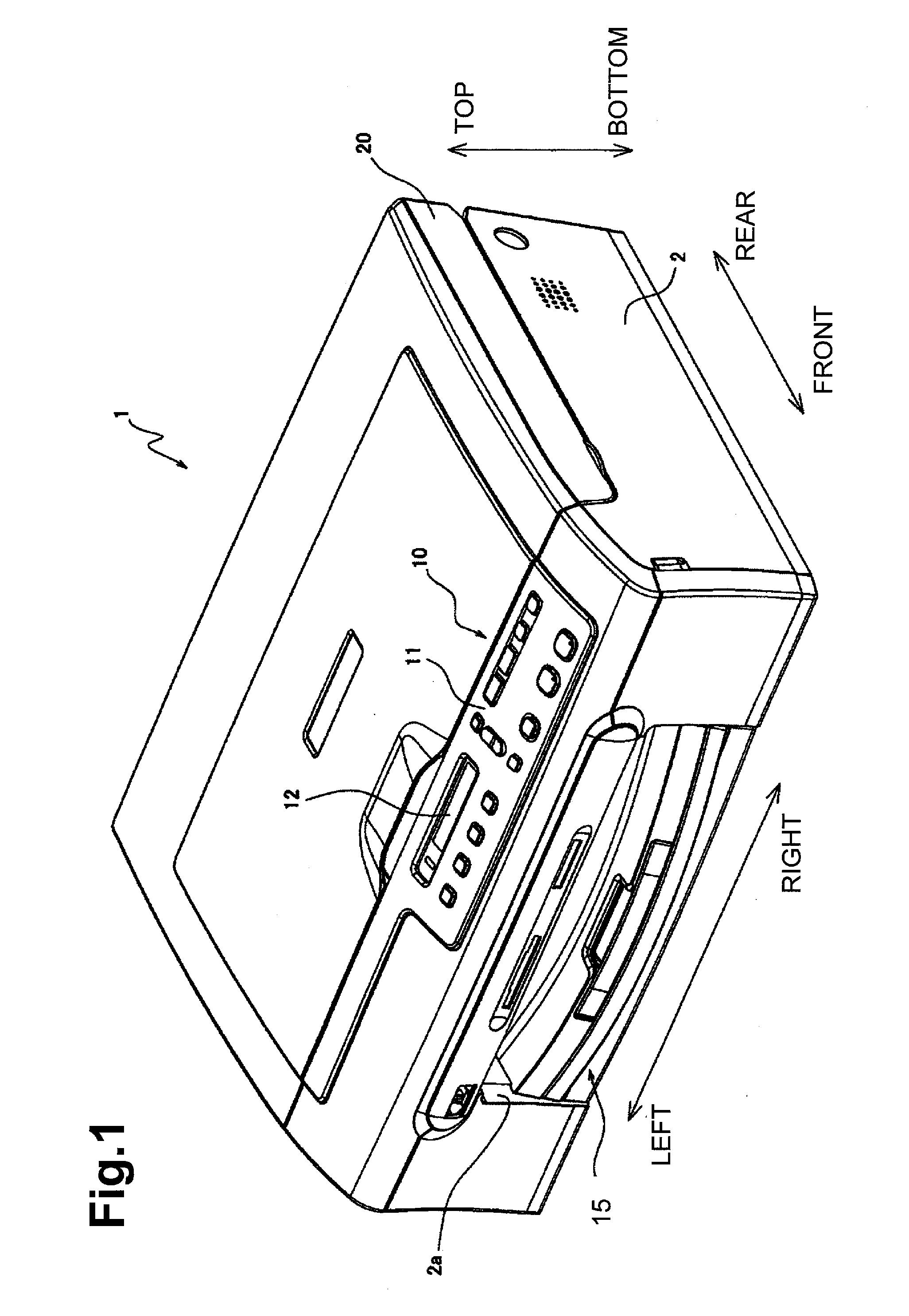

Feeding Device And Image Recording Apparatus Equipped With The Feeding Device

ActiveUS20060163803A1Weak elasticityReduction in sheet feeding forceArticle feedersArticle deliveryImage recordingEngineering

A feeding device including a drive roller and a driven roller opposed to the drive roller and biased toward the drive roller, such that the drive and driven rollers cooperate to feed a sheet while holding the sheet therebetween. The driven roller includes a toothed wheel portion and a contactable portion having a diameter smaller than that of the toothed wheel portion. The drive roller includes first and second portions. A radially outer end of the second portion is more distant from an axis of the drive roller than a radially outer end of the first portion. During absence of the sheet between the drive and driven rollers, the contactable portion of the driven roller is held in contact at its circumferential surface with a circumferential surface of the second portion of the drive roller, while a radially outer end of the toothed wheel portion is not in contact with a circumferential surface of the first portion. Also disclosed is an image recording apparatus including the above-described feeding device.

Owner:BROTHER KOGYO KK

Volleyball spiking training device

A volleyball spike training system comprises a ball holder and an optional net. The training holder comprises a wheeled chassis supporting a vertical stanchion projecting upwardly that supports a hopper and a ball feeding apparatus. The stanchion includes a crank system for vertically adjusting telescoped stanchion segments. Balls dropping from the hopper travel by gravity down an inclined ramp at the top of the frame towards a discharge throat. Balls travelling down the ramp are indexed by a Z-shaped lever that serially separates them. A pair of downwardly projecting hands, one fixed and one pivoted, receive dropping balls and temporarily hold them for shooting. The pivoting hand controls the indexing lever to jam successive balls when the device is loaded. When a ball is shot and removed from between the feed hands, another ball is freed by the indexing lever to automatically drop into a shooting position between the hands.

Owner:ACU PAC INC

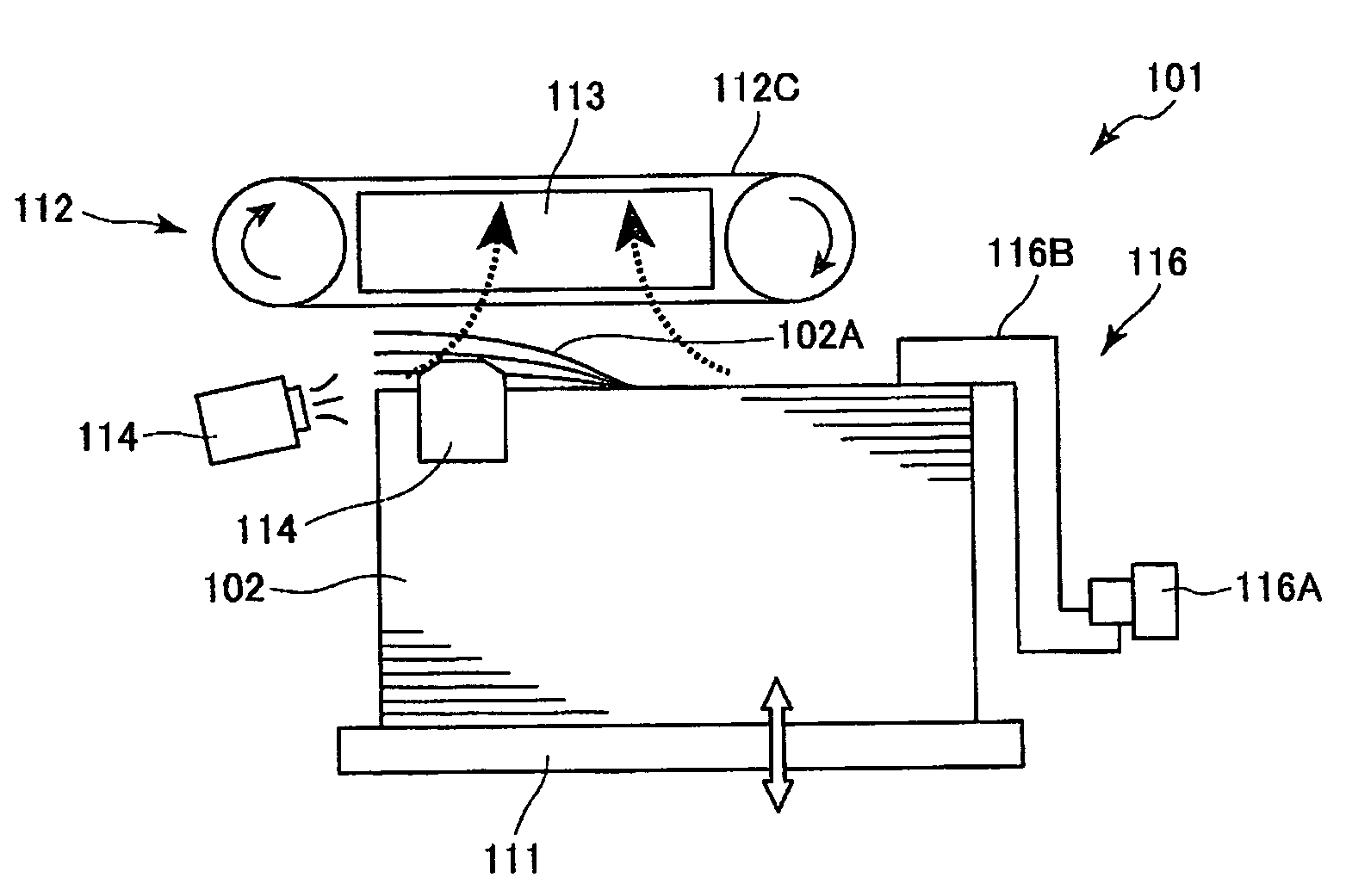

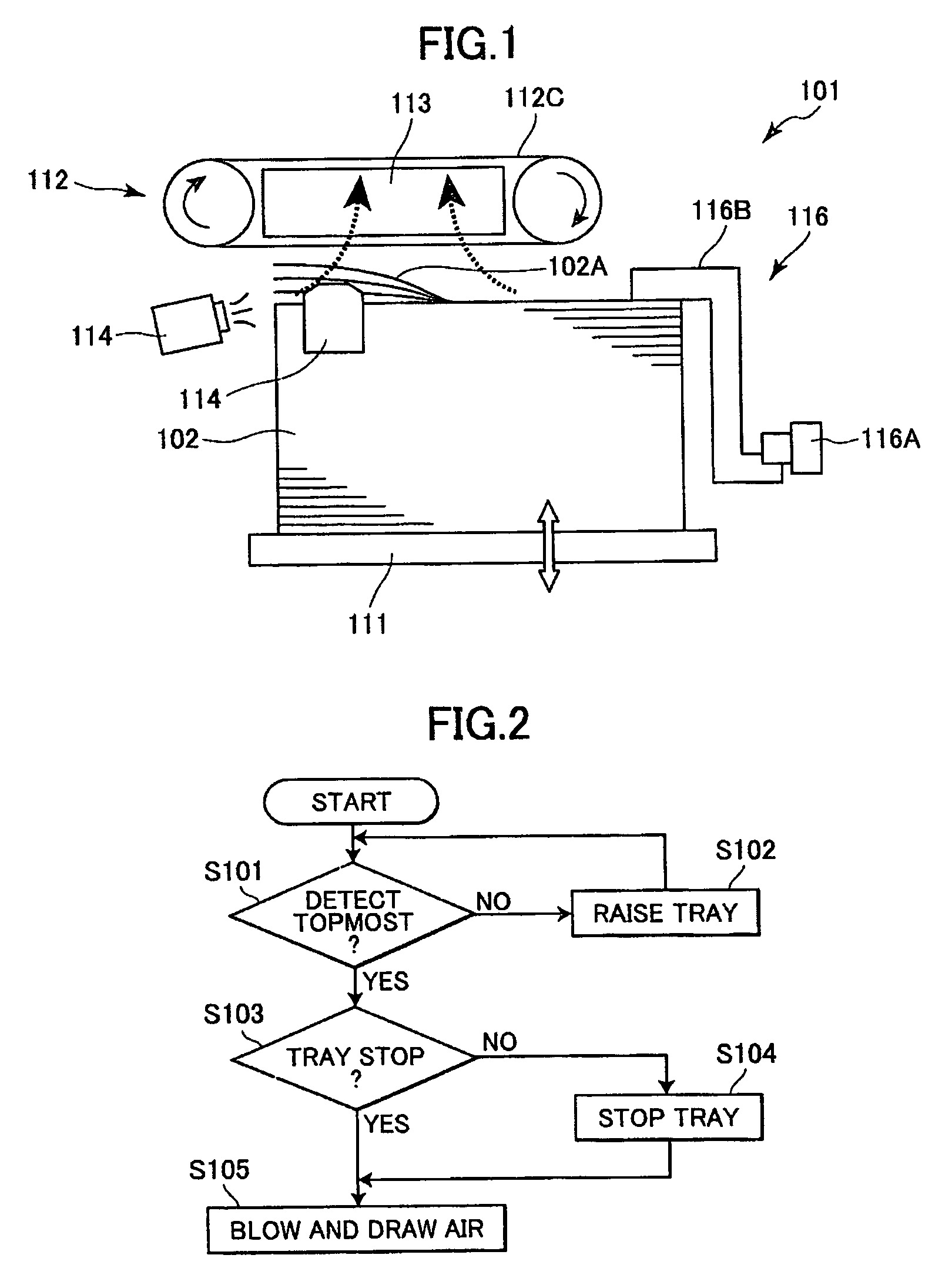

Sheet-supplying device

A sheet-supplying device has a sheet-accommodating tray, a raising / lowering unit, a first position sensor, a second position sensor, a controlling unit. The raising / lowering unit raises and lowers the sheet-accommodating tray substantially. The first position sensor detects a first position indicating a position in the stacked direction of one end portion of a topmost sheet stacked in the sheet-accommodating tray. The second position sensor detects a second position indicating a position in the stacked direction of another end portion of the topmost sheet. The controlling unit controls the raising / lowering unit to raise or lower the sheet-accommodating tray based on both the first position detected by the first position sensor and the second position detected by the second position sensor so that one end of the topmost sheet in the stacked status is positioned at a prescribed position in the stacked direction.

