Patents

Literature

344results about How to "Smooth steering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

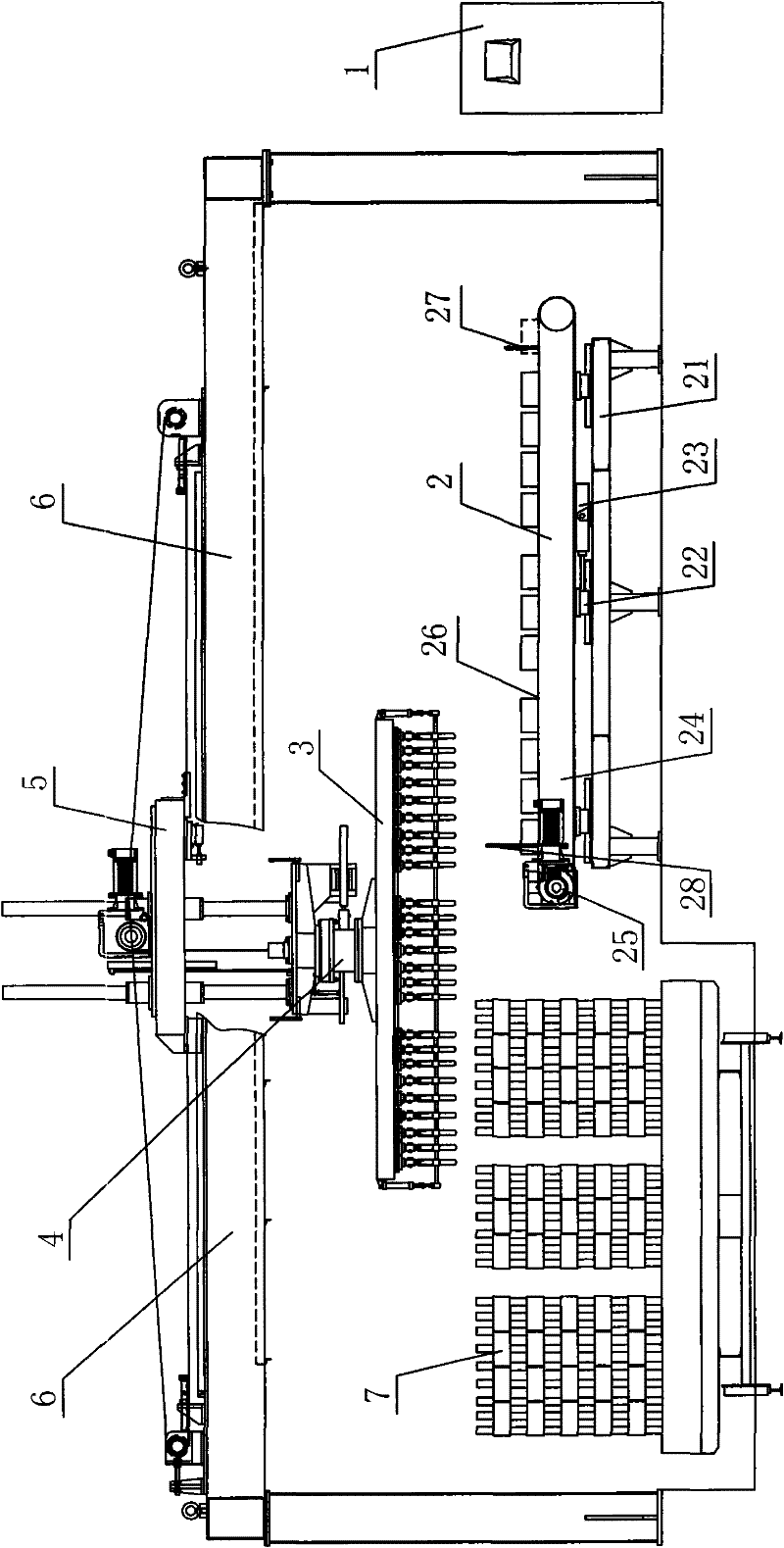

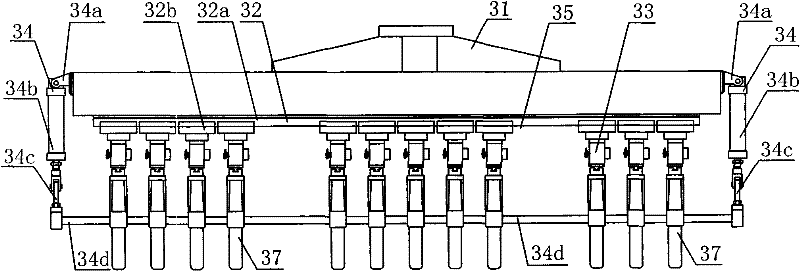

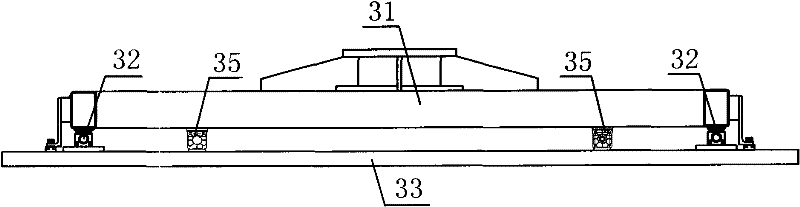

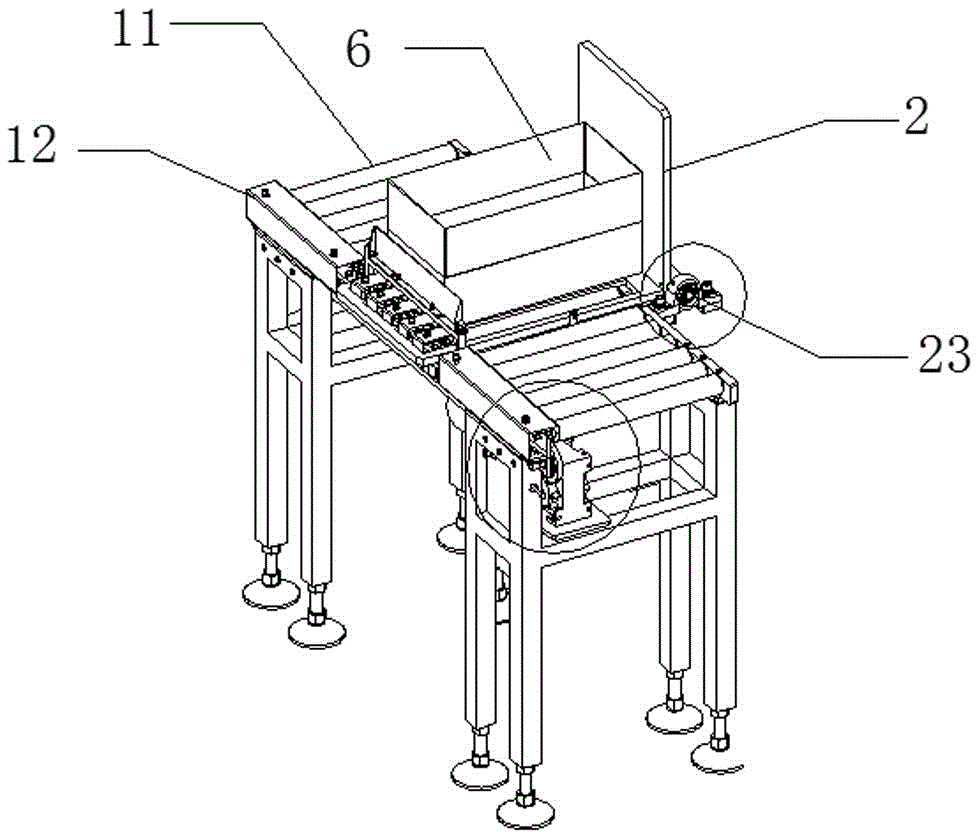

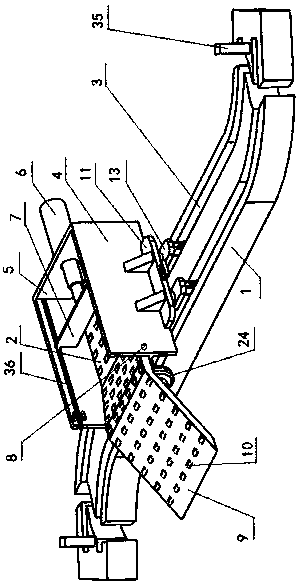

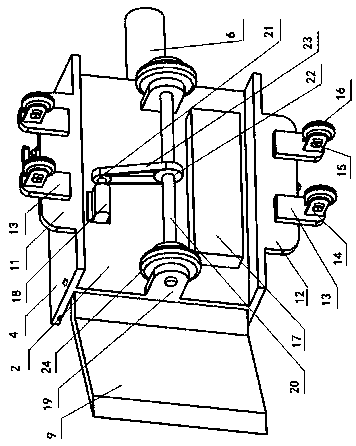

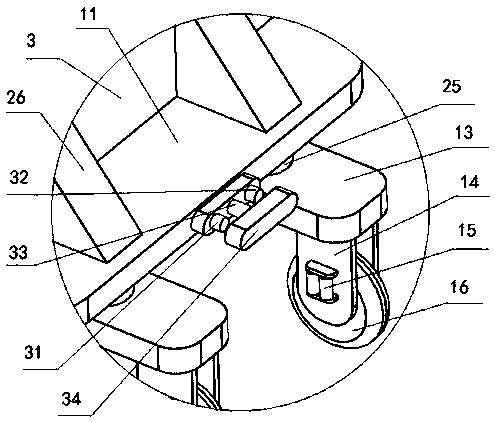

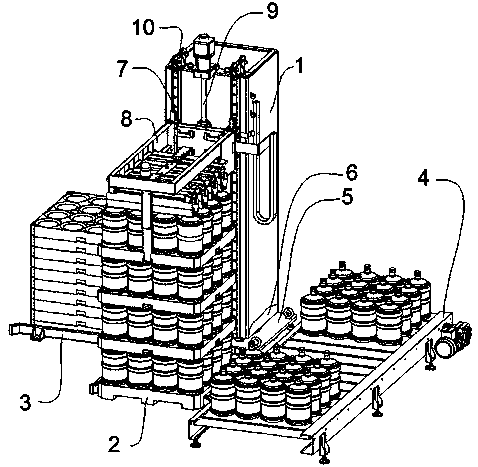

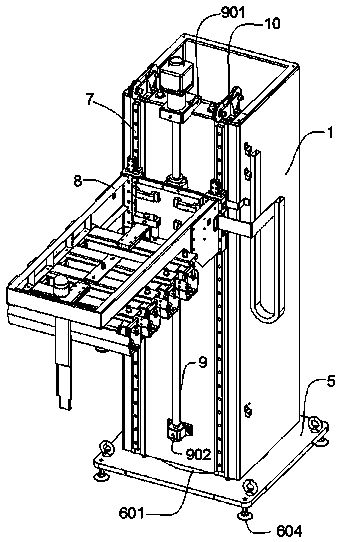

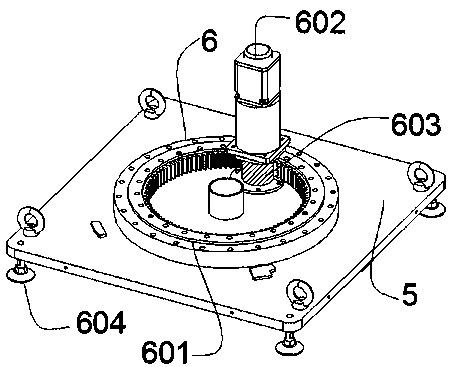

Automatic adobe stacking device

ActiveCN102225719AIncrease productivityImprove stack qualityDischarging arrangementStacking articlesAutomatic controlMechanical engineering

The invention provides an automatic adobe stacking device. The device comprises an automatic control device, an adobe group conveying mechanism, a horizontal travelling mechanism, a vertical lifting mechanism arranged on the horizontal travelling mechanism, a rotation mechanism fixed on the lower end of the vertical lifting mechanism and an adobe grabbing mechanism fixed on the lower end of the rotation mechanism, wherein the adobe group conveying mechanism is arranged below the adobe grabbing mechanism; and the automatic control device is respectively connected with the adobe group conveyingmechanism, the horizontal travelling mechanism, the vertical lifting mechanism, the rotation mechanism and the adobe grabbing mechanism so as to control the operation of the mechanisms. The adobe automatic stacking device has the advantages of accurate positioning, stable direction steering, neatly stacked adobes, firmly overlapped upper and lower adobes, simple structure, high automatic degree and easiness for operation, so that the labor intensity of workers is reduced, the production efficiency of stacking is greatly improved, and the stacking quality of adobe stacks is improved.

Owner:信阳雄狮装备科技股份有限公司

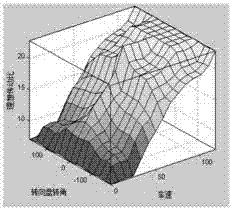

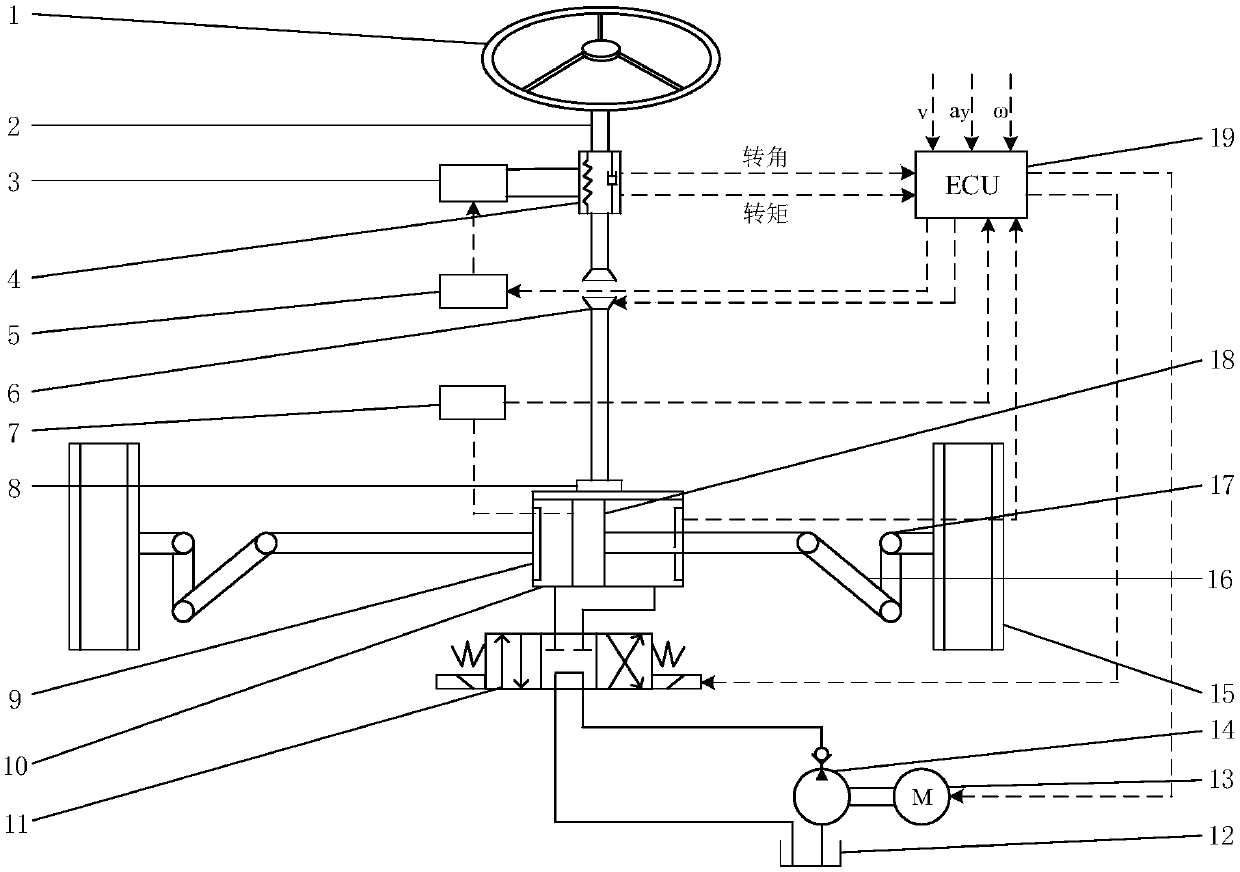

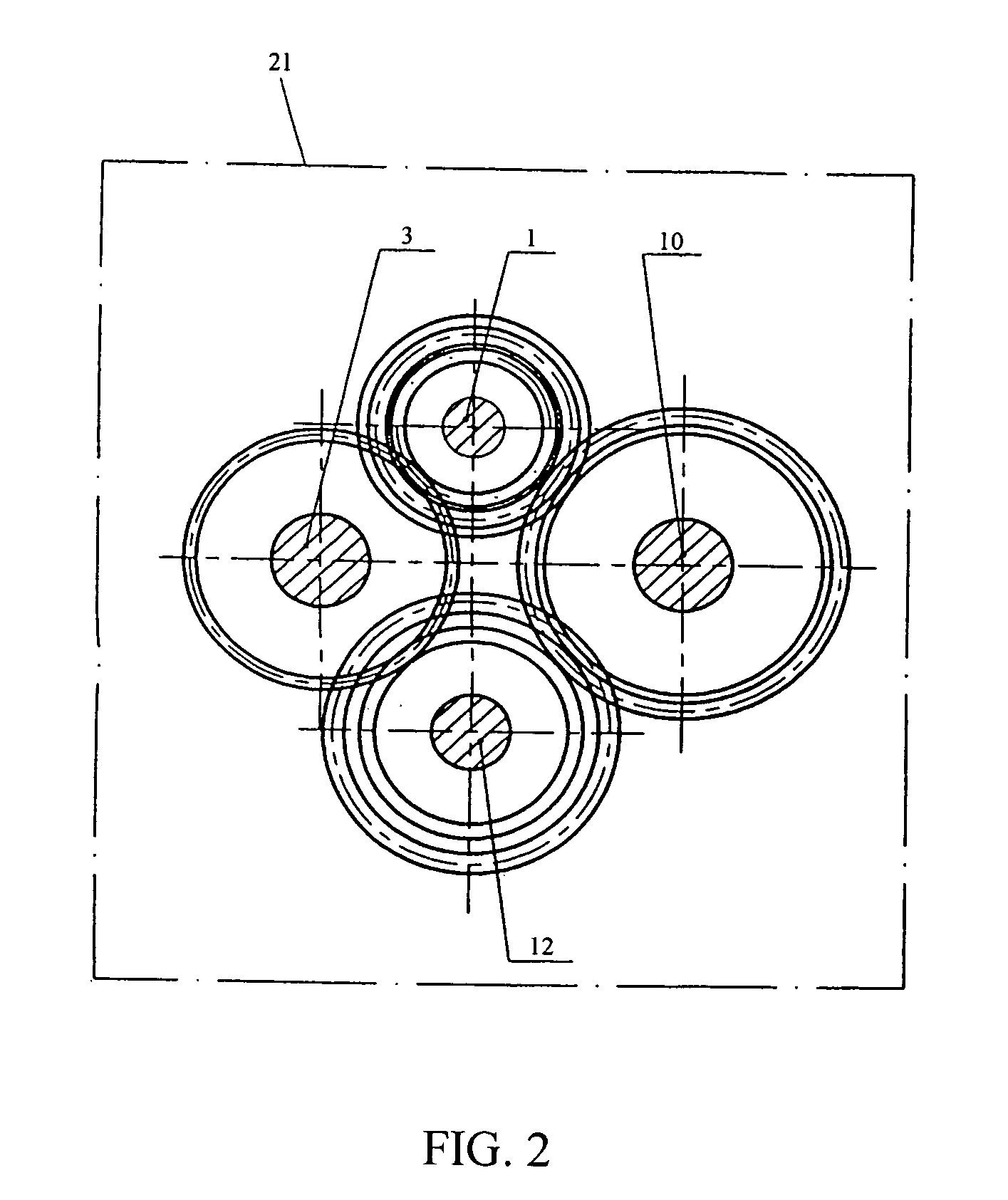

Steer-by-wire system and stability control method thereof

ActiveCN107512305AExact gear ratioRealize variable transmission ratio controlSteering linkagesAutomatic steering controlSteering wheelFeedback controller

The invention provides a steer-by-wire system and a stability control method thereof. The steer-by-wire system comprises a steering wheel module, a front wheel steering module and an ECU electronic control unit, wherein the ECU electronic control unit comprises a variable transmission ratio controller, a fuzzy self-adaptive PID controller and a full state feedback controller. The stability control method is as follows: the variable transmission ratio controller calculates an ideal transmission ratio at the moment according to a steering wheel rotation angle signal and a vehicle speed signal, to obtain an ideal front wheel rotation angle at the moment; the full state feedback controller of an automobile calculates a compensation rotation angle of front wheels according to a yaw rate signal and a lateral acceleration signal of the automobile, to realize the outer ring control of the steer-by-wire system; and finally the fuzzy self-adaptive PID controller is designed, to realize the inner ring control of the steer-by-wire system. The operating stability of the automobile is effectively improved through the coordinated control of inner and outer rings of the steer-by-wire system.

Owner:NANJING AUTOMOBILE GROUP CORP

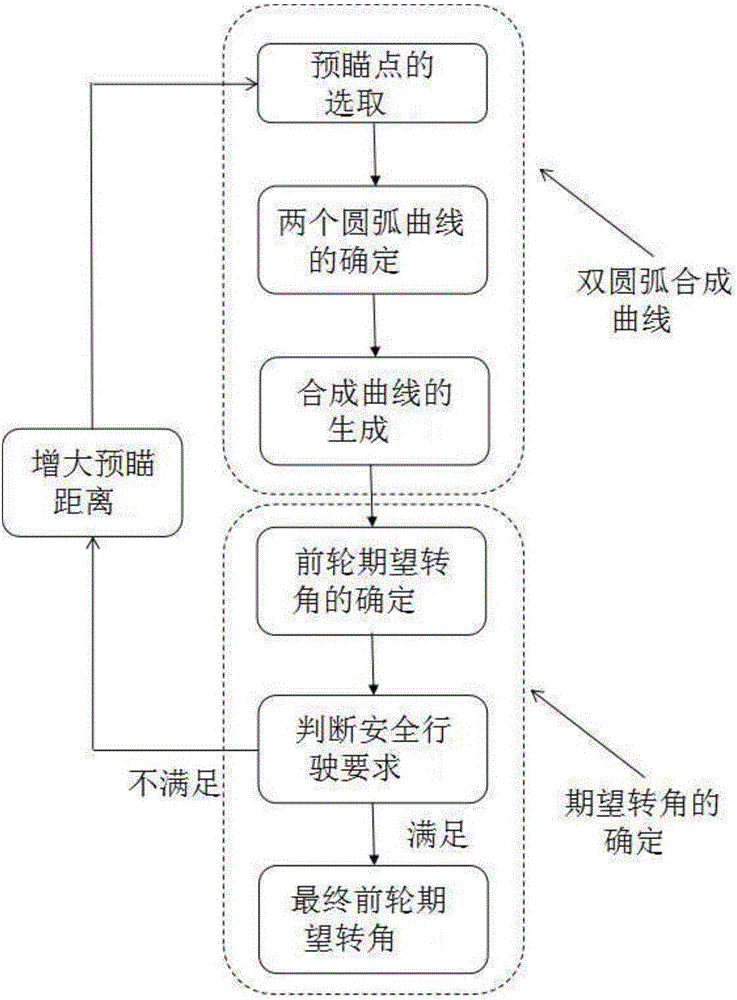

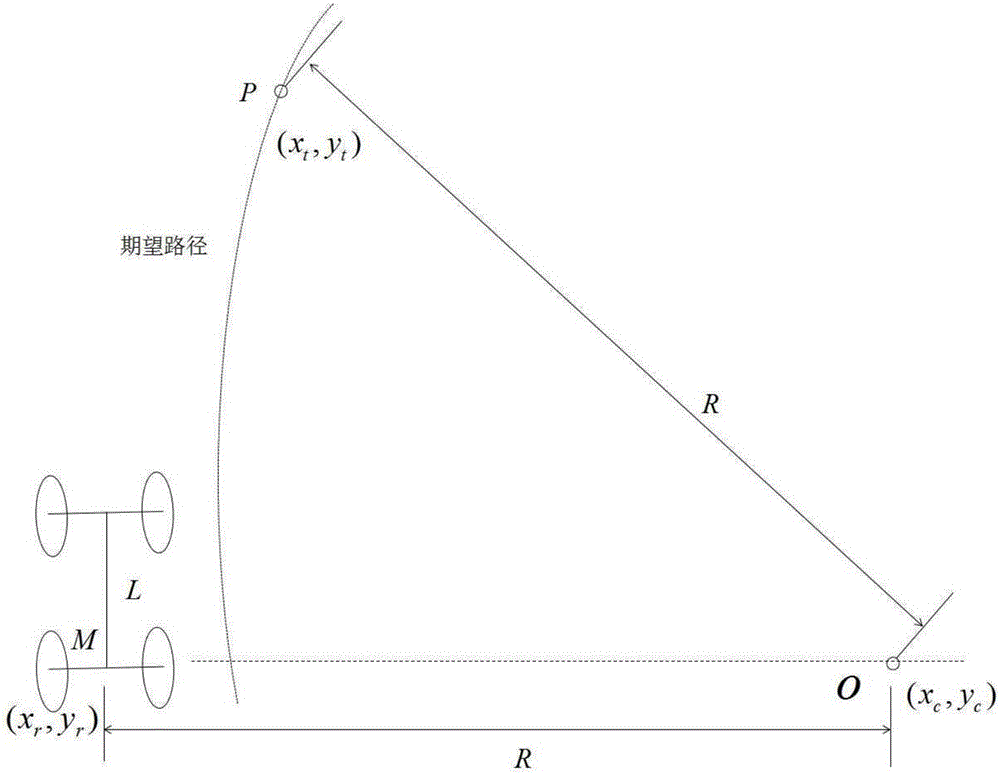

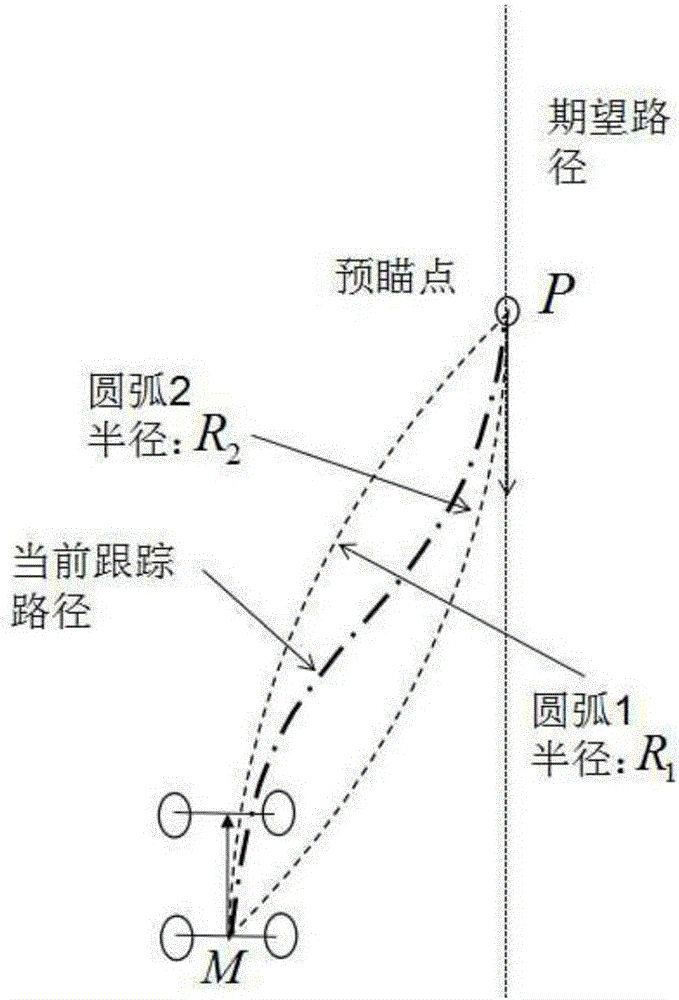

Steering control method and device of intelligent vehicle

ActiveCN106275066ACurvature changes are easy to controlSmooth steeringSteering linkagesAutomatic steering controlSteering controlMechanical engineering

The invention discloses a steering control method and device of an intelligent vehicle. The method comprises: step 1, collecting driving information, expected path information and obstacle information from the vehicle; step 2, according to the information collected in the step 1, selecting a minimum preview distance and a maximum preview distance; step 3, according to the minimum preview distance and the maximum preview distance, determining a current preview distance and a current preview point corresponding to the current preview distance; step 4, according to the current preview point and vehicle information, generating a double-circular-arc synthetic curve; step 5, according to the double-circular-arc synthetic curve, determining a front wheel expected rotating angle; step 6, judging whether the double-circular-arc synthetic curve meets a safety driving principle or not; if so, determining the front wheel expected rotating angle as a final front wheel expected rotating angle; otherwise, returning back to the step 3. The steering control method and device of the intelligent vehicle, provided by the invention, can be used for controlling the vehicle to steer according to the double-circular-arc synthetic curve; finally, the direction of the vehicle is the same as that of an expected path.

