Patents

Literature

47results about How to "Achieve shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

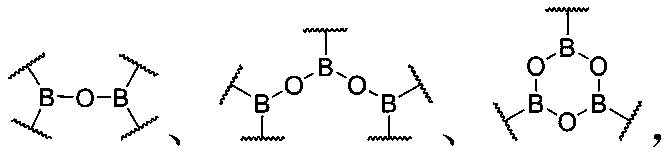

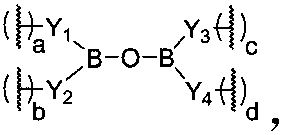

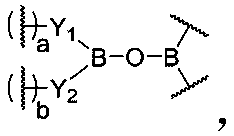

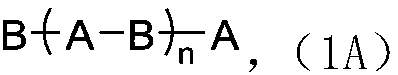

Combined hybrid cross-linked dynamic polymer and application thereof

The invention discloses a combined hybrid cross-linked dynamic polymer, which contains at least one boron-containing dynamic covalent bond, at least one other dynamic covalent bond and an optional hydrogen bond, and contains at least one dynamic covalent cross-linked network, wherein the cross-linking degree of other dynamic covalent bond cross-linking reaches a gel point or above. By introducingthe boron-containing dynamic covalent bonds with different dynamics, other dynamic covalent bonds and optional hydrogen bonds into the combined hybrid cross-linked dynamic polymer, a dynamic polymer material with a wide controllable range, rich structures and various properties can be prepared. The dynamic polymer contains the difference between the boron-containing dynamic covalent bond, the other dynamic covalent bond and the hydrogen bond, so that the polymer can show dynamic reversible effects with orthogonality and synergism under different conditions, and therefore, the polymer shows good self-repairing characteristics and rich stimulus responsiveness. The dynamic polymer can be widely applied as a self-repairing material, a tough material, a sealing material, an interlayer adhesiveand the like.

Owner:厦门逍扬运动科技有限公司

Physical split phase supramolecular dynamic polymer and application thereof

The invention discloses a physical split phase supramolecular dynamic polymer, which contains a block polymer molecule with hard and soft segments simultaneously. The hard segments of the block polymer molecule can be mutually mixed to and / or independently form crystal phases and / or phases incompatible with the soft segments, thus forming split phase physical crosslinking and / or polymerization based on hard segments, and all the soft segments of the block polymer molecule are amorphous. At least one soft segment of the block polymer molecule contains at least one ligand group, which can form dynamic metal-ligand interaction with a metal center. Moreover, at least one soft segment of the block polymer molecule contains at least one hydrogen bond group with hydrogen bond donor and hydrogen bond receptor simultaneously, and the hydrogen bond group forms a dynamic hydrogen-bond interaction. The dynamic polymer has shape memory function, self-repair function and super-toughness, and has wide application in biomedical materials, military, aerospace, energy, construction and other fields.

Owner:厦门天策材料科技有限公司

Software robot actuator with rigidity independently controllable

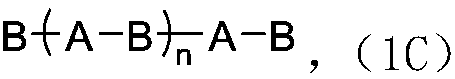

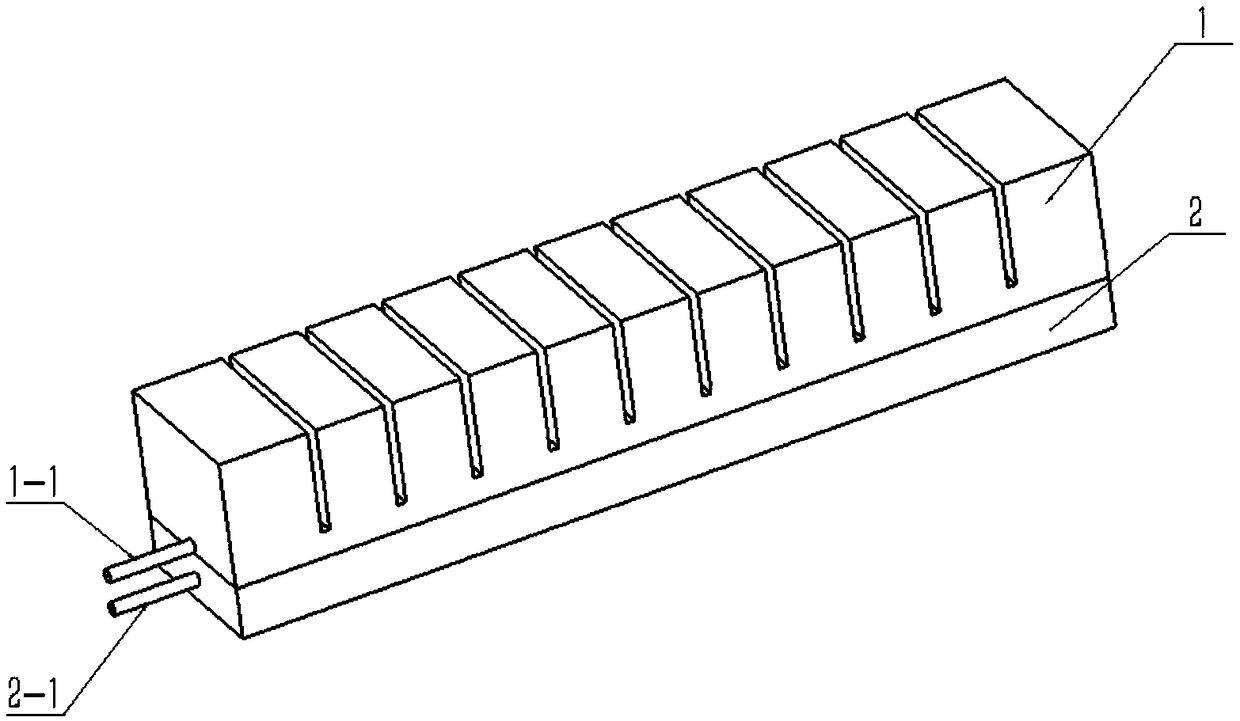

InactiveCN109048856AChange the stiffnessIncrease stiffnessProgramme-controlled manipulatorGripping headsExpansion chamberActuator

The invention provides a software robot actuator with rigidity independently controllable. The software robot actuator with rigidity independently controllable comprises a gas actuation portion and arigidity adjustment portion. The rigidity adjustment portion comprises a rigidity adjustment chamber and a granular medium yarn bag. The rigidity adjustment chamber is located at the bottom of the gasactuation portion. The granular medium yarn bag is tiled inside the rigidity adjustment chamber. The rigidity of the actuator is changed by changing the gas pressure in the rigidity adjustment chamber. The upper surface of the gas actuation portion is zigzag. The rigidity adjustment chamber is adhered to the lower surface of the gas actuation portion. The gas actuation portion comprises a plurality of gas actuation expansion chambers. Each gas actuation expansion chamber is arranged inside one single saw tooth, and every two adjacent gas actuation expansion chambers communicate with each other through an internal channel. According to the software robot actuator with rigidity independently controllable, the rigidity of the gas actuator can be changed on the premise that the motion flexibility is not affected, and the controllability is higher.

Owner:JIANGSU UNIV

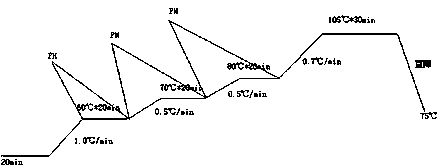

Process for producing texture feeling nylon fabric

ActiveCN108729268AImprove liquidityLess coatingLiquid/gas/vapor removalHeating/cooling textile fabricsWrinkle skinEngineering

The invention discloses a process for producing a texture feeling nylon fabric. The process comprises the following steps: collecting cloth, performing cold padding, desizing, dyeing, dewatering and scotching, drying, setting, coating and fixing. The dyeing process comprises the following sub-steps: adopting a rope dyeing manner of an overflow dyeing machine, raising the temperature to the highestdyeing temperature according to the dyeing process, maintaining the temperature, reducing to a set temperature according to a cooling rate of 2.5-5.0 DEG C per minute, enabling the cloth surface to wrinkle, and forming warp wrinkles; the setting process comprises the following sub-steps: performing advanced weft feed in front of a fabric top board under the necking condition, and enabling the fabric to have upwards weft wave wrinkles before entering a drying oven; and the coating process comprises the following sub-steps: adopting a polyacrylate coating, and coating a coating for shaping andhighlighting texture on one side of the fabric. The texture feeling nylon fabric produced by the process for producing the texture feeling nylon fabric disclosed by the invention has three-dimensionaltexture, full hand feel as well as waterproof and windproof ventilation functions.

Owner:台华高新染整(嘉兴)有限公司

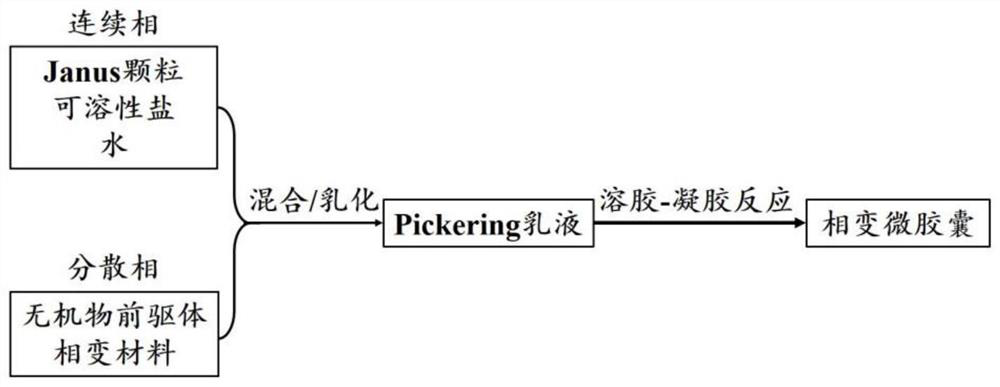

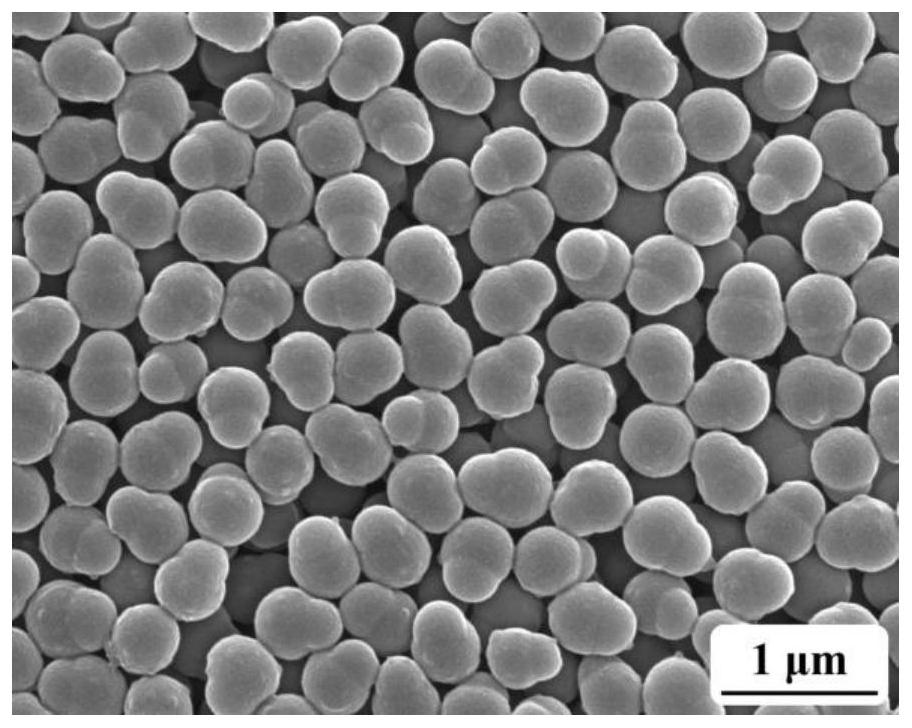

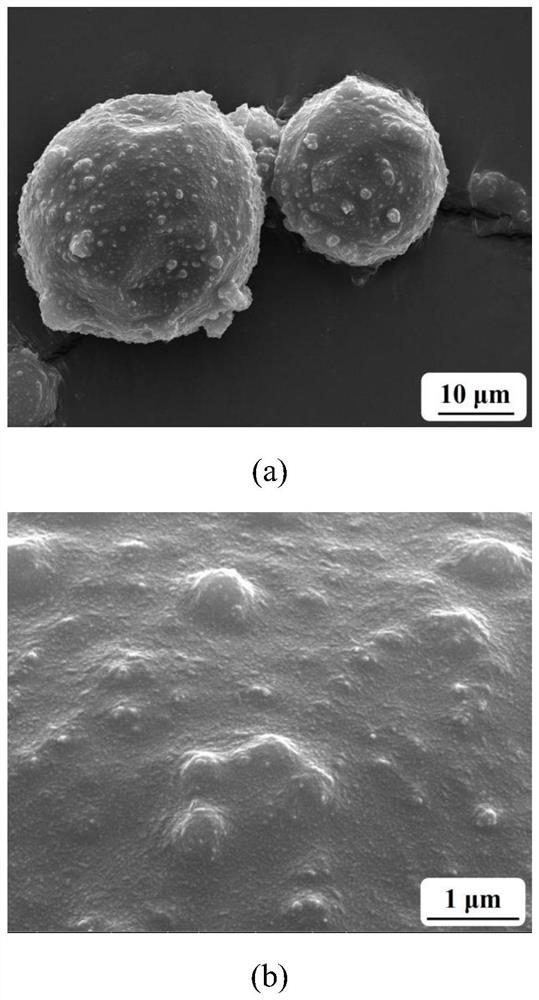

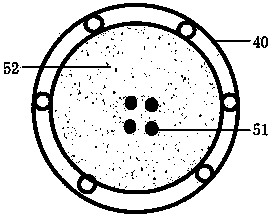

Phase-change microcapsule based on inorganic shell layer and preparation method and application thereof

ActiveCN111621265AStable structureImprove performanceHeat-exchange elementsMicroballoon preparationJanus particlesEmulsion

The invention provides a phase-change microcapsule based on an inorganic shell layer and a preparation method and application thereof. The Janus particle-containing composite wall material-coated phase change microcapsule based on the inorganic shell layer is obtained by stabilizing an emulsion through Janus particles and utilizing a sol-gel reaction at a water-oil interface. The phase change microcapsule based on the inorganic shell layer has controllable phase change temperature and high enthalpy retention rate, and the supercooling degree of a solid-liquid phase change material is effectively reduced. The phase-change microcapsule based on the inorganic shell layer is low in breakage rate in the using process, free of leakage of phase-change materials and volatile gas, excellent in using stability, safe and environmentally friendly. In addition, the phase change microcapsule coated with the composite wall material can be prepared in a green manner, and no toxic volatile substance isgenerated in the preparation process. The phase change microcapsule is simple in process and short in production period, and has a prospect of industrial batch production.

Owner:TSINGHUA UNIV

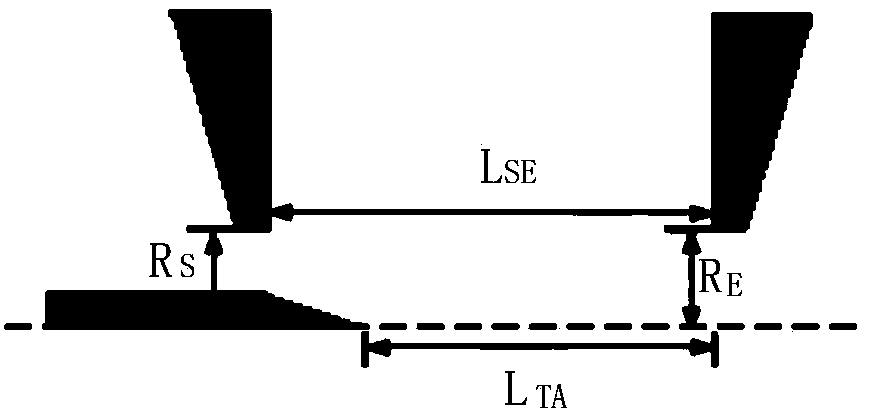

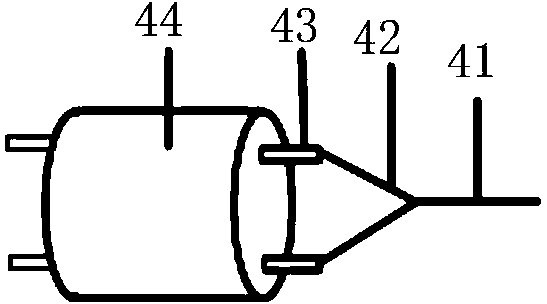

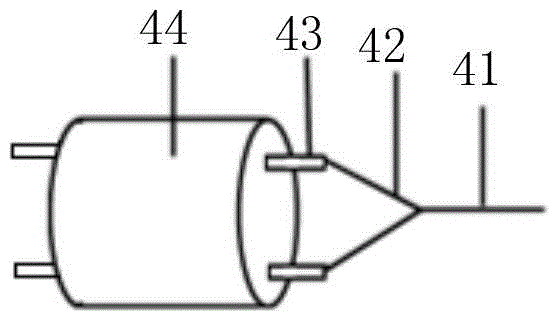

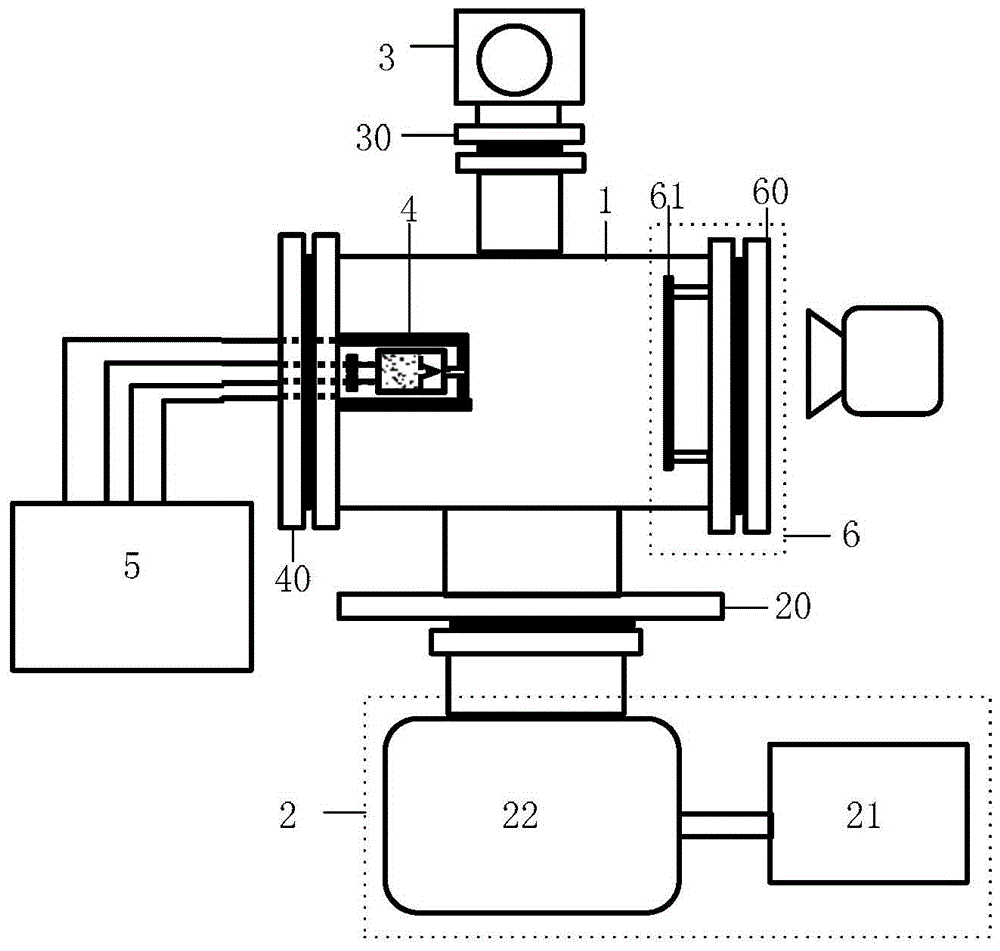

Shaping device and method for field emission electron source emitter tip

ActiveCN103943437ALarge emission currentHigh angular current densityCold cathode manufactureVacuum pumpingElectron source

The invention discloses a shaping device and method for a field emission electron source emitter tip. The shaping device comprises a vacuum chamber, a vacuum pumping system, a vacuum degree measuring system, an electronic gun assembly, a power source system and an electron beam imaging system. The method comprises the steps that the field emission electron source emitter tip is heated to be passivated, a critical electric field is applied to an anode to form field emission, the balance, on the surface, between the surface tension of the emitter tip and the electric field force produced by the additional electric field is achieved, and therefore shaping is achieved; after the field emission electron source emitter tip is shaped, a stable emission surface is formed on the emitter tip. The stable emission surface can make electronic beam current emitted by a field emission electron source have the advantages that the emission current is large, emission directions are concentrated, the density of angle current is high, monochromaticity is good, and beam current emission is stable.