Owner:RICOH KK

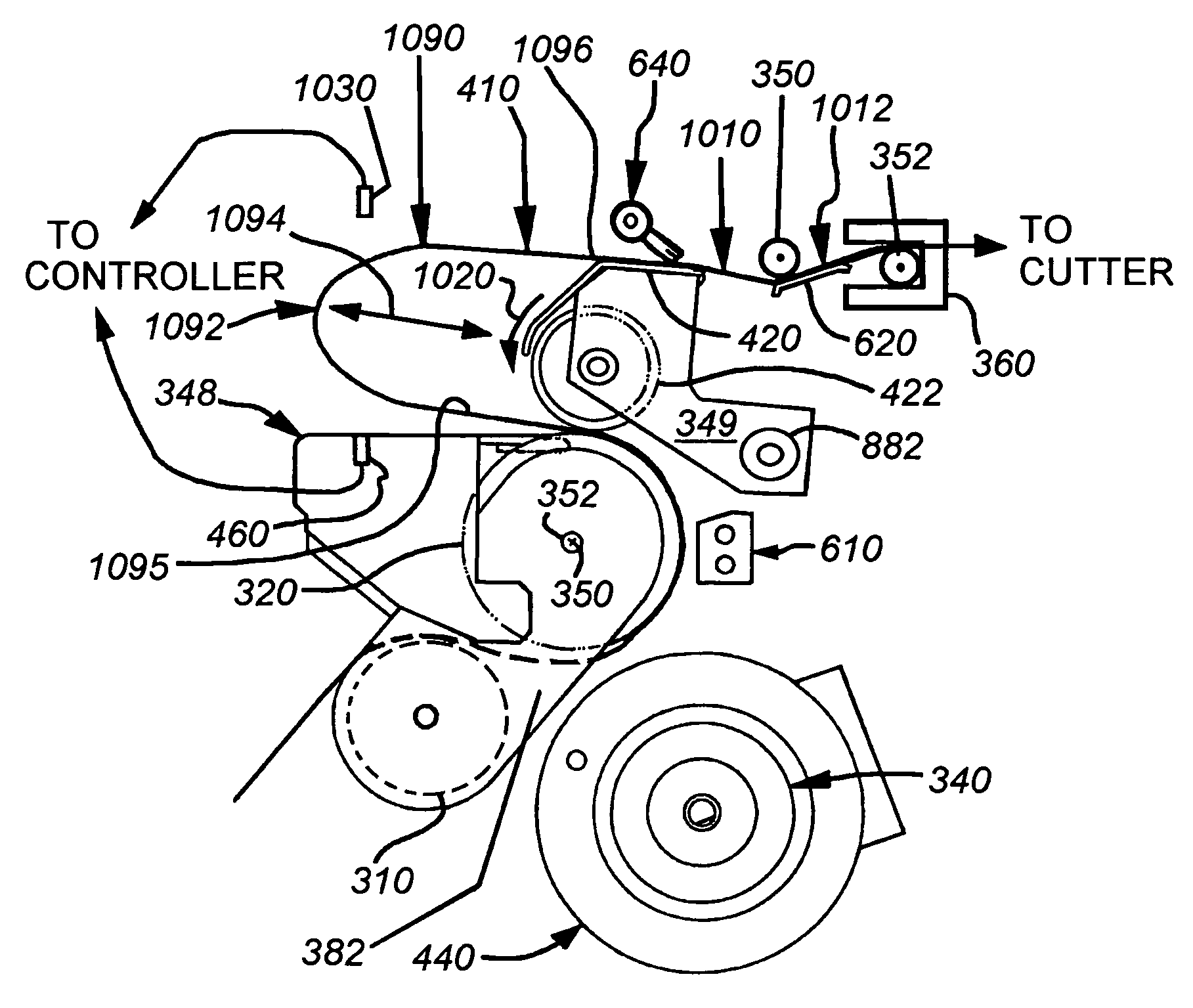

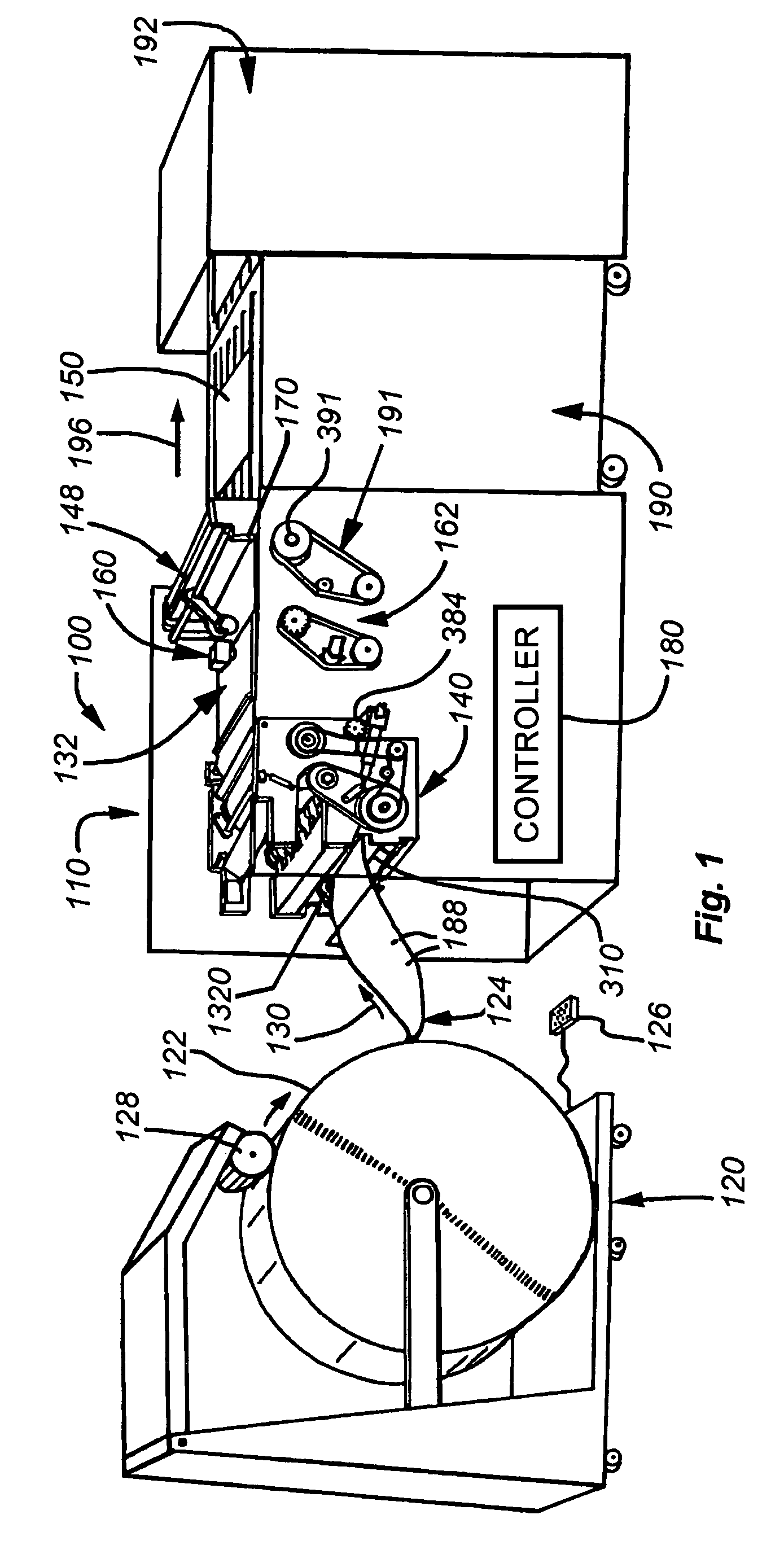

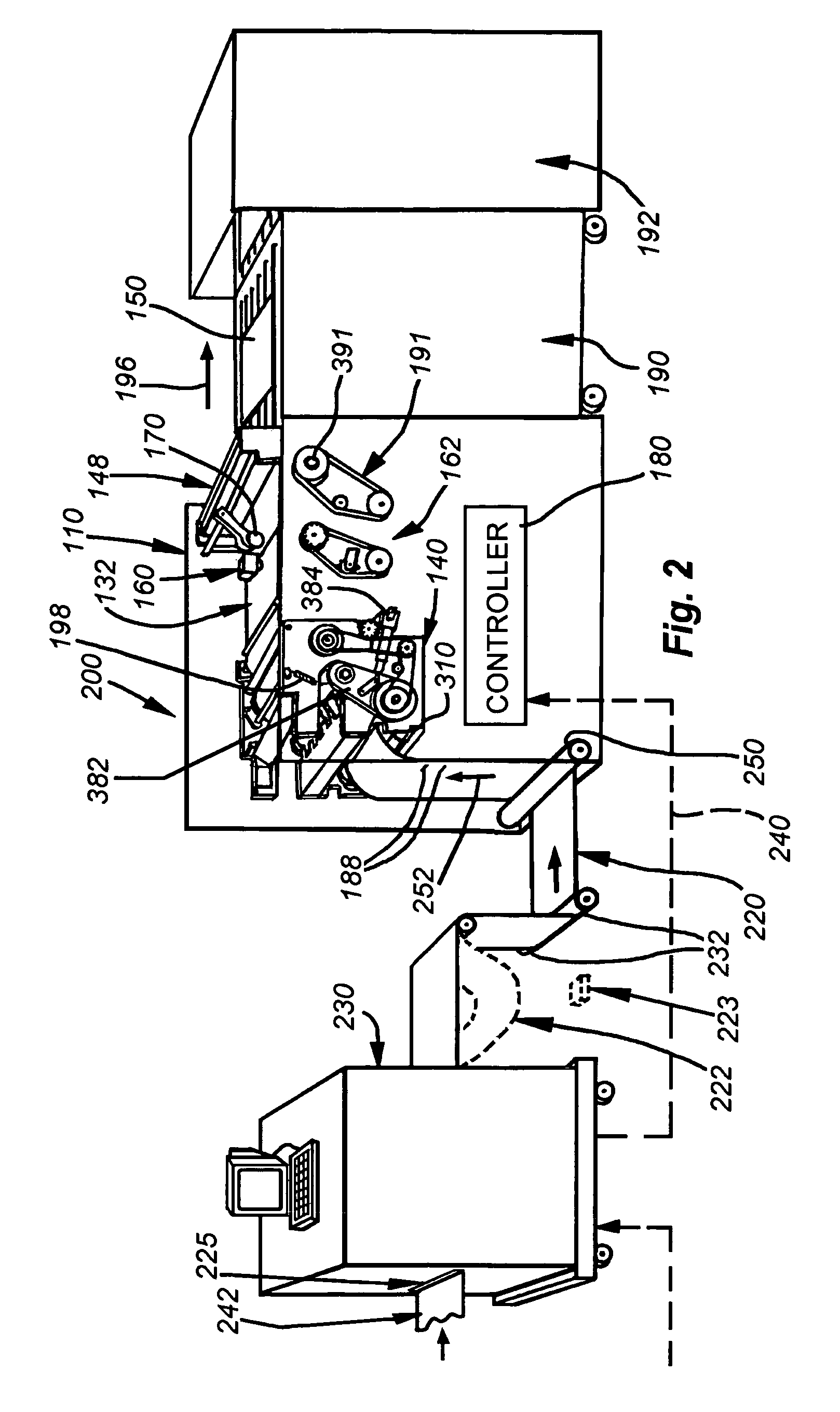

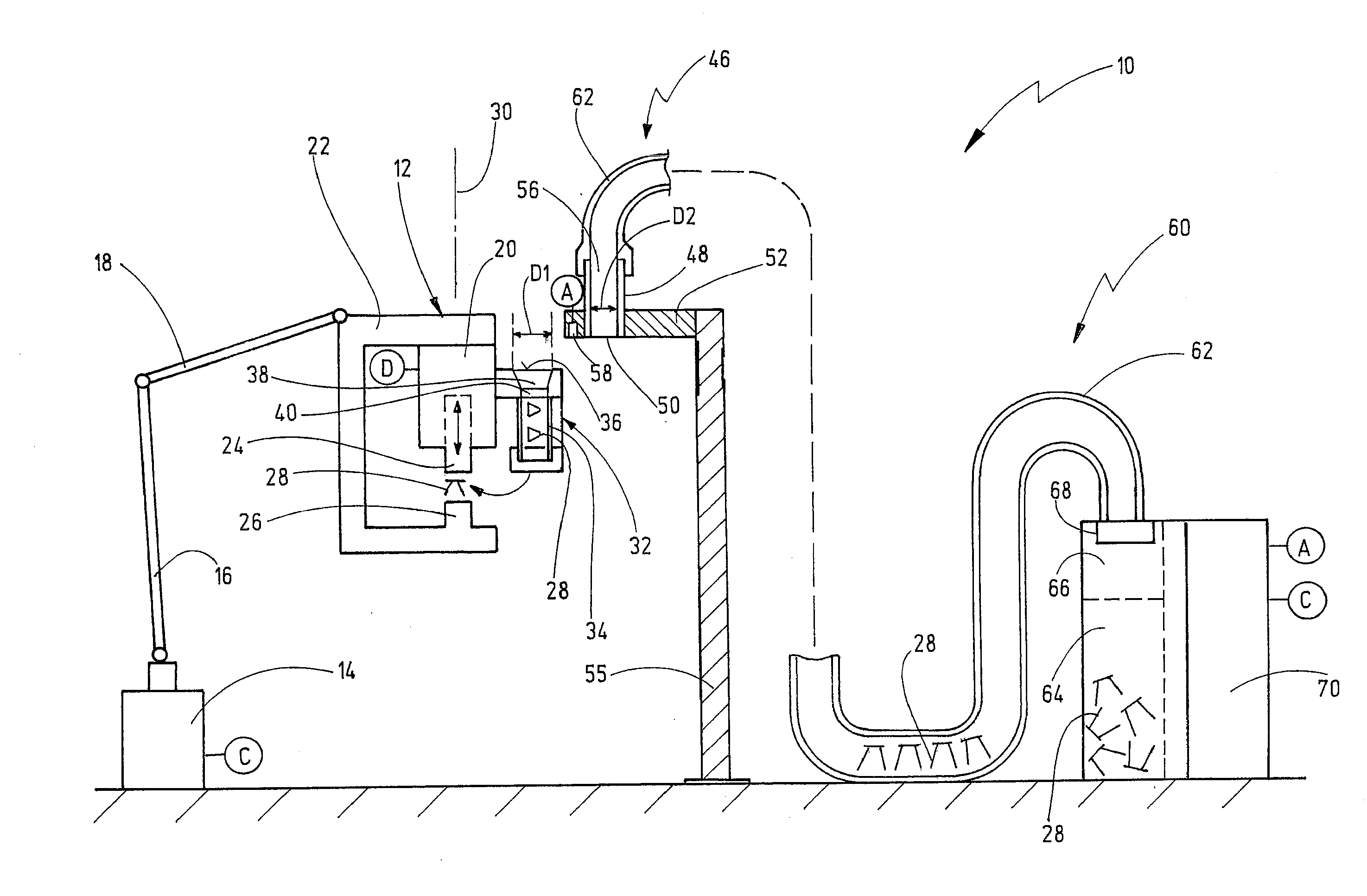

System and method for cutting continuous web

InactiveUS7404349B1Reliable feedingAccurate centerGang saw millsStock shearing machinesEngineeringDrive motor

A system and method for cutting continuous web that provides a simplified and direct feed path during loading, and thereafter a more-complex serpentine feed path at an infeed unit for reliable infeed of the web, arranged as either a free loop or a moderately tensioned configuration. Downstream, an indexing drive intermittently pauses the web for the cutter knife to operate. The indexing drive and infeed unit's drive are synchronized by a controller to produce a small horizontally disposed buffer loop therebetween. The buffer loop is maintained within a predetermined range using a sensor, operatively with the controller, that measures the location of the end of the loop, modulating the drives to maintain the buffer loop's (returning) end within a predetermined location about the sensor's sensing field. The system includes an adjustment drive motor for moving a plurality of edge guide sets toward and away from each other in synchronization.

Owner:ROLL SYST

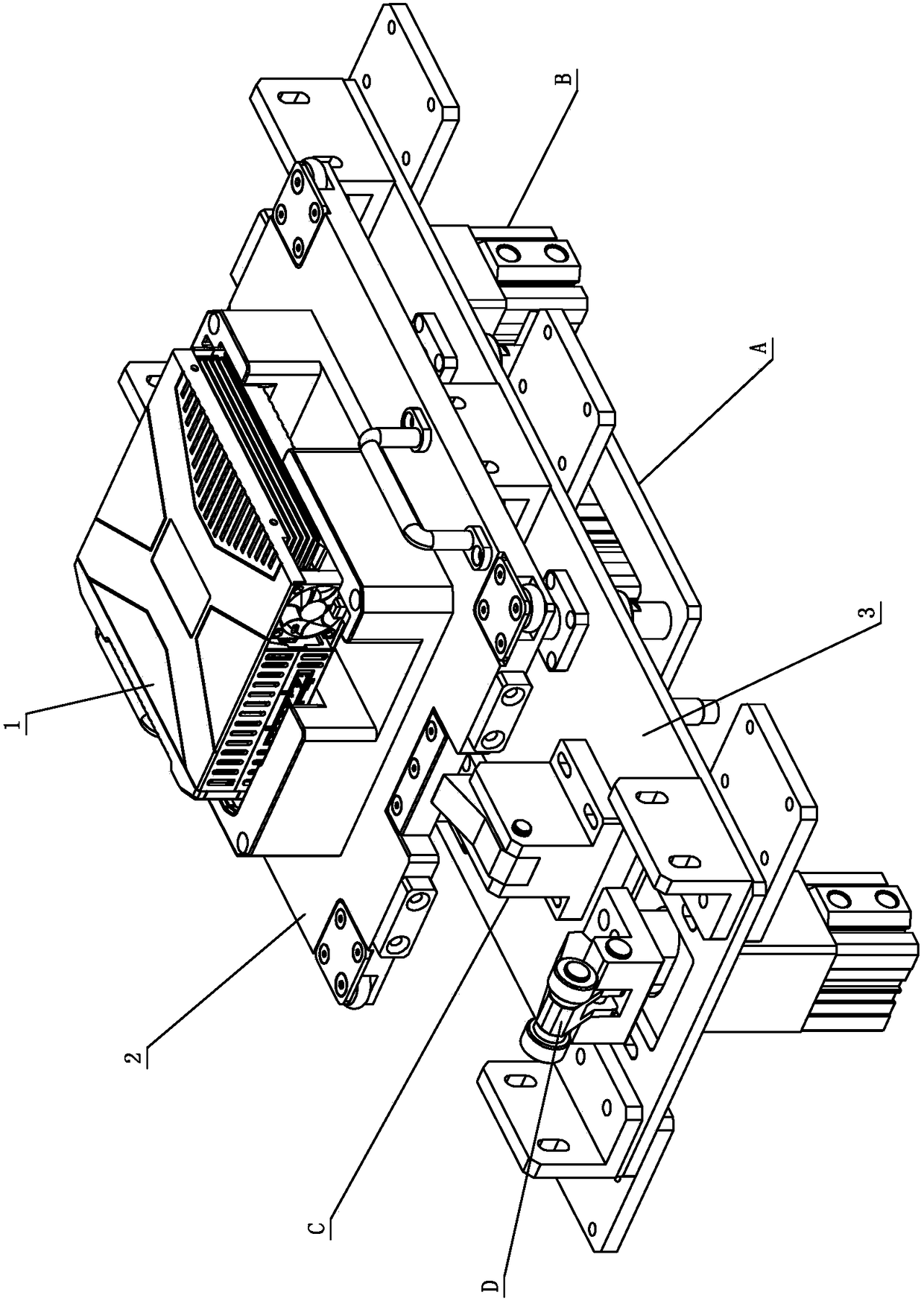

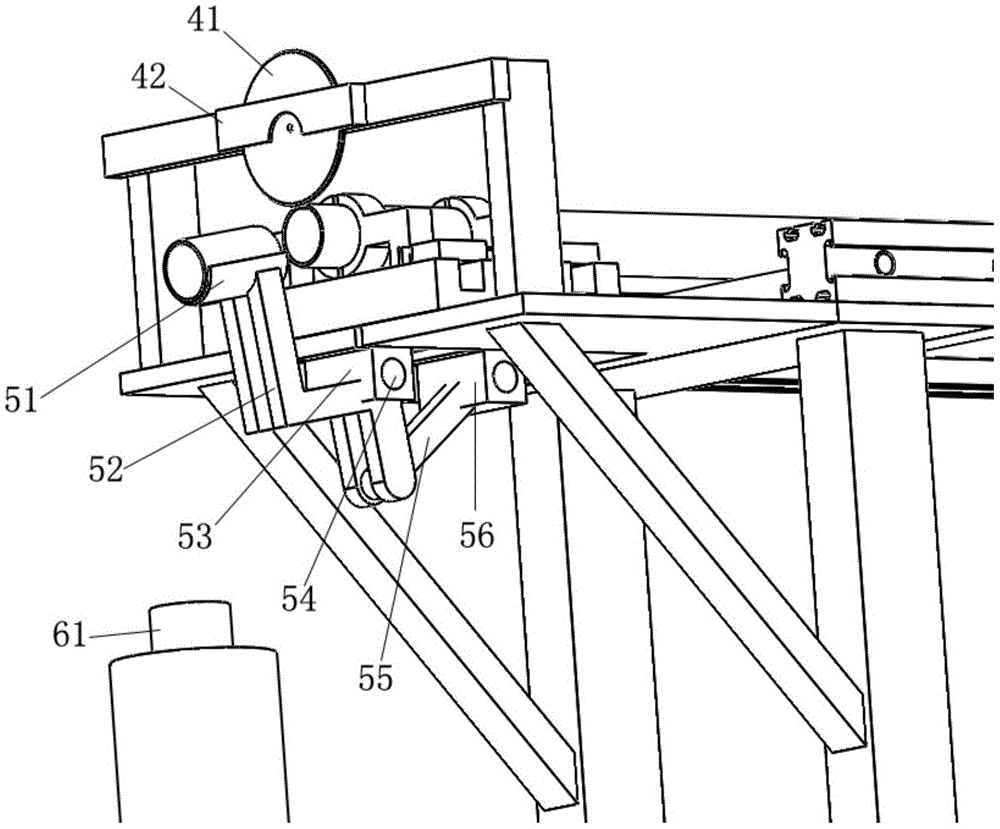

Tool plate jacking and positioning device

The invention discloses a tool plate jacking and positioning device which comprises a feeding carrier plate. A jacking module, a jacking blocking module and a non-return module are arranged on the feeding carrier plate, the jacking module comprises a jacking air cylinder and a jacking supporting plate, the jacking supporting plate is located in a jacking station, the jacking air cylinder drives the jacking supporting plate to ascend and descend, a tool bottom plate is supported on the jacking supporting plate and ascends and descends along the jacking supporting plate, the jacking blocking module comprises a jacking blocking air cylinder and a jacking blocking block, the jacking blocking air cylinder drives the jacking blocking block to do reciprocating motion, the jacking blocking block limits the front end of the tool bottom plate, the non-return module comprises a non-return elastic block doing elastic reset motion, and the non-return elastic block limits the rear end of the tool bottom plate. The structure is simple and reasonable, feeding operation is completed in a full-automatic mode, operation is convenient and fast, the labor intensity is greatly reduced, feeding work is stable and reliable, working efficiency is improved, feeding precision is effectively ensured, and safety coefficients are improved.