Owner:BEIJING ZHIXINGZHE TECH CO LTD

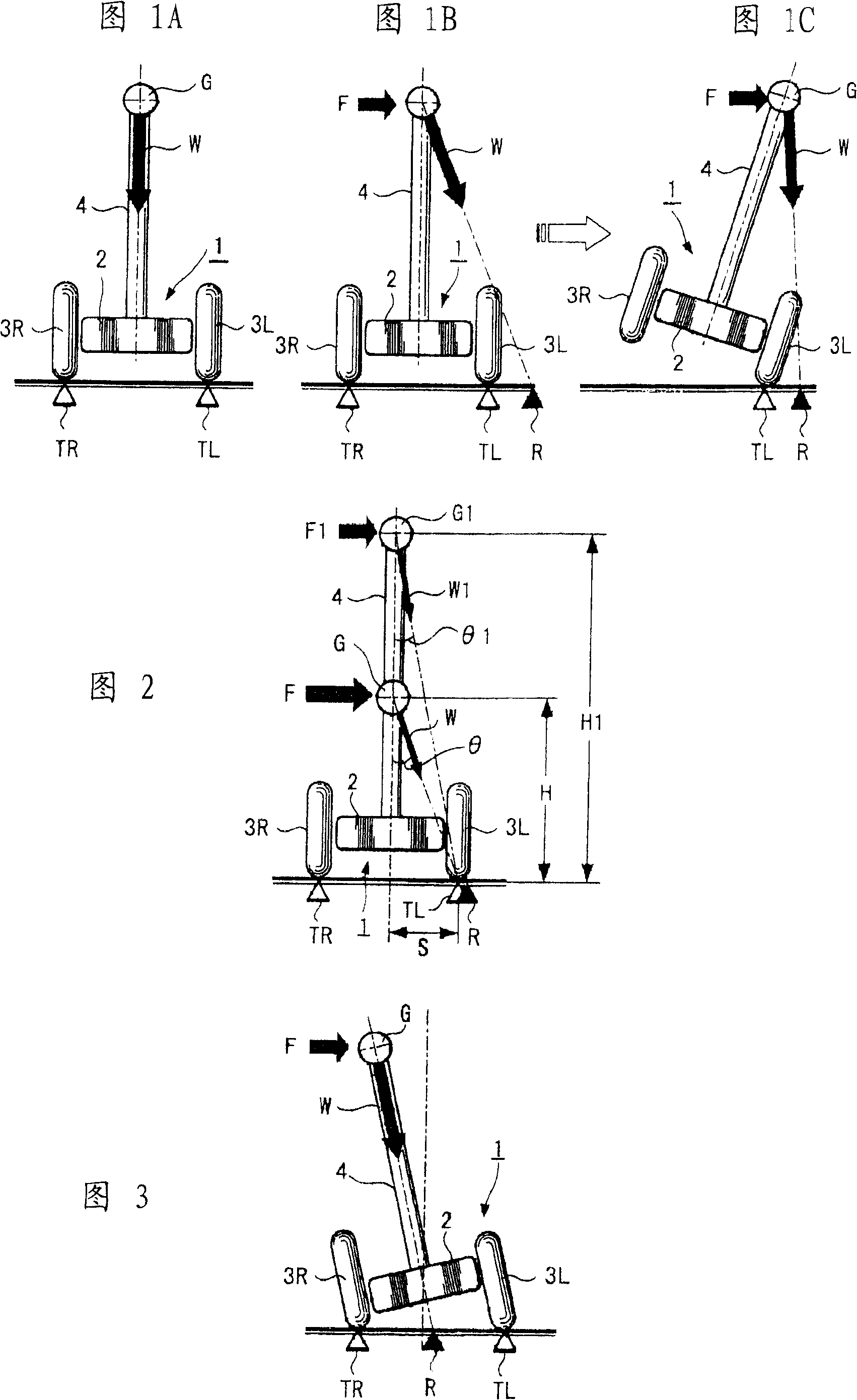

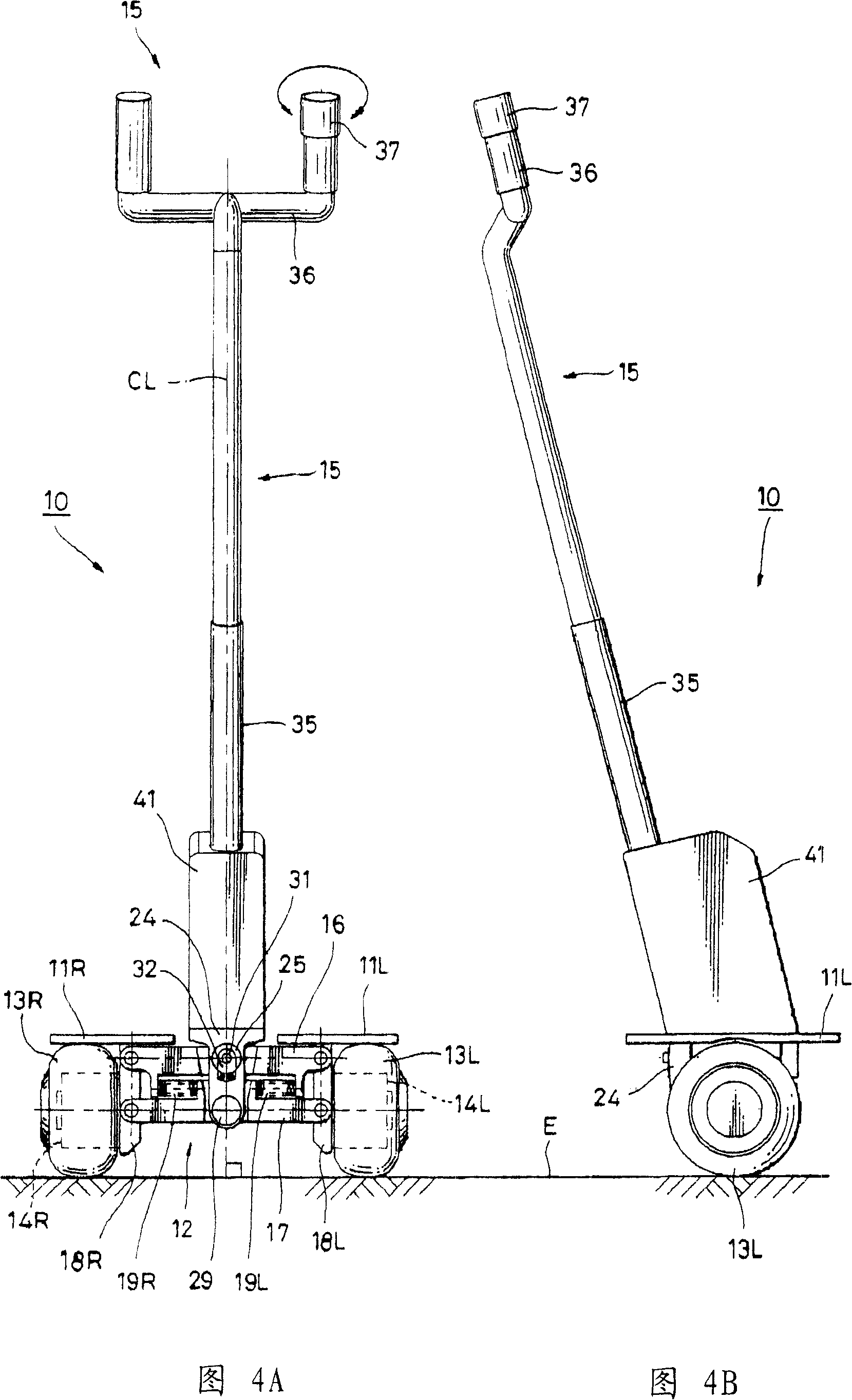

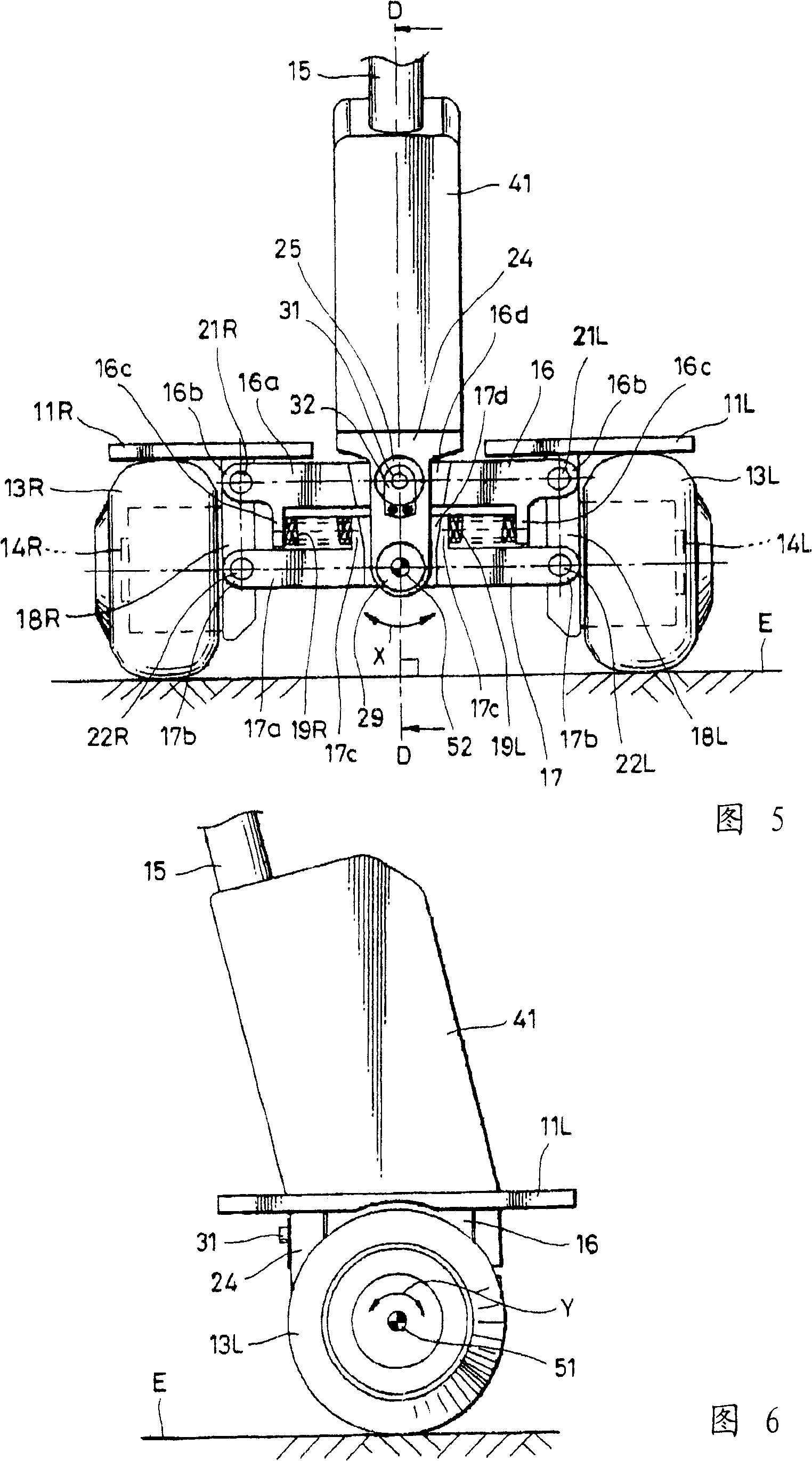

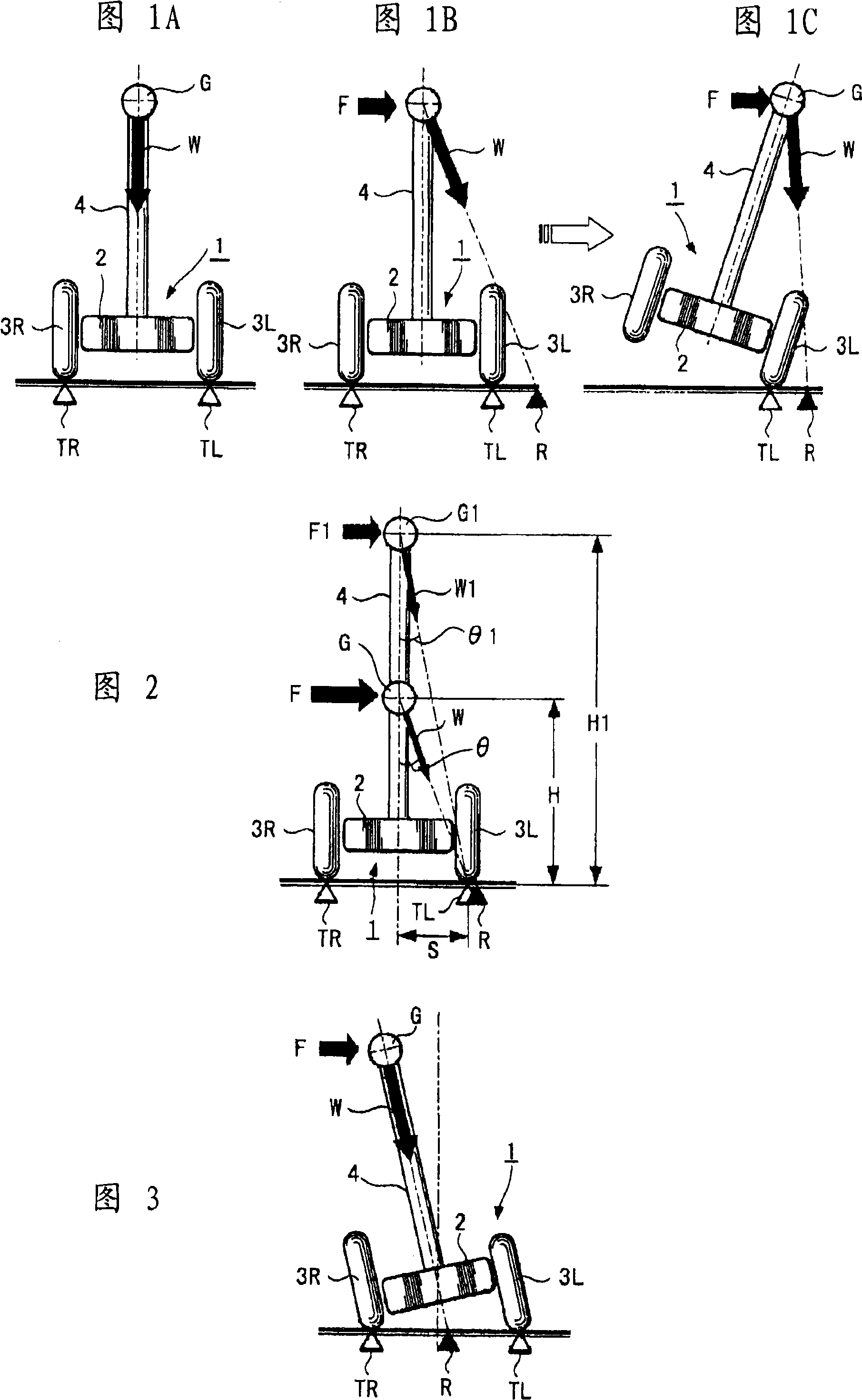

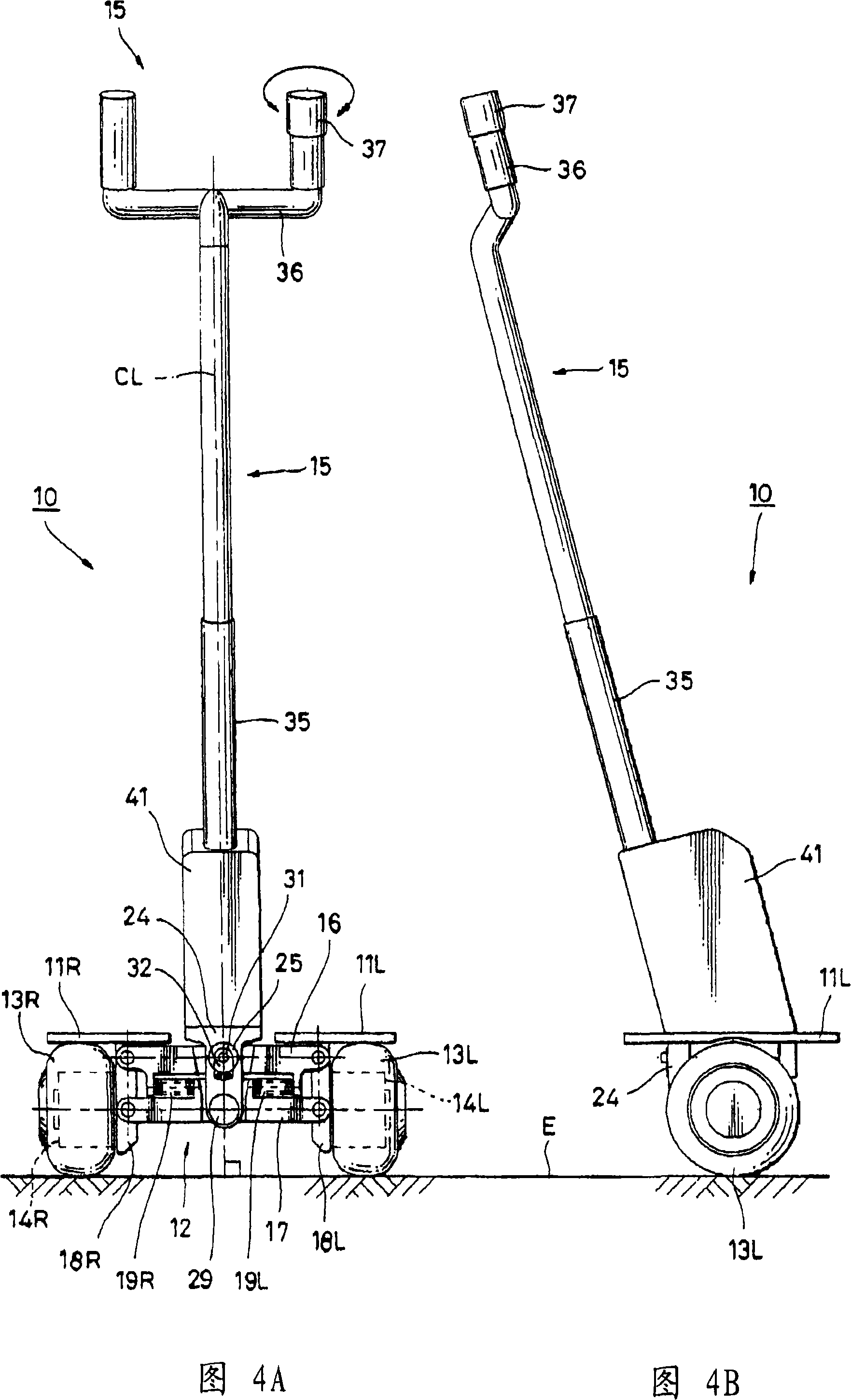

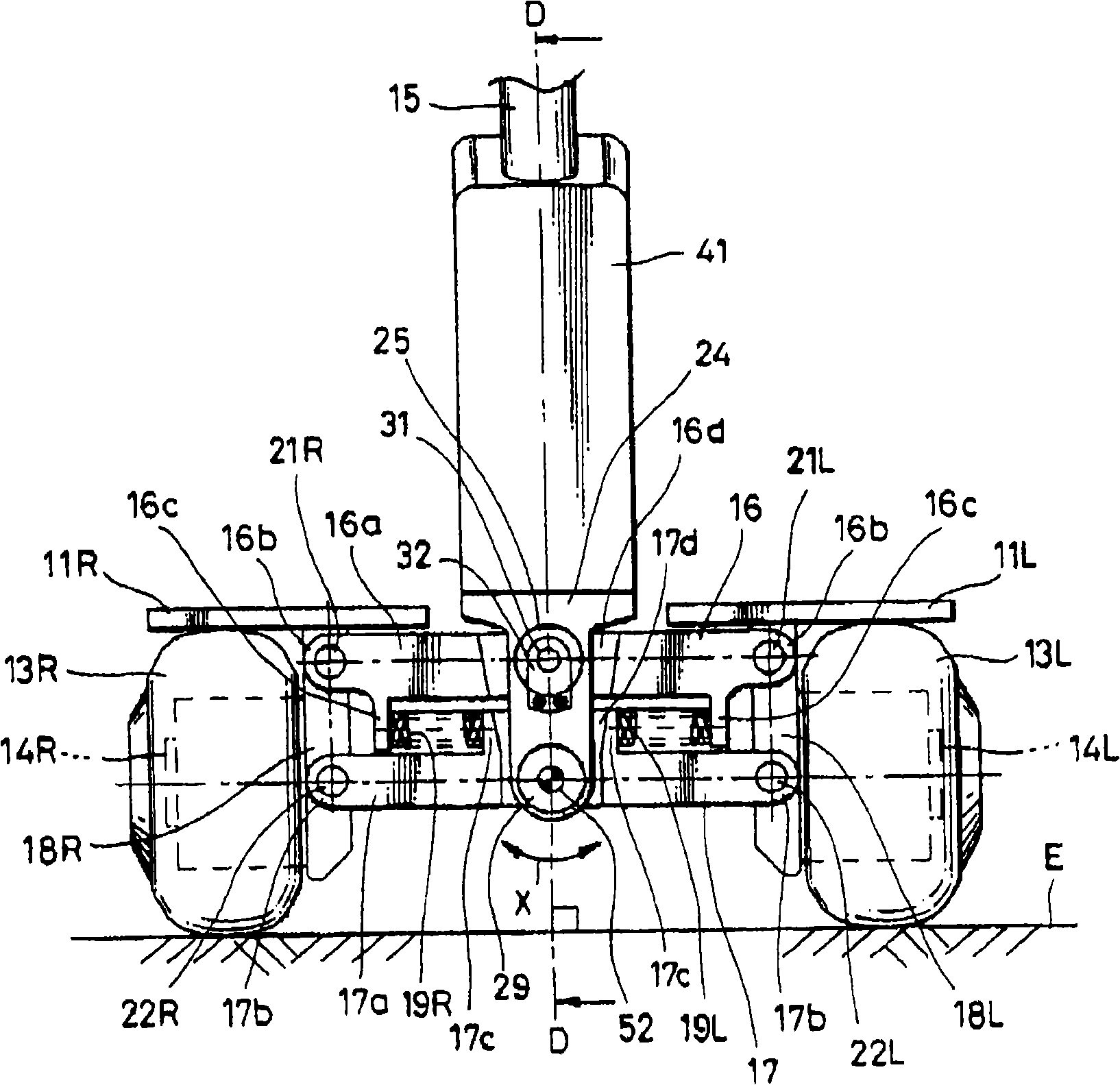

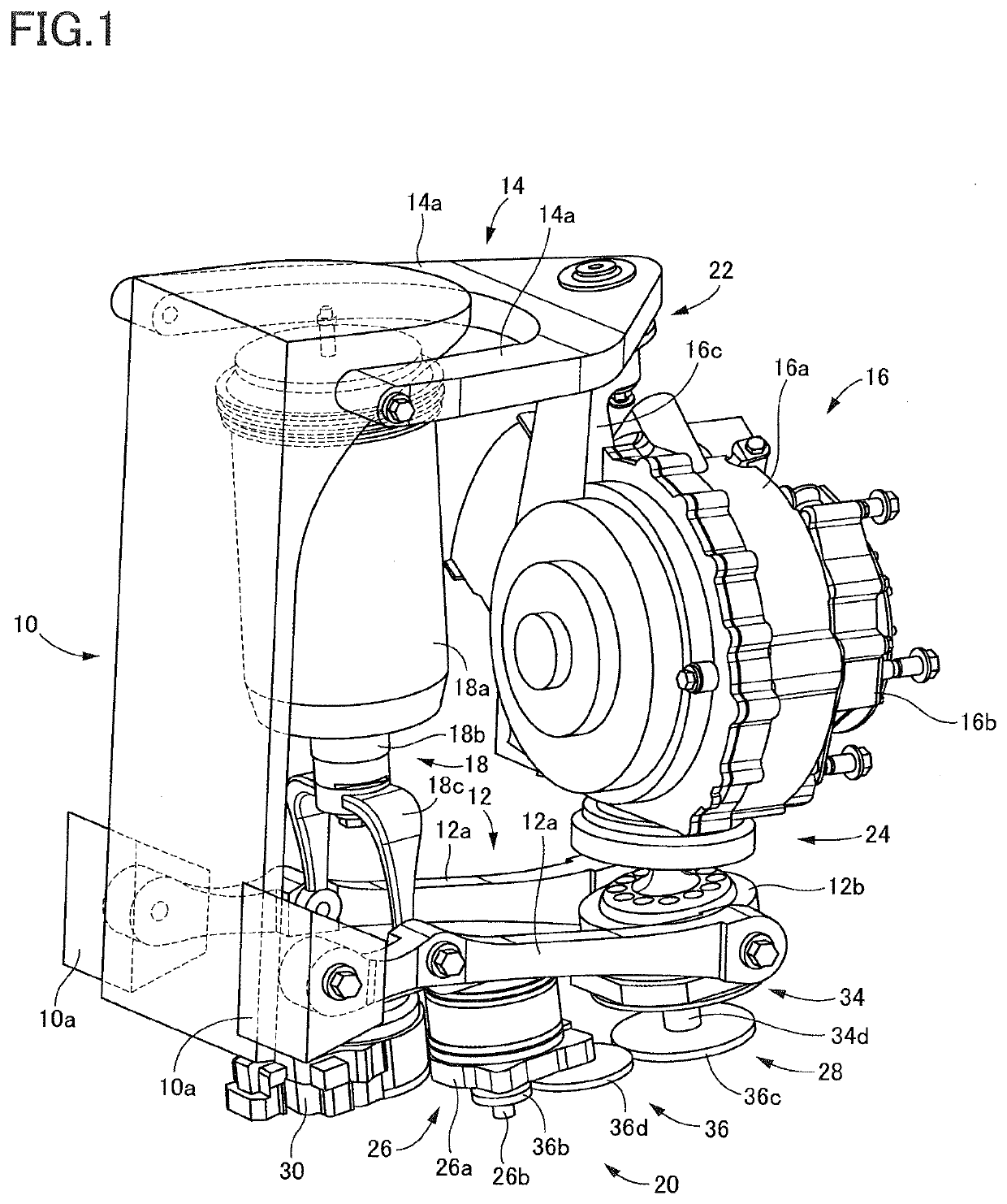

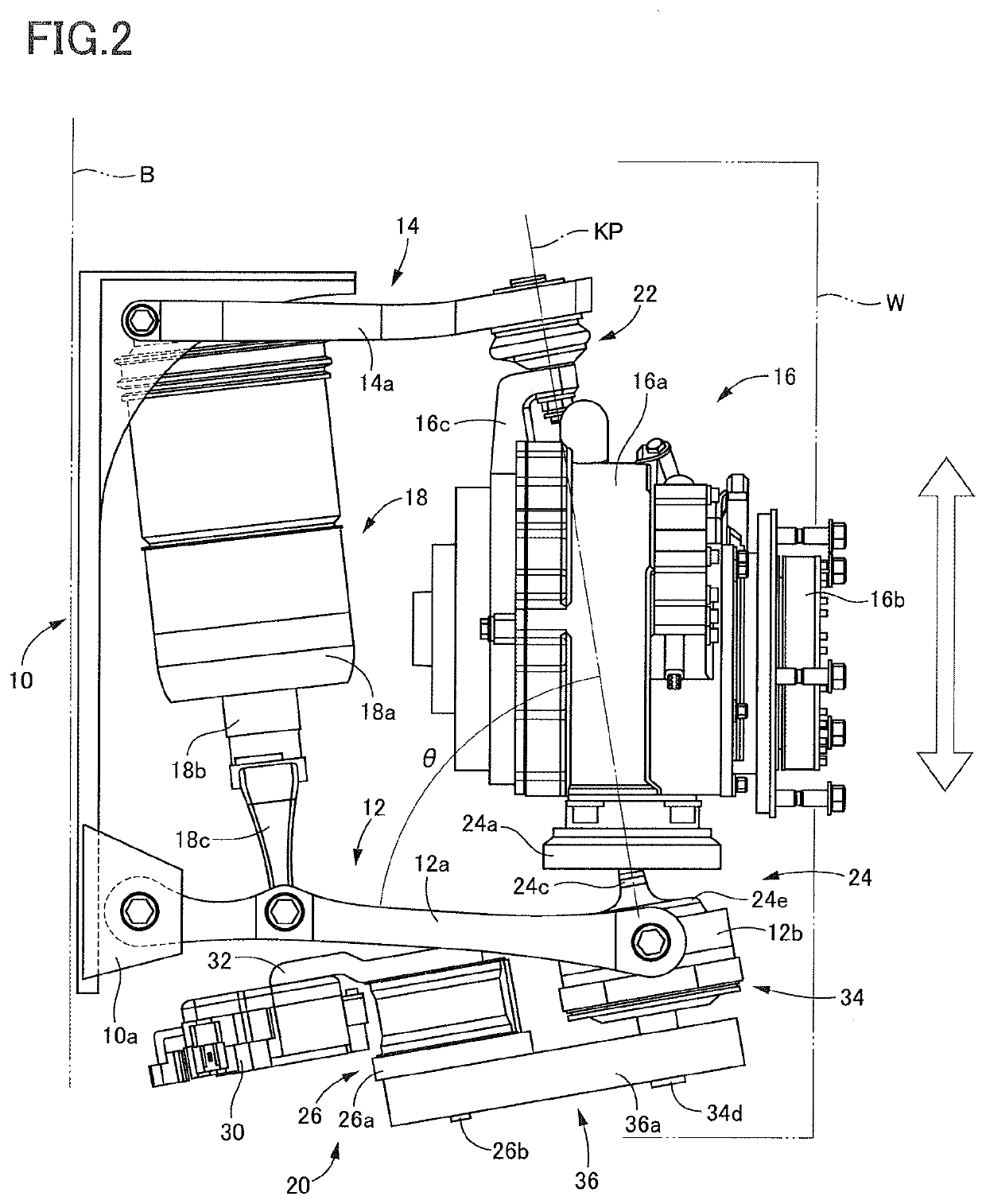

Coaxial two-wheel vehicle

A coaxial two-wheel vehicle with which a rider stably travels without the upper body being swayed left and right in a riding state of the center of gravity being positioned high is provided. The coaxial two-wheel vehicle includes: a step plate for a driver to ride; a vehicle body that supports the step plate to be capable of changing a posture in a roll direction of rotating around a roll axis as the center, when a traveling direction is made the roll axis; a pair of wheels disposed on both sides on the same axis in the direction orthogonal to the traveling direction of the vehicle body and rotatably supported by the vehicle body; a pair of wheel drive means to drive and rotate the pair of wheels independently; and a handle for directly changing a posture of the step plate or indirectly changing the posture through the vehicle body.