Owner:PEKING UNIV

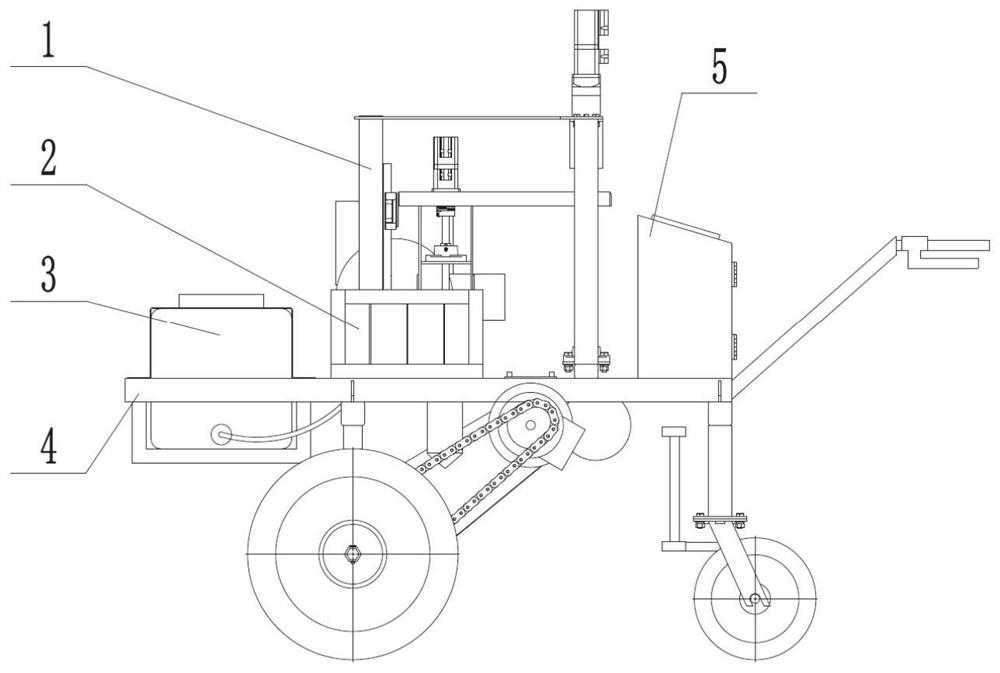

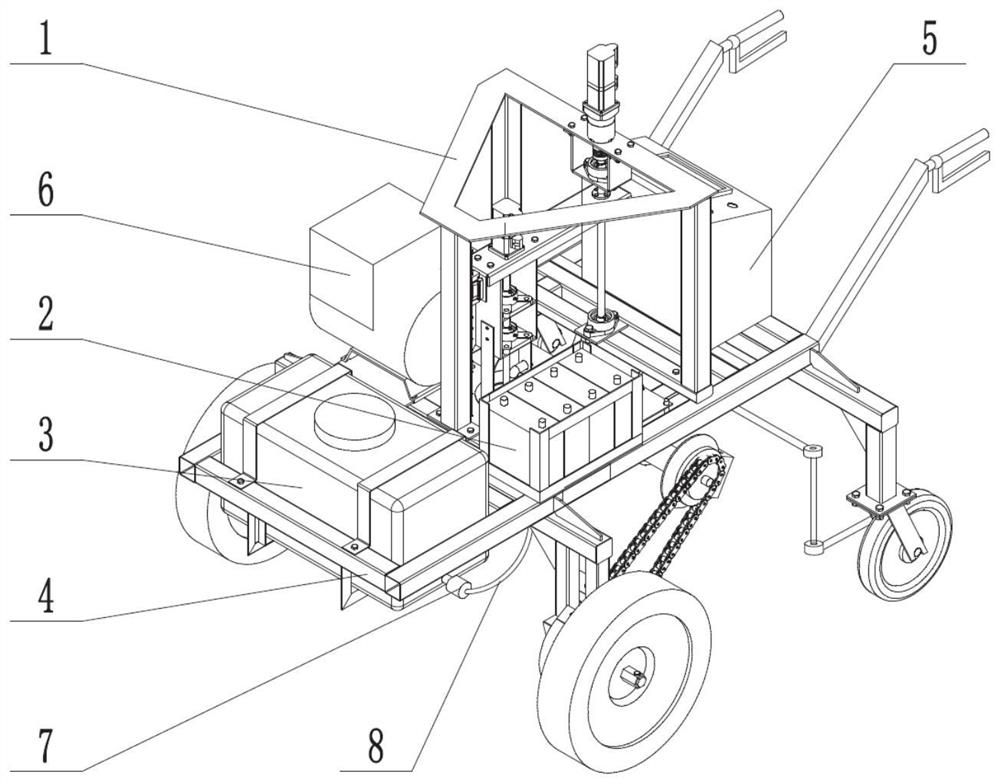

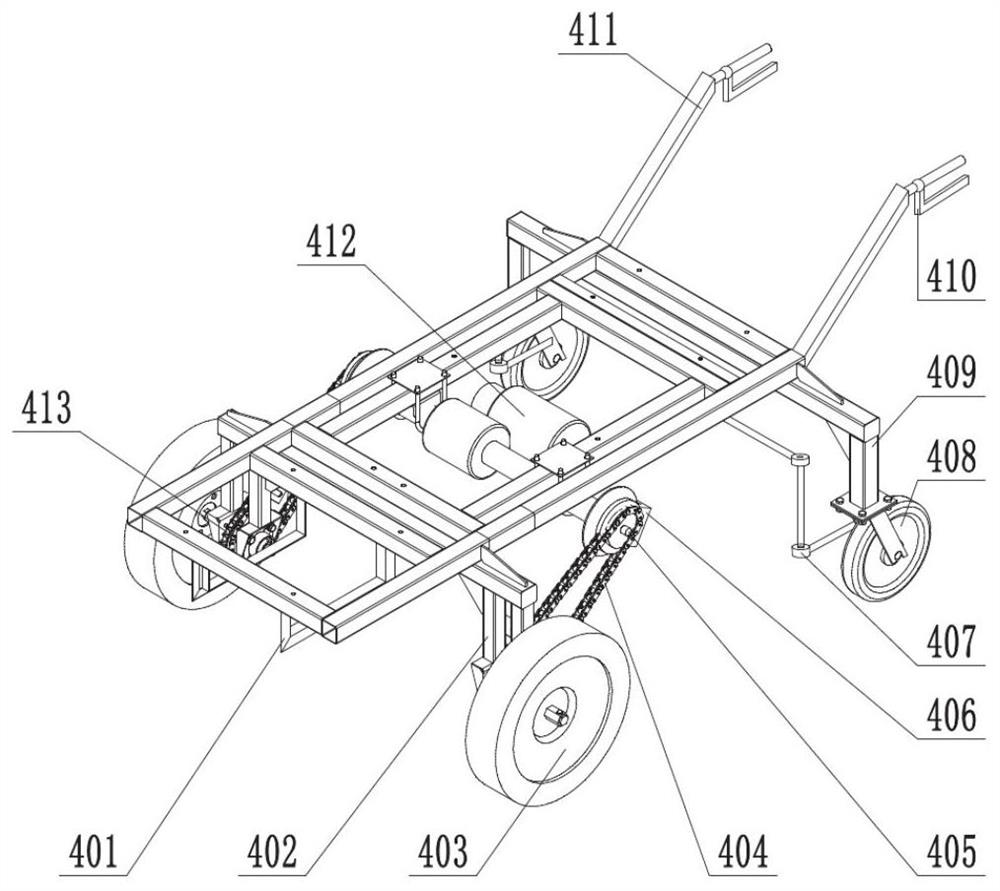

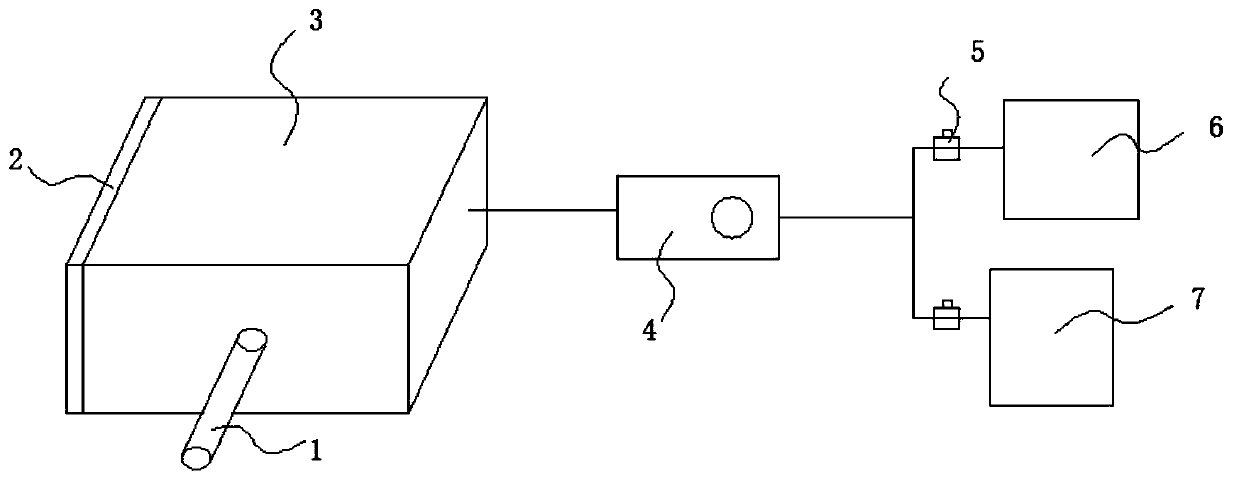

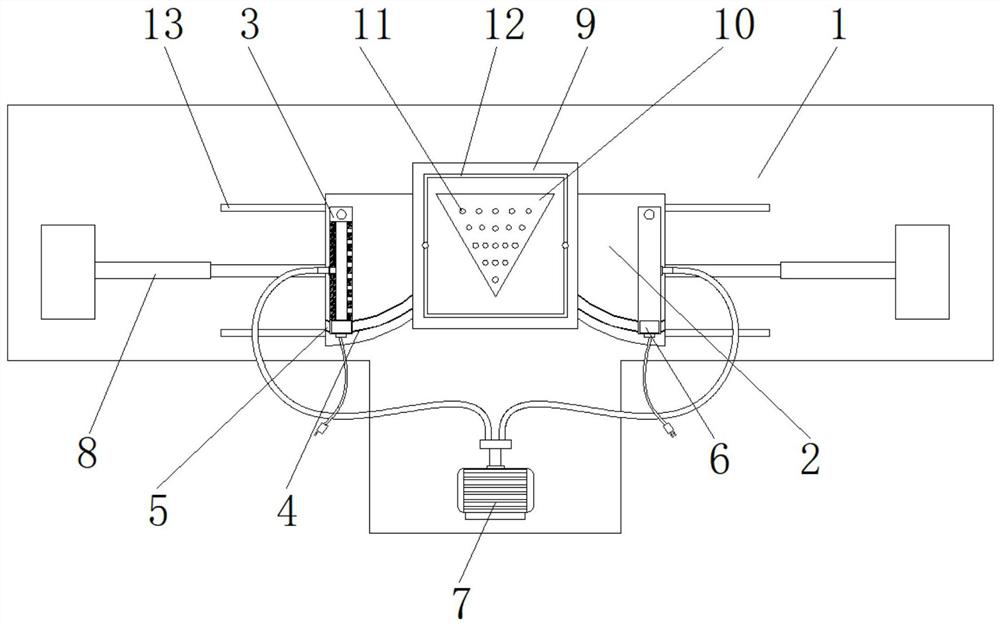

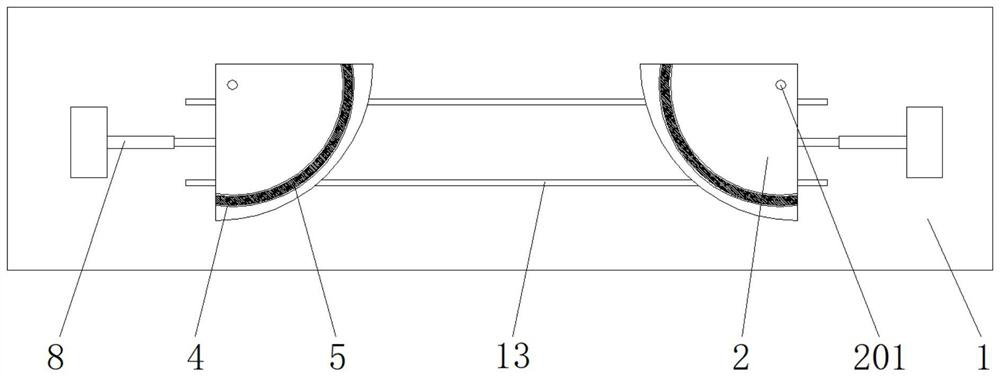

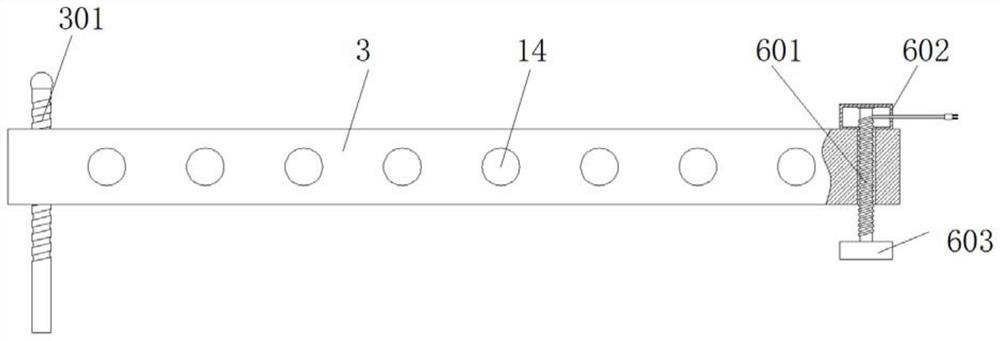

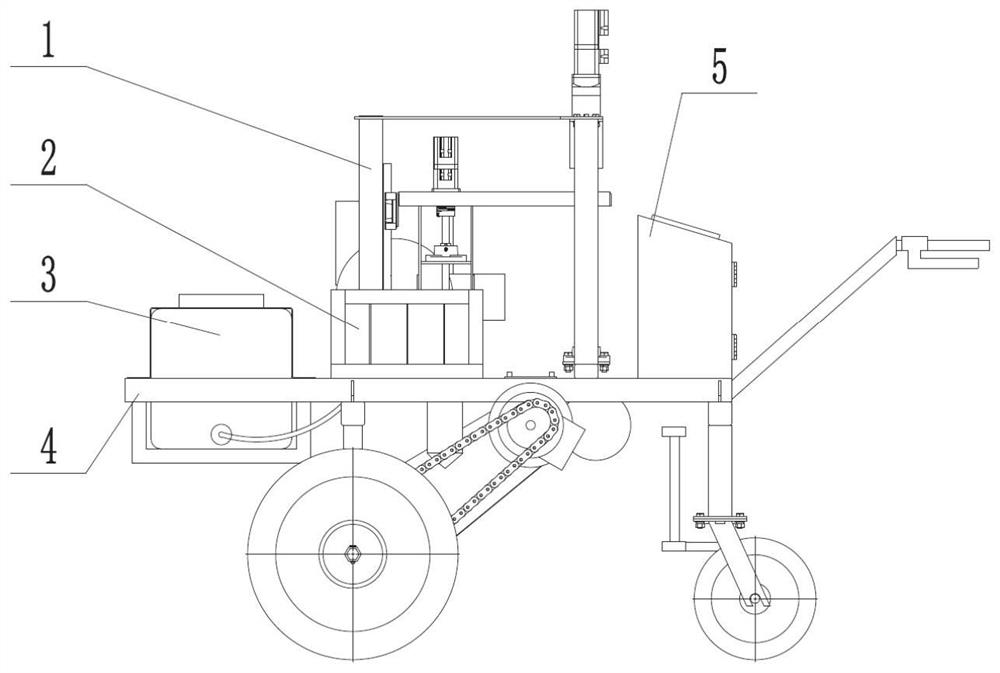

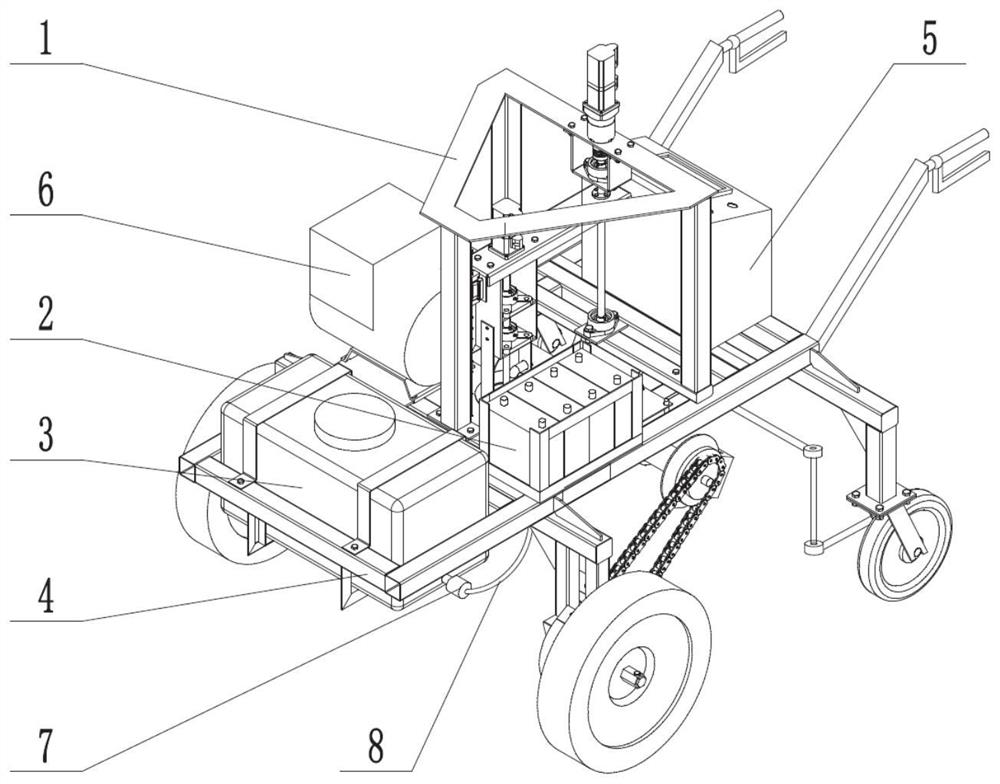

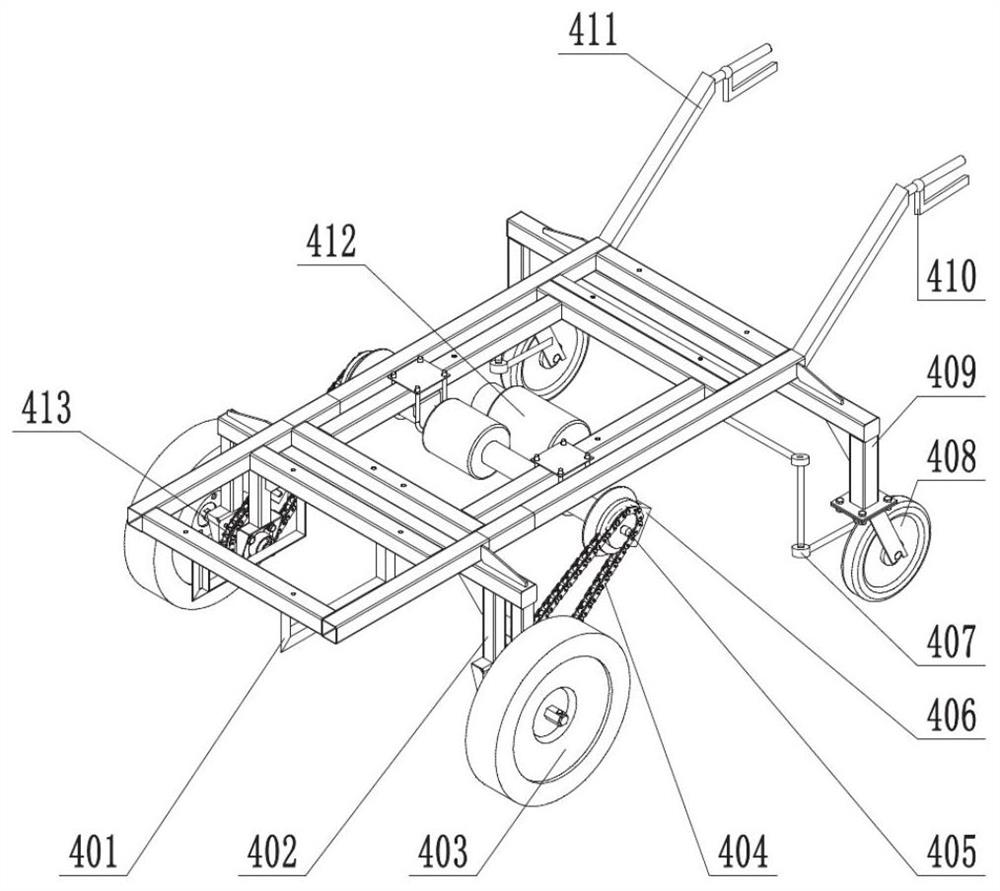

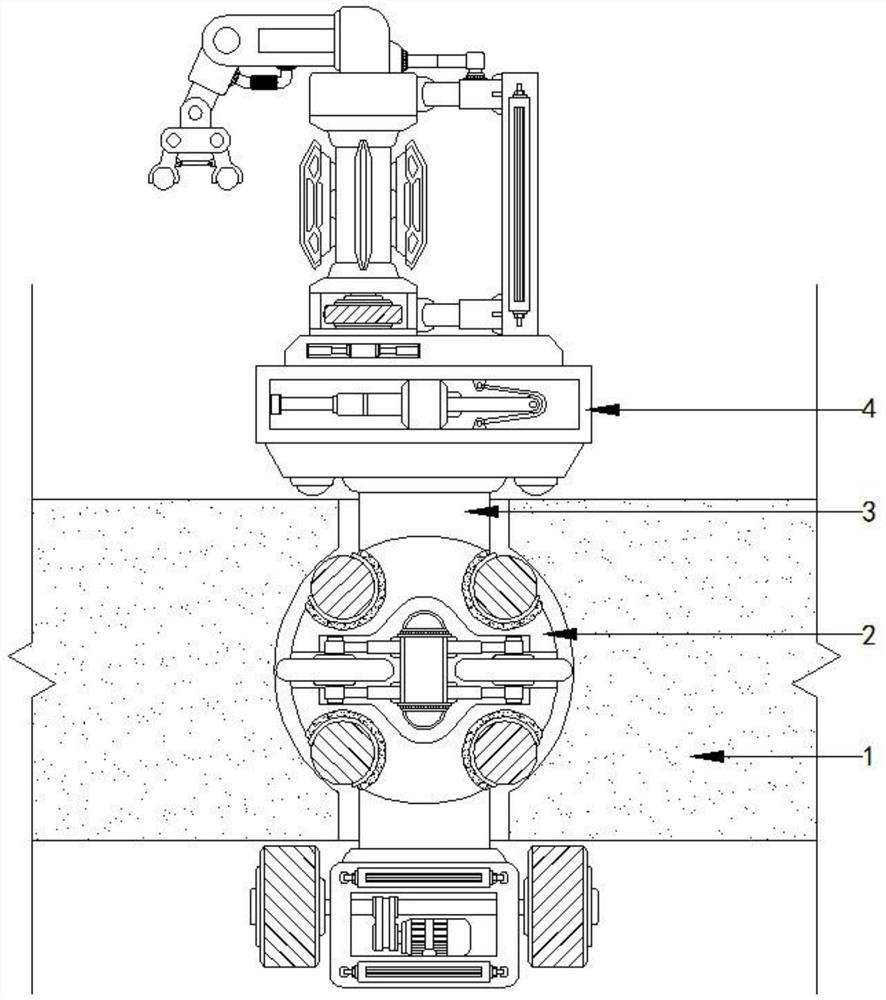

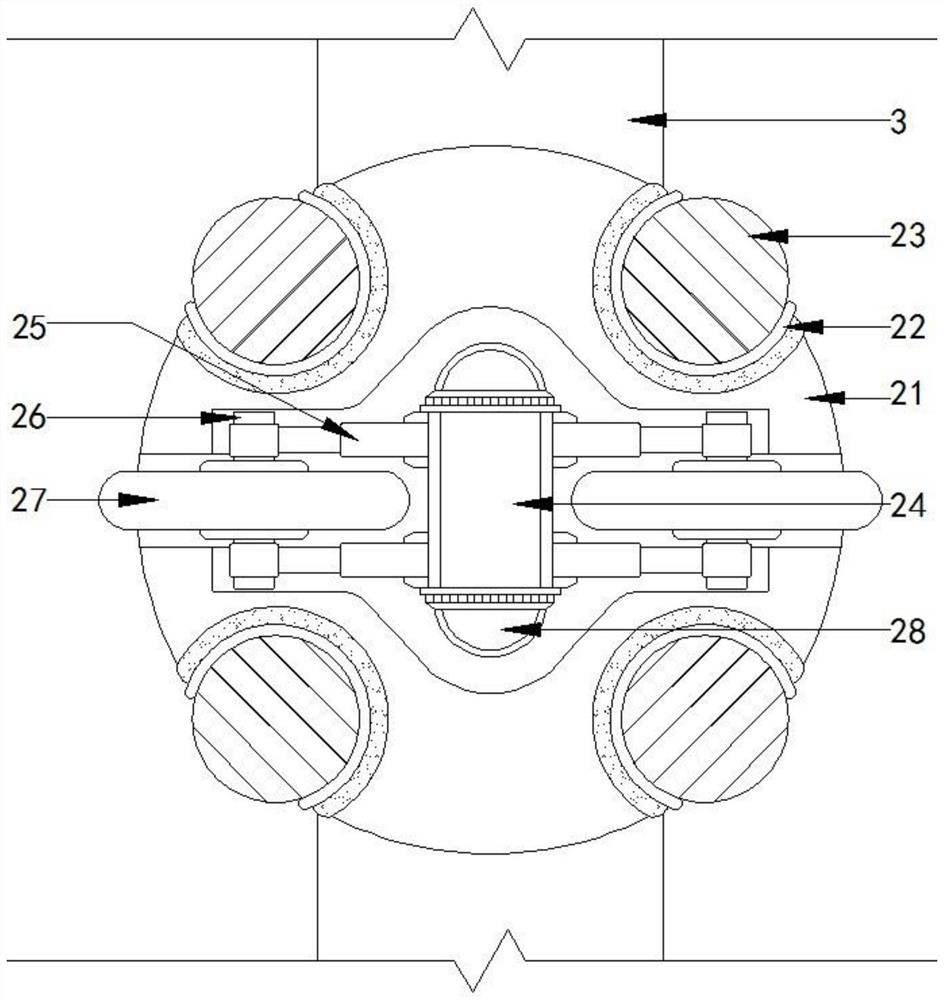

Intelligent electric-drive self-propelled tobacco well cellar water-injecting and punching machine and method

