Liquid piston heat engine

A technology of liquid piston and heat engine, applied in the field of thermal energy and power, can solve the problems that are difficult to realize, large Stirling engine, Stirling engine with limited heating efficiency and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

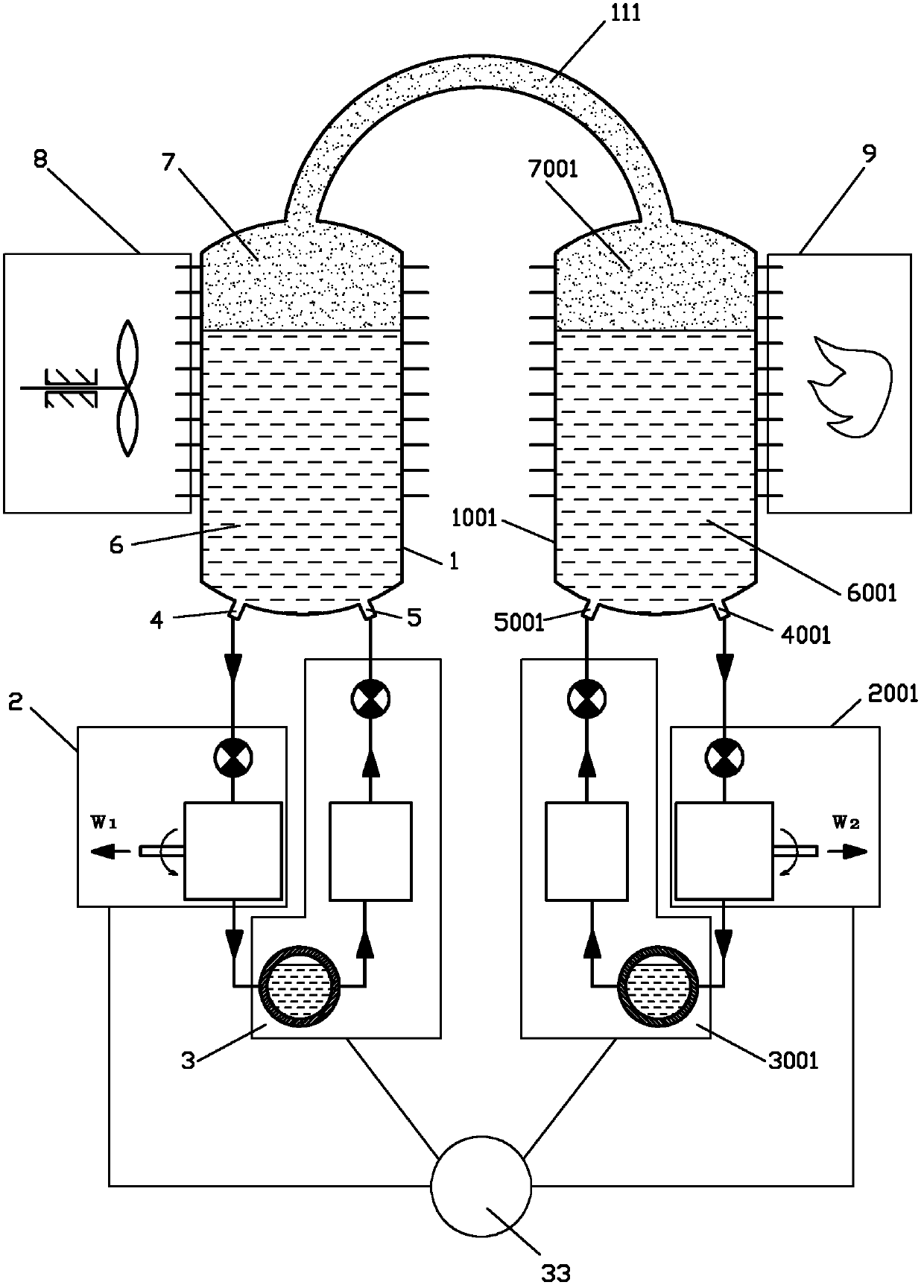

Embodiment 1

[0050] Such as figure 1 The liquid piston heat engine shown includes a cold gas liquid cylinder 1, a hot gas liquid cylinder 1001, a cold hydraulic power mechanism 2, a hot hydraulic power mechanism 2001, a cold liquid working medium return system 3 and a hot liquid working medium return system 3001. The liquid cylinder 1 communicates with the hot gas liquid cylinder 1001 through the gas working fluid communication pipeline 111, a cooler 8 is provided on the cold gas liquid cylinder 1, and a heater 9 is provided on the hot gas liquid cylinder 1001;

[0051] The cold gas-liquid cylinder 1 is provided with a cold liquid working medium outlet 4 and a cold liquid working medium return port 5, and the cold liquid working medium outlet 4 communicates with the power liquid inlet of the cold hydraulic power mechanism 2, and the cold hydraulic power The liquid outlet of the mechanism 2 communicates with the cold liquid working medium return system 3, and the cold liquid working medium...