Owner:TOYOTA JIDOSHA KK

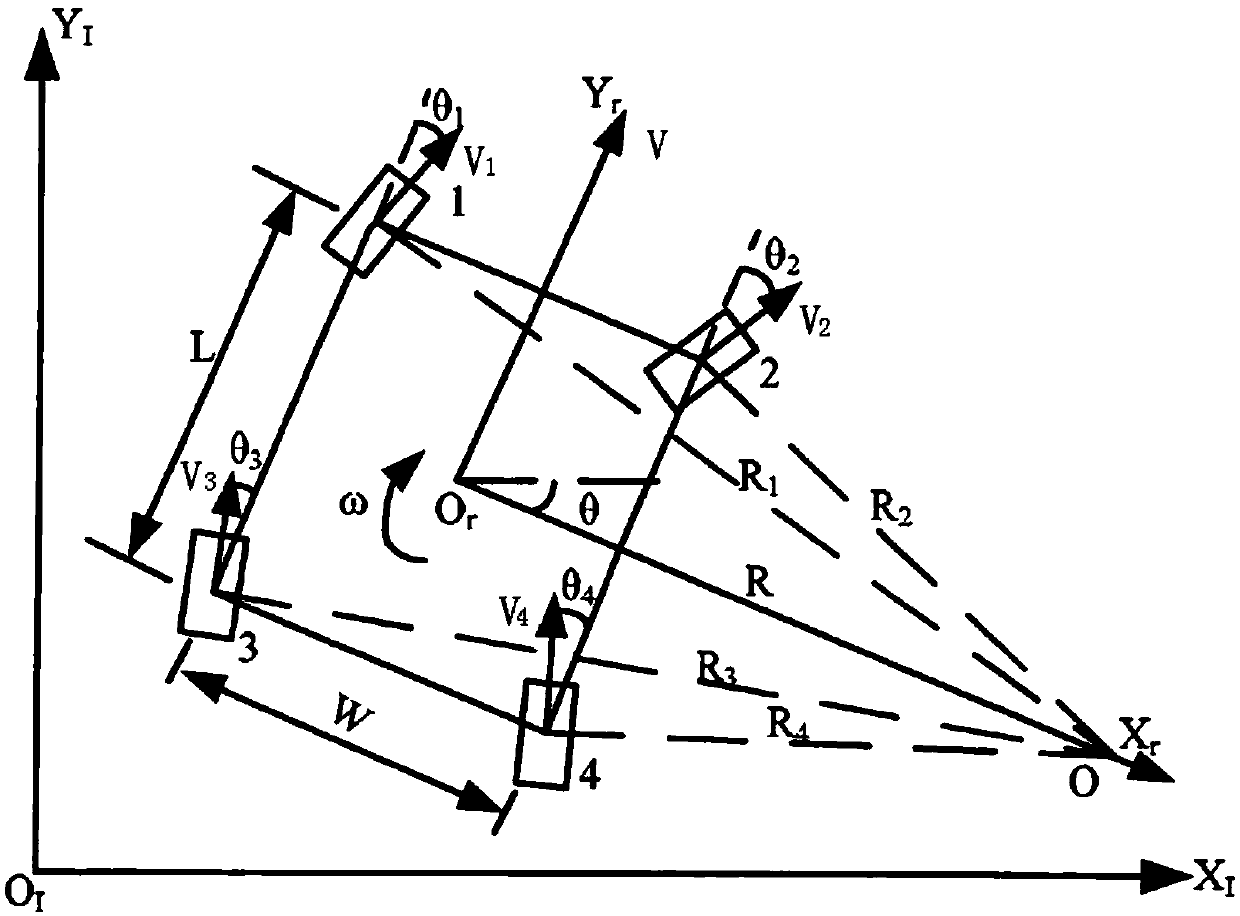

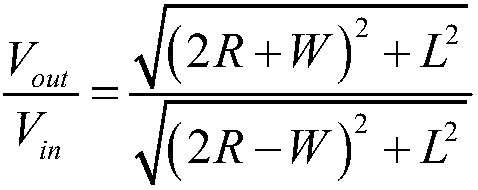

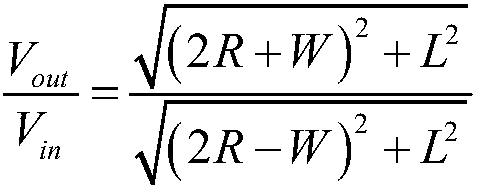

Four-wheel drive steering control method and device

InactiveCN107783540ASmooth steeringMeet flexibilityPosition/course control in two dimensionsVehiclesRolloverDrive wheel

The invention relates to a four-wheel drive steering control method and device. The control method comprises the following steps: acquiring turning radius of a vehicle body of an AGV and speed of onedriving wheel; calculating speeds of other driving wheels according to the turning radius of the vehicle body and speed of one driving wheel acquired, wherein a mathematical expression is described inthe specification, Vout is speed of a front outside driving wheel or a rear outside driving wheel of the AGV, Vin is speed of a front inside driving wheel or a rear inside driving wheel of the AGV, Wand L are distance between an inner driving wheel and an outer driving wheel and distance between a front driving wheel and a rear driving wheel of the AVG, respectively, and R is the turning radiusof the vehicle body; and according to the speeds of all the driving wheels, adjusting the speeds of all the driving wheels accordingly, so as to complete steering. The control method provided by the invention has the advantages that the turning radius of the vehicle body of the AGV and the speed of one driving wheel are acquired in real time, and the speeds of other driving wheels are calculated accordingly and are adjusted, so that steady steering of all the driving wheels is achieved, driving effect is improved, and a rollover phenomenon is avoided.

Owner:河南森源中锋智能制造有限公司

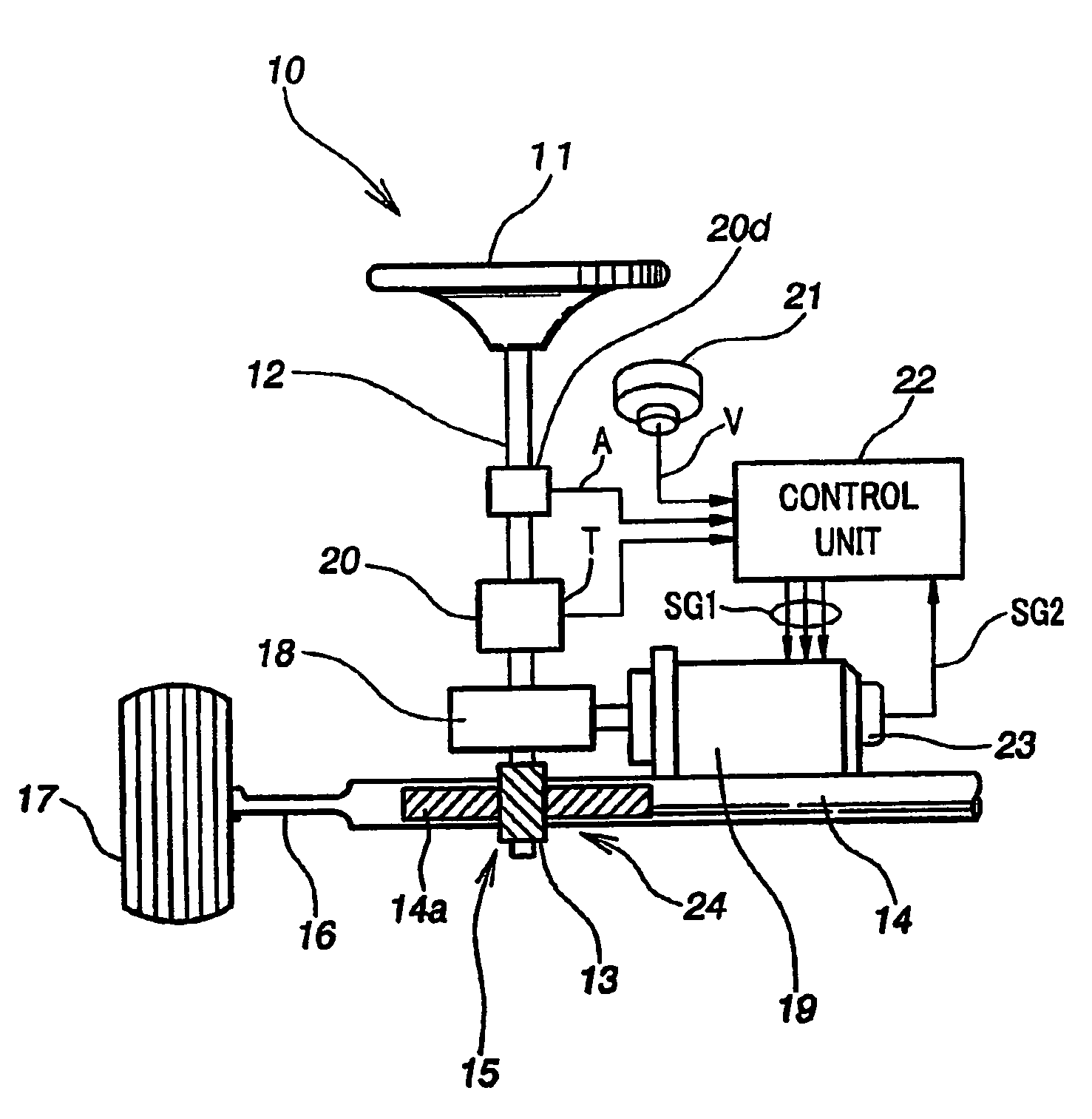

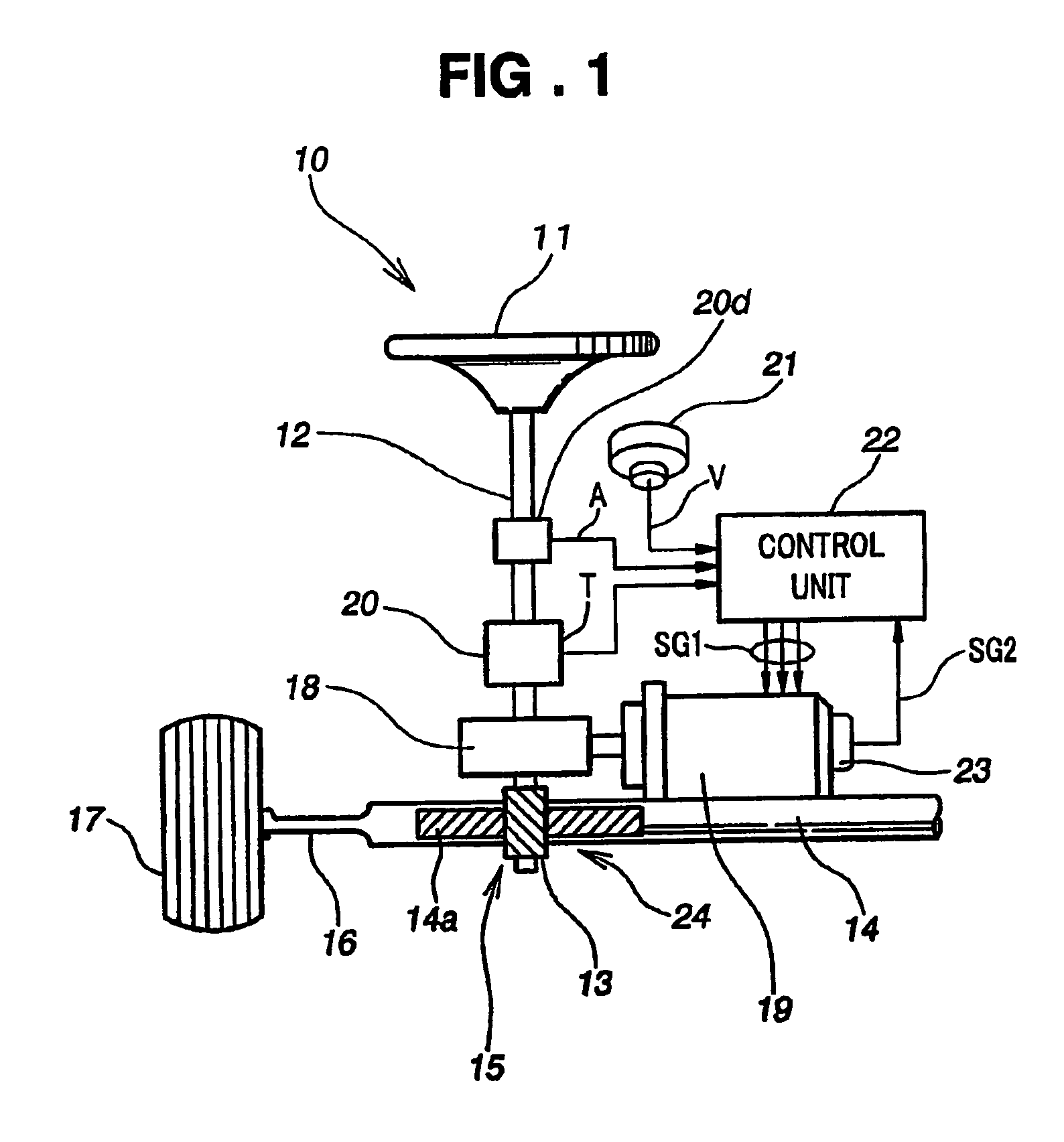

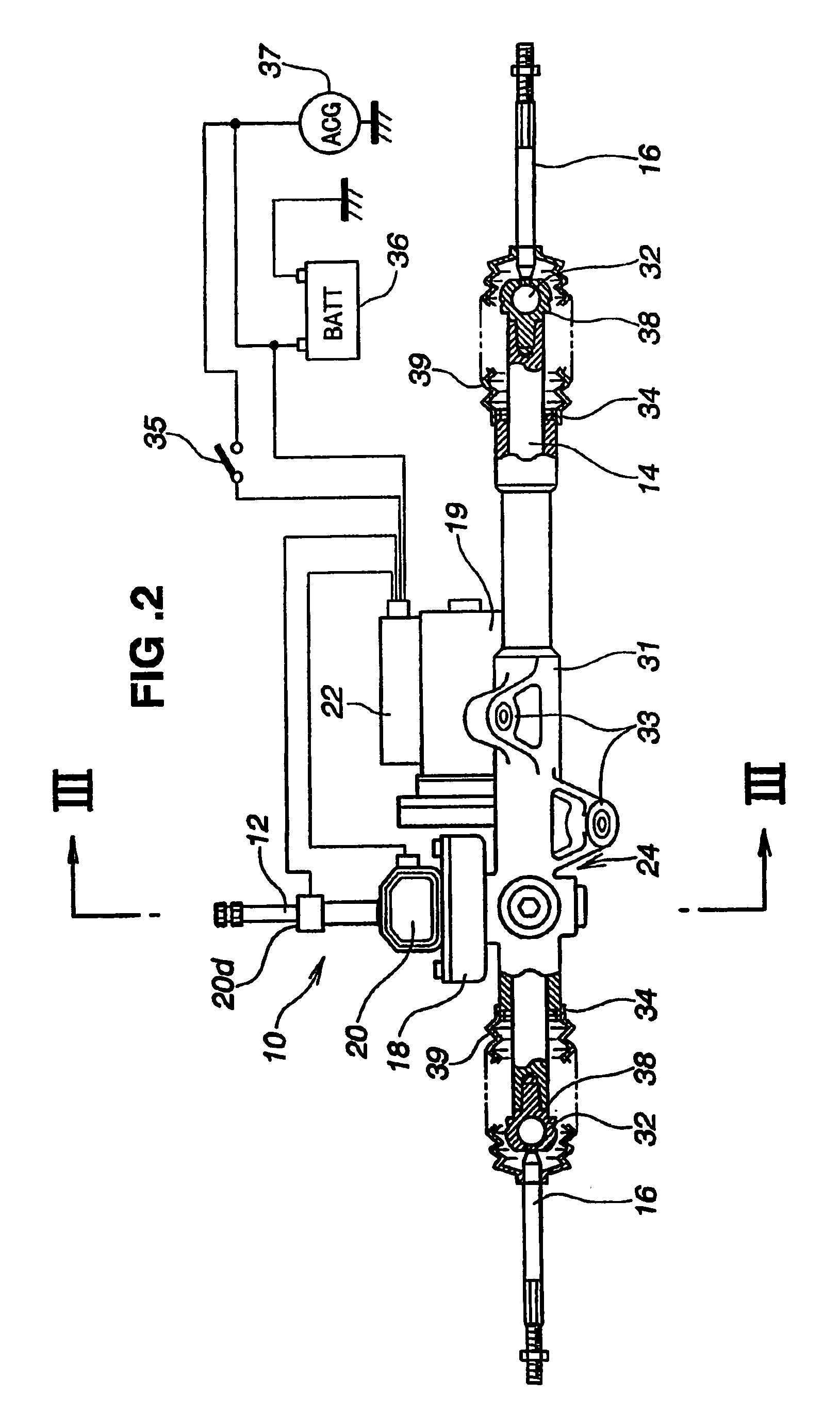

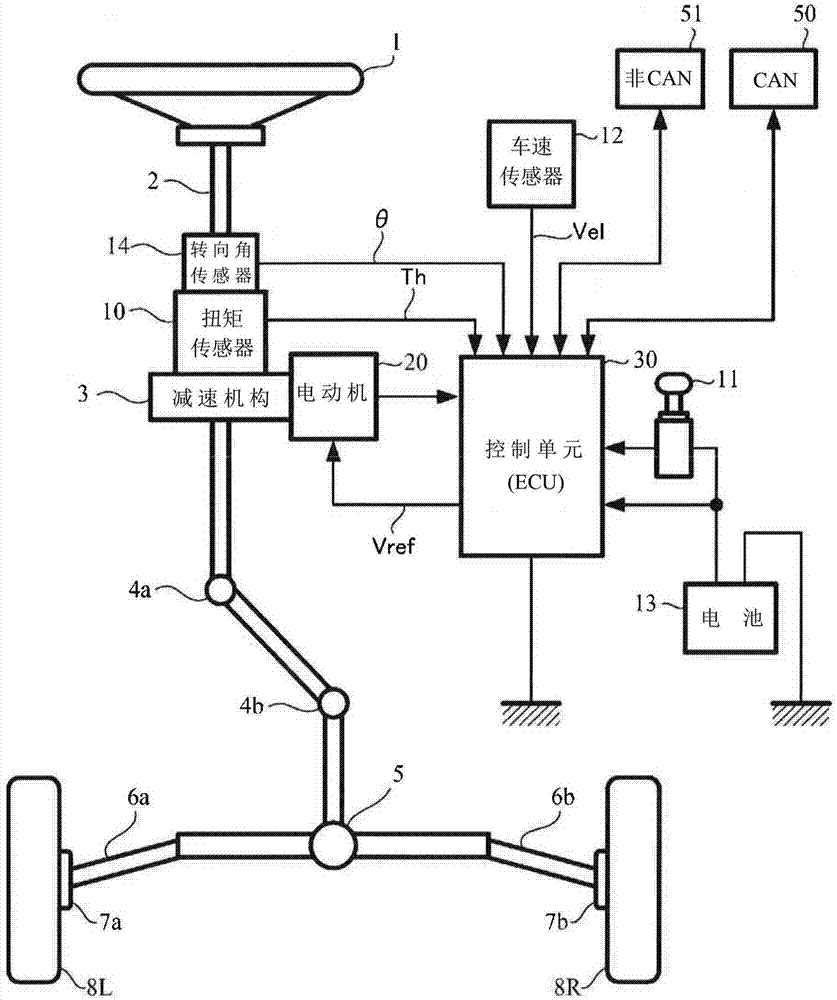

Electric power steering apparatus

ActiveUS6973992B2Smooth steeringSmooth steering touch or feelDC motor speed/torque controlDigital data processing detailsDriver circuitElectric power steering

An elect power steering apparatus includes a motor drive circuit for PWM-driving an electric motor to generate a steering assist torque corresponding to a steering torque. The motor drive circuit includes a bridge circuit formed by a plurality of FETs, and a predrive circuit for driving FETs at a positive potential. Series connected first and second voltage step-up circuits for stepping up a line voltage at two stages are provided in front of the predrive circuit so that the FETs are driven by the predrive circuit with an output voltage from the second voltage step-up circuit supplied to the predrive circuit.

Owner:HONDA MOTOR CO LTD

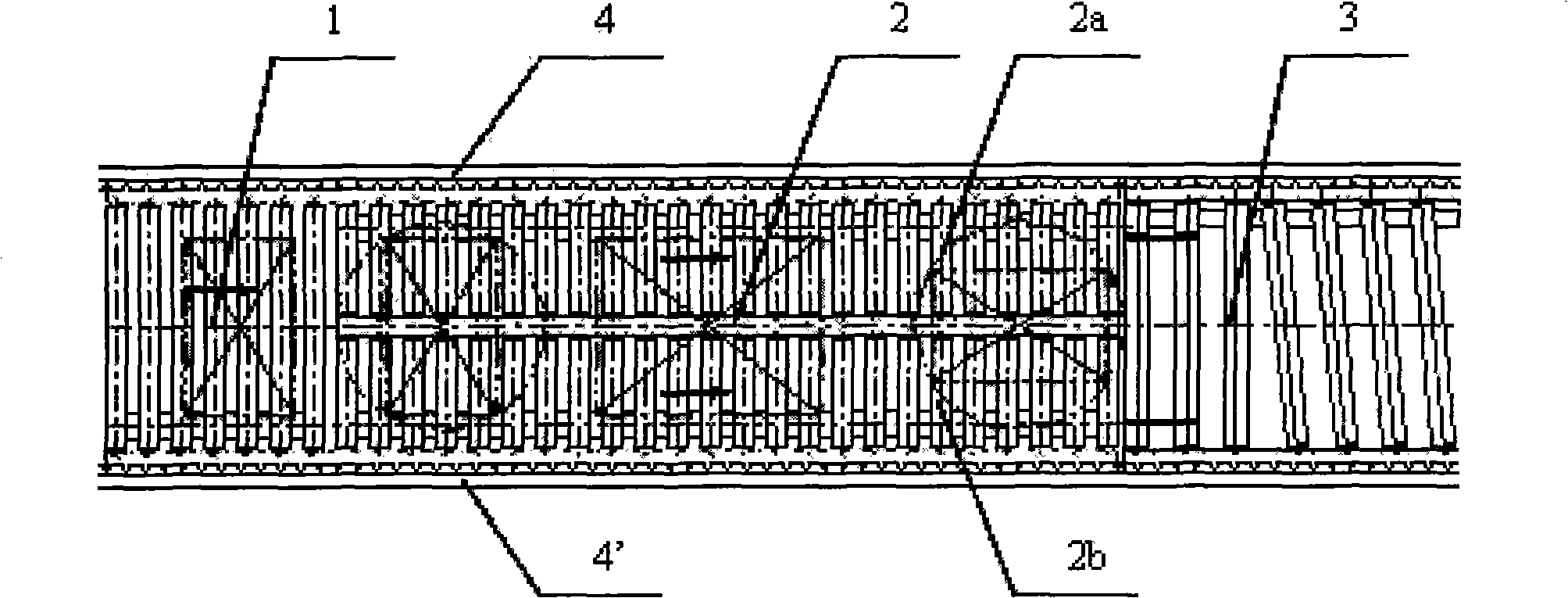

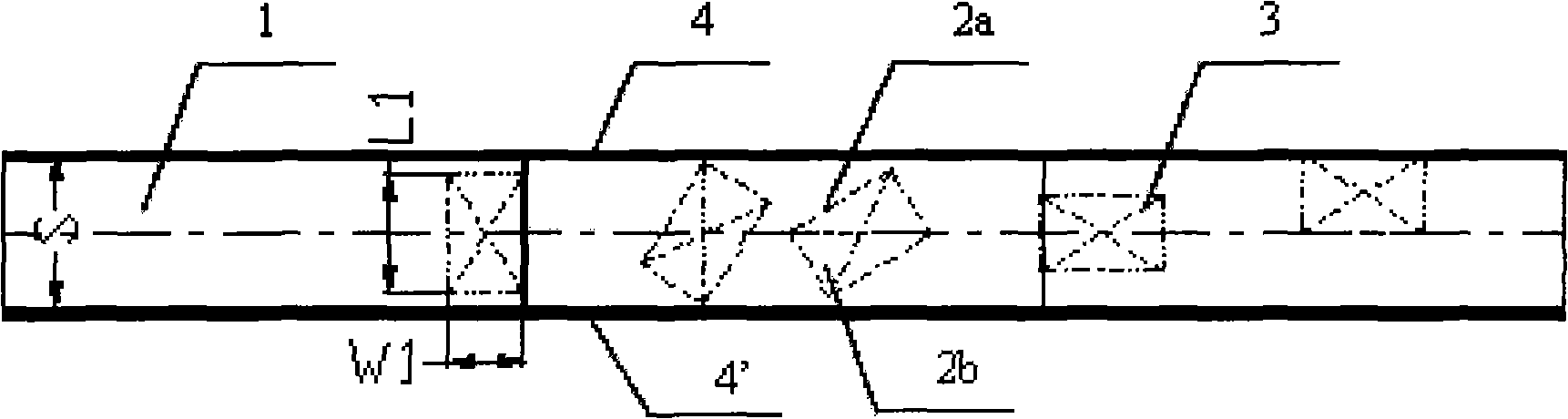

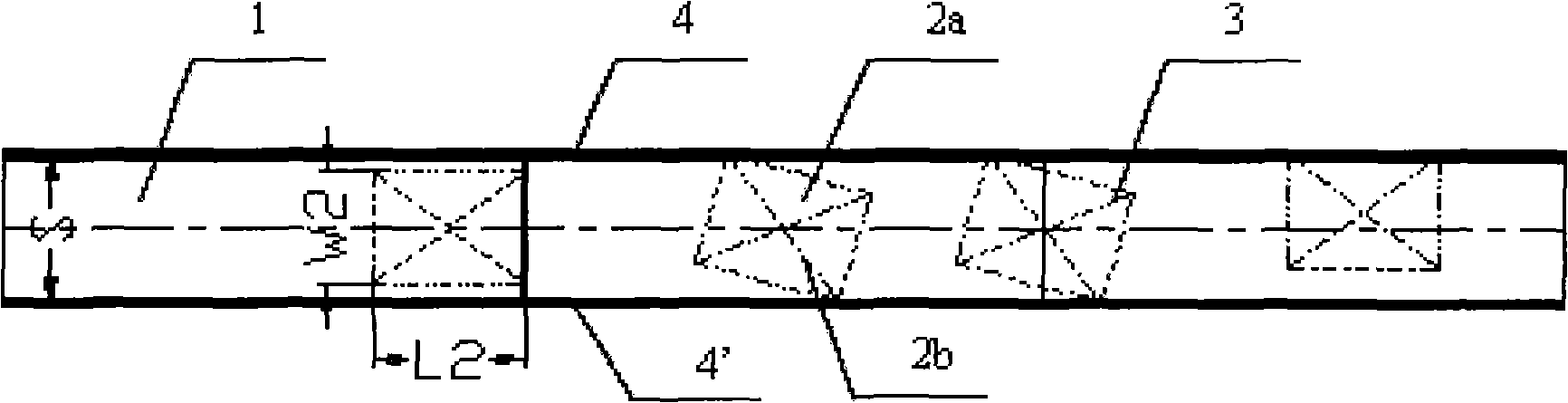

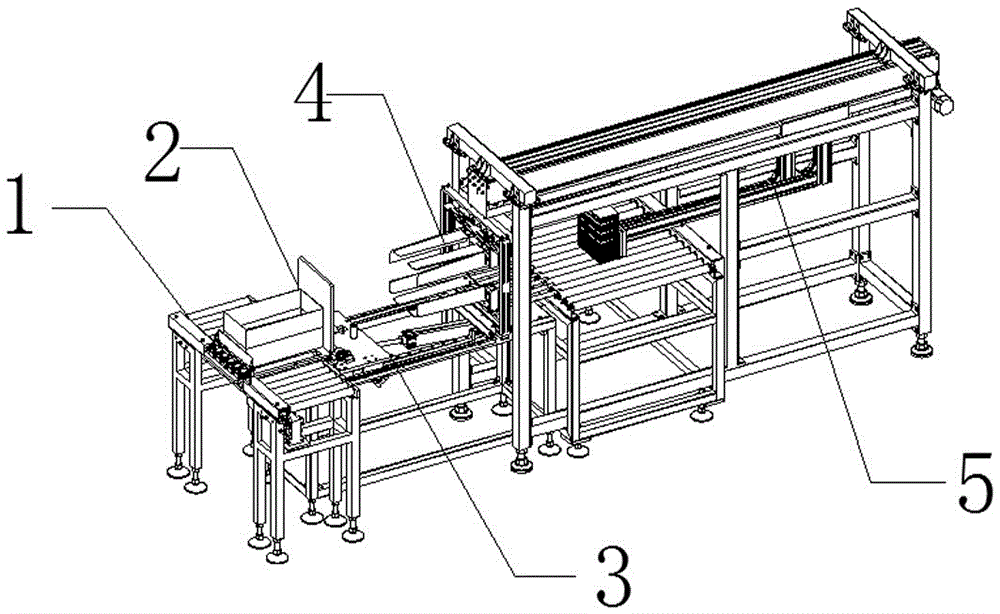

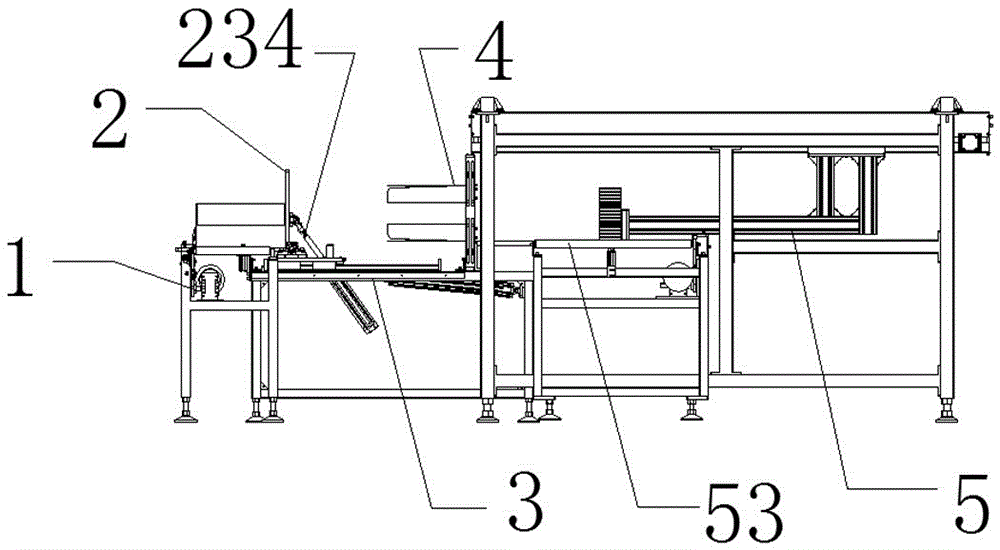

Self-selecting differential steering conveying equipment

The invention provides a self-selective differential-steering conveying device, which comprises an upper course input mechanism (1), a differential conveying mechanism (2) and a lower course output mechanism (3) which are connected in sequence, and guide guardrails(4,4') which are arranged on both sides of the upper course input mechanism, the differential conveying mechanism and the lower course output mechanism; the distance between the two guide guardrails(4,4') is larger than the diagonal length of the conveyed materials with minimal dimension and is less than the diagonal length of the conveyed materials with maximal dimension; the differential conveying mechanism consists of two conveying mechanisms (2a, 2b) with different conveying speeds in parallel; and the conveying surface (3a) of the lower course output mechanism is a web roll conveying surface. When the conveying device conveys the materials with different outside dimensions, the conveying device does not need to be provided with detecting equipment, can automatically turn the materials with smaller dimension 90 DEG and then output the materials, and can output the materials with larger dimension without turning so as to solve the problems that the equipment investment is large, the system resource is consumed, the equipment service life is influenced, and the like.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

