Patents

Literature

228 results about "Thermal hydraulics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal hydraulics (also called thermohydraulics) is the study of hydraulic flow in thermal fluids. The area can be mainly divided into three parts: thermodynamics, fluid mechanics, and heat transfer, but they are often closely linked to each other. A common example is steam generation in power plants and the associated energy transfer to mechanical motion and the change of states of the water while undergoing this process. Thermal-hydraulic analysis can determine important parameters for reactor design such as plant efficiency and coolability of the system.

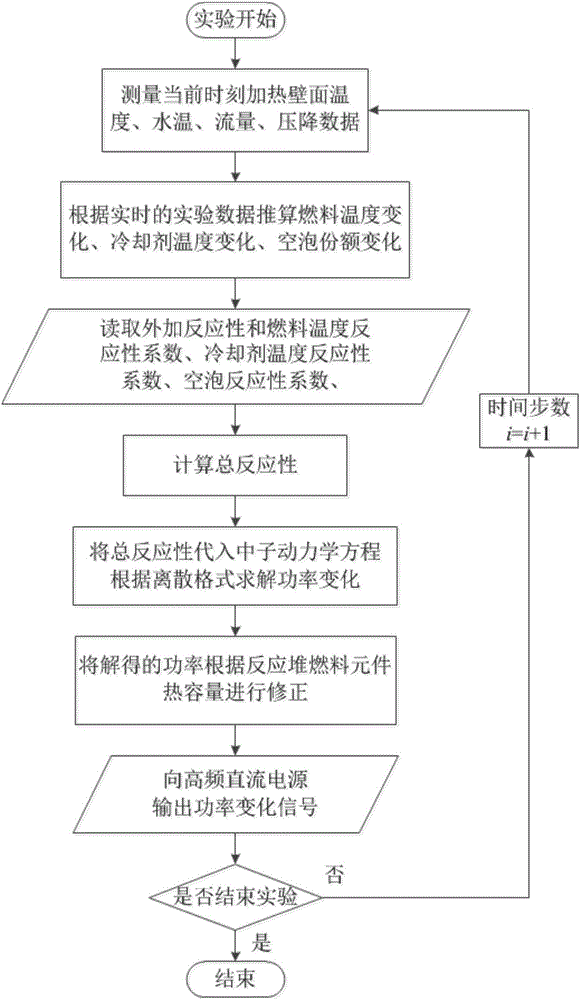

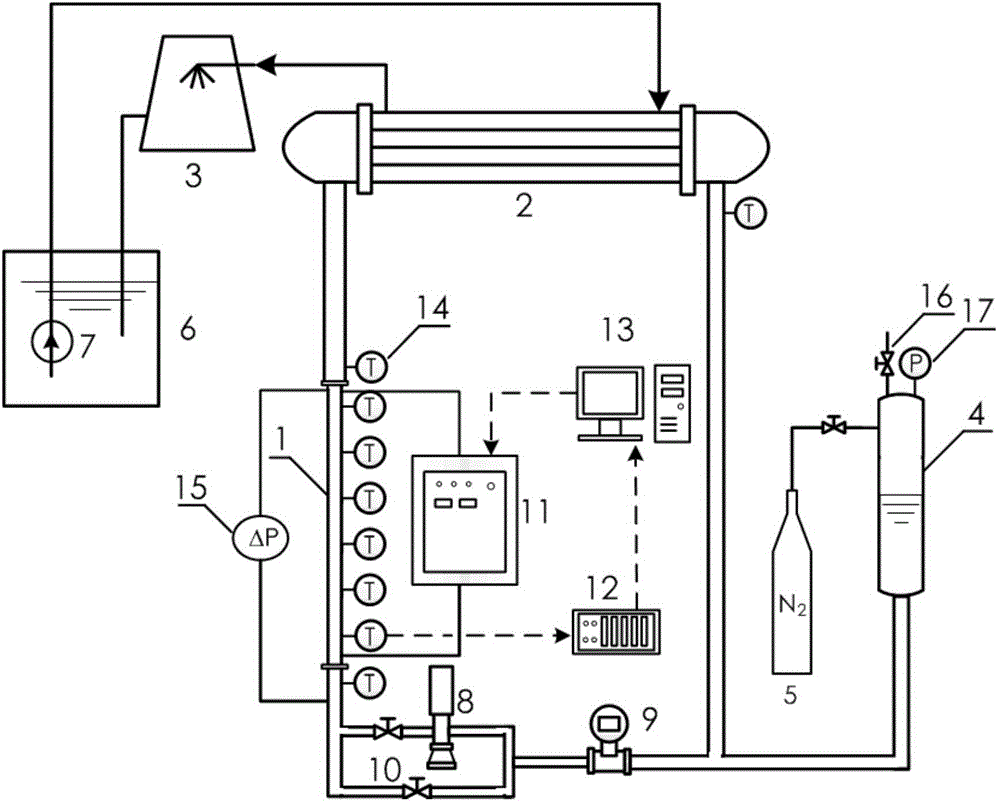

Thermal hydraulic experiment device and method for simulating nuclear reactor neutron reactivity feedback process

ActiveCN105869685ACapable of natural circulationApplicable to a wide range of working conditionsNuclear energy generationNuclear monitoringResponse processMeasuring instrument

The invention provides a thermal hydraulic experiment device and method for simulating a nuclear reactor neutron reactivity feedback process. The thermal hydraulic experiment device comprises an electric heating experiment section, a shell-tube type cooler, a voltage stabilizer, a pressurizing nitrogen gas tank, a circulating pump, a cooling water pump, a cooling water tank, a cooling water tower, a pipeline, a valve, a measuring instrument, a data acquisition system, a control computer, a high-frequency direct-current power supply and a conductive copper bar. The high-frequency direct-current power supply is used for electrifying the electric heating experiment section. The circulating pump is connected with an inlet of the electric heating experiment section through a pipeline; the circulating pump is provided with a bypass pipeline; an outlet of the electric heating experiment section is connected with a pipe side inlet of the shell-tube type cooler through a pipeline. A control system for simulating nuclear reactor neutron reactivity is additionally arranged on the thermal hydraulic experiment device, and can be used for simulating the reactivity feedback process and a thermal hydraulic response process of nuclear reactors under various instant working conditions; the thermal hydraulic experiment device has the advantage of simulating various types of experiment working conditions, which are not easy to carry out in the nuclear reactor, under a nuclear-radiation-free environment.

Owner:HARBIN ENG UNIV

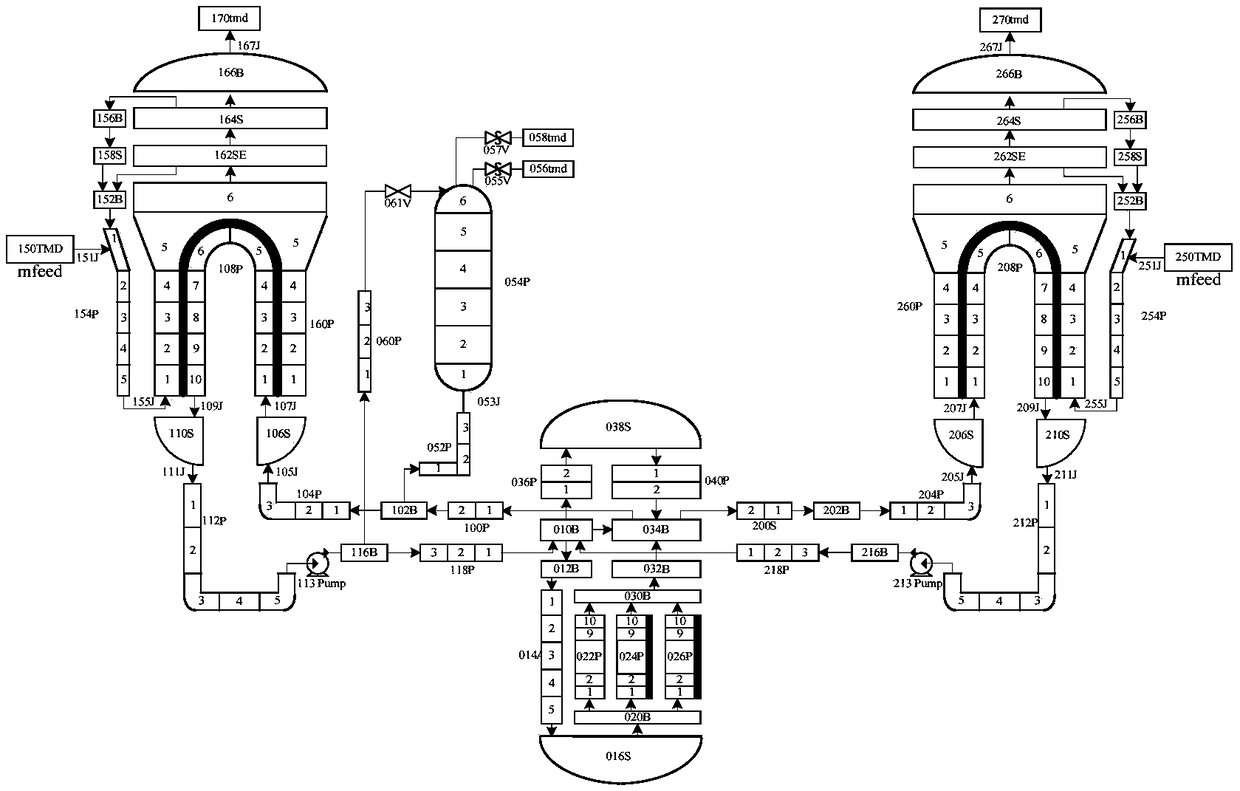

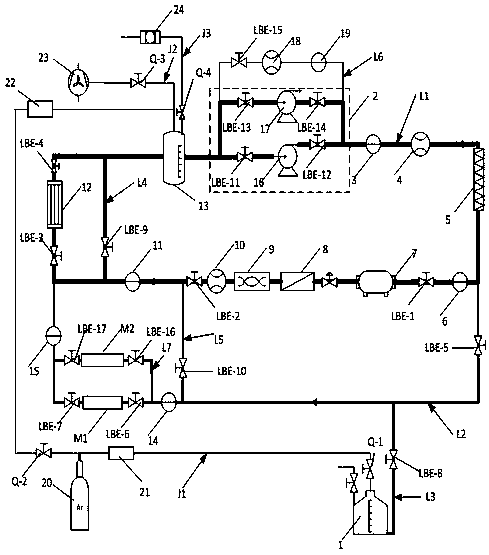

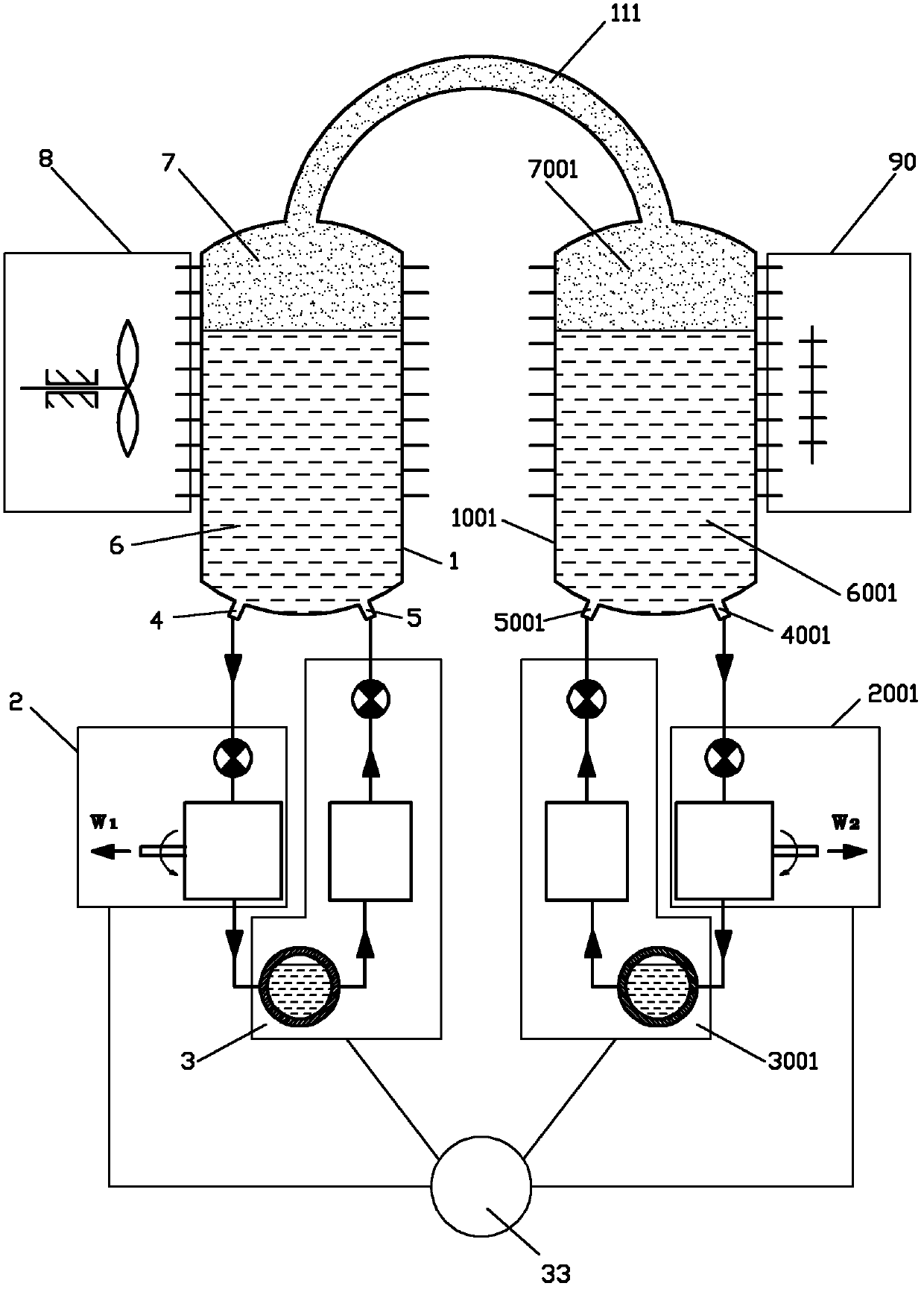

Liquid metal sodium boiling two-phase thermal-hydraulic test loop system and test method thereof

InactiveCN102915777AMeet the requirement of boiling two-phase testGuaranteed tightnessNuclear energy generationNuclear monitoringData acquisitionLiquid metal

The invention discloses a liquid metal sodium boiling two-phase thermal-hydraulic test loop system and a test method thereof. The loop system is divided into three parts comprising a high temperature part, a low temperature part and an argon branch, wherein the low temperature part comprises a sodium storage tank, an electromagnetic pump, an electromagnetic flowmeter, a purification cold trap, four sodium valves and corresponding connecting pipelines; the low temperature part is made of 316L stainless steel; the high temperature part comprises a regeneration heater, a preheater, a test section, an upper expansion box and corresponding connecting pipelines; the high temperature part is made of Incoloy 800 and allows the operating temperature to reach 1,200 DEG C; and the argon branch comprises an argon bottle, an expansion pressure stabilizing box, a vacuum pump, three pressure gauges, ten vacuum diaphragm valves and corresponding connecting pipelines. The system is suitable for operating at high temperature, has a good sealing property and can realize analysis and research on the liquid metal sodium boiling two-phase heat exchange flow characteristic by adding different test sections and a data acquisition system.

Owner:XI AN JIAOTONG UNIV

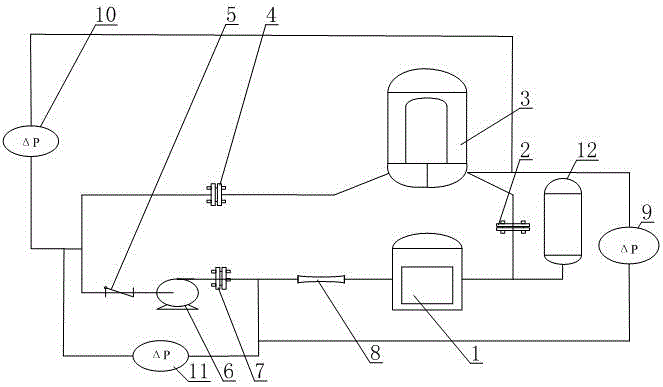

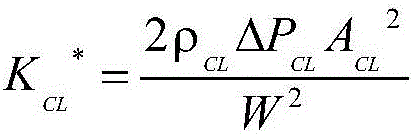

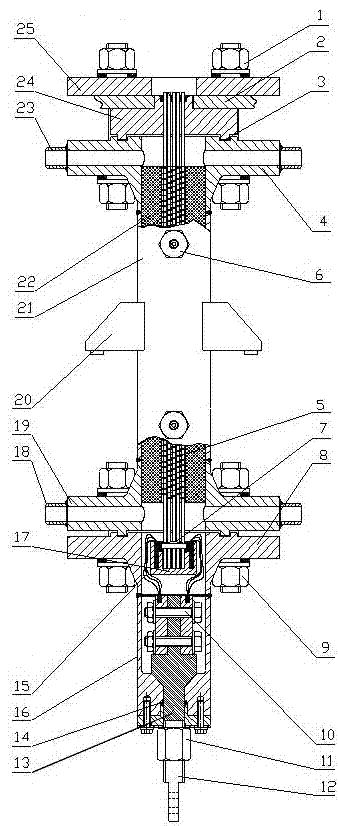

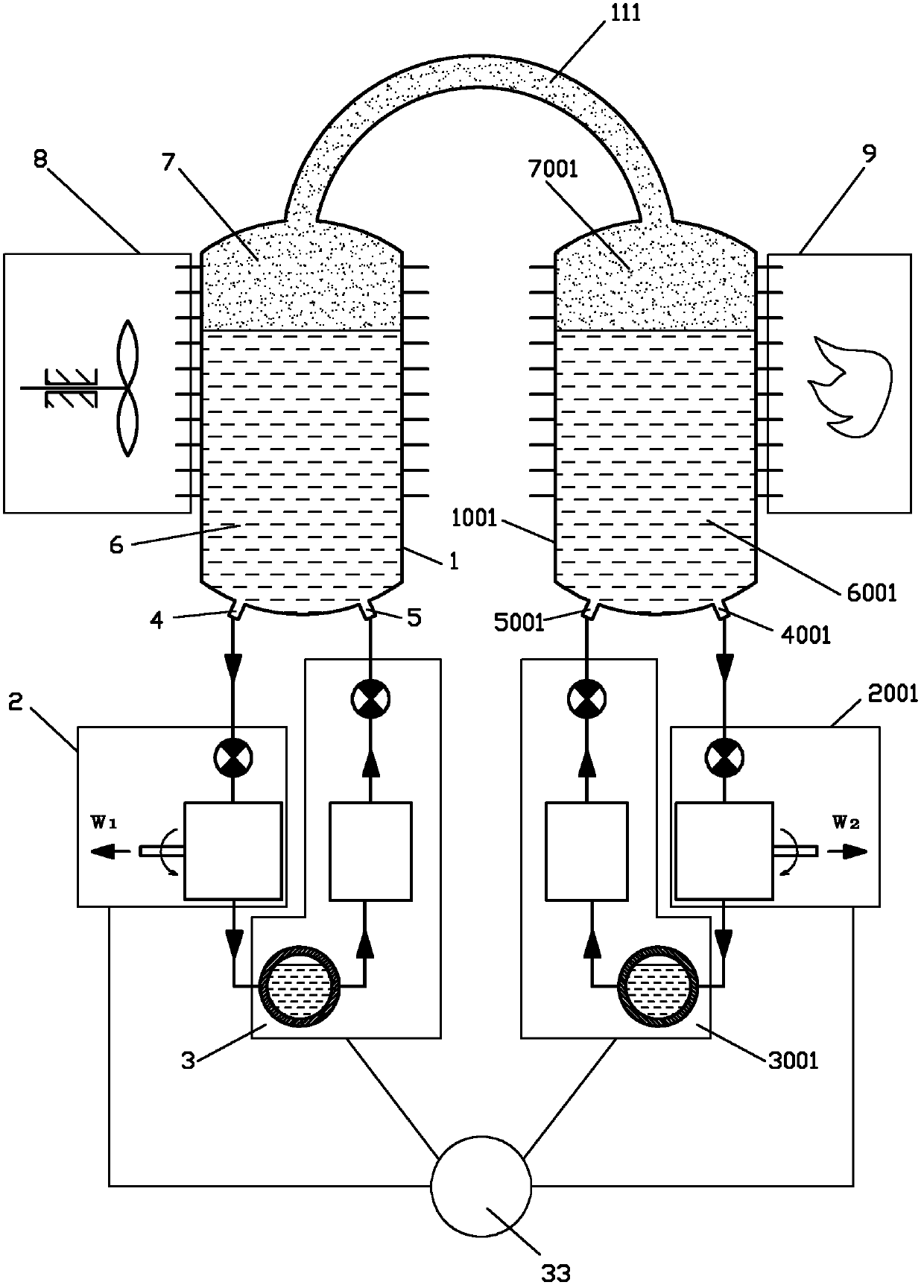

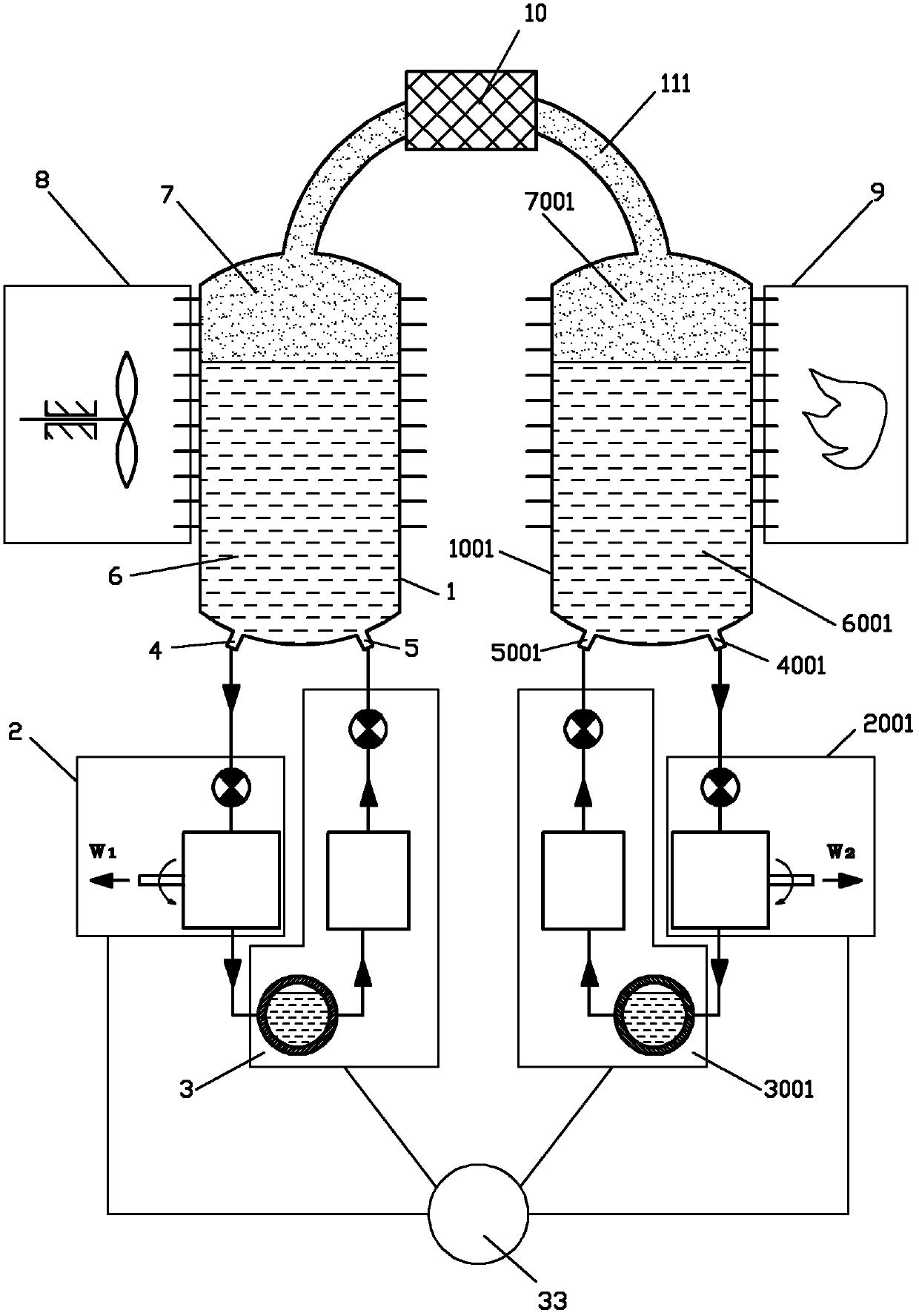

Reactor thermal-hydraulic simulation testing apparatus and fluid dynamics characteristic simulation method

ActiveCN106340329ASimulation is accurateConsistent Kinetic PropertiesNuclear energy generationNuclear monitoringEngineeringCheck valve

The invention discloses a reactor thermal-hydraulic simulation testing apparatus which comprises a reactorsimulation body, a vapor generator simulation body and a main circulating pump. The inlet and the outlet of the vapor generator simulation body are communicated with the outlet of the reactorsimulation body and the inlet of the main circulating pump, and the outlet of the main circulating pump is communicated with the inlet of the reactorsimulation body. A heat-section resistance adjusting part is arranged on the pipeline between the inlet of the vapor generator simulation body and the outlet of the reactorsimulation body, a cold-section resistance adjusting part and a stop valve are arranged on the pipeline between the outlet of the vapor generator simulation body and the inlet of the main circulating pump, and a pump way resistance adjusting part and a Venturi flowmeter are arranged on the pipeline between the outlet of the main circulating pump and the inlet of the reactorsimulation body. The invention further discloses a fluid dynamics characteristic simulation method based on the reactor thermal-hydraulic simulation testing apparatus. During application, fluid dynamics characteristics are adjusted to be consistent to a reactor prototype for implementation, and the testing efficiency of a simulation test can be improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

