Patents

Literature

32 results about "Helium temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The normal liquid form is called helium I and exists at temperatures from its boiling point of 4.21 K (−268.9 °C) down to about 2.18 K (−271 °C). Below 2.18 K, thermal conductivity of helium-4 becomes more than 1,000 times greater than that of copper.

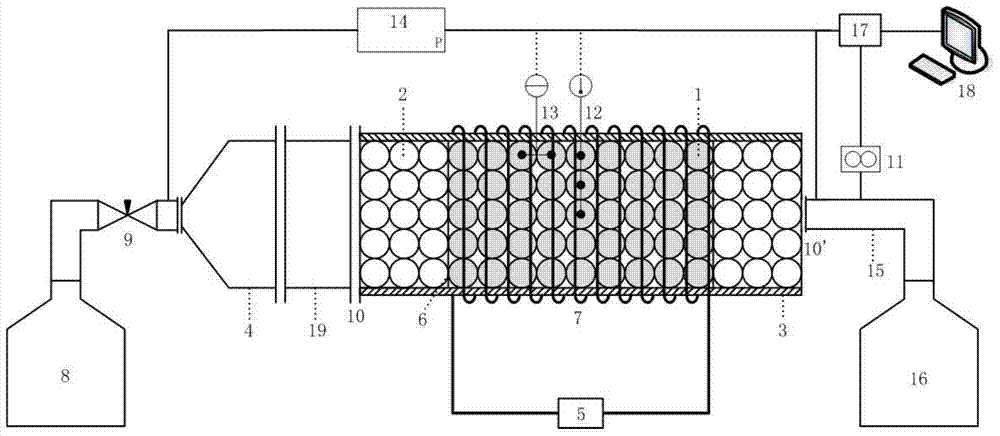

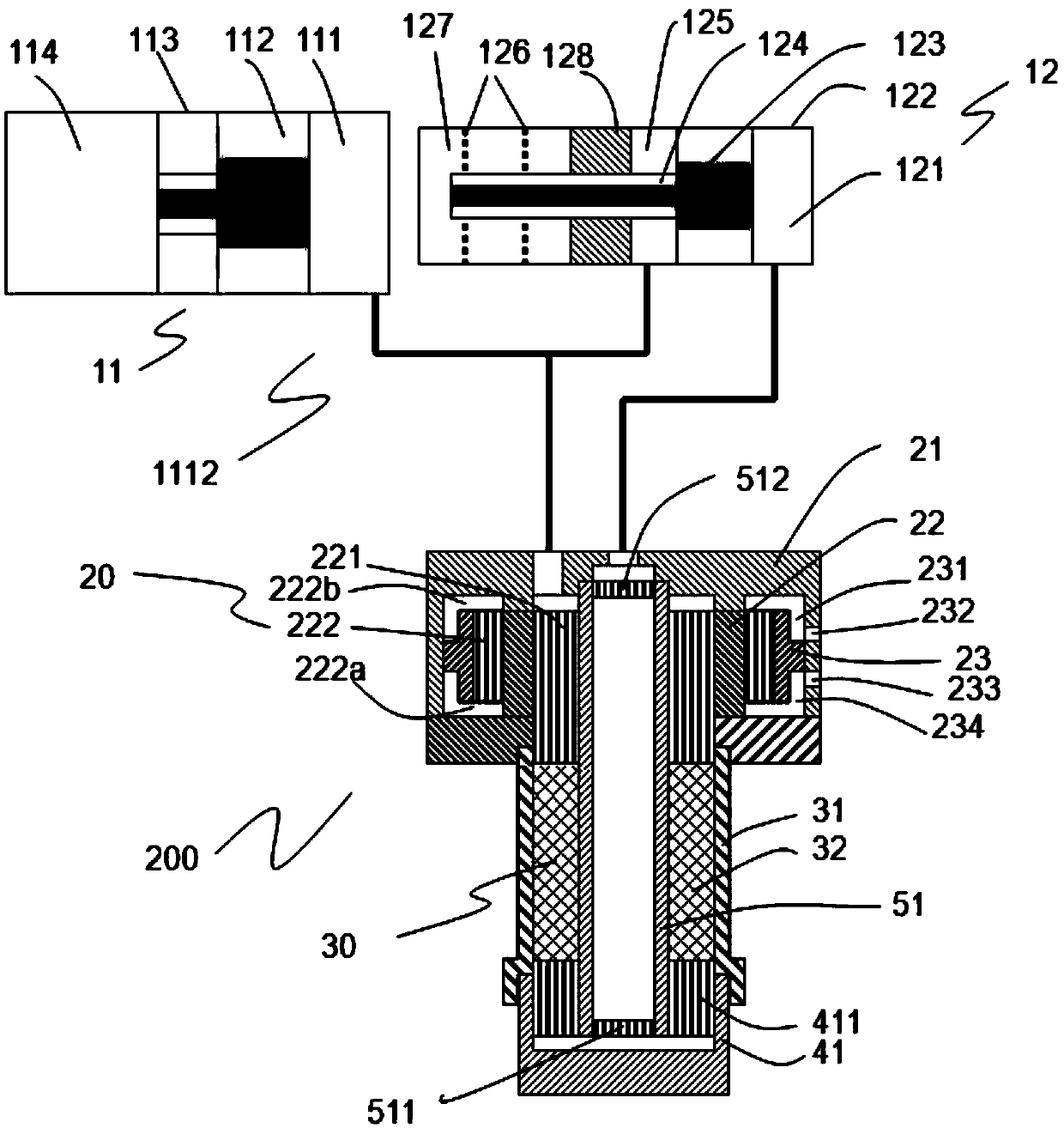

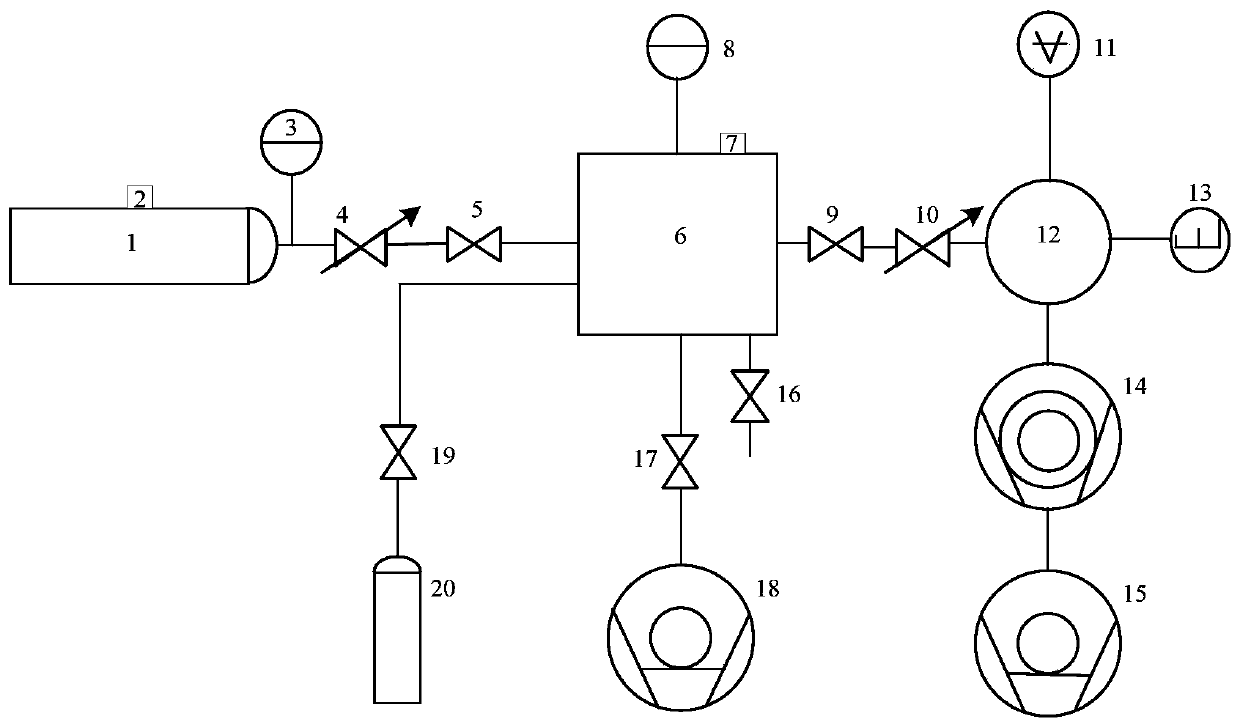

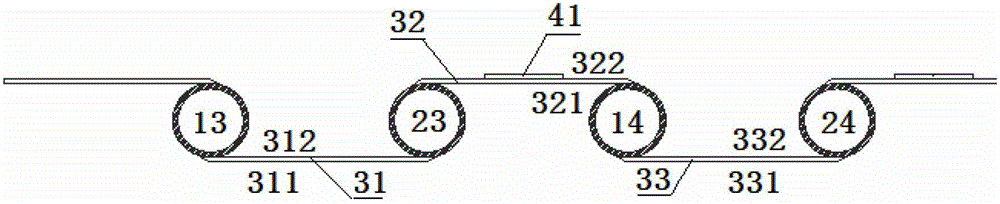

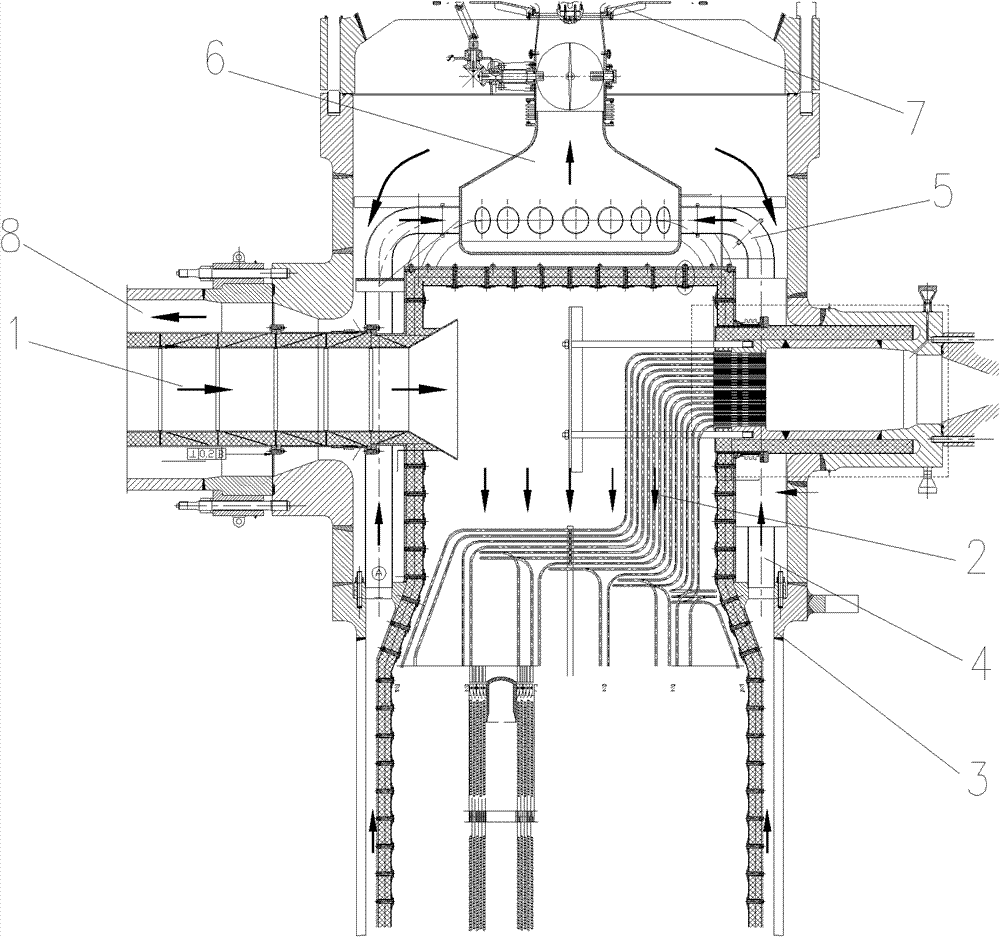