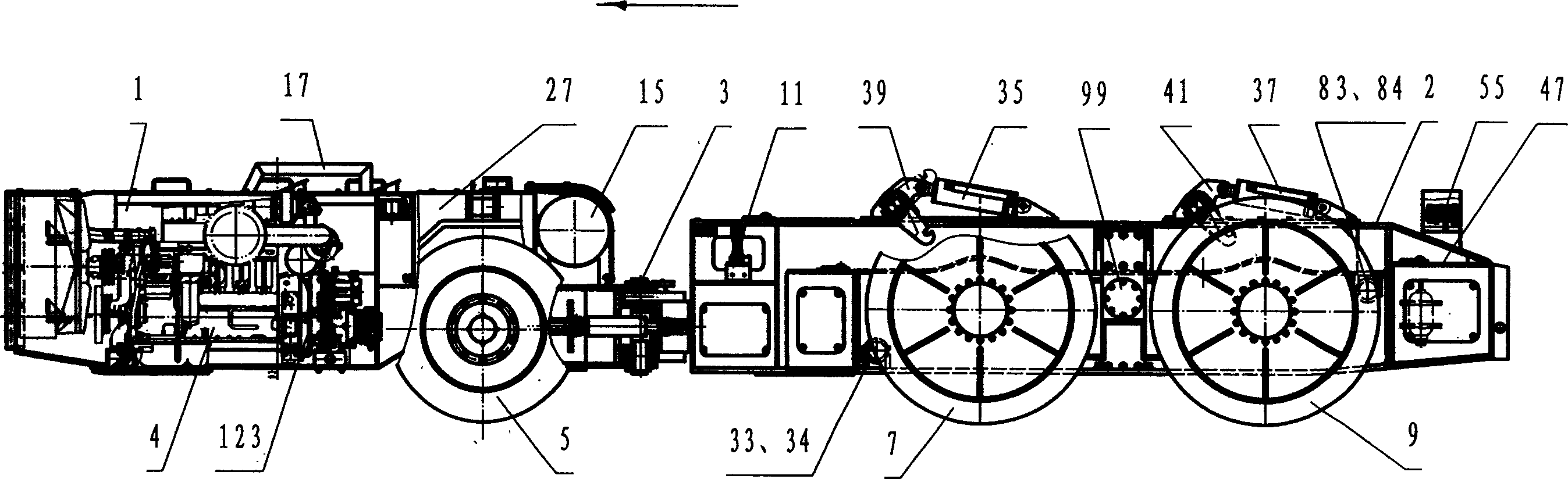

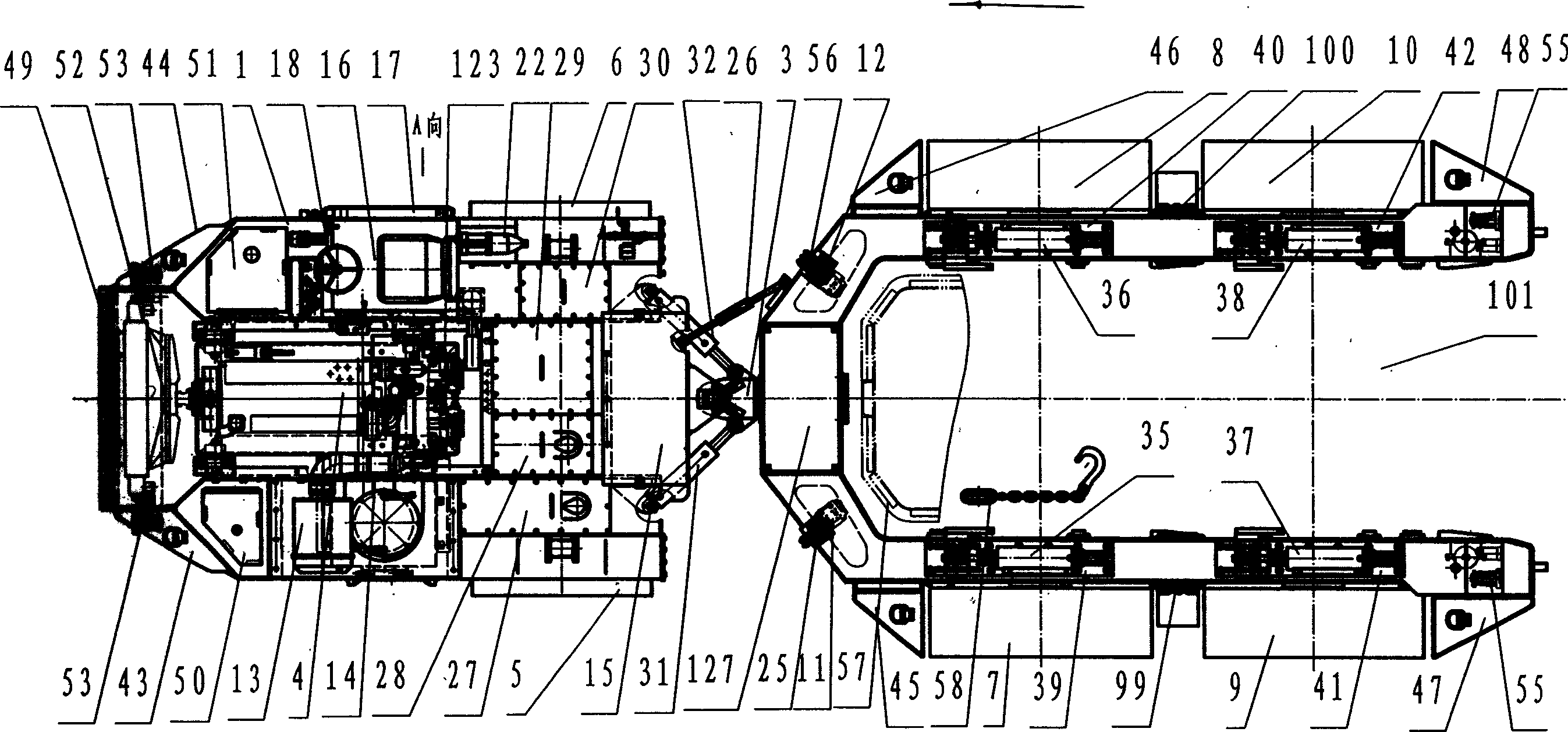

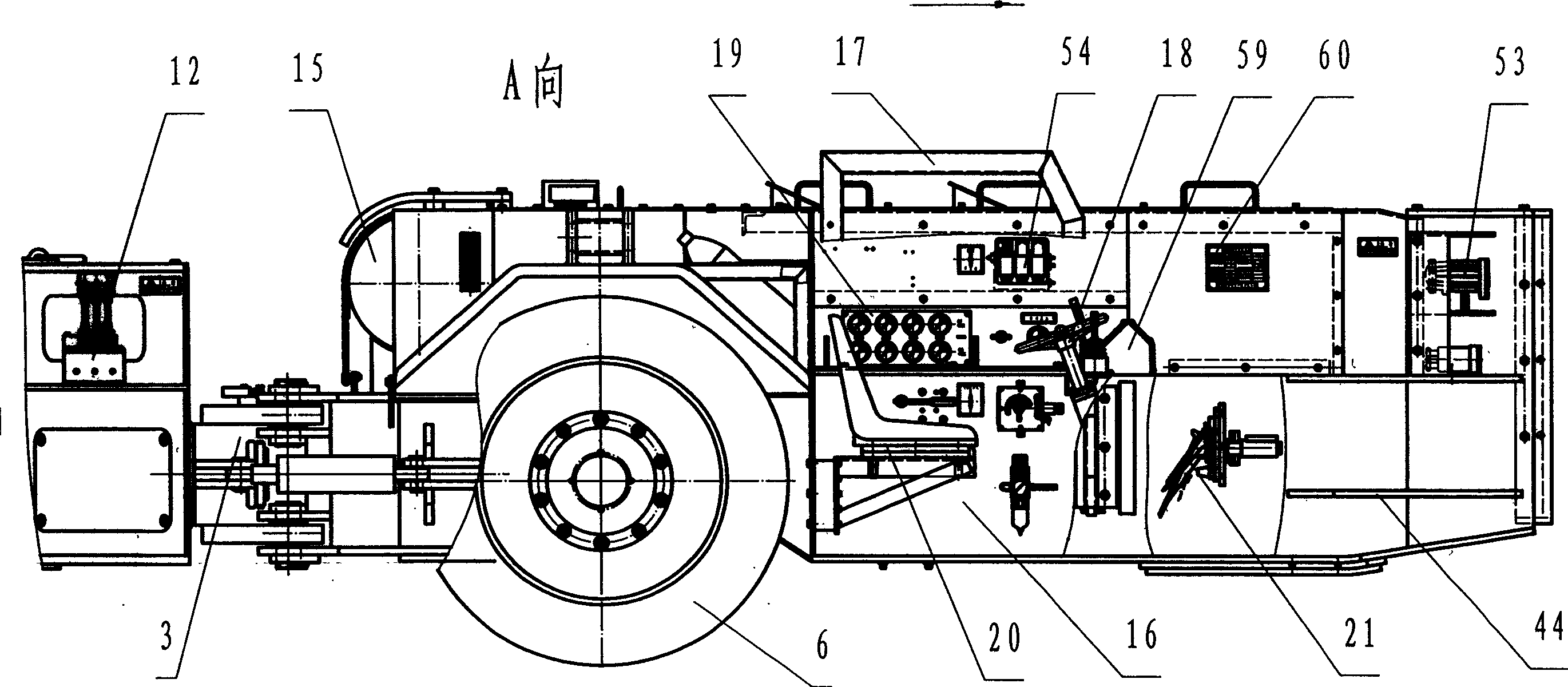

Explosion-proof support transporting vehicle for coal mine

ActiveCN1792673AAdvancedReasonable design structureItem transportation vehiclesElectricityControl system

An anti-explosion carrier vehicle for transporting supporting frames or heavy machines in coal mine is composed of front and back machine frames, steering linkwork, diesel engine, hydraulic system, lifting mechanism, clamping unit, admission and exhaust protecting unit, water cooling unit, running mechanism, feeding hopper, and operation control system. The hydraulic drive is used to control running, lifting, clamping and steering. The water, electricity, gas and hydraulic system are controlled in linkage mode. The anti-explosion design is taken.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

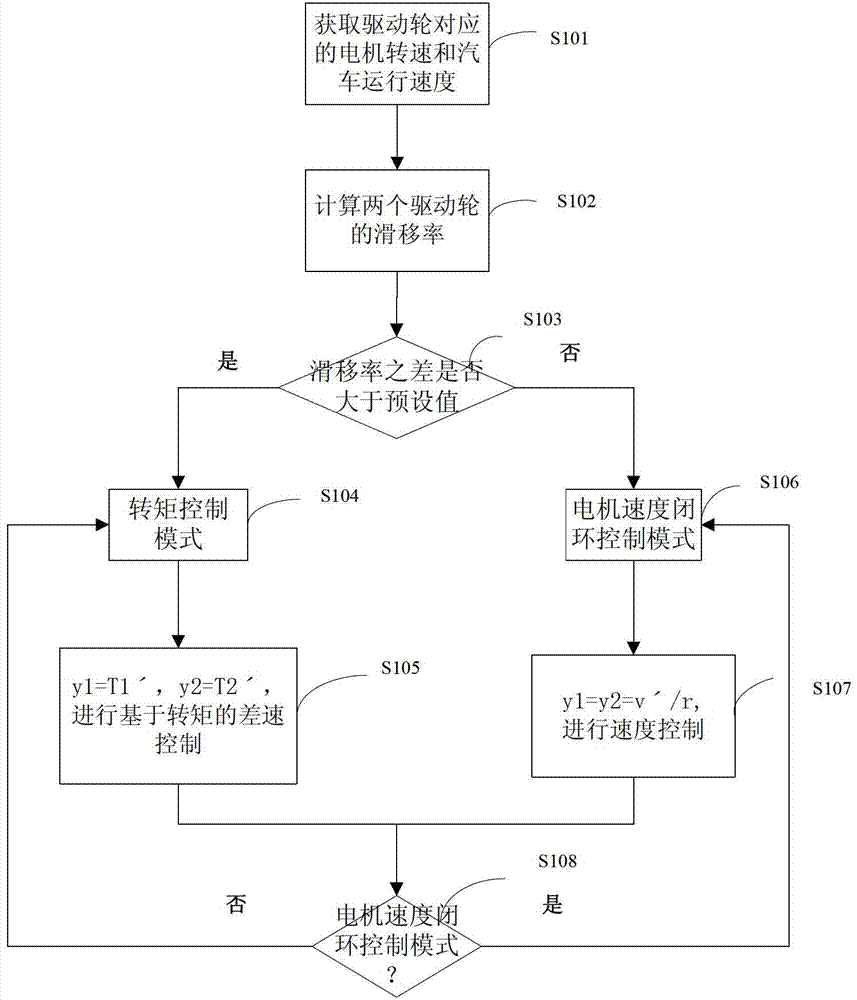

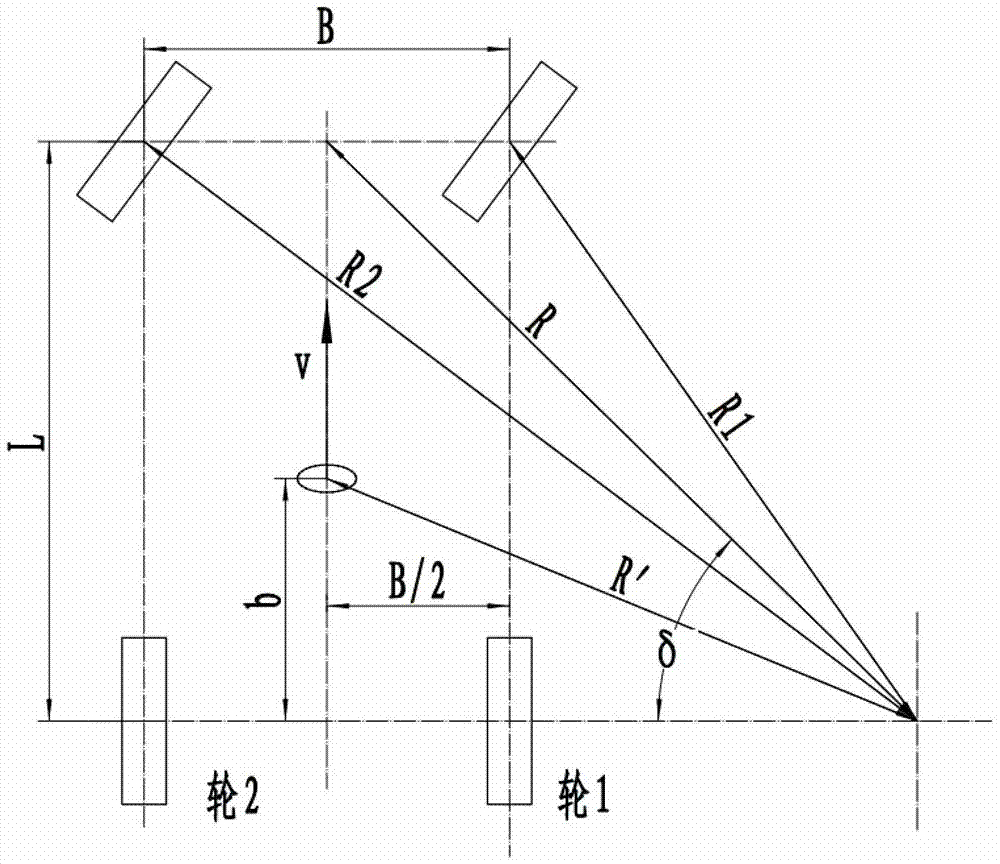

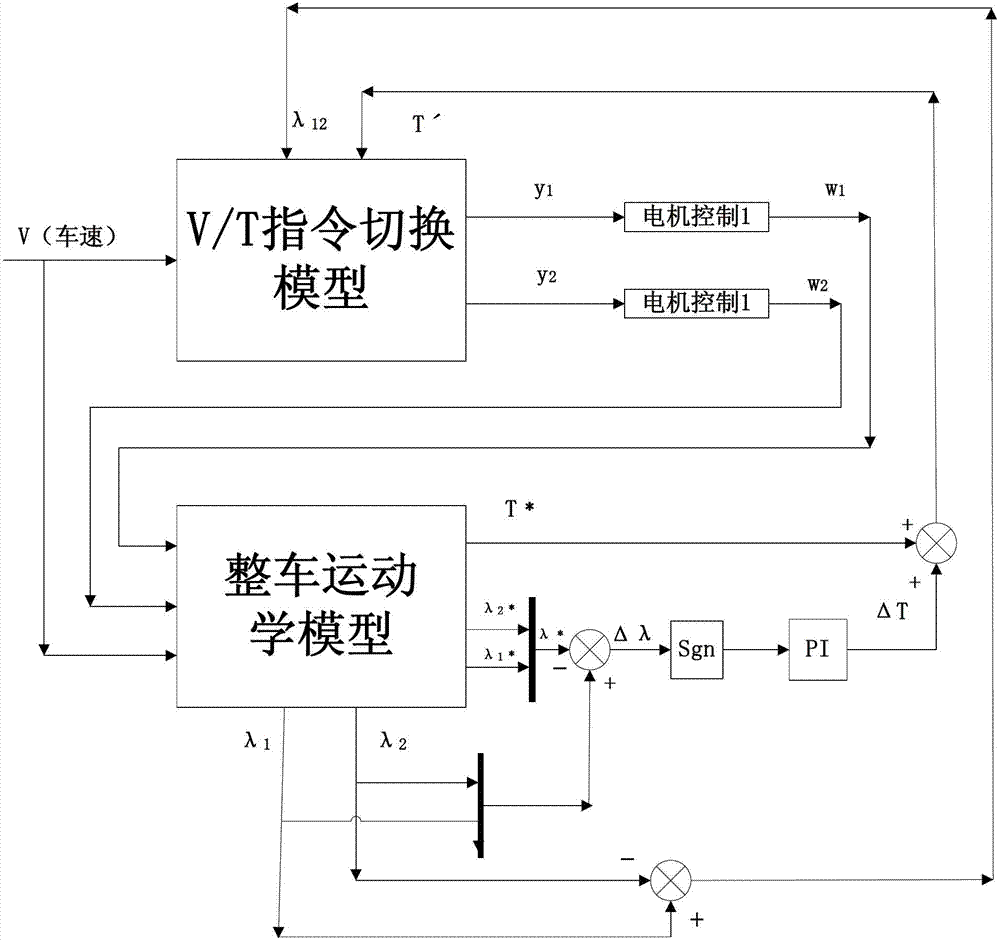

Self-adaption electronic differential control system

ActiveCN103112365AAdaptive Electronic Differential Control RealizationGuaranteed synchronizationSpeed controllerElectric energy managementArea networkDrive wheel

The invention discloses a self-adaption electronic differential control system which comprises a vehicle controller, an upper computer, two inverters and two driving motors which correspond to two driving wheels. The upper computer is connected with the vehicle control system, the upper machine is connected with two inverters through a controller area network (CAN) bus, and the driving motors are controlled to rotate by the inverters. Difference between slip rate of two driving pulleys is taken as a steering signal of an automobile so as to achieve self-adaption steering and switching. In the process of direct movement, the control system can guarantee that wheel speed is synchronous to vehicle speed, and simultaneously, motor power is changed in a real-time mode along with resisting moment of motion so as to achieve stable motion. In the process of bending movement, a torque control model based on best slip rate is used for revising a torque command in a real-time mode so as to control the slip rate to achieve the best place and stable steering. In addition, the self-adaption steering control based on the slip rate does not need a steering sensor and can save cost.

Owner:HUBEI AXLE

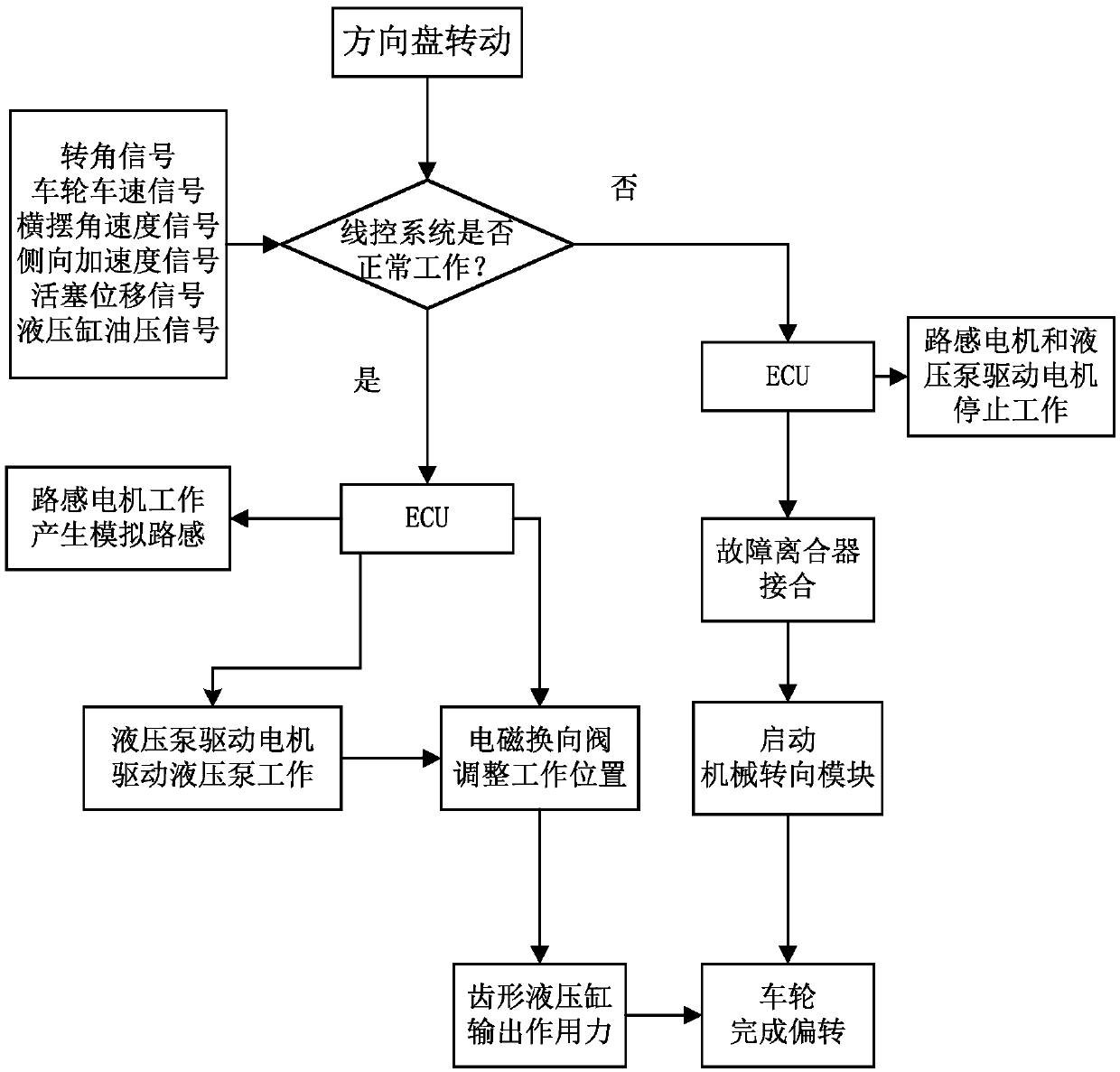

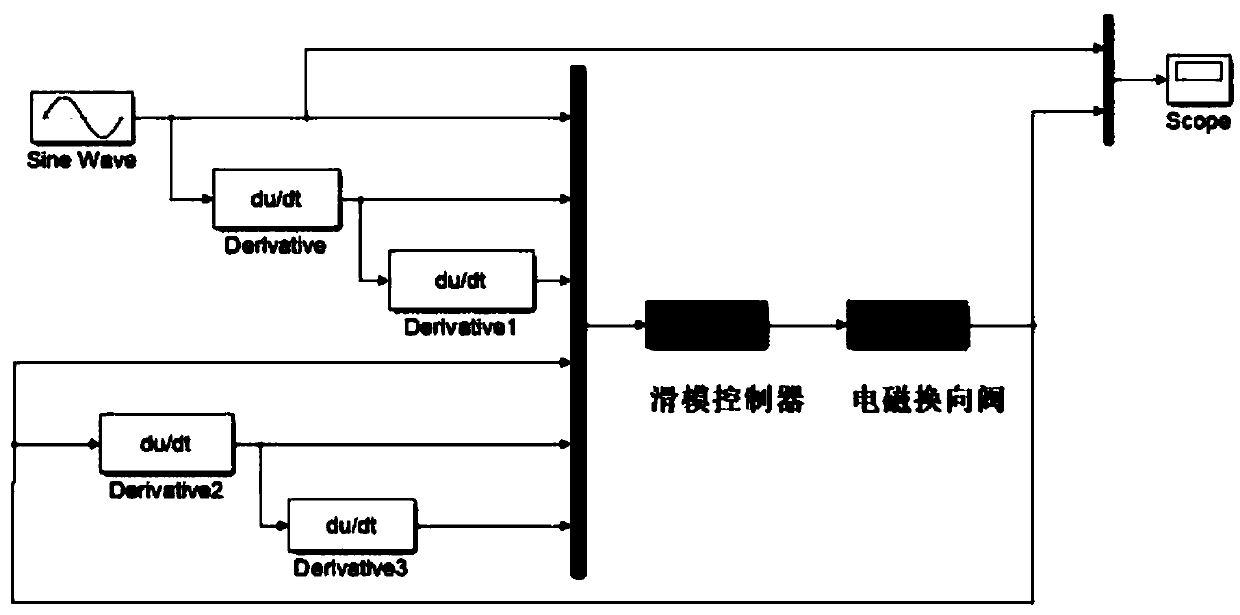

Steering control method of drive-by-wire hydraulic steering system of commercial vehicle

ActiveCN108820035AReduce the burden onImprove responsivenessMechanical steeringFluid steeringHydraulic pumpEngineering

The invention discloses a steering control method of a drive-by-wire hydraulic steering system of a commercial vehicle. The drive-by-wire hydraulic steering system comprises a steering wheel module, amechanical steering module, a hydraulic transmission module and a control module. An electronic control unit (ECU) in the control module outputs signals to control the operation of a hydraulic pump driving motor and an electromagnetic reversing valve, and drives a connecting rod mechanism to change the turning angle of wheels by changing oil pressure on two sides of a piston of a hydraulic cylinder; and the ECU also outputs current signals and feeds corresponding steering feel back to a driver through a steering feel motor to complete drive-by-wire hydraulic steering. When the drive-by-wire hydraulic steering fails, the ECU outputs commands to engage a failure clutch to start the mechanical steering module. The steering control method of the drive-by-wire hydraulic steering system of thecommercial vehicle is capable of intelligently setting a variable transmission ratio so as to improve the response ability and safety of the steering system of the commercial vehicle and improve the steering performance of the vehicle in general. In addition, in the event of failure of the drive-by-wire hydraulic steering, the steering system can be switched to a reliable mechanical transmission so as to ensure the operability of vehicle steering by the driver in emergencies and ensure the safety of the vehicle.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