ActiveCN111788900AQuality improvementReduce dependencePlantingFurrow making/coveringPunchingWater flow

The invention relates to an intelligent electric-drive self-propelled tobacco well cellar water-injecting and punching machine and a method, and belongs to the field of tobacco transplanters. The punching machine comprises a mobile base and a punching mechanism arranged on the mobile base; the punching mechanism comprises a punching support and a punching drill which is perpendicular to the ground; the punching support conducts vertical movement on the mobile base; the punching drill is rotatably fixed onto the punching support; the top of the punching drill is connected with a flow-guiding cover capable of irrigating the punching drill with water flows; and an intelligent control box which controls the base to move, controls the punching support to move vertically and controls the drill to rotate is arranged on the mobile base. According to the disclosed punching machine, through the punching mechanism, installed on the upper portion, in coordination with the control box, punching work is completed between clearances of a walking mechanism, and meanwhile, water is injected into the punching mechanism from a water tank, so that the punching quality is guaranteed.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI +1

Physical split phase dynamic polymer and application thereof

InactiveCN109206826AImprove performanceSimple structureBulk chemical productionPolymer sciencePhase dynamics

The invention discloses a physical split phase dynamic polymer, which contains a block polymer molecule. The block polymer molecule contains at least two hard segments, and the hard segments are interconnected by at least one soft segment to form a hard segment-soft segment-hard segment structure in the block polymer molecule. The hard segments can be mutually mixed to and / or independently form crystal phases and / or phases incompatible with the soft segments, thereby forming split phase physical crosslinking points based on the hard segments. All the soft segments of the block polymer moleculeare amorphous, and at least one soft segment contains at least one ligand group, which can form dynamic metal-ligand interaction with a metal center. And the soft segments of the block polymer molecule do not contain secondary amino or hydrogen bond donor group containing secondary amino. The dynamic polymer has shape memory function, self-repair function and super-toughness, and has wide application in biomedical materials, military, aerospace, energy, construction and other fields.

Owner:厦门天策材料科技有限公司

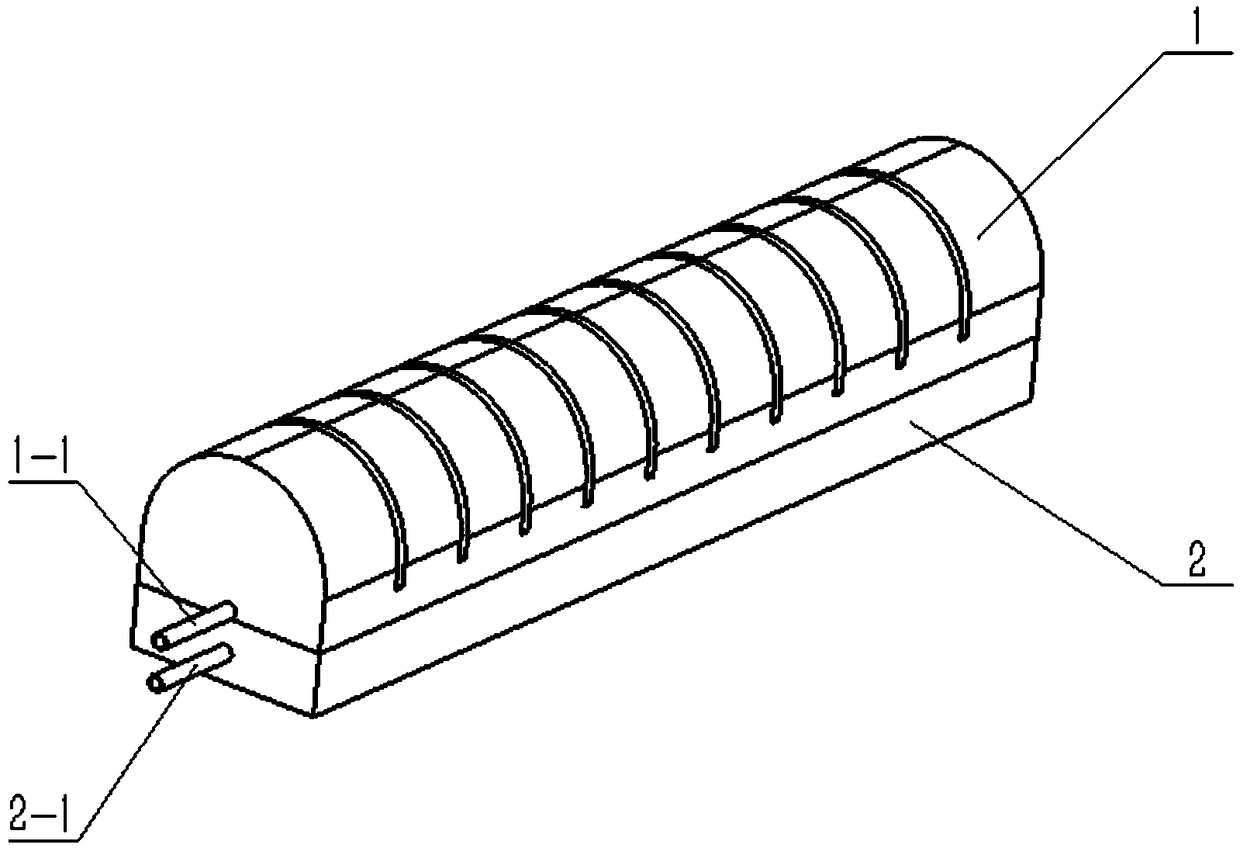

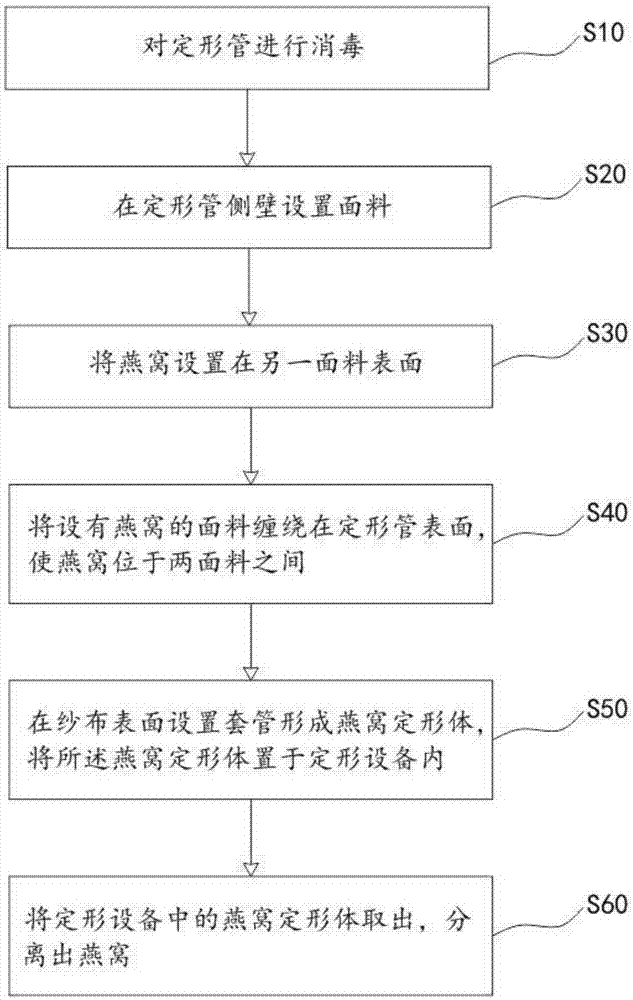

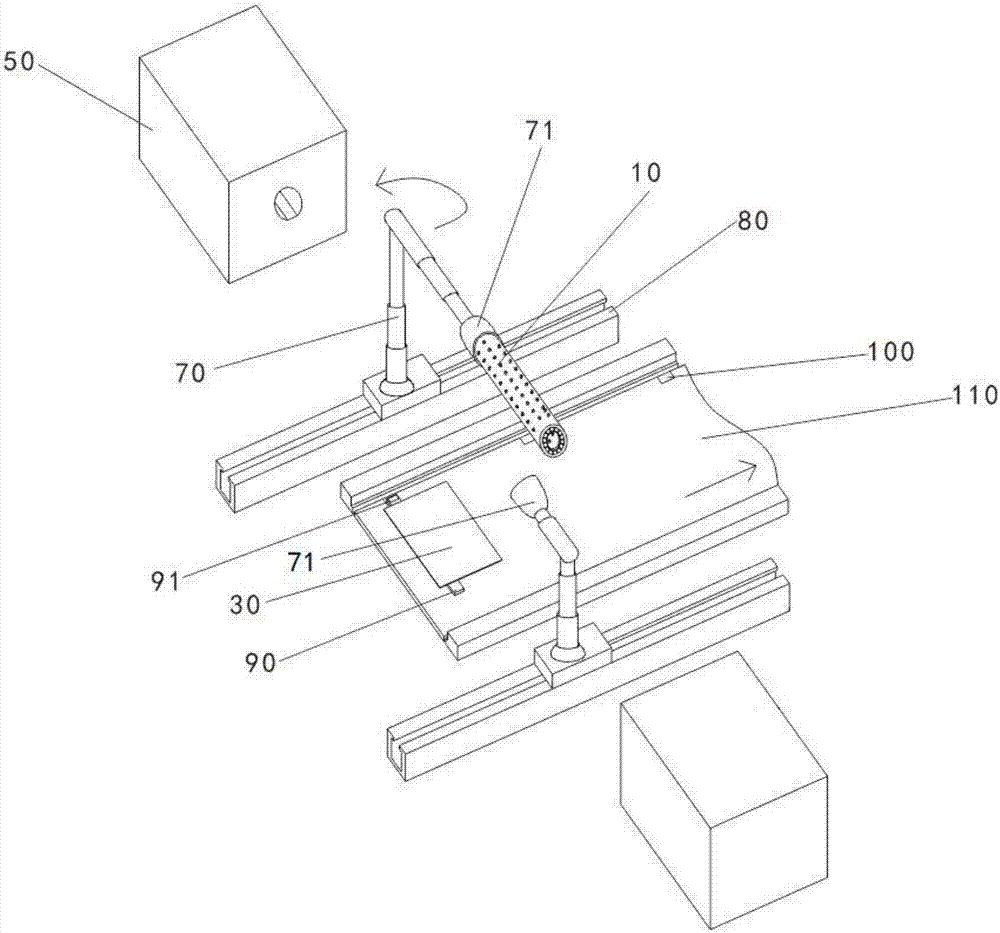

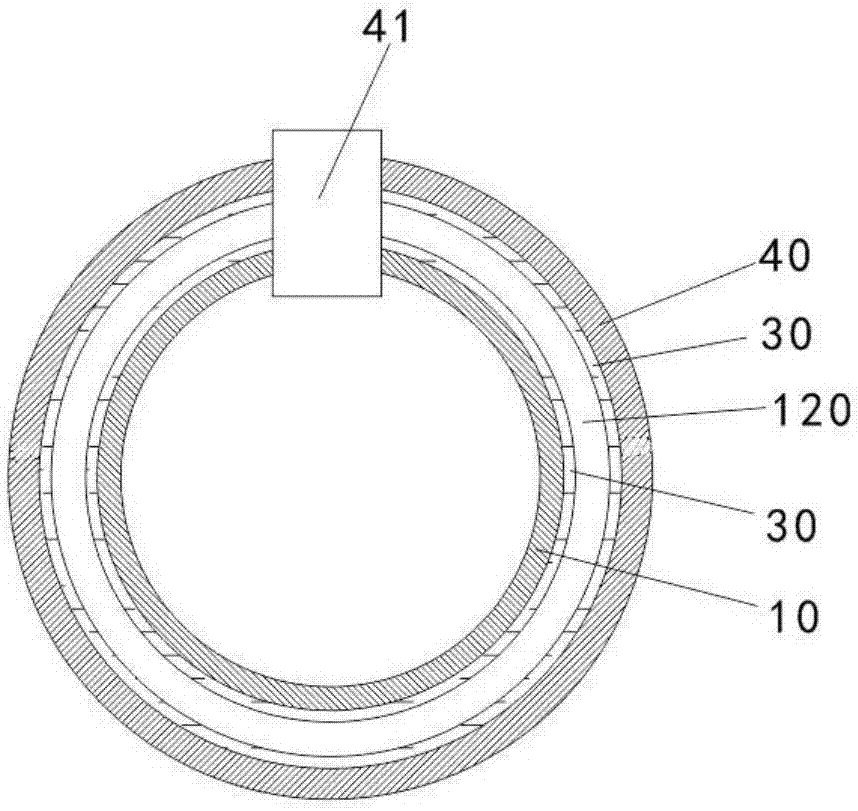

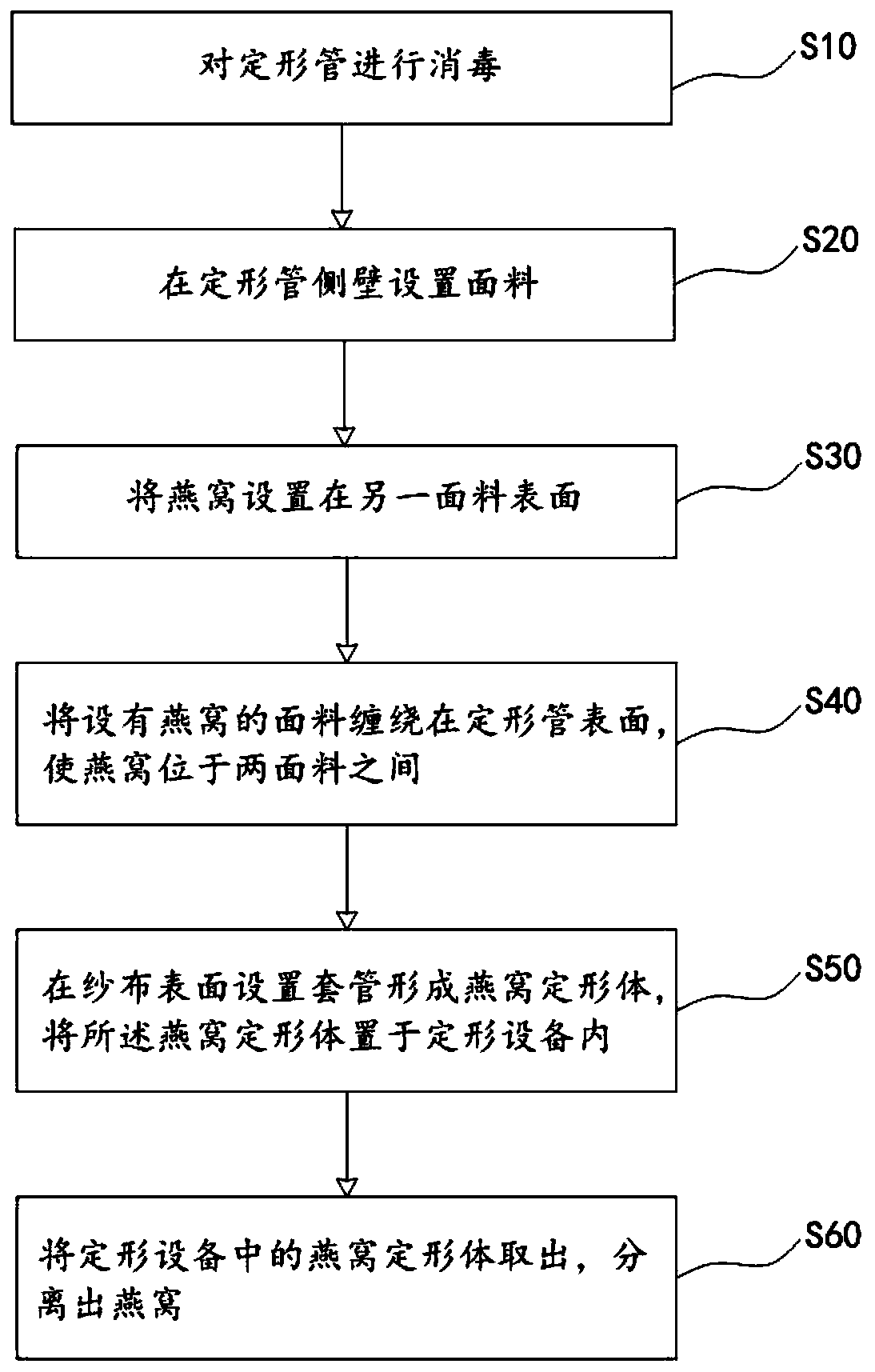

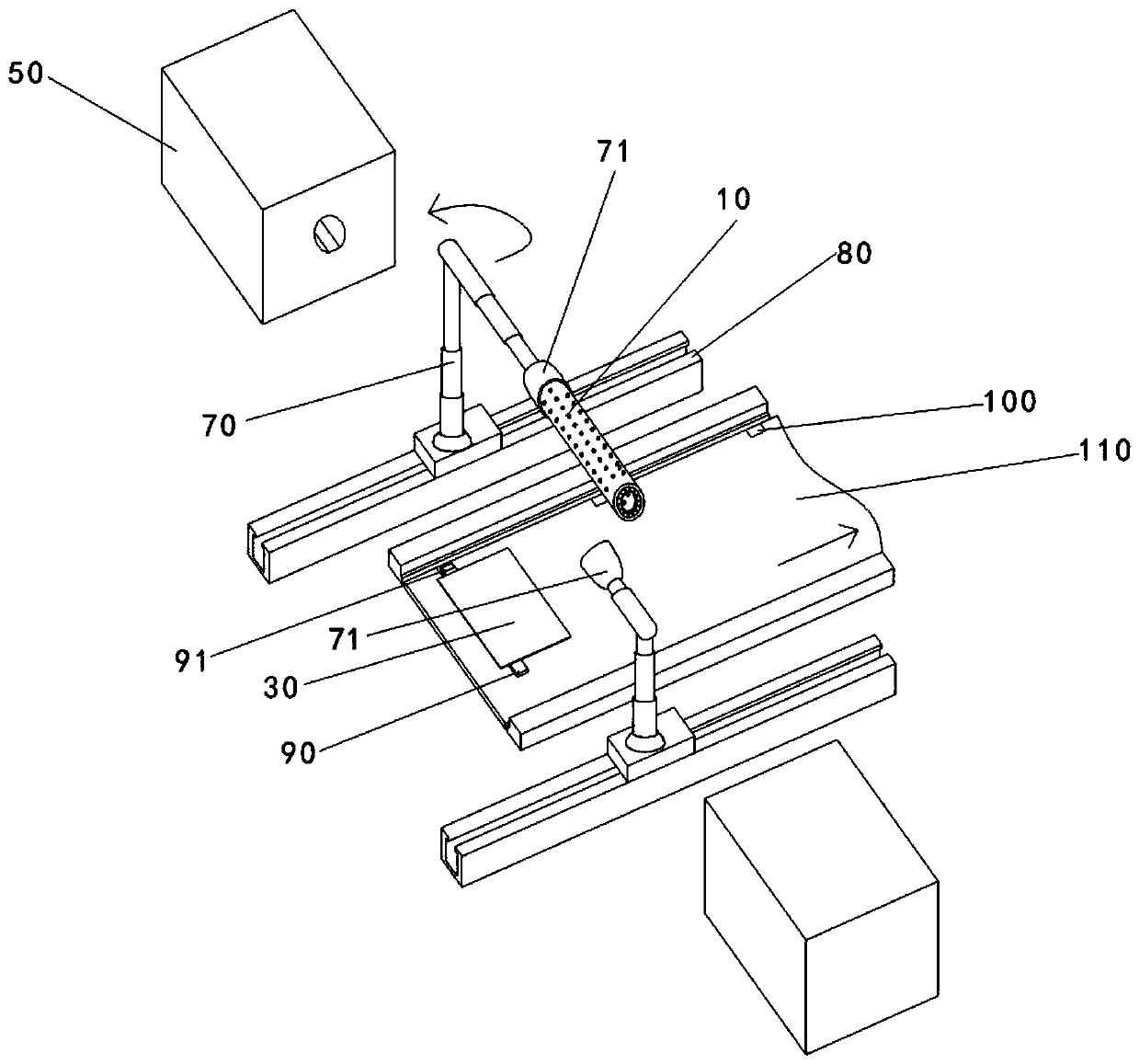

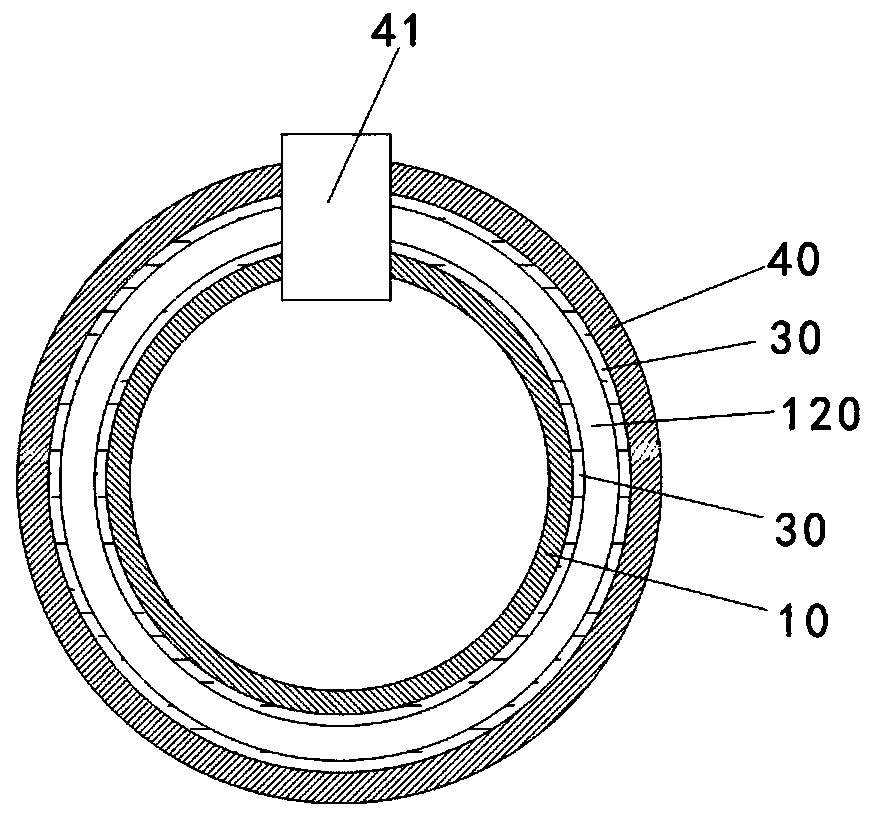

Stewed-bird's-nest setting method and system

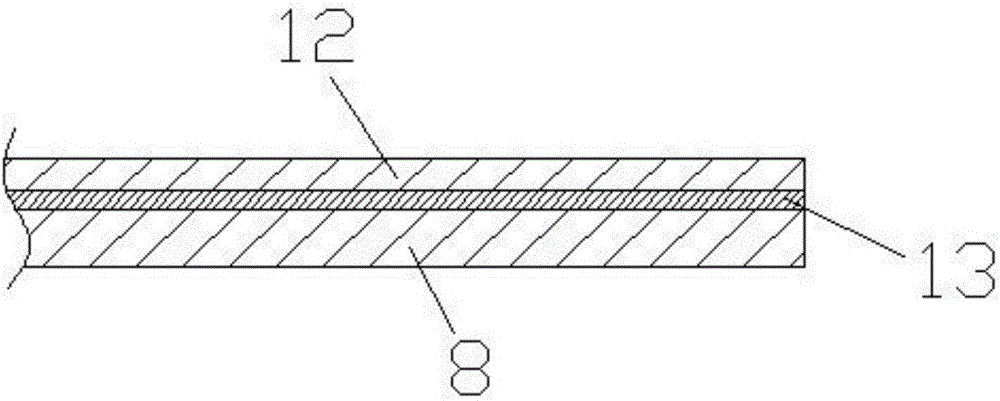

The invention provides a stewed-bird's-nest setting method and system. The method specially includes: disinfecting a setting tube; arranging fabric on the side wall of the setting tube; placing bird's nest on the surface of the other fabric; coiling the fabric with the bird's nest on the surface of the setting tube to allow the bird's nest to be located between the two fabric; arranging a sleeve on the surface of a gauze to form a bird's nest setting body and arranging the bird's nest setting body in setting equipment; taking out the bird's nest setting body from the setting equipment to have the bird's nest separated out. With the method, the stewed bird's nest is short in stewing time, easy to disperse evenly and better in taste; the setting system used for implementing the stewed-bird's-nest setting method is simple in structure, the fabric is fixed through a fabric coiling system, fixing efficiency of the fabric is improved, and integral setting efficiency of the bird's nest is increased; through cooperation use of various parts of the entire setting system, setting of the stewed bird's nest is realized.