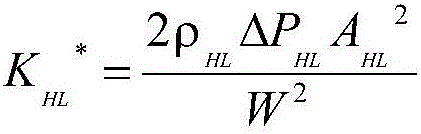

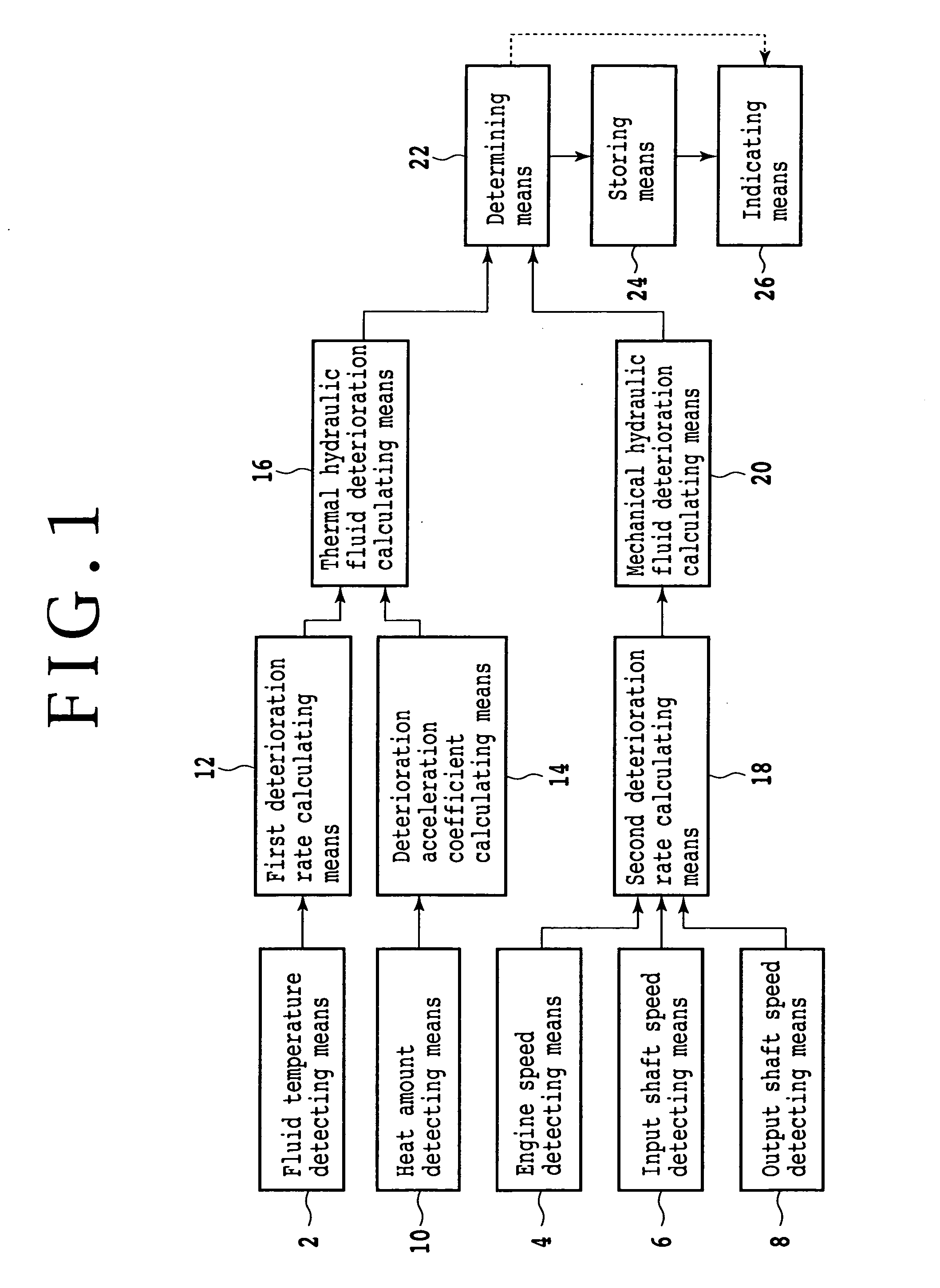

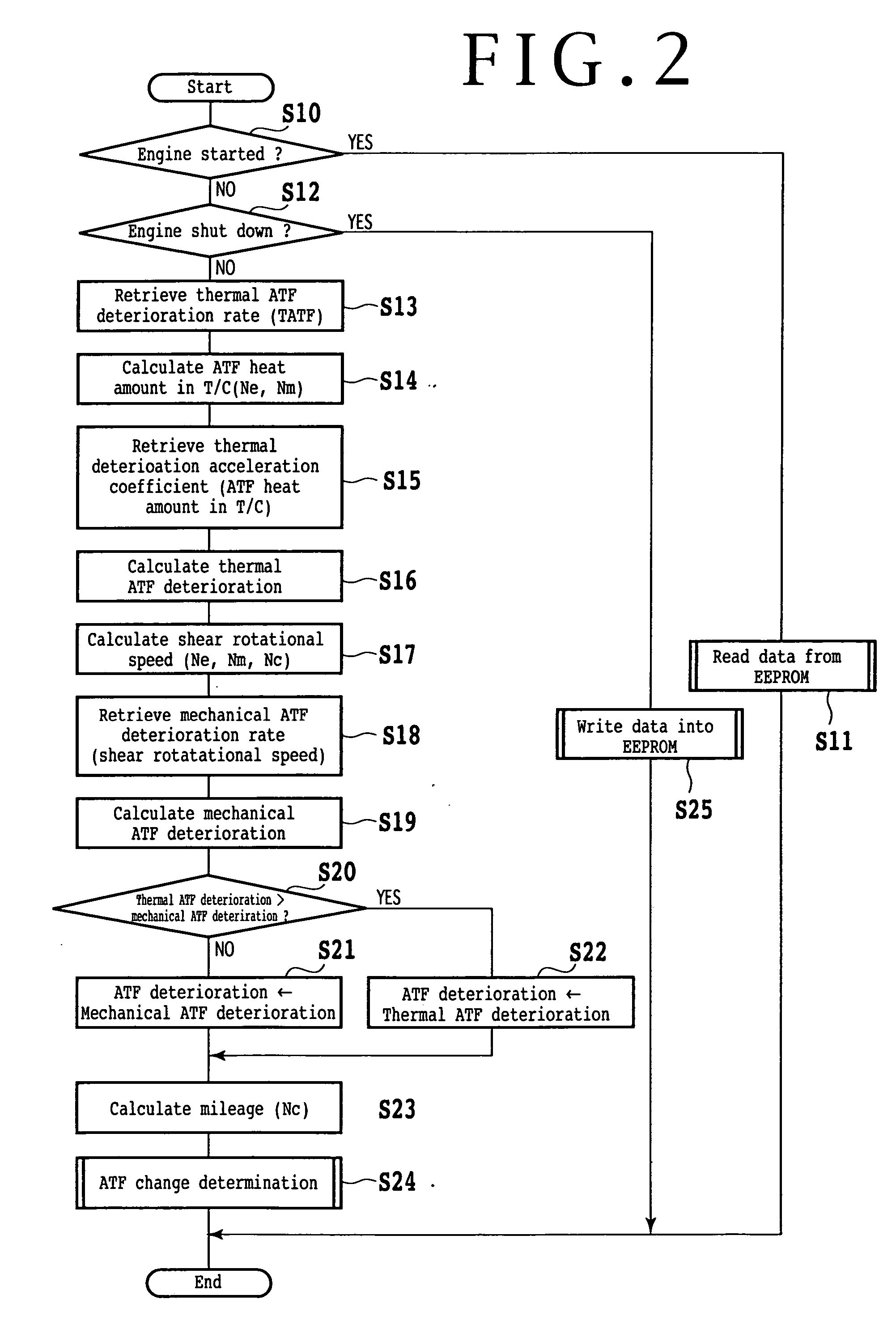

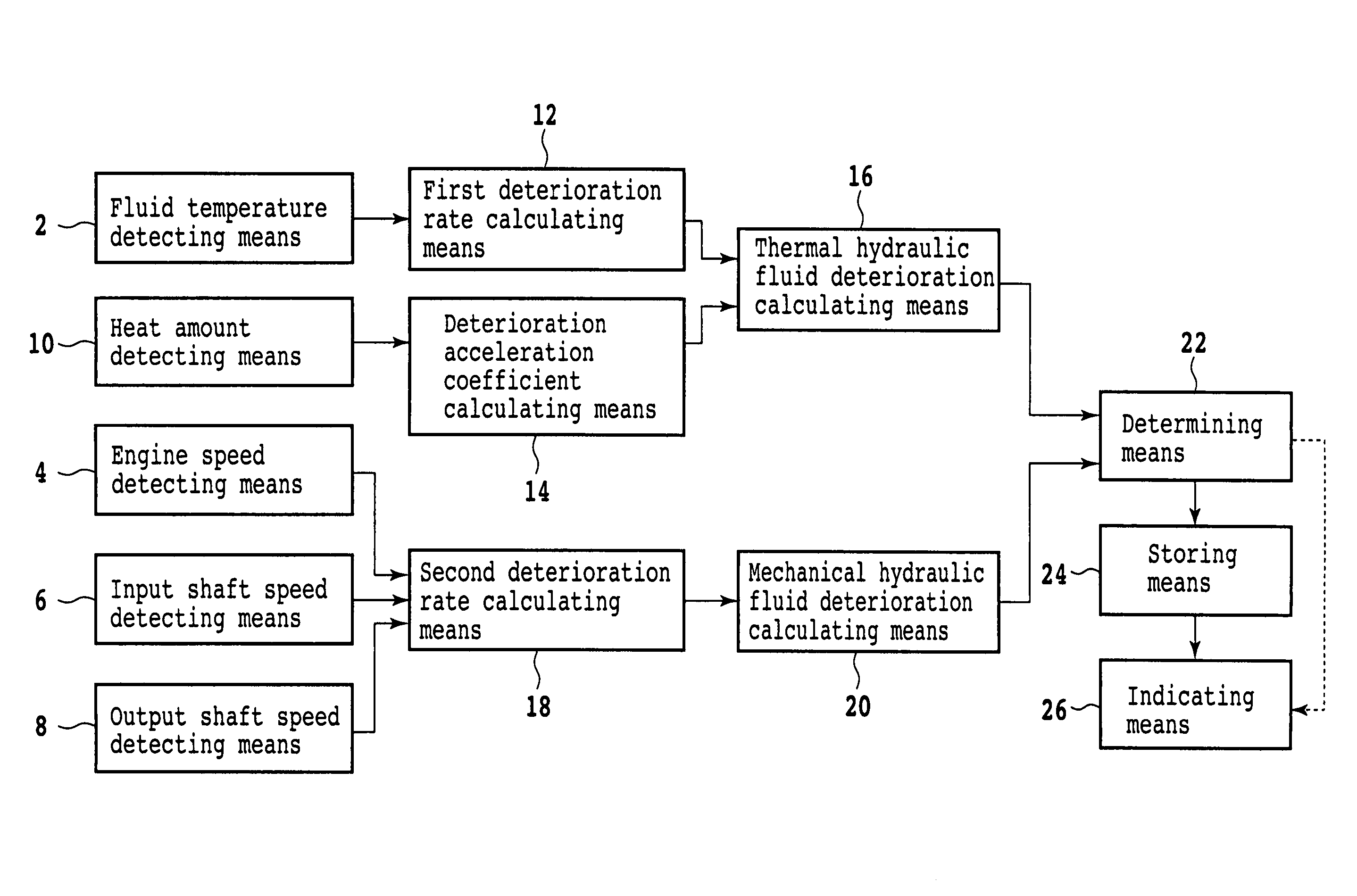

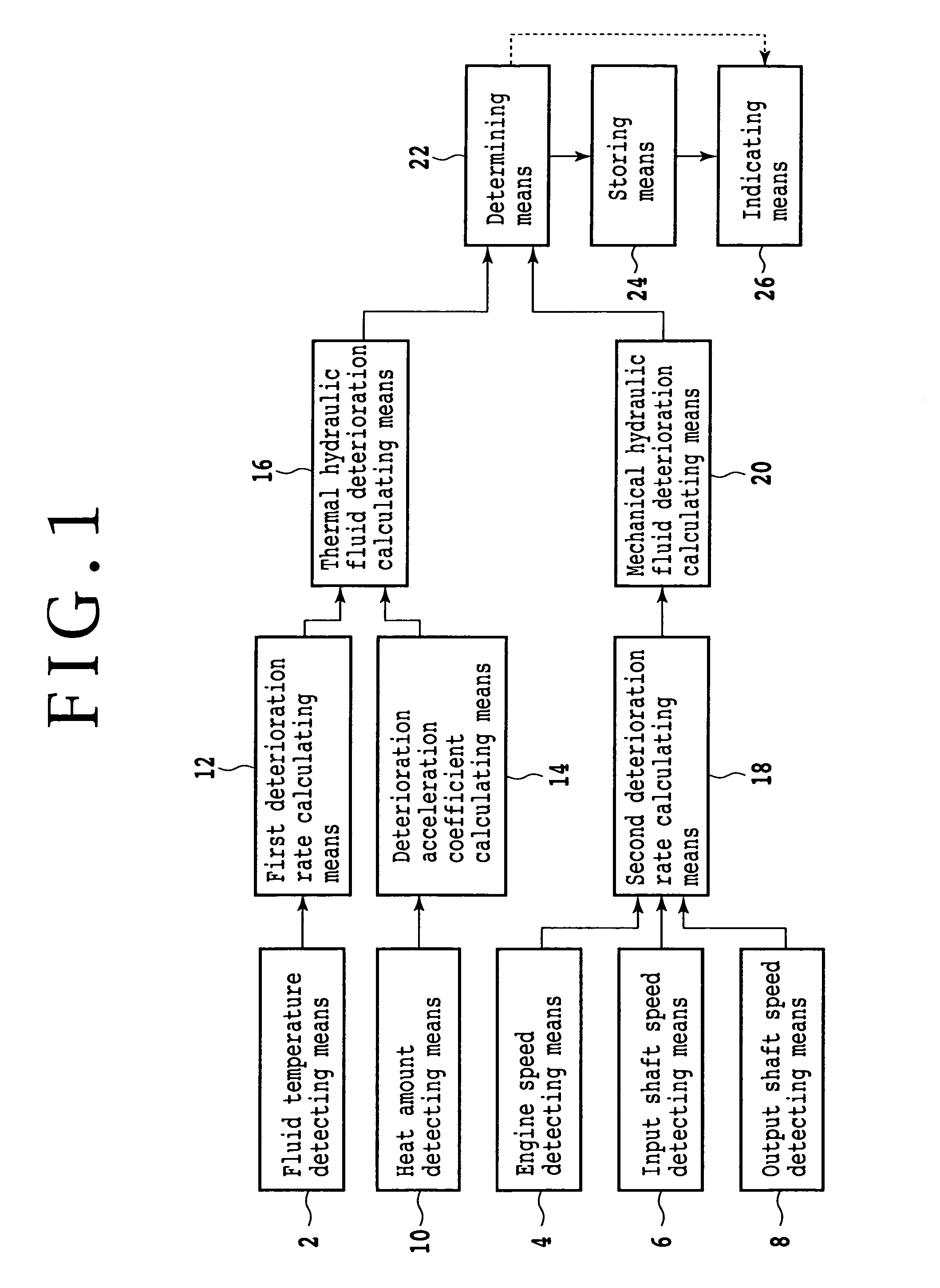

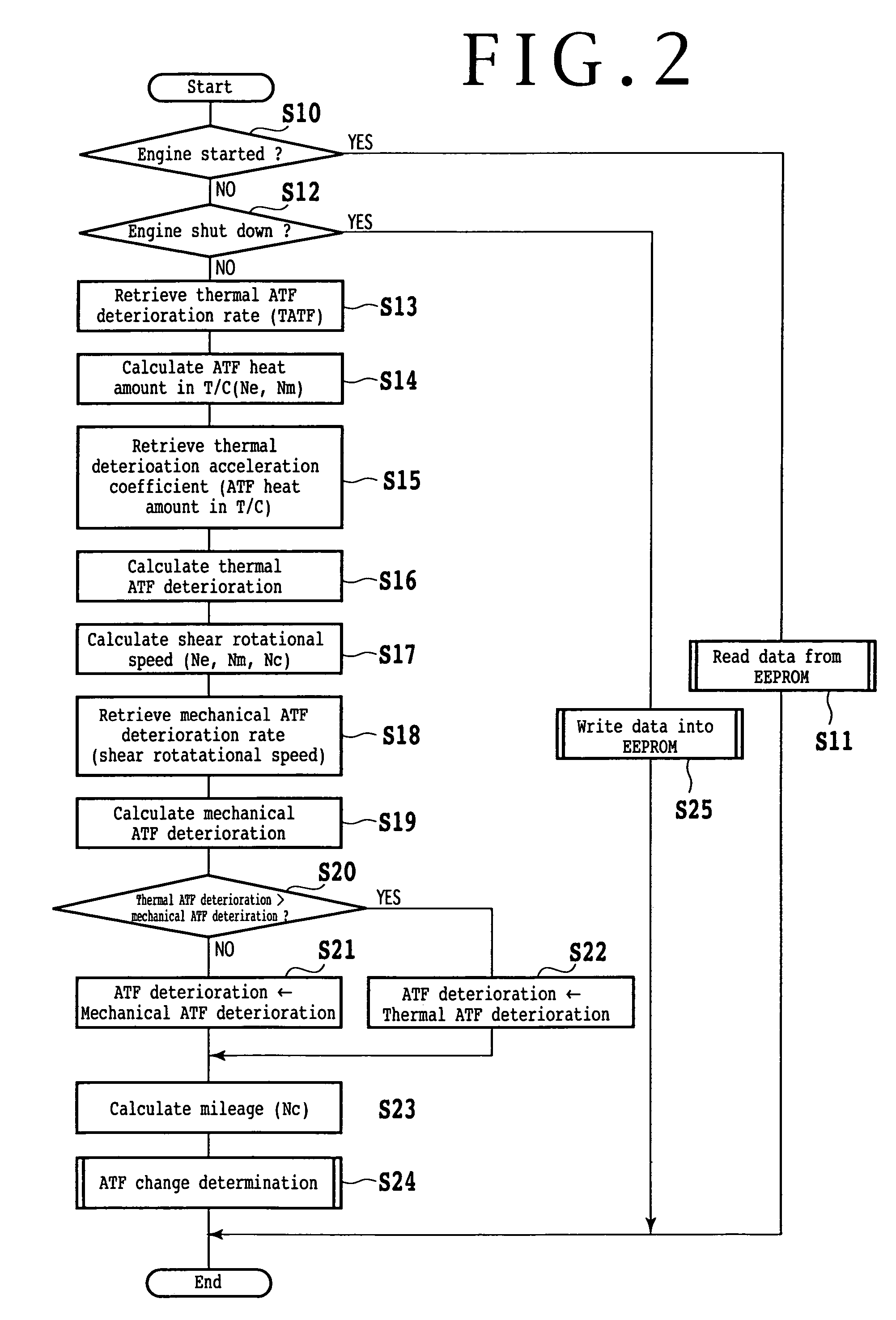

Hydraulic fluid change indicating device for automatic transmission

InactiveUS20050131599A1Improve detection accuracyImprove accuracyVehicle testingRegistering/indicating working of vehiclesDeterioration rateAutomatic transmission

A hydraulic fluid change indicating device for an automatic transmission includes a first deterioration rate calculating unit; a deterioration acceleration coefficient calculating unit; and a thermal hydraulic fluid deterioration calculating unit for calculating a thermal hydraulic fluid deterioration according to the first deterioration rate and the deterioration acceleration coefficient. The device further includes a second deterioration rate calculating unit according to an engine speed, input shaft speed, and output shaft speed; a mechanical hydraulic fluid deterioration calculating unit for calculating a mechanical fluid deterioration according to the second deterioration rate; and a determining unit for determining whether or not the thermal hydraulic fluid deterioration or the mechanical hydraulic fluid deterioration is greater than a predetermined hydraulic fluid change threshold.

Owner:HONDA MOTOR CO LTD

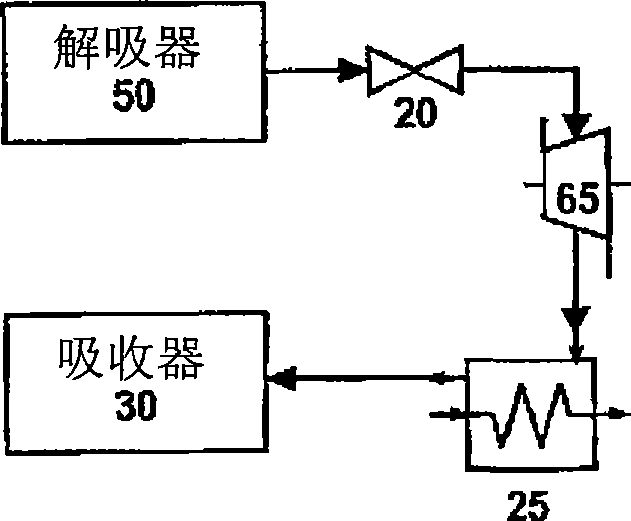

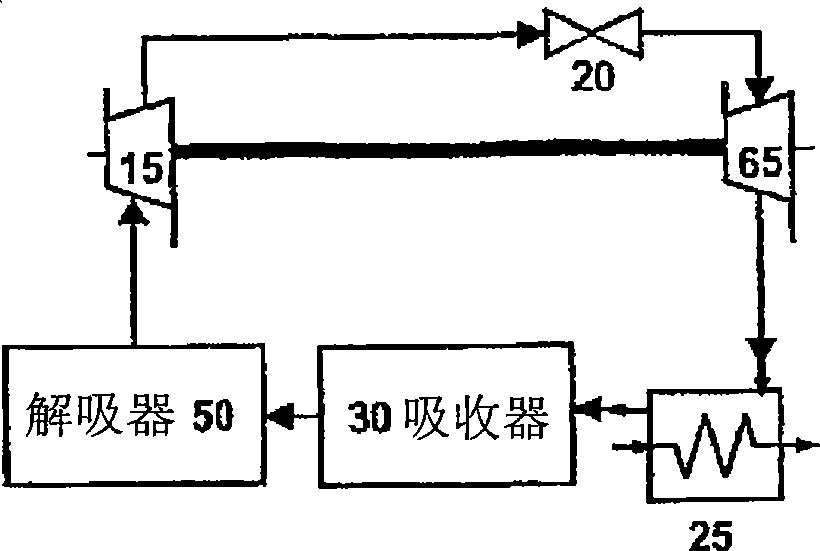

High efficiency absorption heat pump and methods of use

InactiveCN101506596AImprove energy efficiencyHeat pumpsHeat-exchange elementsWorking fluidMechanical energy

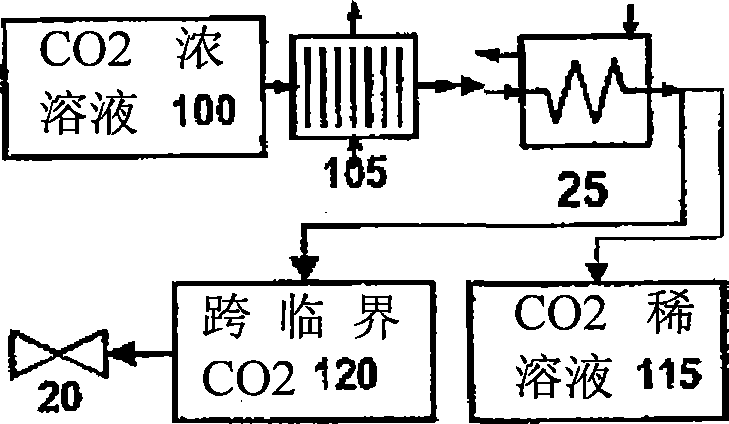

An energy conversion system including a high efficiency absorption heat pump cycle is disclosed using a high pressure stage, a supercritical cooling stage, and a mechanical energy extraction stage to provide a non-toxic combined heat, cooling, and energy system. Using the preferred carbon dioxide gas with partially miscible absorber fluids, including the preferred ionic liquids as the working fluid in the system, the present invention desorbs the CO.sub.2 from an absorbent and cools the gas in the supercritical state to deliver heat. The cooled CO.sub.2 gas is then expanded, preferably through an expansion device transforming the expansion energy into mechanical energy thereby providing cooling, heating temperature lift and electrical energy, and is returned to an absorber for further cycling. Strategic use of heat exchangers, preferably microchannel heat exchangers comprised of nanoscale powders and thermal-hydraulic compressor / pump can further increase the efficiency and performance of the system.