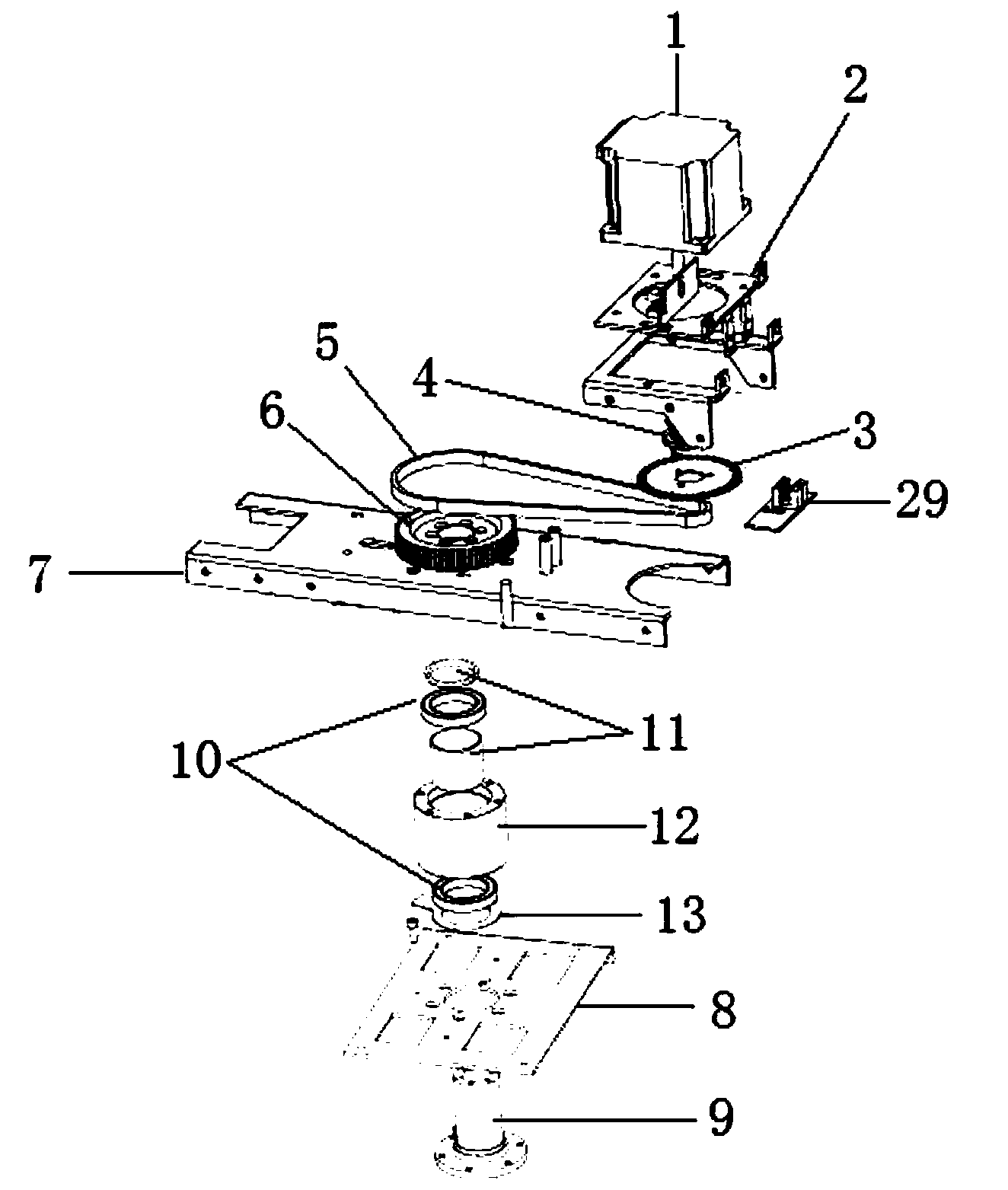

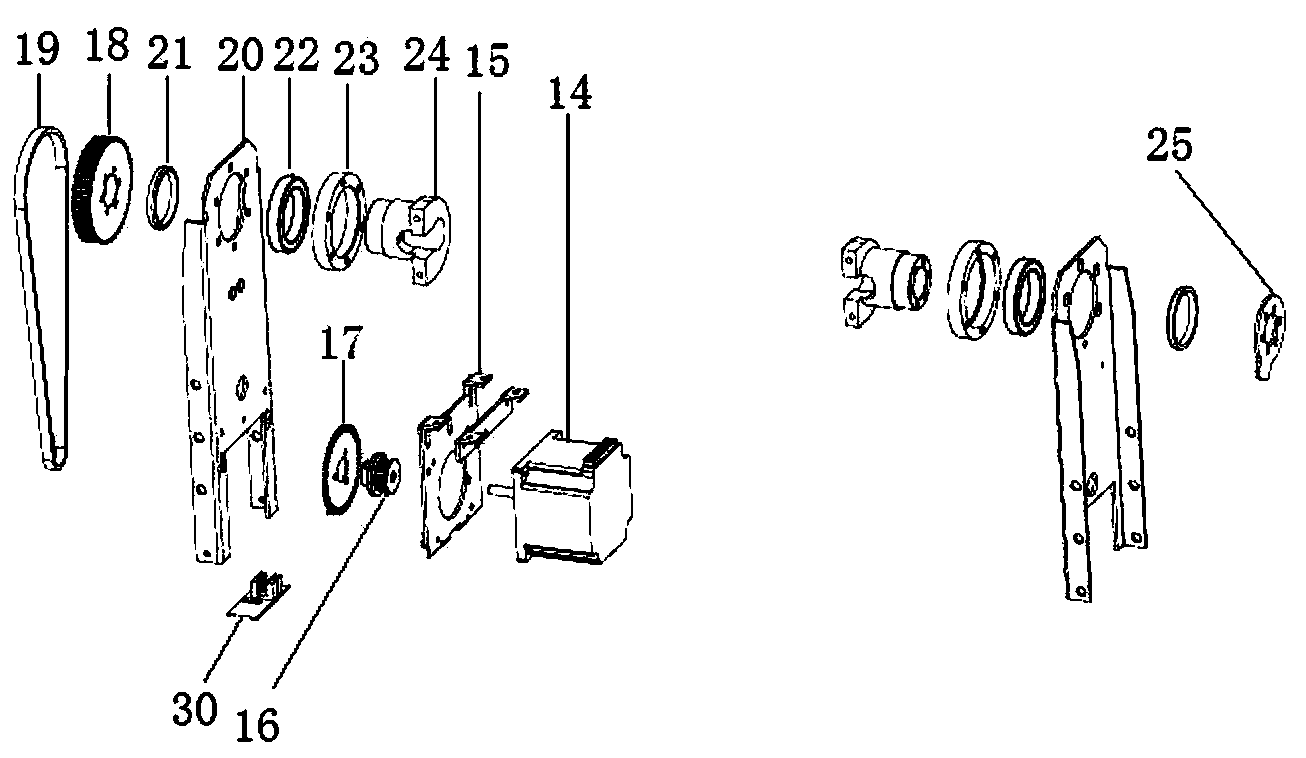

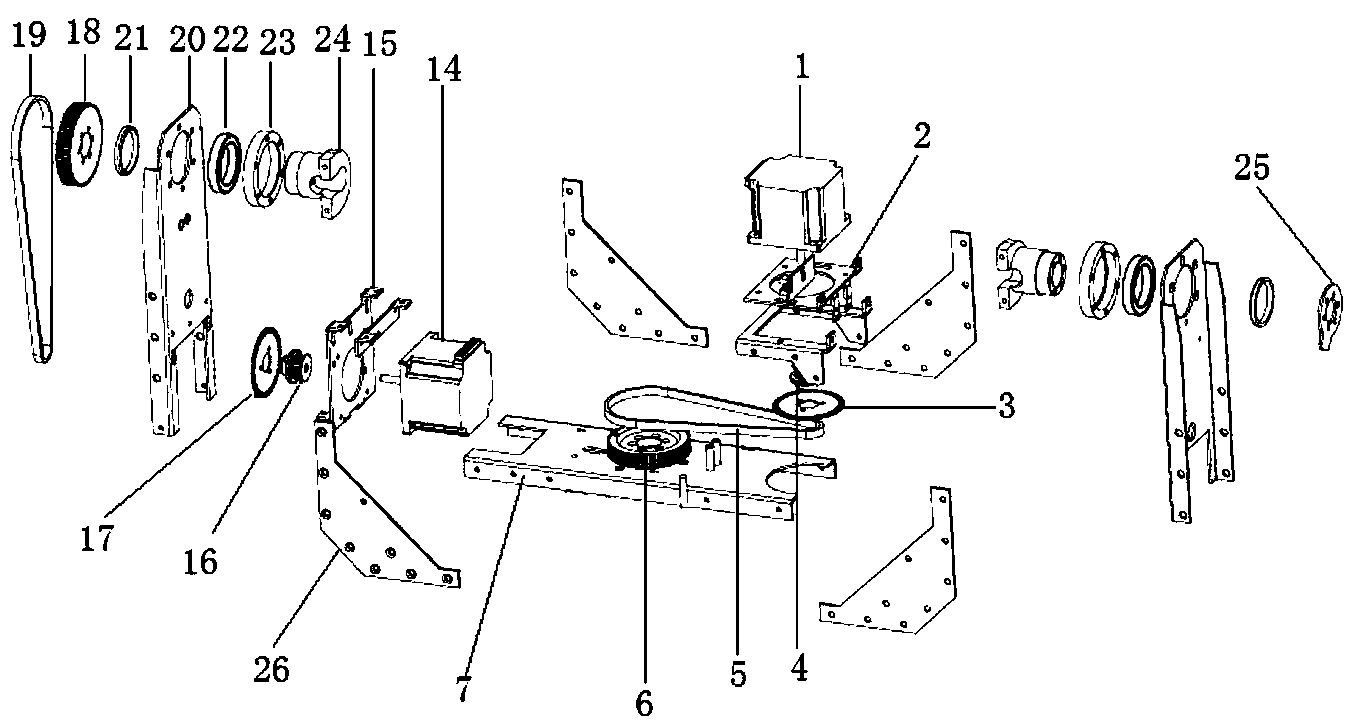

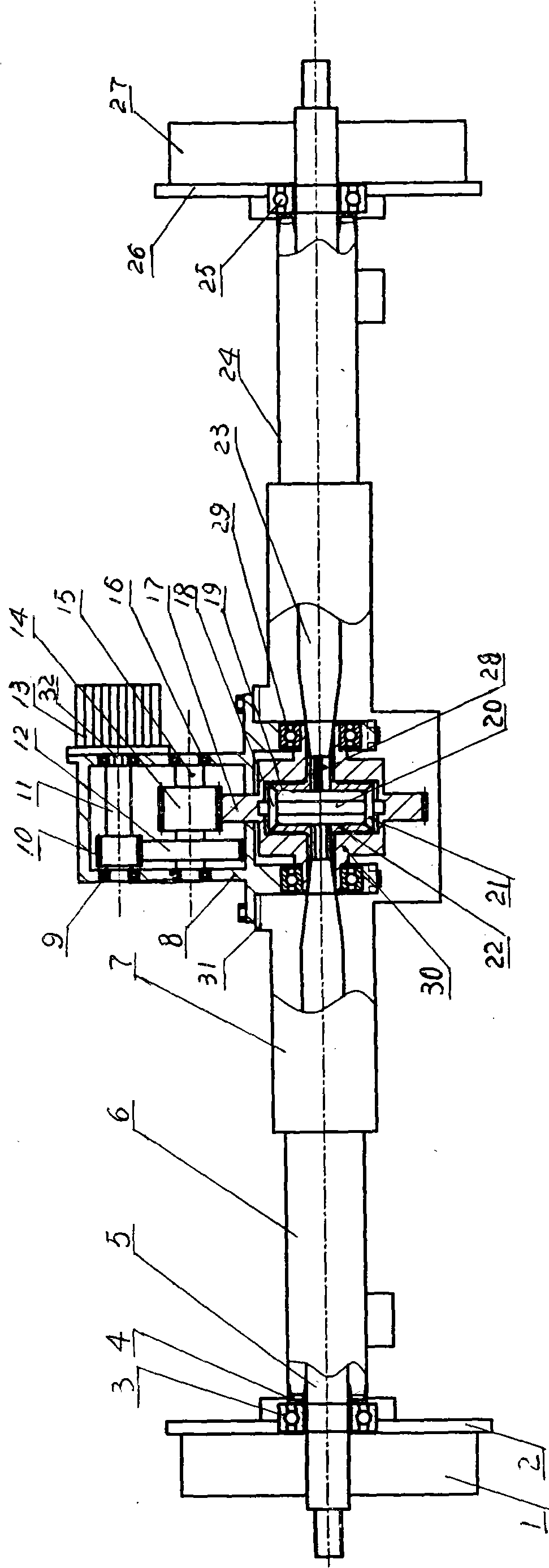

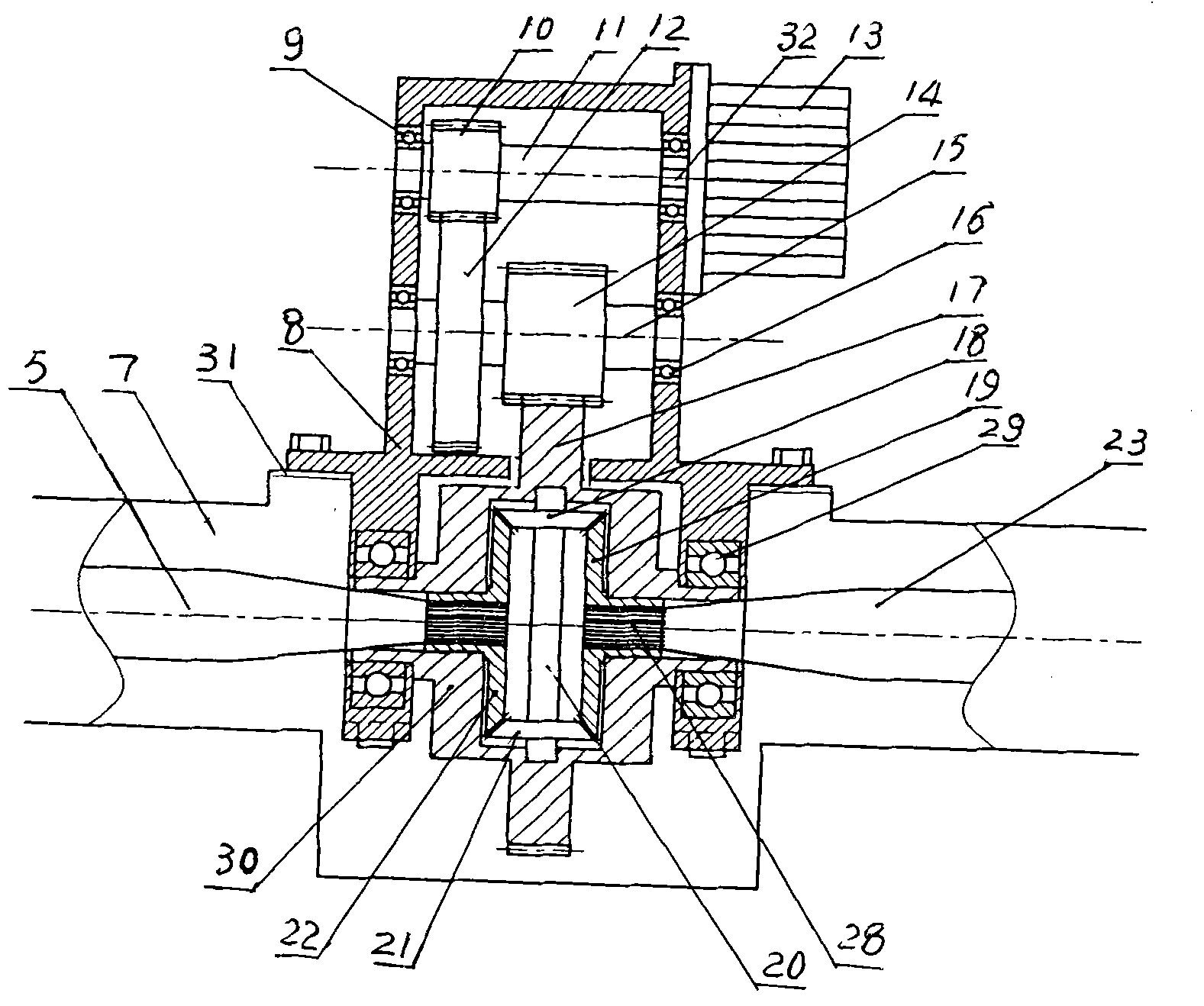

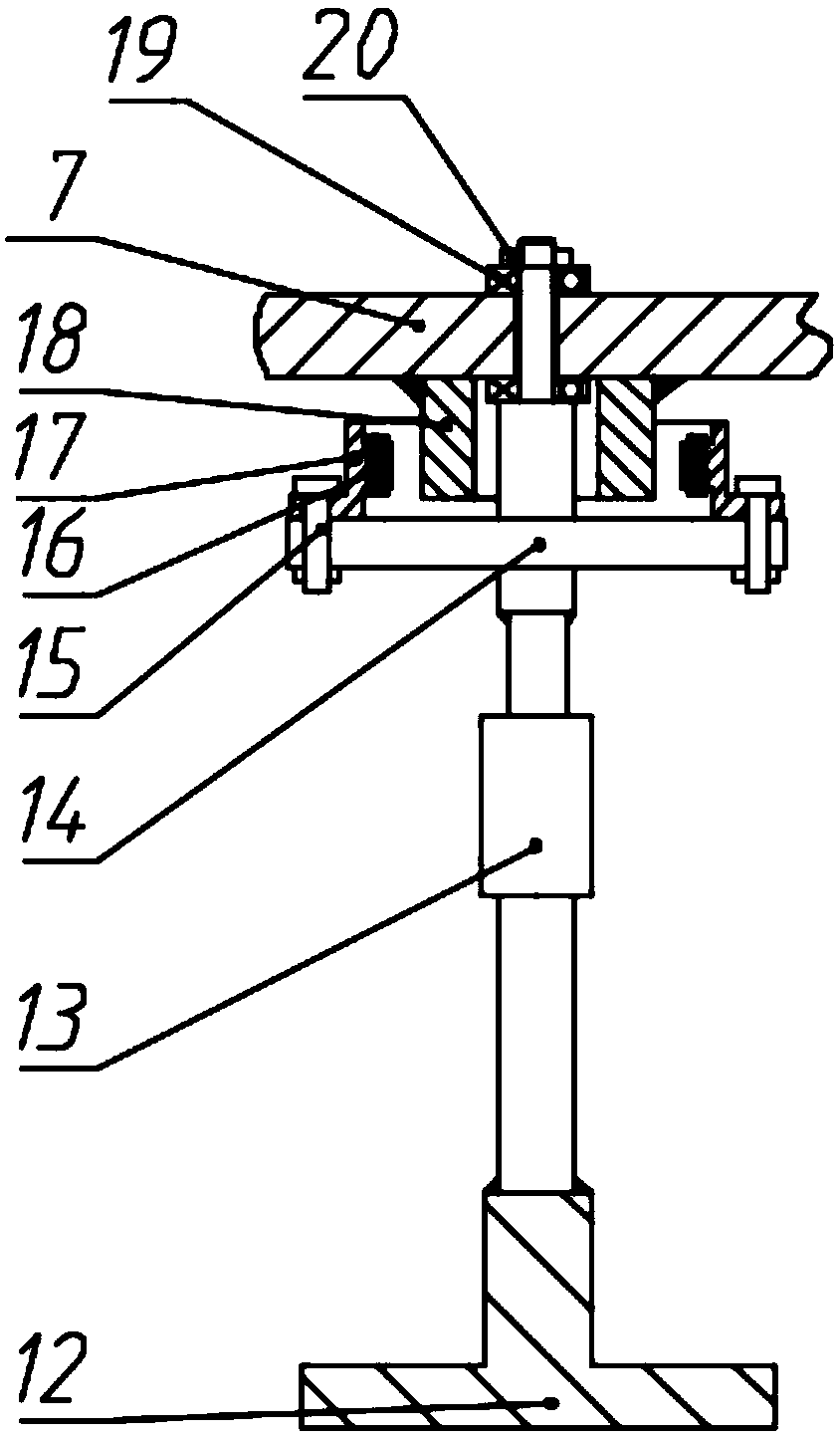

Cradle head device for X shaft and Y shaft of LED head-moving lamp

InactiveCN103644544APrecise positioningSmooth steeringLighting support devicesPoint-like light sourceEngineeringTripod head

The invention discloses a cradle head device for an X shaft and a Y shaft of an LED head-moving lamp. The cradle head device comprises the X shaft and the Y shaft, wherein the shaft core part of the X shaft is mounted in a lamp base; a left shaft and a right shaft of the Y shaft are perpendicularly mounted on the X shaft; the X shaft and the Y shaft are fixed through a connection board to form the cradle head device together. Through the adoption of a coded disc, a Hall sensor and a high-performance motor, the number of gears of the coded disc required to rotate of the head-moving range of the lamp is calculated through an LED head-moving lamp computer control unit to achieve stable moving and accurate positioning of the LED head-moving lamp; the LED head-moving lamp has the advantages of accurate positioning, stable moving and the like; the illuminating performance is well; the LED head-moving lamp can be widely applied to the fields of stage shows, stadiums, entertainment venues and the like.

Owner:HUNAN MINGHE OPTO TECH

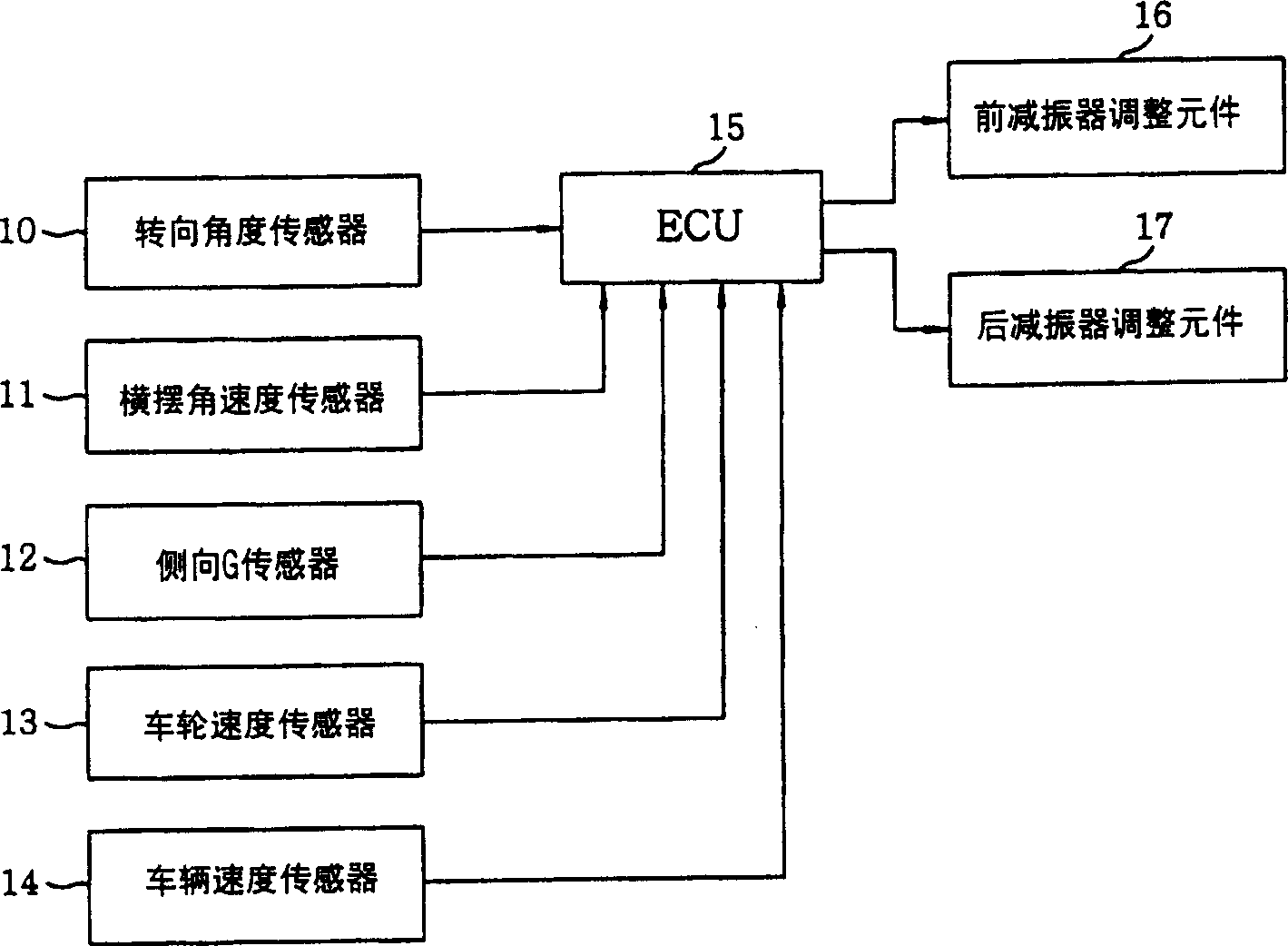

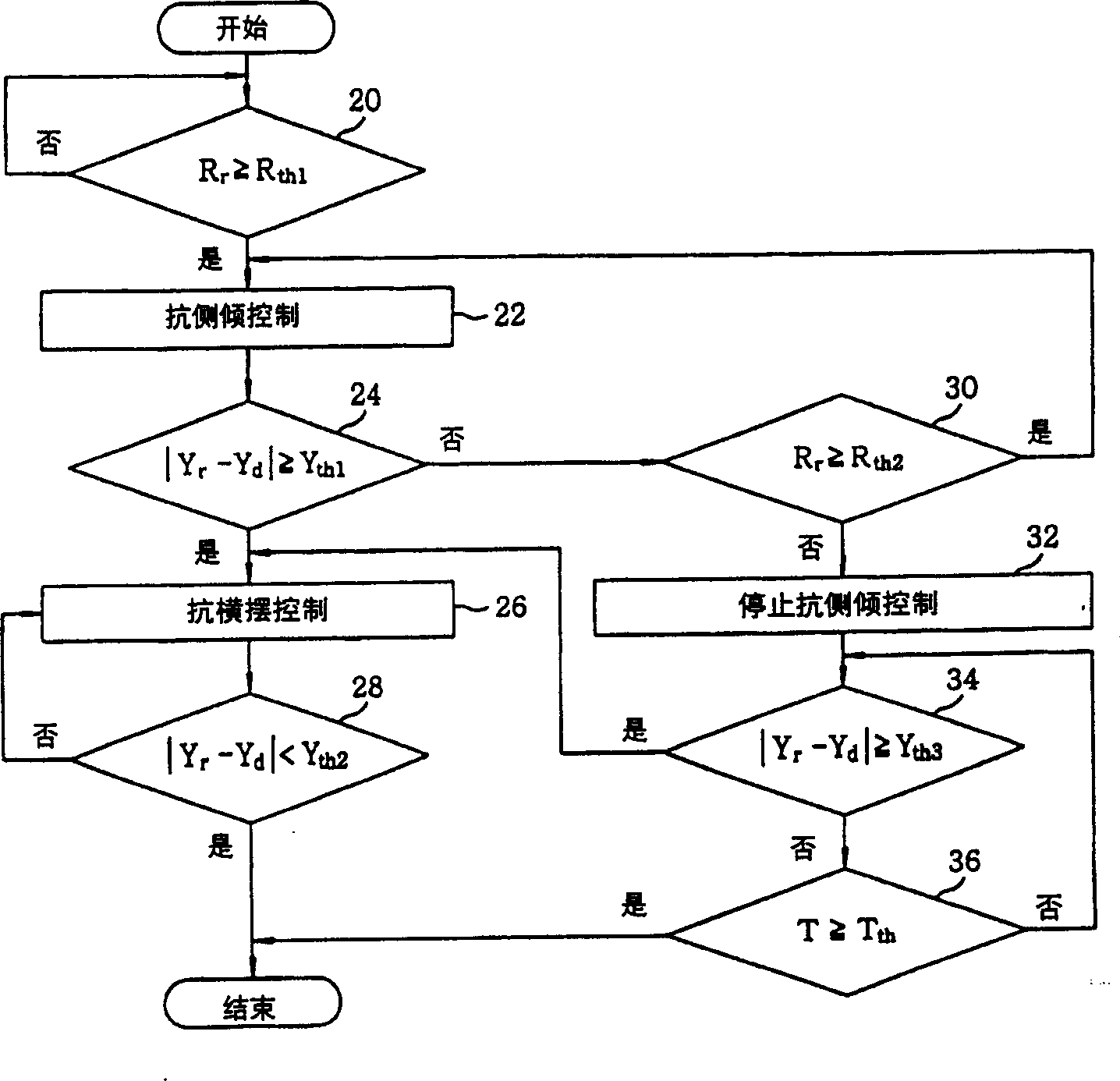

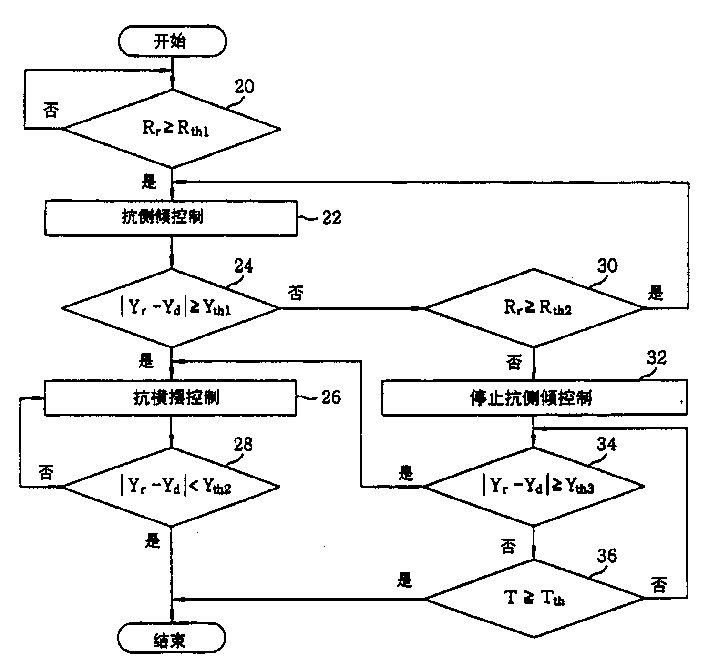

Method for anti-side listing /anti-cross oscillating controlling vehicles

This method for controlling anti roll and anti yaw of the vehicle includes a step comparing a vehicle roll rate with a predetermined threshold roll rate and determining whether anti roll control is required or not, a step carrying out anti roll control when the vehicle roll rate is larger than the predetermined threshold roll rate, a step comparing difference between an actual yaw rate and a desired yaw rate with a predetermined threshold yaw rate and determining whether anti yaw control is required or not, and a step carrying out anti yaw control when the difference between the actual yaw rate and the desired yaw rate is larger than the predetermined threshold value. Front and rear wheel left and right dampers are simultaneously controlled to hard during anti roll control. Front wheel left and right dampers are controlled to hard and rear wheel left and right dampers are controlled to soft during anti yaw control. Consequently, ride comfort is improved and an accident due to unstable vehicle behavior is prevented.

Owner:HL MANDO CORP

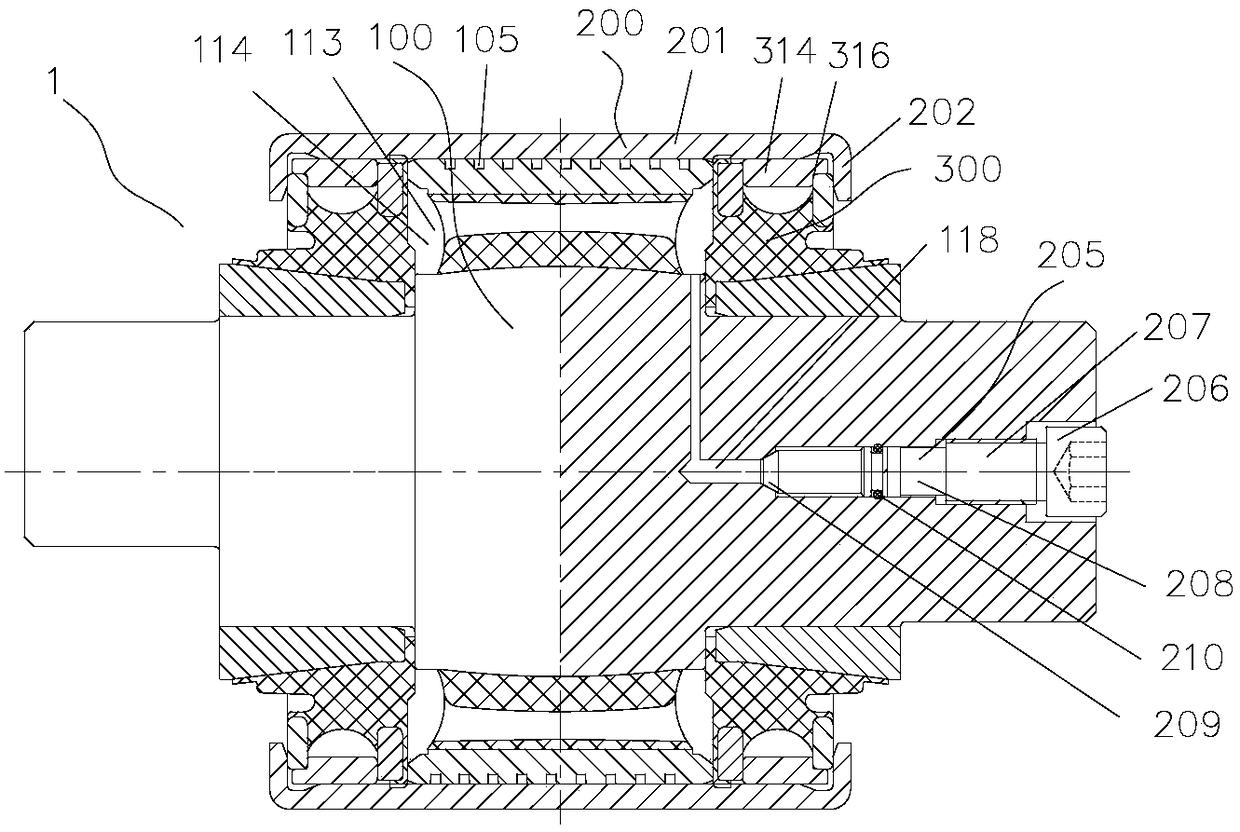

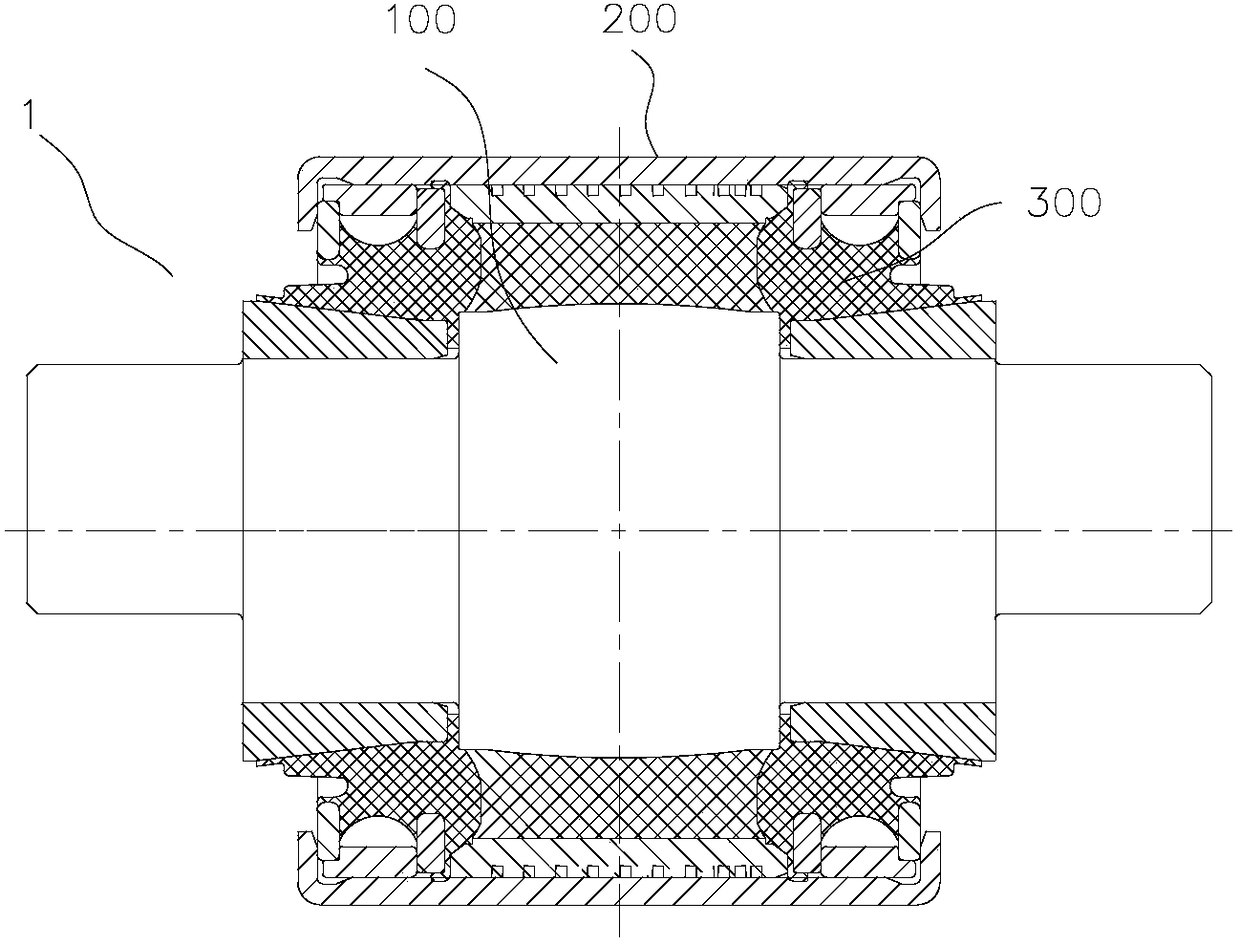

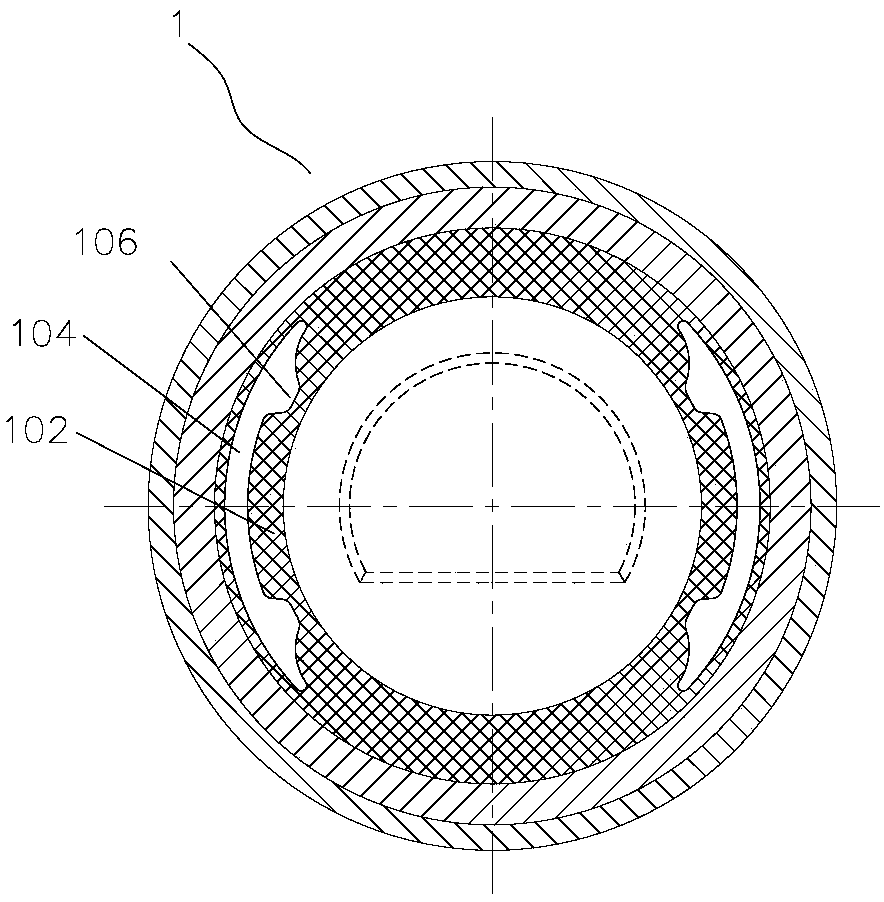

Hydraulic bushing

The invention relates to a hydraulic bushing which comprises a core shaft, a first rubber body, a sleeve, a jacket and sealing assemblies, wherein the core shaft is provided with a first stepped surface, so that the core shaft can be constructed as a stepped shaft of which the middle segment has a diameter greater than the two end parts; the first rubber body is arranged on the outer wall of the middle segment of the core shaft in a sleeving manner; two liquid cavities distributed in a spacing manner are arranged on the first rubber body; the sleeve is arranged on the outer wall of the first rubber body in a sleeving manner; a groove is formed in the outer wall of the sleeve; the jacket is arranged on the outer side of the sleeve in a sleeving manner; a first passageway used for communicating with the two liquid cavities is formed by adopting the jacket and the sleeve in the groove; and the sealing assemblies are arranged at two ends of the core shaft, and are in sealing contact with the first stepped surface and end surfaces of the sleeve. The hydraulic bushing is conducive to the stable traveling of a rail train, and the abrasion to train wheels and rails in the curve traveling state can be reduced.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Tile cartonning device and application process

The invention discloses a tile cartonning device, which comprises a rack body, and is characterized in that a carton conveying rack, a carton placing rack, a carton driving mechanism, a carton erecting device and a tile pushing mechanism are sequentially arranged on the rack body from left to right. The tile cartonning device provided by the invention has the characteristics of reasonable and scientific structure design, reliability in operation, high cartonning efficiency, high cartonning quality and the like.