Owner:GUANGDONG LXD ROBOTICS CO LTD

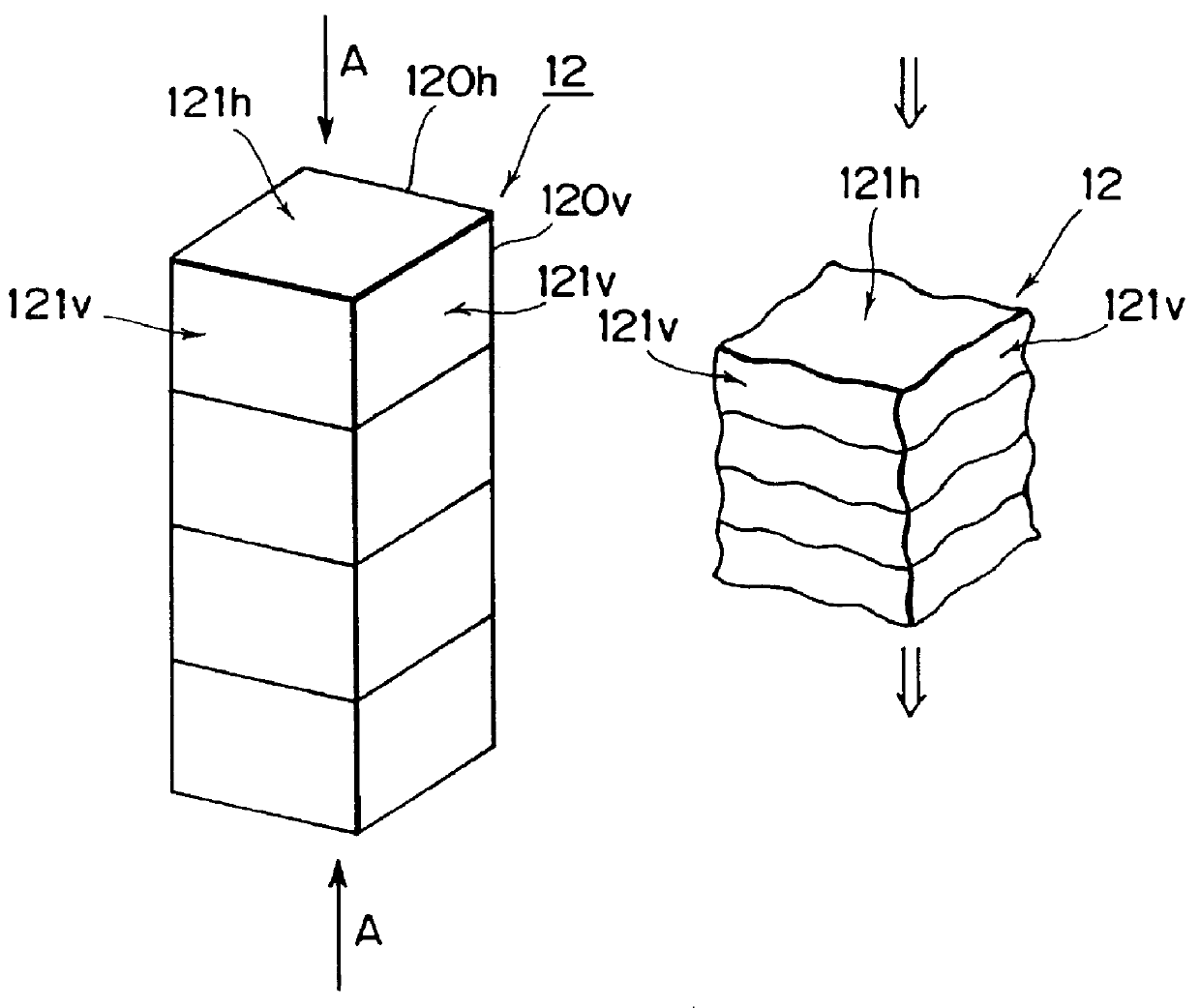

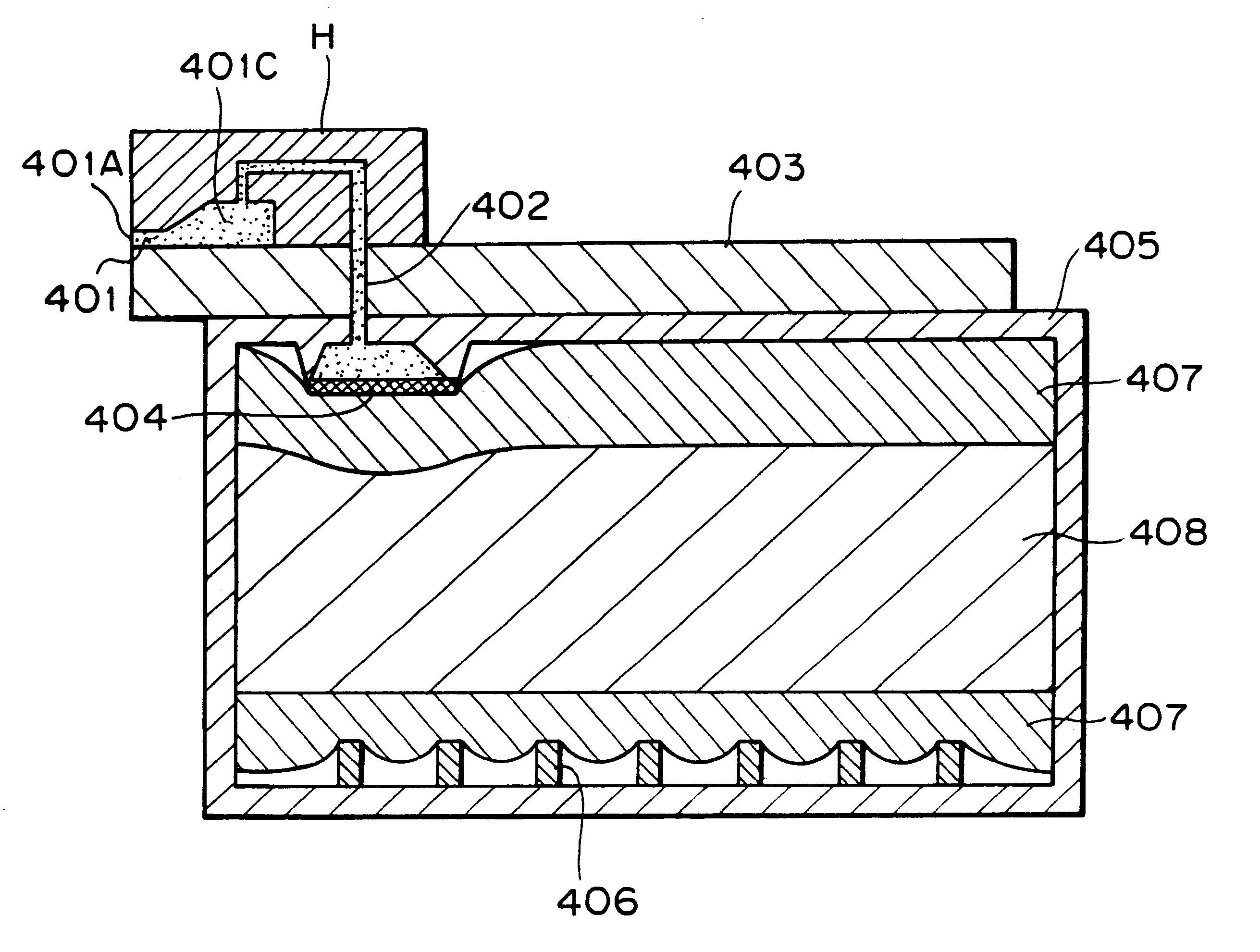

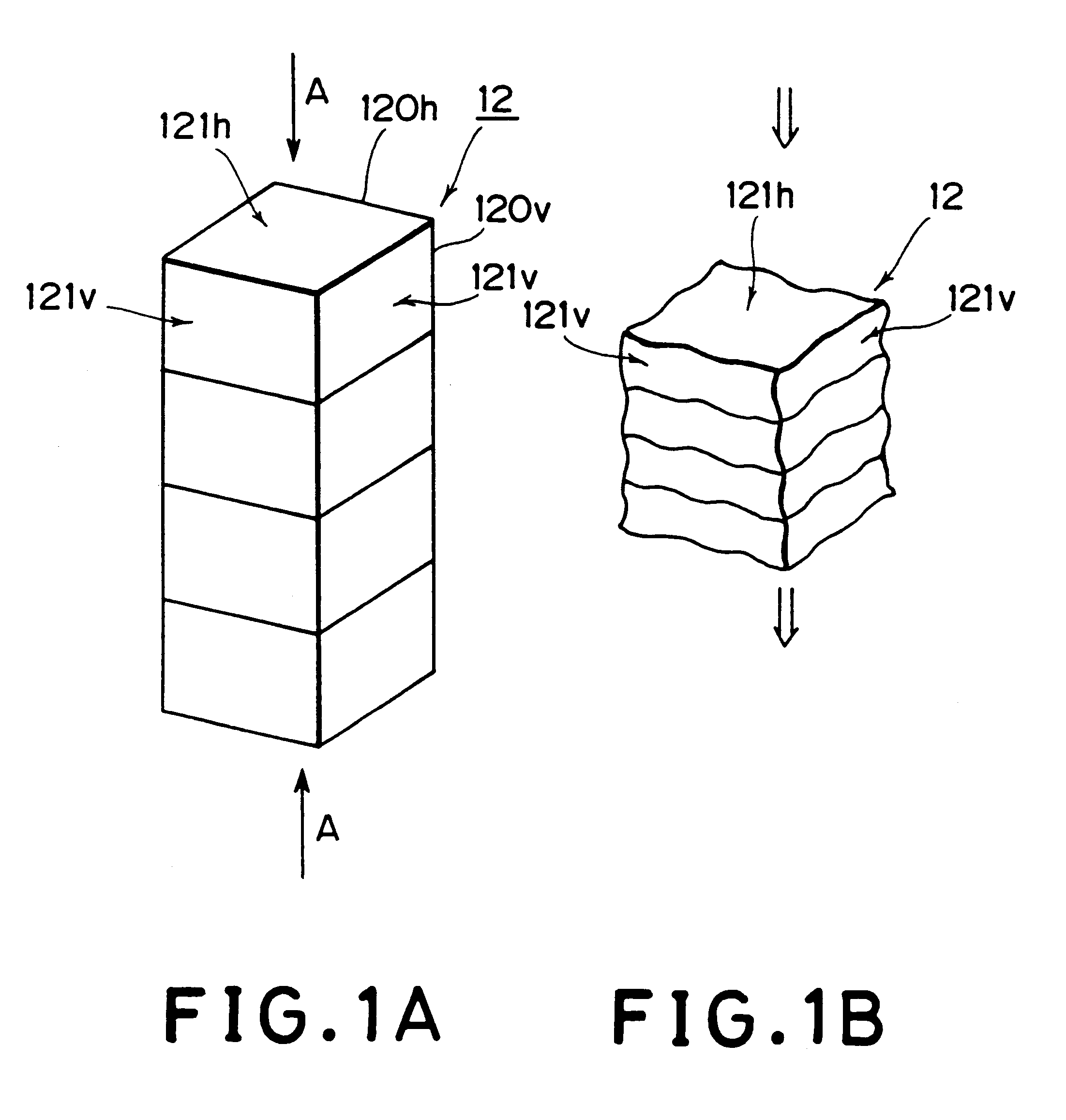

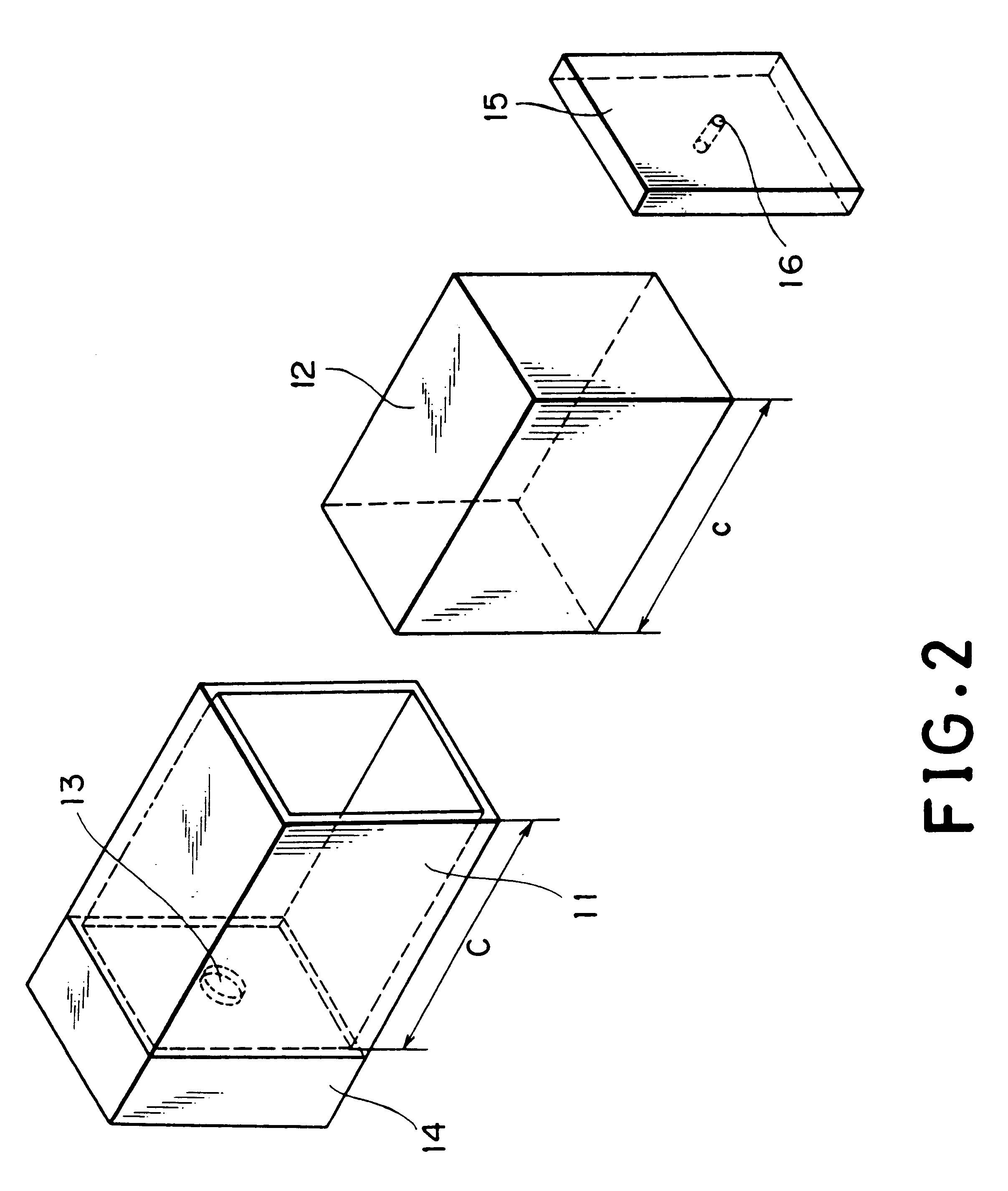

Ink tank, head cartridge and ink jet printing apparatus

A length of a melamine foamed block to be accommodated in an ink tank housing as measured in the longitudinal direction is dimensioned to be larger than a length of the ink tank housing as measured in the longitudinal direction. Thus, while the foamed block is accommodated in the ink tank housing, it is compressed in the direction orienting toward an ink feeding port from which ink is fed to a printing head, i.e., in the ink feeding direction. Consequently, the ink retaining force induced by the capillary force is not intensified in the compressing direction of the melamine foamed block, resulting in an ink feeding capability of the printing head being improved. On the contrary, the ink retaining force effective at a right angle relative to the compressing direction of the melamine foamed block is intensified.

Owner:CANON KK

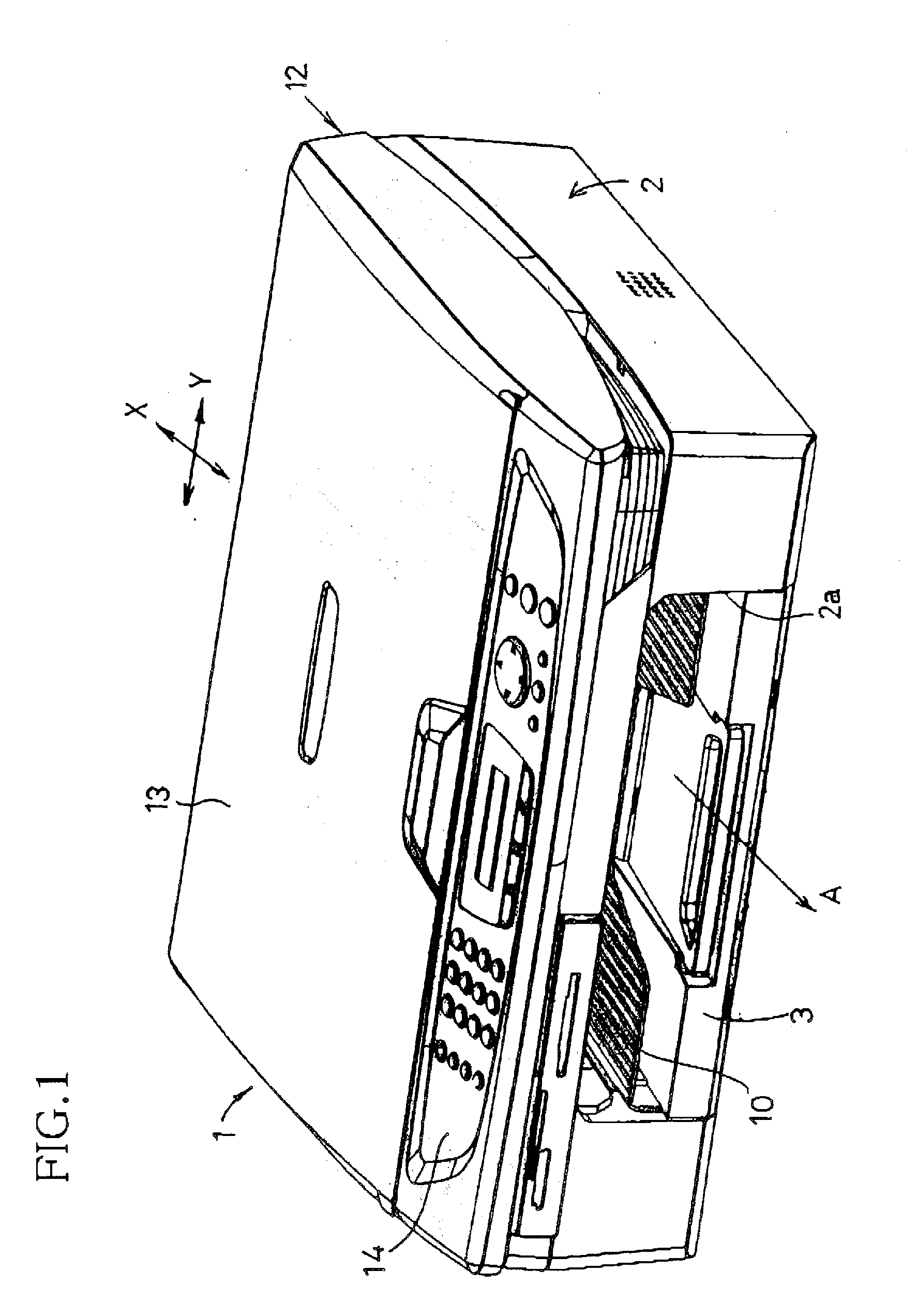

Mobile phone polaroid laminating machine capable of reliably laminating polaroid

InactiveCN105242419AGood for extrusionEasy to operateNon-linear opticsEngineeringMechanical engineering

The invention relates to a mobile phone polaroid laminating machine capable of reliably laminating a polaroid. A polaroid loading mechanism comprises a loading platform longitudinally lifting mechanism, a loading platform station switching mechanism installed on the loading platform longitudinally lifting mechanism and a polaroid loading platform installed on the loading platform station switching mechanism; the polaroid loading platform comprises a laminated polaroid transferring substrate and a laminated polaroid transferring hinged side panel which is installed on the loading platform station switching mechanism, the laminated polaroid transferring substrate is hinged to the bottom end of the laminated polaroid transferring hinged side panel, the side, opposite to the hinged point, of the laminated polaroid transferring substrate can longitudinally rotate around the laminated polaroid transferring hinged side panel, the laminated polaroid transferring substrate is connected with a laminated polaroid transferring cylinder which drives one side edge of the laminated polaroid transferring substrate to rotate, a polaroid aligning mechanism is installed on the laminated polaroid transferring substrate, a vacuum adsorption plate which can absorb and fix the polaroid is installed at the bottom of the laminated polaroid transferring substrate in an attached mode, and a high-speed camera is arranged on the side edge of a vacuum adsorption seat which is fixed through a glass substrate. The mobile phone polaroid laminating machine capable of reliably laminating the polaroid has the advantages of being reasonable in polaroid laminating action and good in polaroid laminating quality.