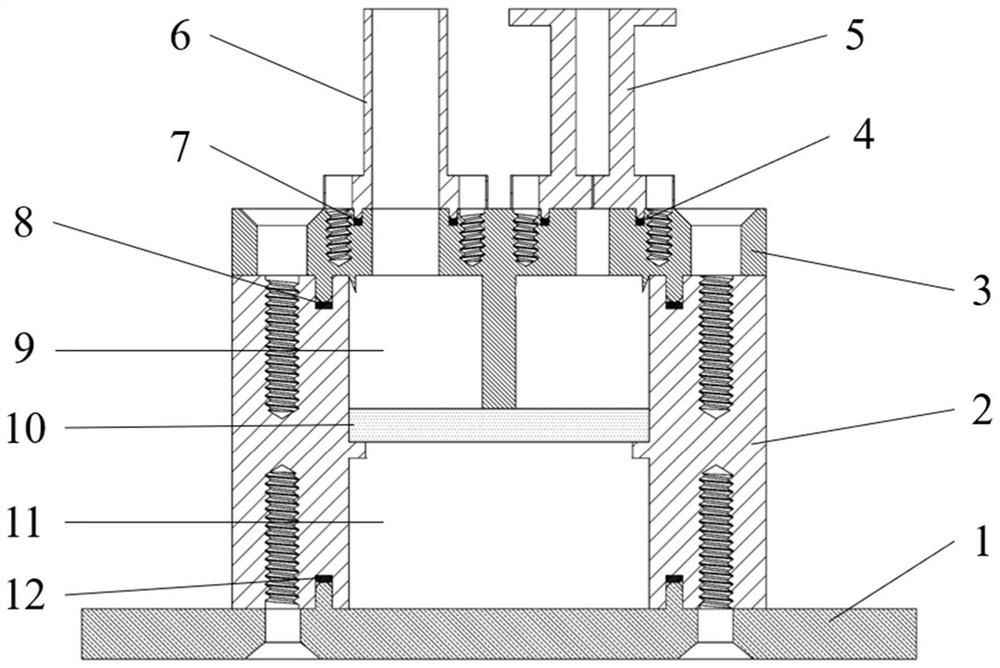

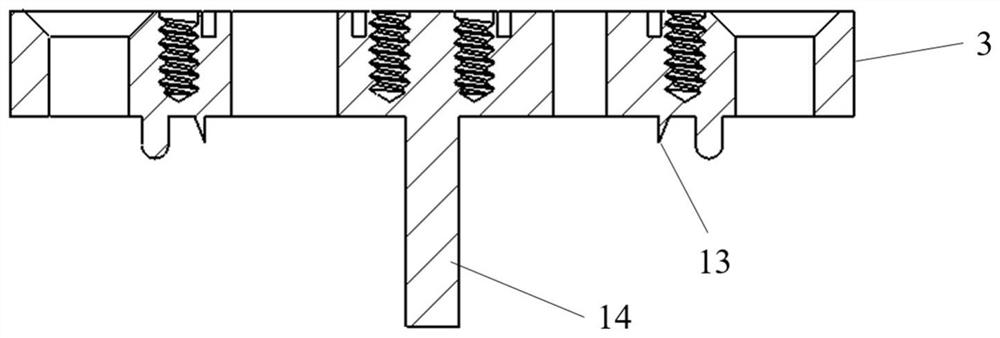

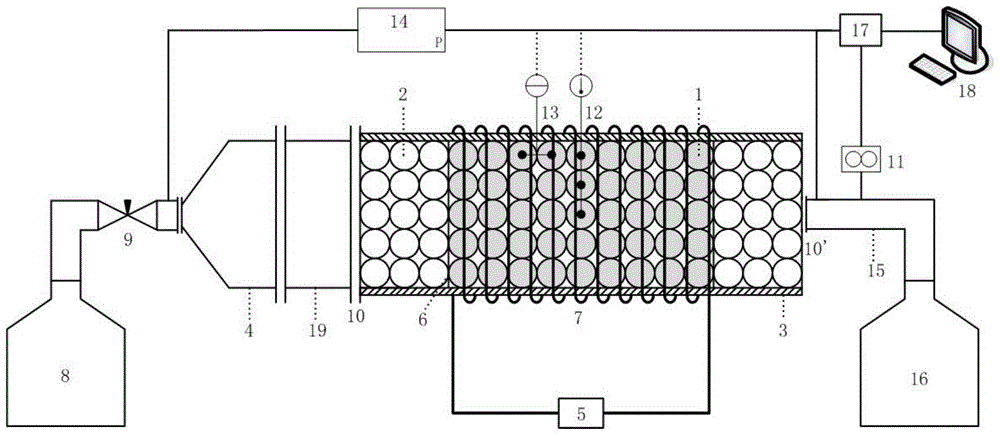

Thermal hydraulic characteristic testing device and method for tritium blowing helium of breeding blanket pebble bed of fusion reactor