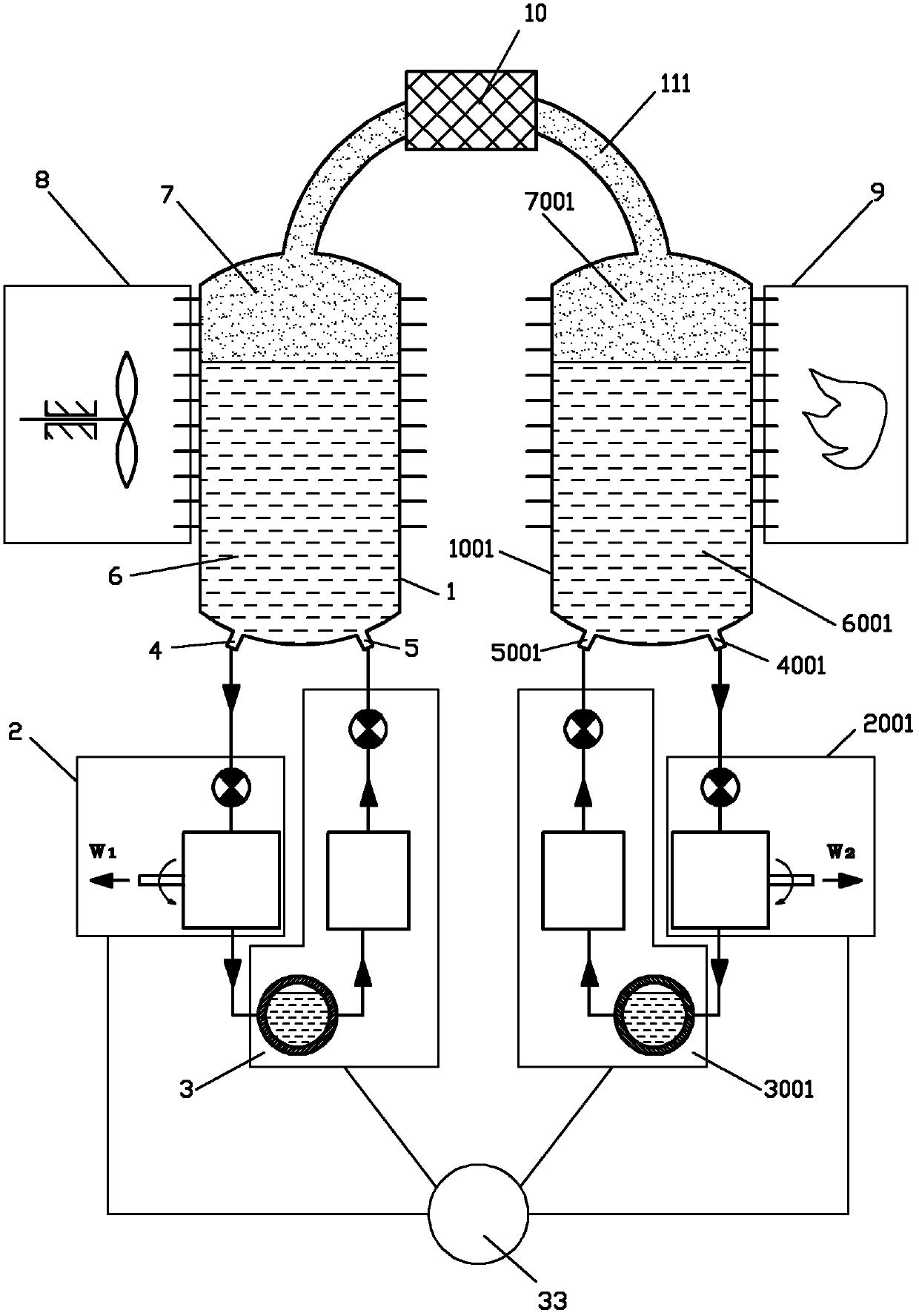

Embodiment 2

[0055] Such as figure 2 The difference between the shown liquid piston heat engine and Embodiment 1 is that a regenerator 10 is provided on the gas working fluid communication pipeline 111 .