Owner:WENZHOU ZHIXIN ELECTROMECHANICAL TECH

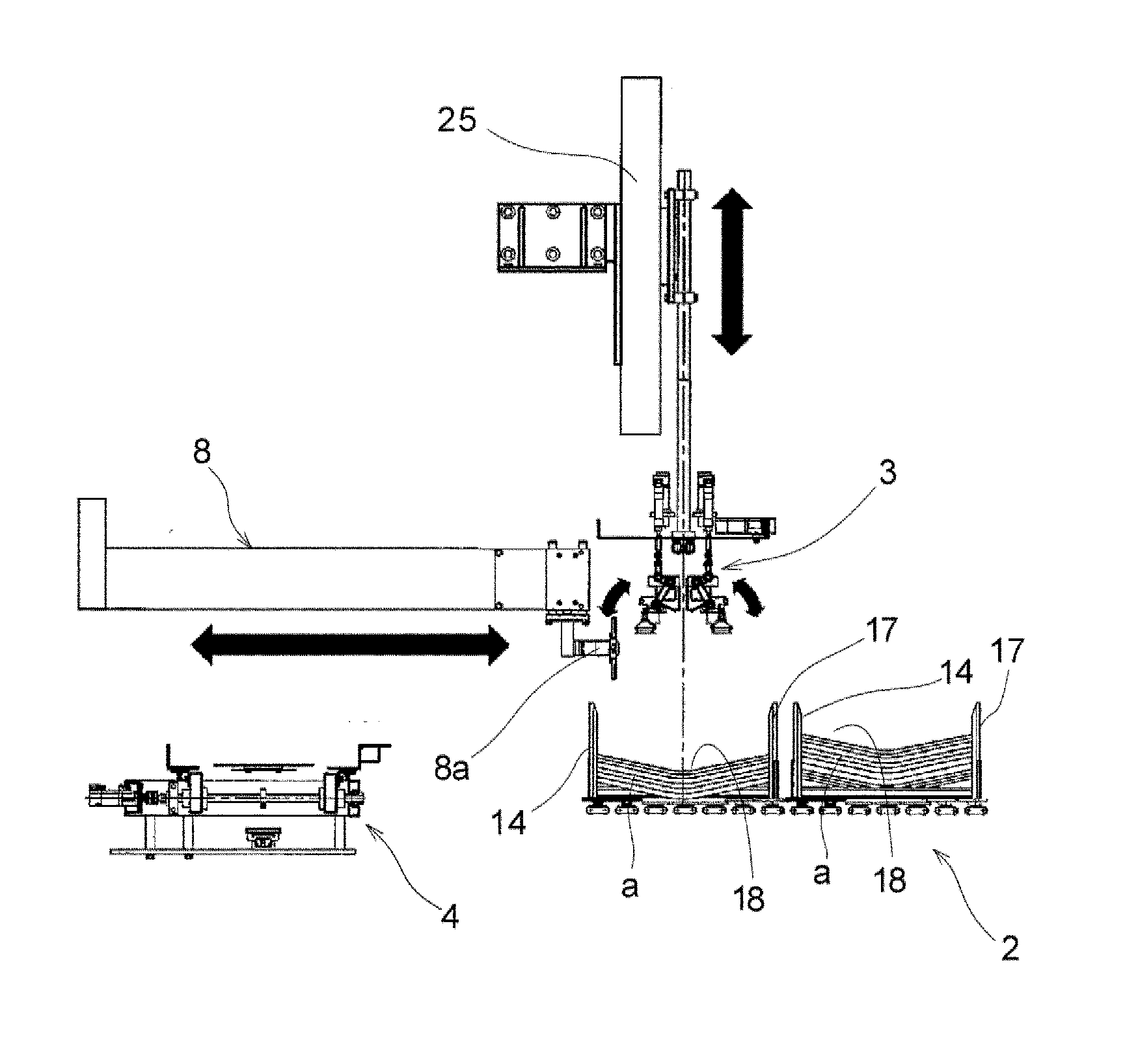

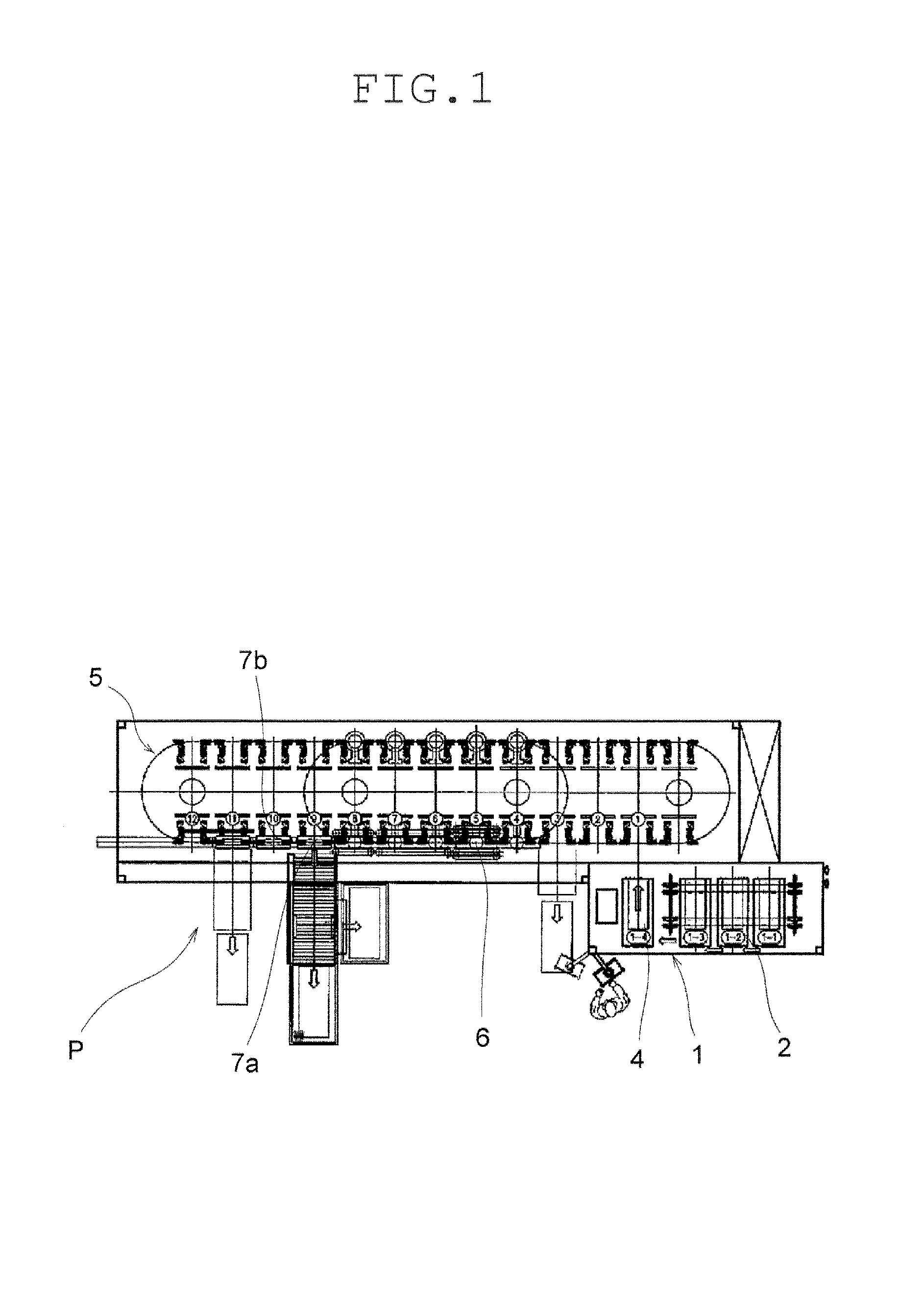

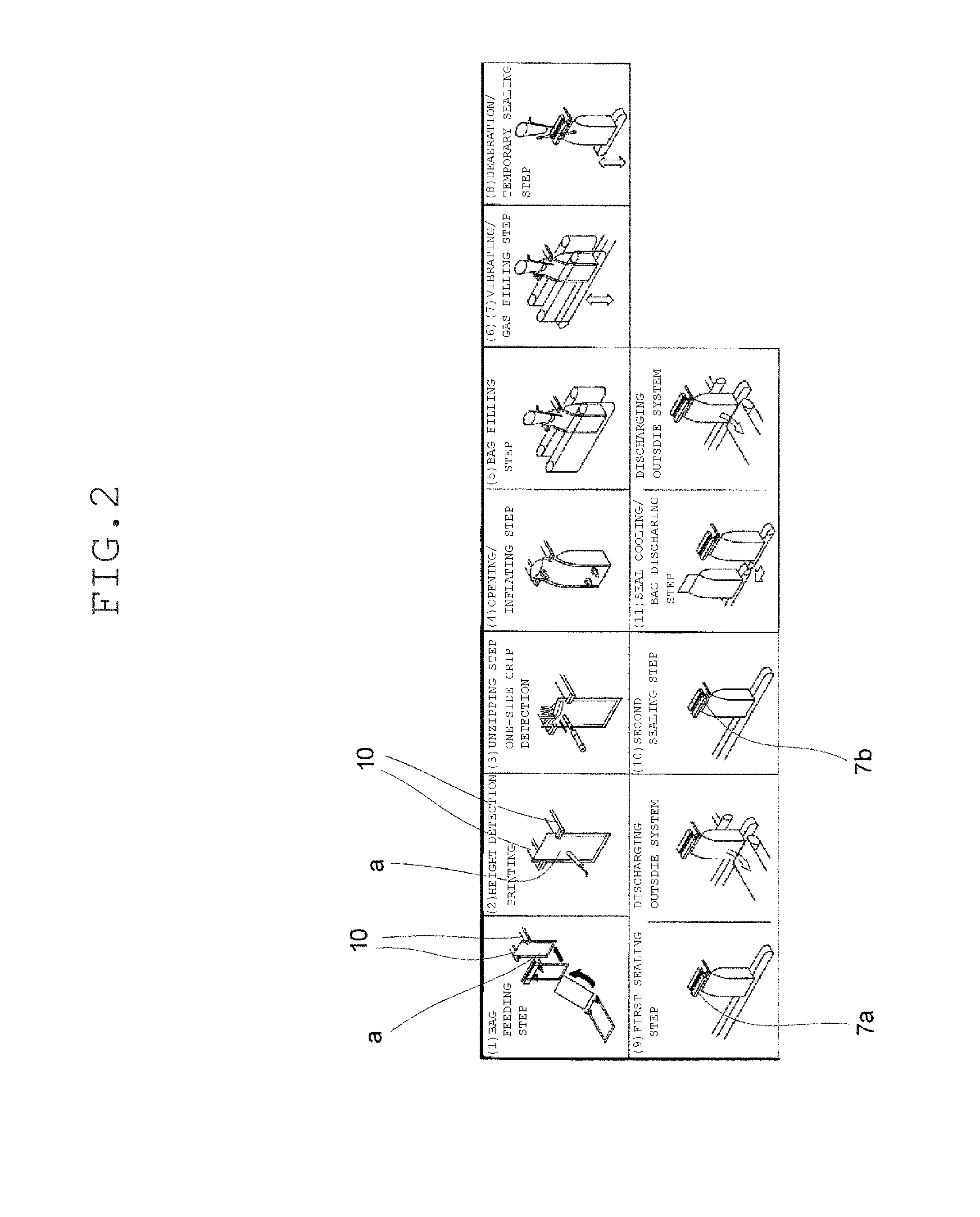

Packaging Bag Feeder in Packaging Machine

ActiveUS20140334909A1Save spaceIncrease productivityWrapper twisting/gatheringDe-stacking articlesBiomedical engineeringPackaging machine

A packaging bag feeder in a packaging machine includes a bag magazine capable of accommodating a number of packaging bags in a stacked state, a separating mechanism which is configured to separate one of the packaging bags stacked on the bag magazine and a bag placement section on which the separated bag is placed. Every time one bag is placed on the bag placement section, the bag is held and fed to a subsequent packaging step.