InactiveCN104122071ASolve the problem that it is difficult to obtain high-energy neutrons to generate nuclear heat in the breeder pelletHydrodynamic testingNuclear engineeringConvection heat

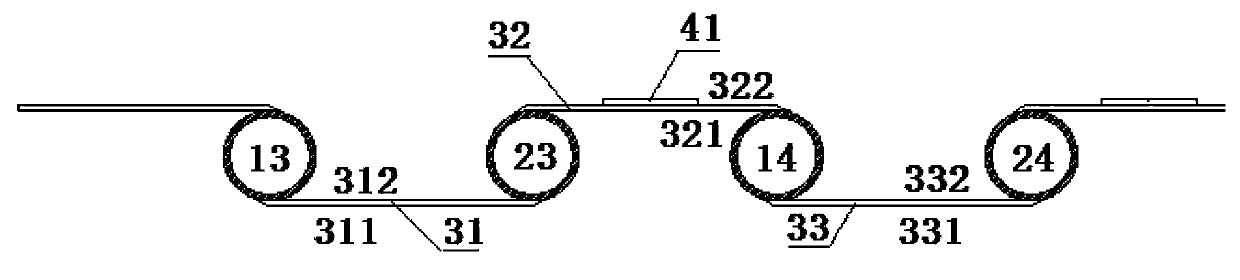

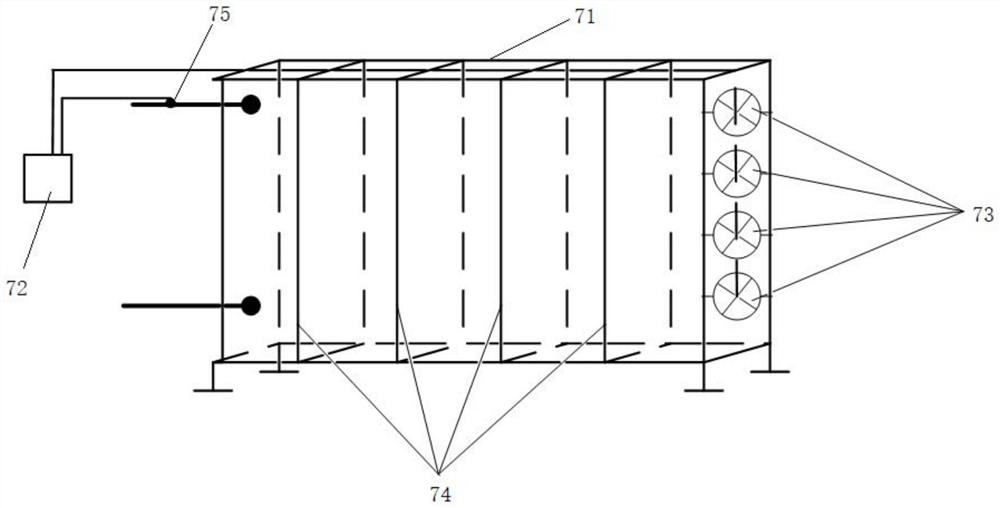

The invention discloses a thermal hydraulic characteristic testing device and method for tritium blowing helium of a breeding blanket pebble bed of a fusion reactor. The thermal hydraulic characteristic testing device for the tritium blowing helium of the breeding blanket pebble bed of the fusion reactor is mainly used for researching the flow and heat transfer characteristics of the tritium blowing helium of the solid breeding blanket layer of the fusion reactor between breeding agent pebbles of the pebble bed. The thermal hydraulic characteristic testing method includes that using a non-contact type high-frequency induction power to heat quasi metal breeding agent pebbles to simulate high-power density nuclear heat generated by the breeding agent pebbles in the pebble bed, researching the thermal hydraulic characteristics of the pebble bed under changed tritium blowing helium temperature, speed and pressure, breeding agent pebble arrangement mode, size and power density and the like, measuring the temperature distribution of the breeding agent pebbles and pebble bed wall surface, and obtaining a convection heat transfer correlation equation and a flow resistance relation to provide supports for testing and demonstrating the nuclear heat transmission of the neutron deposition in the pebble bed on the breeding agent pebbles and the tritium blowing helium flow and heat transfer characteristics under laboratory conditions, verifying the feasibility of a solid breeding blanket designing scheme and the correctness of a numerical method and data, and researching and developing Chinese solid experiment blanket modules of ITER.