Owner:JINJIANG CITY CHAOJUN MACHINE CO LTD

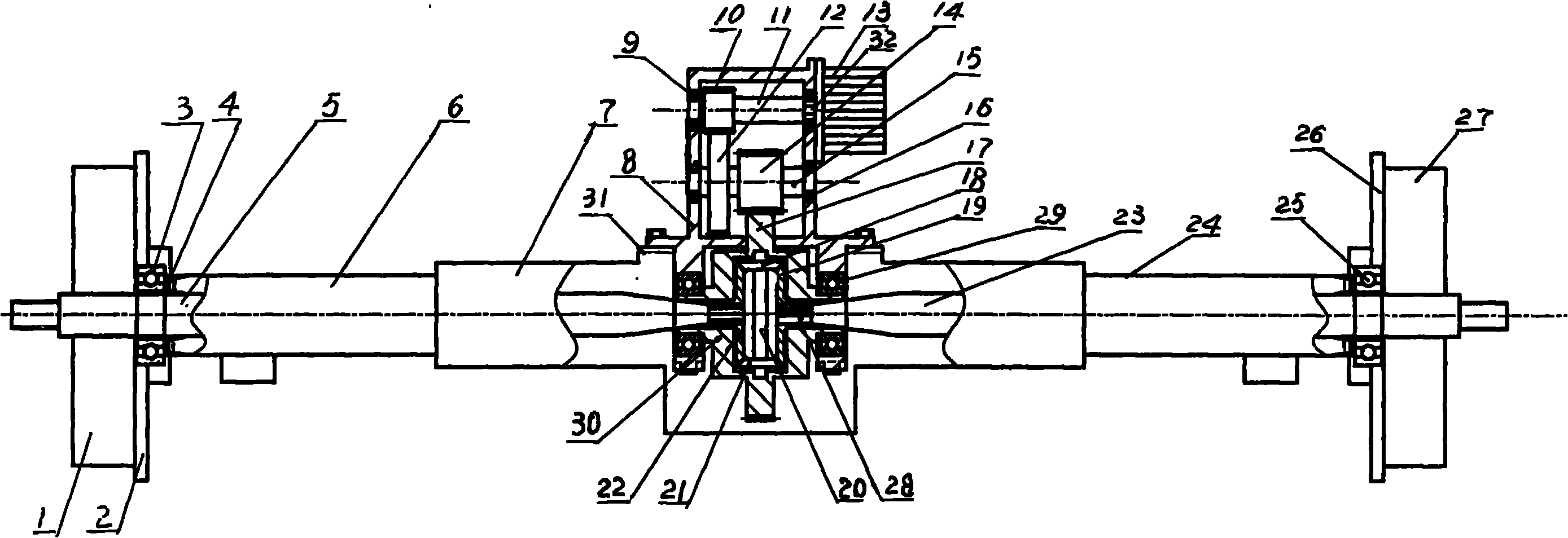

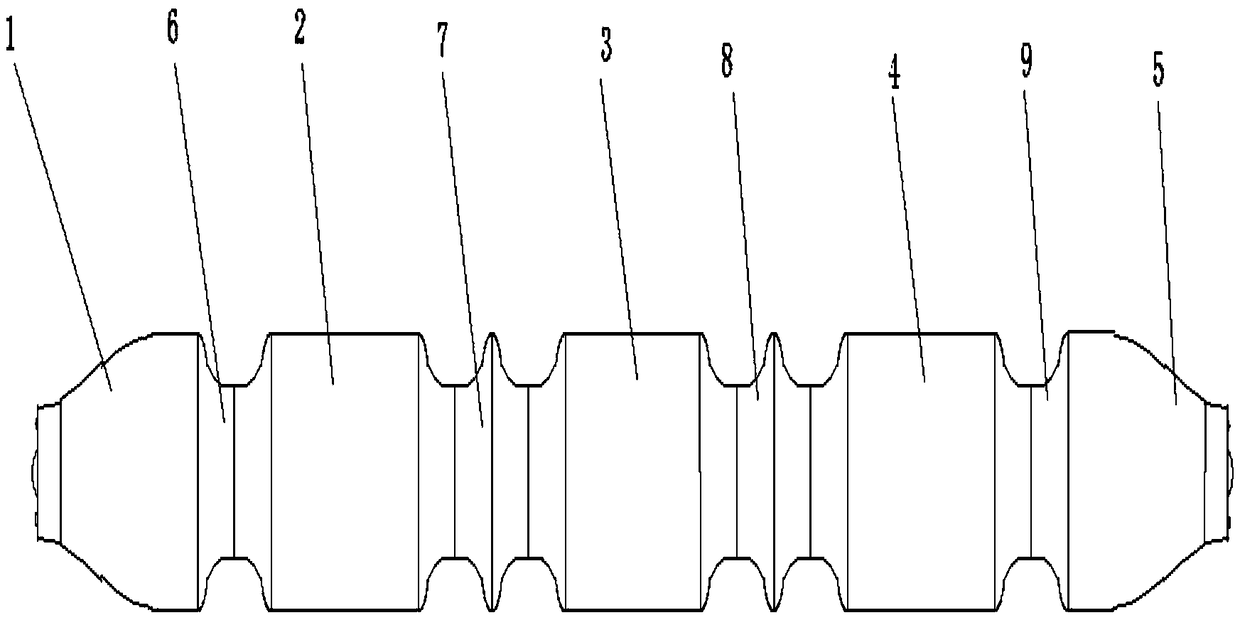

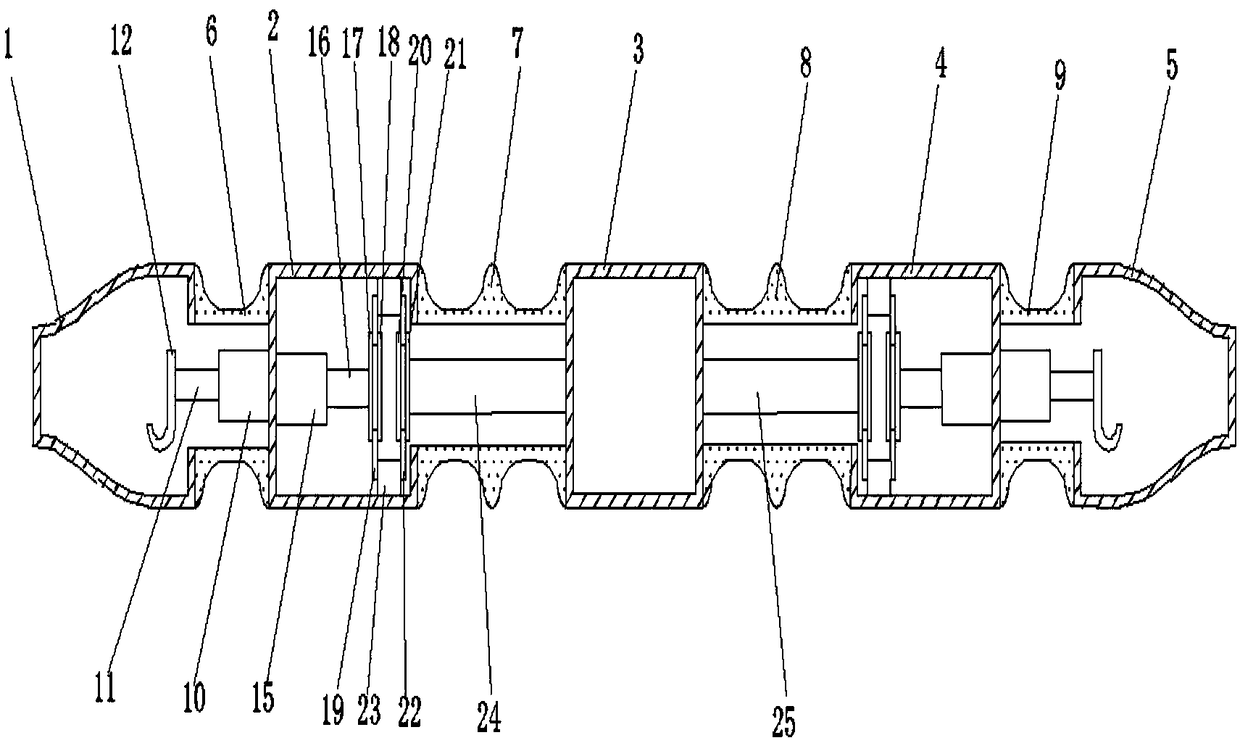

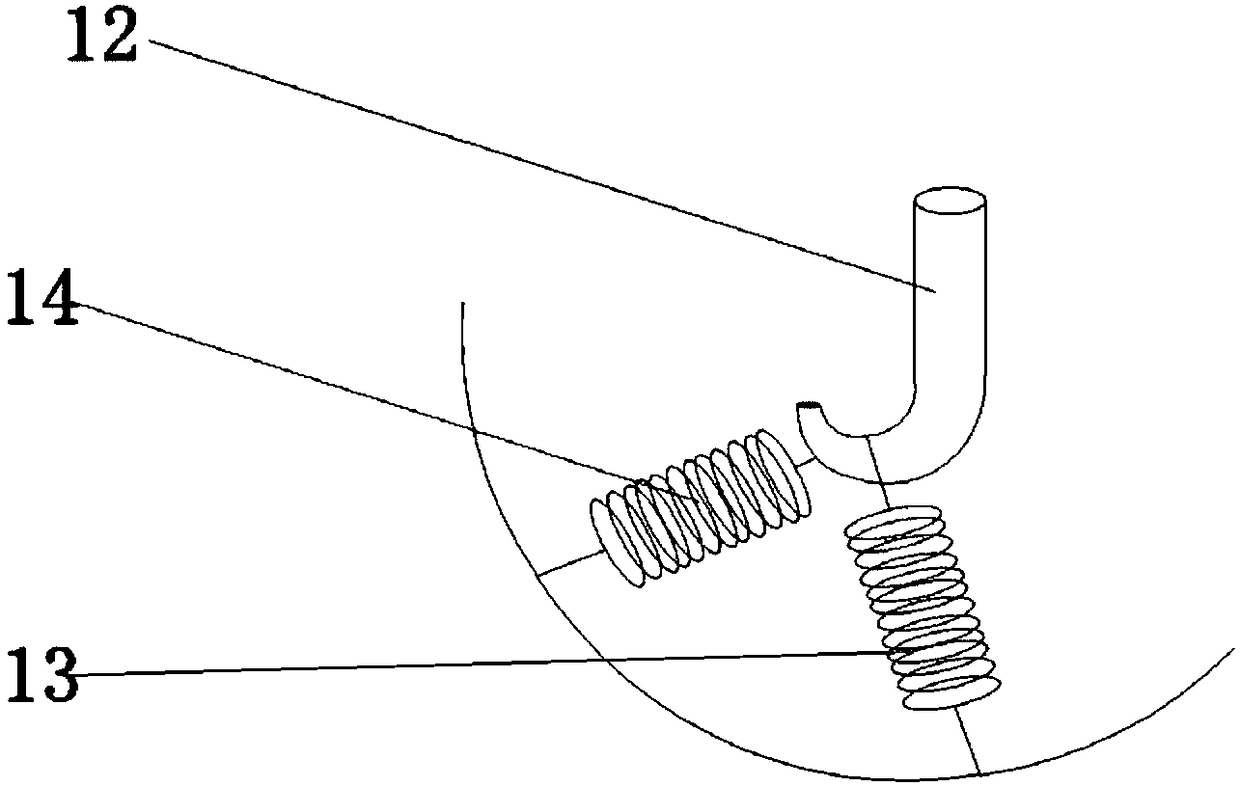

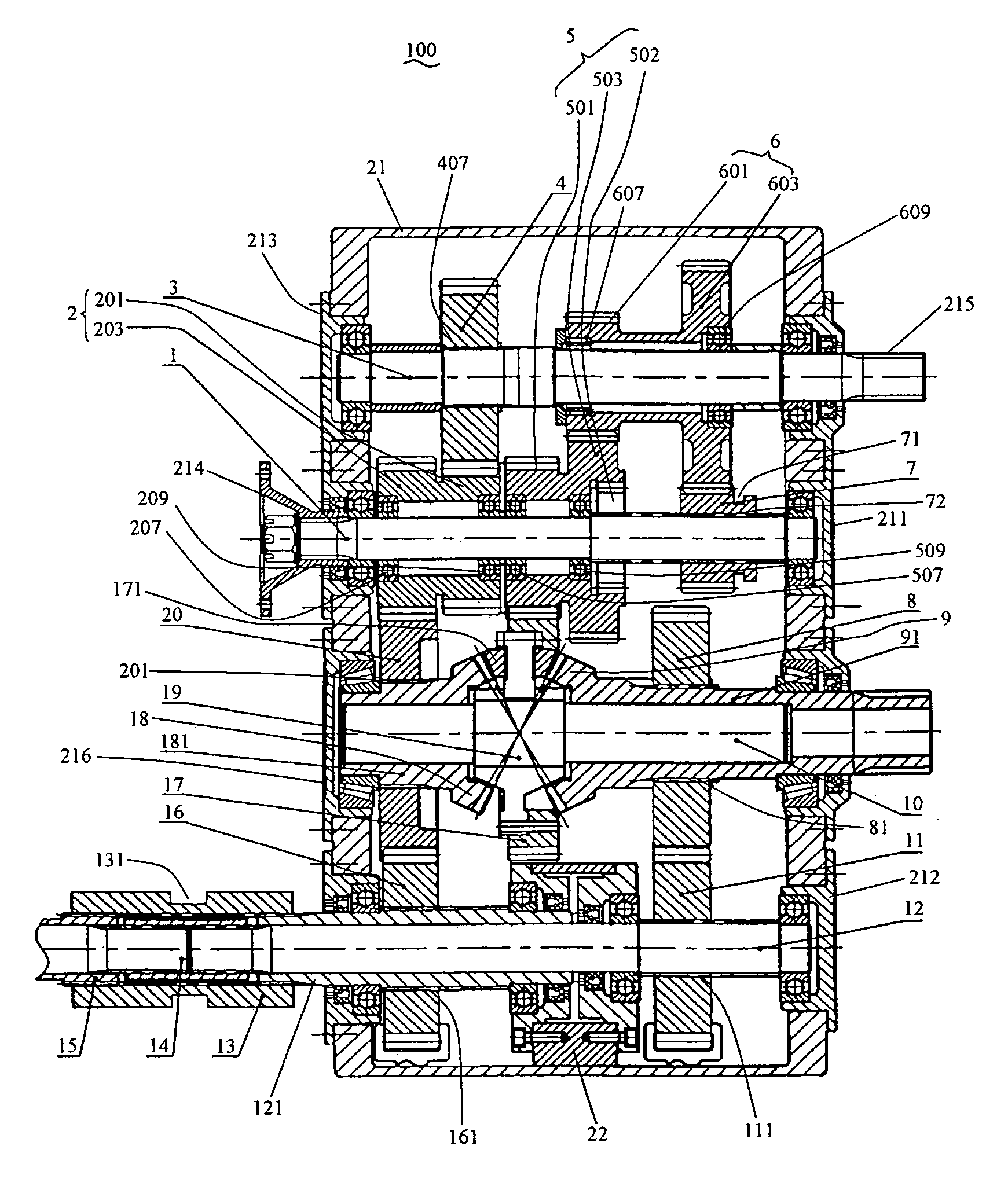

Electric vehicle deceleration and differential integrated rear axle assembly

The invention relates to an electric vehicle reduction and differentiation integrated rear axle assembly which is an integrated assembly of a motor, a reducing mechanism, a differential mechanism and a rear axle of an electric vehicle. The integrated assembly is applied to rear axle drive systems of freight vehicles, passenger vehicles, electric three-wheeled vehicles, electric four-wheeled vehicles and the like. The integrated assembly comprises the motor, the reducing mechanism, the differential mechanism, a reduction and differential case and the rear axle. The rear axle comprises a rear axle stand, a first drive half-axle, a second drive half-axle, a first braking fixed plate, a second braking fixed plate, a brake block, a brake cam, a first hub and a second hub. The reduction and differential case is installed on the rear axle stand and is fixed by screws; the reducing mechanism comprises a reducing gear shaft, a reduction transition gear and a reduction transition pinion; and the differential mechanism comprises a differential mechanism housing, a differential gear, a first satellite gear, a second satellite gear, a satellite gear shaft, a first spline gear, a second spline gear and a fifth bearing. The differential mechanism housing is installed below the reduction and differential case through the fifth bearing and a bearing support, and the differential gear is arranged outside the differential mechanism housing.

Owner:薛建南

Earthworm-bionic robot capable of flexible steering

InactiveCN108297081AFlexible steeringSmooth steeringProgramme-controlled manipulatorTerrainLife detection

The invention provides an earthworm-bionic robot capable of flexible steering. The robot includes a robot body, the robot body includes a head, a first trunk part, a middle part, a second trunk part and a tail, the head is connected with the first trunk part through a first telescopic part, and the first trunk part is connected with the middle part through a second telescopic part. According to the robot, a steering engine drives a motion part to rotate, meanwhile, a motion wheel itself also conducts autorotation, combined with tractive force of the steering engine and rotational force of themotion wheel, the head is pushed to move forwards, a first electric push rod cooperatively conducts extension and contraction to pull the middle part, a second electric push rod synchronously conductsextension and contraction to pull the second trunk part and the tail, and therefore the robot conducts lumbricoid wriggle on the ground. The flexibility is good, the robot can smoothly move under complex and harsh terrain environments such as caves, pipelines, tile ruins and hill stones, and meanwhile conduct life detection and other activities.

Owner:HUZHOU JIACHUANG AUTOMATION TECH CO LTD

Coaxial two-wheel vehicle

InactiveCN101353070AAvoid flippingSmooth steeringSpeed controllerMotorcyclesGravity centerWheel drive

The present invention discloses a coaxial two-wheel vehicle with which a rider stably travels without the upper body being swayed left and right in a riding state of the center of gravity being positioned high is provided. The coaxial two-wheel vehicle includes: a step plate for a driver to ride; a vehicle body that supports the step plate to be capable of changing a posture in a roll direction of rotating around a roll axis as the center, when a traveling direction is made the roll axis; a pair of wheels disposed on both sides on the same axis in the direction orthogonal to the traveling direction of the vehicle body and rotatably supported by the vehicle body; a pair of wheel drive means to drive and rotate the pair of wheels independently; and a handle for directly changing a posture of the step plate or indirectly changing the posture through the vehicle body.

Owner:TOYOTA JIDOSHA KK

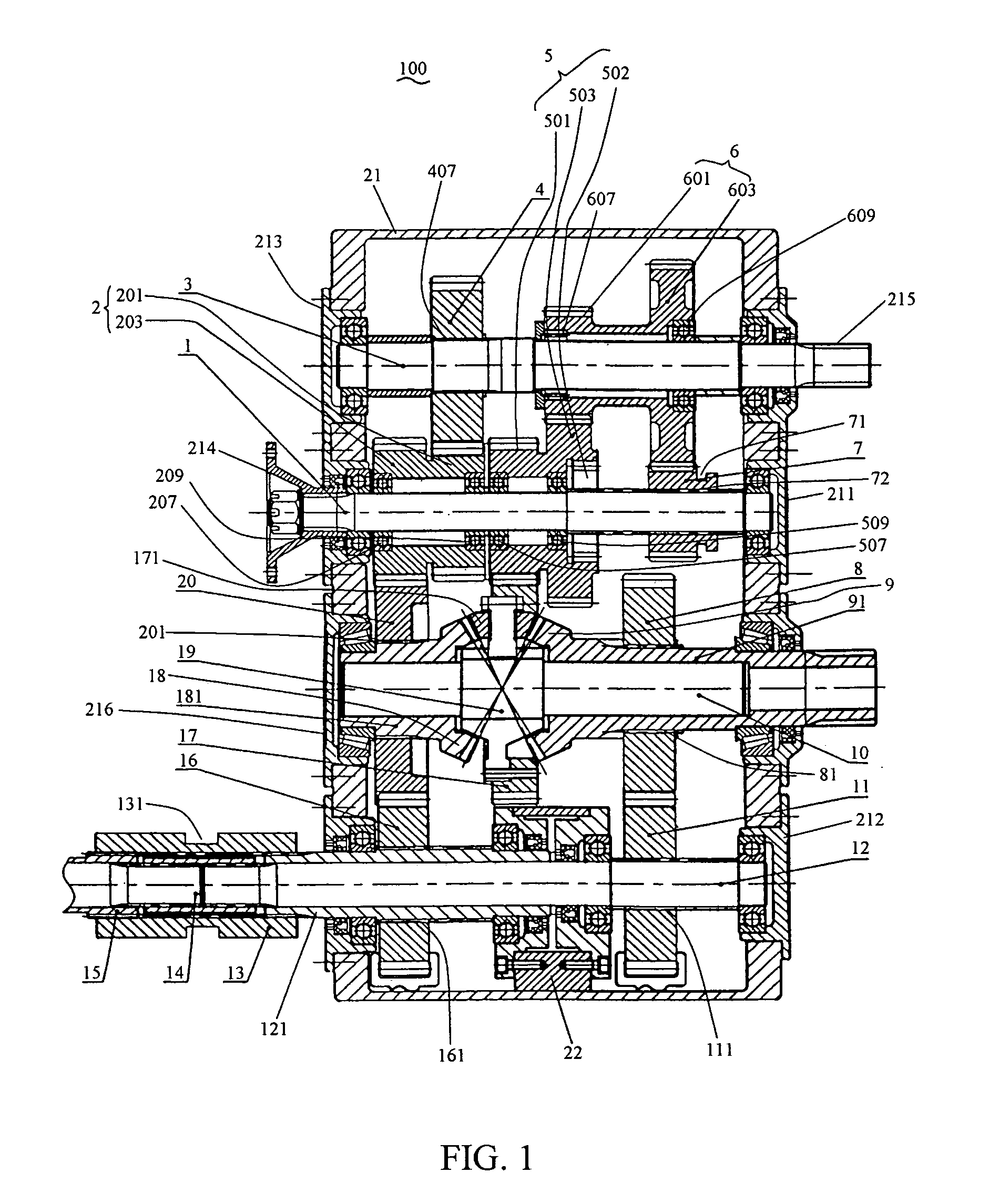

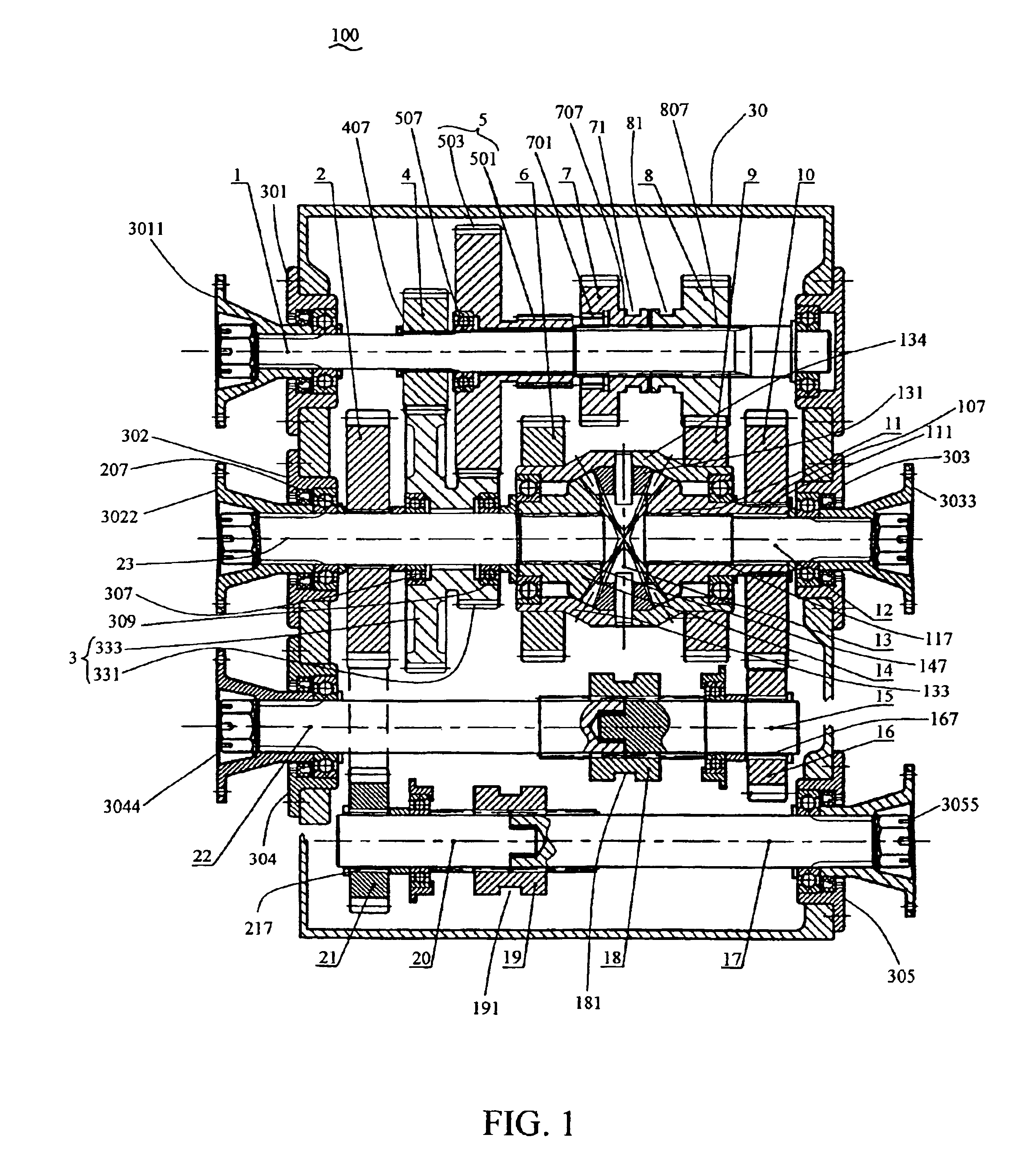

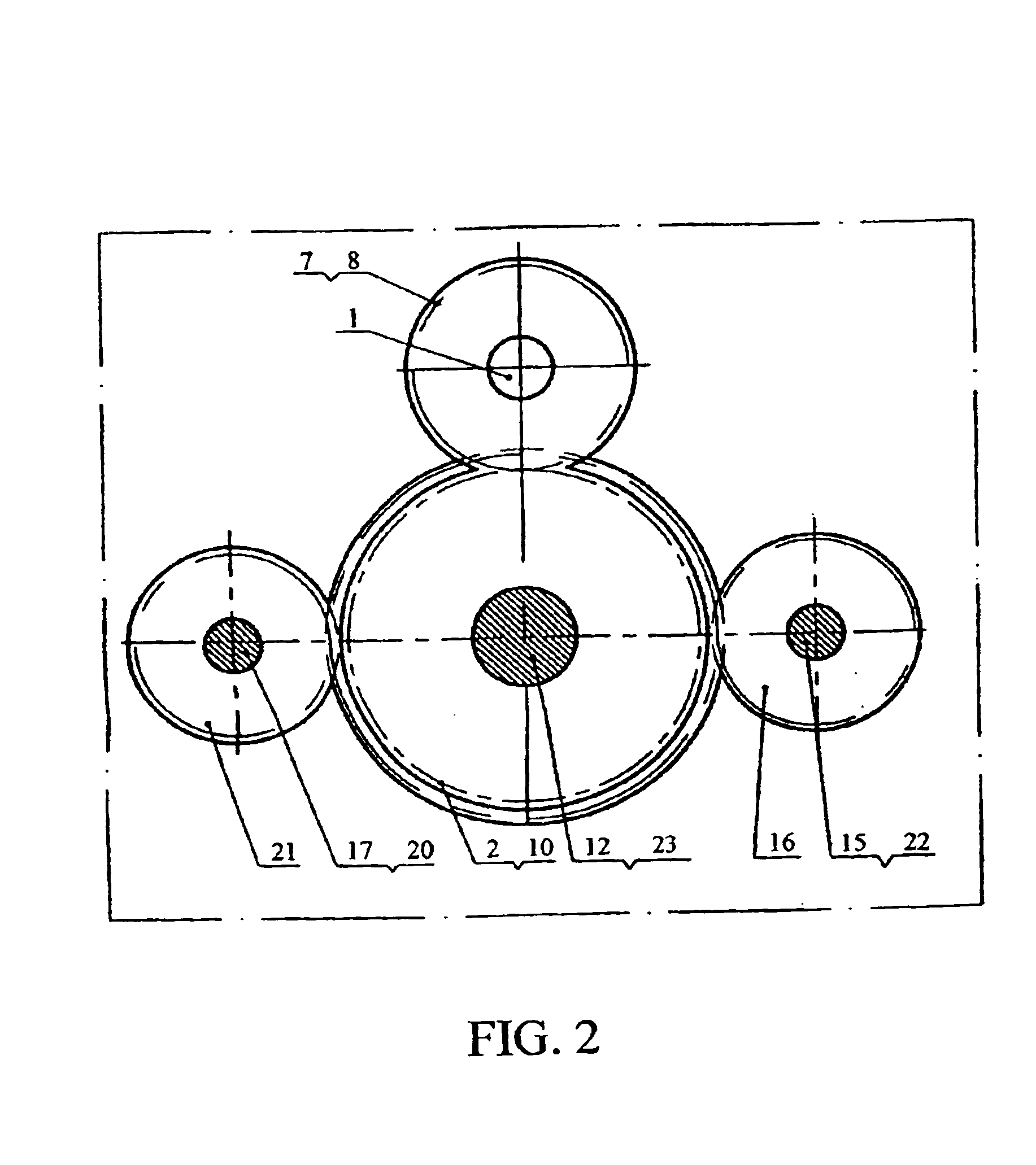

Transmission mechanism with a caseless differential mechanism

InactiveUS20040050196A1Increase the gapImprove performanceToothed gearingsDifferential gearingsMobile vehicleMotorized vehicle

The present invention provides a transmission mechanism with a caseless differential mechanism for an automotive vehicle to drive four wheels instead of two differential mechanisms of the prior art disposed on the front axle and rear axle. The transmission mechanism of the invention is of a compact structure and a relatively less cost of manufacturing, and makes a clearance between the chassis of the automotive vehicle and the ground increased. The performance of the automotive vehicle equipped with the transmission mechanism of the invention can be improved.