Owner:GENERAL PACKER

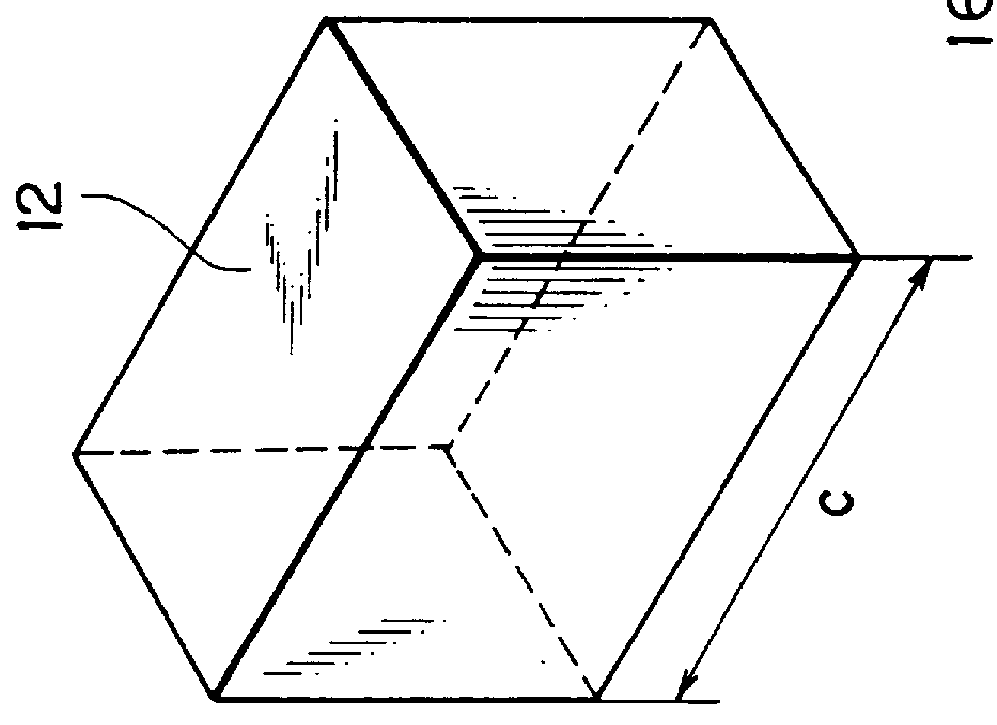

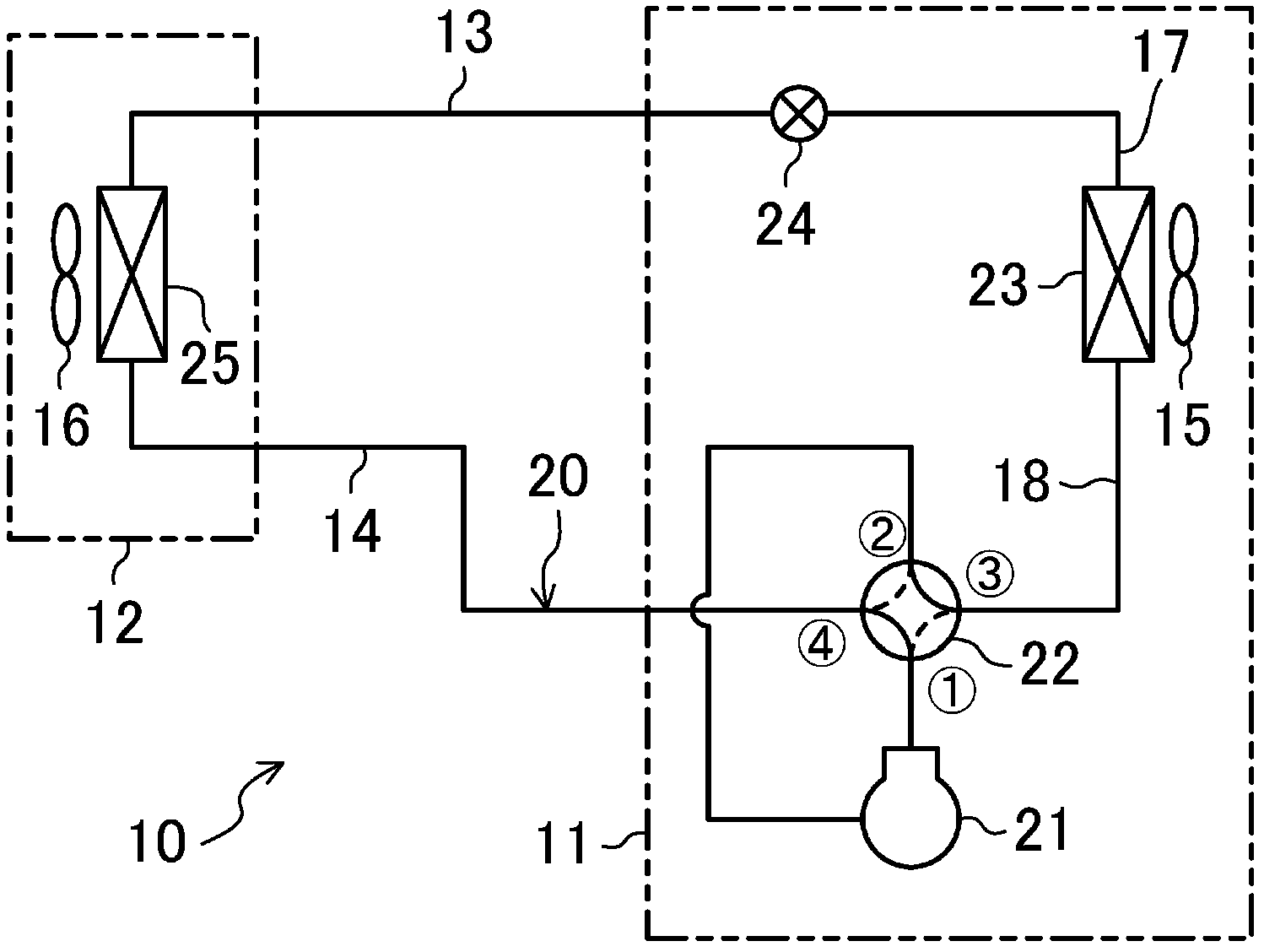

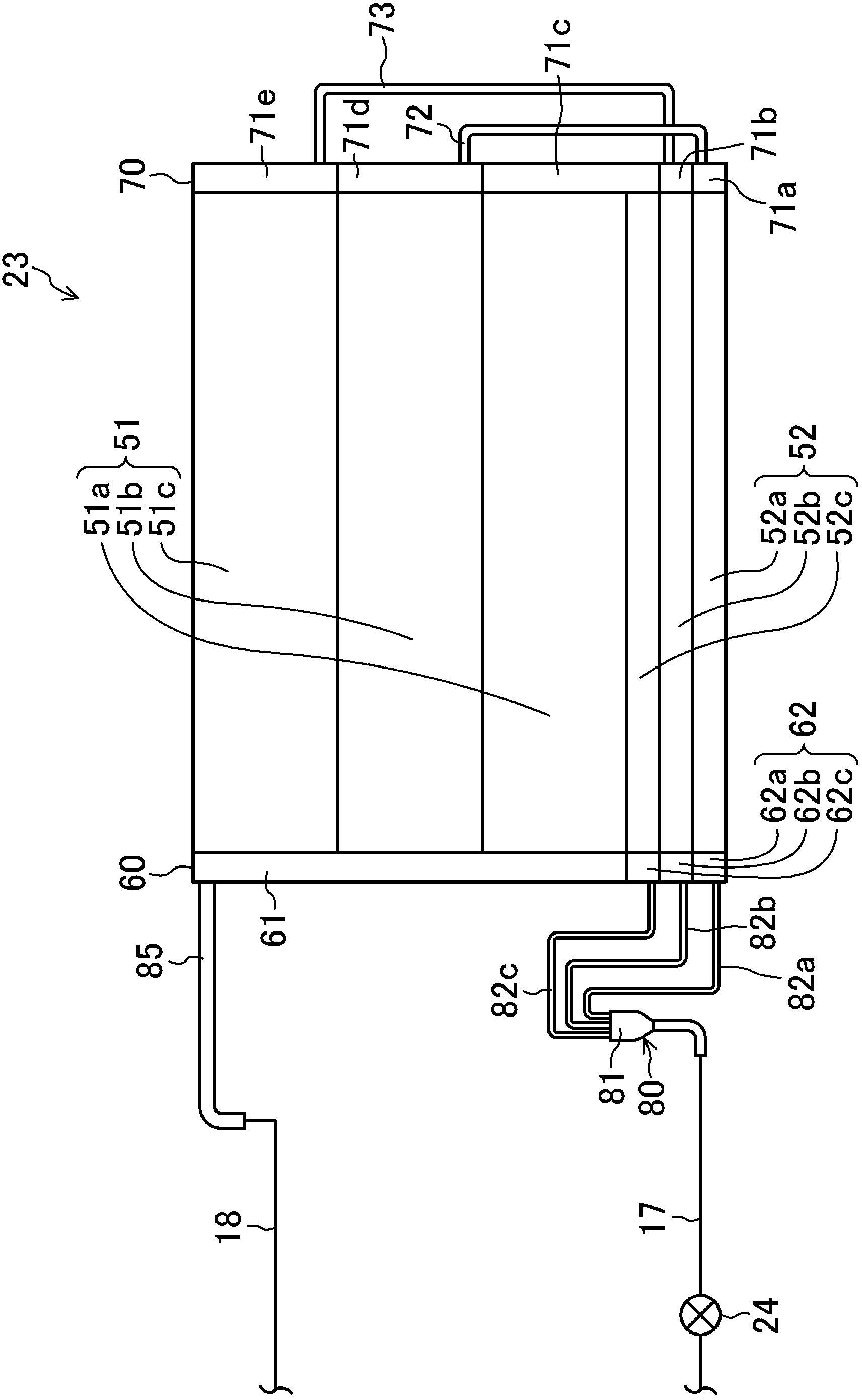

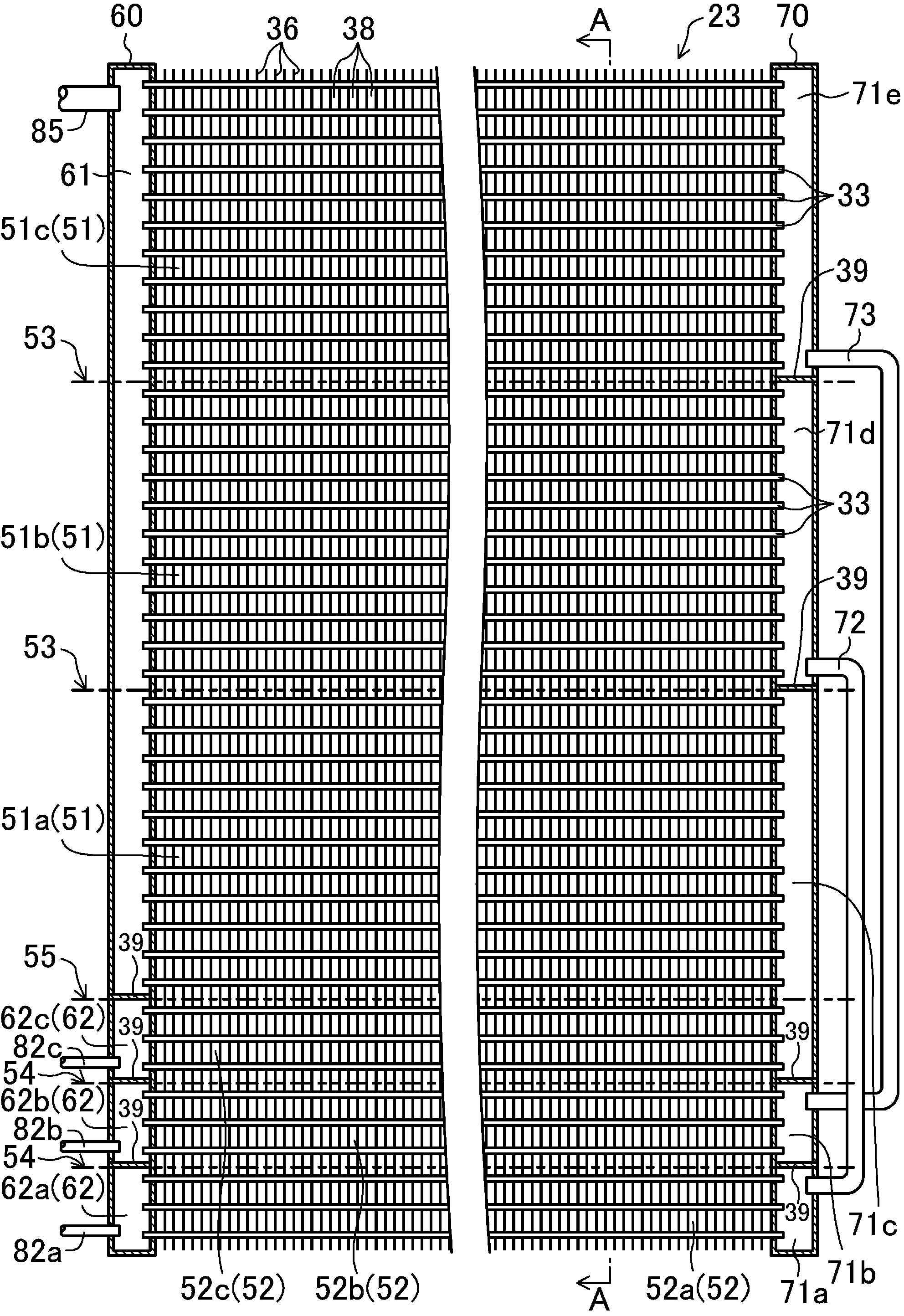

Heat exchanger and air conditioner

ActiveCN103348212AReduce heat exchange efficiencySuppress heat lossEvaporators/condensersHeat exhanger finsEngineeringHeat exchanger

Owner:DAIKIN IND LTD

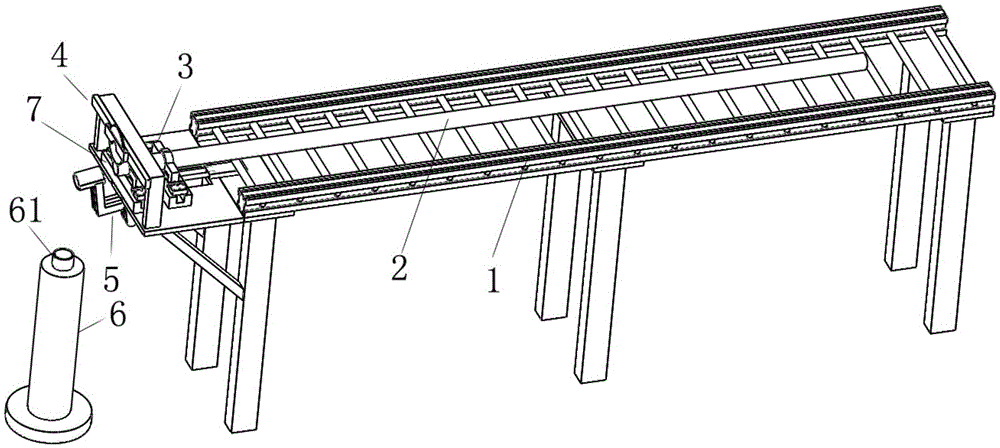

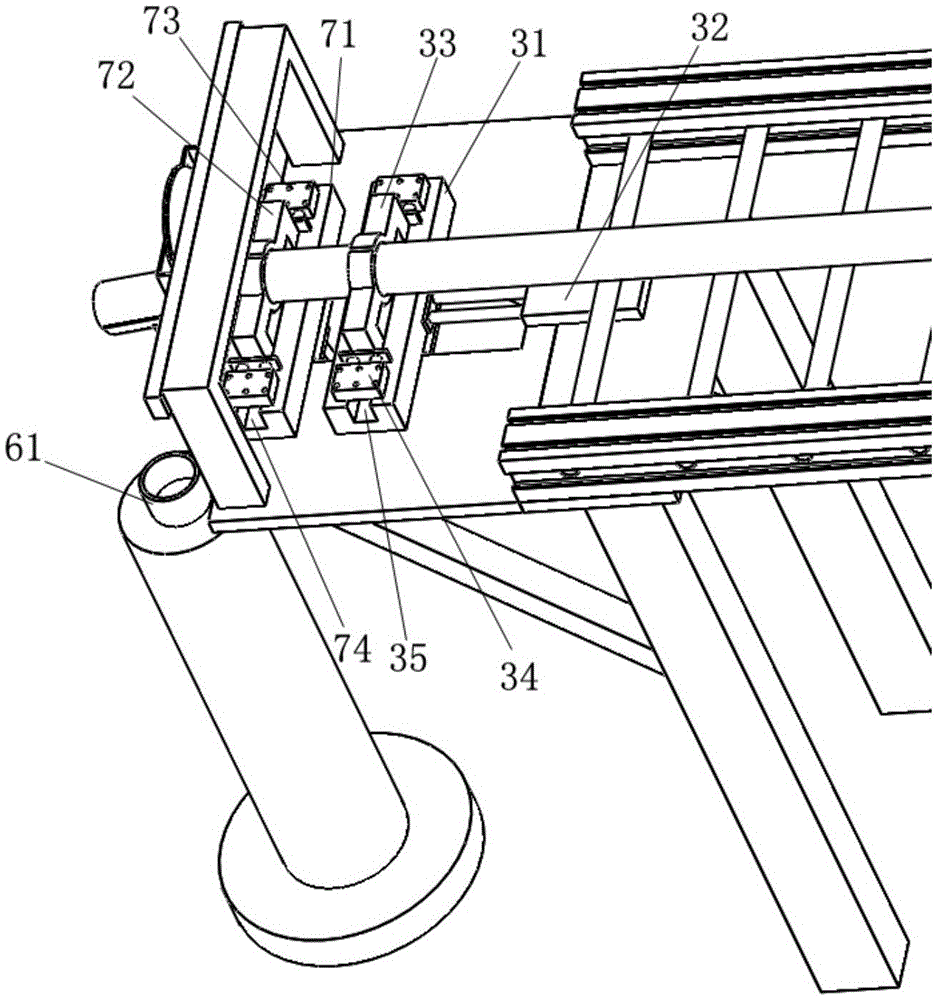

Pipe blanking equipment

InactiveCN105618847AControl cutting lengthHigh degree of automationMetal sawing devicesEngineeringManipulator

The invention discloses pipe blanking equipment. The pipe blanking equipment comprises a pipe supporting frame, wherein a pipe conveying device and a pipe cutting device are arranged on one side of the pipe supporting frame, the pipe cutting device is suspended above a to-be-cut end of a to-be-cut pipe, the pipe conveying device comprises a telescopic clamping conveying mechanism, and the telescopic clamping conveying mechanism comprises a moving sliding block, a driving part for driving the moving sliding block to move in the axial direction of the pipe and a first clamping manipulator arranged on the moving sliding block and used for clamping and releasing the pipe. The pipe blanking equipment can realize even cutting, fixed-length cutting or head-and-tail cutting of the pipe and is high in automation degree, high in blanking speed and easy to control.

Owner:SHANDONG UNIV OF SCI & TECH

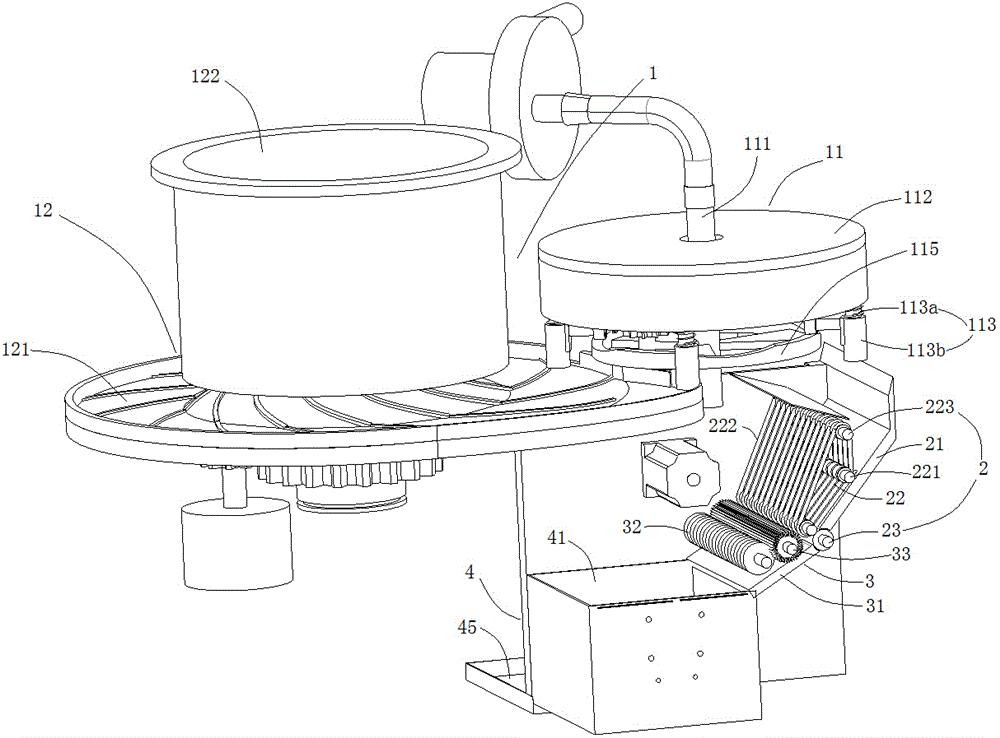

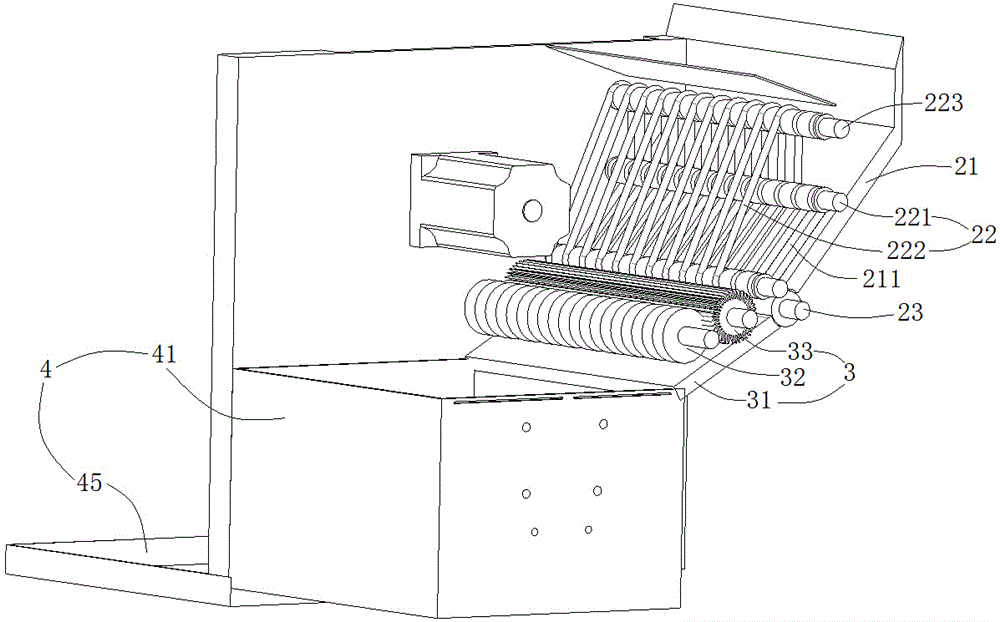

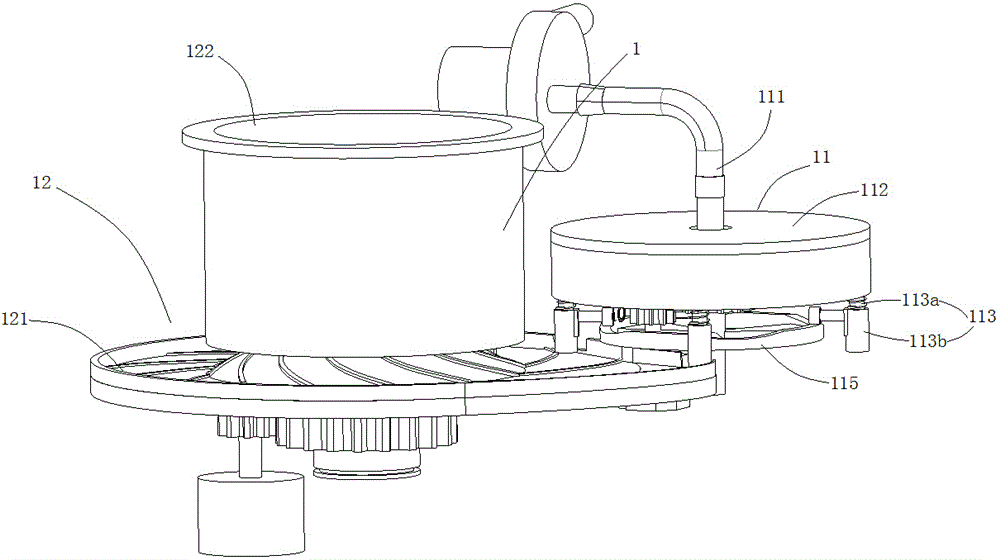

Paper money friction flattening device

InactiveCN105600531ARelieve pressureReduce frictionArticle feedersArticle deliveryPulp and paper industryTotal thickness

The invention discloses a paper money friction flattening device. The paper money friction flattening device is characterized in that: the paper money friction flattening device comprises a loading mechanism, and a flattening mechanism, a shaping mechanism and a paper money collecting box, which are connected sequentially, wherein the flattening mechanism comprises a rectangular bottom plate which is arranged obliquely in a length direction, so that the paper money can slip long the upper surface of the bottom plate; a friction mechanism is arranged above the bottom plate, one side of the friction mechanism, close to the bottom plate, can move downwards in a length direction of the bottom plate, and a gap between the friction mechanism and the bottom plate is smaller than the total thickness of two paper moneys; a material inlet is formed between the upper end of the bottom plate and the friction mechanism and is arranged under a material outlet end of the loading mechanism. In general, the paper money friction flattening device has the advantages that the device can realize the grabbing, loading, automatic flattening and collection of the paper money, can grab the paper money reliably, has appropriate loading pace, high flattening speed, high efficiency and good reliability, is favor for reducing the labor intensity of workers, and can improve the working efficiency.

