Mobile phone polaroid laminating machine capable of reliably laminating polaroid

A polarizer and laminating machine technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of affecting the quality of polarizer lamination, poor air removal effect, glass substrate cracking, etc., saving time and workload , Improve the quality of the patch and reduce the effect of residual air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

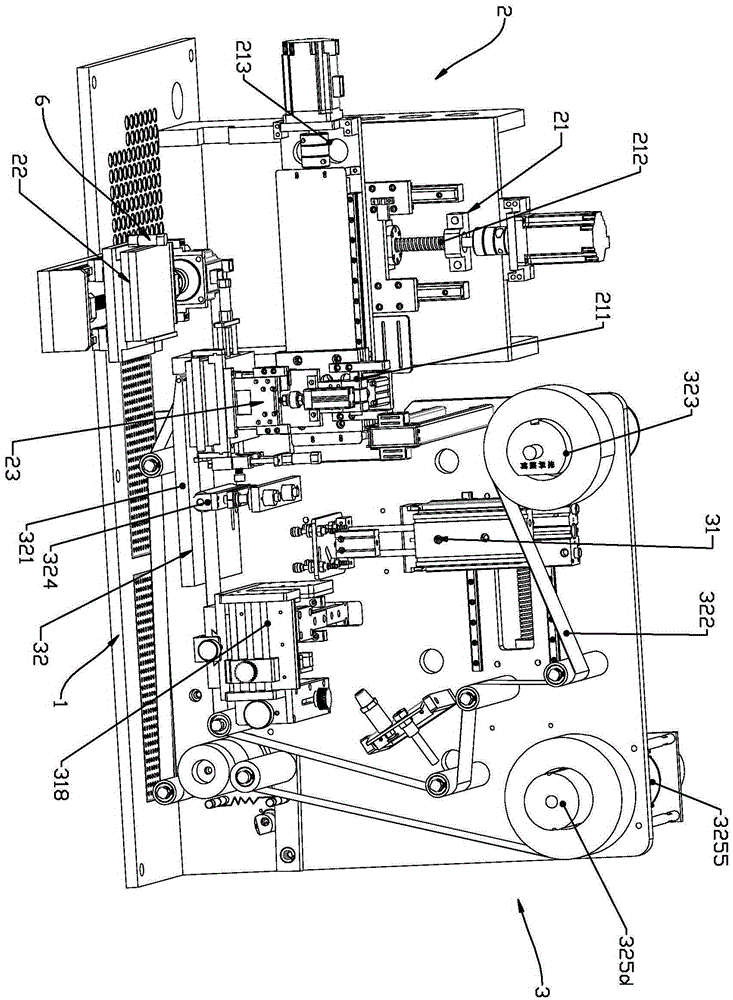

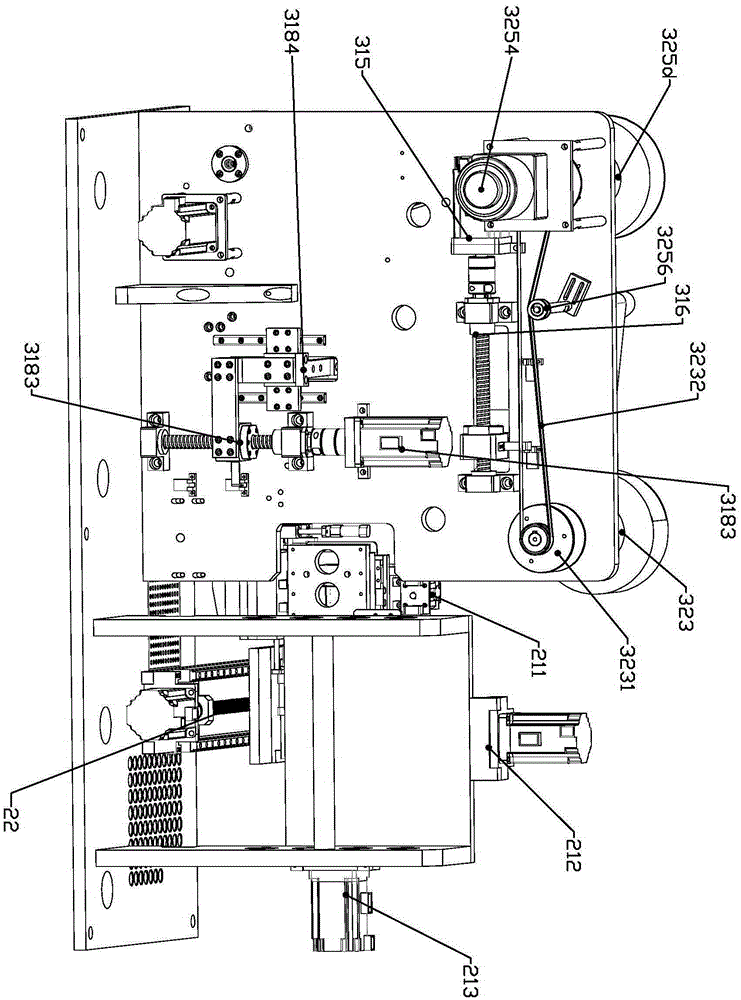

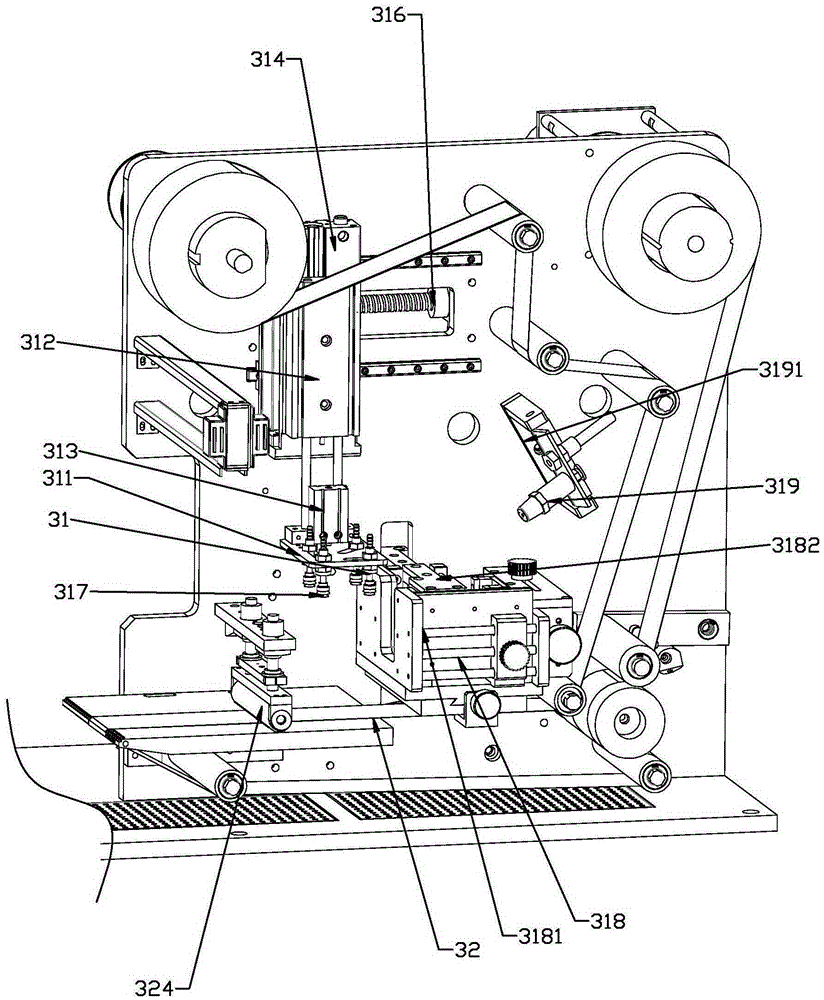

[0033] like Figure 1~Figure 7 As shown, a mobile phone polarizer automatic bonding machine with reliable patching disclosed by the present invention includes an organic base, and a placement device 2 installed on the base 1. The placement device 2 includes a device for absorbing and fixing the polarizer. The polarizer loading mechanism 21, the substrate loading mechanism 22 used for absorbing and fixing the glass substrate, and the patch rolling mechanism 23 that rolls after the polarizer and the glass substrate are pre-attached, are provided in front of the polarizer loading mechanism 21 process. Polarizer automatic feeding device 3 for automatic loading and film removal of polarizers. The substrate loading mechanism 22 includes a vacuum suction seat 223 for positioning and fixing the glass substrate. A high-speed camera is installed on the side of the vacuum suction seat 223 to take pictures of the bonding process 6. The polarizer loading mechanism 21 includes a polarizer l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com