Owner:中国人民解放军陆军军官学院

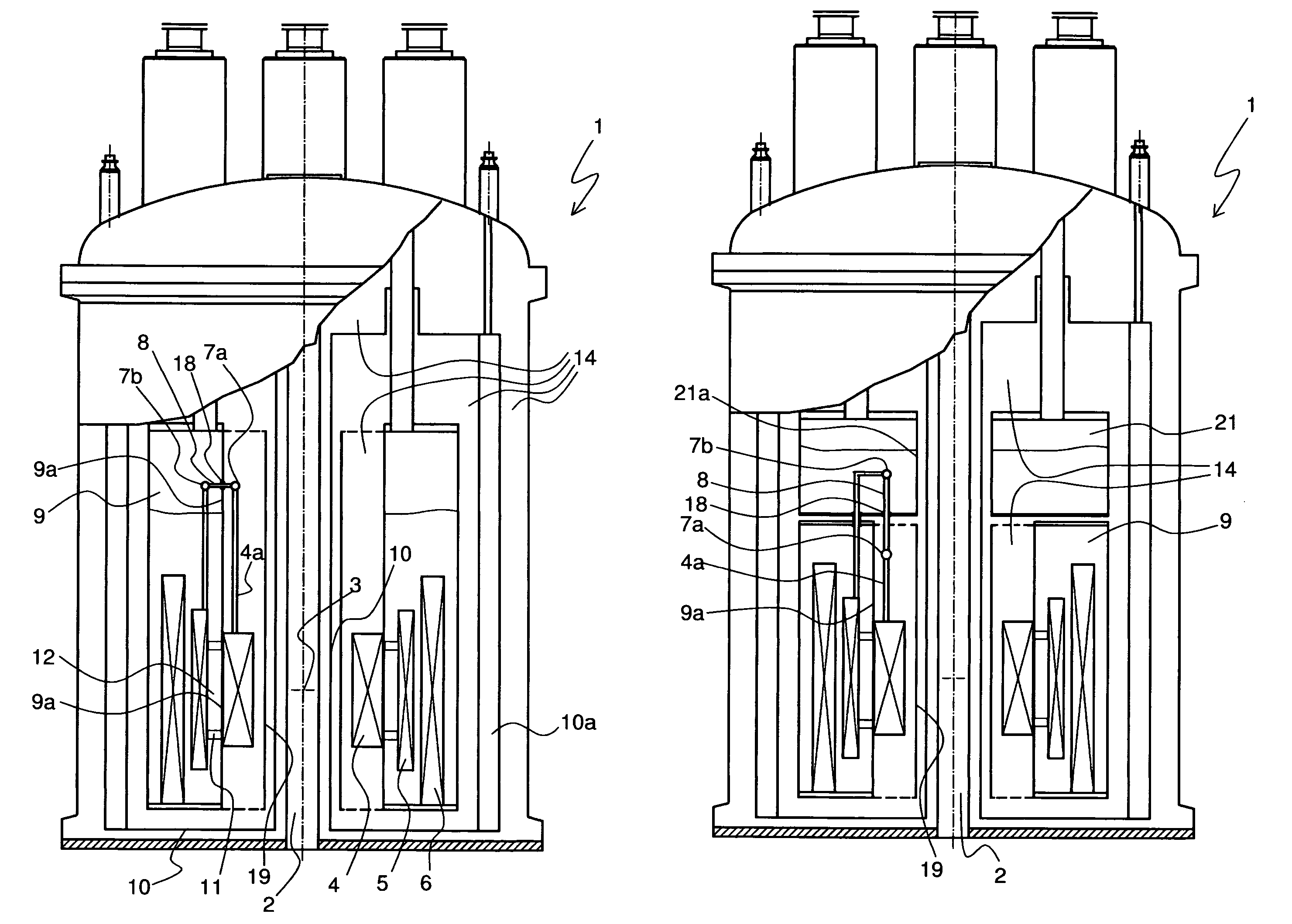