Owner:REXORCE THERMIONICS INC

Pressurized water reactor compact steam generator

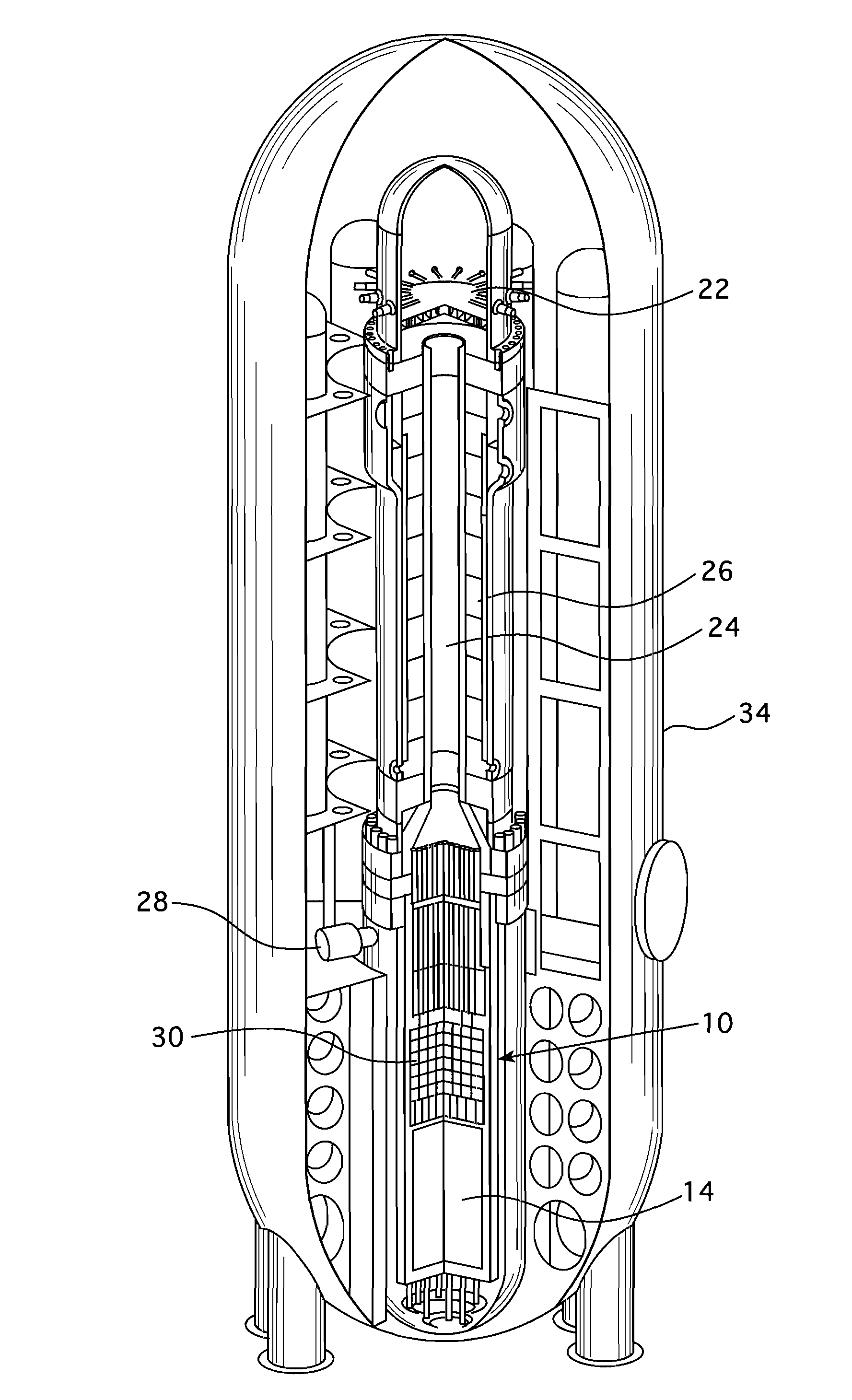

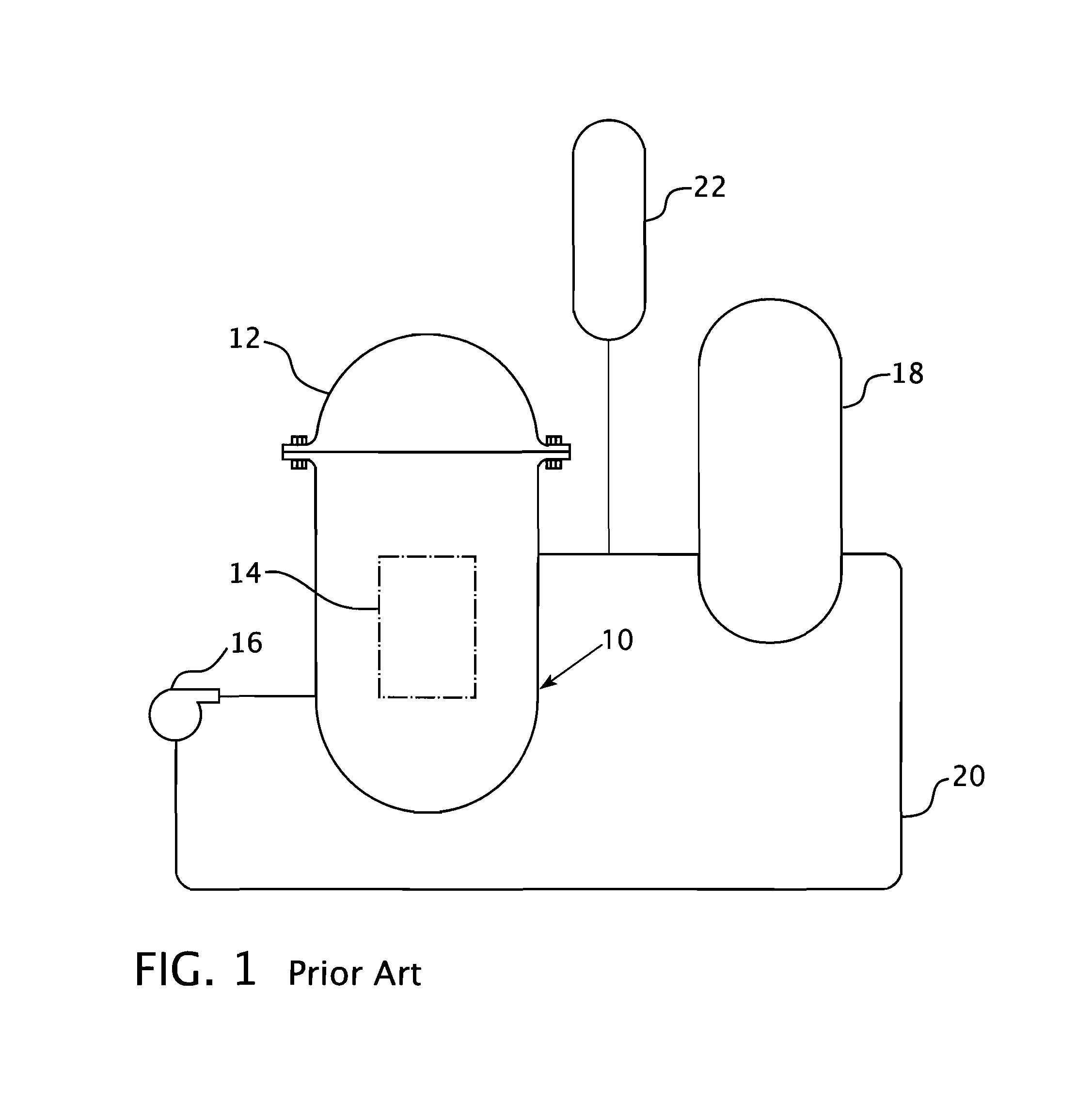

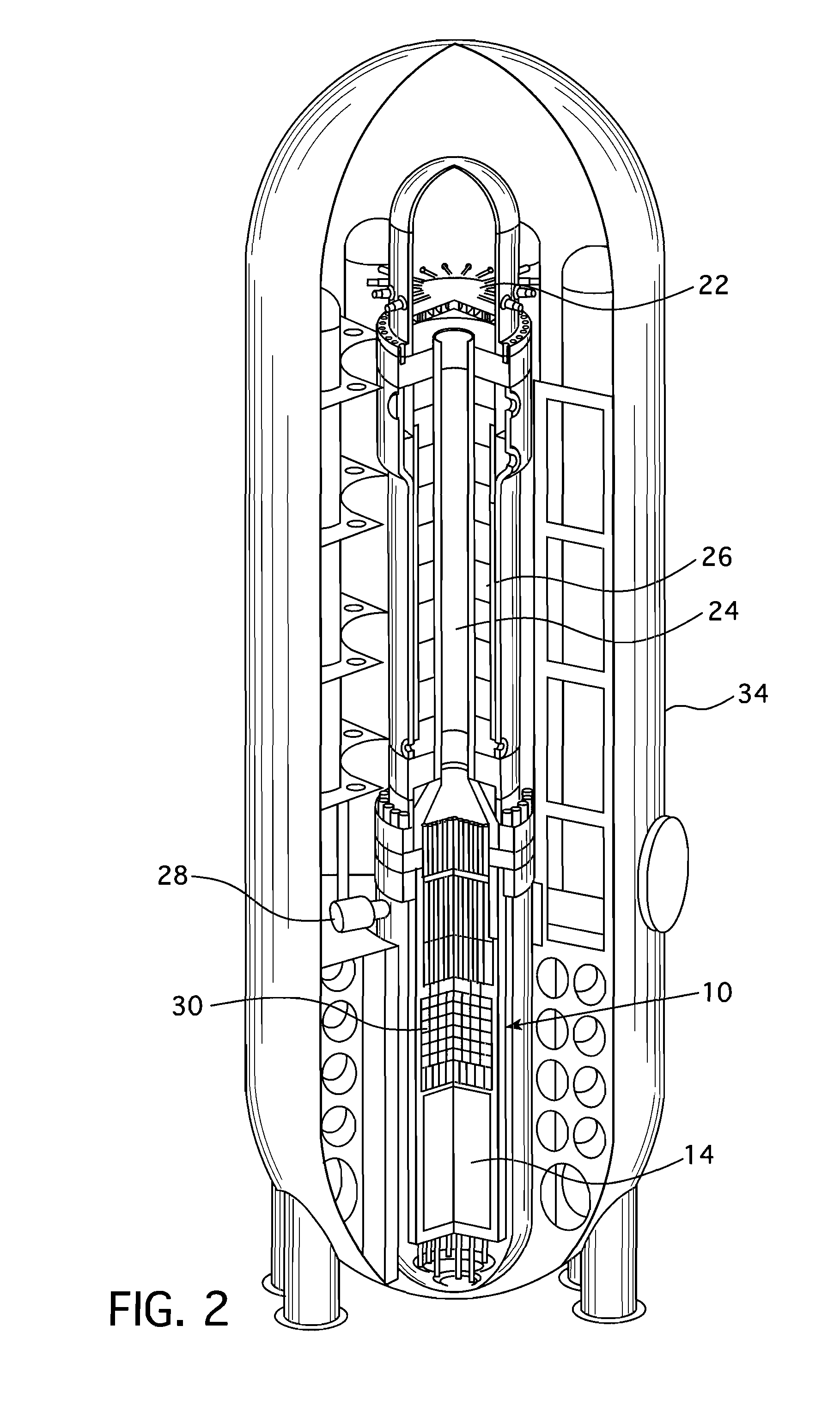

ActiveUS20130336442A1Facilitate natural recirculation of recirculatingBoiler drums/headersIntegral reactorsPressurized water reactorSteam drum

A steam generator system for a pressurized water reactor which employs an external to containment steam drum and recirculation loop piping. The steam generator system changes the arrangement of a typical pressurized water reactor recirculation steam generator by relocating the functions of steam separation and feedwater preheating outside of the reactor coolant system. The steam generator system and thermal hydraulic conditions are selected in order to minimize the size of the steam generator heat exchanger component volume inside of the containment. The external steam drum component can be isolated in accident conditions when desired and is used as a source of secondary fluid inventory for improved decay heat removal capability and tolerance for loss of feedwater events. Thus, the steam generator component volume inside of the containment is reduced and the amount of maintenance required for the reactor coolant system components are similarly reduced.

Owner:WESTINGHOUSE ELECTRIC CORP

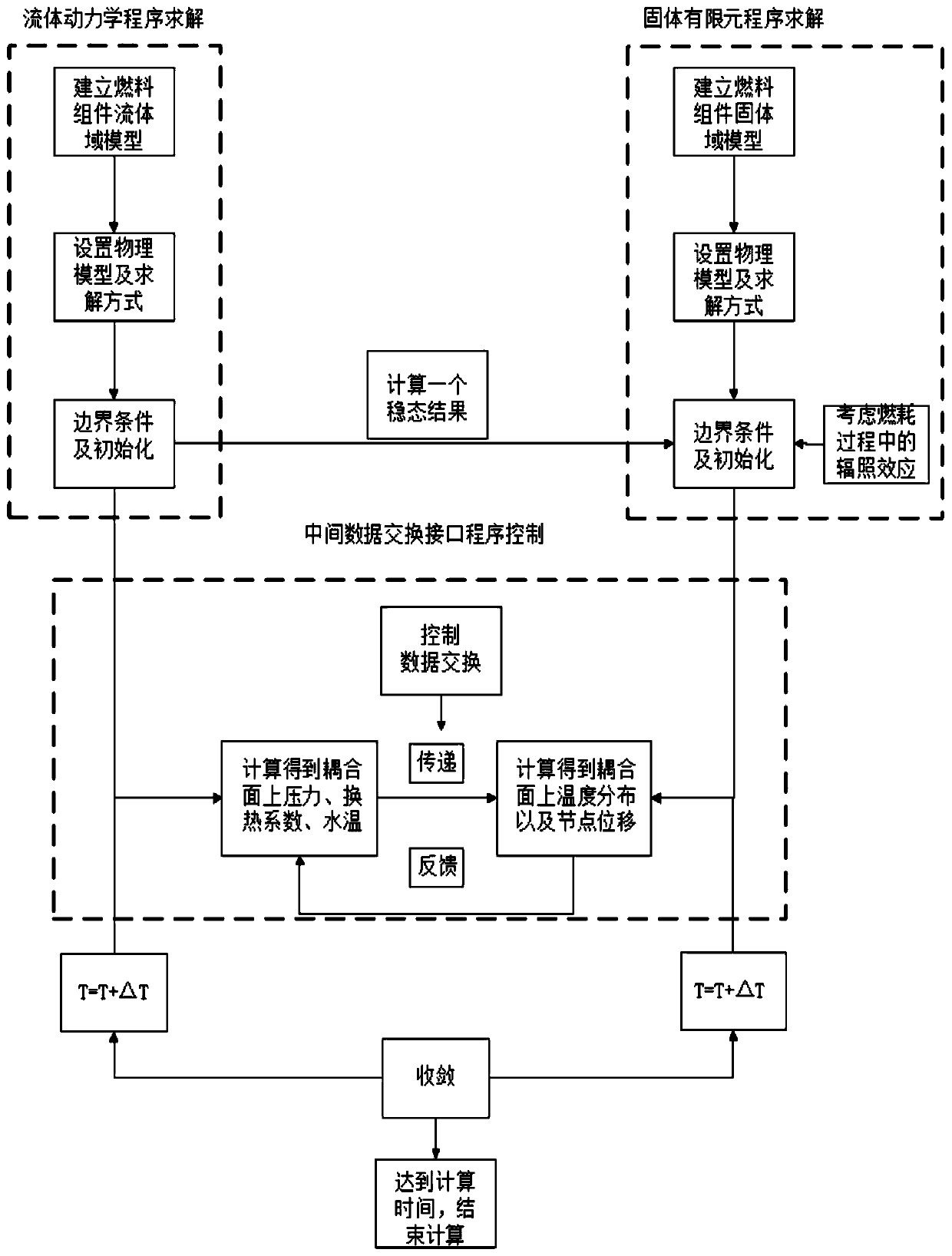

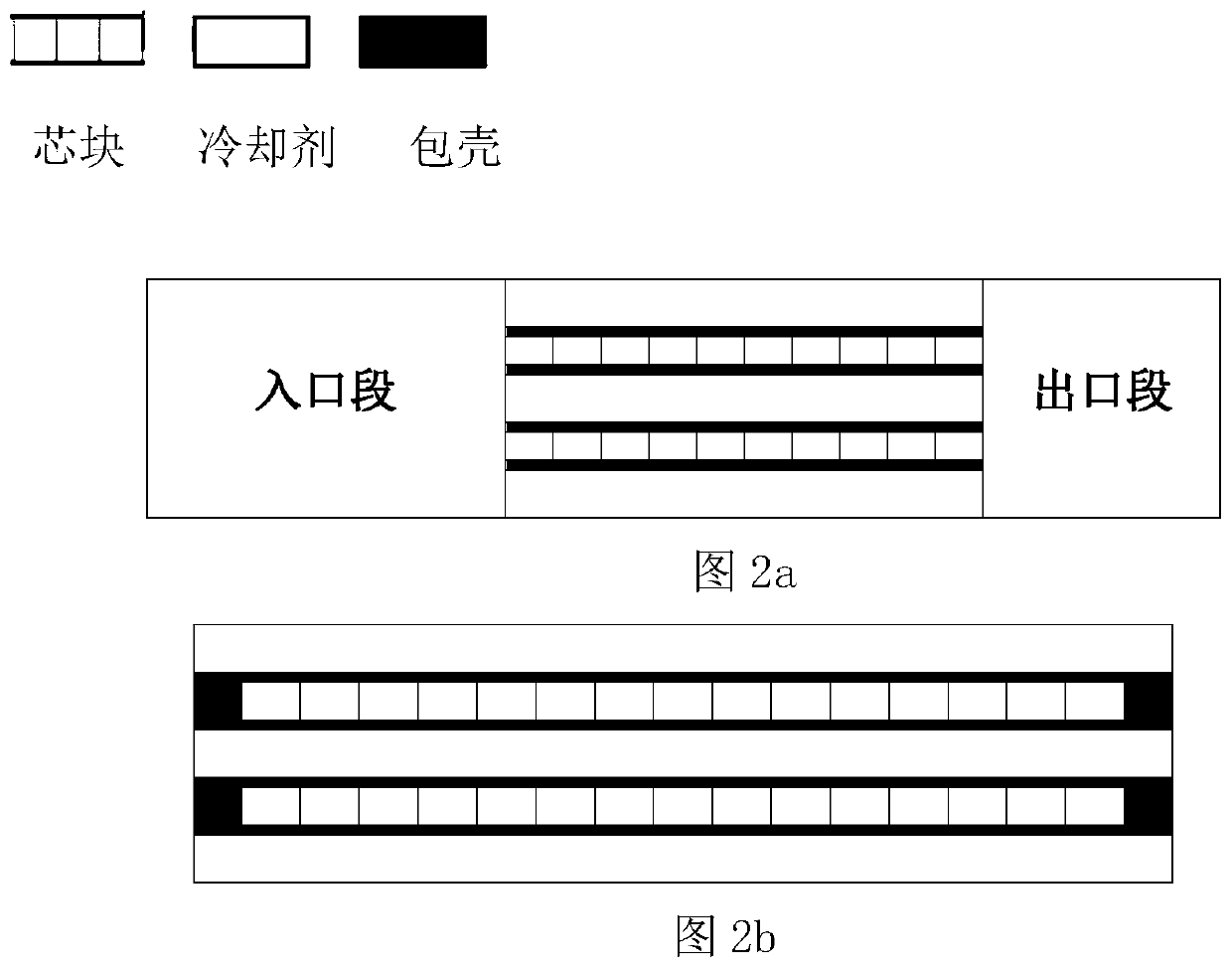

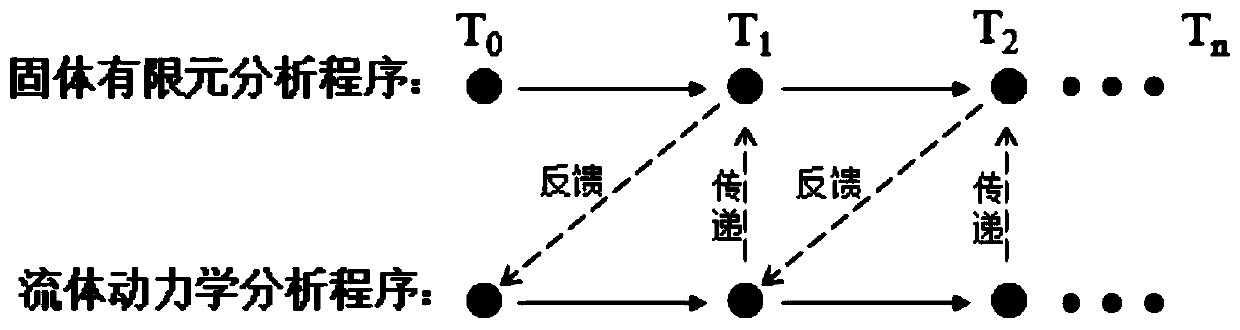

Reactor core fluid-solid coupling calculation method of nuclear reactor dispersion type plate fuel element

ActiveCN110598324AImplement coupled analysisComplies with operating conditionsSpecial data processing applicationsNuclear reactor coreNuclear reactor

The invention discloses a reactor core fluid-solid coupling calculation method of a nuclear reactor diffusion type plate fuel element. The method comprises the following steps: 1, establishing a nuclear reactor diffusion type plate fuel assembly fluid domain calculation model; 2, establishing a nuclear reactor dispersion type plate fuel assembly solid domain calculation model; 3, writing the irradiation effect in the burnup process of the reactor core into a solid finite element analysis program in a subprogram form; 4, carrying out steady-state calculation on the model in the step 1; 5, calling a result in the step 4 by utilizing an intermediate data exchange interface program, calling the calculation models in the step 1 and the step 2, continuously exchanging data between the fluid dynamics calculation program and the solid finite element analysis program subjected to secondary development in the step 3, and performing iterative calculation; and 6, performing iterative computation until the set computation termination time is reached, and stopping the computation. The detailed instantaneous thermal-hydraulic phenomena on the two sides of fluid and solid under the irradiation condition of the nuclear reactor plate-type fuel element core are obtained through calculation, and the method has important significance in design and safety analysis of a nuclear reactor.

Owner:XI AN JIAOTONG UNIV

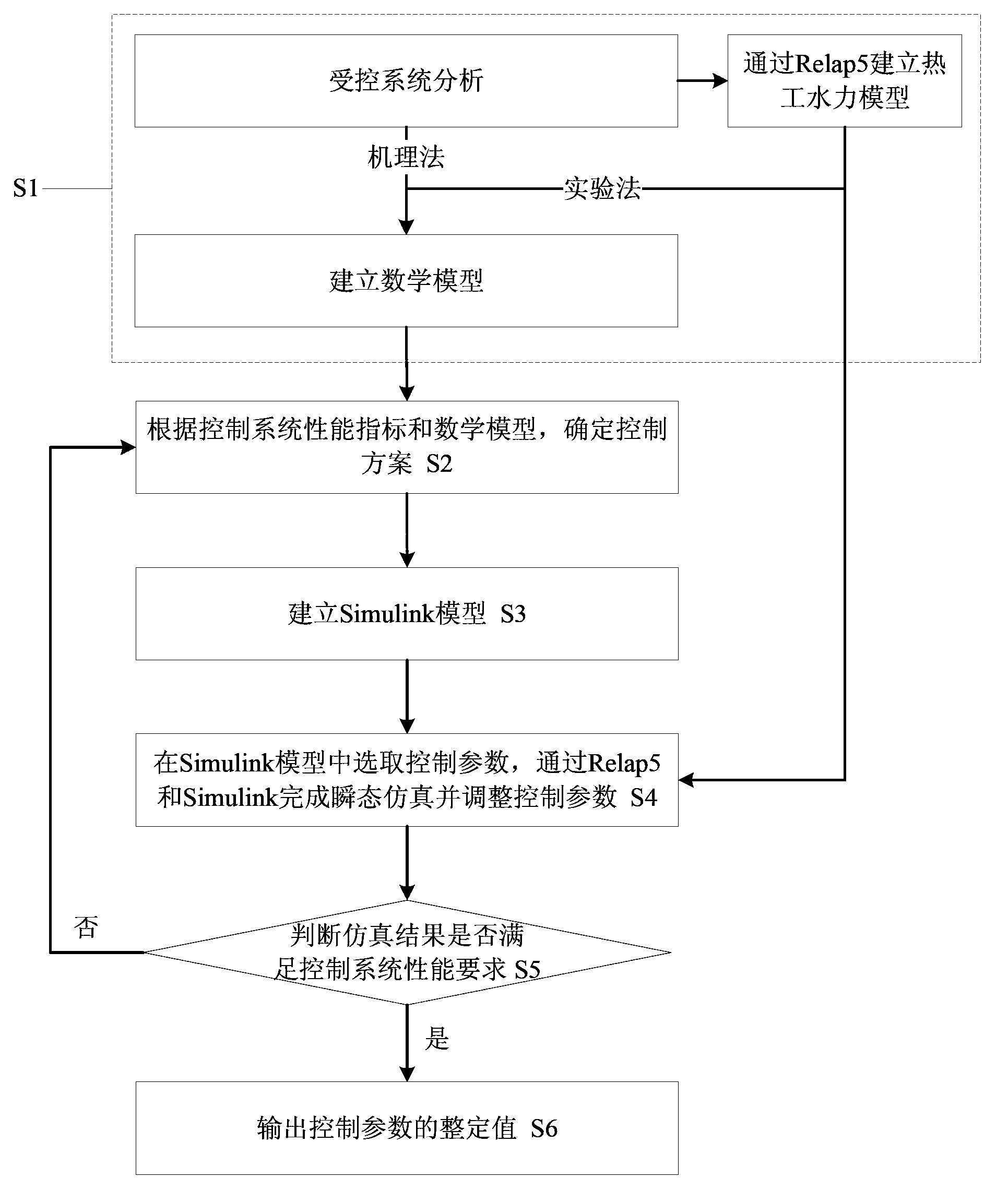

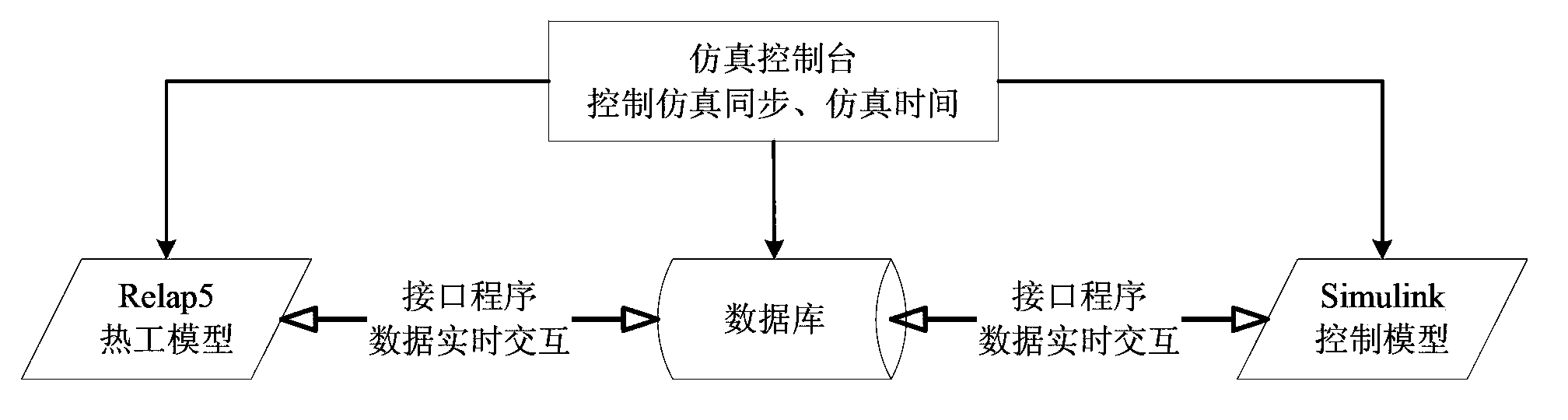

Design method for nuclear power station reactor control system

InactiveCN103853052AFlexible and convenient designFlexible and convenient simulationSimulator controlControl systemNuclear power

The invention provides a design method for a nuclear power station reactor control system. The design method comprises that: S1. a Relap5 thermal-hydraulic model and a mathematical model are established; S2. a control scheme is confirmed according to performance indexes of a reactor control system and the mathematical model; S3. a Simulink model is established for the reactor control system; S4. different control parameters are respectively selected in the Simulink model, and transient simulation is completed via the Relap5 and the Simulink and the control parameters are adjusted; S5. whether the simulation result meets the performance requirement of the reactor control system is judged; if the judgment result is no, the process of the method returns to the S2; and if the judgment result is yes, S6 is executed; and S6. setting values of the control parameters are outputted. Design of the reactor control system is realized via the control system modeling simulation method based on the Relap5 and the Simulink, , and design and simulation of the reactor control system, especially setting and optimization of the control parameters, can be flexibly and conveniently completed.