Owner:CHONGQING UNIV OF TECH

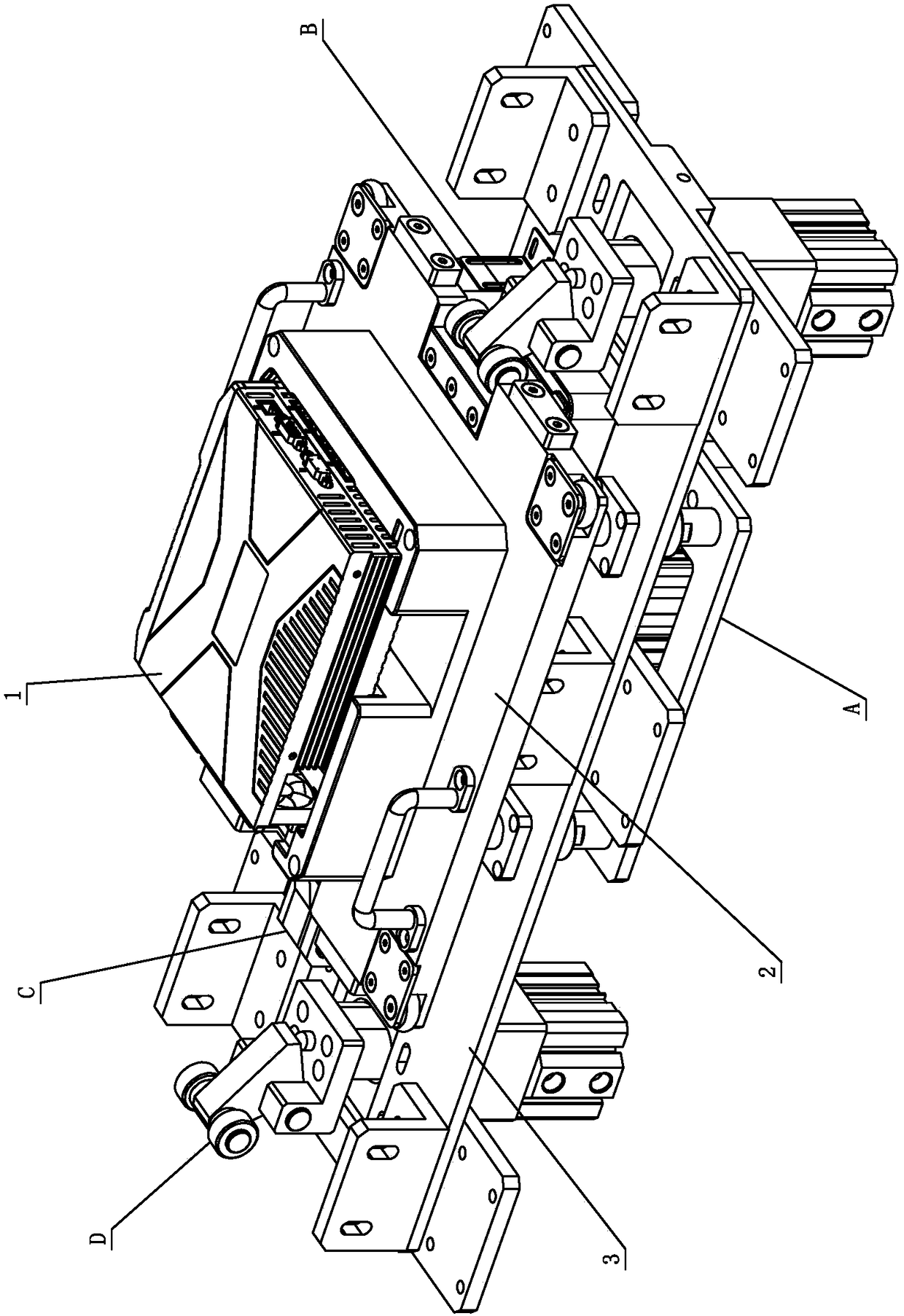

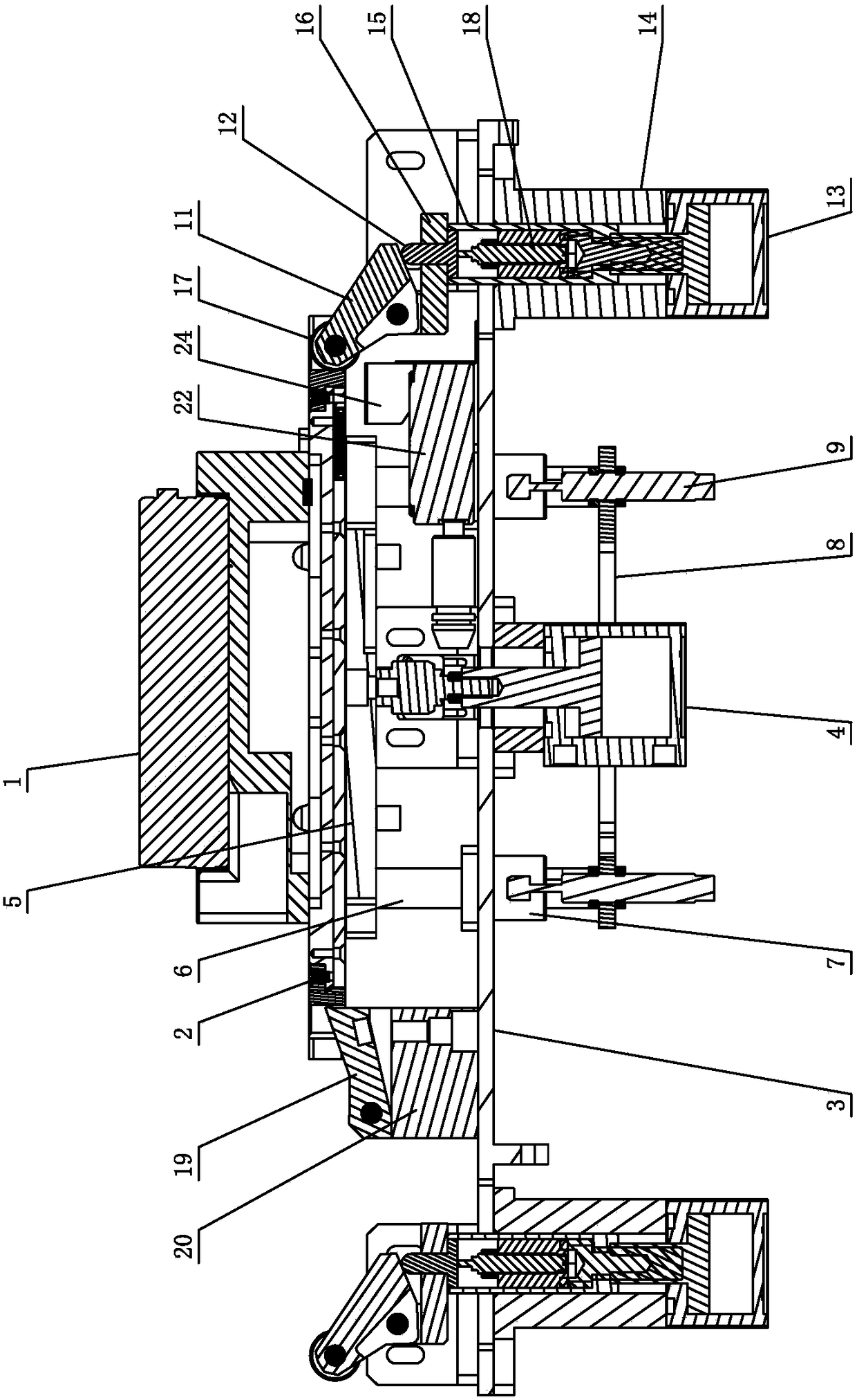

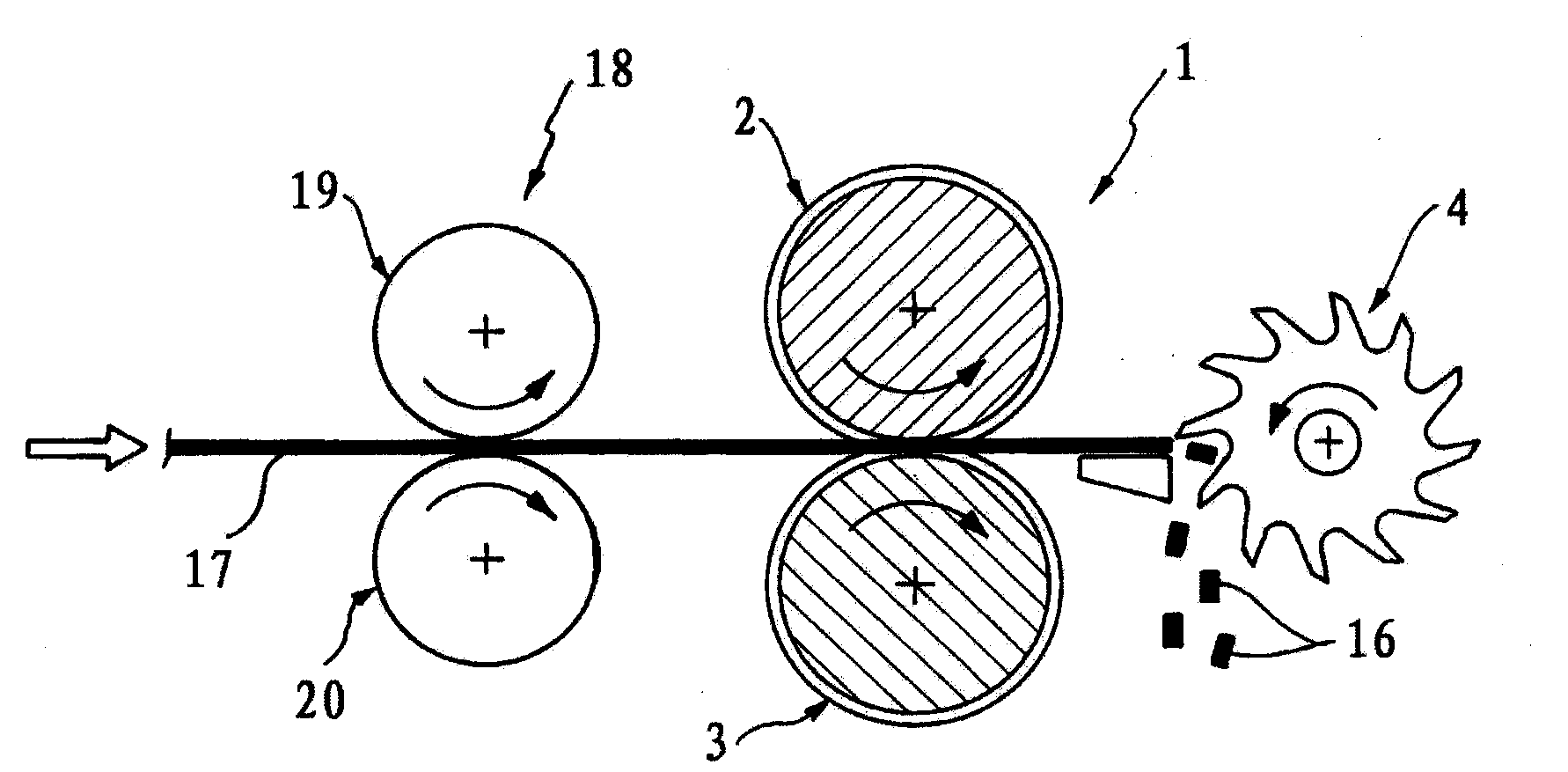

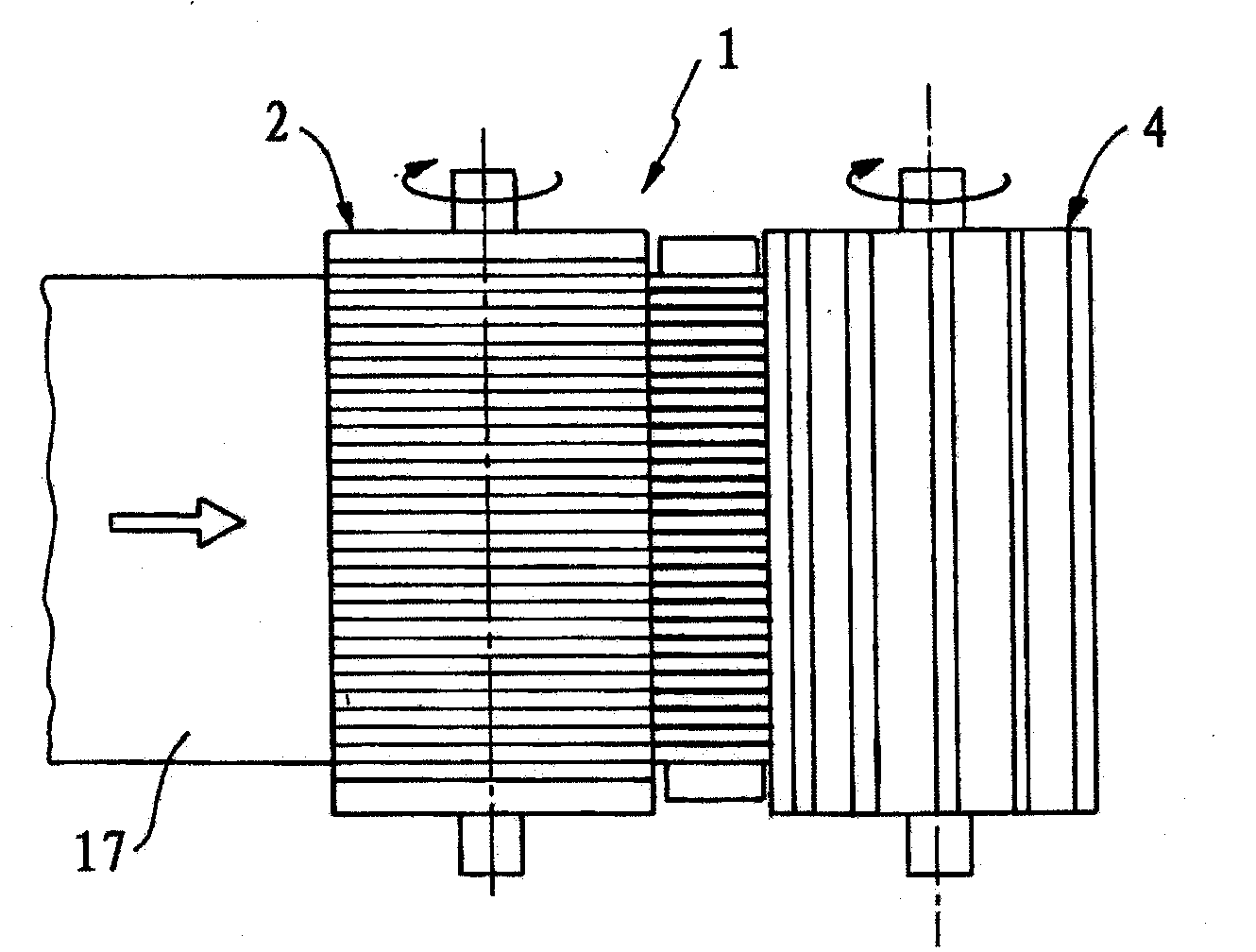

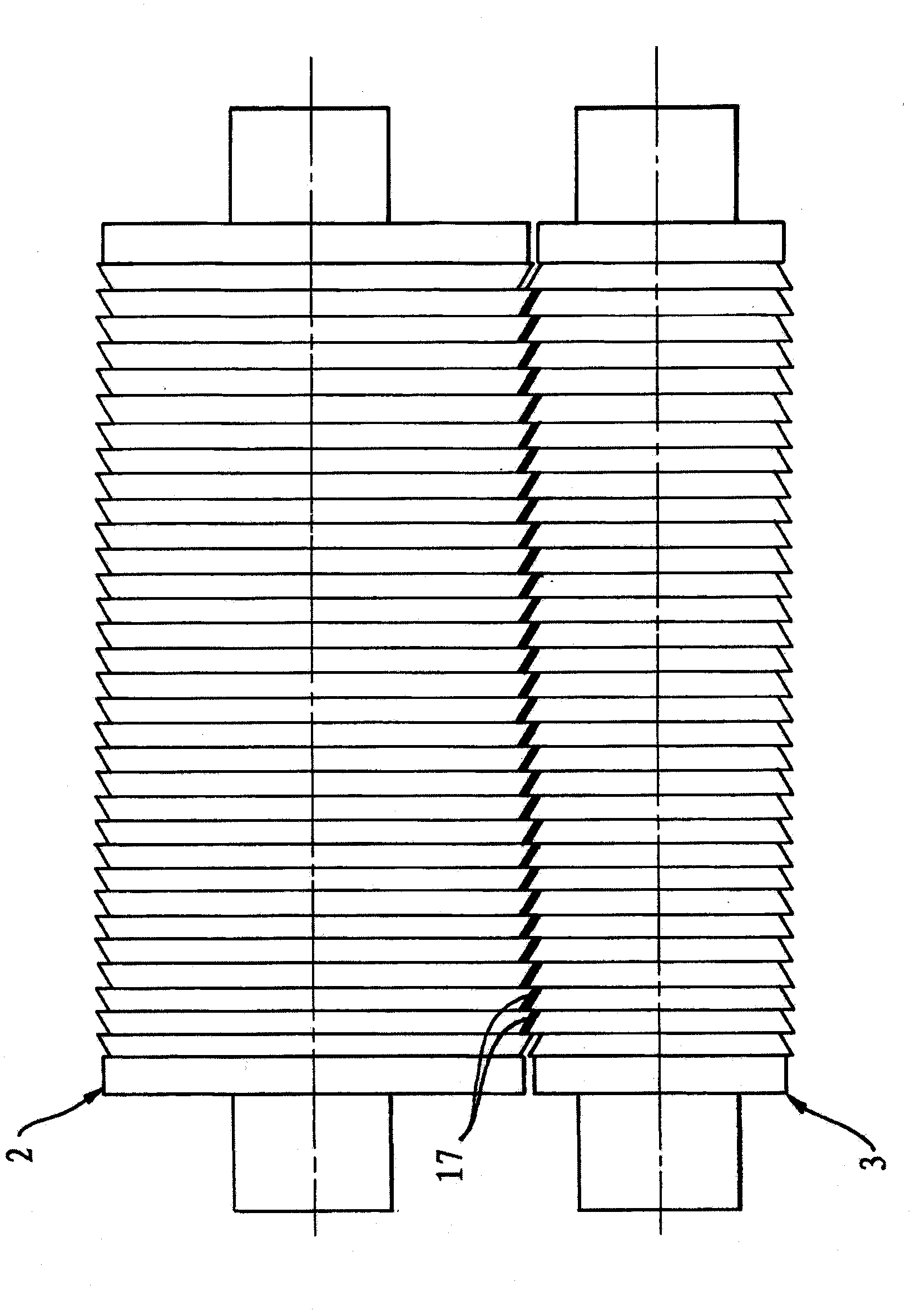

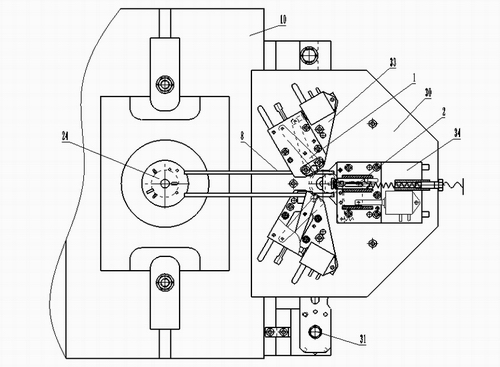

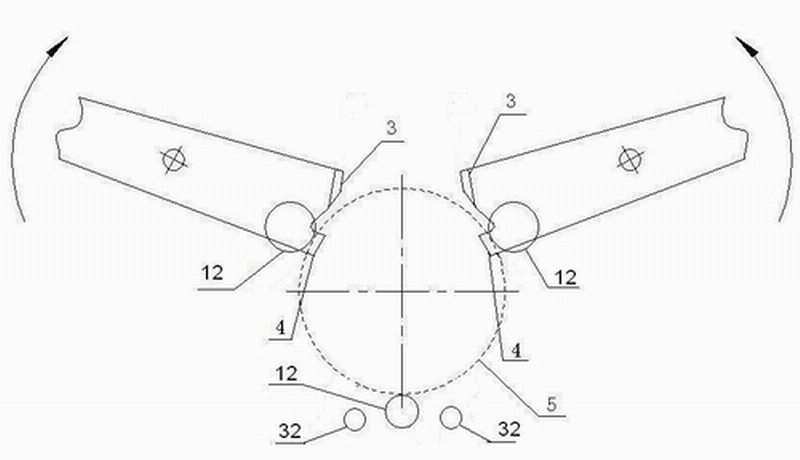

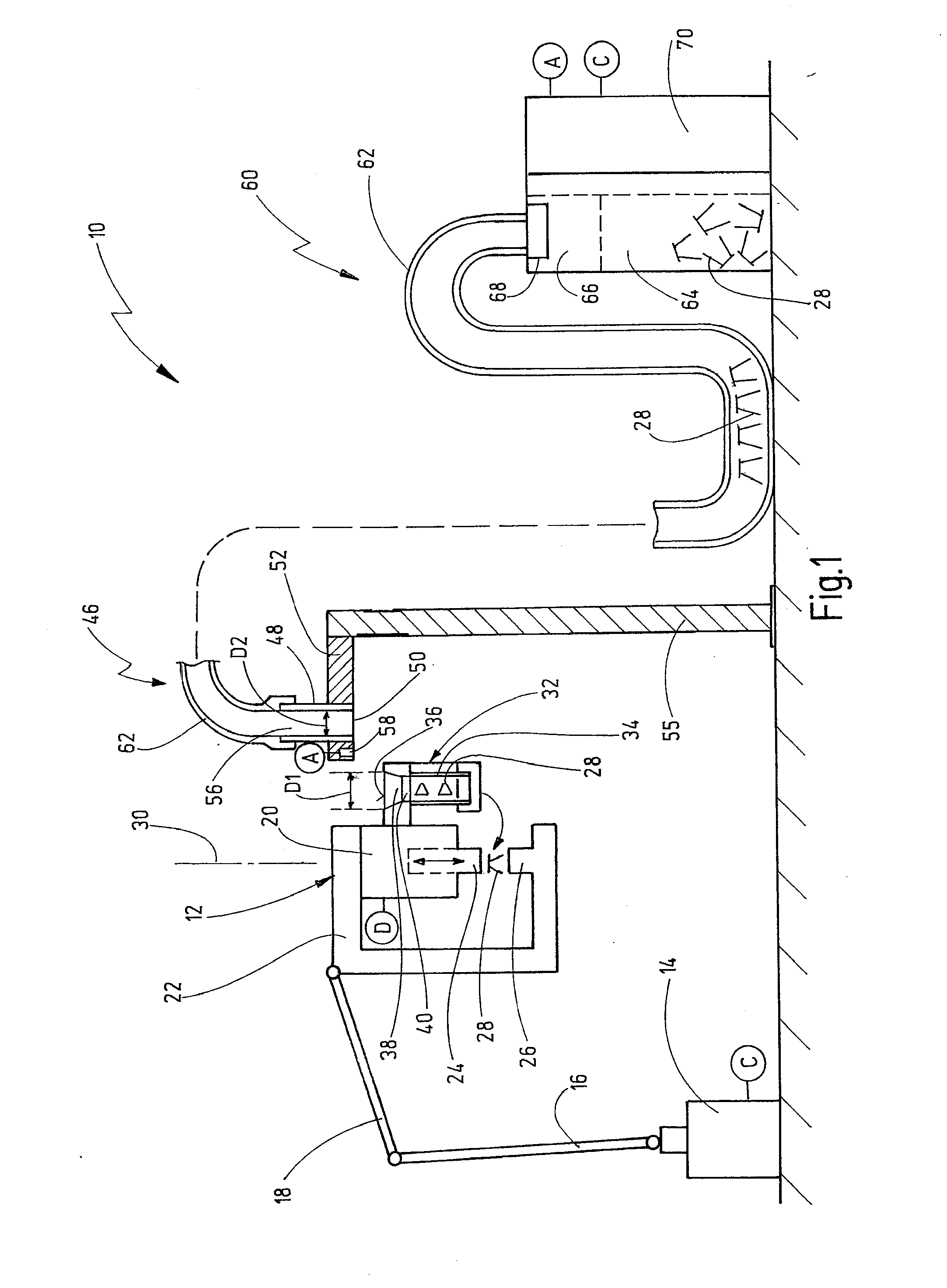

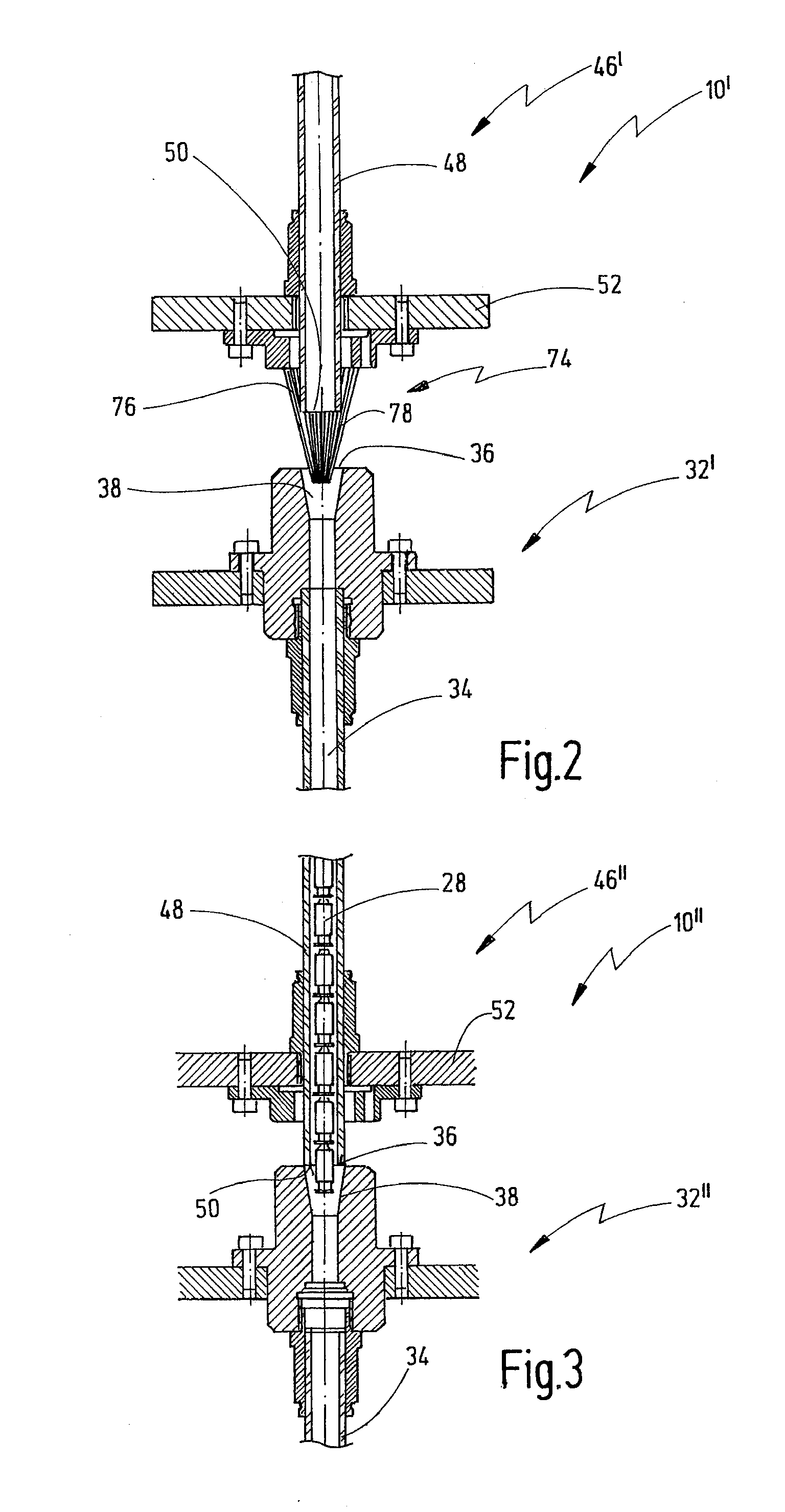

Comminution device for the production of particles from a strip-shaped material

InactiveCN102046294AFavorable resharpening effectReliable feedingGrain treatmentsMetal working apparatusEngineeringComminution

The invention relates to a comminution device for the production of particles (16) from a strip-shaped material (17), said device comprising a longitudinal cutting device (1) having a first cutting roller (2) and having a second cutting roller (3), and a transverse cutting device (4), which is disposed downstream from the longitudinal cutting device (1), wherein the first cutting roller (2) and the second cutting roller (3) each have special profiles according to the invention.

Owner:AUTOMATIK PLASTICS MASCH GMBH

Sheet feeding apparatus

InactiveUS6942208B2Reliable feedingReliable measurementElectrographic process apparatusArticle feedersSheet material

Owner:KONICA CORP

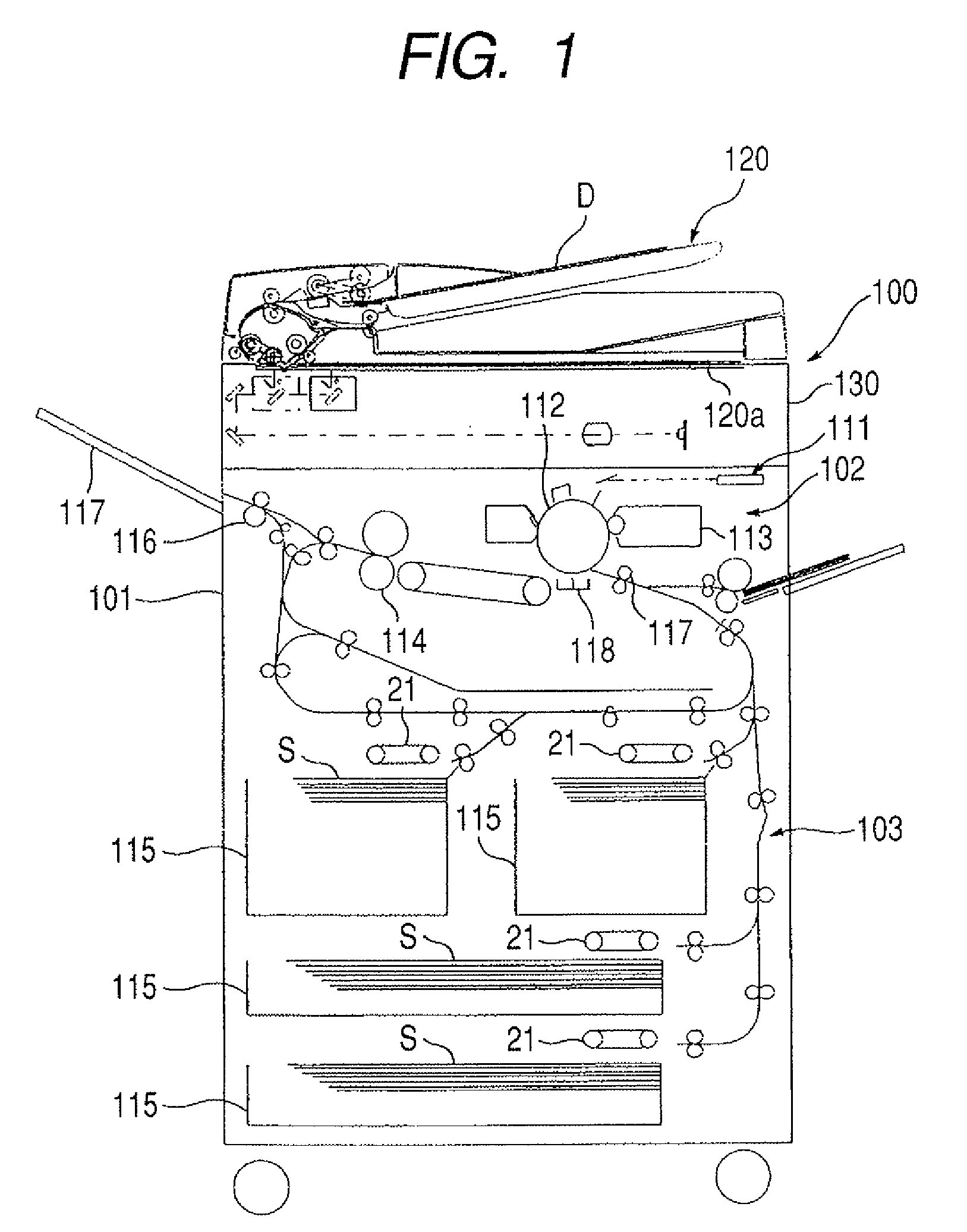

Image forming apparatus

ActiveUS7744081B2Reliable feedingFunction indicatorsElectrographic process apparatusImage formationElectrical and Electronics engineering

Owner:CANON KK

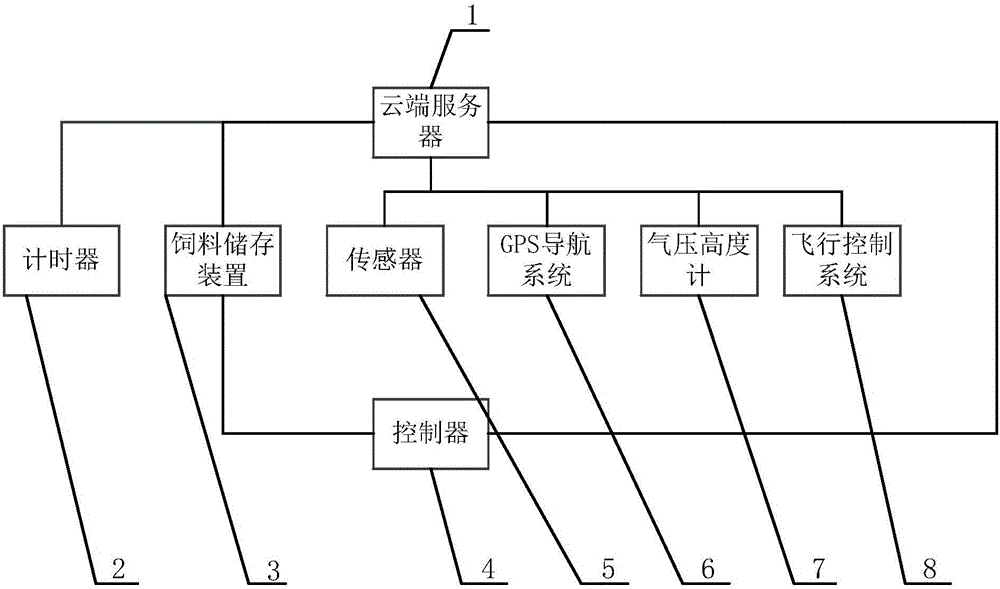

Automatic aquaculture unmanned aerial vehicle

ActiveCN106719230AGuaranteed uniformityGuaranteed punctualityClimate change adaptationPisciculture and aquariaFlight control modesControl signal

The invention discloses an automatic aquaculture unmanned aerial vehicle. The automatic aquaculture unmanned aerial vehicle includes a feed storage device, a timer, a sensor, a flight control system, a GPS navigation system, an air pressure altimeter, a cloud server, a controller and a power supply system, wherein the feed storage device is arranged at the bottom of an unmanned aerial vehicle body, a valve is arranged at the bottom of the feed storage device, the timer is used for setting the opening time of the valve, the sensor is used for controlling the valve to close according to the height of feed in the feed storage device, the flight control system is used for controlling the flight of the unmanned aerial vehicle body, the GPS navigation system is used for locating the position coordinate of the unmanned aerial vehicle body, the air pressure altimeter is used for determining the flight height according to air pressure, the cloud server is used for collecting data and analyzing the data, and the controller is used for generating and sending a control signal according to the analysis result of the cloud server. By means of the automatic aquaculture unmanned aerial vehicle, automatic timed quantitative fixed-location feeding can be achieved, no manual operation is needed, manpower and time can be saved, feeding is reliable, at the same time, it is ensured that the feed can be uniformly and timely threw in, and the automatic aquaculture is achieved.

Owner:GUANGDONG UNIV OF TECH

Supply Tray And Image Forming Apparatus For Use Therewith

ActiveUS20070182803A1Reliable feedingOther printing apparatusArticle feedersLocking mechanismRecording media

A supply tray includes a first tray configured to receive a stack of recording medium thereon, and a second tray configured to receive at least one recording medium thereon, which is different in size or type, or both, from the stack of recording medium received on the first tray. The second tray is disposed in an upper portion of the first tray and is slidable within a predetermined direction. The supply tray further includes a locking mechanism configured to place and to fix the second tray in position with respect to the first tray.