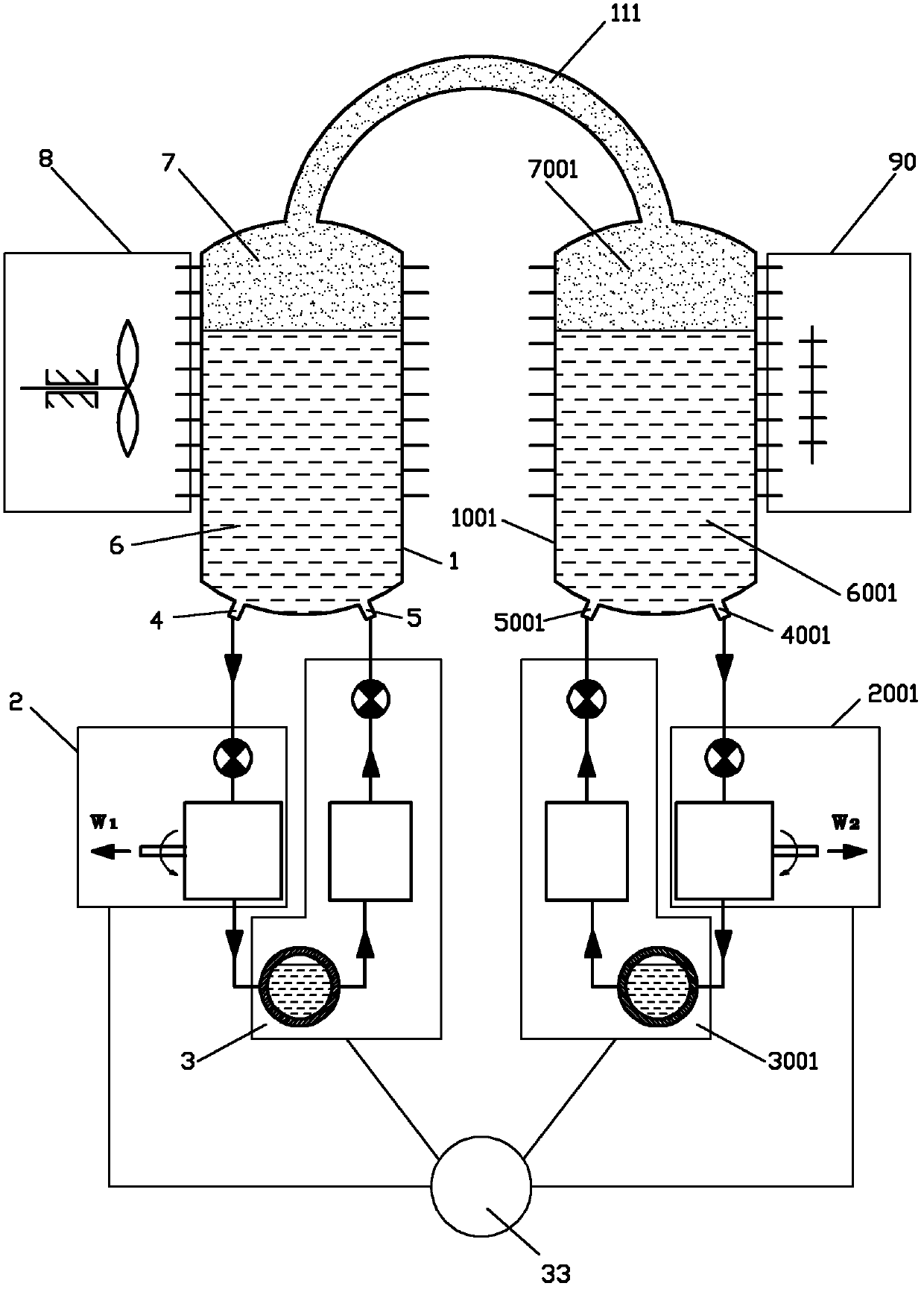

Embodiment 3

[0057] Such as image 3 The difference between the shown liquid piston heat engine and Embodiment 1 is that the heat source of the heater 9 is set as a low-grade heat source 90 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com