Owner:燕之初健康美(厦门)食品有限公司

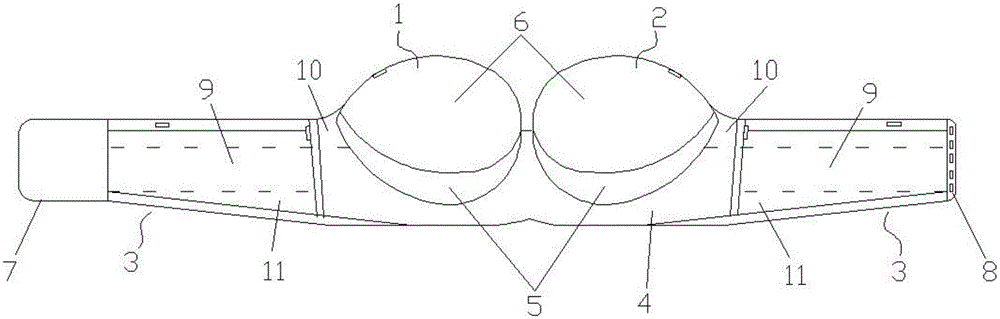

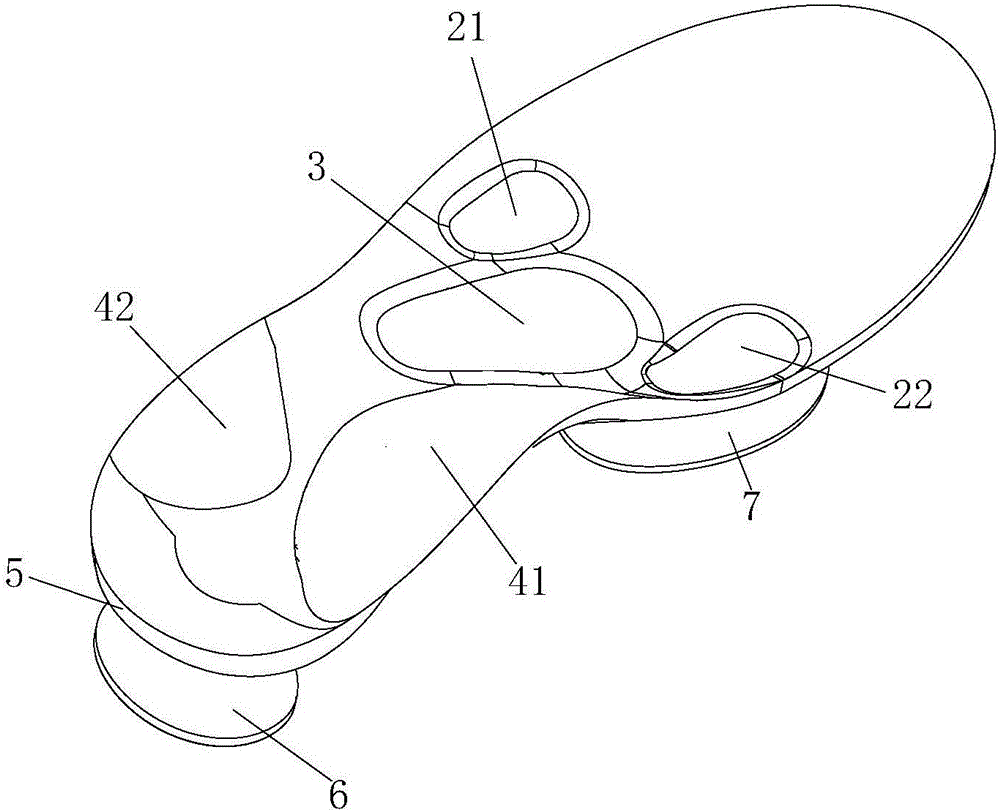

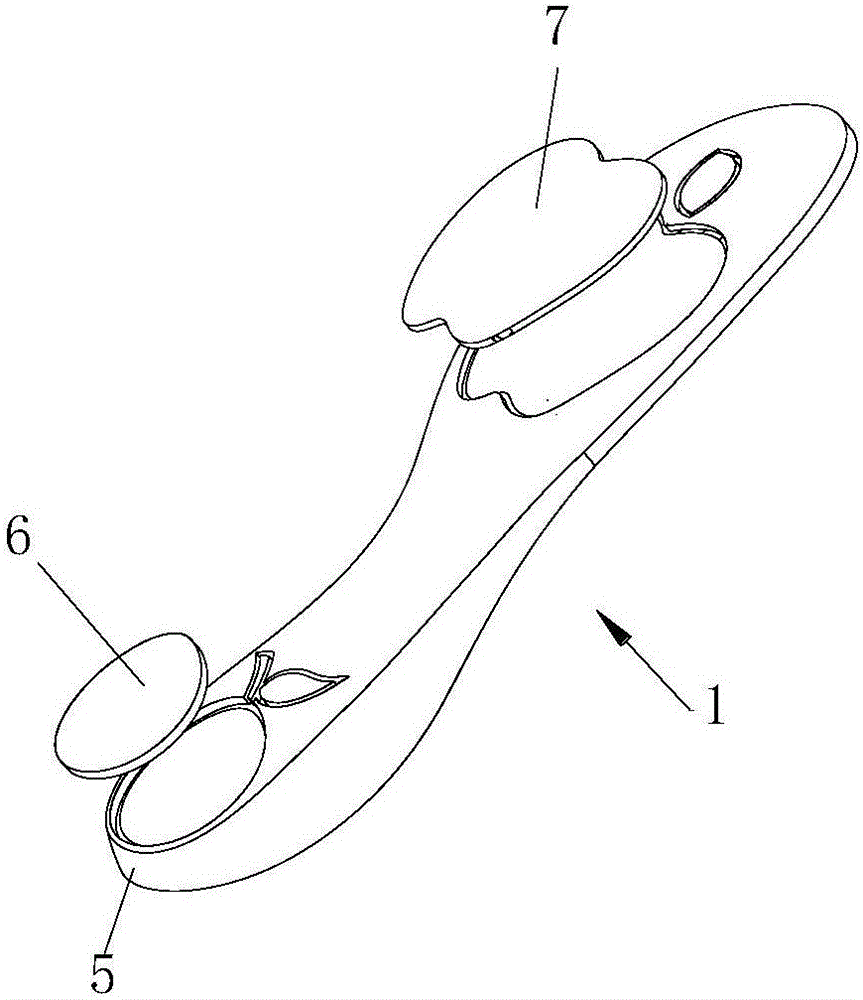

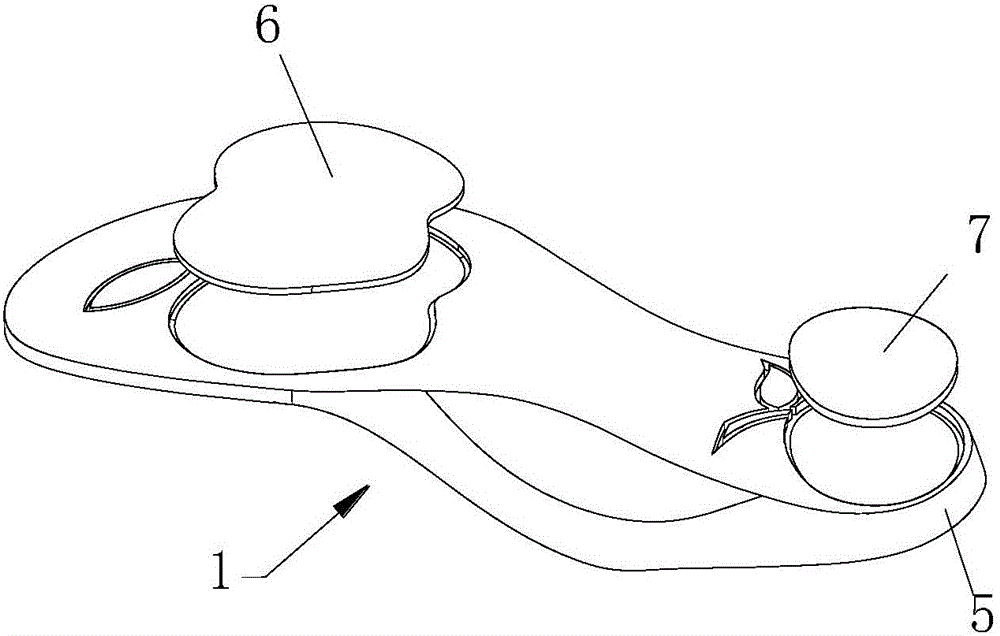

Bra without shoulder straps and steel rings

InactiveCN105942596ATo achieve the effect of lifting and gatheringAchieve shapeBrassieresEngineeringUpper limb girdle

Owner:金爱香

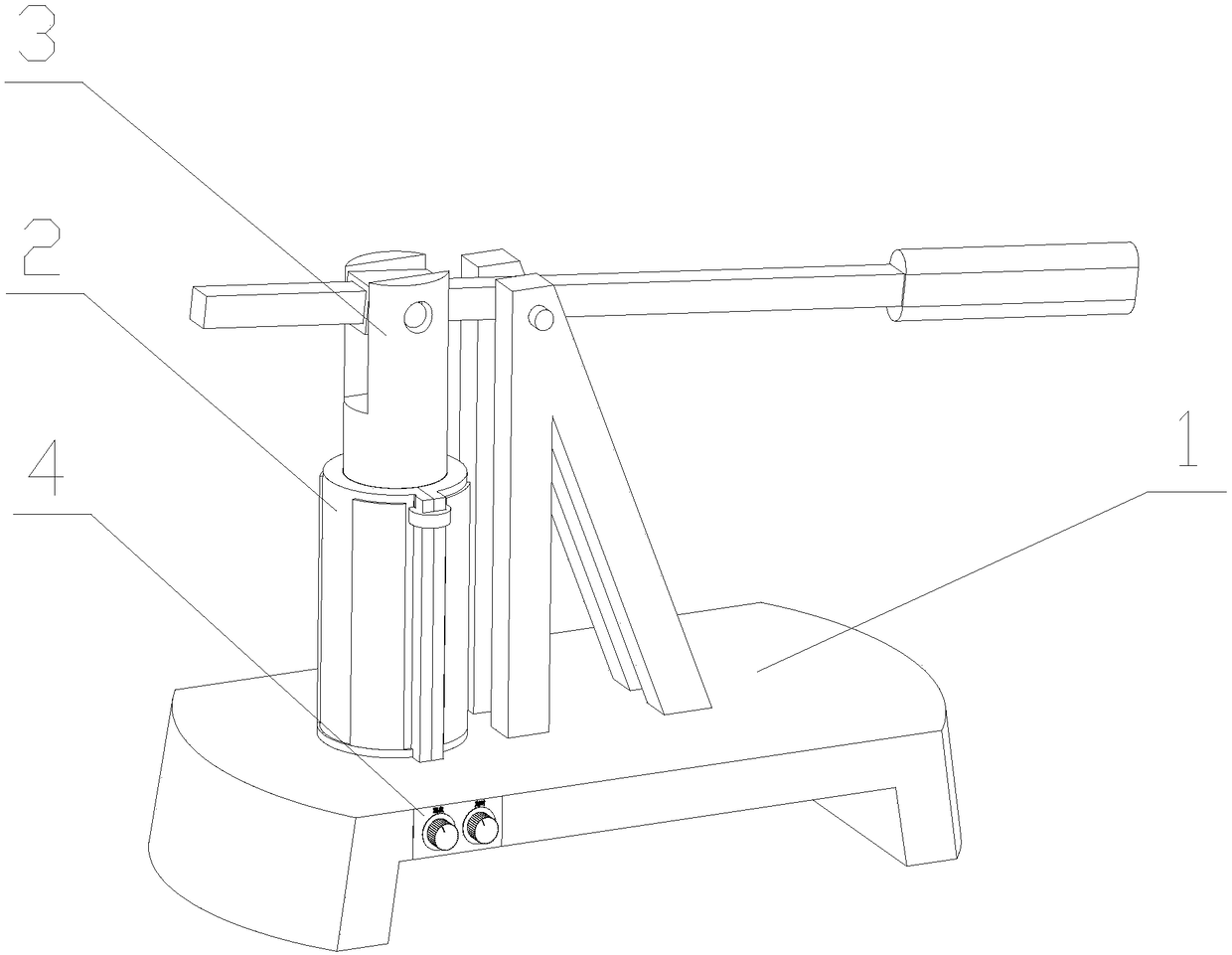

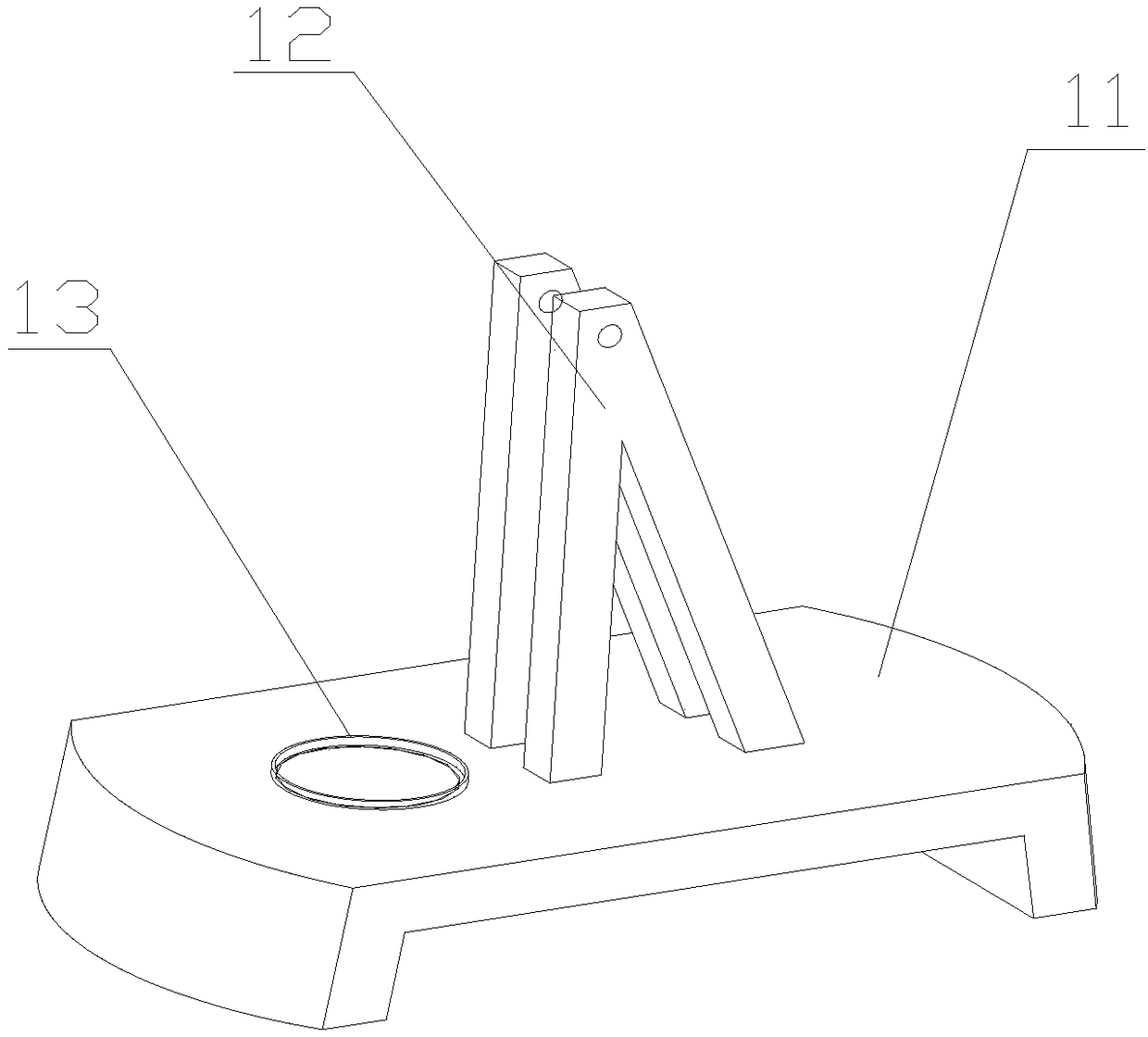

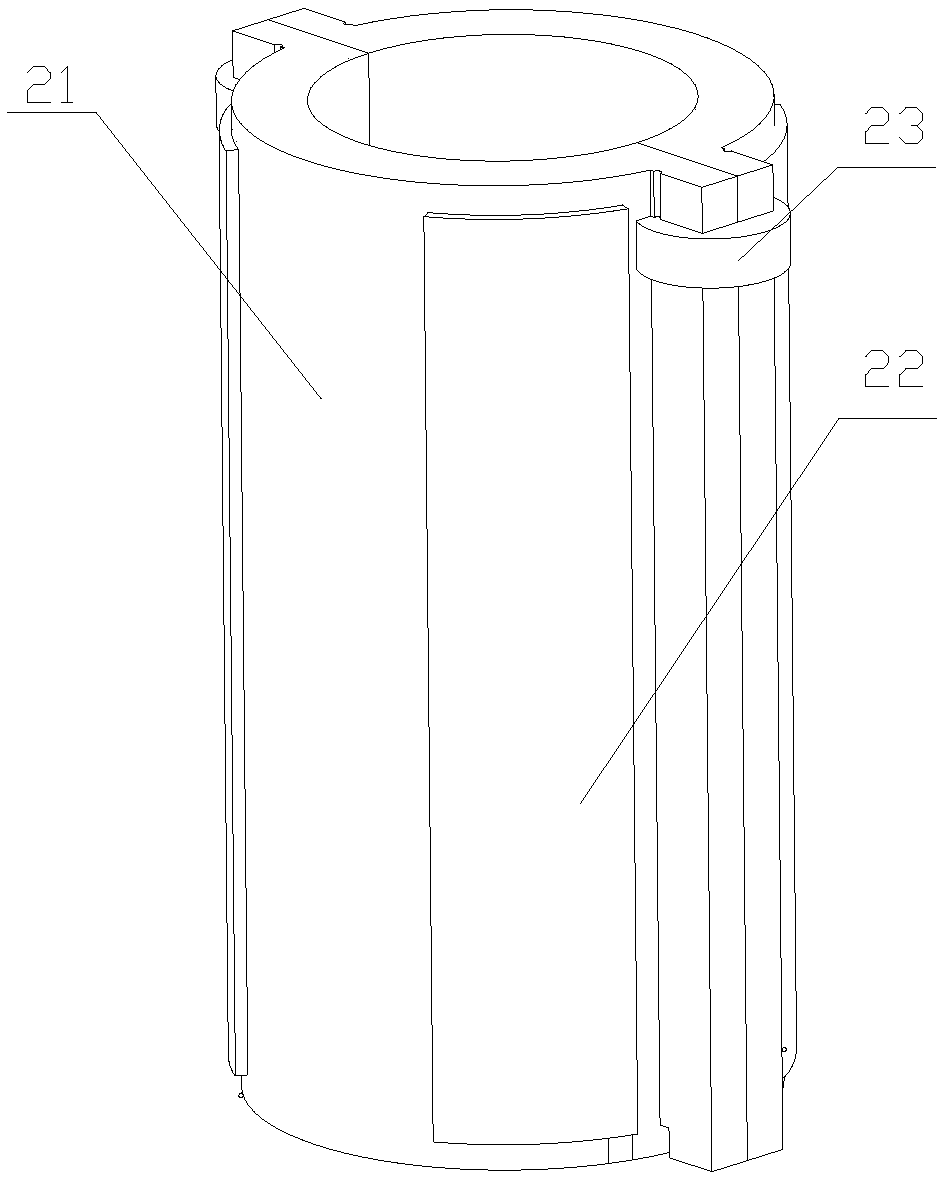

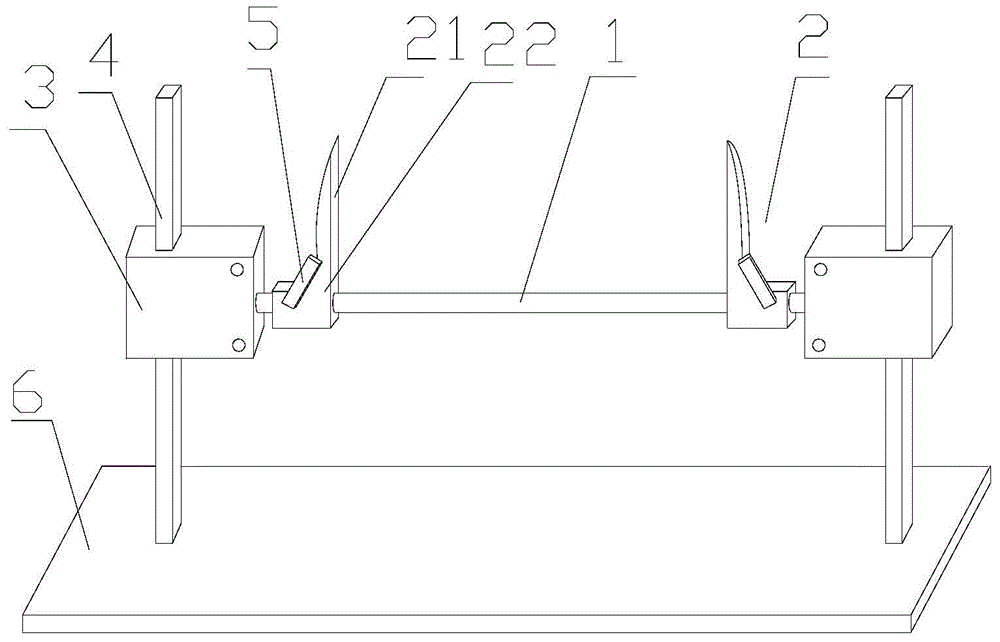

Device for producing cylindrical test piece for rock and soil test

InactiveCN109470536AAchieve supportAchieve fixed supportPreparing sample for investigationTemperature controlEngineering

The invention discloses a device for producing a cylindrical test piece for a rock and soil test, aims to achieve rapid production of the cylindrical test piece for the rock and soil test through a lever compacting device and an electric heating matched mould device integrating electric heating sheets, overcomes the defects of high labor consumption, long drying time, low production efficiency andthe like during the conventional smashing hammer knocking compaction, and achieves test piece production with high efficiency and low labor consumption. The device for producing the cylindrical testpiece for the rock and soil test comprises a machine frame device, the electric heating matched mould device, the lever compacting device and a timing and temperature control device. The device for producing the cylindrical test piece for the rock and soil test is convenient to operate and easy to maintain, and has a broad application prospect in the production of rock and soil test pieces.