Owner:中广核工程有限公司 +1

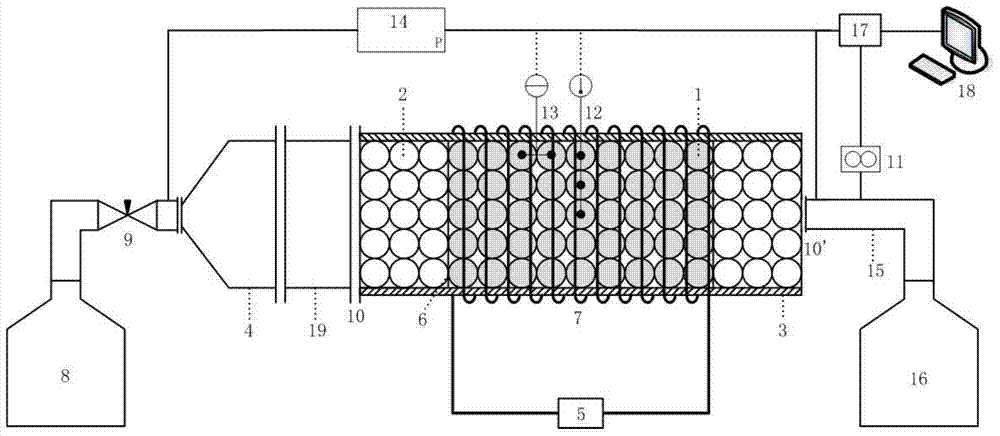

Thermal hydraulic characteristic testing device and method for tritium blowing helium of breeding blanket pebble bed of fusion reactor

InactiveCN104122071ASolve the problem that it is difficult to obtain high-energy neutrons to generate nuclear heat in the breeder pelletHydrodynamic testingNuclear engineeringConvection heat

The invention discloses a thermal hydraulic characteristic testing device and method for tritium blowing helium of a breeding blanket pebble bed of a fusion reactor. The thermal hydraulic characteristic testing device for the tritium blowing helium of the breeding blanket pebble bed of the fusion reactor is mainly used for researching the flow and heat transfer characteristics of the tritium blowing helium of the solid breeding blanket layer of the fusion reactor between breeding agent pebbles of the pebble bed. The thermal hydraulic characteristic testing method includes that using a non-contact type high-frequency induction power to heat quasi metal breeding agent pebbles to simulate high-power density nuclear heat generated by the breeding agent pebbles in the pebble bed, researching the thermal hydraulic characteristics of the pebble bed under changed tritium blowing helium temperature, speed and pressure, breeding agent pebble arrangement mode, size and power density and the like, measuring the temperature distribution of the breeding agent pebbles and pebble bed wall surface, and obtaining a convection heat transfer correlation equation and a flow resistance relation to provide supports for testing and demonstrating the nuclear heat transmission of the neutron deposition in the pebble bed on the breeding agent pebbles and the tritium blowing helium flow and heat transfer characteristics under laboratory conditions, verifying the feasibility of a solid breeding blanket designing scheme and the correctness of a numerical method and data, and researching and developing Chinese solid experiment blanket modules of ITER.

Owner:中国人民解放军陆军军官学院

Adjustable charge-discharge type high temperature and high pressure helium gas experimental system and method

InactiveCN105118536AMeet the tightness requirementsMeet the needs of different experimental conditionsNuclear energy generationNuclear monitoringClosed loopCharge discharge

The invention discloses an adjustable charge-discharge type high temperature and high pressure helium gas experimental system and an adjustable charge-discharge type high temperature and high pressure helium gas experimental method. The method comprises: supplying gas by a high pressure helium gas tank set, reducing the pressure of the helium gas to desired pressure through a pressure reducing valve, performing the closed-loop control on the pressure reducing valve by using a pressure transmitter, heating the helium gas by an electric heater, performing the closed-loop control on heating power of the electric heater by using a temperature transmitter, adjusting opening degree of a control valve according to a set flow value and a difference value measured by a flow gauge so as to obtain the helium gas with a rated pressure, temperature and flow quantity, and introducing the helium gas to a thermal hydraulic power experiment section to perform experiment. The high-temperature helium gas enters a gas storage tank for collection after a cooler exchanges heat, the helium gas recycled in the gas storage tank is pressed into the high pressure helium tank set through a helium gas compressor to carry out experiment repeatedly. According to the system provided by the present invention, a high temperature and high pressure section is only in an experimental section, so that high temperature and high pressure sealing performance requirements of other experimental devices in a loop are reduced, pressure, temperature and flow quantity of the experiment helium gas are adjusted, and requirements on a working condition for high temperature and high pressure helium gas thermal hydraulic power experiment can be met.

Owner:中国人民解放军陆军军官学院

Thermal hydro-mechanical drawing forming method for dot matrix self-impedance electrical heating plates

InactiveCN102139304ARealize controllable flexible heatingRaise the forming limitShaping toolsOhmic-resistance heating detailsDot matrixEngineering

The invention relates to a thermal hydro-mechanical drawing forming method for dot matrix self-impedance electrical heating plates, and belongs to the technical field of the thermal hydraulic forming of the plates. The method comprises the following steps of: fully filling liquid into a cavity of a female die serving as a liquid pond; when the plates are driven by a male die to enter the female die, forming the plates by reverse pressure generated when the liquid is compressed; embedding pin type electrodes inside pressure plates according to the distribution of dot matrixes, and performing self-impedance electrical heating on flanges of the plates by using contact resistors between the electrodes and the plates; adjusting the distribution of temperature fields of the flanges by changing the distribution law of the dot matrixes of the electrodes and adjusting the heating current of each heating electrode; adjusting the flow stress of heating points by changing the temperature of each mass point on the flanges so as to control the flow of metal by the asynchronous flow of the metal mass points on the flanges; and coordinating the deformation process of the metal by the asynchronousdeformation of each mass point on the flanges due to the temperature to fulfill the aim of improving the limit drawing ratio of the plates. The method has the advantages that: the heating speed is high, the effect is good, the plates can be heated controllably and flexibly, and the forming limit of the plates is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

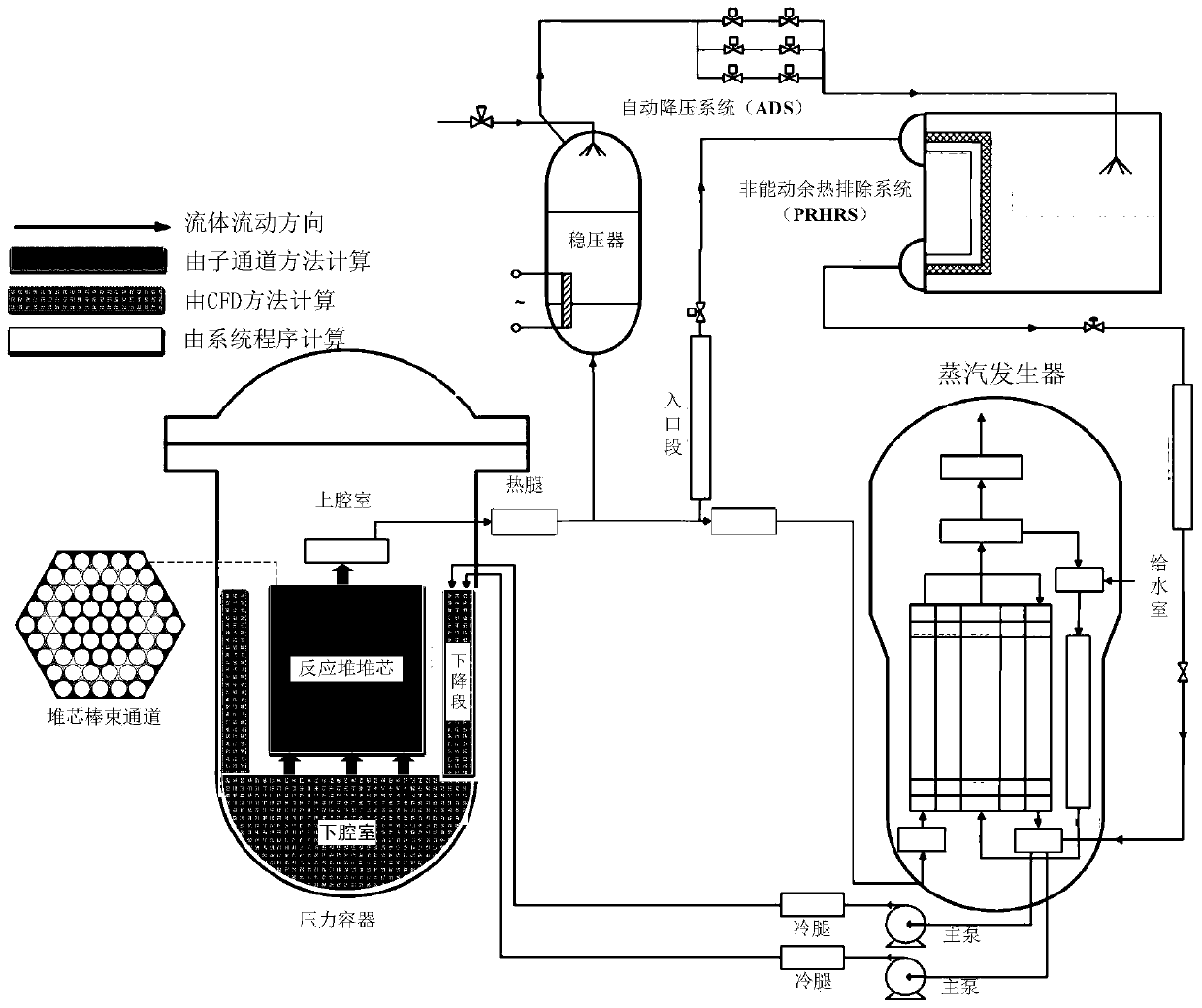

Nuclear power system interdimensional coupling simulation method

ActiveCN109903870ADo not change modeling propertiesEasy to implementNuclear energy generationNuclear power plant controlSystems analysisCoupling

The invention discloses a nuclear power system interdimensional coupling simulation method which includes the steps: firstly, performing modeling on components of a nuclear power system through different reactor thermal hydraulics analysis programs; secondly, preliminarily calculating a reactor thermal hydraulic system analysis program and a reactor thermal hydraulic sub-channel analysis program according to set initial boundary conditions; thirdly, taking calculation results of the reactor thermal hydraulic system analysis program and the reactor thermal hydraulic sub-channel analysis programas boundary conditions of computational fluid dynamics software to perform calculation; fourthly, taking calculation results acquired in the third step as boundary conditions of the reactor thermal hydraulic system analysis program to calculate thermal hydraulic parameters of next time step reactor; fifthly, taking calculation results acquired in the fourth step as boundary conditions of the thermal hydraulic sub-channel analysis program to calculate thermal hydraulic parameters of a reactor core; sixthly, repeating the third step to the fifth step until full time calculation is completed.