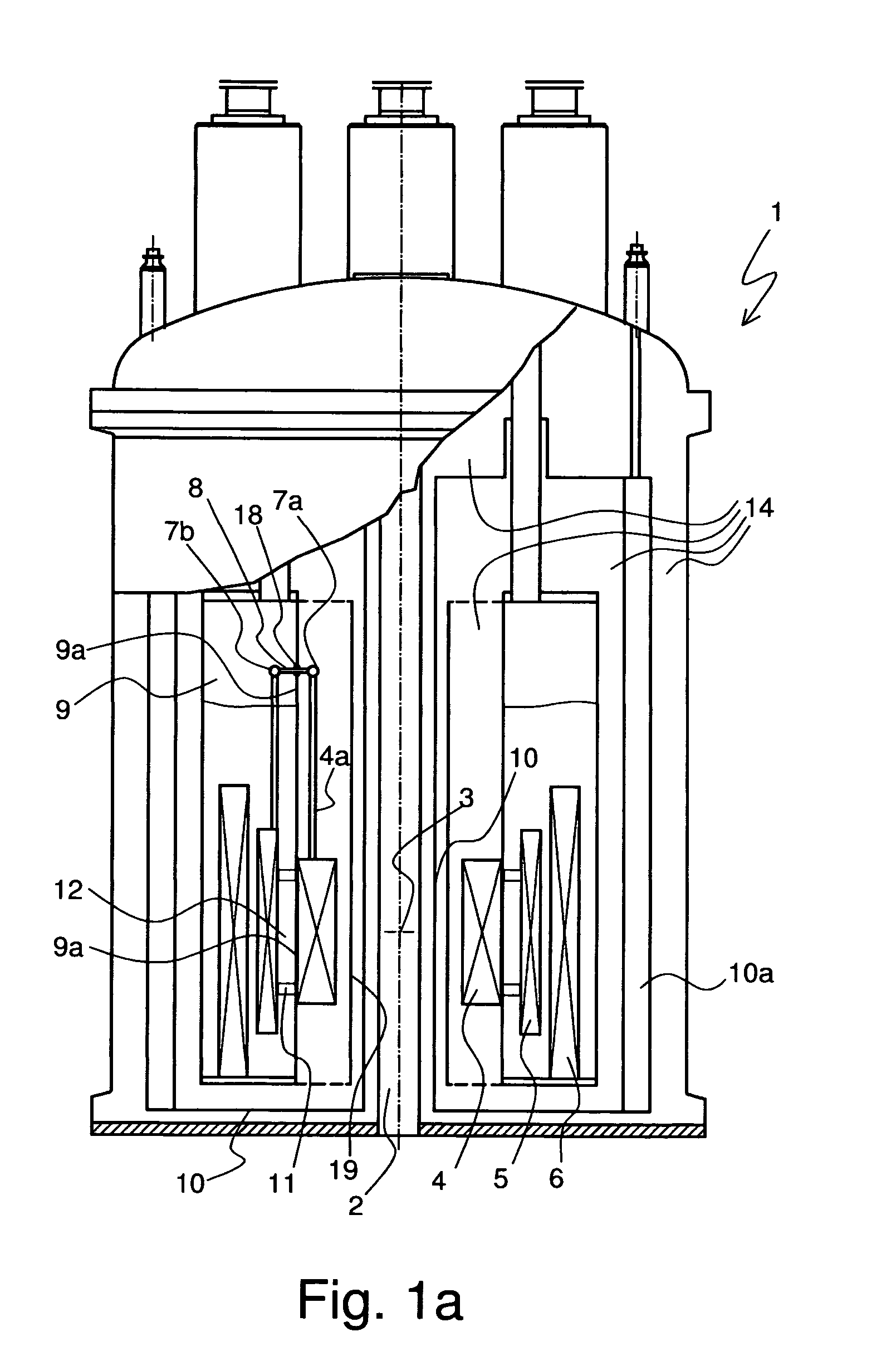

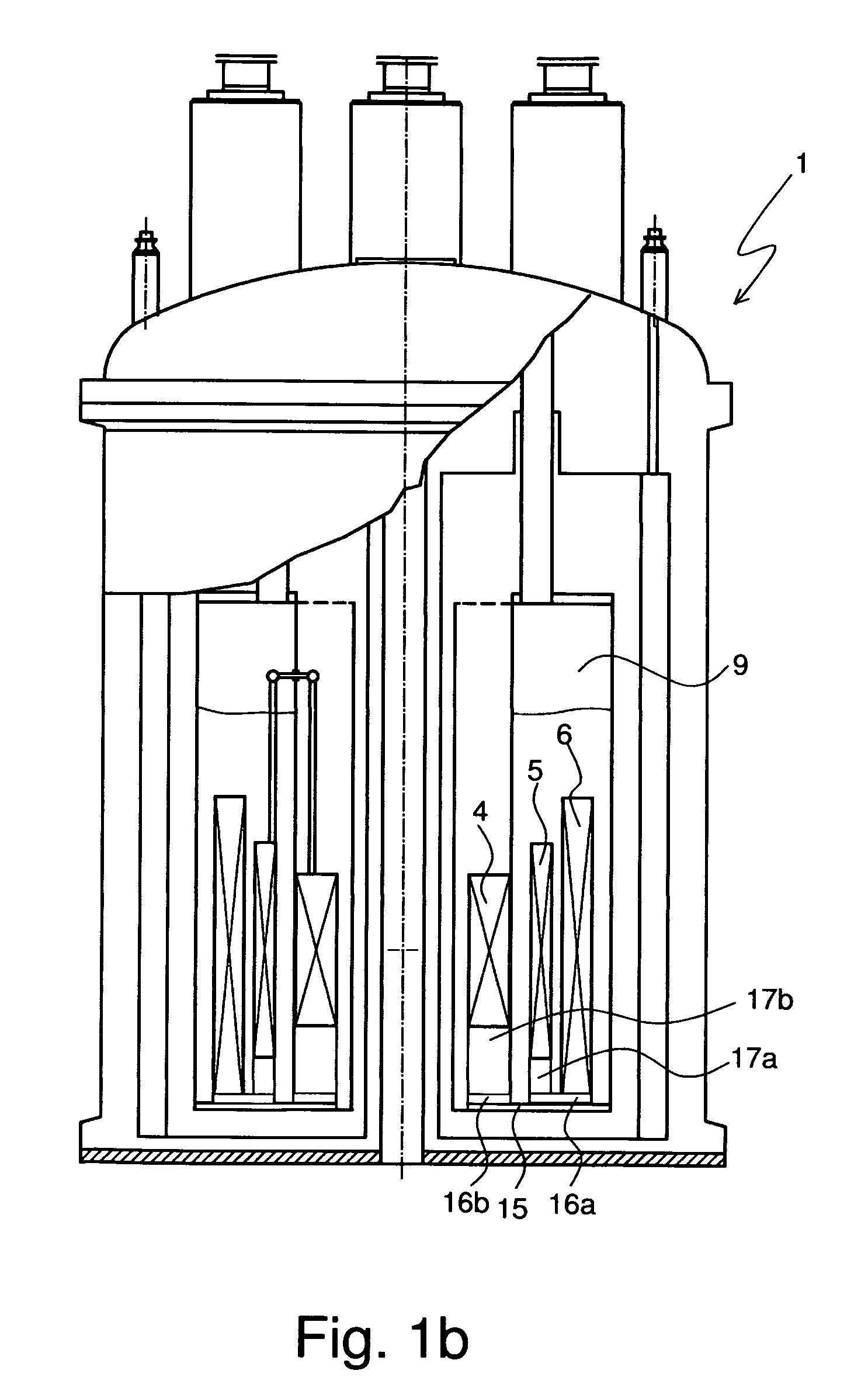