Owner:QINGDAO UNIV OF SCI & TECH

Shoe-pad for shaping and correcting flatfoot during growth stage

The invention relates to the field of shoe-pads, and in particular relates to a shoe-pad for shaping and correcting flatfoot during growth stage. The shoe-pad comprises a shoe-pad body, wherein the shoe-pad body comprises a shoe-pad main body; the inner sides on two sides at the middle of the shoe-pad main body are respectively a left arch structure and a right arch structure; a U-shaped convex edge matched with a heel is arranged at the heel end edge of the shoe-pad main body; a middle bulge is arranged at the middle part of the surface of the shoe-pad main body; a left concave point and a right concave point are respectively and correspondingly arranged on two sides of the middle bulge; a slotted hole A and a slotted hole B are respectively formed in the forefoot and the heel at the under face of the shoe-pad main body; a damping piece A and a damping piece B are respectively embedded in the slotted hole A and the slotted hole B. The shoe-pad for shaping and correcting flatfoot during the growth stage is simple in structure, capable of playing a role of shaping, correcting and improving flatfoot, and capable of damping an impact force when a flatfoot steps on ground and a bigger ground gripping force after the flatfoot steps on ground; the impact force when the flatfoot steps on ground is effectively damped, so that the flatfoot is effectively protected.

Owner:唐潇

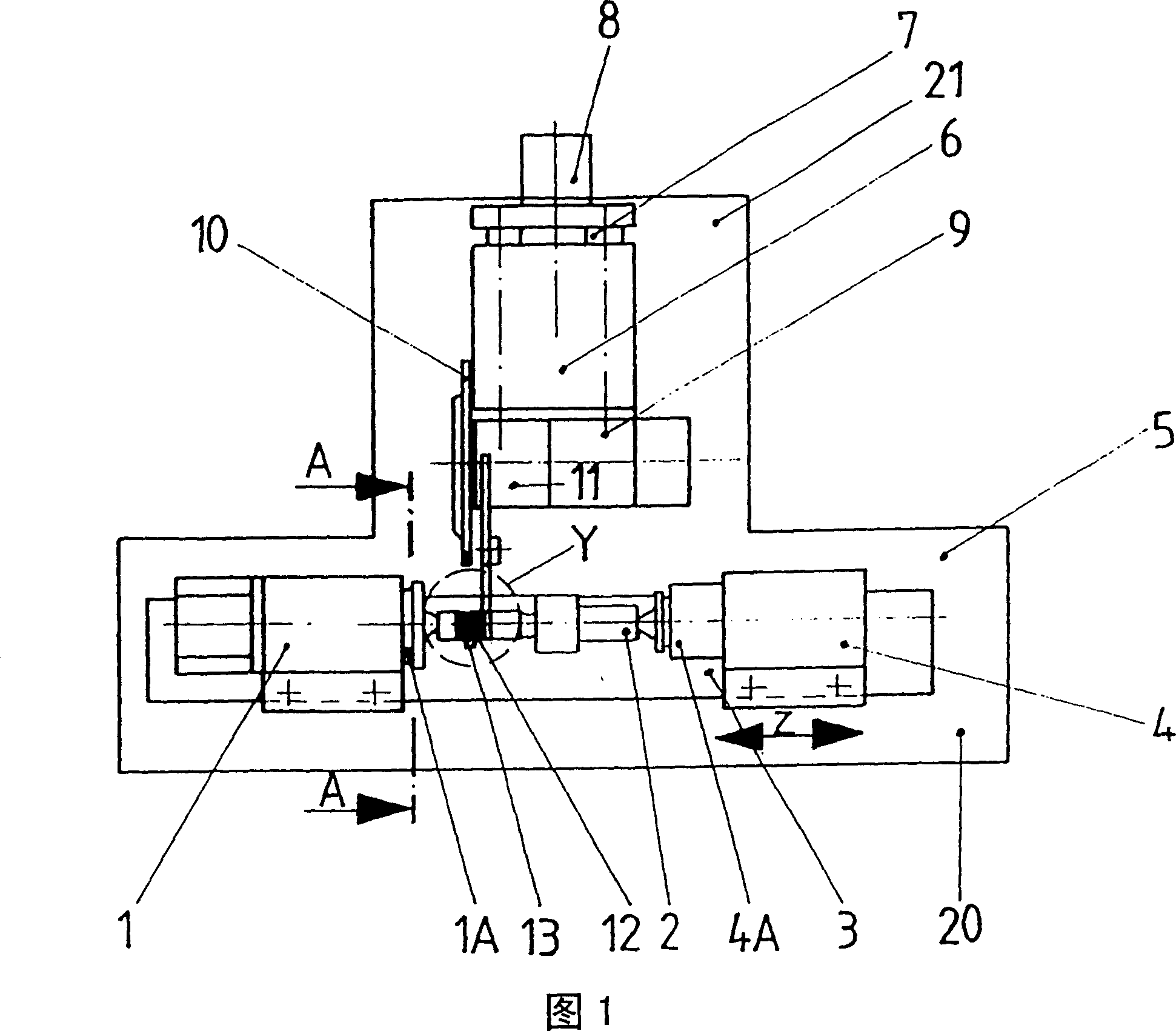

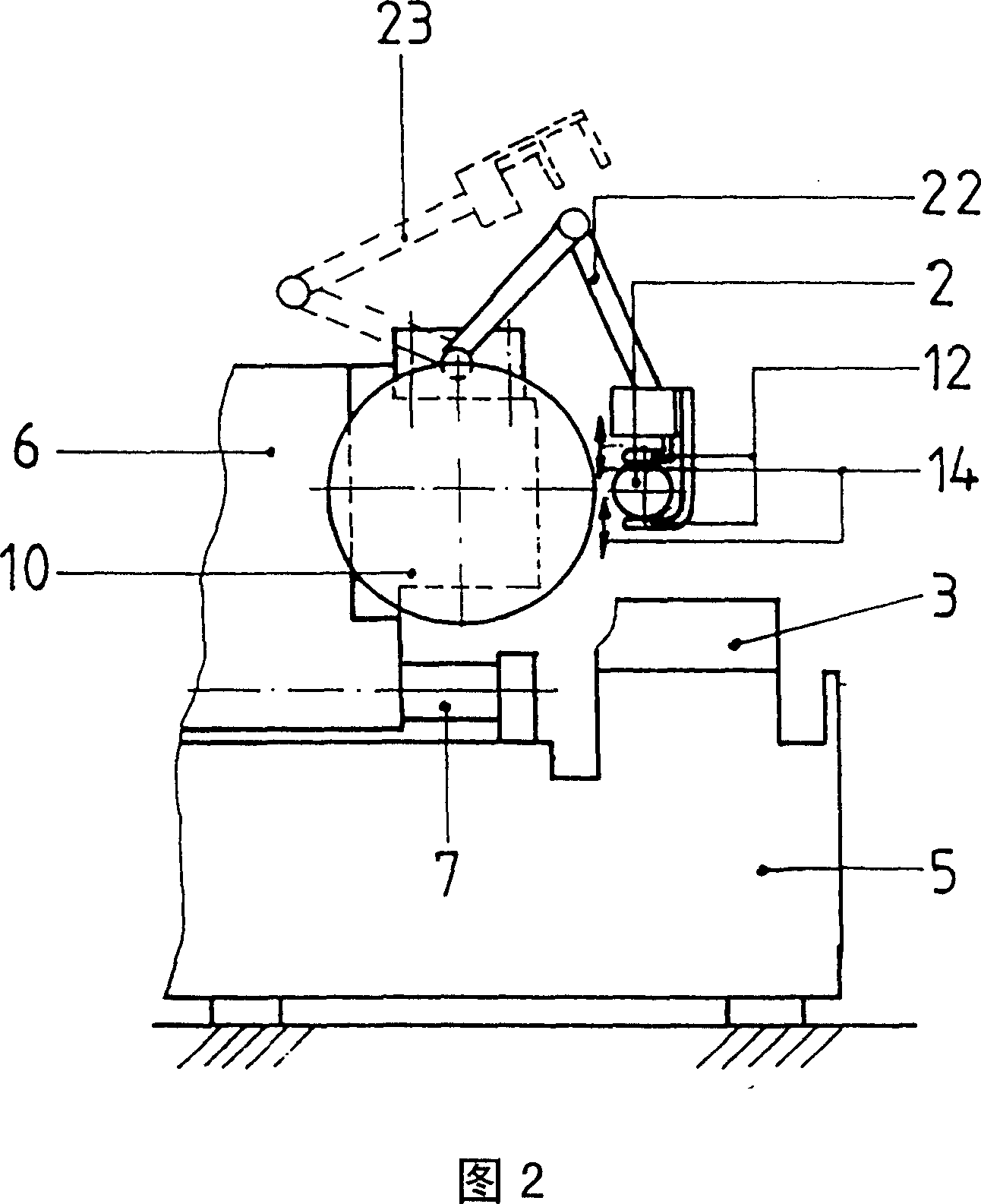

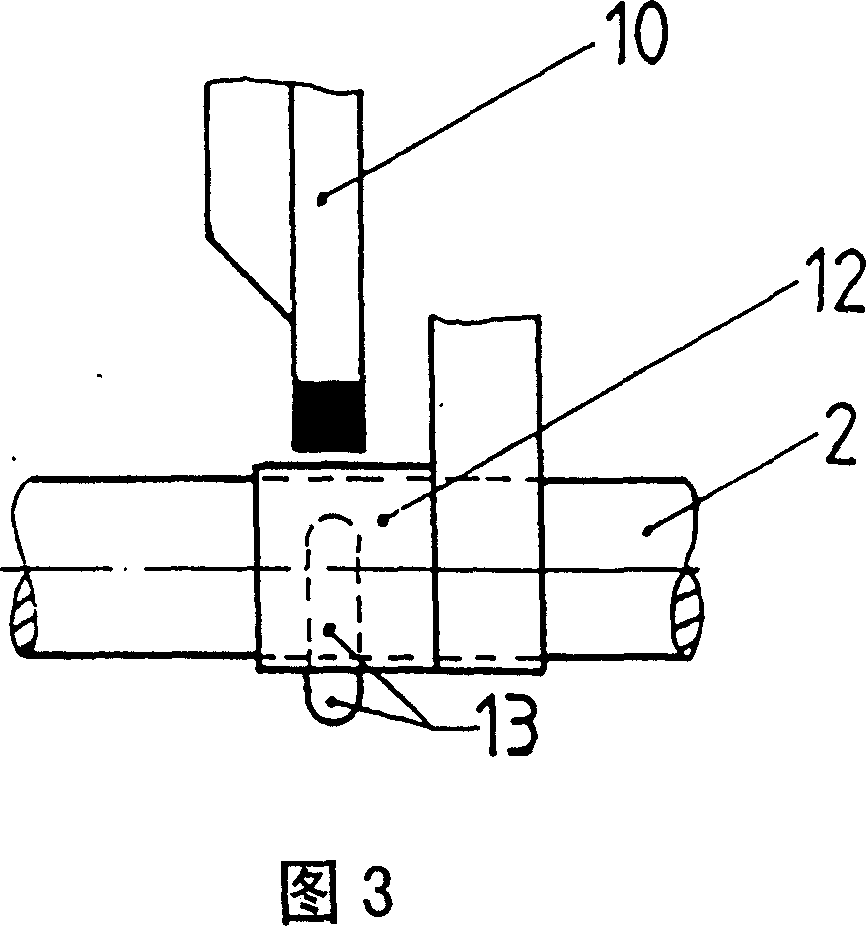

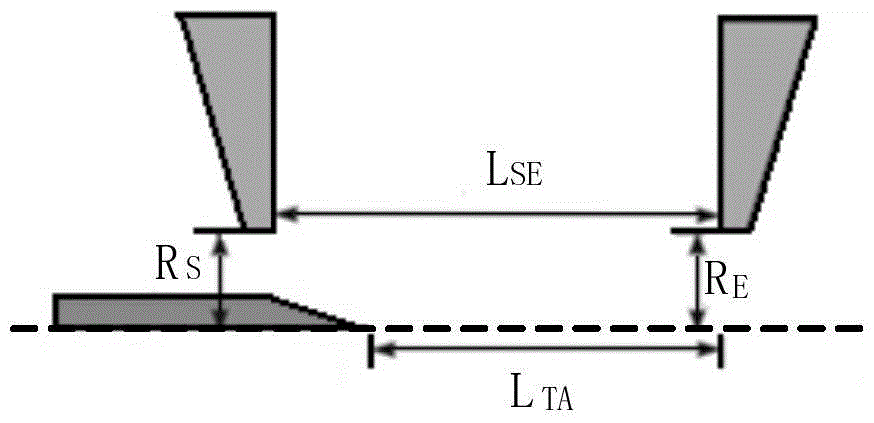

Method and grinding machine for controlling process during grinding of workpiece

InactiveCN100339184CReduce wearAvoid substandard sizesProgramme controlRevolution surface grinding machinesMachining processEngineering

The invention relates to a method for controlling the process during rough grinding of a workpiece in which, according to the invention, the workpiece is measured during grinding by a sensor to ascertain an actual size, and the measured actual size is corrected in a continuously automatic manner to attain a predetermined specified size according to grinding time. The invention also relates to a grinding machine which is provided for carrying out the method and which comprises a grinding wheel for rough grinding a workpiece on a grinding spindle head. The grinding machine also has a sensor for detecting a ground workpiece dimension, and comprises a machine control, whereby the workpiece is held between a workpiece spindle and a tail spindle. According to the invention, the sensor is arranged primarily in a plane formed by the contact area of the grinding wheel which turns on the workpiece, and during rough grinding, said sensor continuously transmits measurement signals to the machine control. Said machine control controls the grinding wheel based on these signals in such a way that the grinding process can be executed as an in-process control.

Owner:ERWIN JUNKER MASCHNINENFAB

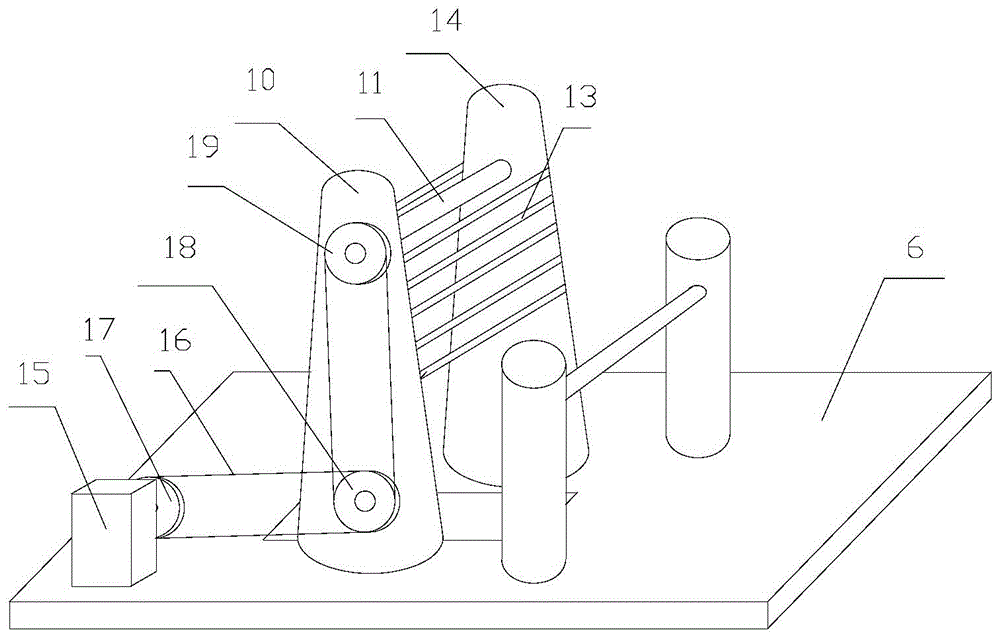

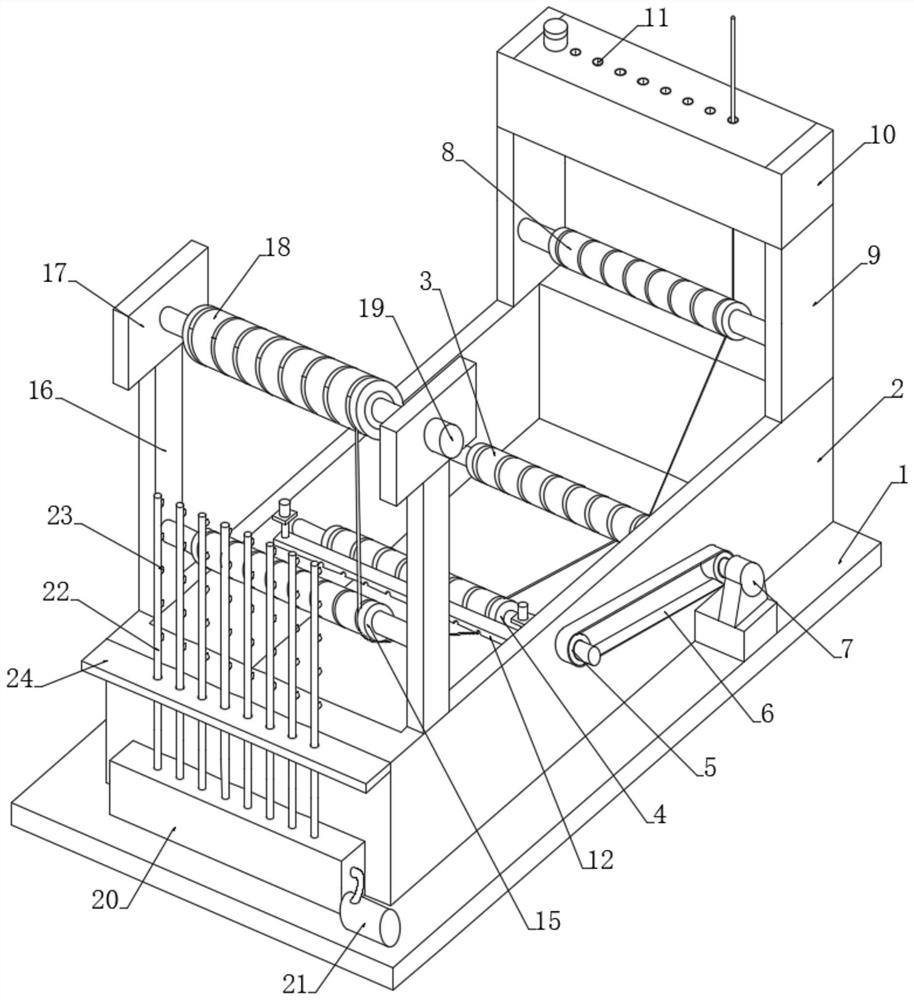

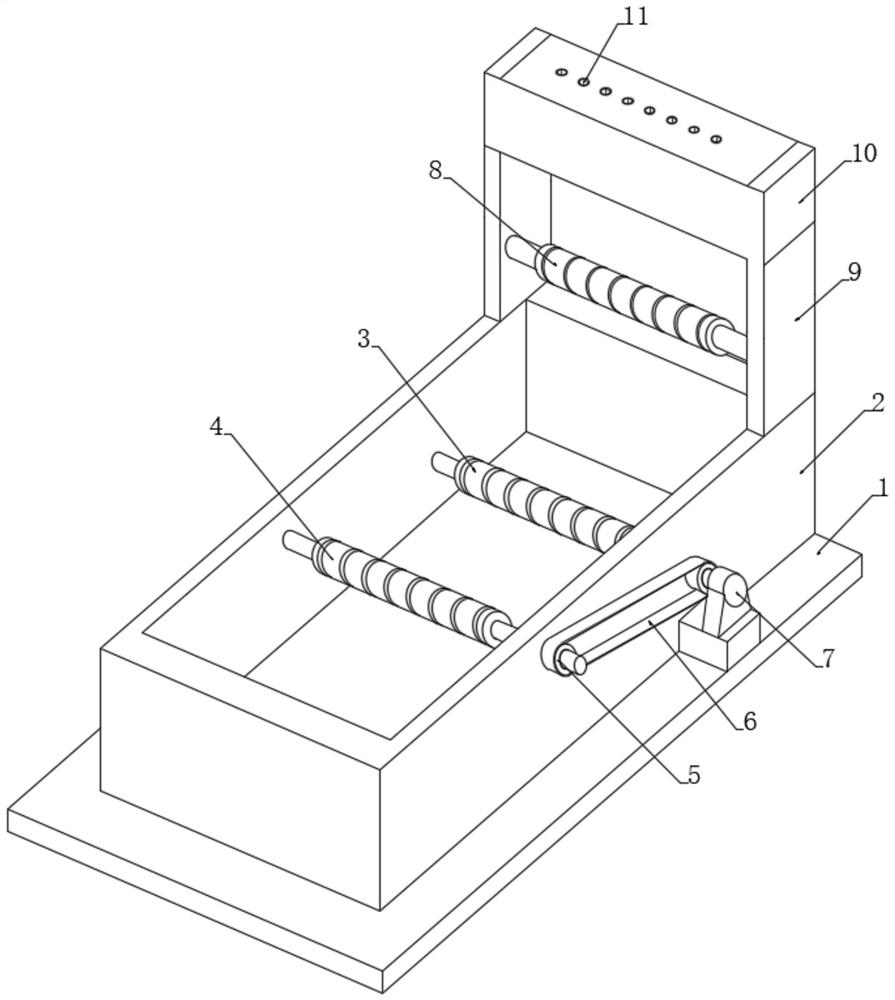

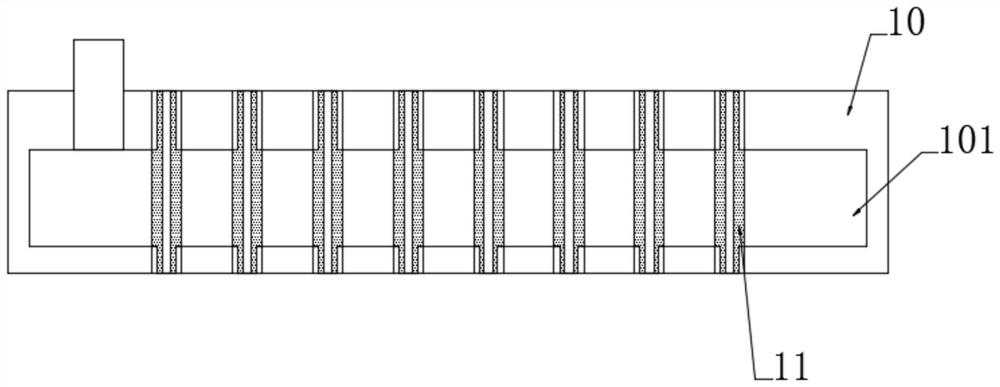

Bag making device

The invention discloses a bag making device which comprises supports, a conveying rotating shaft (11), a transmission mechanism, a bottom plate (6) and multiple shaping rods (13), wherein a discharging opening is formed in the bottom plate (6), the supports are arranged on the bottom plate (6) and at two sides of the discharging opening (3); the shaping rods (13) are fixedly connected to the supports and are arranged right above the discharging opening; the conveying rotating shaft (11) is arranged at the top ends of the supports and is driven to rotate through the transmission mechanism.According to the bag making device, the problem in the prior art that the raw material is likely to deform when blown out of the discharging opening can be solved and the raw material shaping during the blowingout process is realized.