Owner:XI AN JIAOTONG UNIV

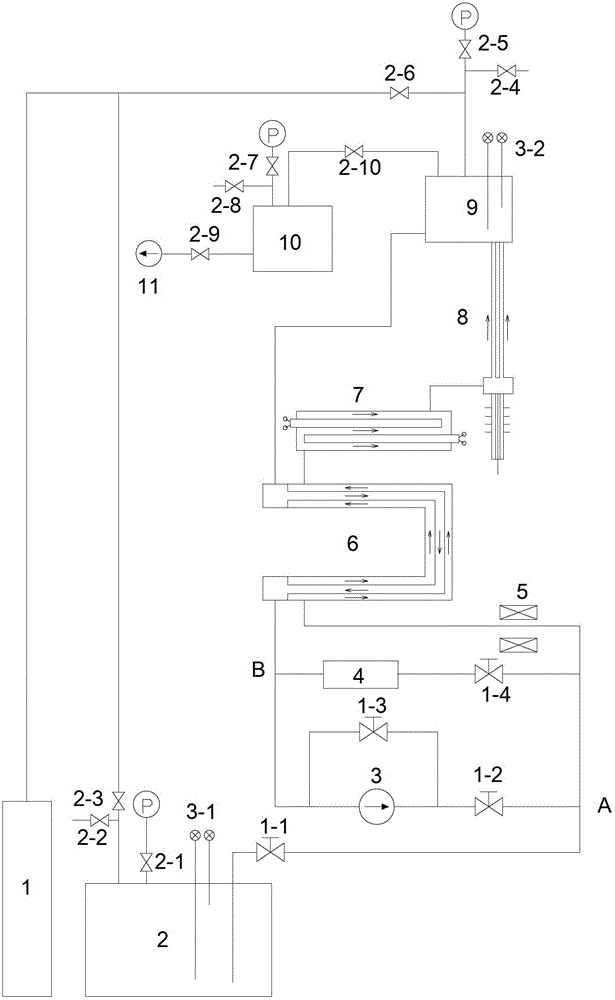

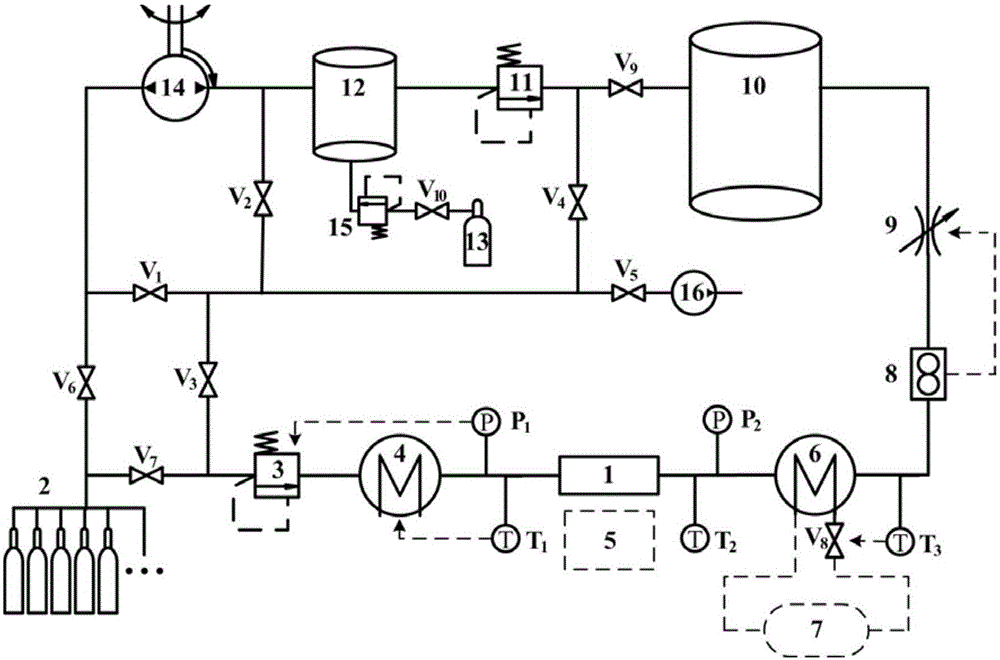

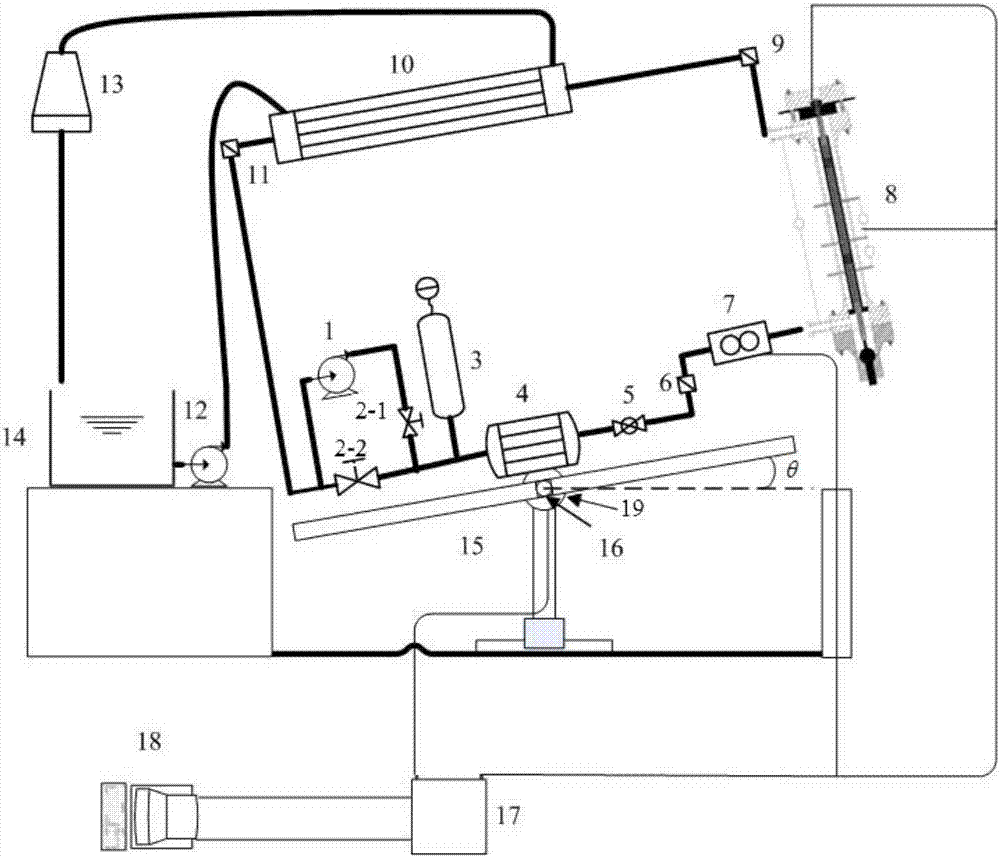

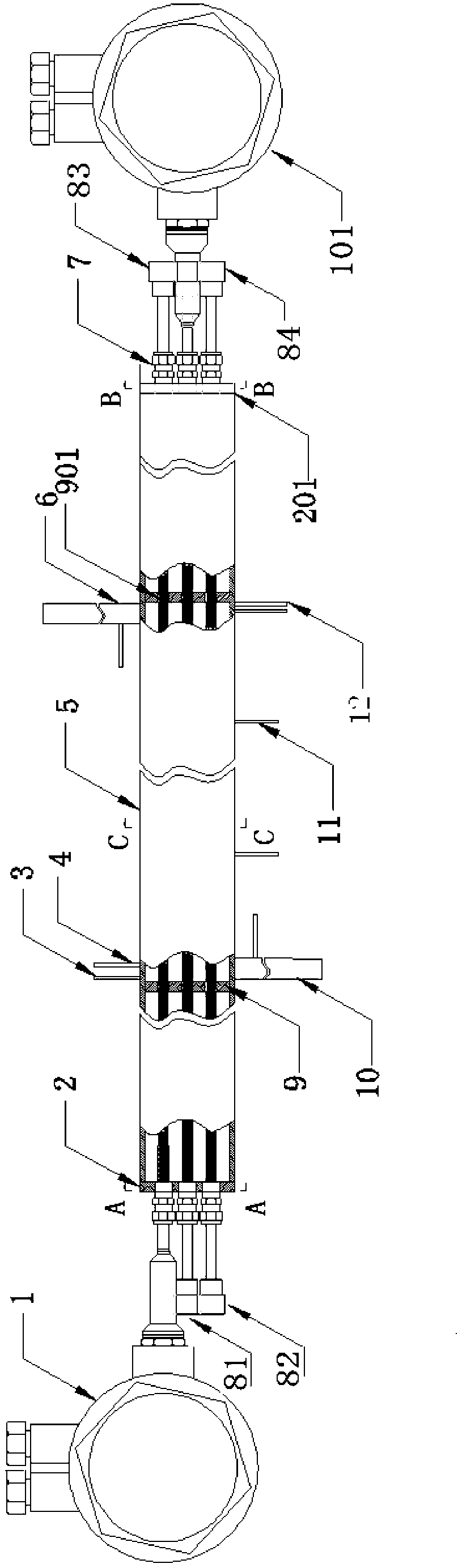

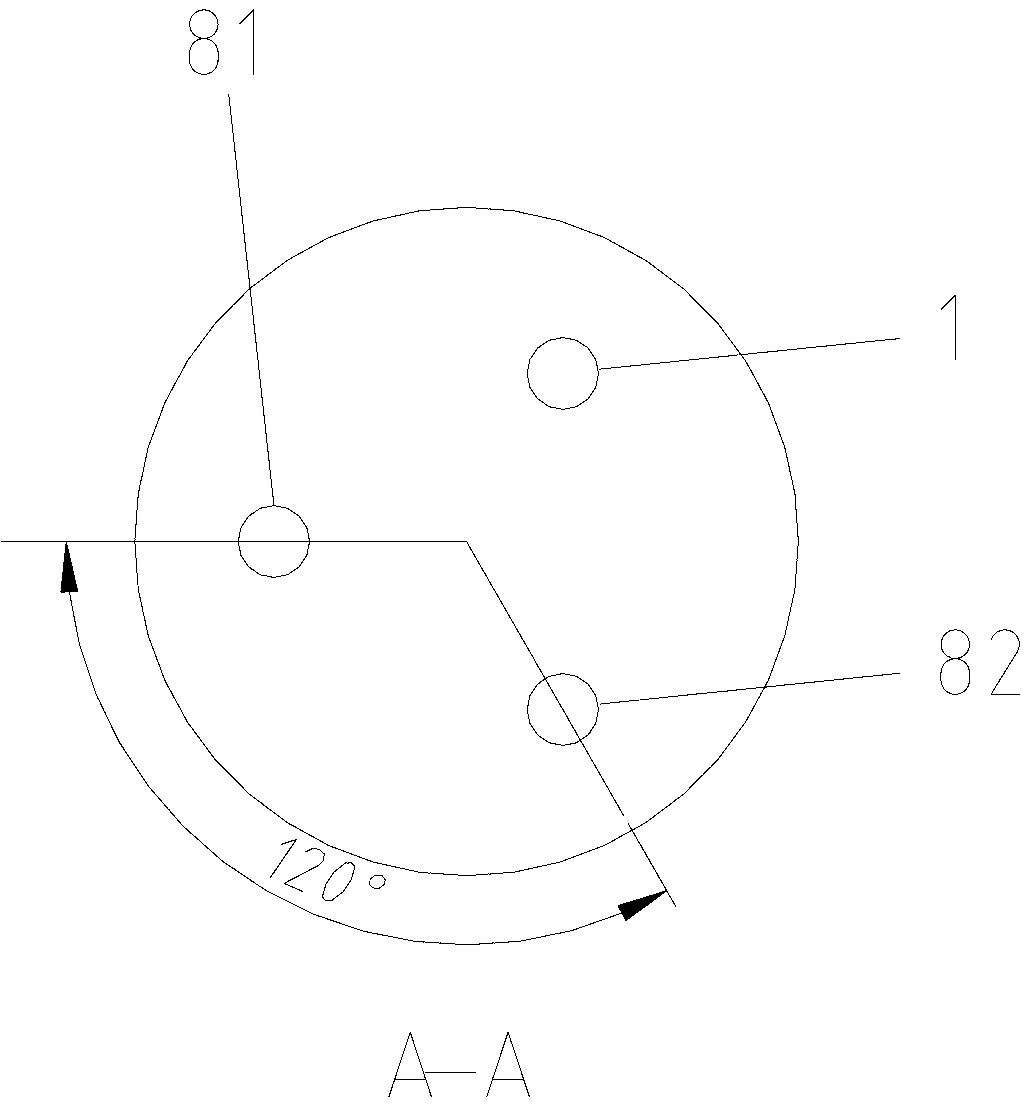

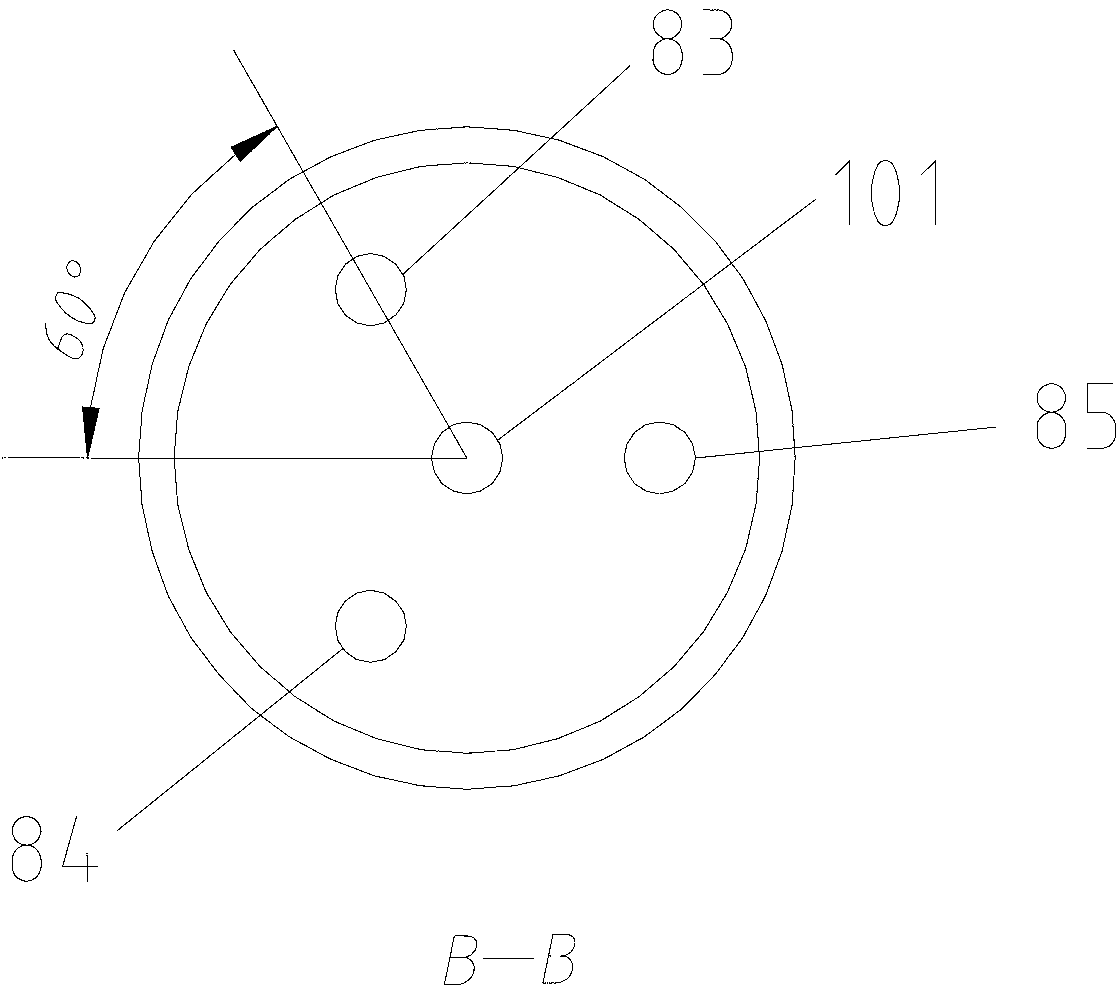

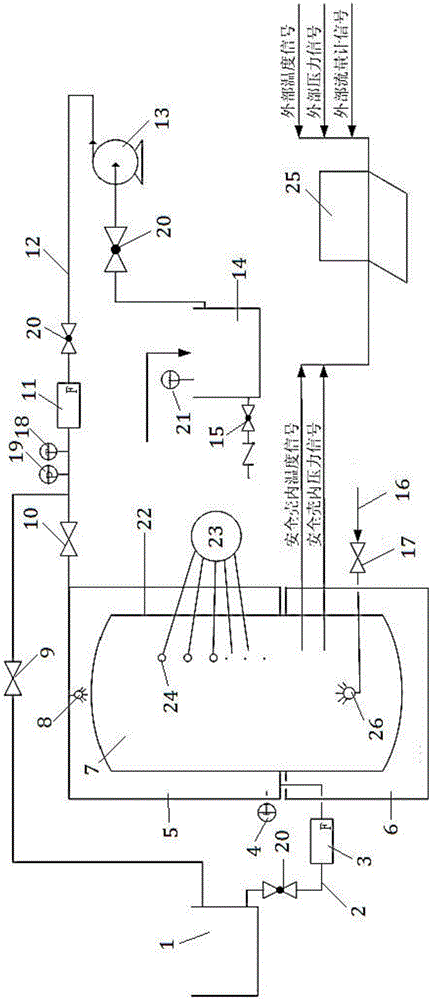

Experiment apparatus for researching thermal hydraulic characteristics in heating rod bundle channel under dynamic condition

InactiveCN107402231AEasy to operateExperimental data is stableMaterial heat developmentHydrodynamic testingExhaust valveCooling tower

The invention provides an experiment apparatus for researching thermal hydraulic characteristics in a heating rod bundle channel under a dynamic condition. An experimental loop system comprises a circulating water pump, a first control ball valve, a preheater, a filter, a first sub-header, an electromagnetic flow meter, a rod bundle channel experiment body, a second sub-header, a condenser and an exhaust valve, the end part of the exhaust valve is connected with the circulating water pump, and the circulating water pump is connected with the first control ball valve and then is provided with a second control ball valve in a parallel manner; a circulating cooling water system comprises a water storage tank, and a cooling water pump and a cooling tower which are respectively connected with the water storage tank, and the end part of the cooling water pump and the end part of the cooling tower are respectively connected with the condenser through pipelines; and a control and data acquisition system comprises an angle sensor, a differential pressure gauge and pressure gauge and thermocouple, a signal acquirer and a computer. The apparatus has the advantages of simplicity, easiness in operation, obtaining of stable experimental data, and facilitation of the scientific research of the flow and heat transfer in the rod bundle channel and the engineering design of a passive safety system.

Owner:HARBIN ENG UNIV

Hydraulic fluid change indicating device for automatic transmission

InactiveUS7433770B2Improve detection accuracyImprove accuracyVehicle testingRegistering/indicating working of vehiclesAutomatic transmissionDeterioration rate

A hydraulic fluid change indicating device for an automatic transmission includes a first deterioration rate calculating unit; a deterioration acceleration coefficient calculating unit; and a thermal hydraulic fluid deterioration calculating unit for calculating a thermal hydraulic fluid deterioration according to the first deterioration rate and the deterioration acceleration coefficient. The device further includes a second deterioration rate calculating unit according to an engine speed, input shaft speed, and output shaft speed; a mechanical hydraulic fluid deterioration calculating unit for calculating a mechanical fluid deterioration according to the second deterioration rate; and a determining unit for determining whether or not the thermal hydraulic fluid deterioration or the mechanical hydraulic fluid deterioration is greater than a predetermined hydraulic fluid change threshold.

Owner:HONDA MOTOR CO LTD

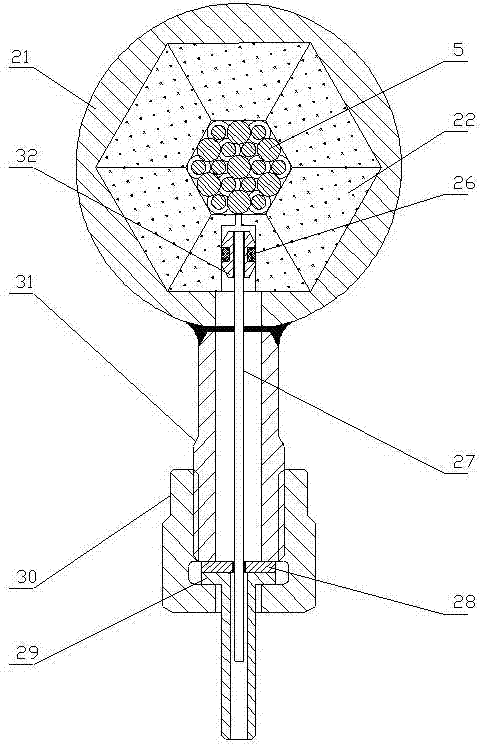

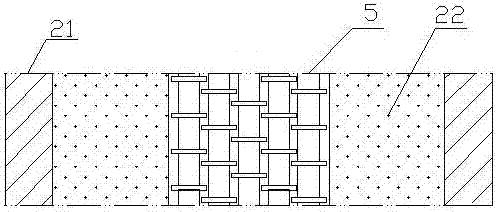

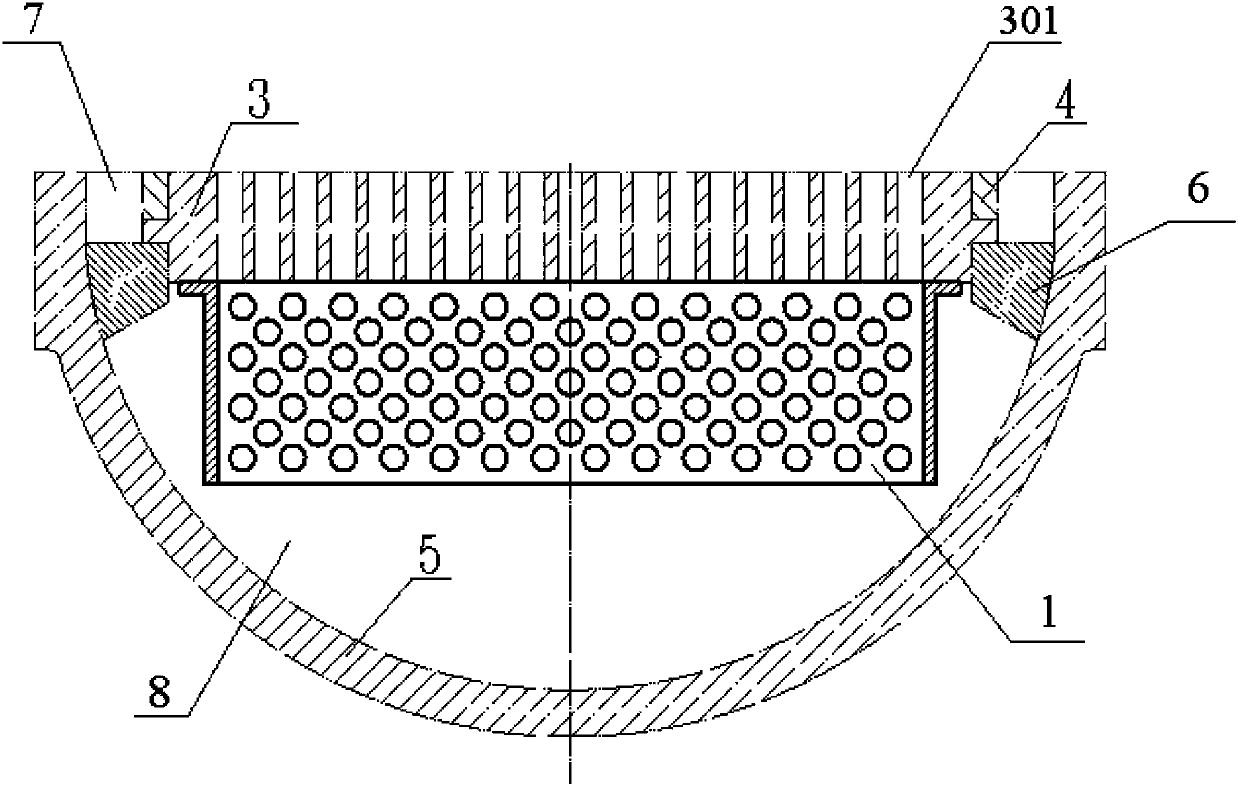

Spherical flue element equivalent model thermotechnical waterpower experimental apparatus

ActiveCN102855802AReflect thermal hydraulic characteristicsRealize electric heatingEducational modelsThermal expansionEngineering

The invention discloses a spherical flue element equivalent model thermotechnical waterpower experimental apparatus comprising a pressure-bearing component, an electric heating component, an insulation component, a seal component, a pressure measurement component and the like, and field assembly and disassembly can be realized between the components. According to the spherical flue element equivalent model thermotechnical waterpower experimental apparatus, a banded fin thin rod bundle electric element is taken as an equivalent model structure of the spherical flue element, electrical heating method is realized, single-phase water flow and heat transfer experiment can be developed, and thermal-hydraulics of the spherical flue element can be reflected. The pressure measurement component can be assembled and disassembled on spot, consumables such as an O-shaped seal ring and a lead pressure pipe are convenient to replace, thereby reducing loss and cost. A grid spacer plays a role in transverse orientation for the banded fin thin rod bundle electric element, and a single-cone structure of the grid spacer can guide a plurality of the banded fin thin rod bundles to assemble, thereby reducing the difficulty of assembling and improving the efficiency of assembling. Copper braid is adopted to connect a lower conducting element and a lower conductive contact to realize flexible connection, so that the problem caused by electric component thermal expansion is effectively solved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

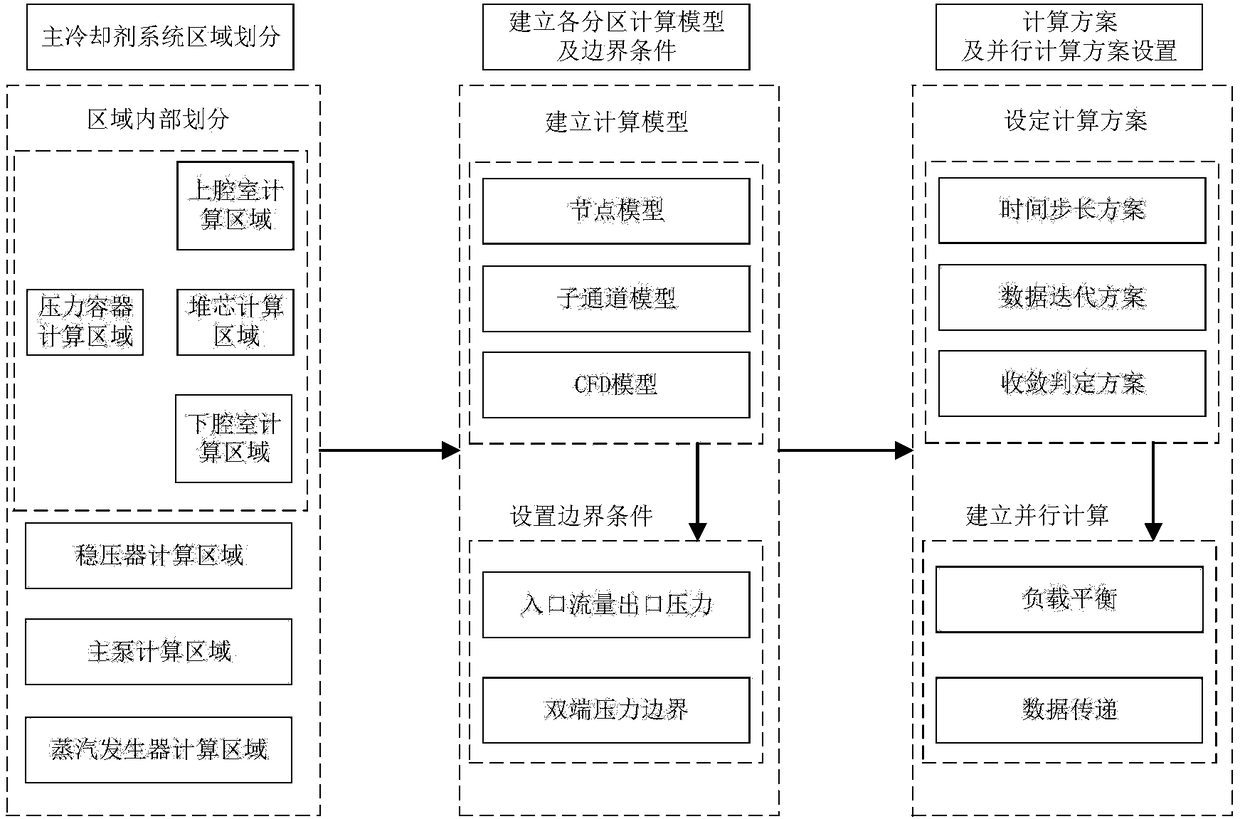

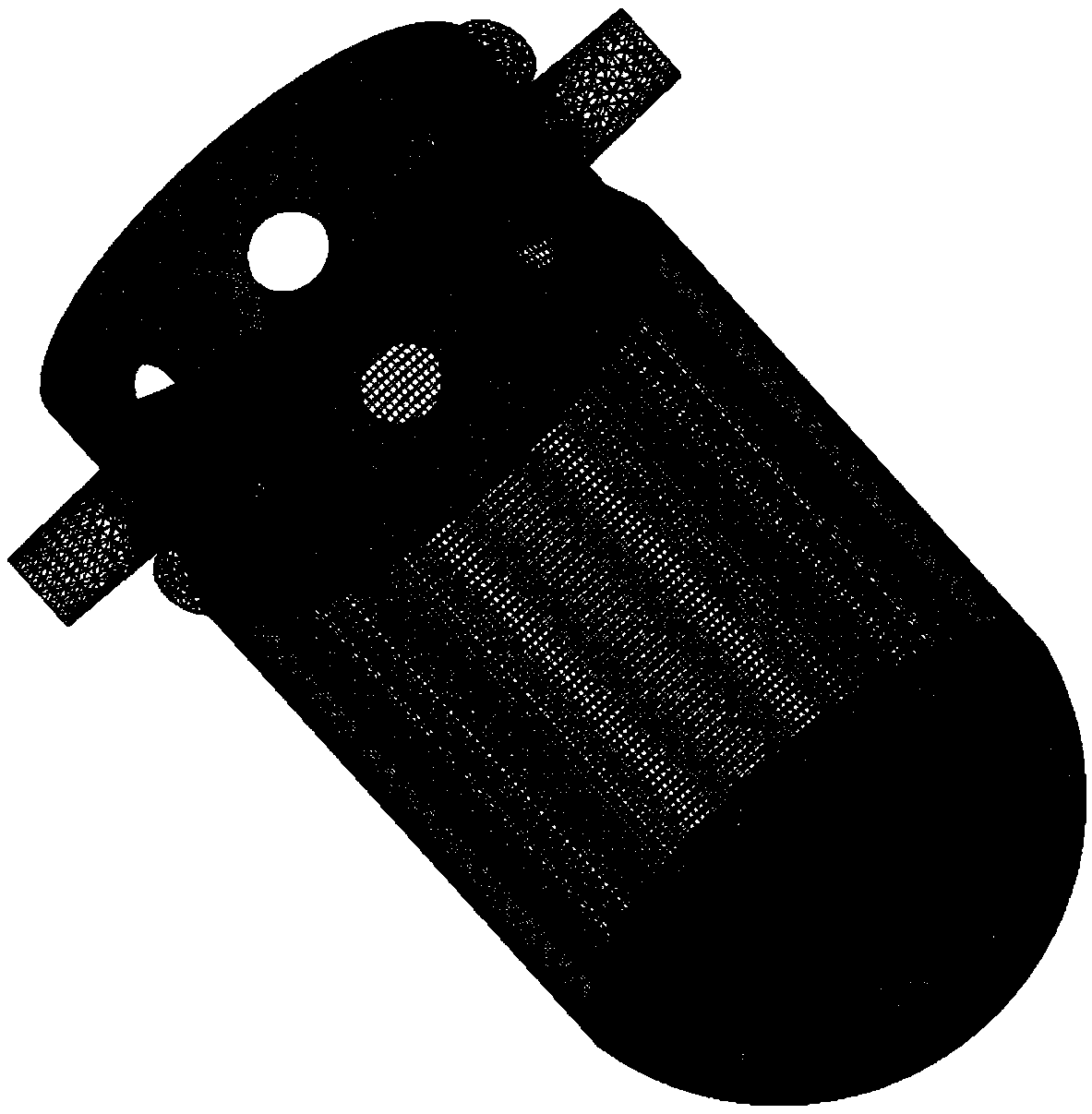

Thermal hydraulic multi-scale partition simulation method of nuclear power device main-coolant system

InactiveCN108875212AImprove local calculation precisionAchieve scientific splitDesign optimisation/simulationSpecial data processing applicationsScale modelMathematical model

The invention provides a thermal hydraulic multi-scale partition simulation method of a nuclear power device main-coolant system. The method comprises the following steps: (1) performing computation region division on a main coolant system; (2) establishing a mathematic model for each region, realizing system loop multi-scale modelling and compiling a simulation program, wherein the multi-scale model program comprises a thermal hydraulic system program, a thermal hydraulic sub-channel program and a computational fluid dynamics program; (3) establishing a boundary interface scheme and a data transmission scheme of each region; (4) establishing a time step length setting scheme, a data exchange scheme and a convergence judgment setting scheme according to the scale feature of each region; and (5) configuring the main-coolant system multi-scale program distributed parallel computational environment to realize the multi-region combined simulation. The method provided by the invention is suitable for the multi-scale partition modelling combined simulation method of the thermal hydraulic computation of the nuclear power device main coolant system, the precision of the local computation can be guaranteed, and the fastness of the computation can be guaranteed.

Owner:HARBIN ENG UNIV

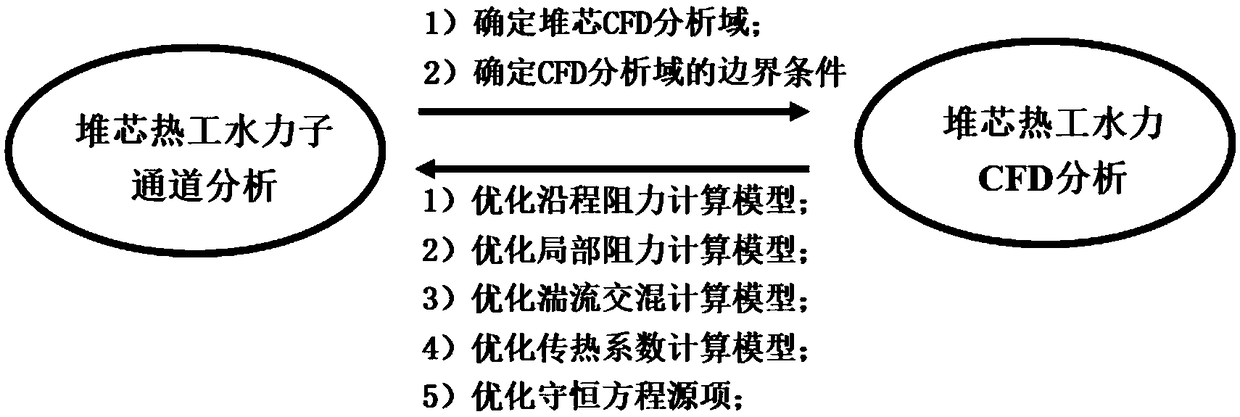

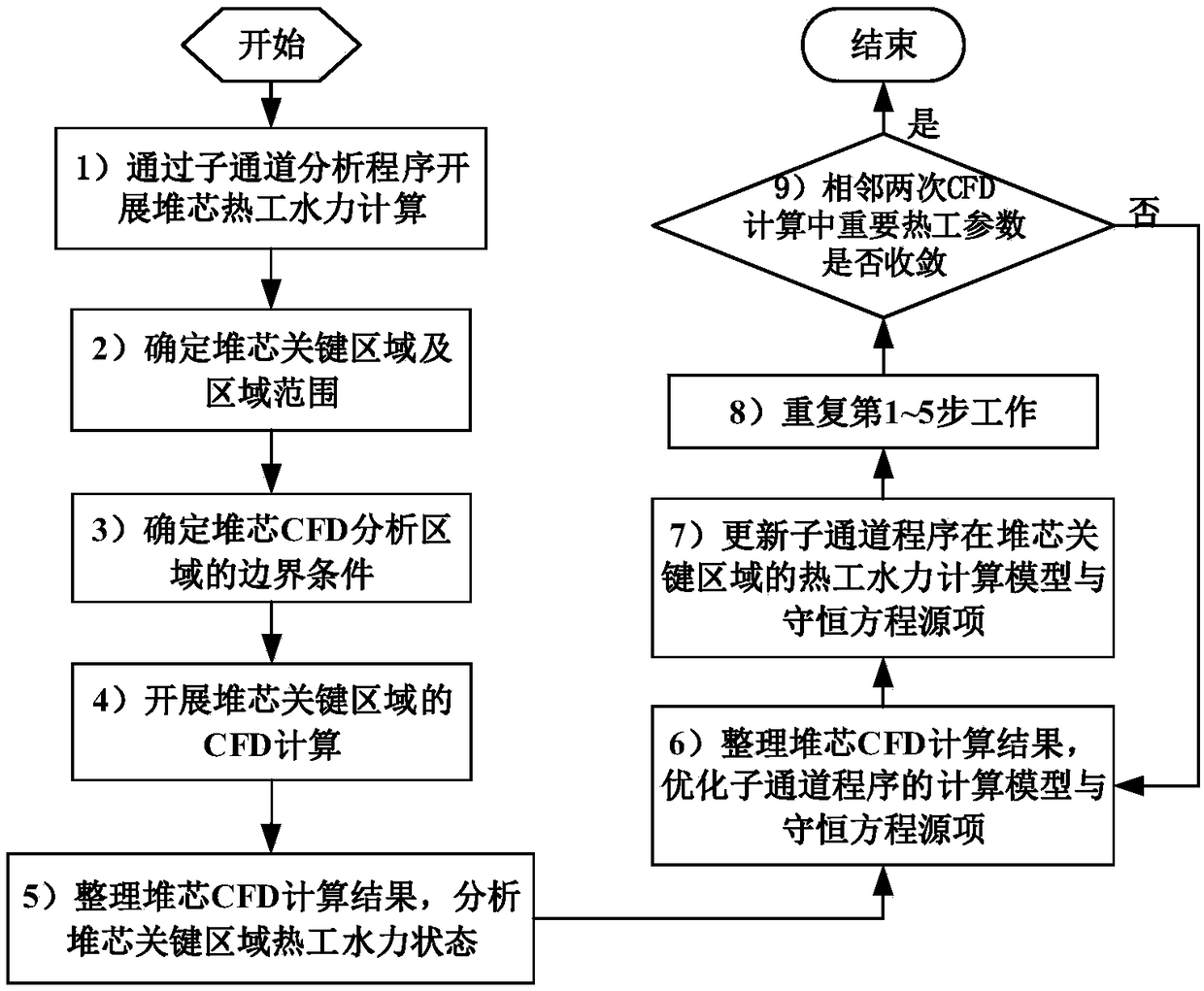

Multiscale reactor core thermal hydraulic analysis method

ActiveCN108875213AImprove applicabilityGuaranteed analytical efficiencyGeometric CADDesign optimisation/simulationState predictionNuclear engineering

The invention provides a multiscale reactor core thermal hydraulic analysis method. The method comprises the following steps of: 1, carrying out reactor core thermal hydraulic calculation through a reactor core sub-channel analysis program; 2, determining a position and an area range of a reactor core key area; 3, determining a boundary condition of a reactor core CFD analysis area; 4, carrying out CFD calculation on the reactor core key area; 5, arranging the CFD calculation result ad analyzing states of thermal hydraulic important parameters of the reactor core key area; 6, arranging the CFDcalculation result and optimizing a calculation model and a conservation equation source item of the sub-channel program; 7, updating a thermal hydraulic calculation model and a conservation equationsource item, in the reactor core key area, of the sub-channel program; 8, repeating the steps 1 to 5 via the updated sub-channel program; and 9, comparing important parameter values of the key area in two adjacent key area CFD calculations so as to judge whether convergence is carried out or not. The method is capable of comprehensively ensuring the accuracy and efficiency of thermal hydraulic state prediction for reactor cores.