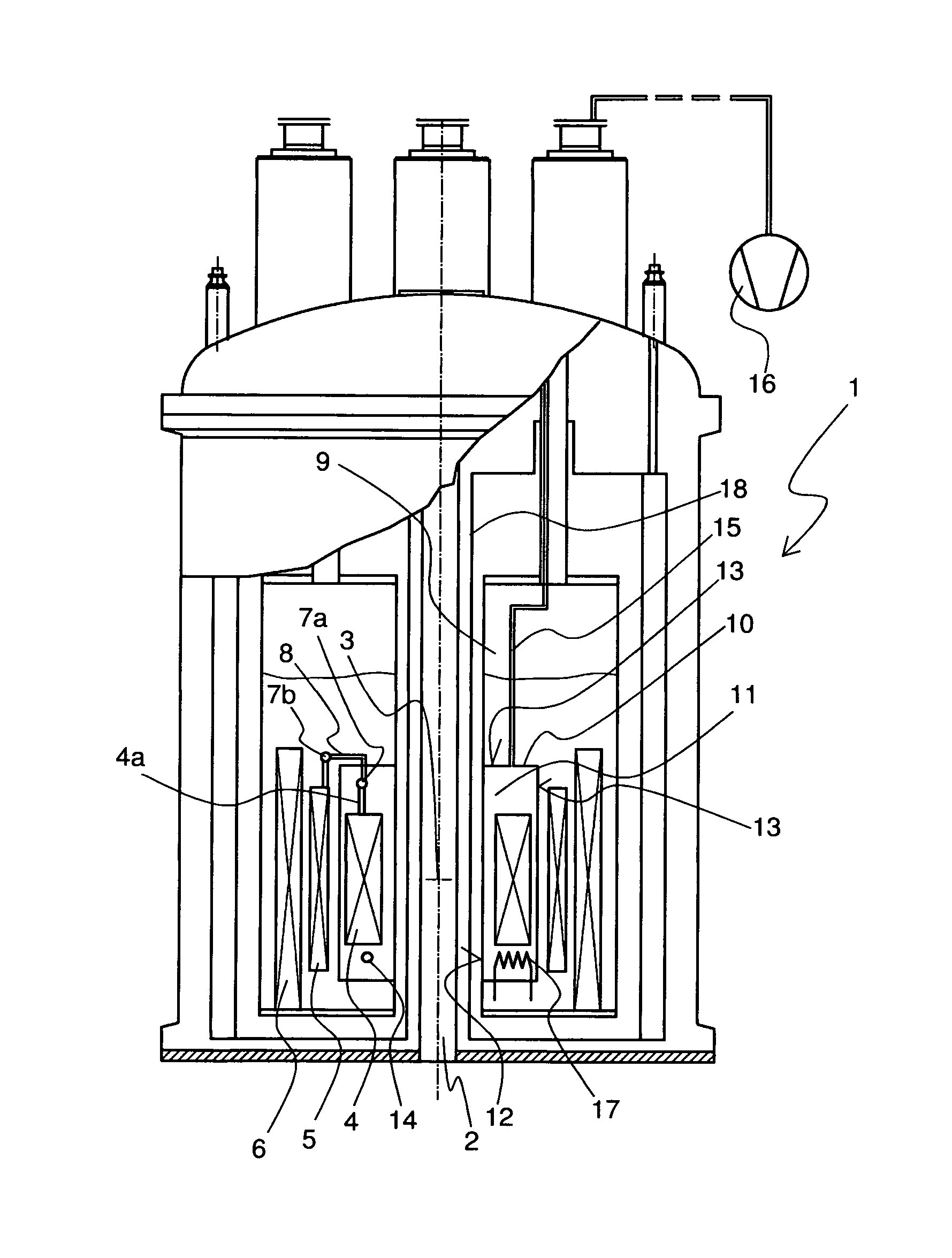