Owner:TONGLING FOUNDER PLASTICS TECH

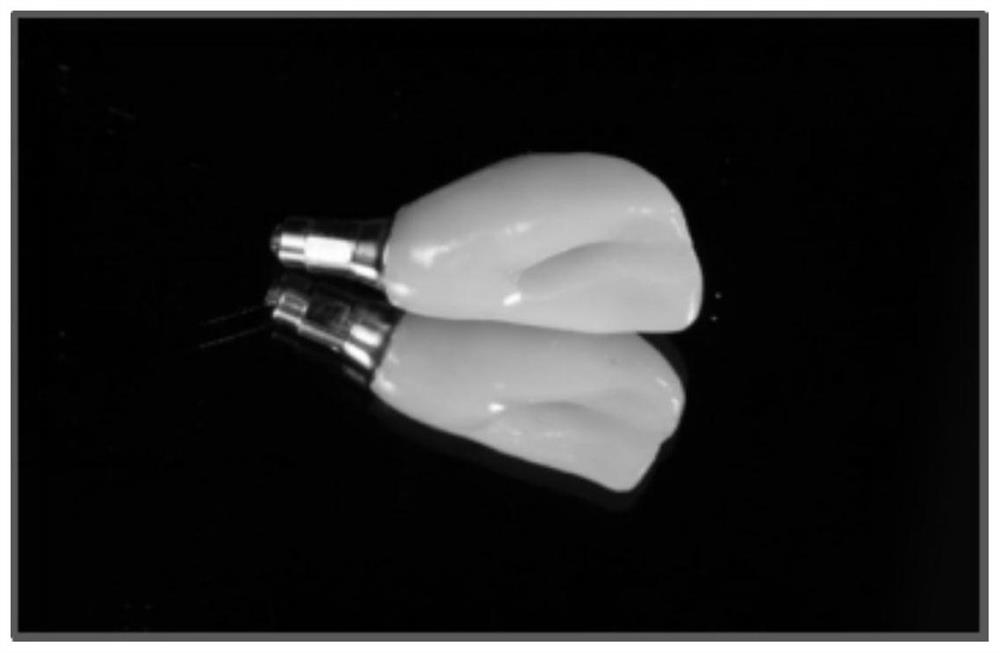

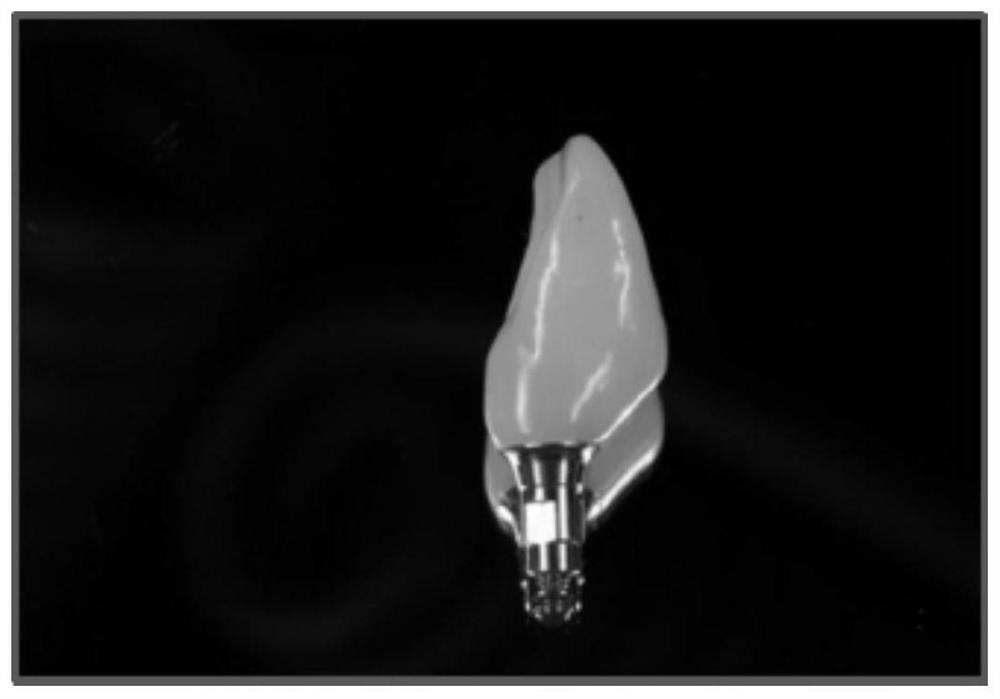

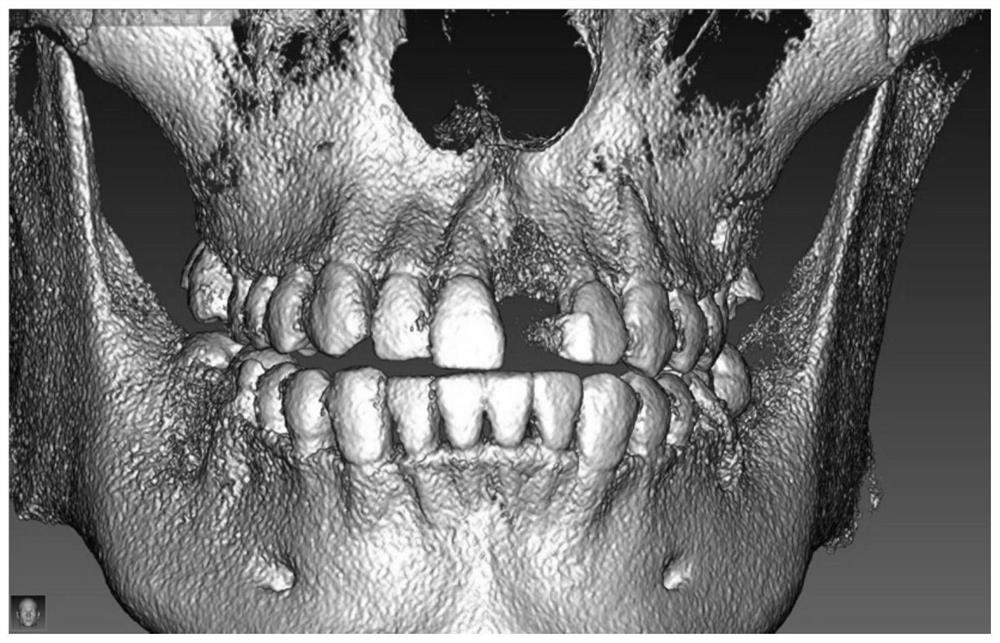

Individualized abutment-crown integration provisional prosthesis and preparation method and application thereof

ActiveCN111728719AGood application effectEsthetic soft tissue morphology around implantsDental implantsTooth crownsProsthesisTooth crown

The invention discloses an individualized abutment-crown integration provisional prosthesis. The provisional prosthesis comprises a tooth crown and a titanium base, wherein the tooth crown is bonded to the titanium base integrally; and a gum penetrating outline of the provisional prosthesis is in harmony with that of a natural tooth. The invention also discloses a preparation method and application of the individualized abutment-crown integration provisional prosthesis. The ideas of transplanting individualized aesthetic repairing and digital repairing are combined, the individualized abutment-crown integration provisional prosthesis which is suitable for an individual patient and is in harmony with the gum penetrating outline of the natural tooth is manufactured through digitization mirror image technical design; after an implant is transplanted for 3-6 months and stable synostosis is achieved, the provisional prosthesis is placed on a dental implant for parenchyma moulding on the aesthetic region implant periphery to obtain the individualized and aesthetic implant periphery parenchyma form, and ideal tooth implantation and repairing aesthetic effect is achieved.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