Owner:HARBIN ENG UNIV

Experimental system for thermal-hydraulic characteristics and corrosive properties of liquid lead-bismuth alloy

PendingCN108761022AAvoid problems caused by solidificationEfficient heatingWeather/light/corrosion resistanceMaterial heat developmentLead bismuthLiquid state

The invention provides an experimental system for thermal-hydraulic characteristics and corrosive properties of a liquid lead-bismuth alloy. The experimental system comprises a liquid lead-bismuth cycling experiment device, wherein the liquid lead-bismuth cycling experiment device specifically comprises a power pump group, a preheater, a first experimental section, a second experimental section, aheat exchanger, an oxygen control system, a purification system, an expansion box, a storage box, a plurality of flow meters, a plurality of pressure transmitters and a plurality of lead-bismuth valves. By controlling opening or closing of different lead-bismuth valves, different loops are selected for completing experiments on the thermal-hydraulic characteristics and corrosive properties of equipment associated with the liquid lead-bismuth alloy in different experimental sections of the system, as well as experiments on compatibility characteristics of equipment materials and lead-bismuth.With implementation of the system, defects in the prior art can be overcome, and analytical study on the thermal-hydraulic characteristics and corrosive properties of the liquid lead-bismuth alloy isrealized.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

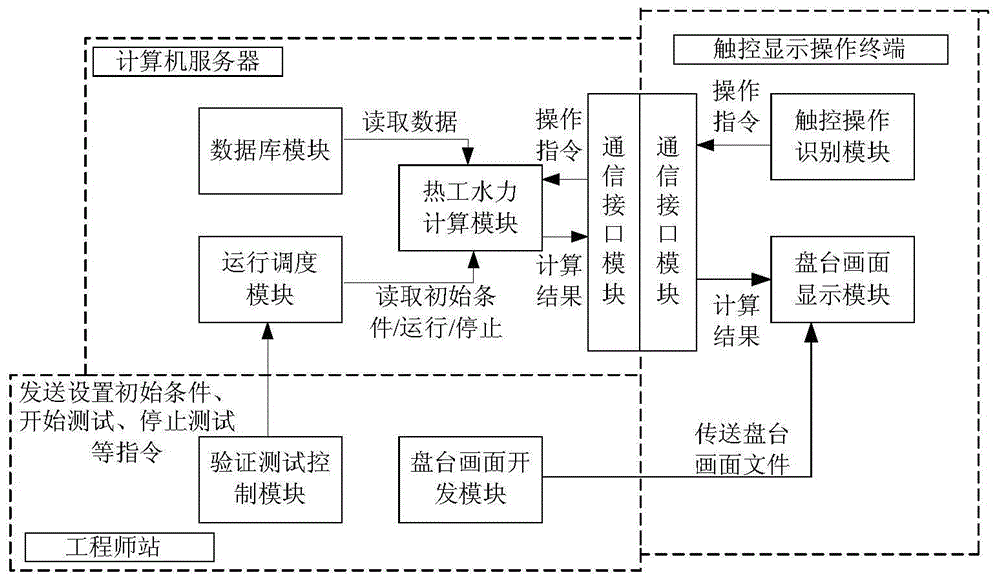

Nuclear power station virtual disk table and virtual disk table testing method

ActiveCN105810273AImprove accuracyShorten the design cycleNuclear energy generationNuclear power plant controlComputer-on-moduleCommunication interface

The invention belongs to the verification technical field of nuclear power stations and particularly relates to a nuclear power station virtual disk table. The disk table comprises a computer server module, an engineer station module, a touch control display operation terminal, and a communication interface module. The computer server module comprises a database module, a thermal hydraulic calculation module and an operation scheduling module. The engineer station module comprises a verification test control module and a disk table frame development module. The touch control display operation terminal includes a disk table frame display module. A touch control operation identification module identifies the button and knob operation executed on the touch control display operation terminal as an operation instruction and then sends the operation instruction to the thermal hydraulic calculation module. The thermal hydraulic calculation module calculates the actual values of the thermal hydraulic parameters of a process system in a nuclear power station and then sends the actual values to the disk table frame display module. The virtual disk table is capable of realizing the virtual functions of the switching among the button operation, the knob operation and the disk table operation, the meter displaying and the like. Meanwhile, the auxiliary design and verification process of the disk table in the nuclear power station can be realized, and the design cycle is shortened.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Liquid piston heat engine

InactiveCN102434311ARealize stepless speed changeImplement speed changesInternal combustion piston enginesHot gas positive displacement engine plantsHydraulic cylinderCold air

The invention discloses a liquid piton heat engine which comprises a cold air hydraulic cylinder, a hot air hydraulic cylinder, a cold hydraulic power mechanism, a hot hydraulic power mechanism, a cold liquid medium return system and a hot liquid medium return system, wherein the cold air hydraulic cylinder is communicated with the hot air hydraulic cylinder through an air medium communicating pipeline, a cooler is arranged on the cold air hydraulic cylinder, a heater is arranged on the hot air hydraulic cylinder, a cold liquid medium outlet of the cold air hydraulic cylinder is communicated with a cold liquid medium return hole through the cold hydraulic power mechanism and the cold liquid medium return system, a hot liquid medium of the hot air hydraulic cylinder is communicated with a hot liquid medium return hole through the hot hydraulic power mechanism and the hot liquid medium return system, and the cold hydraulic power mechanism, the cold liquid medium return system, the hot hydraulic power mechanism and the hot liquid medium return system are controlled by a progress control mechanism. According to the invention, a piston crank connecting rod mechanism of an engine is omitted, and a large-power thermomotor with high efficiency and small volume and light weight can be manufactured.

Owner:ZEROQ SCI & TECH

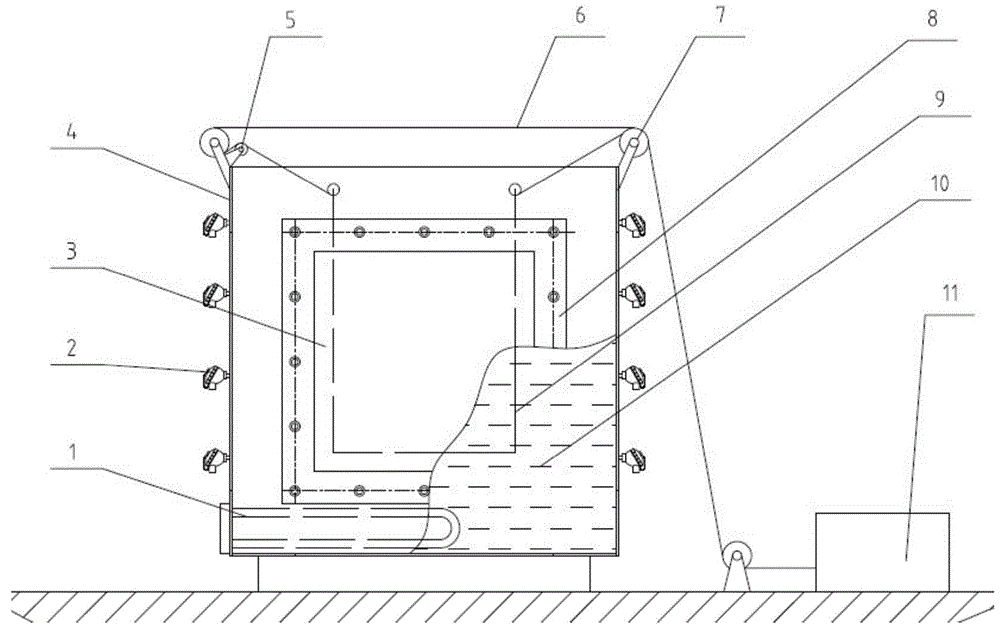

Melts and coolant interacting relative thermal-hydraulic research experiment water tank

InactiveCN103913544AAids in Mechanistic ResearchControl lift heightMaterial analysisWater infusionEngineering

The invention discloses a melts and coolant interacting relative thermal-hydraulic research experiment water tank, a main body of the water tank is used for inlet and outlet and storage of a coolant, a thermocouple and a pressure sensor are provided outside the main body of the water tank, a visual window is arranged on the wall surface of the main body of the water tank, the visual window and the main body of the water tank are sealed; a heating device is arranged in the main body of the water tank and is used for heating of the coolant in the water tank and controlling the temperature; a lifting mechanism is connected to a metal collection plate for controlling the lifting and decrease of the metal collection plate; the metal collection plate is arranged in the main body of the water tank for collecting the metal after the teats and measuring the size of the metal particles. According to the invention, water-infusion amount is changed, visualization is realized, temperature and pressure enable real-time acquisition, the metal particles after tests are collected, and the particles size is measured. In the experiment process, a reaction process can be observed from four directions simultaneously, and the experiment water tank is helpful for researching the interacting types of the molten metal and the coolant and a generation mechanism.

Owner:SHANGHAI JIAO TONG UNIV

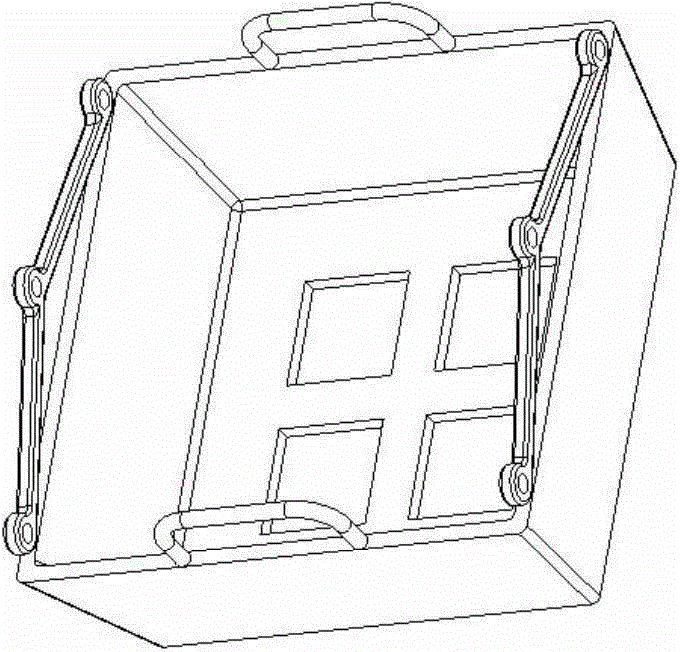

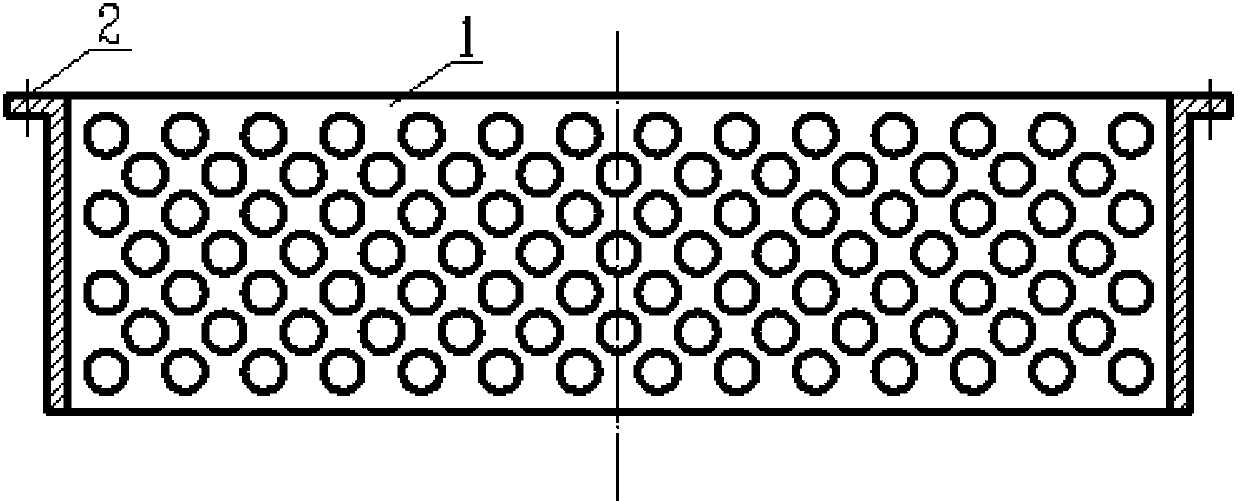

Experiment segment based on fusion and fission mixed pile water cooling cladding layer and experiment method of experiment segment

InactiveCN103280143AMeet operational requirementsGuaranteed spacingEducational modelsElectricityNuclear reactor

The invention relates to an experiment segment based on a fusion and fission mixed pile water cooling cladding layer and an experiment method of the experiment segment. The experiment segment comprises a high-temperature resistance stainless steel pipe, an electric heating rod with a thermocouple at the inside, an electric heating rod without a thermocouple, cover plates, separation plates, pressure taking pipes and an inlet and outlet branch pipe, wherein the electric heating rods are respectively assembled in the high-temperature resistance stainless steel pipe, the cover plates are welded at the two ends of the electric heating rods, two stainless steel separation plates are welded in the high-temperature resistance stainless steel pipe, three armored thermowells are simultaneously welded outside the high-temperature resistance stainless steel pipe, the pressure taking pipes are respectively welded on the outer wall surface of the high-temperature resistance stainless steel pipe, three heating rods are placed at the left end of the experiment segment, four heating rods are placed at the right end, and the heating rods at the left end and the heating rods at the right ends are in crossed placement. By aiming at the experiment segment of the fusion and fission mixed pile water cooling cladding layer model manufacture, the flowing heat exchange condition under the structure is simulated, the experiment segment can be used at high temperature and high pressure, the sealing insulation performance is good, the results can be easily measured, the structure is compact, and the experiment segment is suitable for being assembled onto a nuclear reactor thermal hydraulic high-temperature and high-pressure experiment loop.

Owner:XI AN JIAOTONG UNIV

Method for preparing calcium sulfate hemihydrate crystal whisker by ardealite

ActiveCN105350066APromote resource utilizationReduce the impactPolycrystalline material growthFrom normal temperature solutionsDiameter ratioWhiskers

The invention relates to a method for preparing a calcium sulfate hemihydrate crystal whisker by ardealite. The adopted ardealite calcium sulfate dihydrate is low in grade, wide in source, and is not needed to be subjected to acid treatment impurity removal; by simple flotation desilicication, the grade of ardealite is improved and a large quantity of impurities are removed; the calcium sulfate hemihydrate crystal whisker is prepared by calcination, washing excitation, and thermal hydraulic pressure process. The process flow is simple; the raw materials are wide in source; the production cost is low; impact on environment is small; the obtained calcium sulfate hemihydrate crystal whisker has the characteristics of high purity, large length-diameter ratio, uniform shape, stable crystalline form and the like, and has relatively good industrial application value.