Owner:XINJIANG SHENG SHENG

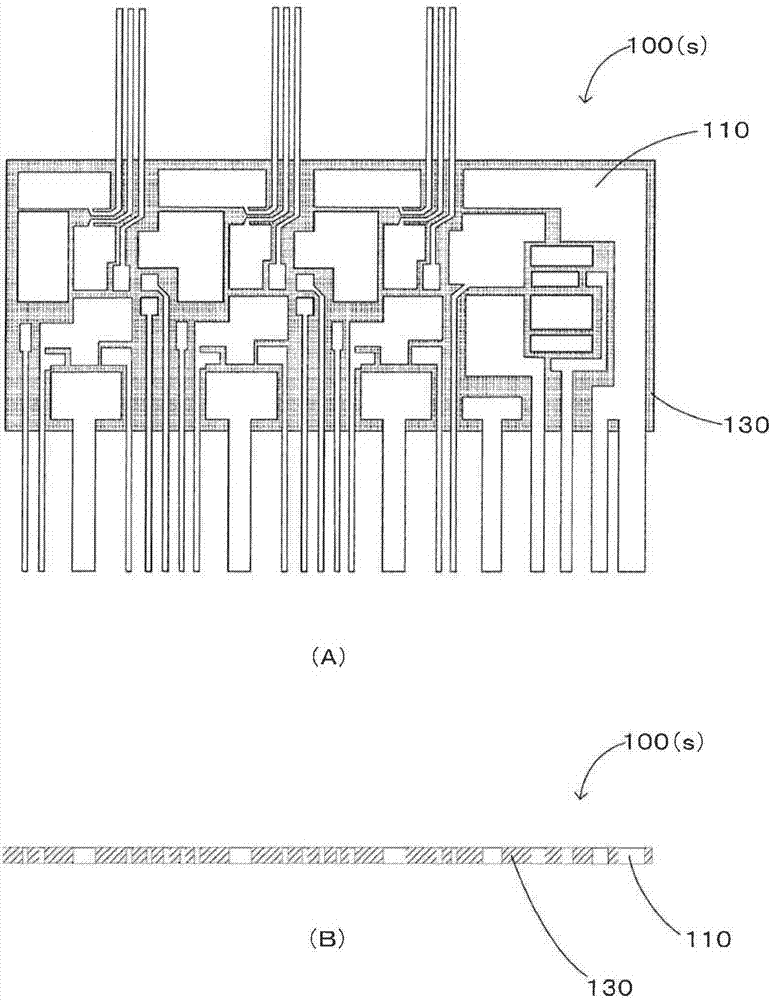

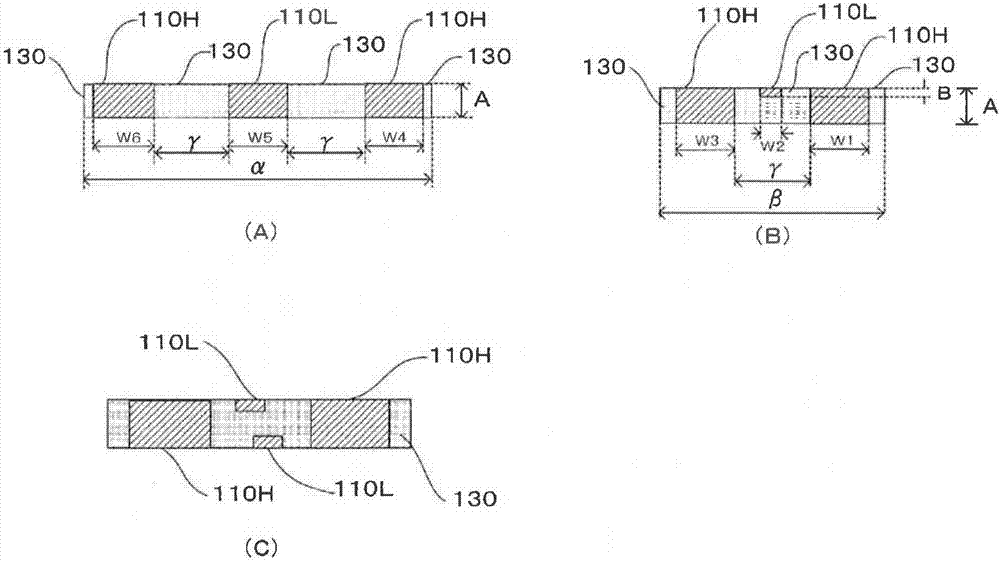

Heat dissipation substrate for mounting electric component

InactiveCN107004647AConsolidate the gapReduce wire resistanceAssociation with control/drive circuitsElectrical measurement instrument detailsElectrical conductorHemt circuits

To provide a heat dissipation substrate for mounting an electric component, said substrate making it possible, even in the case of a circuit using a power semiconductor, etc. in which a large current flows, to achieve an improvement in heat dissipation and a reduction in wiring resistance due to high power operation. This heat dissipation substrate 100(d) for mounting an electric component is formed such that: the substrate is composed of lead frames that are formed into a wiring pattern shape from a conductor plate, and an insulating material 130 that is provided between the lead frames 110; the lead frames have at least two types of thicknesses that are different from each other, wherein a thick lead frame 110H is used for a large current signal and a thin lead frame 110L is used for a small current signal; a component disposition surface plate surface of the lead frames 110 and a component disposition surface-side plate surface of the insulating material 130 form one continuous surface; and the plate surface of the lead frames on the rear surface of the component disposition surface and the plate surface of the insulating material on the rear surface side of the component disposition surface side are formed on the same plane so as to match the plate surface on the rear surface of the component disposition surface of the thickest lead frame from among the lead frames.

Owner:NSK LTD

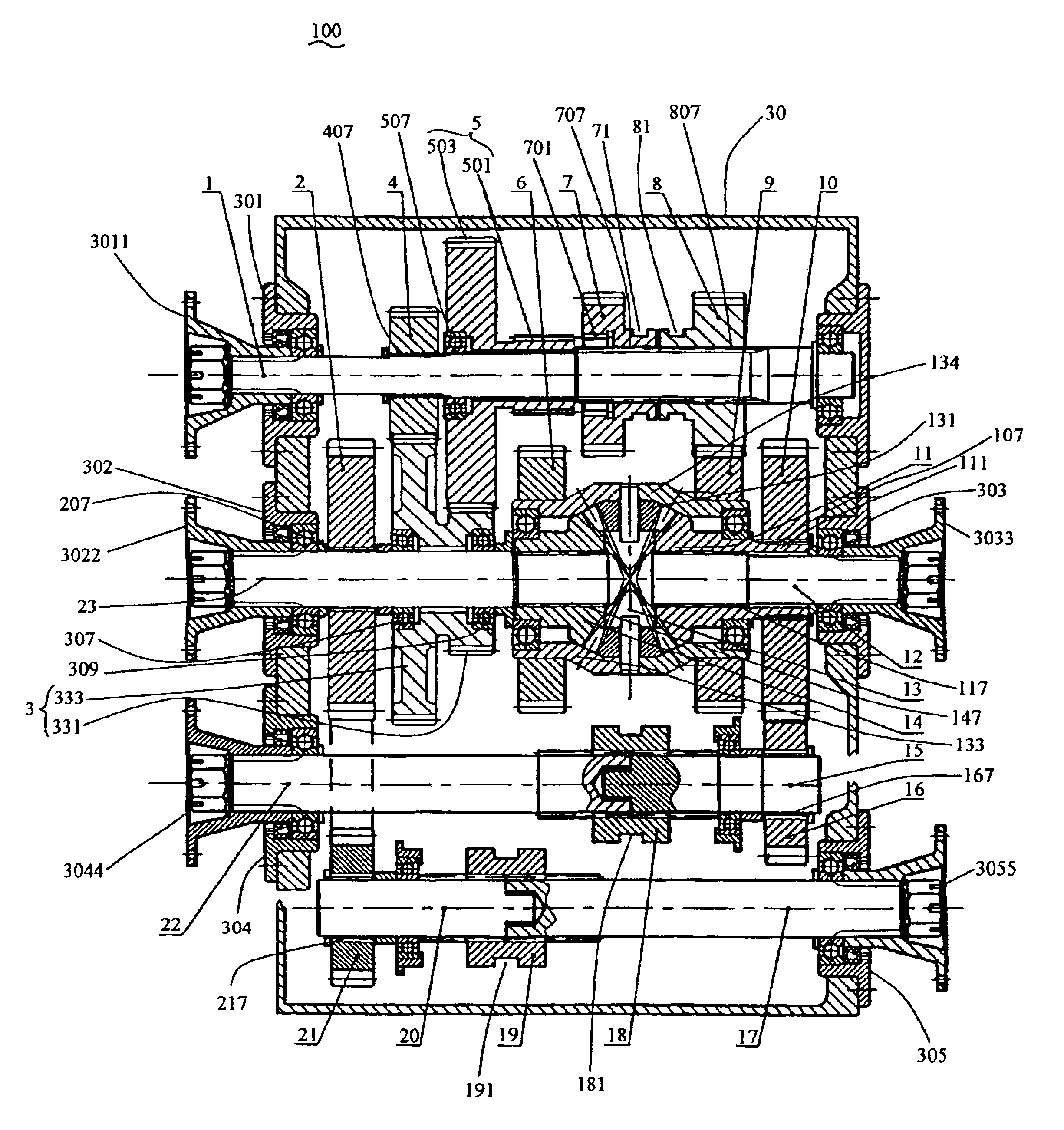

Transmission mechanism with a single differential mechanism for driving four wheels

InactiveUS6843748B2Compact structureReduce manufacturing costToothed gearingsDifferential gearingsMobile vehicleMotorized vehicle

The present invention provides a transmission mechanism with a single differential mechanism for an automotive vehicle. The transmission mechanism of the invention is of a compact structure and a relatively less cost of manufacturing, and makes a clearance between the chassis of the automotive vehicle and the ground increased. The performance of the automotive vehicle equipped with the transmission mechanism of the invention can be improved.

Owner:XINJIANG SHENGSHENG CO LTD

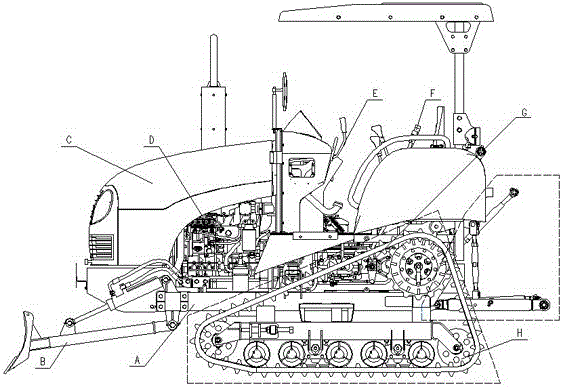

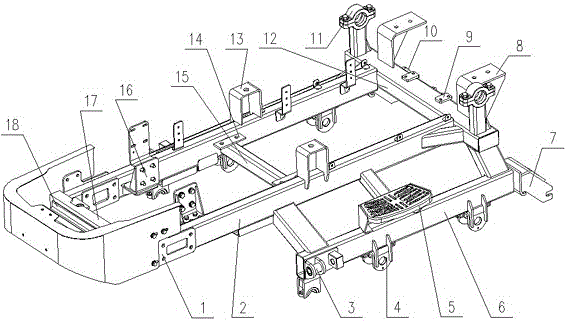

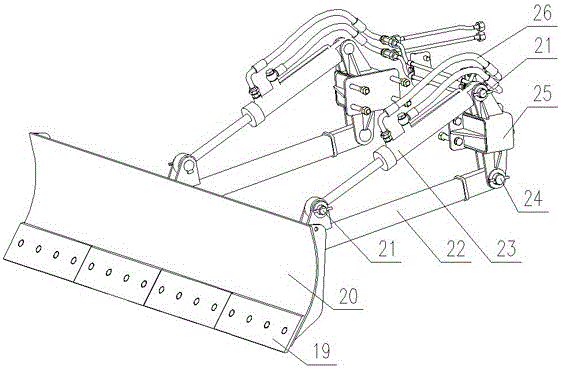

Crawler tractor for paddy field

ActiveCN106275110AReasonable arrangementFunction increaseMechanical machines/dredgersSteering linkagesPaddy fieldTractor

Provided is a crawler tractor for a paddy field. The crawler tractor comprises a frame, a perching knife device, a covering part assembly, a power device and accessories, a steering, braking and operating mechanism, a hydraulic system and a working device, a power transmission device and a walking mechanism; the frame is a basis of the whole crawler tractor, and a perching knife arm support of the perching knife device is fixed to a perching knife installing support of the frame; the covering part assembly is fixed to rear bottom plate installing support frames and front bottom plate installing support frames of the frame separately; an engine assembly of the power device and the accessories is fixed to an engine installing support arranged in the middle of a longitudinal beam of the frame; the steering, braking and operating mechanism and pedals are fixed to the covering part assembly separately; a gear pump of the hydraulic system and work device is connected to the engine assembly, a suspension rod part arranged at the rear end is connected to a suspension installing plate, and the hydraulic system and the working device are connected through a suspension oil cylinder oil pipe; a clutch shell of the power transmission device is connected to the engine assembly, and the rear end of the power transmission device is connected to the frame through a speed changing box support; a wheel train of the walking mechanism is fixed to the frame.

Owner:FIRST TRACTOR

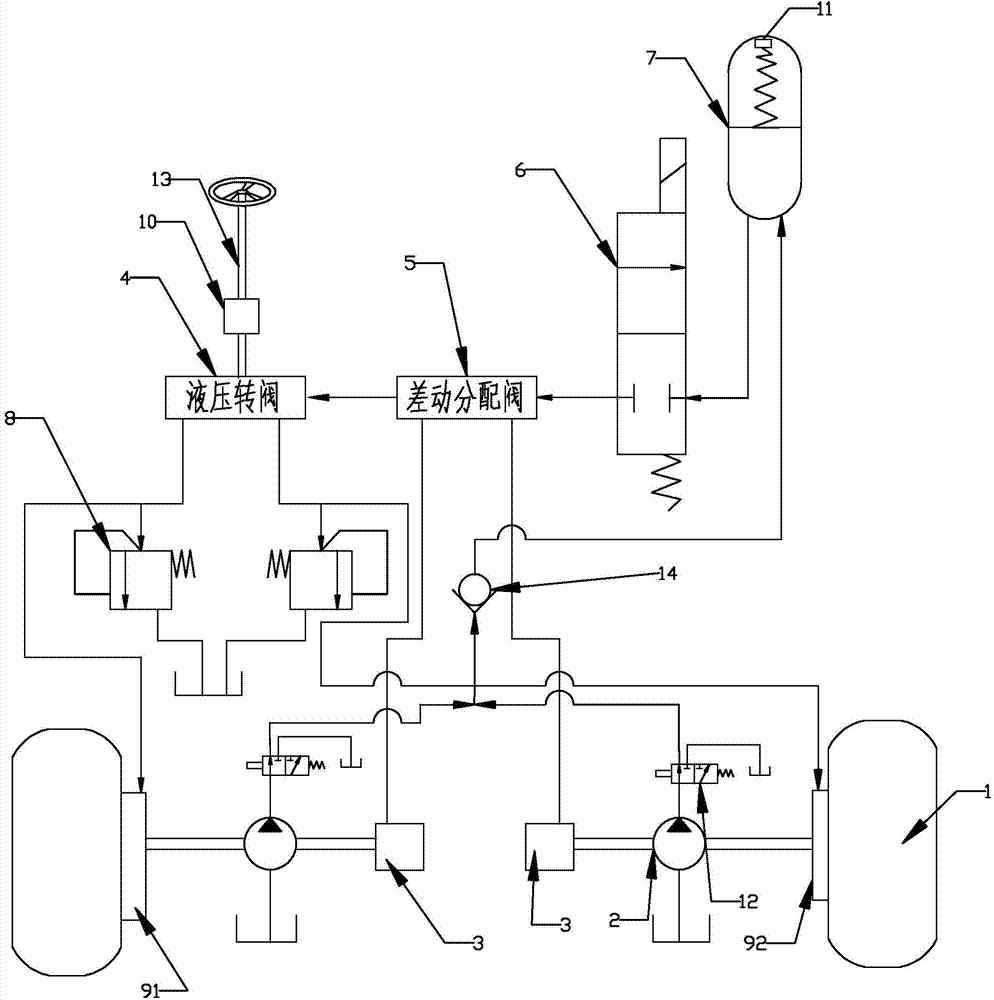

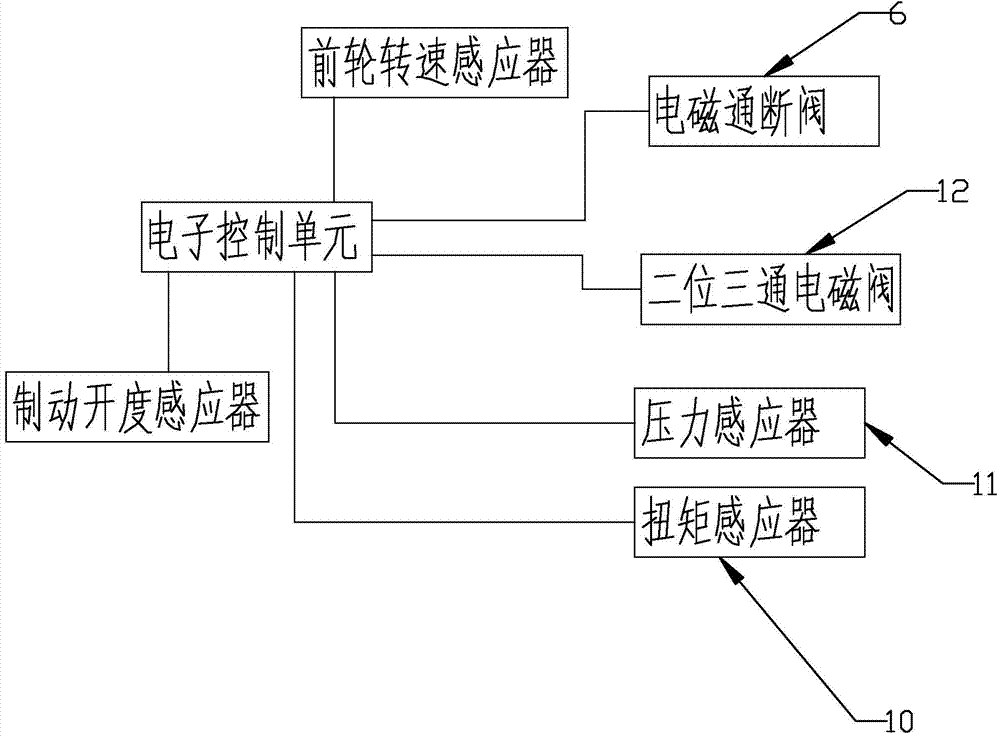

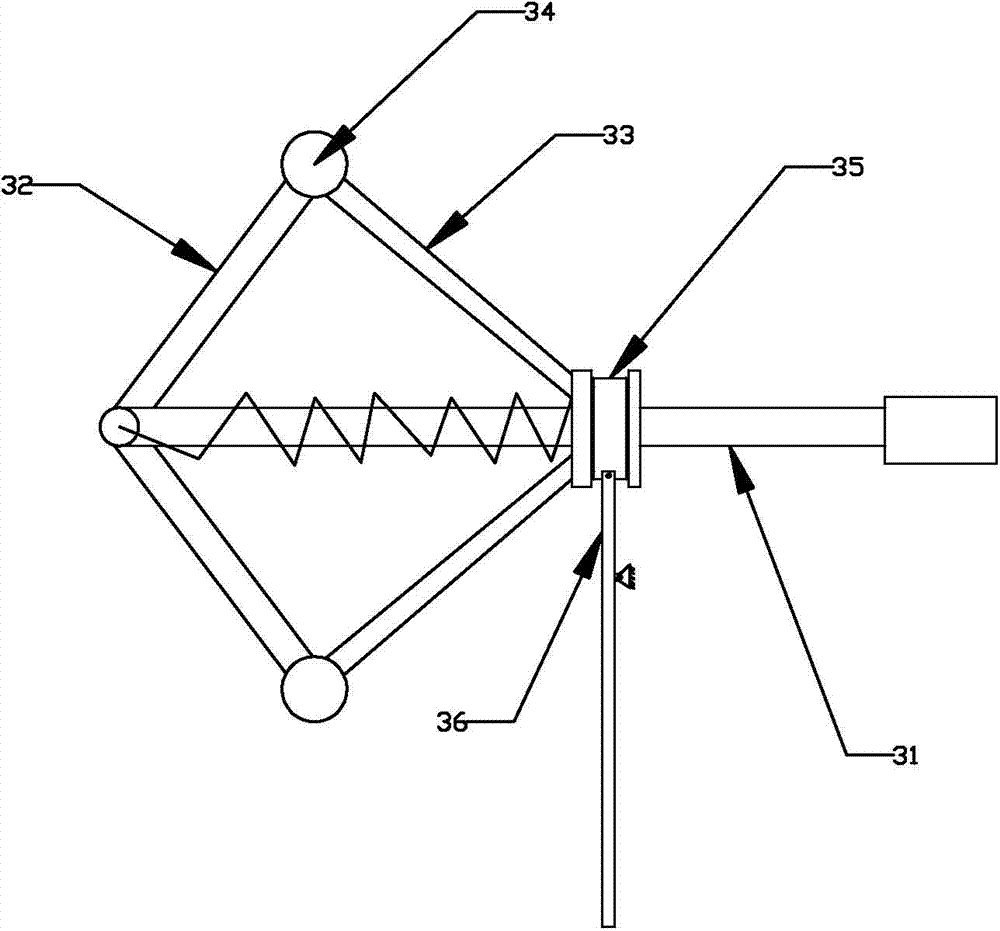

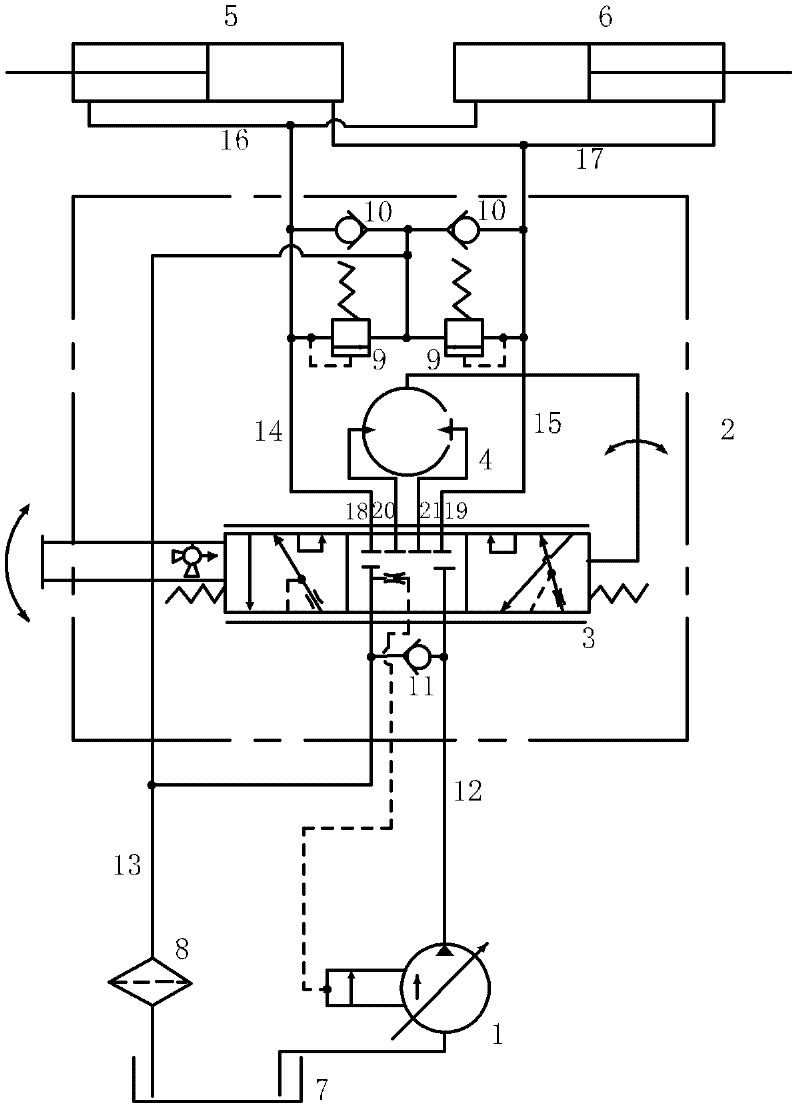

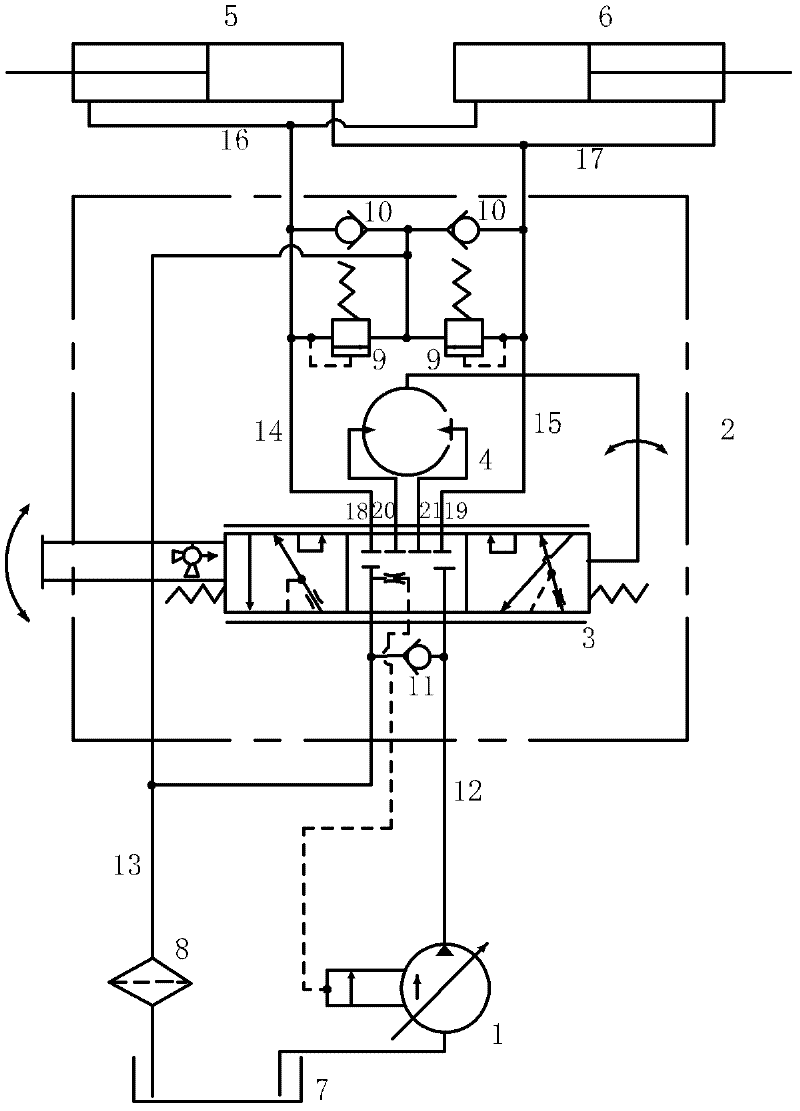

Novel energy-saving differential power-assisted steering system of electric wheel automobile and control method thereof

The invention relates to a novel energy-saving differential power-assisted steering system of an electric wheel automobile. The novel energy-saving differential power-assisted steering system of the electric wheel automobile comprises electric wheels, a steering device and a brake device. The brake device comprises a left brake of the left electric wheel, and a right brake of the right electric wheel; the left brake and the right brake are connected with a hydraulic rotary valve through oil ways; the hydraulic rotary valve is connected with a differential distribution valve, a main oil way of the differential distribution valve is connected with an energy accumulator through a normally-open type electromagnetic on-off valve, and a control mechanism of the differential distribution valve is connected with mechanical centrifugation adjusting devices arranged on the left electric wheel and the right electric wheel respectively. The novel energy-saving differential power-assisted steering system of the electric wheel automobile achieves the power-assisted steering effect through a mechanical mode to help the automobile veer stably under the power loss state of the automobile.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Automobile power-assisted steering system

The invention provides an automobile power-assisted steering system, belonging to the technical field of automobiles. The invention solves problem that the existing automobile power-assisted steering system consumes the engine power during the linear running of an automobile. The automobile power-assisted steering system comprises a steering oil cylinder, an oil tank, an oil return pipeline, a variable pump which can be connected with an engine, and a hydraulic steering mechanism which is provided with a steering valve, wherein the steering valve can be connected with a steering wheel and is provided with a feedback oil port, an oil inlet, an oil return port and at least two bidirectional oil ports; an oil outlet of the variable pump is communicated with the oil inlet of the steering valve; a feedback oil port of the variable pump is communicated with the feedback oil port of the steering valve; the steering oil cylinder is communicated with two bidirectional oil ports of the steeringvalve; and the two ends of the oil return pipeline are communicated with the oil return port of the steering valve and the oil tank respectively, and the oil return port of the oil return pipeline islocated below the oil surface. The automobile power-assisted steering system supplies oil to the steering oil cylinder through the variable pump; and during the linear running of the automobile, low displacement of the variable pump is kept, and the loss of engine power is reduced.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

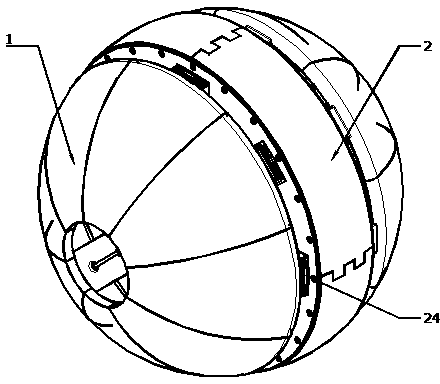

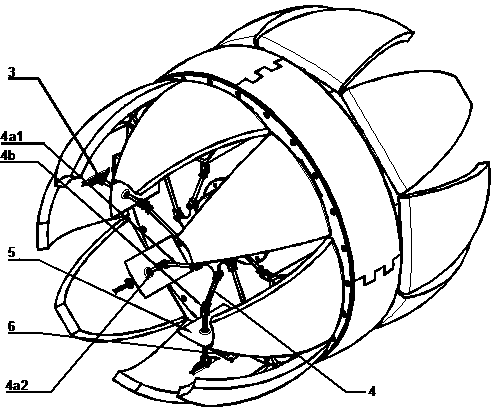

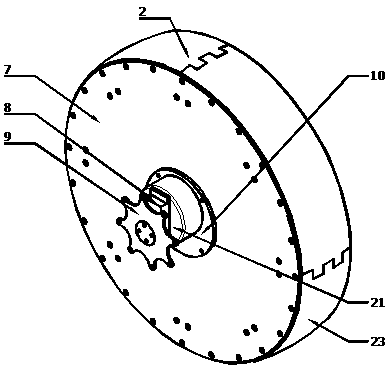

Fast steering spherical robot

The invention discloses a fast steering spherical robot. The fast steering spherical robot comprises eight pairs of spherical surface spherical feet, eight pairs of spherical foot link mechanisms, two spherical foot drive mechanisms, a central spherical wheel frame and a central pendulum bob mechanism, wherein the eight pairs of spherical surface spherical feet are arranged on the two sides in total. The fast steering spherical robot is characterized in that the eight pairs of spherical surface spherical feet are movably connected with the two spherical foot drive mechanisms through the eight pairs of spherical foot link mechanisms respectively, and the two spherical foot drive mechanisms are installed on the two side walls of a central spherical wheel frame body respectively; the central pendulum bob mechanism is fixedly installed in the central spherical wheel frame body; a brushless motor is arranged in the central pendulum bob mechanism to drive the central pendulum bob mechanism to change the center of gravity of the central pendulum bob mechanism, and the robot is controlled to move front and back in the mean axis normal direction; steering engines are arranged in the two spherical foot drive mechanisms respectively, the two spherical foot drive mechanisms change opening and closing angles of the eight pairs of spherical surface spherical feet through the eight pairs of spherical foot link mechanisms, and then left inclination and right inclination of the robot on a mean axis are changed. The robot can smoothly steer in the high-speed advancing process, and is good in flexibility and universal in structure.