Owner:BROTHER KOGYO KK

Sheet stock blank feeding equipment for punching process

InactiveCN101879561AAvoid separationAvoid the effects of plastic deformationMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to sheet stock blank feeding equipment for punching process, comprising a rack. The sheet stock blank feeding equipment is characterized in that the rack is provided with a material delivery platform; a longitudinal blanking guide bracket is arranged above the material delivery platform; the lower port of the longitudinal blanking guide bracket is provided with a single-sheet separation device of a sheet stock blank stacking part; one side of the blanking end of the material delivery platform is provided with an elastic striking mechanism; the single-sheet separation device of the sheet stock blank stacking part comprises at least one pair of single-sheet sidewise shifting rocking blocks, and each single-sheet sidewise shifting rocking block is correspondingly provided with a longitudinal limiting rocking block along a rotating direction; the other side of the lower end part of the sheet stock blank stacking part is correspondingly provided with a supporting telescopic slide block; and the rack is provided with a stop block preventing other sheet stock blank stacking parts from being shifted. The invention has the advantages of simple structure, convenient use, reliable work, high commonality, easy and convenient installation of connecting with a punching machine and capability of high-efficient automatic punching production.

Owner:陈石云

Ink tank, head cartridge and ink jet printing apparatus

A printing system having an ink tank for storing ink, the ink tank having a housing having an ink feeding port formed through a first surface for feeding ink therethrough, and a second surface opposite the first. An ink absorbing member is accommodated in the housing, is a porous member having a three-dimensional net-shaped structure molded of a composition comprising a condensate of (i) a compound having an amino group and (ii) formaldehyde, and has a first surface facing the ink feeding port. An alleviating member having more resilience than the ink absorbing member is disposed between the ink absorbing member and an ink outflow portion formed through the ink feeding port and alleviates pressure applied by the ink outflow portion against the ink absorbing member. Both the alleviating member and the ink absorbing member are deformed by compression against the ink outflow portion. A compensating member having more resilience than the ink absorbing member is disposed between the ink absorbing member and the ink outflow portion and applies a functional force to the ink absorbing member corresponding to deterioration of properties of the ink absorbing member. Another ink absorbing member having more resilience than the ink absorbing member is disposed between the ink absorbing member and the ink outflow portion.

Owner:CANON KK

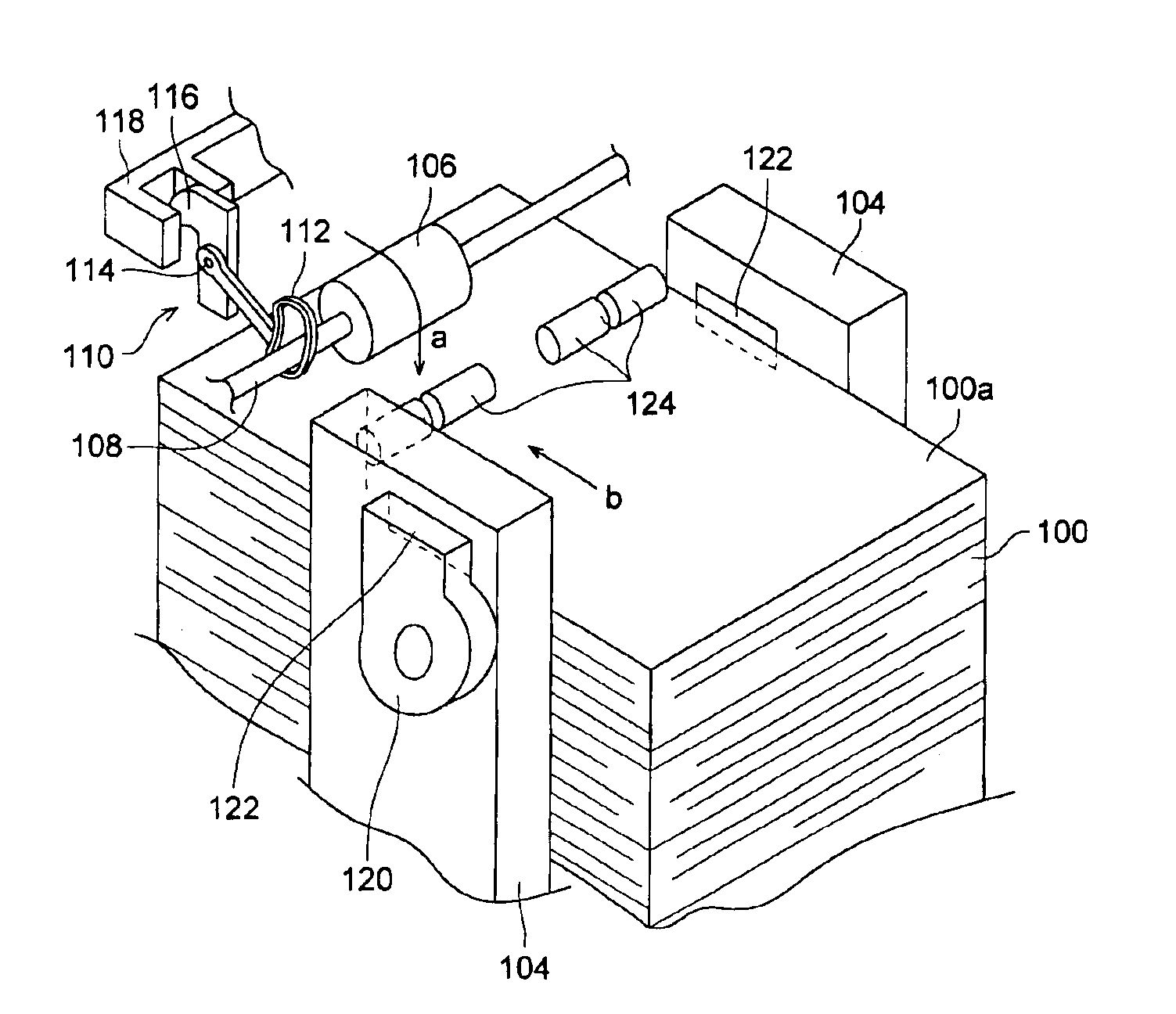

Method and apparatus for feeding joining elements

InactiveUS20130071209A1Easy to fillCarry-out quicklyMetal working apparatusArticle separationMechanical engineering

A method and apparatus for feeding joining elements to a joining tool is presented. The joining tool may be movable by a programmable handling unit, and a magazine for receiving at least one joining element may be mounted on the joining tool. The magazine may be moved to a filling station that has a tubular section with an outlet opening. An inlet opening of the magazine may be oriented in relation to the outlet opening. At least one joining element may be conveyed to the tubular section so that it passes through the tubular section, the outlet opening, the inlet opening, and into the magazine. During the orienting, the magazine may be oriented in relation to the outlet opening such that the magazine is spaced apart from the filling station during the conveying of the at least one joining element.