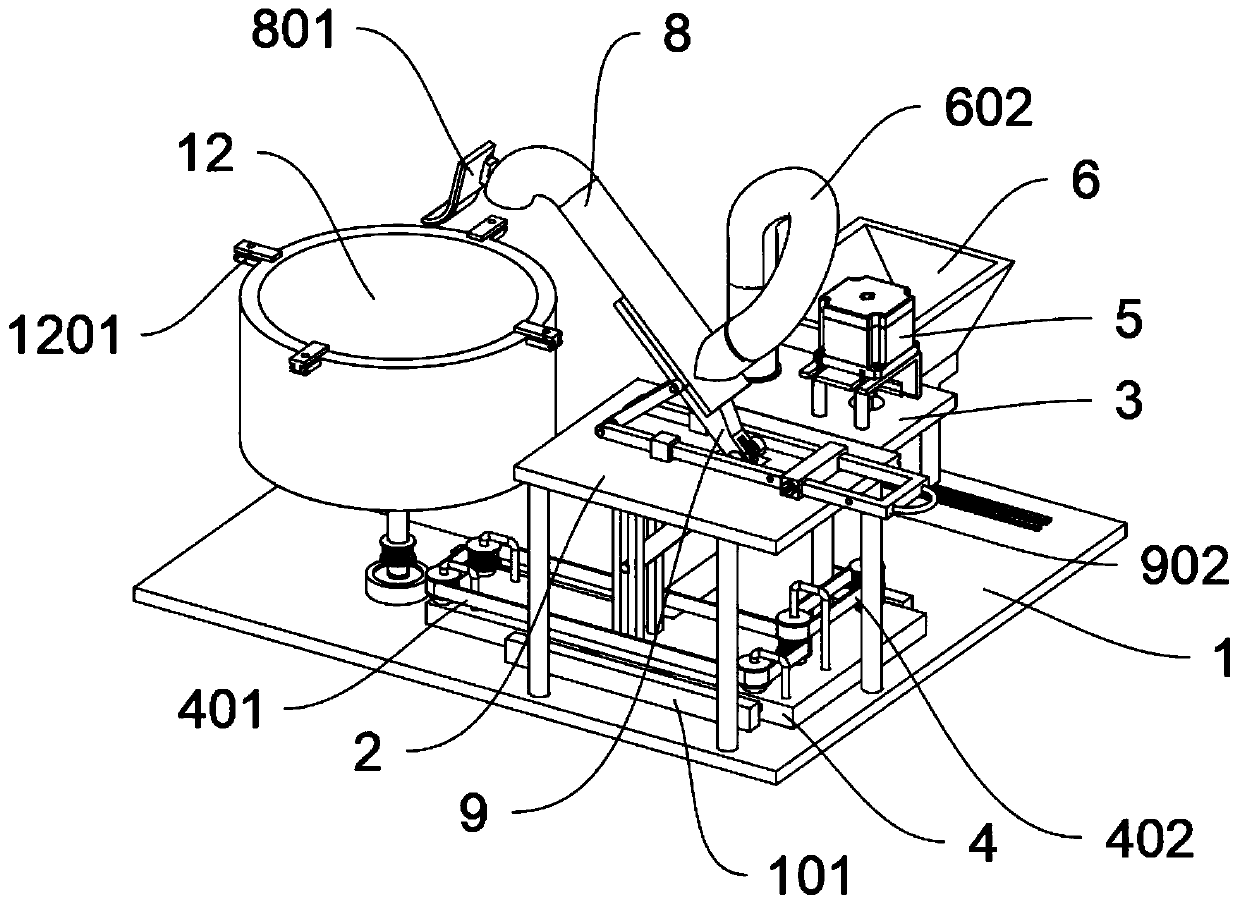

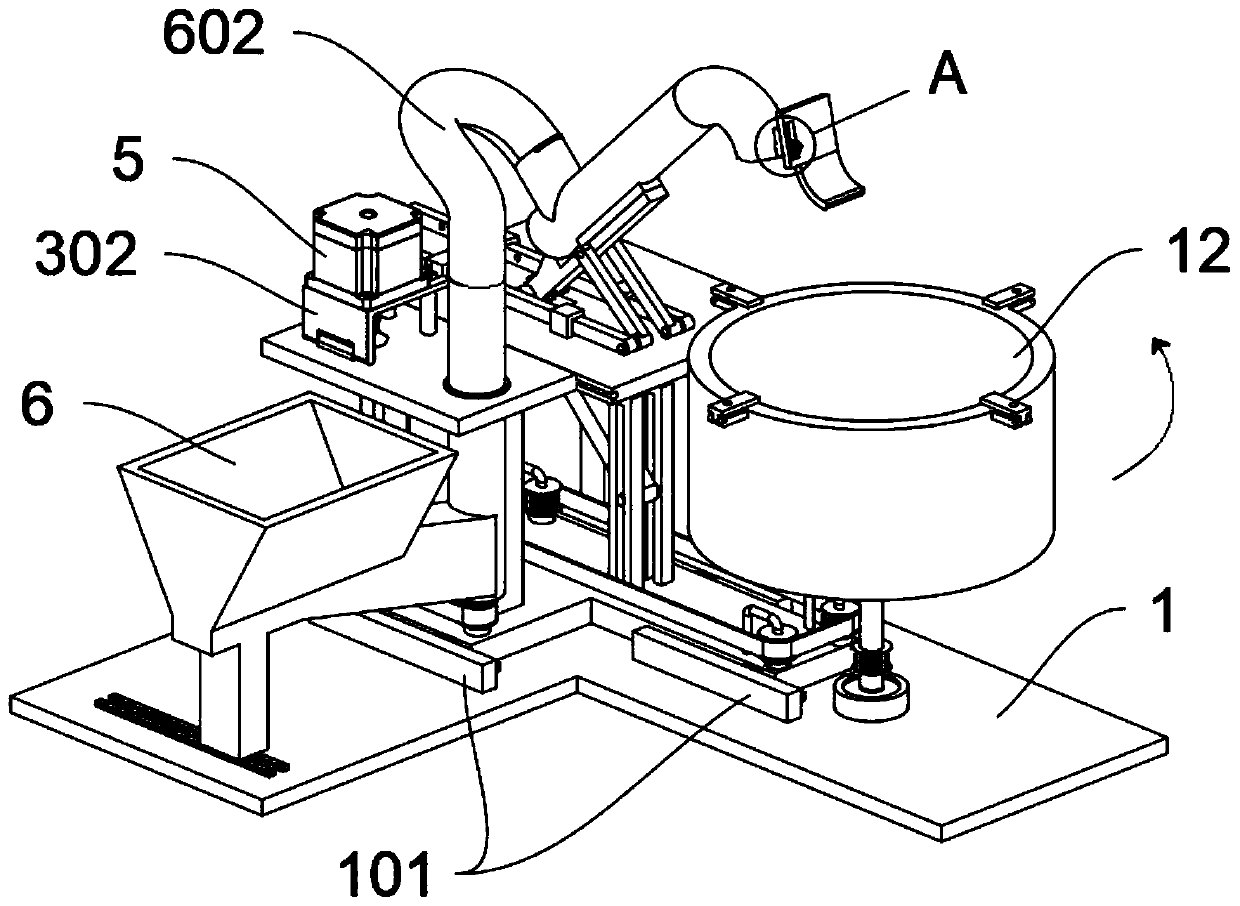

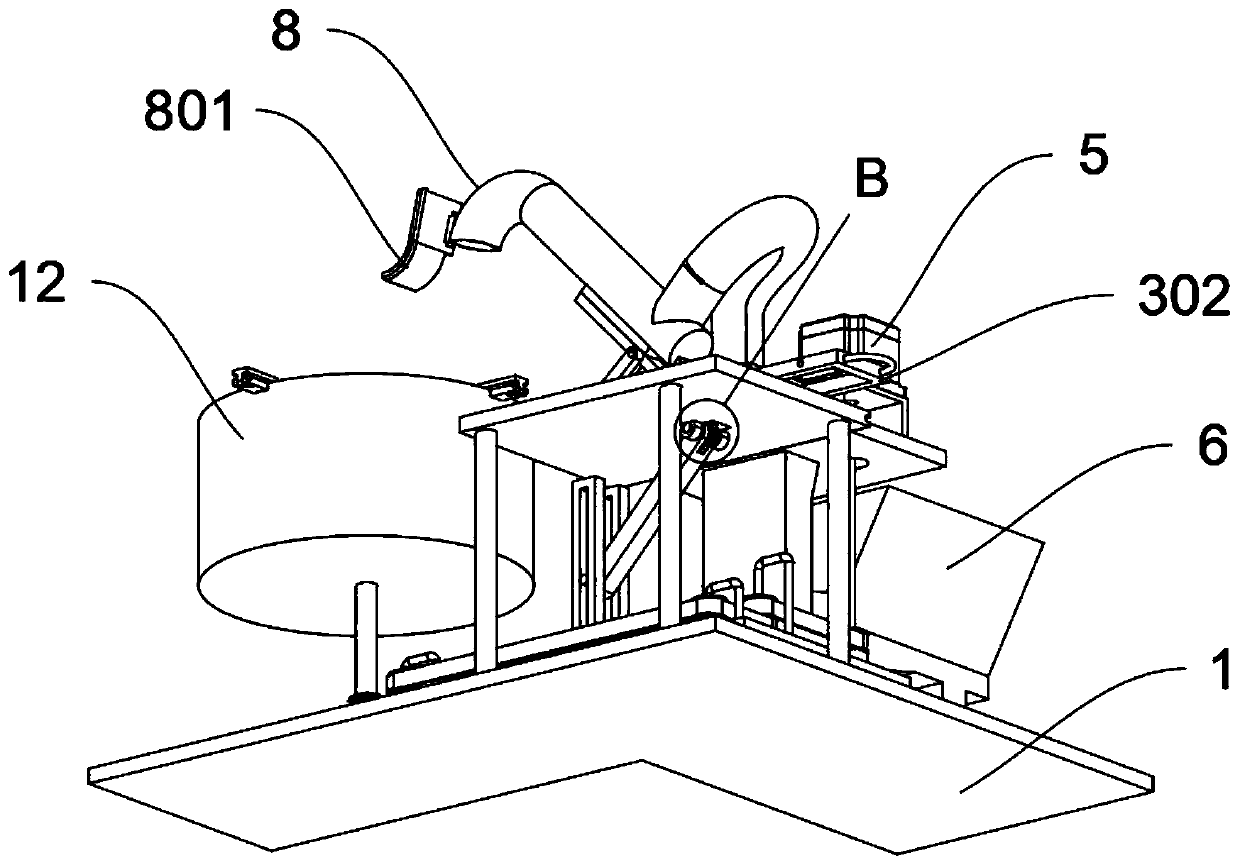

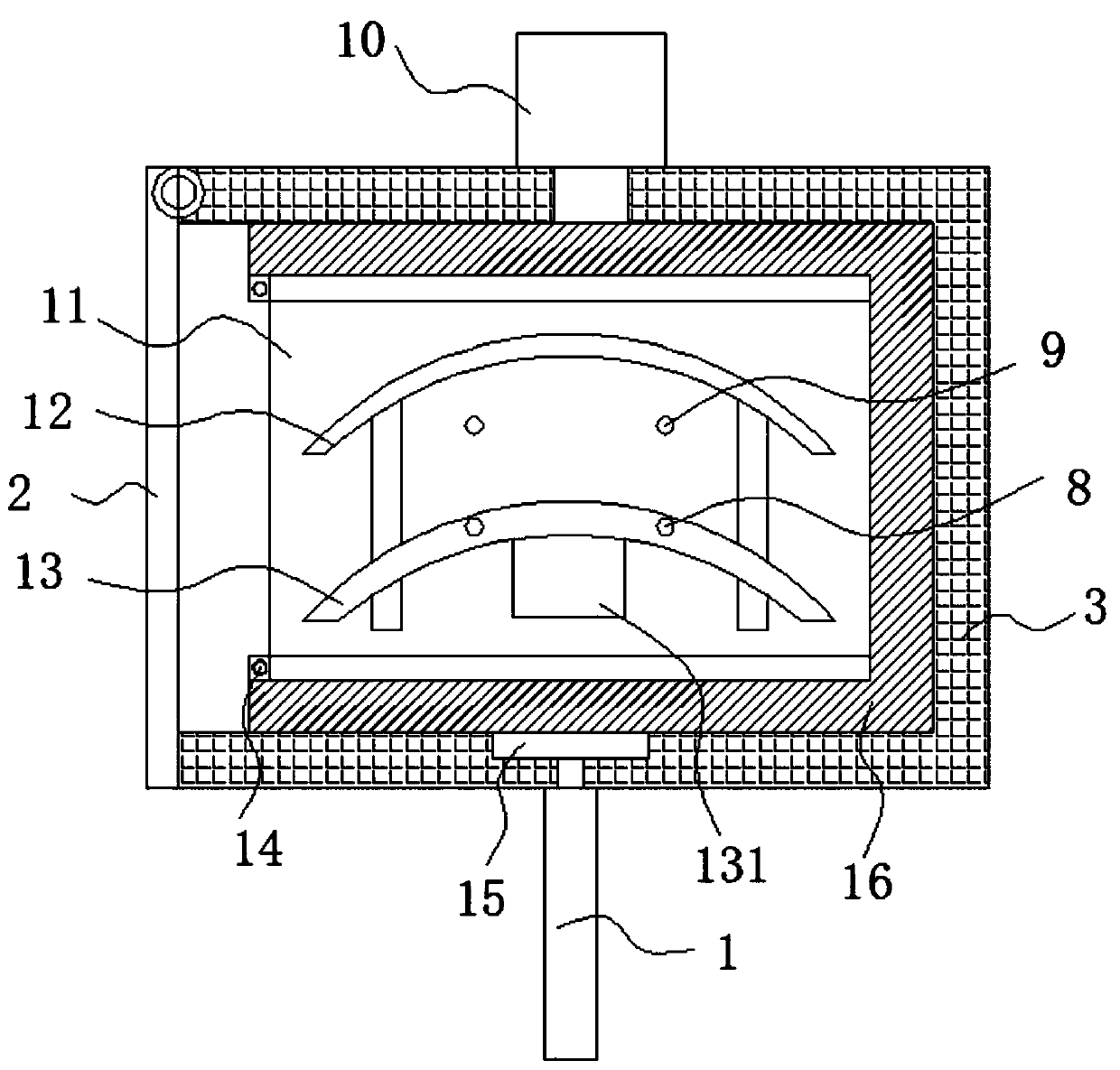

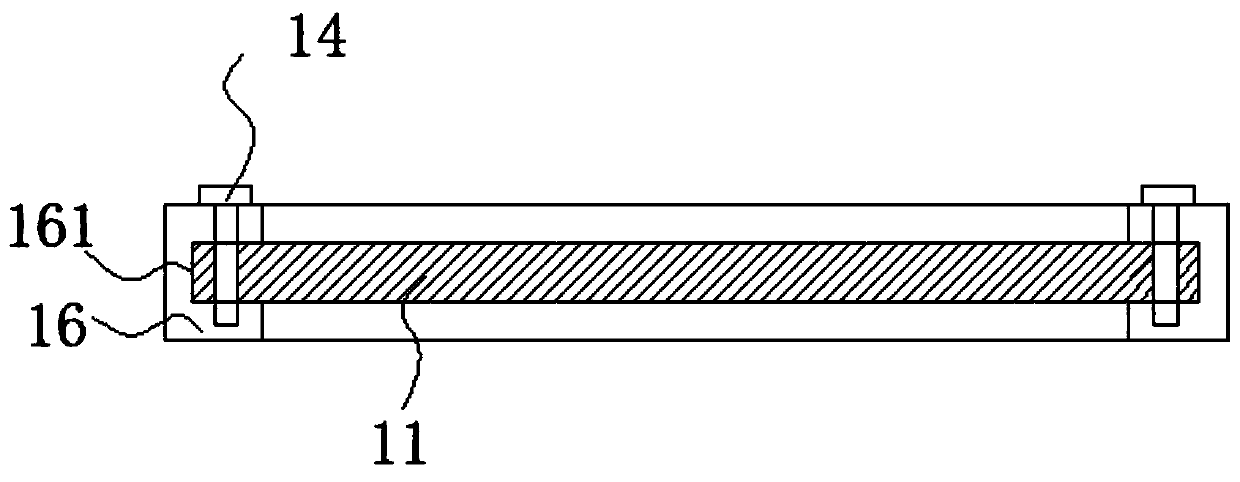

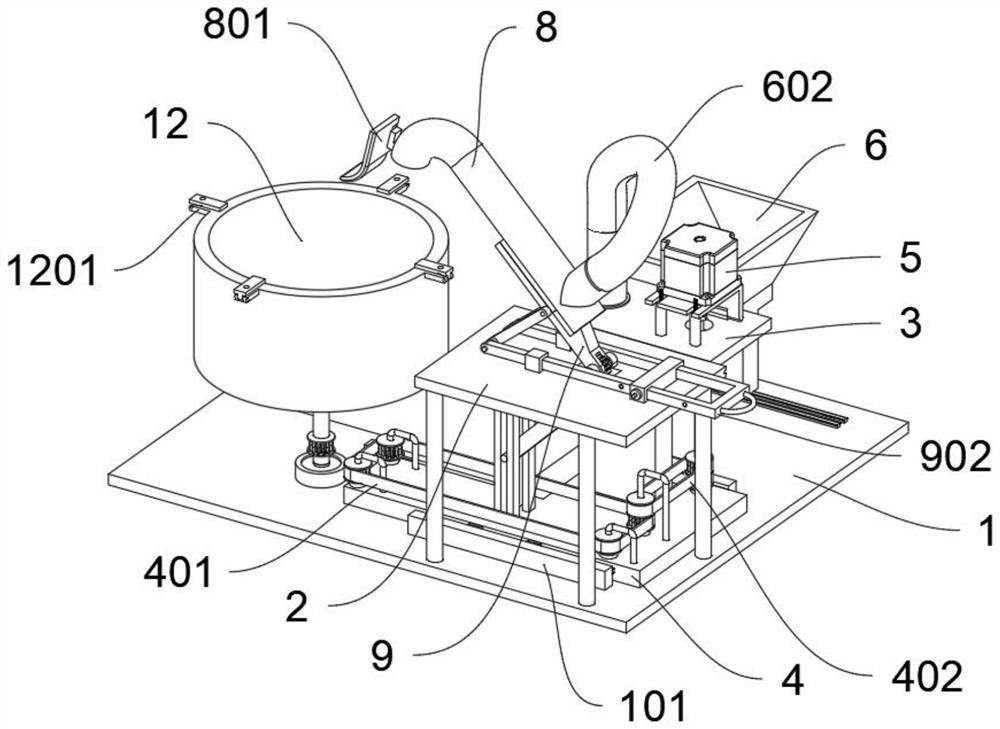

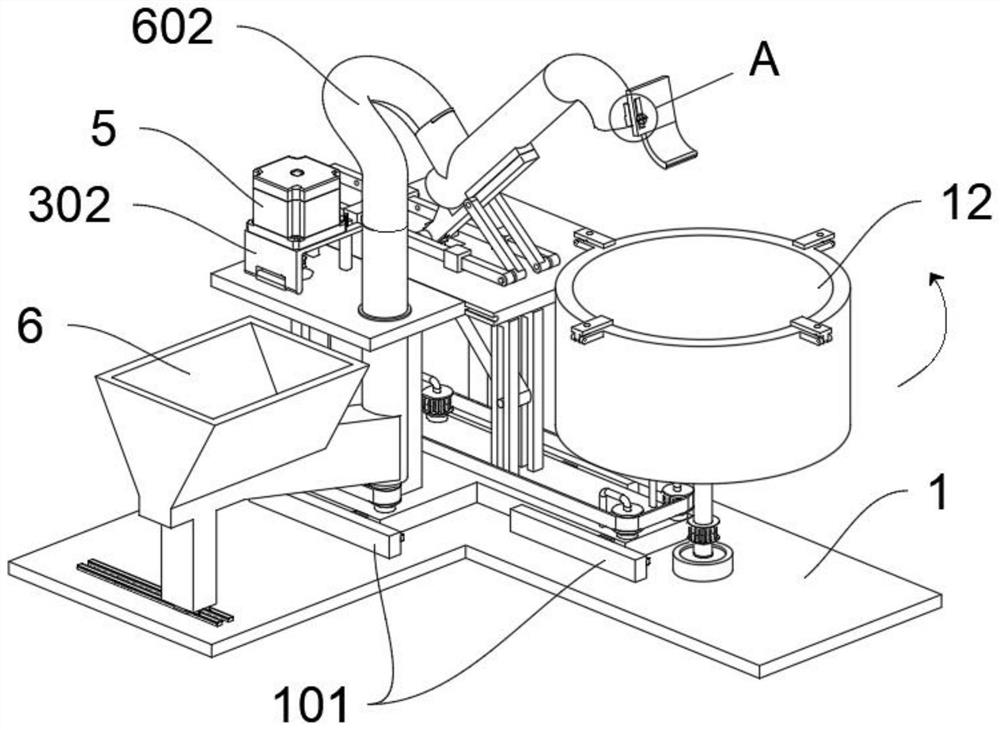

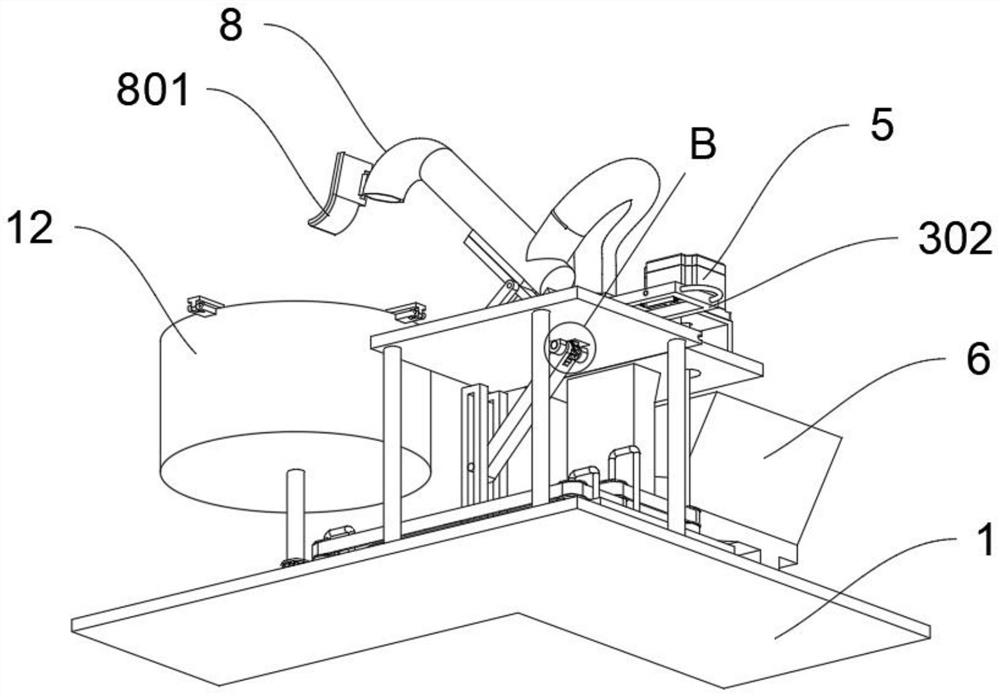

Automatic device used for manufacturing of aluminum pot mold shell

ActiveCN111283147AEasy to replaceFacilitate strippingMoulding machinesEngineeringMechanical engineering

The invention discloses an automatic device used for manufacturing of an aluminum pot mold shell, and relates to the technical field of mold manufacturing. The problems that the manufacturing method used for an aluminum pot mold at preset quite depends on manpower, precision is poor, and the functions of intermittently feeding quantitative cement onto gauze, driving gauze to rotate and floating cement on gauze are not achieved are solved. The automatic device used for manufacturing of the aluminum pot mold shell comprises a bottom plate; a top plate is connected and arranged at the top of thebottom plate through stand columns; a moving top plate is arranged on one side of the top plate through a sliding structure in a sliding manner; and through the arrangement of an upper rotating rod and a lower rotating rod, the function of synchronous material clamping is provided for the shell manufacturing device, a conveying pipe can be lifted at the same time through pull rod movement, an aluminum pot can be replaced conveniently, a moving bottom plate is pulled away, and through contact of a transmission mechanism of a pot rack and motion connection of the pot rack, the pot rack can be stripped and cleared conveniently.

Owner:兰溪太乙金属制品有限公司

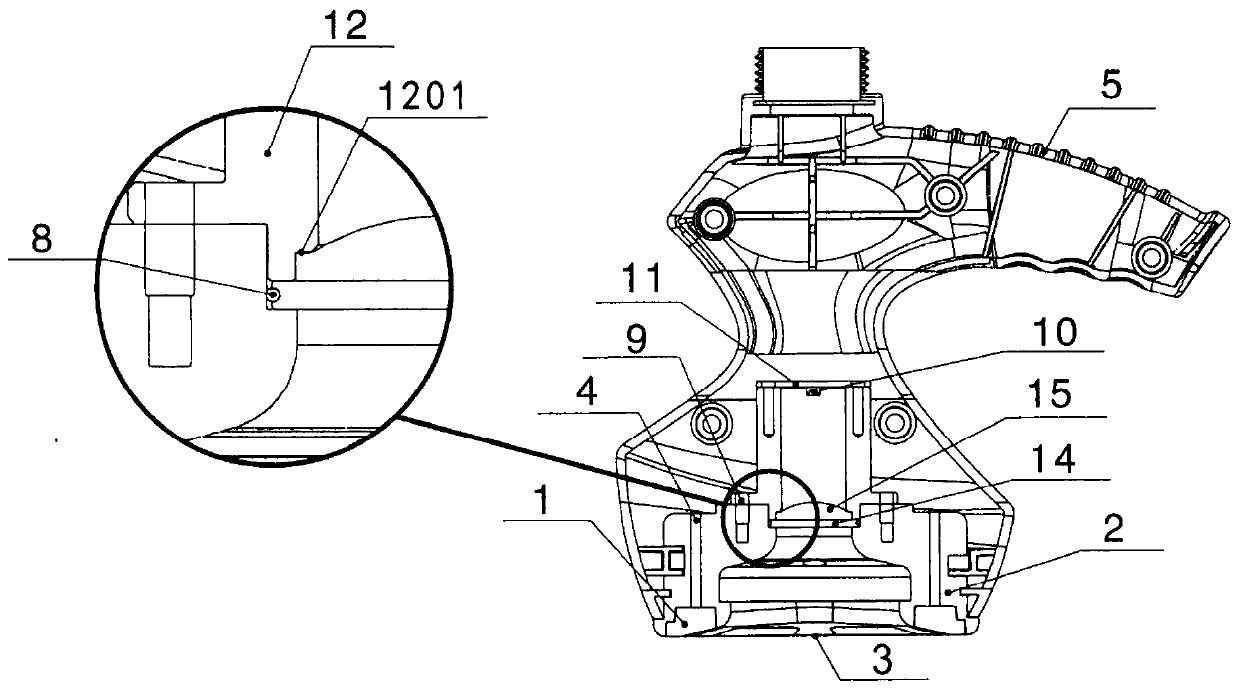

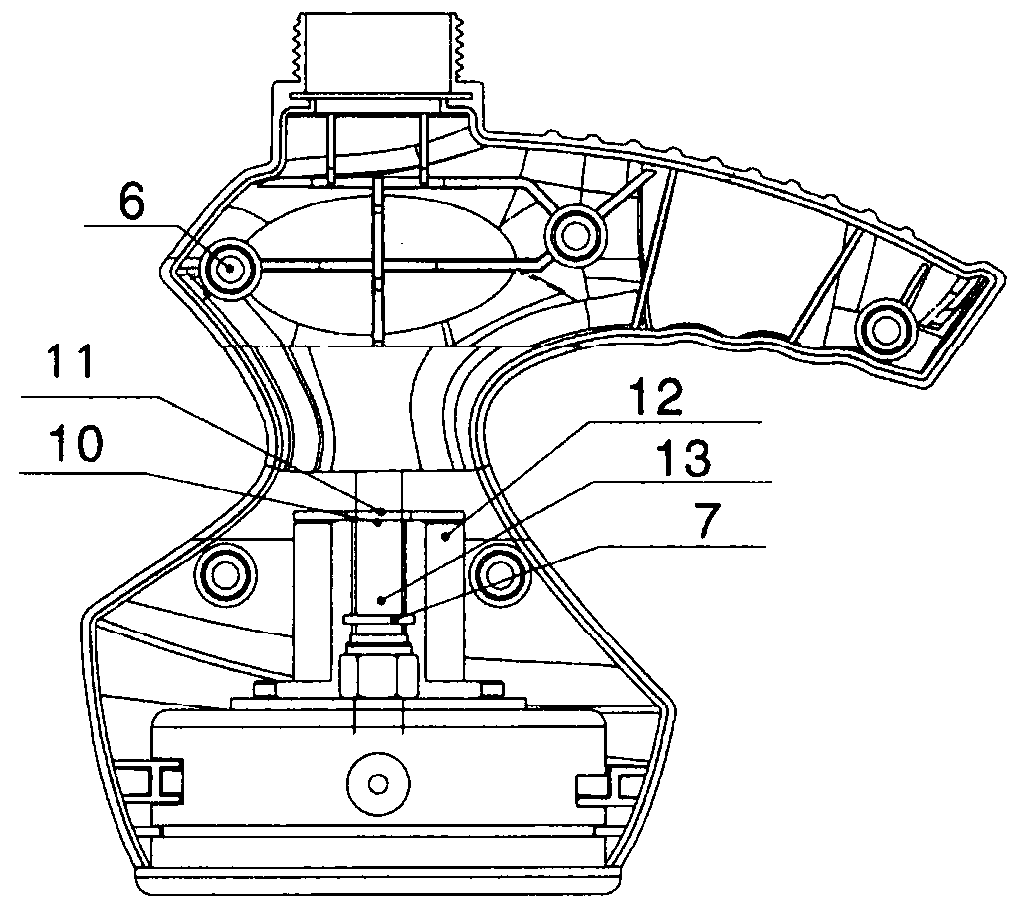

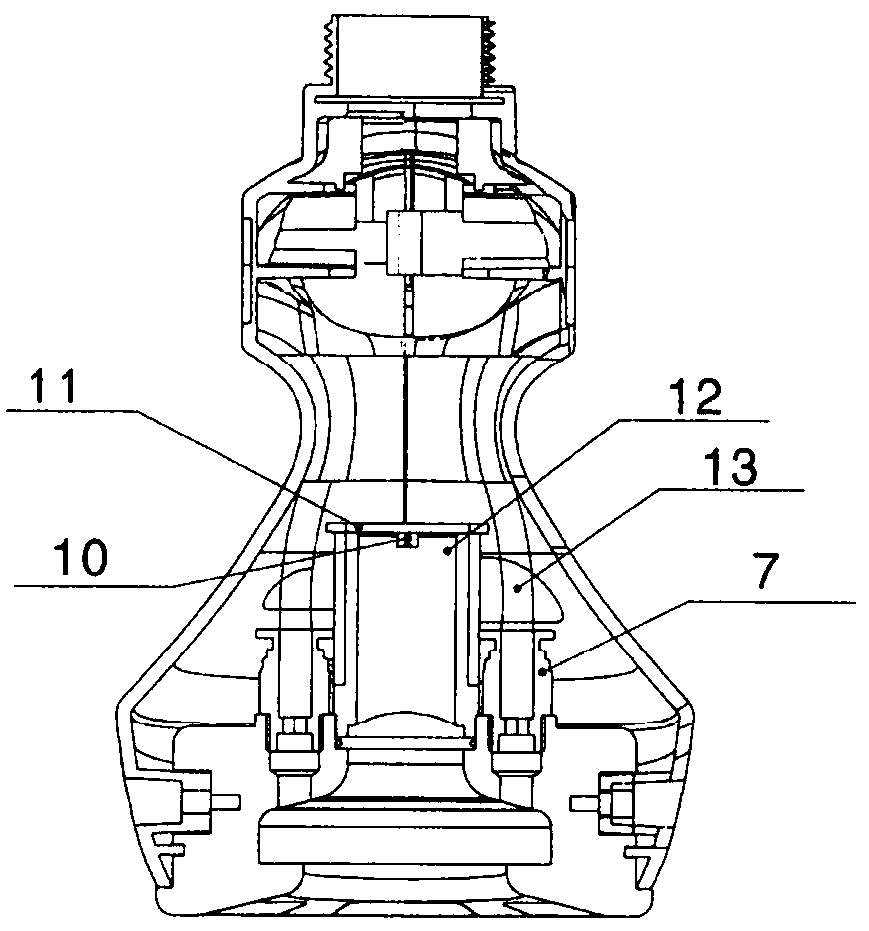

Electrode, negative pressure and infrared integrated operation head of human body conditioning apparatus

PendingCN110179540AAchieve shapeRepair the wound...Pneumatic massageSurgical instruments for heatingInfrared lampIntegrated operations

The invention relates to an electrode, negative pressure and infrared integrated operation head of a human body conditioning apparatus, and relates to the technical field of apparatuses. The electrode, negative pressure and infrared integrated operation head adopts a key technology of "integrating combining an electrode, negative pressure and infrared"; the bottom end of an electrode seat is fixedto the bottom surface, the outer circle of the electrode seat and a handle housing; an electrode placed in an electrode groove of the electrode base is fixed to the electrode seat by electrode screwsthrough screw holes; a lens and a convex mirror are arranged on concave holes in the middle part of the electrode seat, and are fixed to an infrared lamp seat by lamp seat screws; a sealing ring is embedded between the electrode seat and the lens; steps on the infrared lamp seat are clamped with the edge of the lens; the upper end of the infrared lamp seat is fixed to a lamp board; the lamp boardis fixed to an infrared pipe; a gas pipe screw hole of the electrode seat is fixed to a locking head; the locking head is used for extruding one end of the gas pipe; and handle housings of two mirroring structures are fixed by positioning columns. The electrode, negative pressure and infrared integrated operation head disclosed by the invention is used for body conditioning, and is unique and reasonable in concept design, ingenious in structure and good in effects.

Owner:广东伊丽汇美容科技有限公司

External skin care product capable of supplementing skin collagen

InactiveCN106309207AAchieve shapeFade wrinklesCosmetic preparationsToilet preparationsMedicinePotato starch

The invention provides an external skin care product capable of supplementing skin collagen. The skin care product is prepared from grape seeds, grape flesh juice, Chinese wolfberry, potato starch, collagen peptides, glycerol, methylparaben, carbomer, allantoin and lactic acid. The skin care product has the effect of supplementing and repairing the human body skin.

Owner:宁夏清华园知识产权研究与开发有限公司

Balanced varnishing device based on varnished wire processing

InactiveCN111613392ASmooth evenlyImprove not only flatRotary pressesOther printing apparatusMechanical engineeringSurface smoothness

The invention discloses a balanced varnishing device based on varnished wire processing, and belongs to the technical field of varnished wire varnishing. The balanced varnishing device based on varnished wire processing comprises a base and a paint box fixedly installed at the top end of the base, the varnished wire is waxed before the varnished wire is painted, and the surface smoothness of the waxed enameled wire is improved, so that a uniform paint film can be easily formed on the surface of the waxed enameled wire in the subsequent painting process. The varnished wire is dipped in the paint through a lower printing and dyeing roller to be painted, and then an upper printing and dyeing roller is matched with a pressing plate, therefore, the paint on the upper and lower end faces of theenameled wire adhered with the paint can be uniformly flattened, and the situation that the paint surface of the paint is not smooth due to the leveling and gravity effects of the paint, is effectively improved. In addition, drying treatment is carried out through a drying mechanism in the winding process after the enameled wire is painted, so that the situation that the paint surfaces which are not completely dried adhere to one another during winding, and consequently the paint surfaces are uneven, is effectively avoided.

Owner:杭州欣禾工程管理咨询有限公司

A field emission electron source emitter tip shaping device and its shaping method

ActiveCN103943437BLarge emission currentHigh angular current densityCold cathode manufactureVacuum pumpingElectron source

The invention discloses a shaping device and method for a field emission electron source emitter tip. The shaping device comprises a vacuum chamber, a vacuum pumping system, a vacuum degree measuring system, an electronic gun assembly, a power source system and an electron beam imaging system. The method comprises the steps that the field emission electron source emitter tip is heated to be passivated, a critical electric field is applied to an anode to form field emission, the balance, on the surface, between the surface tension of the emitter tip and the electric field force produced by the additional electric field is achieved, and therefore shaping is achieved; after the field emission electron source emitter tip is shaped, a stable emission surface is formed on the emitter tip. The stable emission surface can make electronic beam current emitted by a field emission electron source have the advantages that the emission current is large, emission directions are concentrated, the density of angle current is high, monochromaticity is good, and beam current emission is stable.