Owner:YUNNAN CHEM RES INST

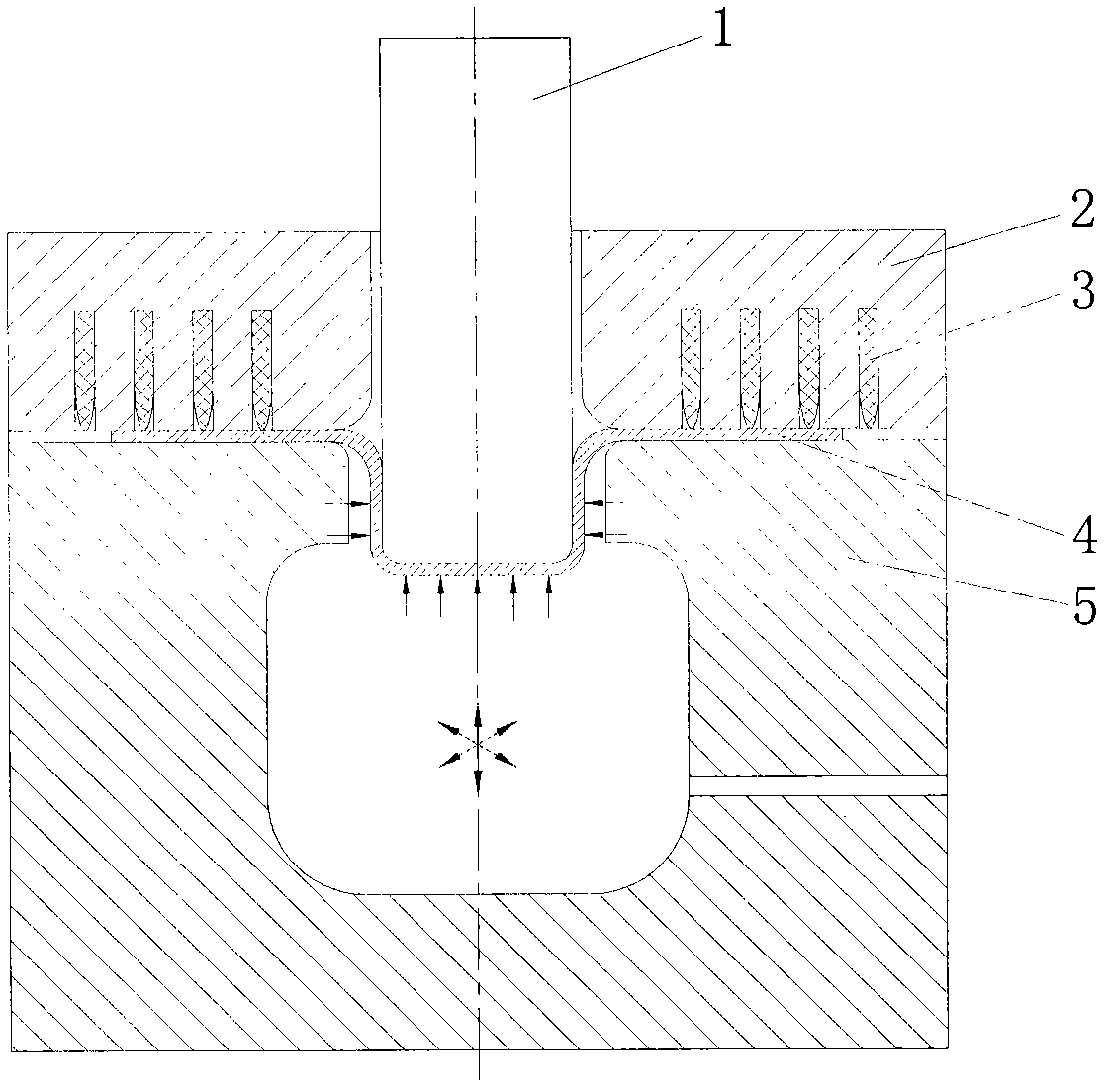

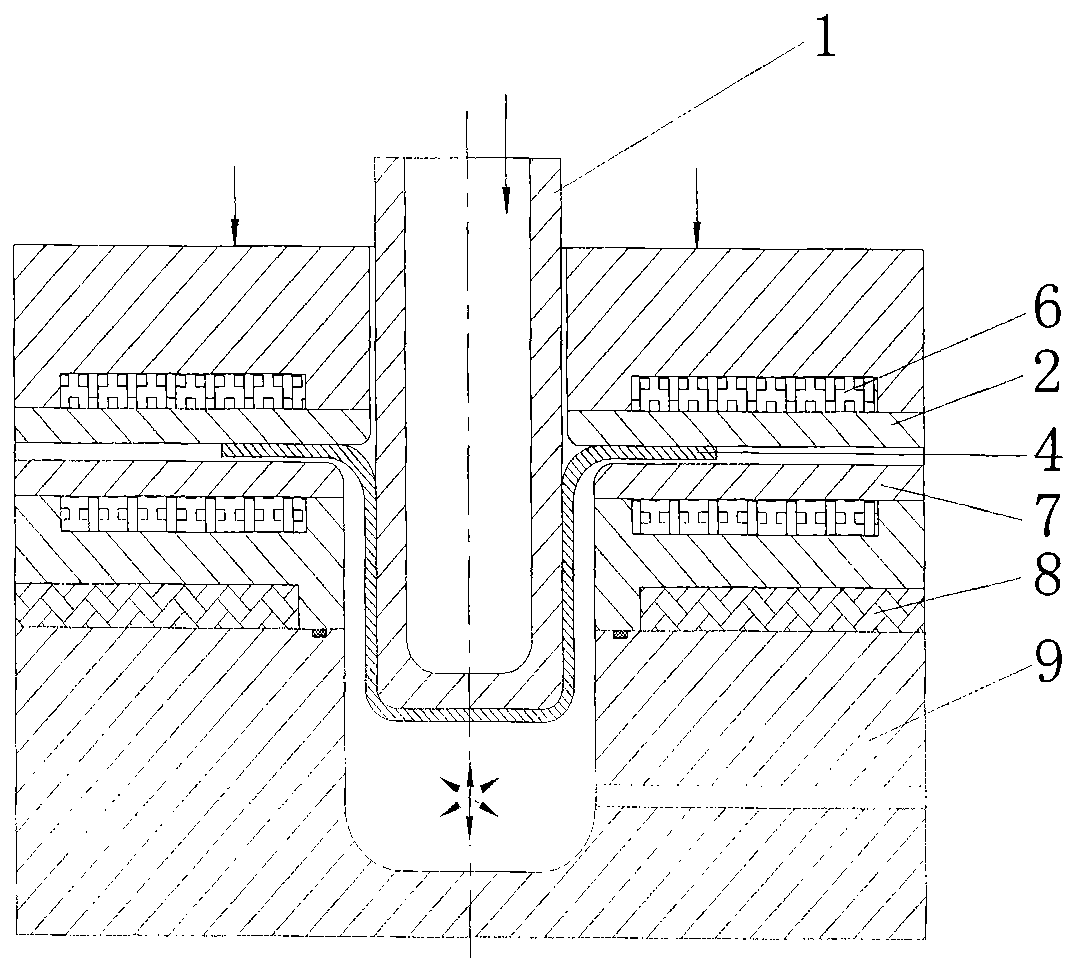

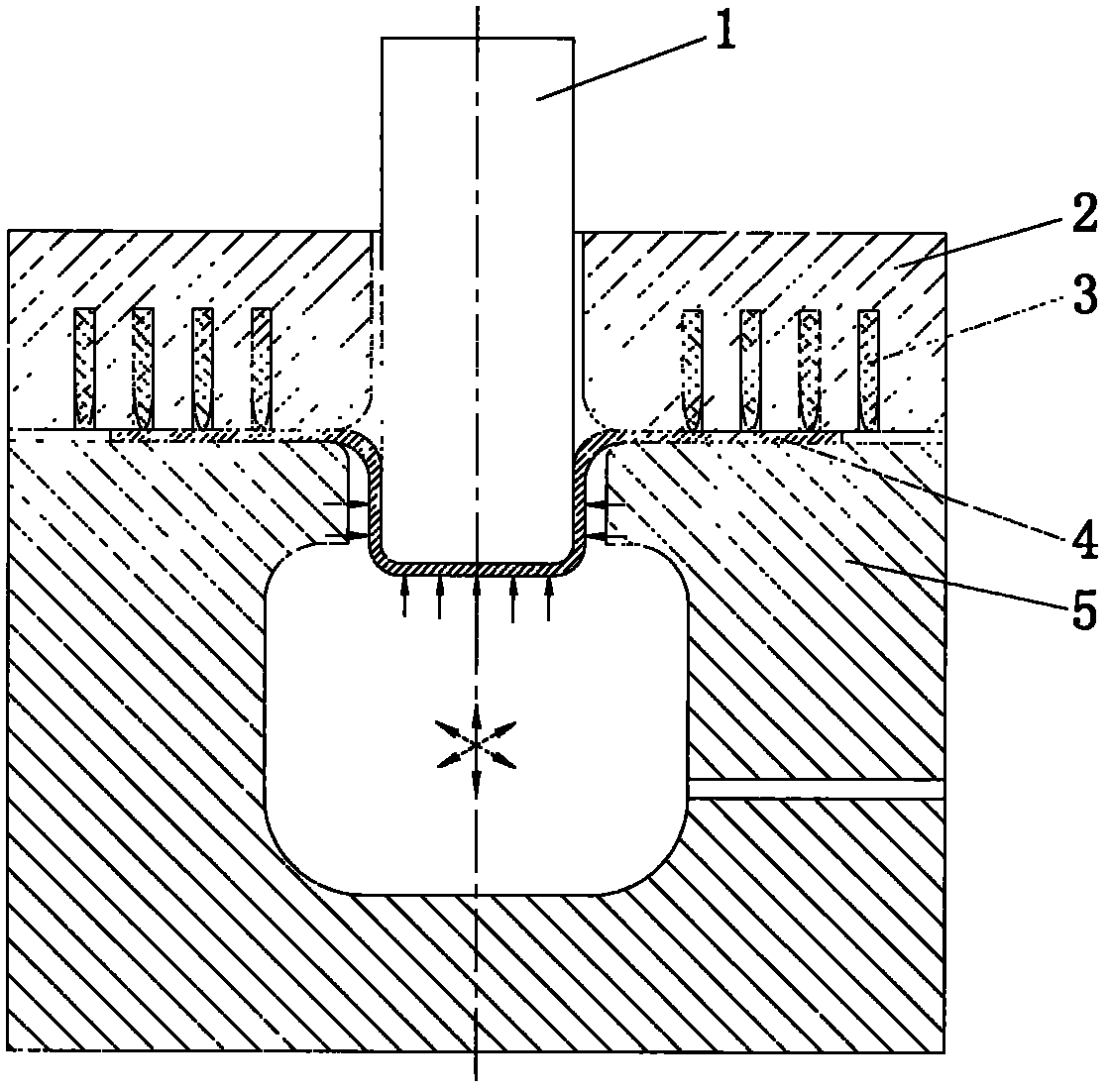

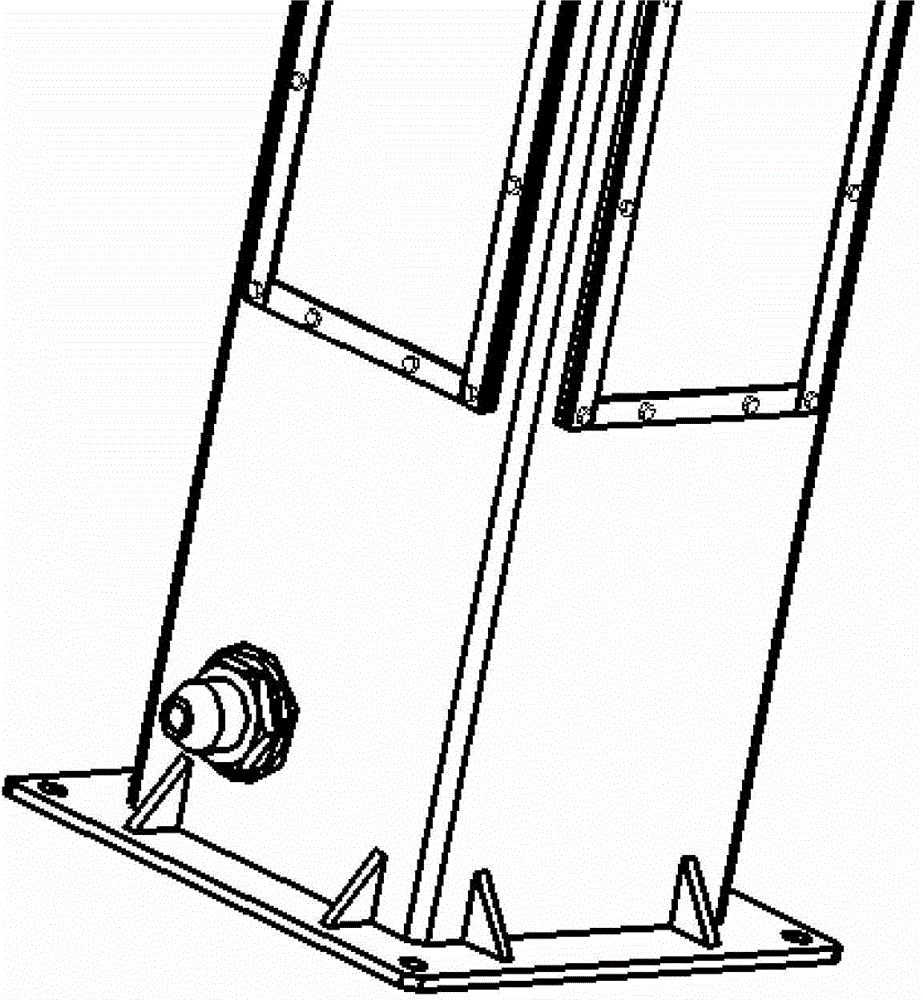

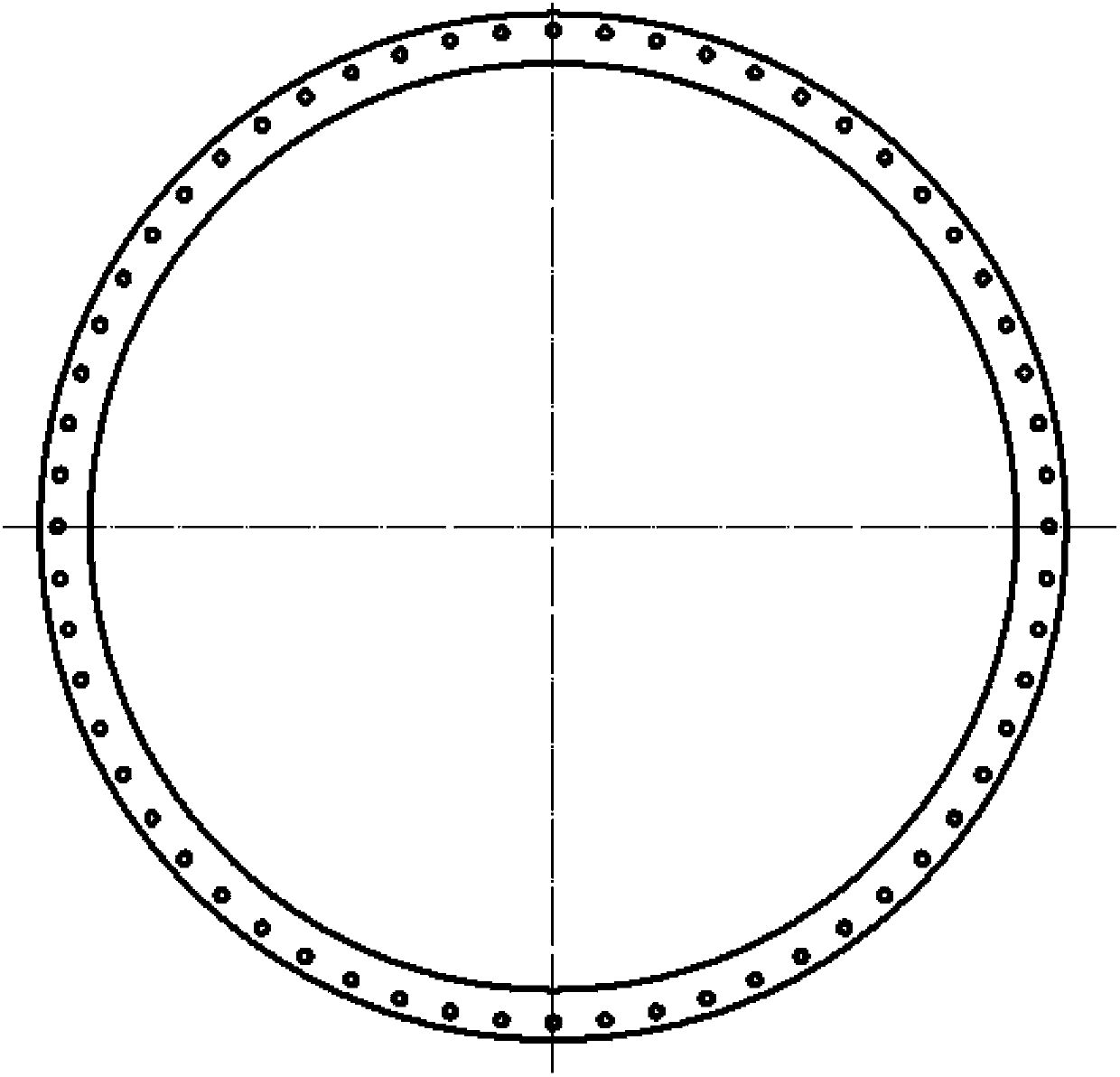

Nuclear reactor lower chamber cylinder-like flow distribution apparatus

ActiveCN103871500ASimple structureImprove structural stabilityNuclear energy generationCooling arrangementNuclear reactorCoolant flow

The present invention relates to a nuclear reactor lower chamber cylinder-like flow distribution apparatus, which is arranged in the lower chamber inside the lower dome of a pressure container, and comprises a flow distribution cylinder, wherein one end of the flow distribution cylinder is provided with an outer flange, the flow distribution cylinder is fixed on the lower surface of the reactor core lower supporting plate in the pressure container through the outer flange, the cylinder wall of the flow distribution cylinder is uniformly provided with 5-8 layers of penetrating water flowing holes from top to bottom, various layers of the water flowing holes are arranged in a staggered manner, and the flow distribution cylinder and the reactor core lower supporting plate share the same axis line. According to the present invention, the reactor lower chamber structure is substantially simplified, and the stability and the reliability of the structure are improved; the coolant flow distribution of the nuclear reactor lower chamber is achieved, and the phenomenon of the uneven flow field on the reactor core inlet region is overcome, and the thermal-hydraulic requirements are met; and the nuclear reactor lower chamber cylinder-like flow distribution apparatus has characteristics of simple structure, cost reducing and economy improving.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

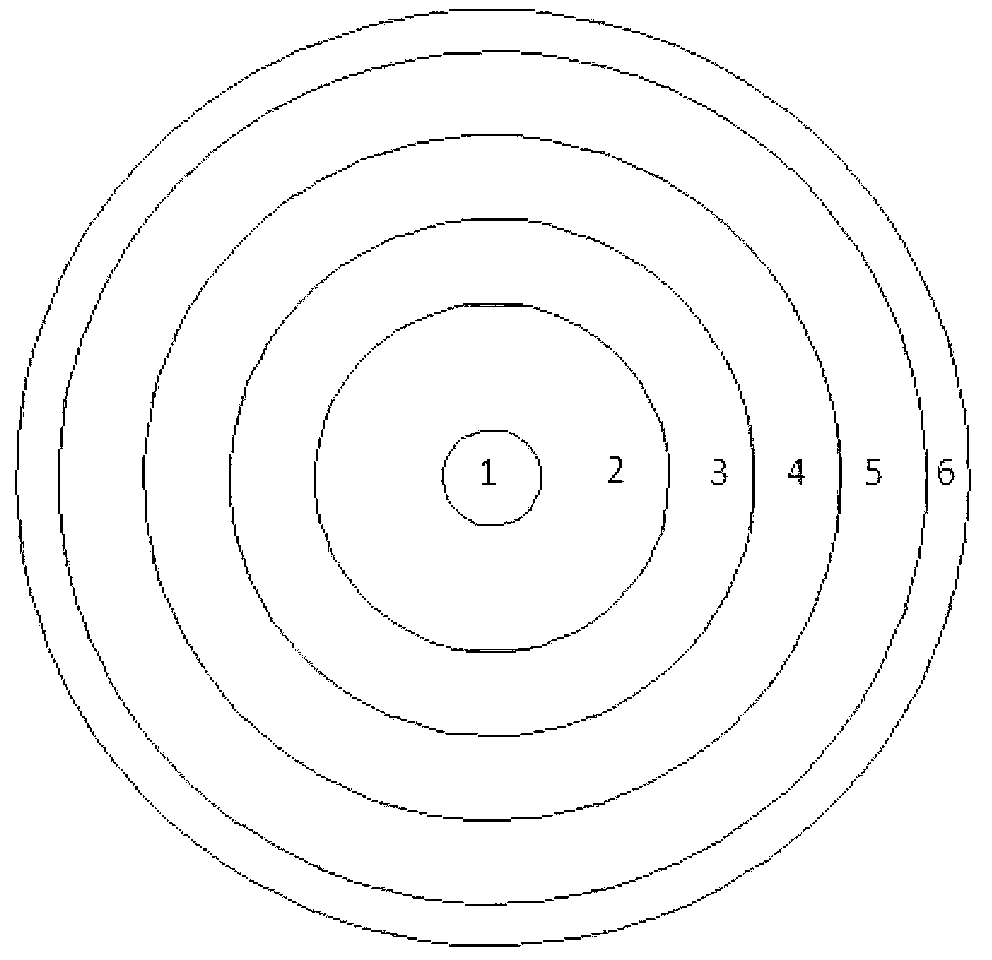

Radial-power-flattened efficient nuclear waste transmutation subcritical core and design method thereof

InactiveCN103077758AEfficient transmutationImprove power generation efficiencyNuclear energy generationReactors manufactureNuclear engineeringSubcritical reactor

The invention relates to a radial-power-flattened efficient nuclear waste transmutation subcritical reactor core and a design method thereof. The reactor core sequentially comprises an outer neutron source region (1), a first transmutation fuel zone (2), a second transmutation fuel zone (3), a third transmutation fuel zone (4), a reflective area (5) and a shielded area (6) from the center outwards. The transmutation fuel zones of the reactor core are arranged in three zones; the reactor core is arranged in a triangular shape, and is subjected to principle design and analysis by analyzing coupled neutronics and thermal-hydraulic principles and using mathematical methods; and aiming at each transmutation zone, specific geometry layer arrangement is performed from inside to outside based on the design principles, so that the power distribution of the transmutation fuel zones can be flattened in the radial direction. The reactor core can utilize fast neutron transmutation TRU (Transuranic) generated by exogenous neutron, is high in neutron utilization, good in radial power flattening, high in power generation efficiency and simple in structure, and has the functions of safety and high efficiency in nuclear waste disposal and economy.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

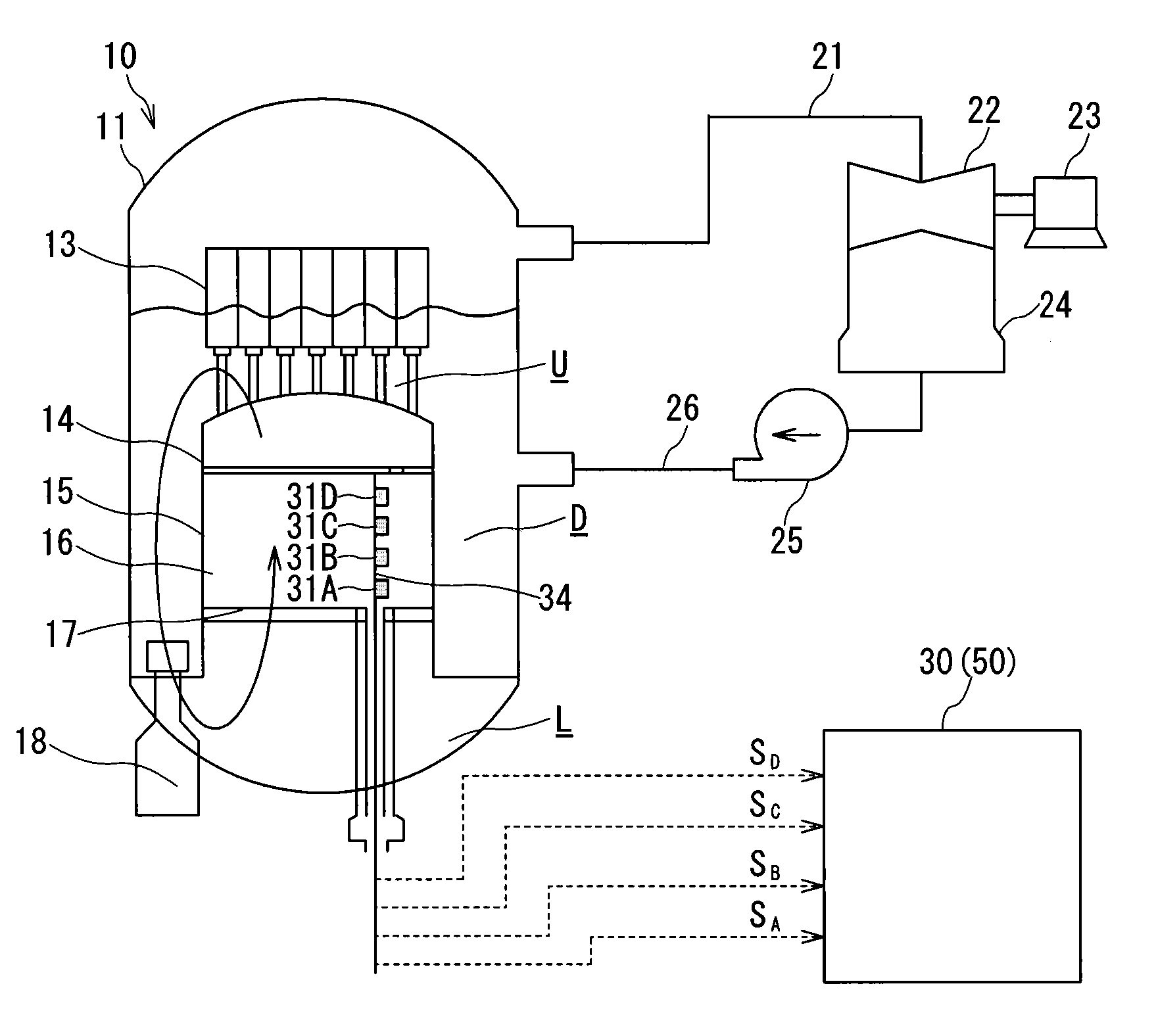

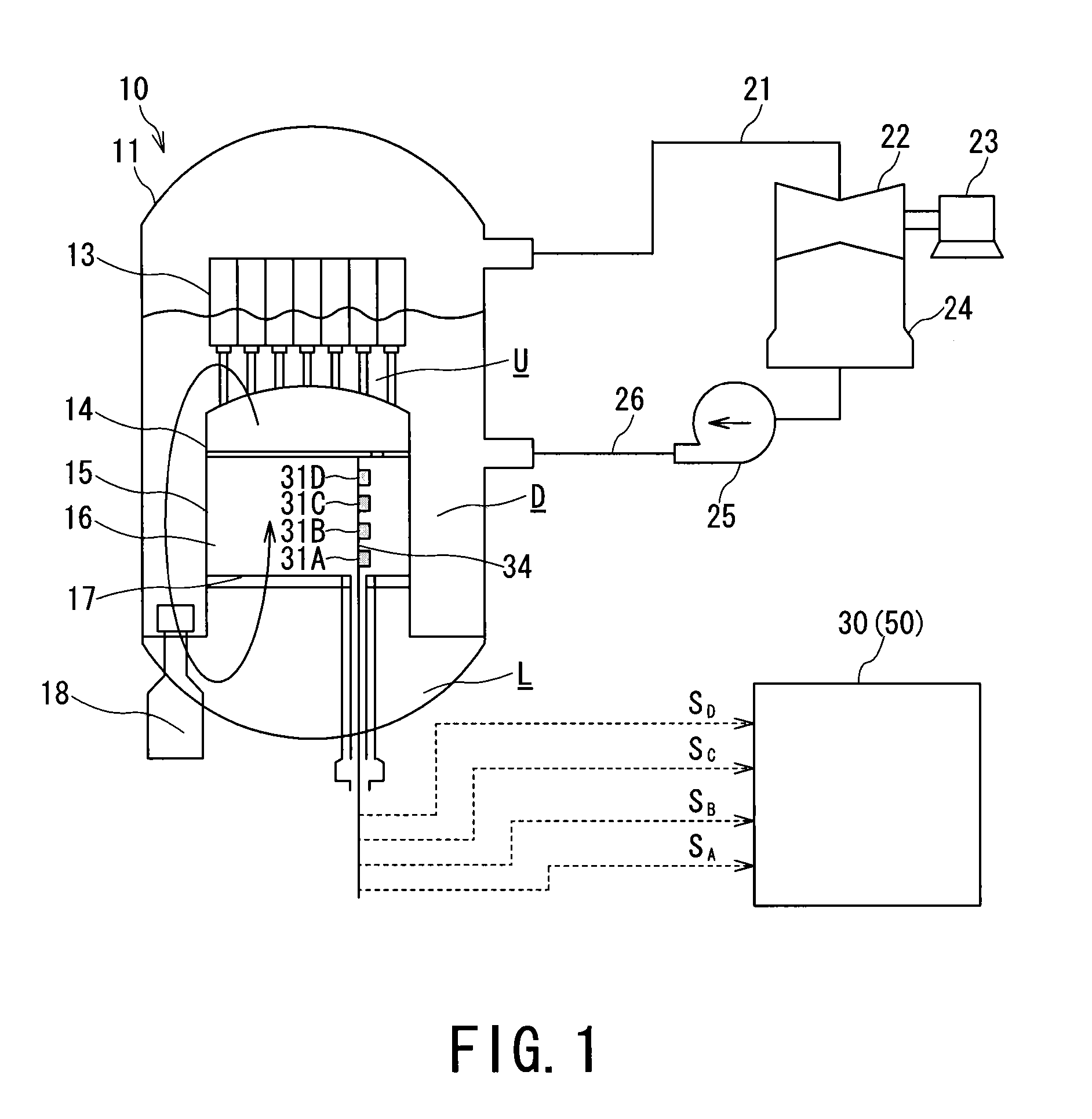

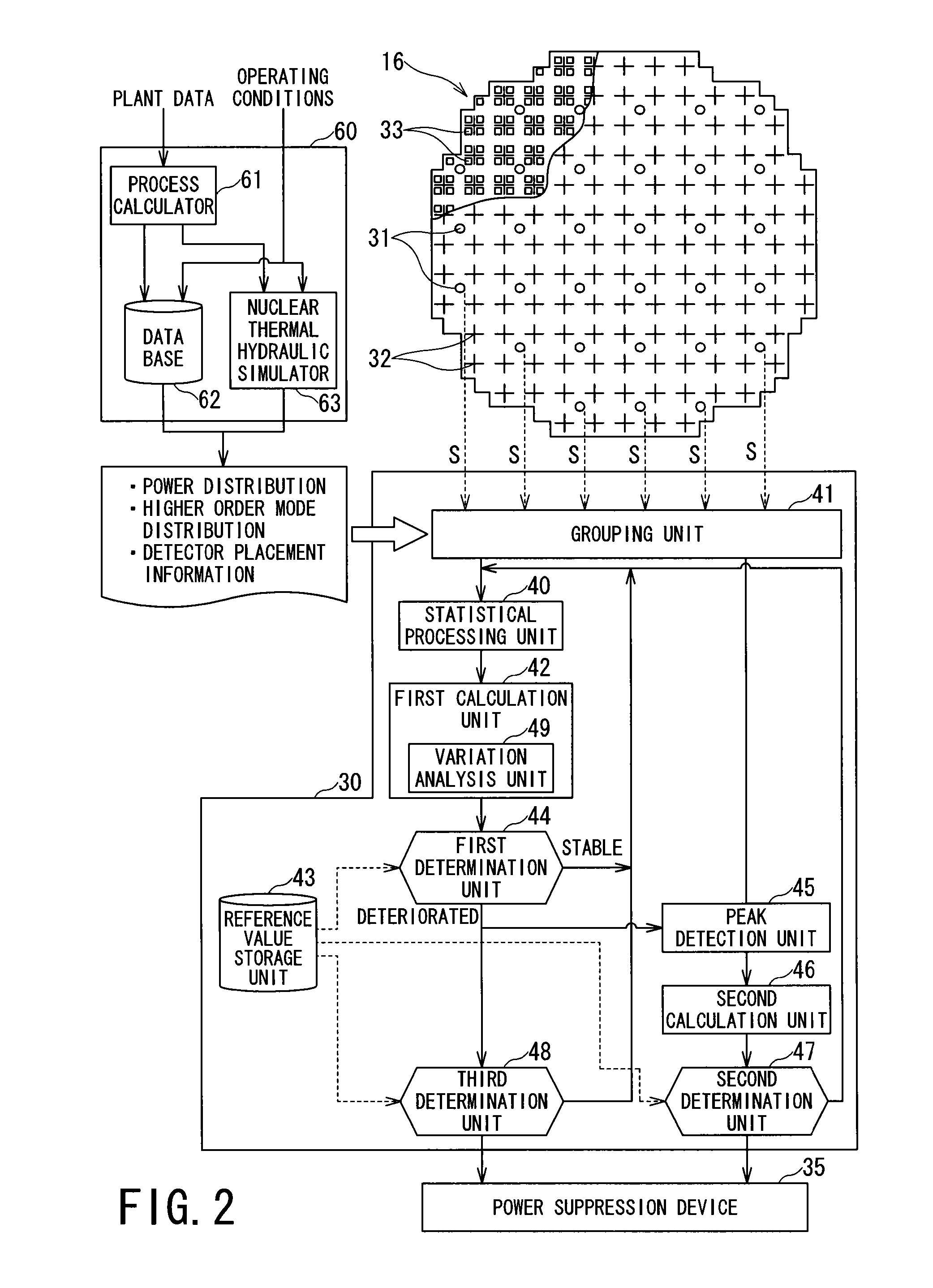

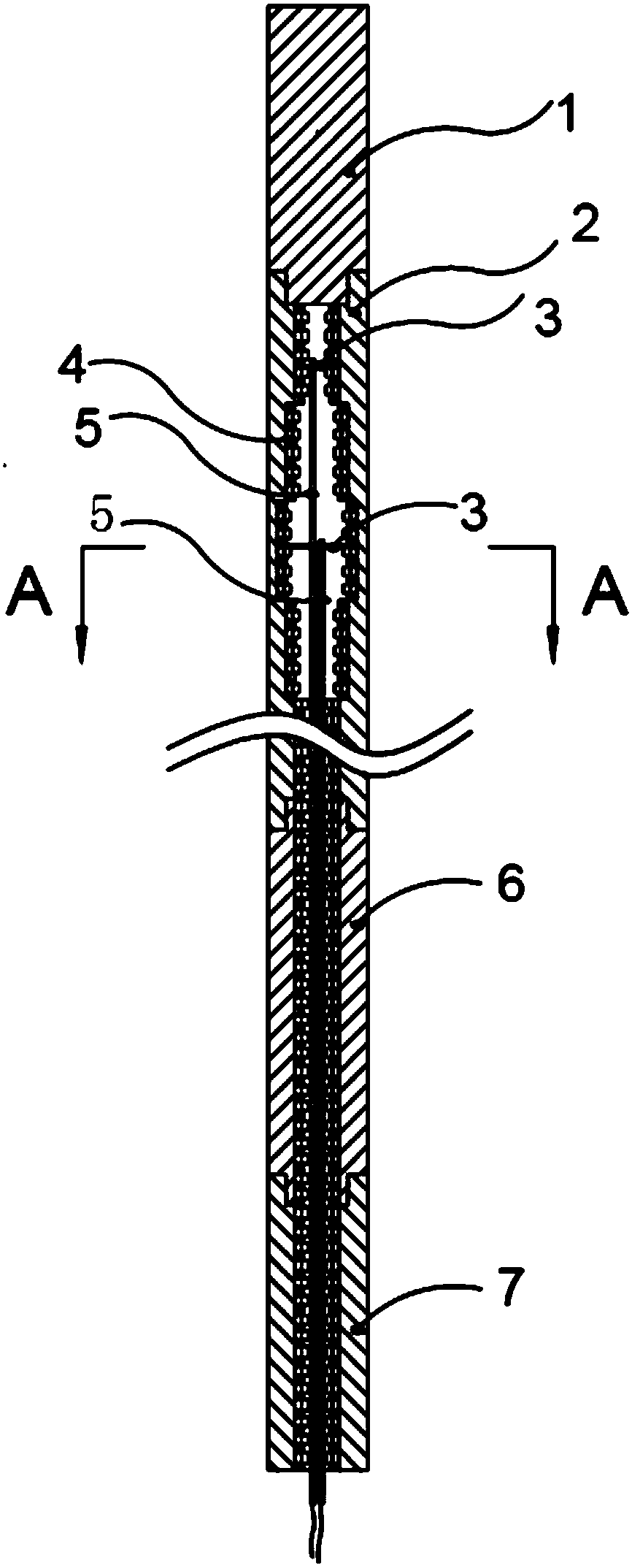

Nuclear reactor power monitor

InactiveUS20130058447A1Improve monitoring accuracyImprove reliabilityNuclear energy generationNuclear monitoringNuclear reactorStability index

Provide a nuclear reactor power monitoring technology for enhancing the monitoring accuracy and reliability in nuclear thermal hydraulic stability.A power monitor 30 includes a first calculation unit 42,52 configured to calculate a first stability index based on time series data indicating power oscillation in nuclear instrumentation signals outputted from a plurality of nuclear instrumentation detectors 31; a first determination unit 44,53 configured to compare the first stability index and a first reference value and determine whether nuclear thermal hydraulic stability of the reactor core is stable or deteriorated; a second calculation unit 46,54 configured to calculate a second stability index of the reactor core based on the time series data when the deteriorated state is determined in the first determination unit 44,53; and a second determination unit 47,55 configured to compare the second stability index and a second reference value and determine whether to perform suppressing operation of the power oscillation.