Owner:NEWFREY

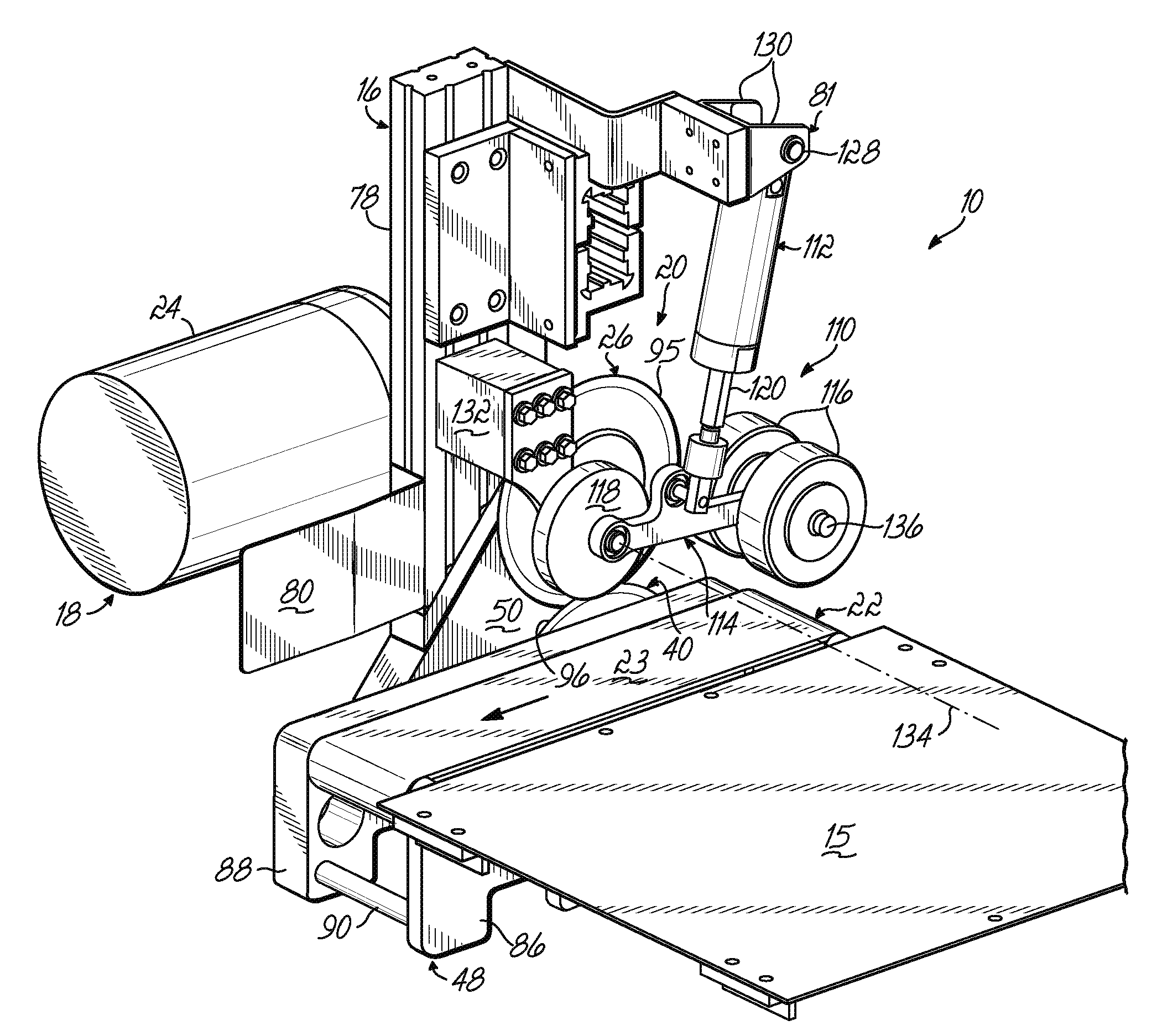

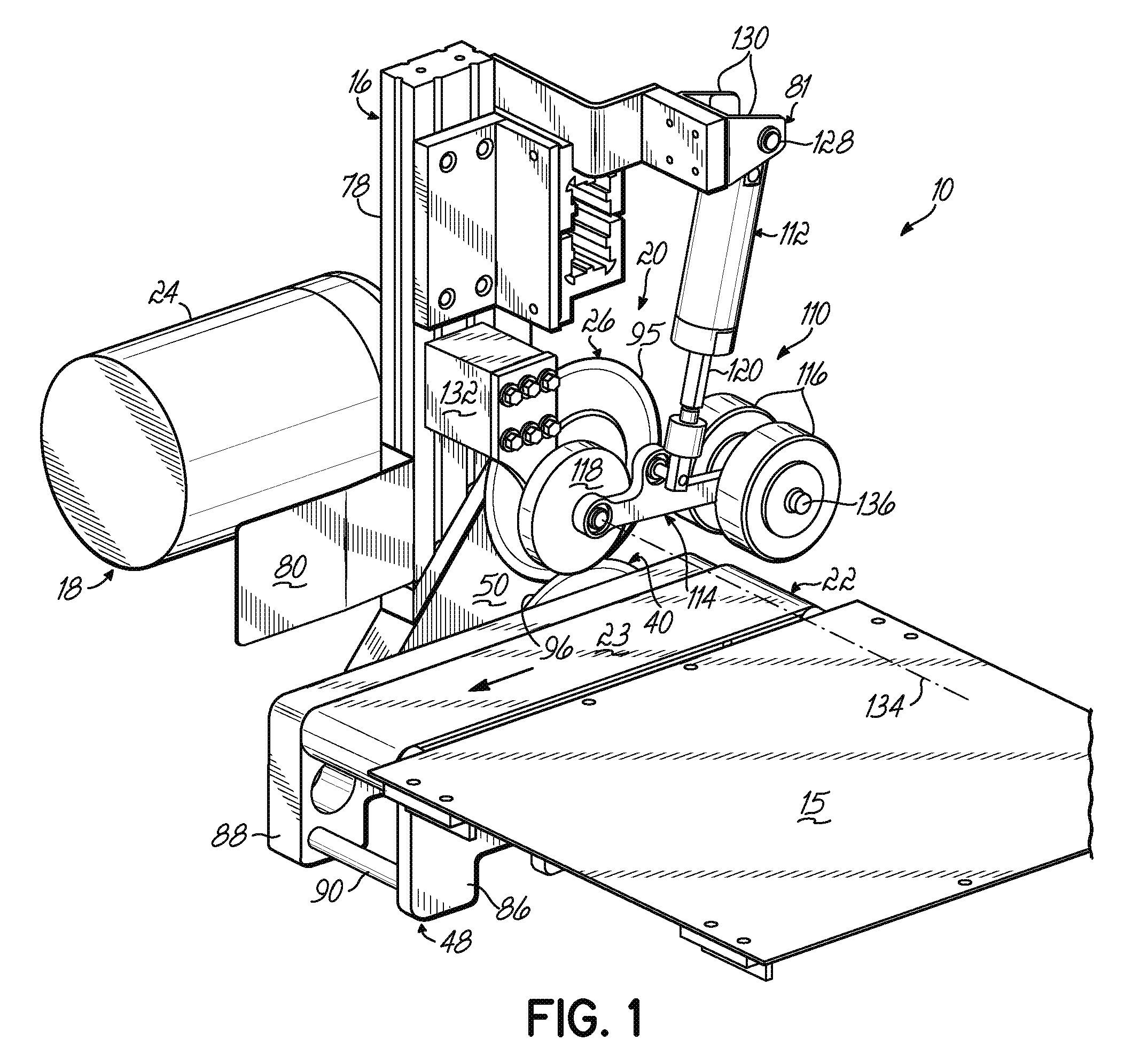

Soft Goods Slitter and Feed System for Quilting

InactiveUS20080264317A1Reliable feedingCompact and inexpensiveWorkpiece carriersLeather sewingEngineeringActuator

An apparatus is provided for feeding and slitting mattress covers, quilts and other soft goods supported on a table. The apparatus has a first slitting wheel rotatable by a motor. A second slitting wheel is rotatable by the motor and contacts the first slitting wheel to provide a cutting action. The apparatus further includes a conveyor operable by the motor for conveying the soft goods past the slitting wheels, and a compression assembly having an actuator, a swing arm, and wheels for compressing the soft goods and holding the soft goods against the conveyor to preventing slippage or twisting.

Owner:L & P PROPERTY MANAGEMENT CO

Recording medium feeder with multiple frictional surfaces and image recording device

InactiveUS7455287B2Increase coefficient of frictionReduce coefficient of frictionArticle separationImage recordingEngineering

A recording medium feeder includes: a tray on which a plurality of recording medium are to be stacked; a feed roller that feeds the recording medium stacked on the tray; a first friction member provided on the tray and having high friction coefficient; and a second friction member provided on the tray at a position opposing the feed roller and having low friction coefficient that is lower than the friction coefficient of the first friction member, wherein the first friction member is configurable to be in one of positions of a protruded position in which a surface of the first friction member is protruded from a surface of the second friction member towards the feed roller and a retracted position in which the surface of the first friction member is arranged to be not higher than the surface of the second friction member.

Owner:BROTHER KOGYO KK

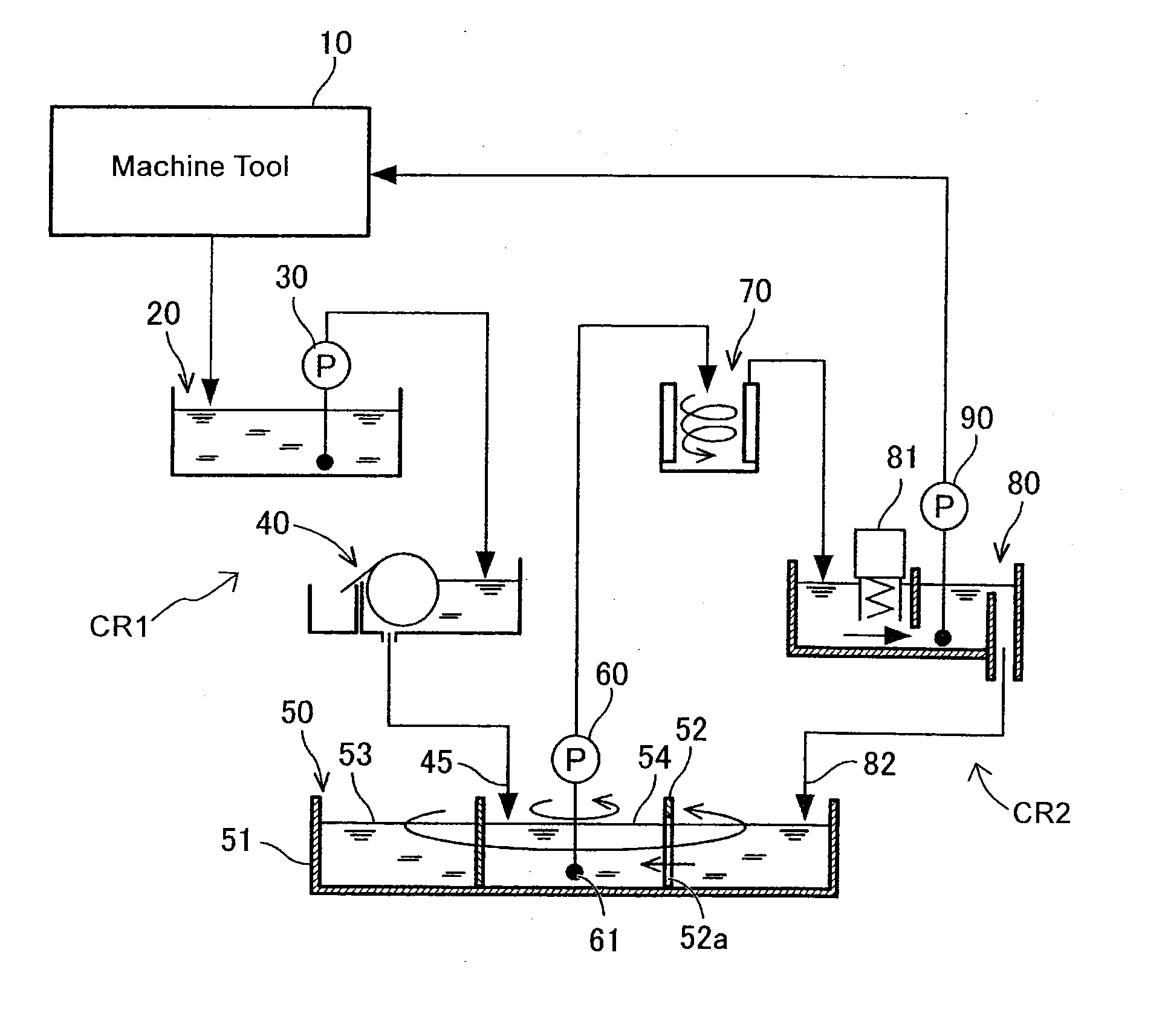

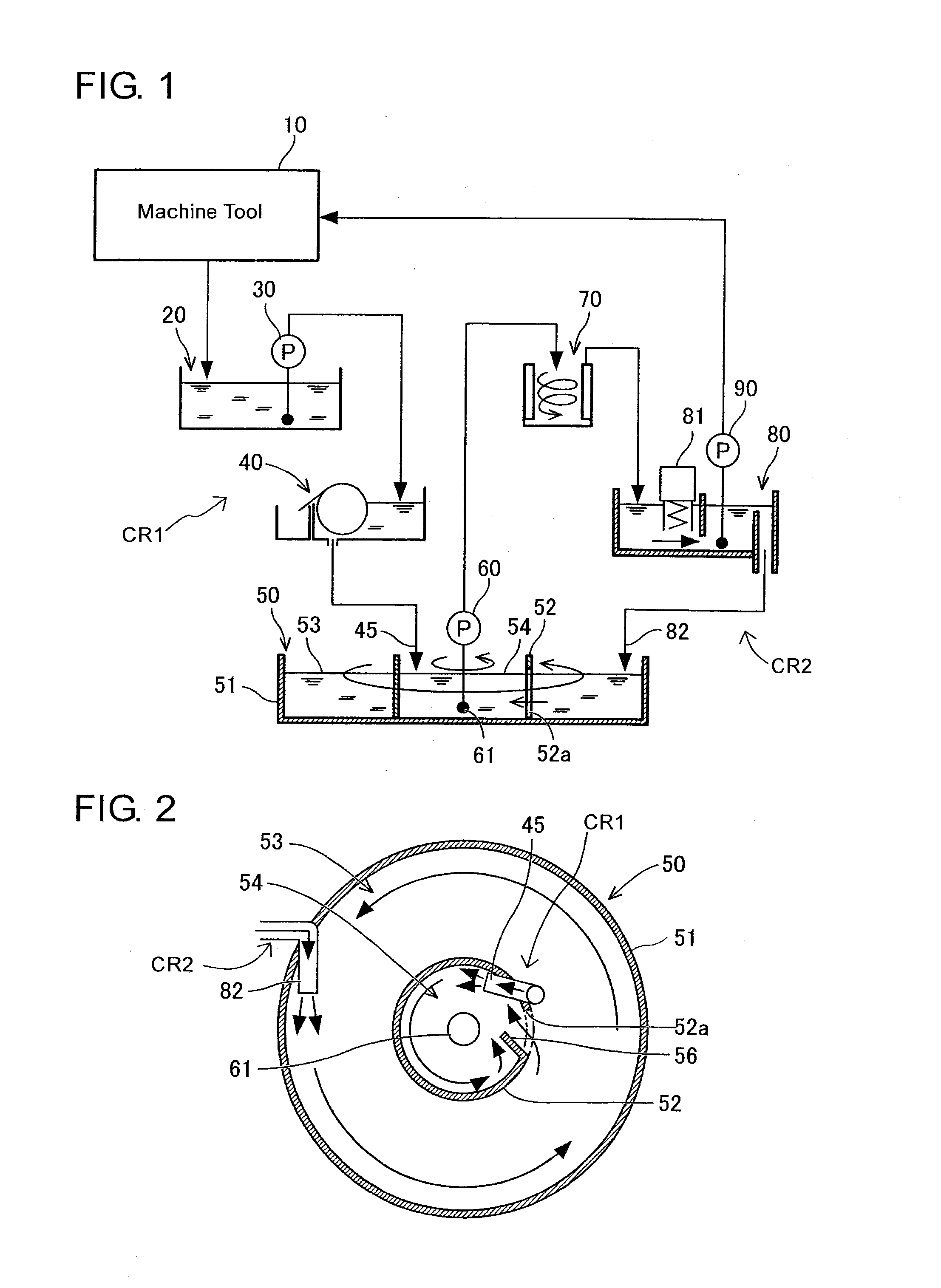

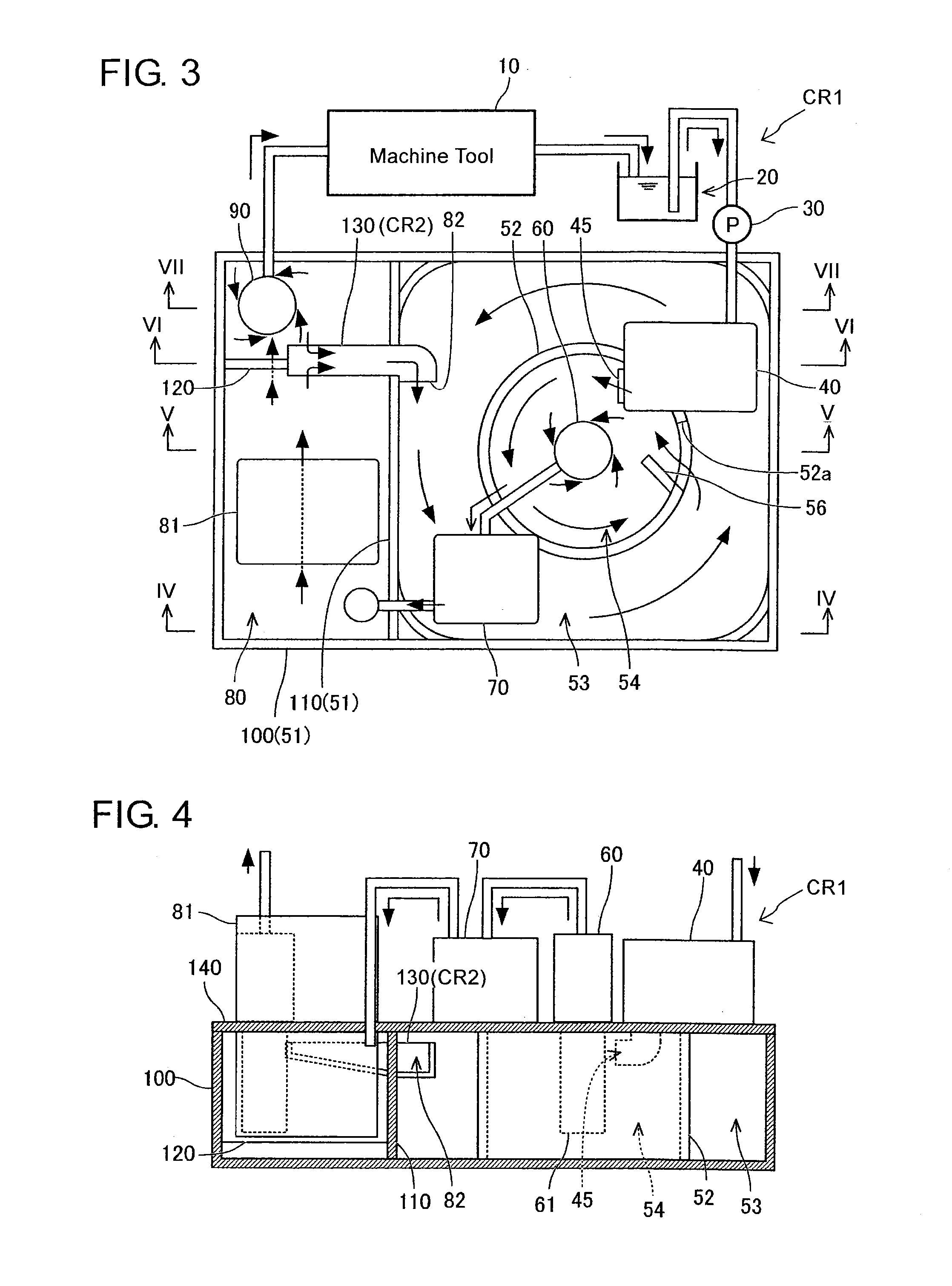

Coolant system

ActiveUS20140116930A1Draw reliableReliable feedingWater/sewage treatmentMagnetic separationEngineeringDepth direction

In a coolant system, the interior of a reservoir frame storing the coolant discharged from a machine tool is partitioned by a partition member into an outer peripheral coolant tub and a central coolant tub. The partition member is formed with a silt that extends in the depth direction to make the outer peripheral coolant tub communicate with the central coolant tub. A suction port of a pump that feeds the coolant in the central coolant tub to a filtering device is arranged in the central coolant tub. The coolant discharged from the machine tool is supplied to the central coolant tub without passing through the outer peripheral coolant tub. At least a part of the coolant filtered by the filtering device is supplied to the outer peripheral coolant tub without passing through the central coolant tub.

Owner:JTEKT CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com