Owner:PEKING UNIV

Intelligent multifunctional machining equipment for furniture processing

InactiveCN110757602AAchieve shapeReduce operating proceduresWood stock bendingStructural engineeringMachining

The invention belongs to the field of furniture processing, in particular to intelligent multifunctional machining equipment for furniture processing. According to the scheme, the intelligent multifunctional machining equipment for furniture processing comprises a shell, wherein an opening is formed in one side of the shell. A box door is hinged to the opening of the shell. A motor is installed onone side wall of the shell. An output shaft of the motor is connected with a fixing frame rotatably connected into the shell. The section of the fixing frame is in a U shape. An installation plate ismovably connected into the fixing frame. A fixing plate clamping plate is fixed to one side of the top end of the installation plate, and a movable clamping plate is slidably connected to the other side of the top end of the installation plate. A connecting block is installed on the movable clamping plate. Two locking screws are connected to the movable clamping plate in a threaded mode. Two fixing holes matched with the locking screws are formed in the installation plate. A first telescopic rod is installed on the other side wall of the shell. An output shaft of the first telescopic rod is connected with a pushing block located on one side of the connecting block. The intelligent multifunctional machining equipment is highly integrated, can rapidly achieve molding of wooden structures offurniture, and is good in machining effect.

Owner:安徽德帝智能科技股份有限公司

Device for accelerating packaging forming

The invention discloses a device for accelerating packaging forming, and relates to the technical field of air suction packaging, in particular to a device for accelerating packaging forming. The device for accelerating packaging forming comprises a platform, the top of the platform is slidably connected with a bottom plate, the upper part of the bottom plate is rotatably connected with a side pressing plate, and the side surface of the side pressing plate is provided with an air blowing hole. A sliding groove is formed in the surface of the bottom plate, a magnetic plate is arranged in the sliding groove, and a fixing mechanism is arranged at one end of the side pressing plate. According to the device for accelerating packaging forming, air blowing holes are formed in the side surfaces of side pressing plates, airflow is pumped into air channels through an air blowing pump and blown to the two side surfaces of a V-shaped packaging at a model through the air blowing holes, the diagonal air blowing forming function on the packaging is added, the side pressing plates are assisted in conducting compression molding on the shape of the packaging, and shaping of the V-shaped packaging is achieved more accurately, and the packaging is formed more rapidly and more attractive; and in addition, the device for accelerating packaging forming is suitable for packaging oil paper materials, and the multifunctionality of the device for accelerating packaging forming is improved.

Owner:江苏萨科斯德智能机械科技有限公司

An intelligent electric-driven self-propelled tobacco well cellar water injection hole punching machine and method

ActiveCN111788900BQuality improvementReduce dependencePlantingFurrow making/coveringStructural engineeringMechanical engineering

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES +1

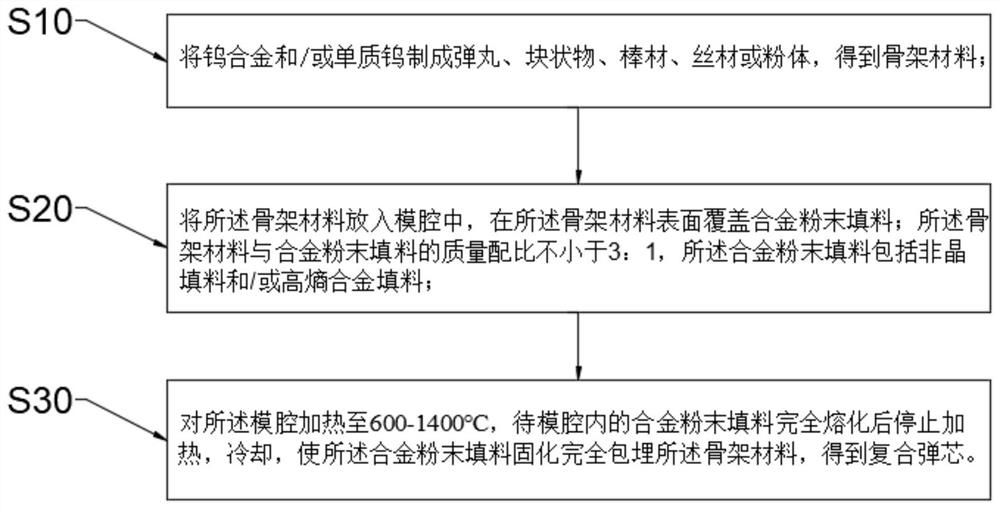

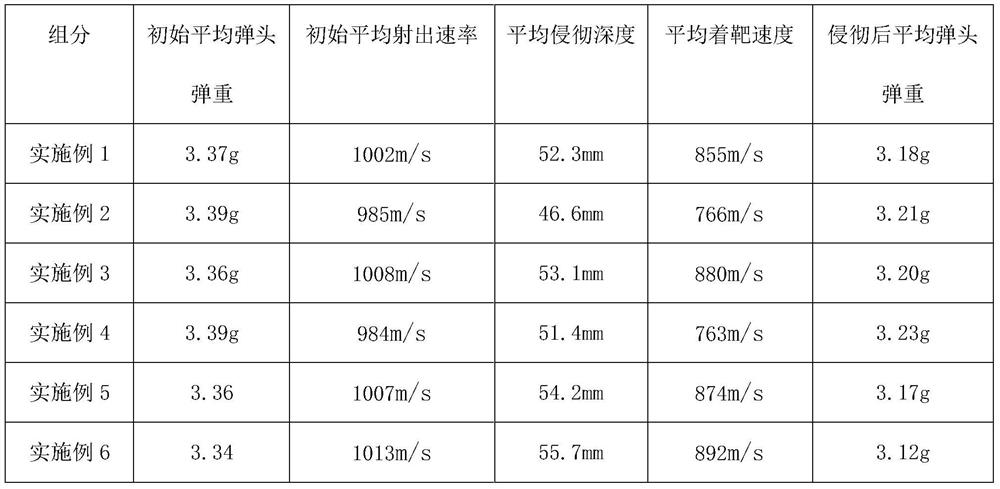

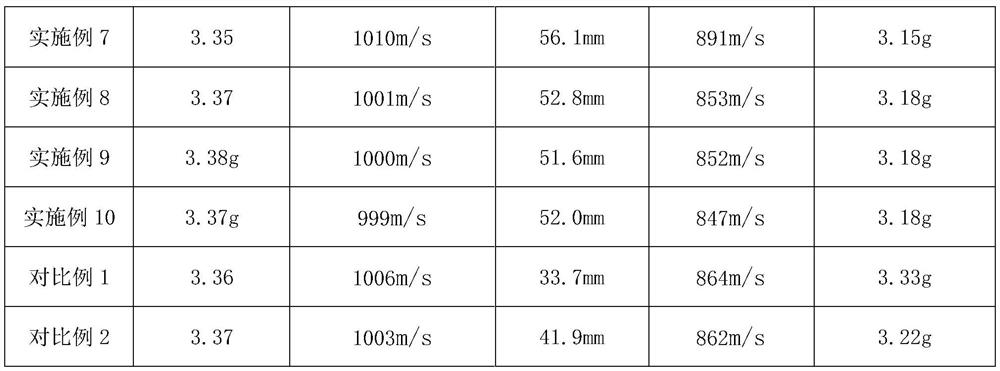

Bullet core preparation method and composite bullet core

PendingCN113732271AHigh breaking strengthQuality improvementAmmunition projectilesProjectilesBreaking strengthHigh entropy alloys

The invention discloses a bullet core preparation method. The bullet core preparation method comprises the following steps that a tungsten alloy and / or elemental tungsten is made into a bullet, a block, a bar, a wire or powder, and a framework material is obtained; the framework material is put into a mold cavity, and the surface of the framework material is covered with alloy powder filler; the mass ratio of the framework material to the alloy powder filler is not less than 3: 1, and the alloy powder filler comprises an amorphous filler and / or a high-entropy alloy filler; and the mold cavity is heated to 600-1,400 DEG C, heating is stopped after the alloy powder filler in the mold cavity is completely melted, cooling is conducted, the alloy powder filler is solidified to completely embed the framework material, and the composite bullet core is obtained. According to the bullet core preparation method, the framework material and the alloy powder filler in a reasonable proportion are compounded, after the alloy powder filler is quickly molten through heating, rapid cooling is conducted, an amorphous tissue structure is formed on the surface of the framework material, and the bullet core higher in breaking strength and hardness can be prepared easily.

Owner:东莞梵铃材料科技有限公司

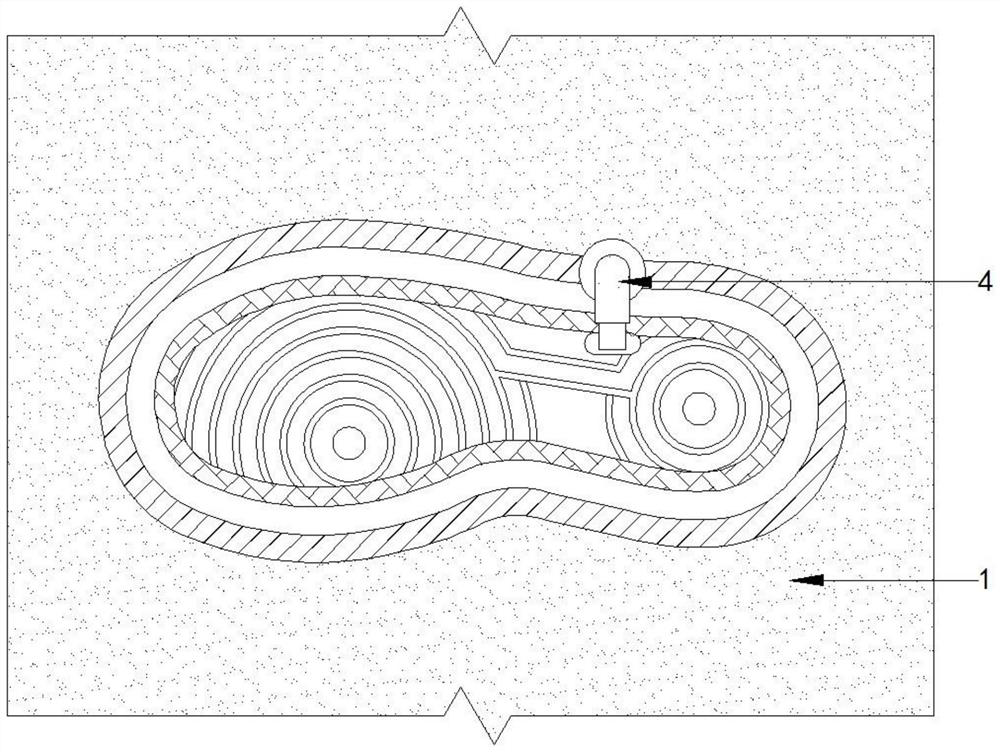

Sole bottom shaping device in shoe processing

ActiveCN112568558ASmooth steeringGuaranteed support effectShoemaking devicesEngineeringMechanical engineering

The invention relates to the technical field of shoe processing, and discloses a shoe sole bottom shaping device in shoe processing, the shoe sole bottom shaping device comprises a main body, a steering assembly and a shaping assembly, the inner wall of the main body is movably connected with the outer wall of the steering assembly, and connecting columns are fixedly mounted at the top end and thebottom end of the steering assembly; the top end of the connecting column located at top is fixedly connected with the bottom end of the shaping assembly. According to the shoe sole bottom shaping device in shoe processing, in the steering assembly process, a limiting ball can provide certain supporting force for a steering ball, the limiting ball can rotate along with movement of the steering ball, and therefore it is guaranteed that the steering ball is smooth in the moving process; when the steering assembly steers, the limiting wheel on one side is extruded, air in the telescopic pipe enters the mounting column, one part of the air in the mounting column enters the air bag, and the other part of the air in the mounting column enters the telescopic pipe on the other side, so that the supporting force of the limiting wheel on the other side is guaranteed, and the steering assembly can steer stably.

Owner:广东万里马实业股份有限公司

Method for making tassel root carving

The invention relates to the technical field of root carving cultivation methods, in particular to a method for making a tassel root carving. The method making the tassel root carving comprises the following steps: firstly, planting tassel in a first container, and replacing the first container for planting with a second container after first set time, wherein the height of the second container isgreater than that of the first container; enabling the root to grow downwards. According to the method, provided by the invention for making the tassel root carving, the shaping of the tassel root isrealized by replacing the container, so that the effect of planning the shape of the tassel root is achieved. The method for making the tassel root carving is simple in process, low in cost, good ineffect and wide in range of promotion; the formed tassel root is attractive and high in ornamental value.

Owner:江沛霖

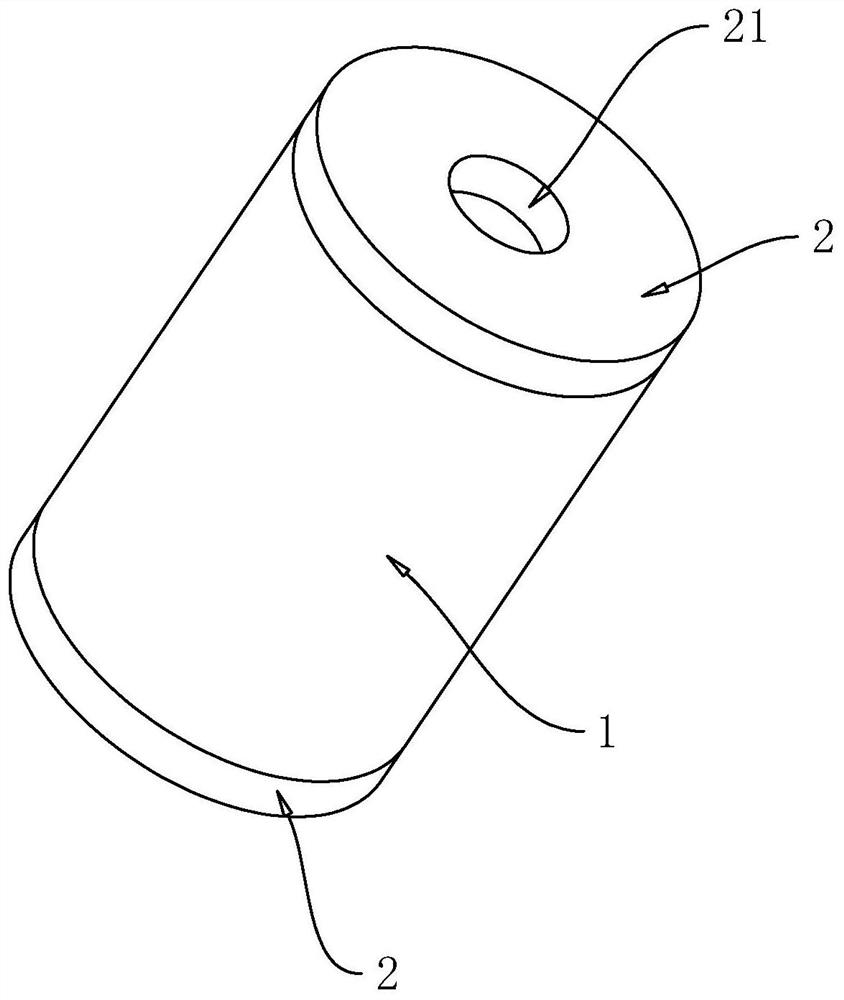

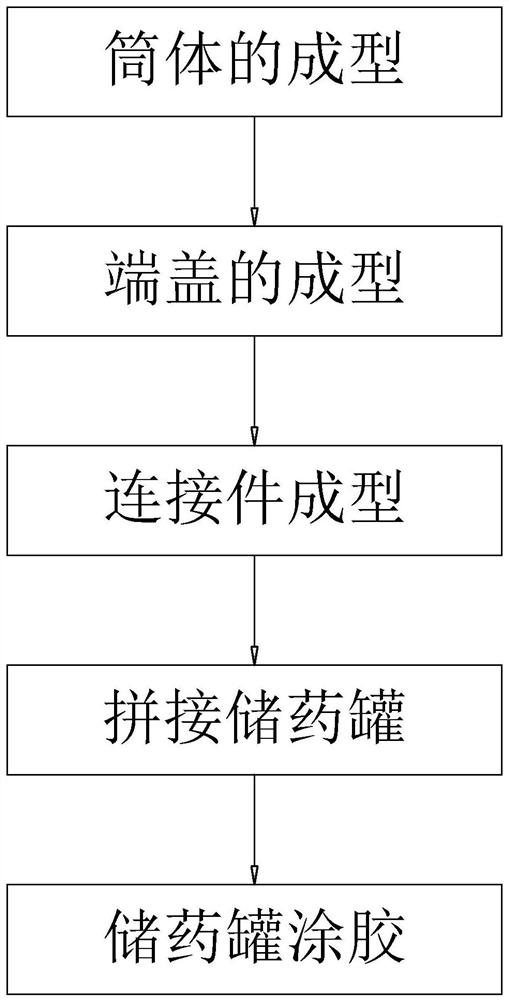

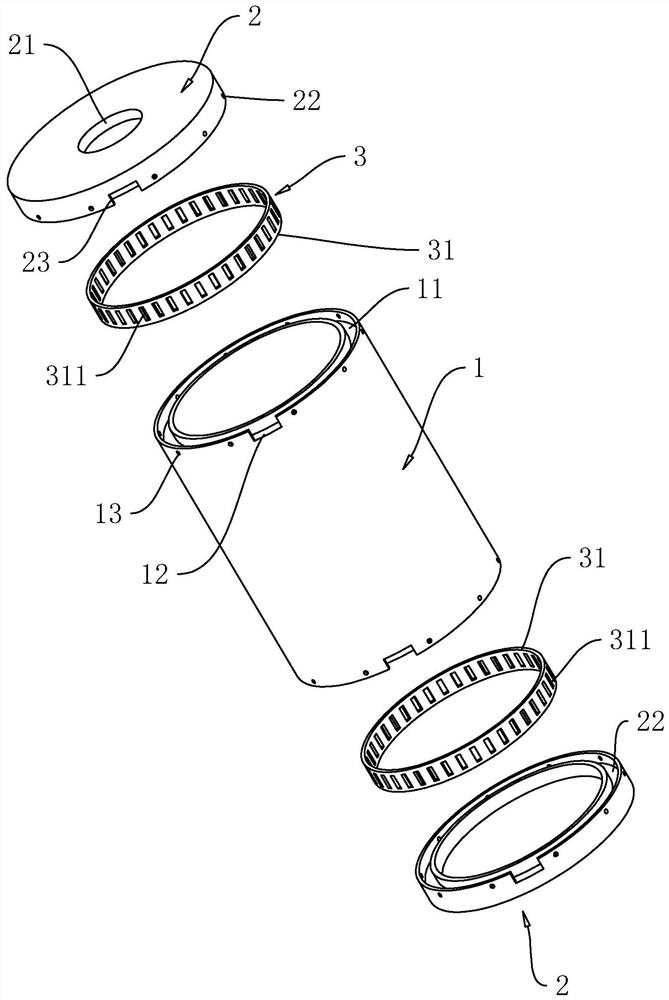

Production process of plastic cylindrical medicine storage tank

InactiveCN112477211AEasy to operatePrecise positioningHollow articlesProcess engineeringMechanical engineering

The invention relates to the field of medicine storage tank production, in particular to a production process of a plastic cylindrical medicine storage tank. The process comprises the following stepsof S1, forming a cylinder; S2, forming an end cover; S3, forming a connecting piece; S4, splicing the medicine storage tank; and S5, gluing the medicine storage tank. According to the production process, splicing positioning of the cylinder and a sealing cover can be ensured, and the effect of ensuring the forming quality of the medicine storage tank is achieved.

Owner:上海升捷工贸有限公司

An automatic device for making aluminum pot mold shell

ActiveCN111283147BEasy to replaceFacilitate strippingMoulding machinesEngineeringMechanical engineering

The invention discloses an automatic device for making an aluminum pot mold shell, relates to the technical field of mold making, and solves the problem that the manufacturing method of an aluminum pot mold currently used is relatively manual, has poor precision, and does not have intermittent quantitative cement. Added to the gauze, it can drive the gauze to rotate, and it can also smooth the cement on the gauze. An automatic device for making an aluminum pot mold shell, comprising a bottom plate; the top of the bottom plate is connected with a top plate through a column; one side of the top plate is slidingly provided with a movable top plate through a sliding structure; The rod provides the function of synchronously clamping the material for the production device of the shell. It can use the movement of the pull rod to lift the conveying pipe at the same time to facilitate the replacement of the aluminum pot, and pull the movable bottom plate away from the transmission mechanism of the pot stand to contact with the movement of the pot stand. Attachment for easy stripping and cleaning of pot holders.

Owner:兰溪太乙金属制品有限公司

A kind of shaping method and shaping system of instant stewed bird's nest

The invention provides a stewed-bird's-nest setting method and system. The method specially includes: disinfecting a setting tube; arranging fabric on the side wall of the setting tube; placing bird's nest on the surface of the other fabric; coiling the fabric with the bird's nest on the surface of the setting tube to allow the bird's nest to be located between the two fabric; arranging a sleeve on the surface of a gauze to form a bird's nest setting body and arranging the bird's nest setting body in setting equipment; taking out the bird's nest setting body from the setting equipment to have the bird's nest separated out. With the method, the stewed bird's nest is short in stewing time, easy to disperse evenly and better in taste; the setting system used for implementing the stewed-bird's-nest setting method is simple in structure, the fabric is fixed through a fabric coiling system, fixing efficiency of the fabric is improved, and integral setting efficiency of the bird's nest is increased; through cooperation use of various parts of the entire setting system, setting of the stewed bird's nest is realized.

Owner:燕之初健康美(厦门)食品有限公司

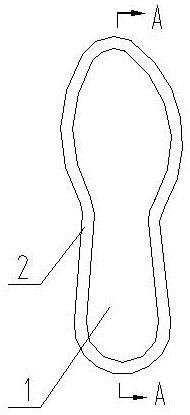

Multi-layer shoe sole, cloth sole shoe and manufacturing method of multi-layer shoe sole

The invention discloses a multi-layer shoe sole and a cloth sole shoe, and belongs to the technical field of shoemaking, the multi-layer shoe sole comprises an upper shoe sole, a middle shoe sole and a lower shoe sole, the upper shoe sole, the middle shoe sole and the lower shoe sole are made of multi-layer cloth, the size of the upper shoe sole is 2-5 yards smaller than that of the middle shoe sole, and the size of the lower shoe sole is 2-5 yards smaller than that of the middle shoe sole. After the upper sole, the middle sole and the lower sole are combined, the middle sole protrudes outwards to form a boss, a rubber layer or a plastic layer is cast on the boss in a die mode, the cloth sole is protected and beautified, casting or bonding with an upper is facilitated, the appearance of a tourist shoe and a sneaker is achieved, and meanwhile the breathable, comfortable and anti-skid effects of a cloth shoe with a multi-layer sole are achieved. The organic combination of the traditional cloth shoe process and the existing shoe making technology is realized.

Owner:云南明湖环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com