Self-selecting differential steering conveying equipment

A technology of differential steering and conveying equipment, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of affecting the service life of equipment, consuming system resources, and large investment in equipment, so as to facilitate flexible selection, reduce investment, and investment cost small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

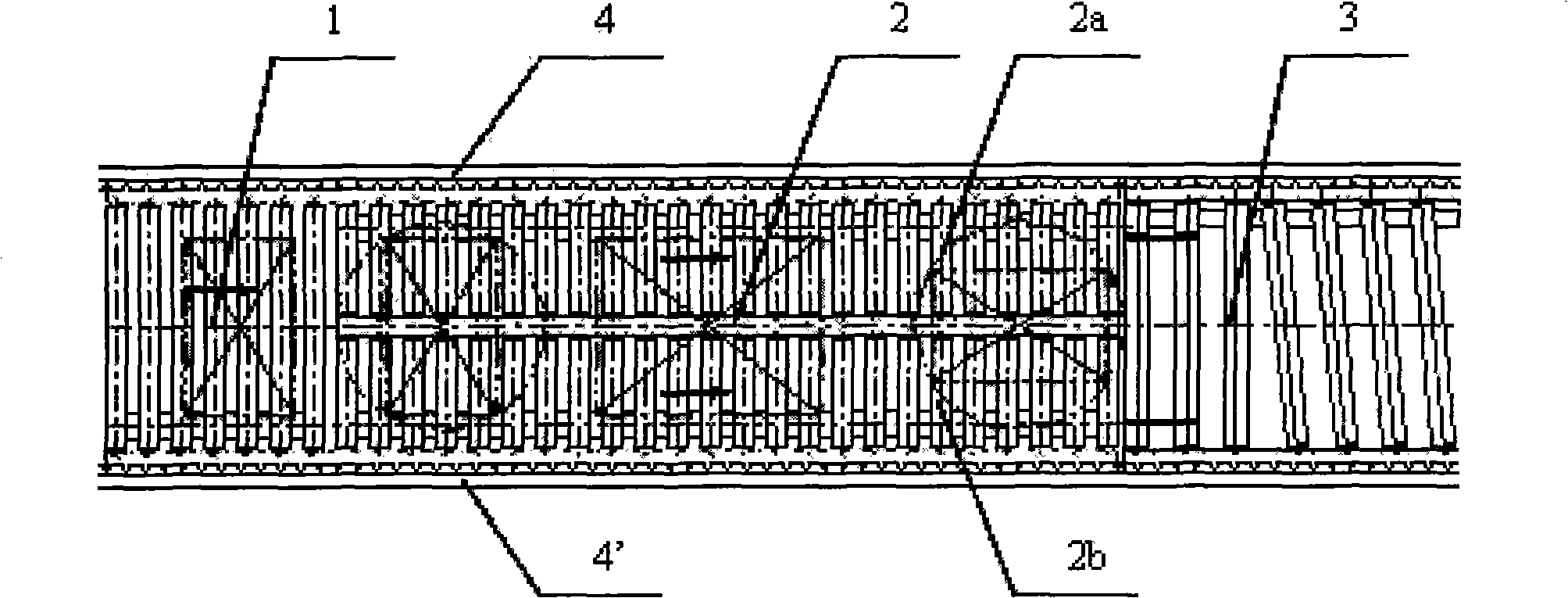

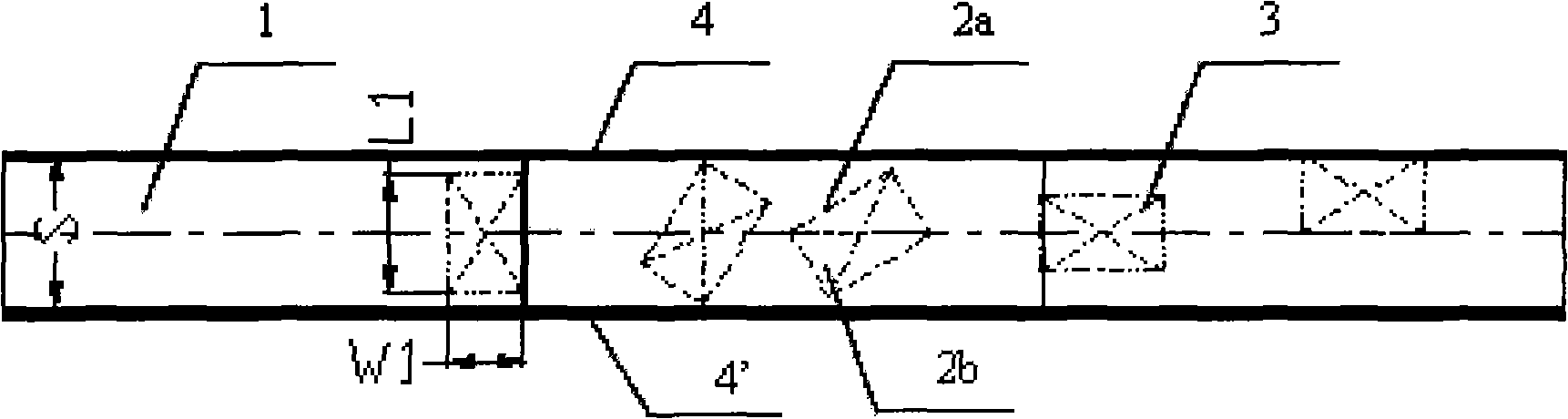

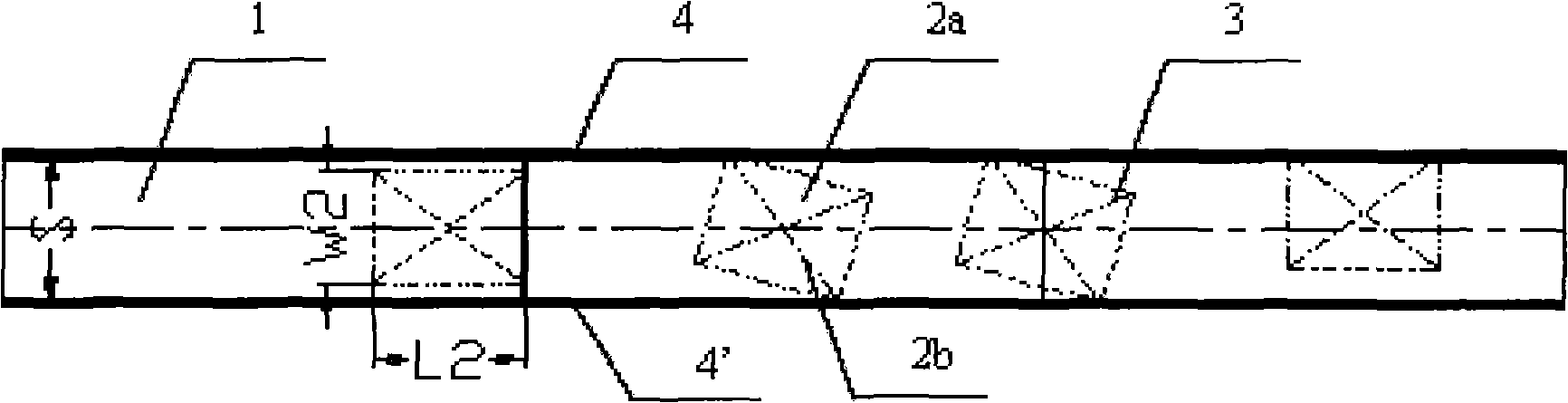

[0014] Such as figure 1 As shown, the present invention includes an upstream input mechanism 1, a differential conveying mechanism 2 and a downstream output mechanism 3 connected in sequence, and guide rails 4, 4'arranged on both sides of the upstream input mechanism 1, the differential conveying mechanism 2 and the downstream output mechanism 3 , The distance between the two guide railings is greater than the diagonal length of the smallest size material conveyed, and smaller than the diagonal length of the largest size material conveyed. In this embodiment, the diagonal length of the smallest size material and the largest size material are taken average of. That is, when the length of the smallest size material is L 1 , Width is W 1 , The length of the largest size material is L 2 , Width is W 2 When, take the distance between the two guide rails S = ( L 1 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com