Owner:KK TOSHIBA

Non-uniform electric heating nuclear fuel simulation rod

PendingCN107945895AUniform heat releasePrecise control over distributionNuclear energy generationNuclear monitoringExperimental researchElectricity

The invention discloses a non-uniform electric heating nuclear fuel simulation rod and a test method thereof, and belongs to the field of reactor experimental research. The nuclear fuel simulation rodprovided by the invention is applied to critical heat flux density experimental research of nuclear fuel assemblies, and relates to the experimental research of thermal hydraulic performance of the fuel assemblies. The nuclear fuel simulation rod provided by the invention takes the situation that a current flows through a conductor to generate heat as the principle, and uses non-uniform heat generated along the axial direction of an electric heating rod to simulate non-uniform heat release along the axial direction of a nuclear fuel rod, so as to perform the critical heat flux density experimental research of the nuclear fuel assemblies.

Owner:CHONGQING UNIV

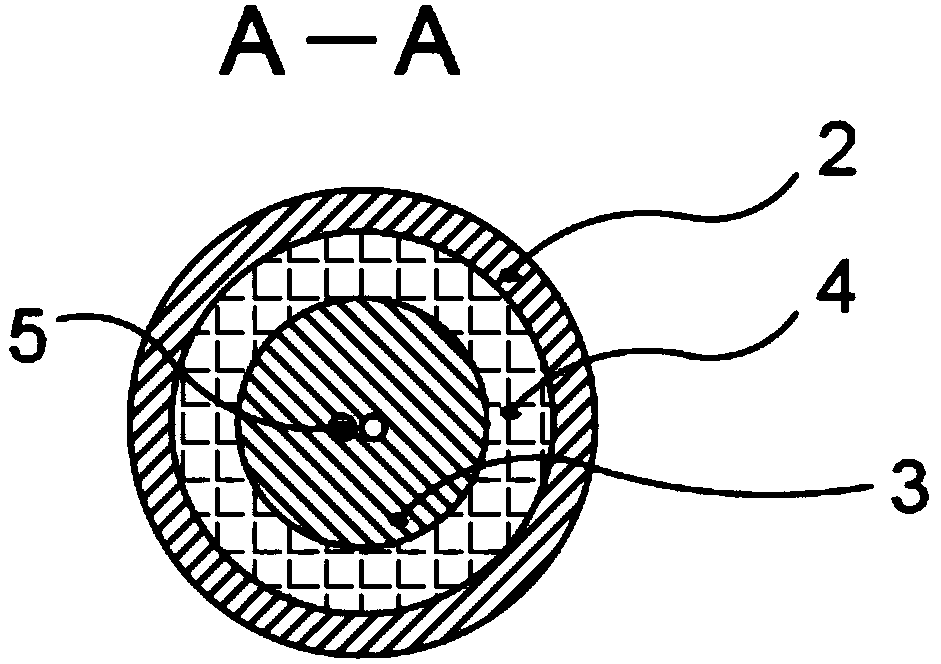

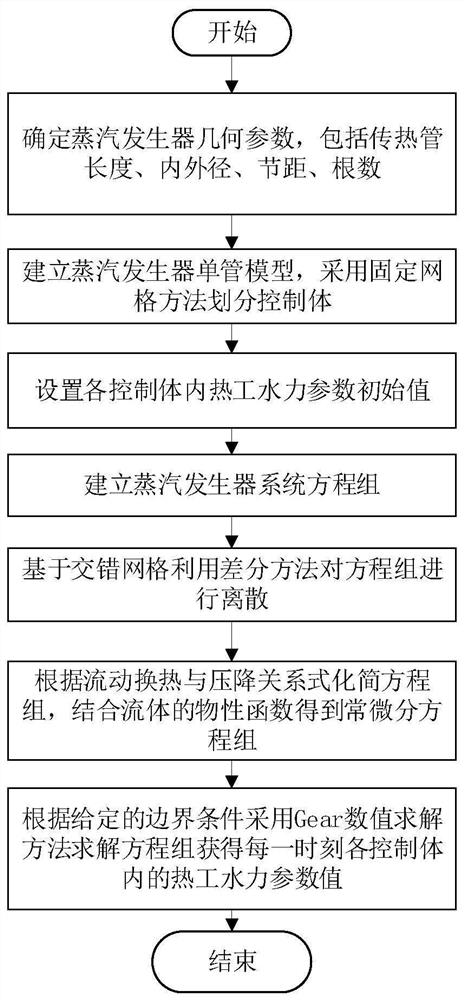

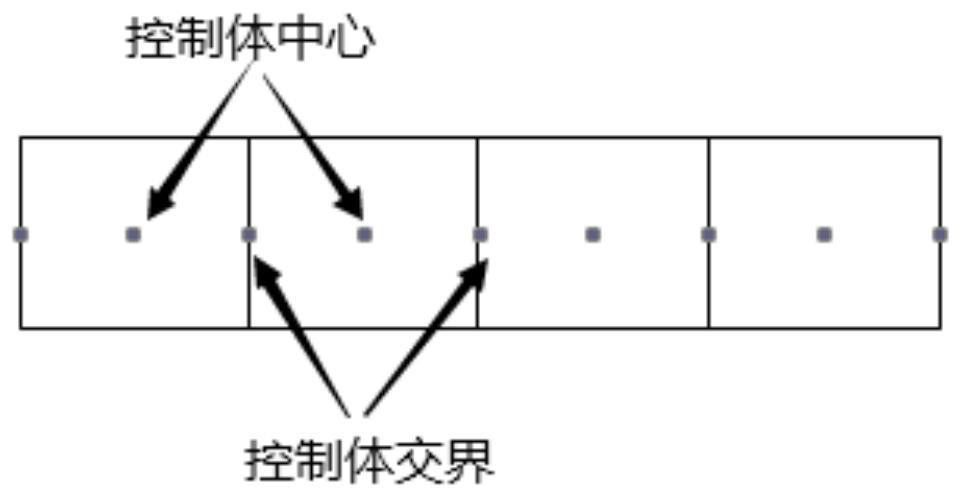

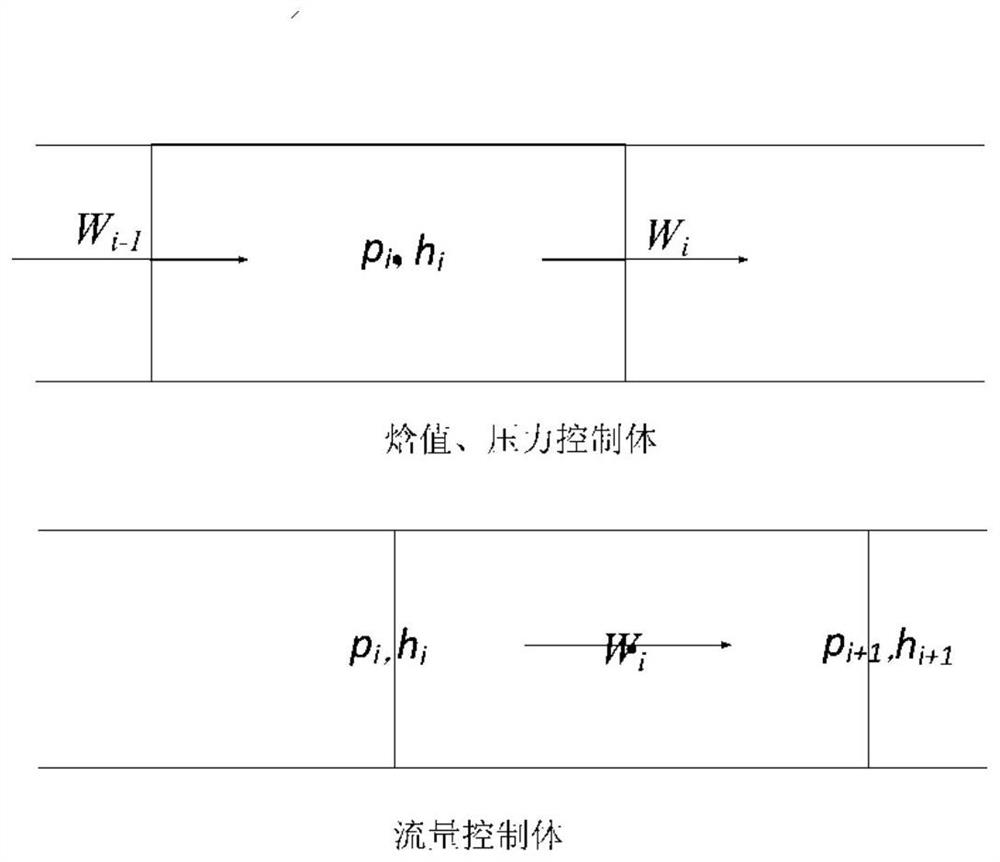

Thermal hydraulic transient calculation method suitable for sodium water once-through steam generator

ActiveCN111680458ASuitable for a wide range of objectsGuaranteed solution accuracyNuclear energy generationNuclear monitoringEngineeringFinite difference method

The invention discloses a thermal hydraulic transient calculation method of a sodium water once-through steam generator. The method comprises the following steps: determining geometric parameters of asteam generator; establishing a steam generator single-tube model, and dividing a control body by adopting a fixed grid method; setting initial values of thermal hydraulic parameters in each controlbody; establishing a steam generator system equation set; discretizing the equation set based on a staggered grid and a finite difference method; obtaining an ordinary differential equation set according to a heat exchange and pressure drop formula and a fluid physical property function; and solving the simplified steam generator system equation set by adopting a Gear numerical solution method according to a given boundary condition to obtain a thermal hydraulic parameter value in each control body at each moment. The method is suitable for modular and integral sodium-water once-through steamgenerators, is convenient to operate, high in universality, flexible to use and high in precision, can completely meet the thermal-hydraulic transient calculation requirement of the sodium-water once-through steam generator, and can provide a software basis for independent design of the sodium-cooled fast reactor in China.

Owner:XI AN JIAOTONG UNIV

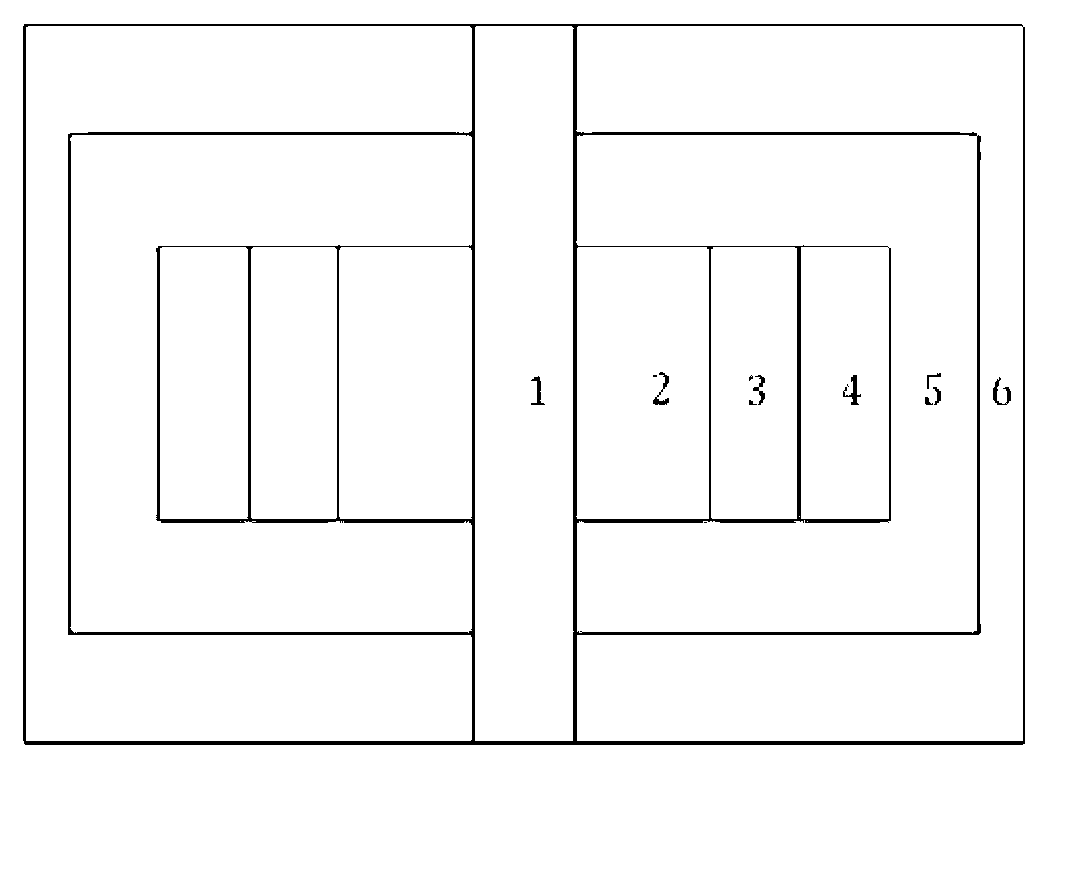

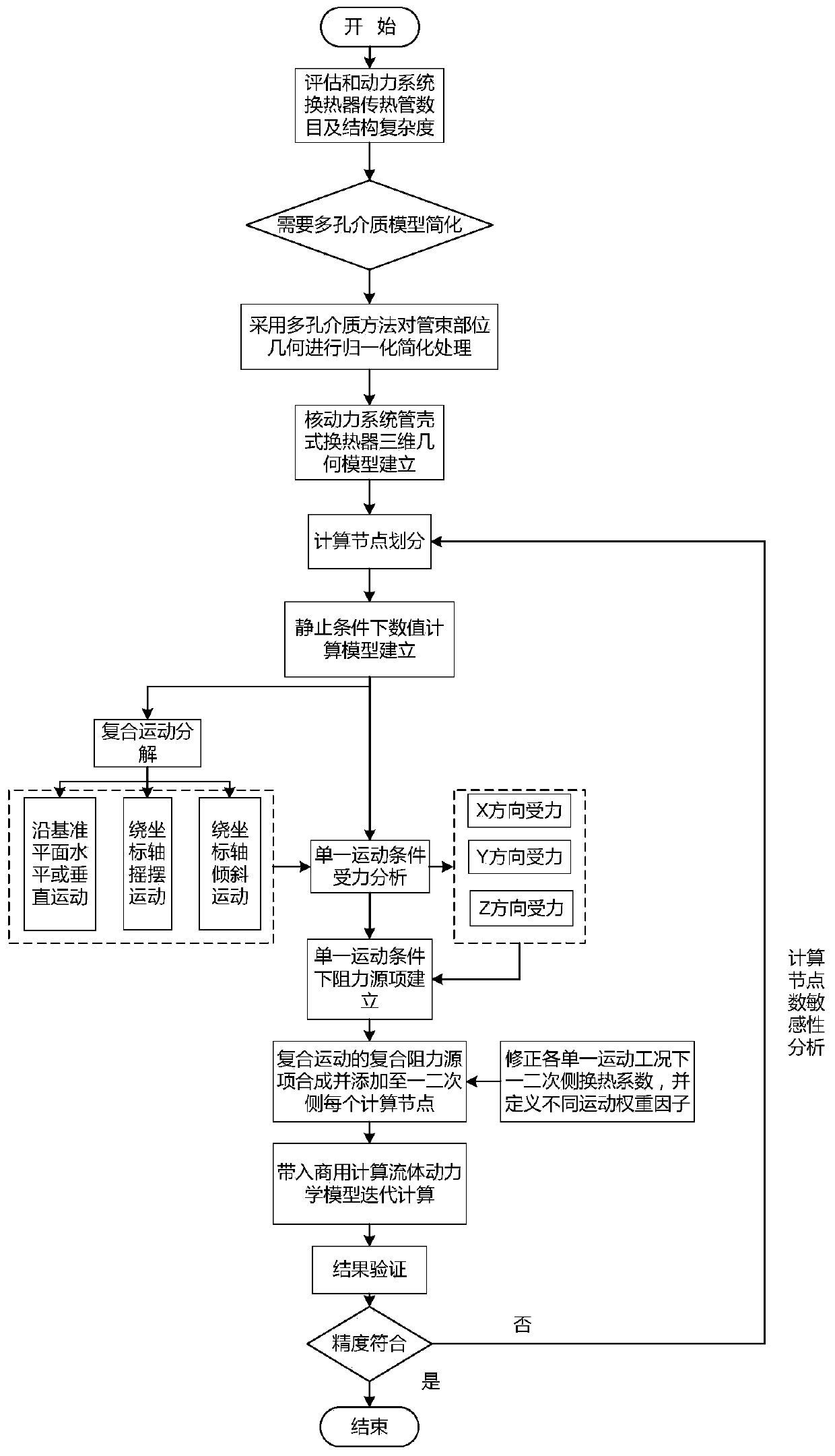

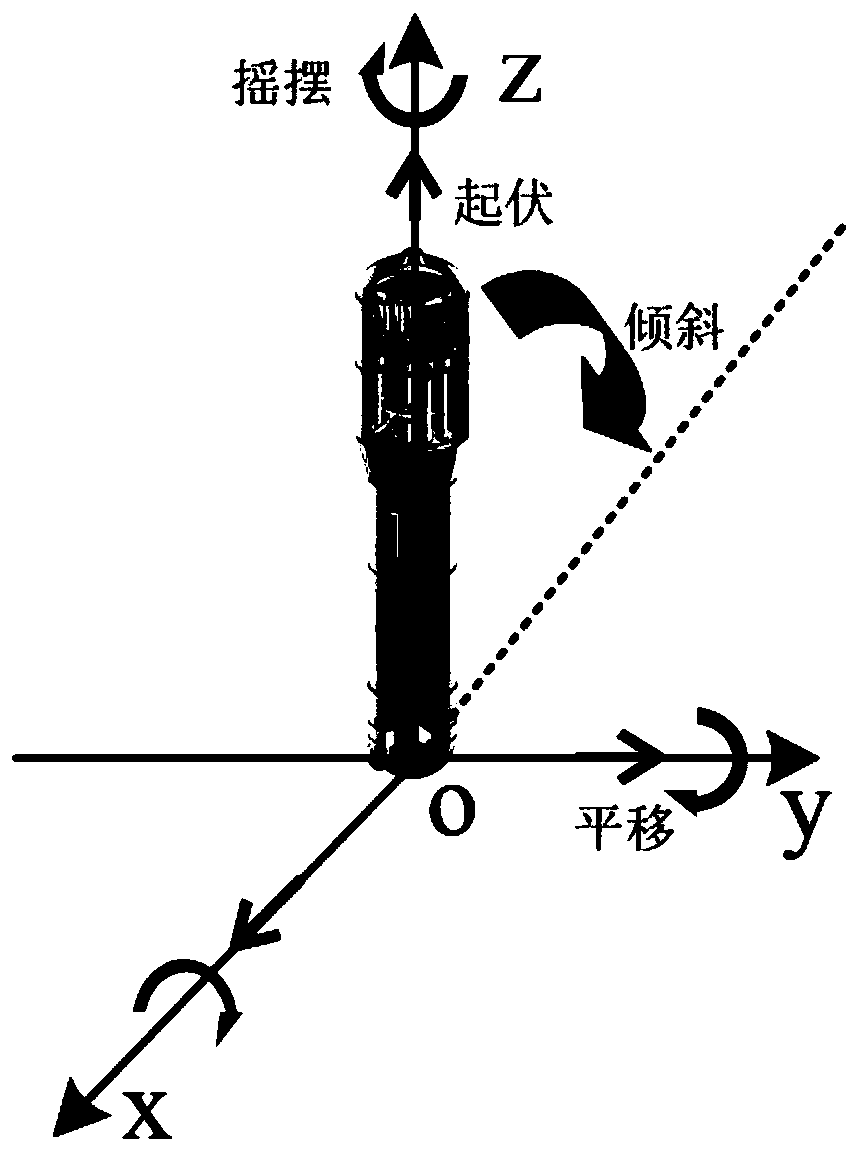

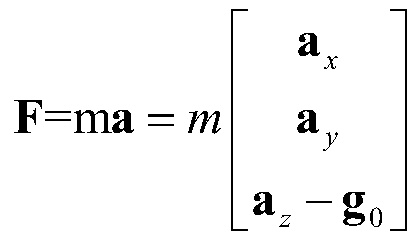

Method for establishing nuclear power system shell-and-tube heat exchanger numerical model under motion condition

ActiveCN111274747AConsider mobilityConsider all featuresDesign optimisation/simulationCAD numerical modellingComputational modelEngineering

The invention discloses a method for establishing a numerical model of a shell-and-tube heat exchanger of a nuclear power system under a motion condition. The method is suitable for establishing a three-dimensional numerical calculation model of large heat exchange equipment of the nuclear power system under the motion condition that different forms are generated under certain external force. Thethree-dimensional numerical calculation model is mainly based on a three-dimensional thermal hydraulic numerical calculation model of the shell-and-tube heat exchanger in static operation. According to the motion forms and the stress characteristics under different motion conditions, the stress is uniform; motion decomposition, stress analysis and decomposition of a single motion, establishment ofan additional force source item acting on a momentum equation under the single motion, and a composite motion additional force source item synthesis process are carried out on a shell-and-tube heat exchanger under a composite motion condition; and finally, establishing a set of numerical calculation model capable of accurately describing the thermal hydraulic characteristics of the shell-and-tubeheat exchanger of the nuclear power system under the composite motion condition.

Owner:XI AN JIAOTONG UNIV

Nuclear reactor containment cooling simulation system and method based on external spraying

ActiveCN105788682ASimple designOptimize layoutPower plant safety arrangementNuclear energy generationNuclear reactor coreThermal spraying

The invention relates to a nuclear reactor containment cooling simulation system and method based on external spraying. The system comprises containment, experiment gas nozzle, a raw water high-level water tank, a variable-frequency spraying water pump, a spraying nozzle and a liquid storage tank, wherein the raw water high-level water tank, the variable-frequency spraying water pump, the spraying nozzle and the liquid storage tank are sequentially connected, the spraying nozzle is located right above the containment, and the experiment gas nozzle is located in the containment; a data collecting device and a mass spectrometer are arranged outside the containment, an inlet flowmeter, an inlet thermocouple, an inlet pressure sensor and an experiment gate valve are sequentially serially connected between the variable-frequency spraying water pump and the spraying nozzle; an outlet thermocouple and an outlet flowmeter are sequentially serially connected between the spraying nozzle and the liquid storage tank. Water is injected through the opening and closing of a water injection gate valve and the experiment gate valve, the spraying nozzle sprays water, and the features and rules of the internal thermal-hydraulic phenomena of the containment after the outside of the containment is sprayed according to obtained data. The nuclear reactor containment cooling simulation system is reasonable in design and widely applicable and provides technical and data support for the engineering construction and design transformation of advanced nuclear reactors of China.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com