Owner:SHANGHAI UNIV

Fixed-track round-trip conveying robot

The invention discloses a fixed-track round-trip conveying robot. The fixed-track round-trip conveying robot comprises a track and a vehicle body plate; side baffles are welded to the two sides of thevehicle body plate, and an end baffle is welded to one end of the vehicle body plate; a multistage oil cylinder is connected to the end baffle and is connected with a pushing plate; the side bafflesare detachably connected with an unloading plate through bolts, and a plurality of rolling columns are mounted on the vehicle body plate and the unloading plate in a rolling mode correspondingly; a forward plate frame and a backward plate frame are welded to one side of each side baffle, and the lower parts of the forward plate frame and the backward plate frame are each rotatably connected with aset of steering frames ; a storage battery and a gear motor are connected to the two sides of the bottom of the vehicle body plate correspondingly; and a driving wheel frame is welded to the middle position of the bottom of the vehicle body plate and is rotatably matched with a wheel shaft. The fixed-track round-trip conveying robot can automatically run to a work station of the next working process after being started with products being loaded and then return to the work station of the precious working process after automatic unloading, operation is easy, using is convenient, and great convenience for conveying work of the products is provided.

Owner:TIANJIN MASTER LOGISTICS EQUIP CO LTD

Steering device and vehicle wheel mounting module including the same

ActiveUS20200207405A1Increase in sizeIncrease profitSteering linkagesElectrical steeringReduction driveSuspension (vehicle)

A steering device, including: a steering knuckle rotatably holding a wheel; an electric motor and a speed reducer configured to decelerate rotation of the electric motor, the electric motor and the speed reducer being fixed to a suspension arm; and a joint through which the steering knuckle is supported by the suspension arm in a state in which a kingpin axis is allowed to incline with respect to the suspension arm, the joint coupling the steering knuckle and an output shaft of the speed reducer such that the steering knuckle pivots about the kingpin axis by an operation of the electric motor.

Owner:TOYOTA JIDOSHA KK

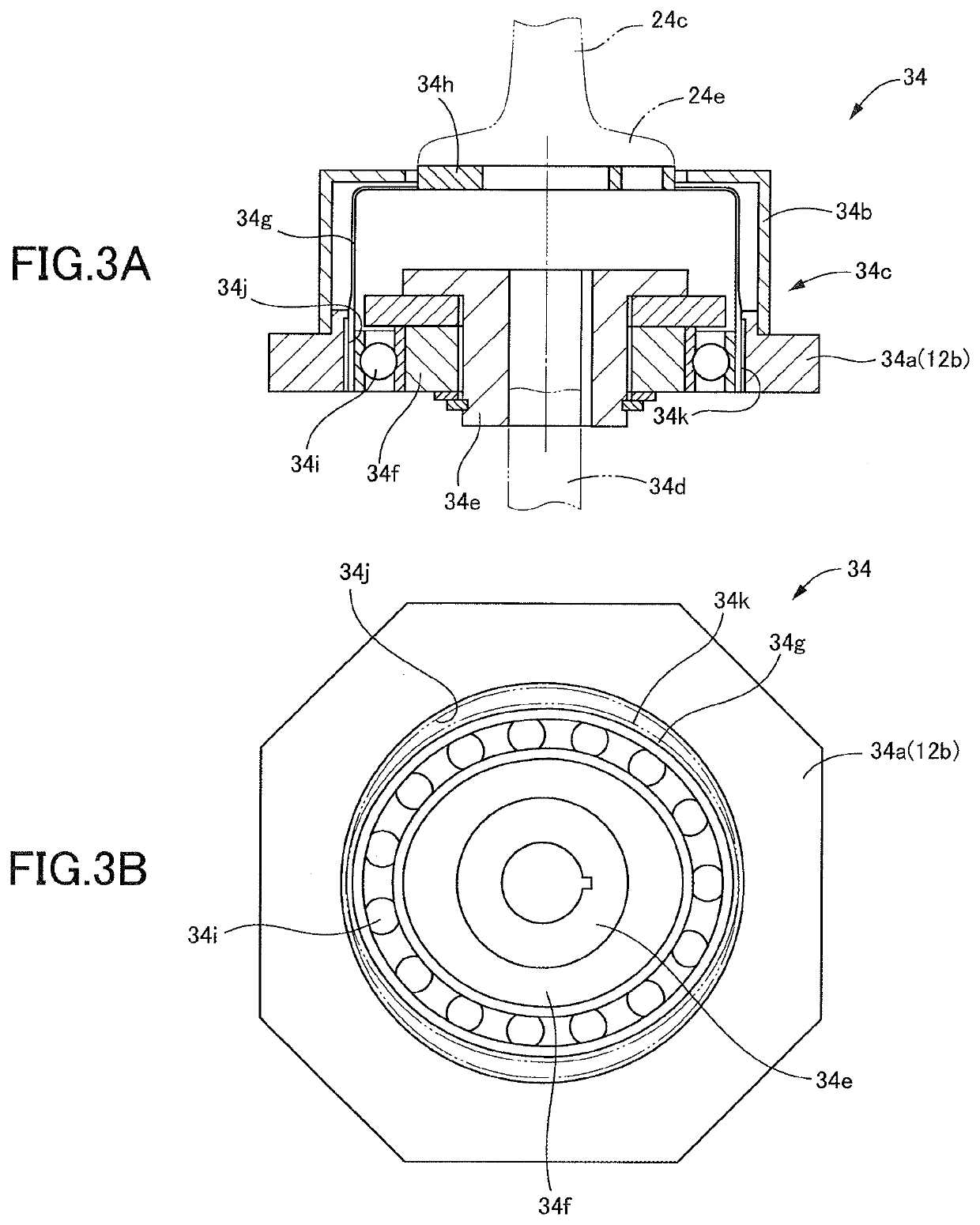

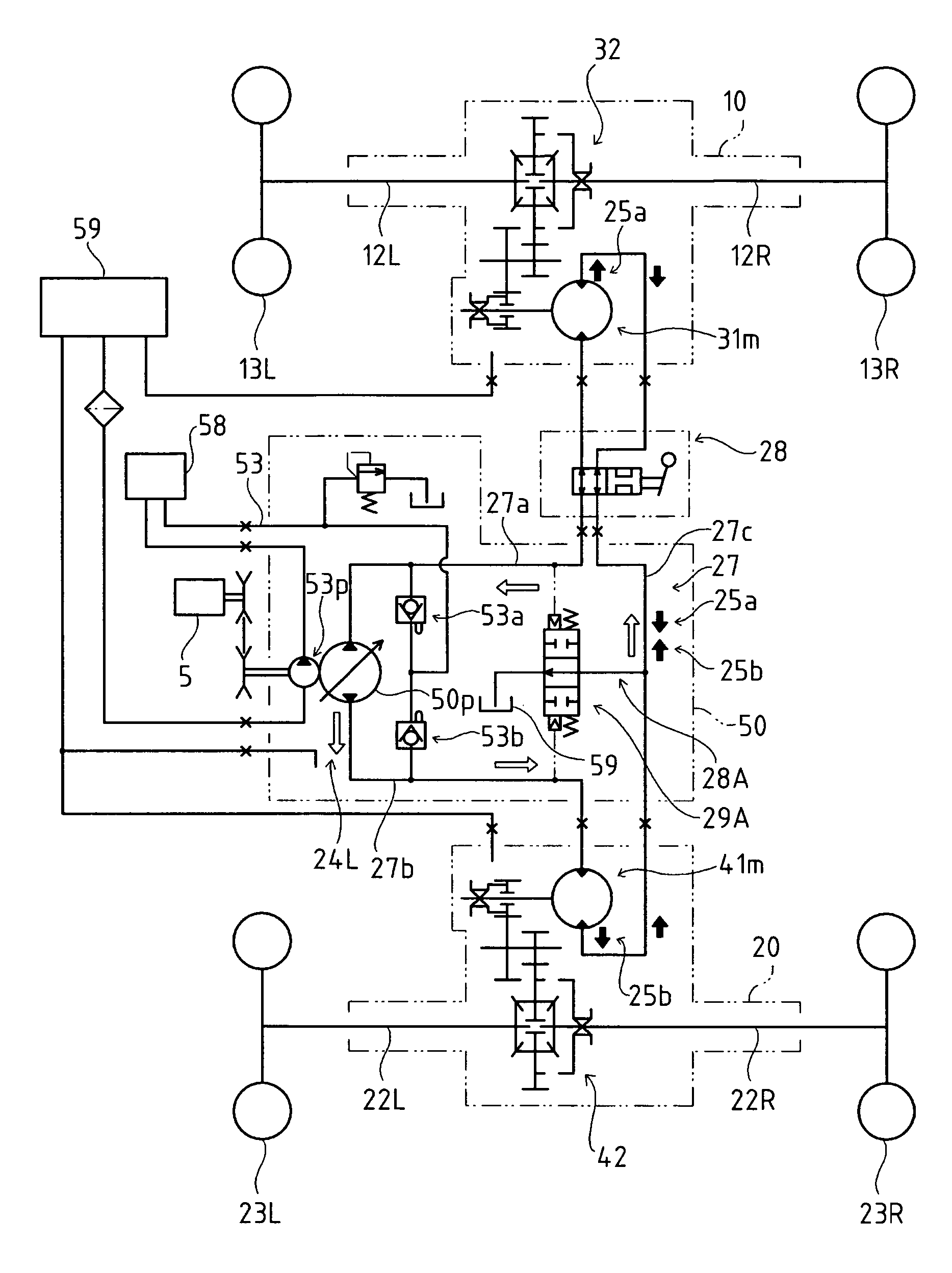

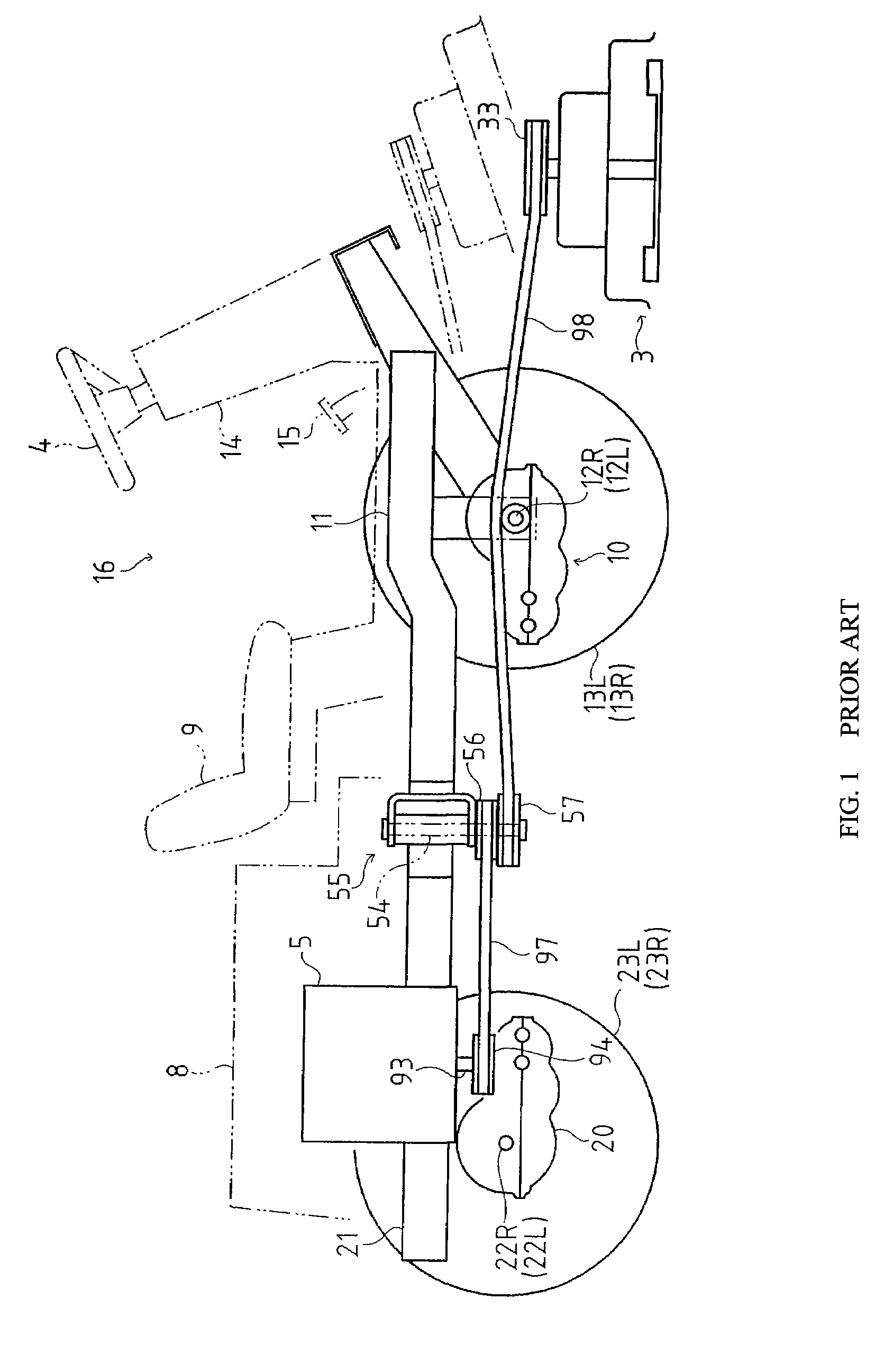

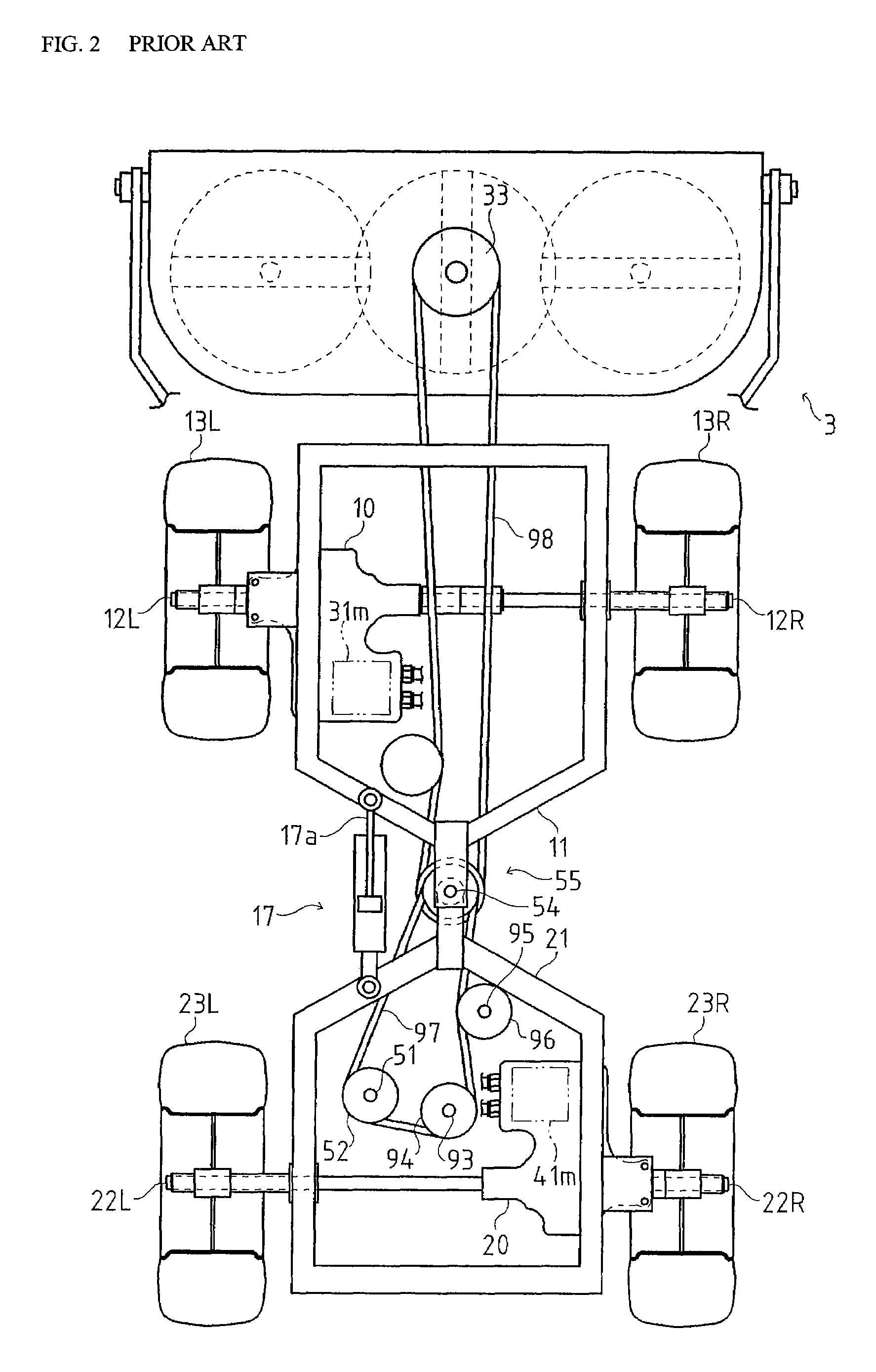

Hydraulic four-wheel driving articulated vehicle

A hydraulic four-wheel driving articulated vehicle comprises: a first frame, on which first axles and a first hydraulic motor driving the first axles are mounted; a second frame, on which second axles and a second hydraulic motor driving the second axles are mounted, wherein the first and second frames are connected to each other so as to be relatively rotatable centering on a vertical axis by a steering operation; a hydraulic pump; a hydraulic circuit fluidly connecting the first and second hydraulic motors in series to the hydraulic pump, wherein the hydraulic circuit includes a passage interposed between the first and second hydraulic motors; and pressure control means for releasing oil from the passage between the first and second hydraulic motors when the first and second frames are relatively rotated by the steering operation of the stationary vehicle and backpressure oil discharged from the first and second hydraulic motors is excessively accumulated in the passage between the first and second hydraulic motors.

Owner:KANZAKI KOKYUKOKI MFG

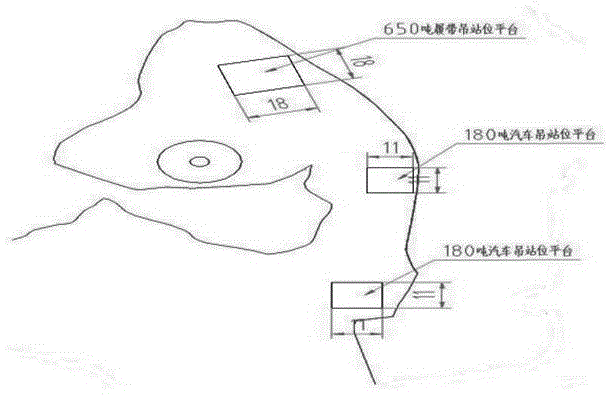

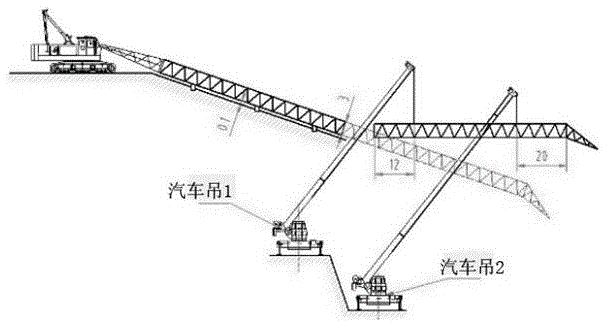

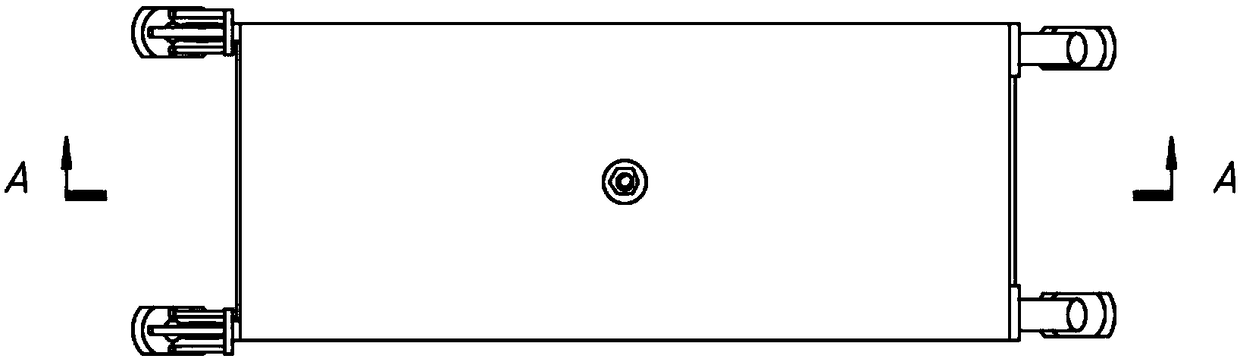

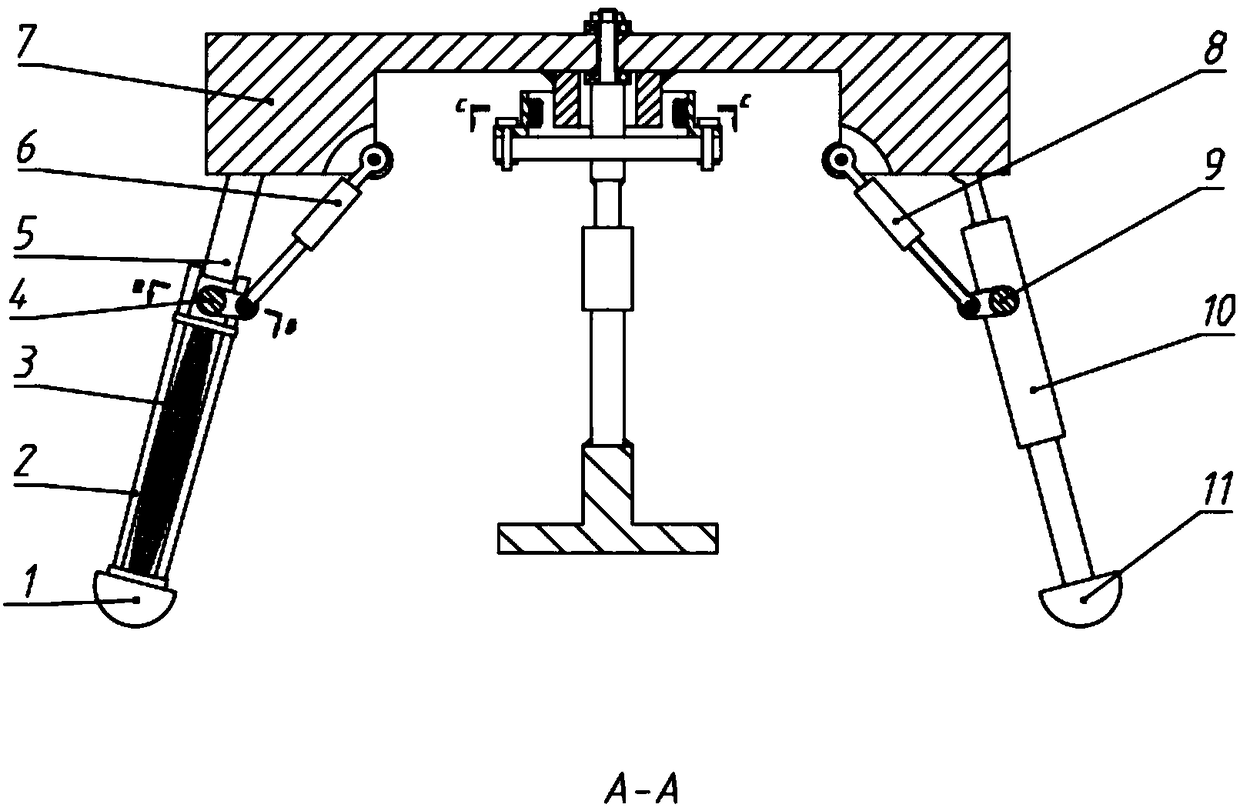

Method for mounting crawler cranes in side slope sites

The invention discloses a method for mounting crawler cranes in side slope sites. The method includes steps of S1, preparing for construction, to be more specific, a, marking out appropriate lifting platforms for truck cranes, treating foundations and leveling the sites; b, selecting the appropriate truck cranes; c, transporting main units, crawlers, counterweights and main arms of the crawler cranes to main unit position platforms and assembling the main units, the crawlers, the counterweights and the main arms; d; respectively driving every two corresponding truck cranes to the corresponding lifting platforms and transporting tower arms onto the lifting platforms; e, respectively computing the stretching length required by each lifting arm of each truck crane, assembling the tower arms besides the lower-end lifting platforms and determining a lifting point for lifting each truck crane on the corresponding tower arm according to the position of the gravity center of each section of each lifting arm in the corresponding tower arm; S2, simultaneously lifting each tower arm by the aid of the two corresponding truck cranes; S3, grouping each tower arm and the corresponding main arm in the air by the aid of the two corresponding truck cranes; S4, operating the lifting arms of the truck cranes and taking off lifting hooks. The method for mounting the crawler cranes in the side slope sites has the advantages of speedy mounting and high efficiency.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Steering device and four-legged robot comprising same

The invention discloses a steering device and a four-legged robot comprising the same. The steering device includes a supporting base, a hydraulic telescopic device is vertically arranged on the supporting base, a disc-shaped supporting shaft is installed at the top of the hydraulic telescopic device, and a stator core is arranged on the upper portion of the supporting shaft. A coil winding is arranged on the stator core, a rotor permanent magnet is arranged in the center of the stator core, and the rotor permanent magnet is fixed to the bottom of a machine body of the robot. The coil windingis controlled to be energized or cut off, a rotating magnetic field is formed, the rotor permanent magnet rotates under the action of the magnetic field, the permanent magnet is fixed together with the machine body of the robot, so that the machine body of the robot rotates at an angle when four feet are off the ground.

Owner:SHANDONG UNIV

Destacking machine

ActiveCN108996248AGuaranteed stabilityReduce manual labor intensityStacking articlesDe-stacking articlesWork cycleEngineering

The invention discloses a destacking machine. The destacking machine comprises a main engine, a stack feeding frame, a stacking frame, an empty bottle conveyor, a base, a steering device, a guide railpair, a pick-and-place device, a lifting device and a balancing mechanism. The pick-and-place device is capable of grabbing multiple empty bottles and a tray of the same layer at a time simultaneously. After the pick-and-place device is elevated by a certain height along the guide rail pair, the pick-and-place device turns right by 90 degrees and descends to the position of an unloading disk of the stacking frame, the tray is unloaded; and after being elevated by a certain height again, the pick-and-place device rotates leftwards by 180 degrees; after descending to the position of the empty bottle conveyer, the empty bottles are unloaded; and a grabbing working cycle is completed. According to the destacking machine, manpower is replaced, and the purpose of grabbing and unloading the bottles is achieved; the working efficiency is high; operation maintenance is simple; the maintenance cost is low; and the problems that stacked empty bottles and trays need to be placed separately, completion of the working procedure depends on manpower, manual labor intensity is high, the labor force cost is high, and the production efficiency is low are expected to be solved.

Owner:KUNMING CIBA MINING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com