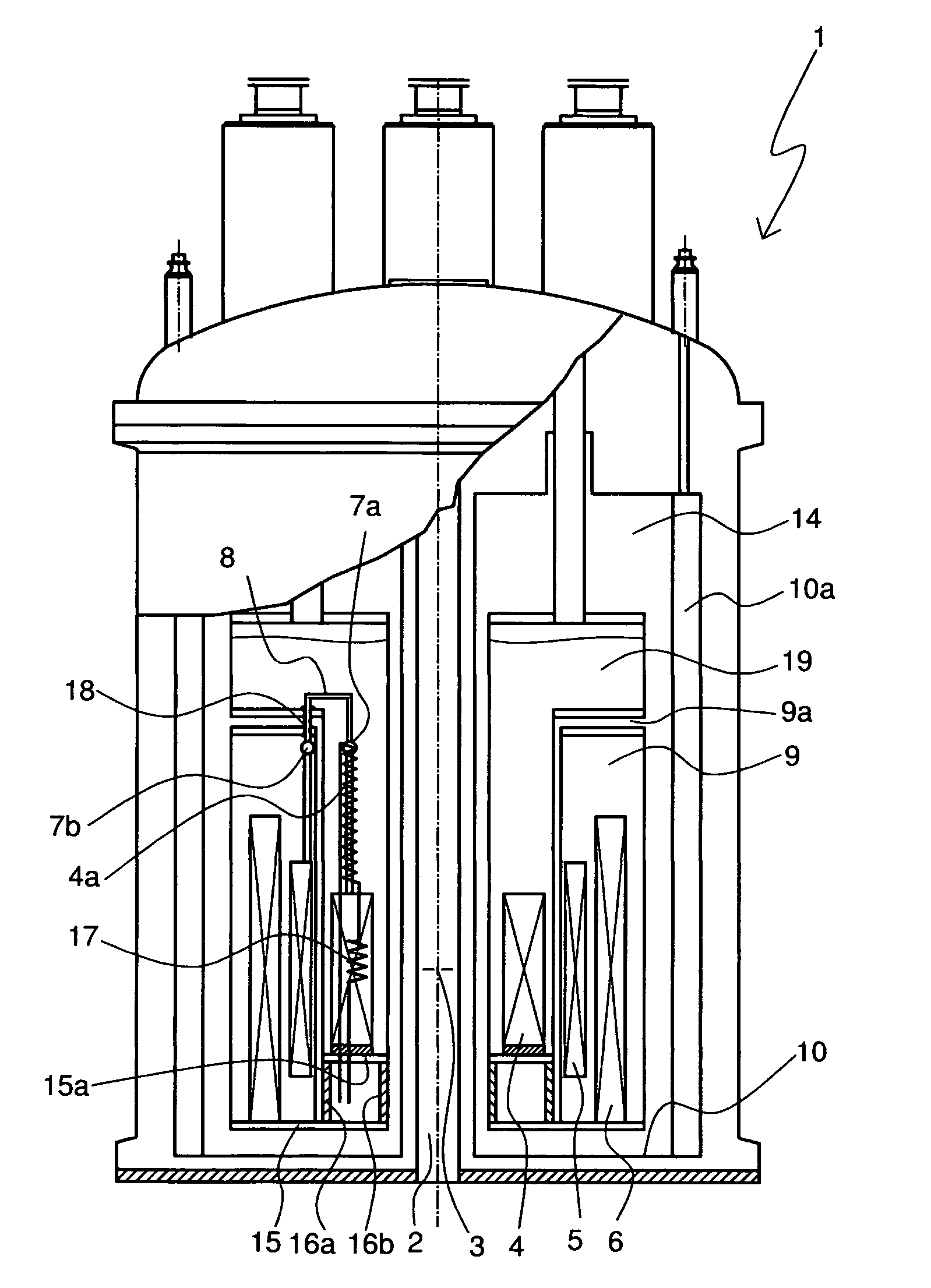

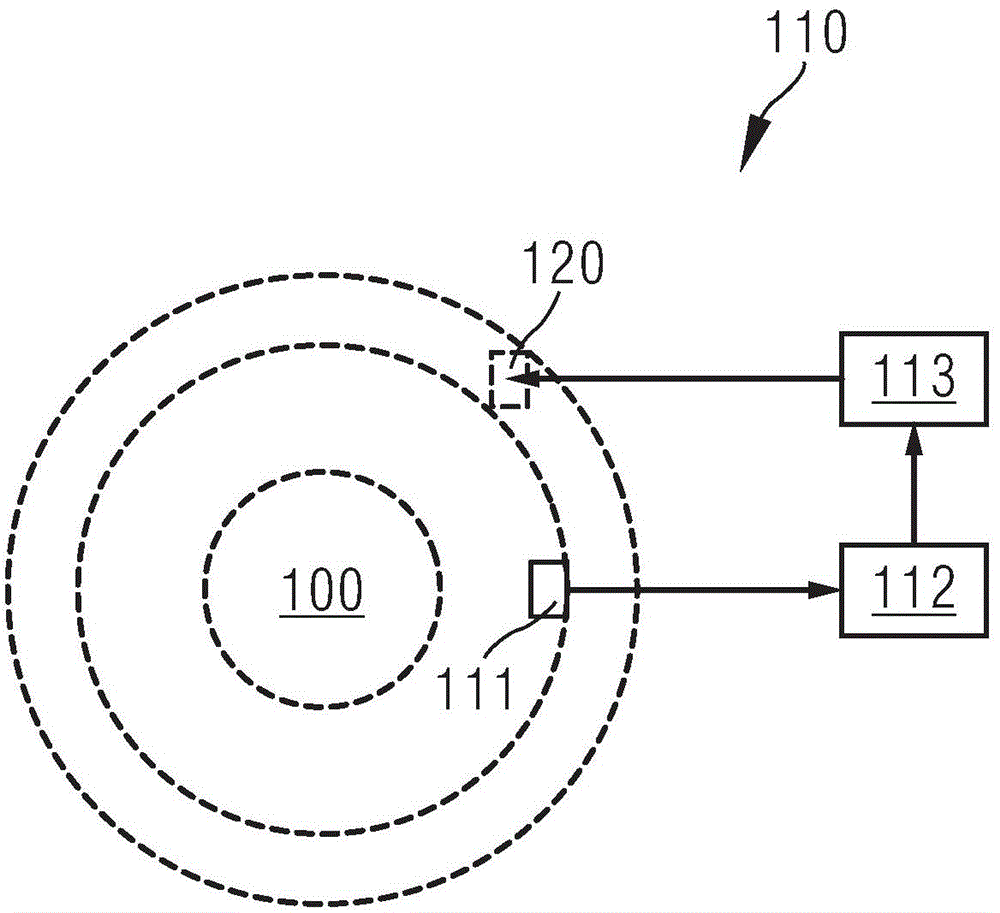

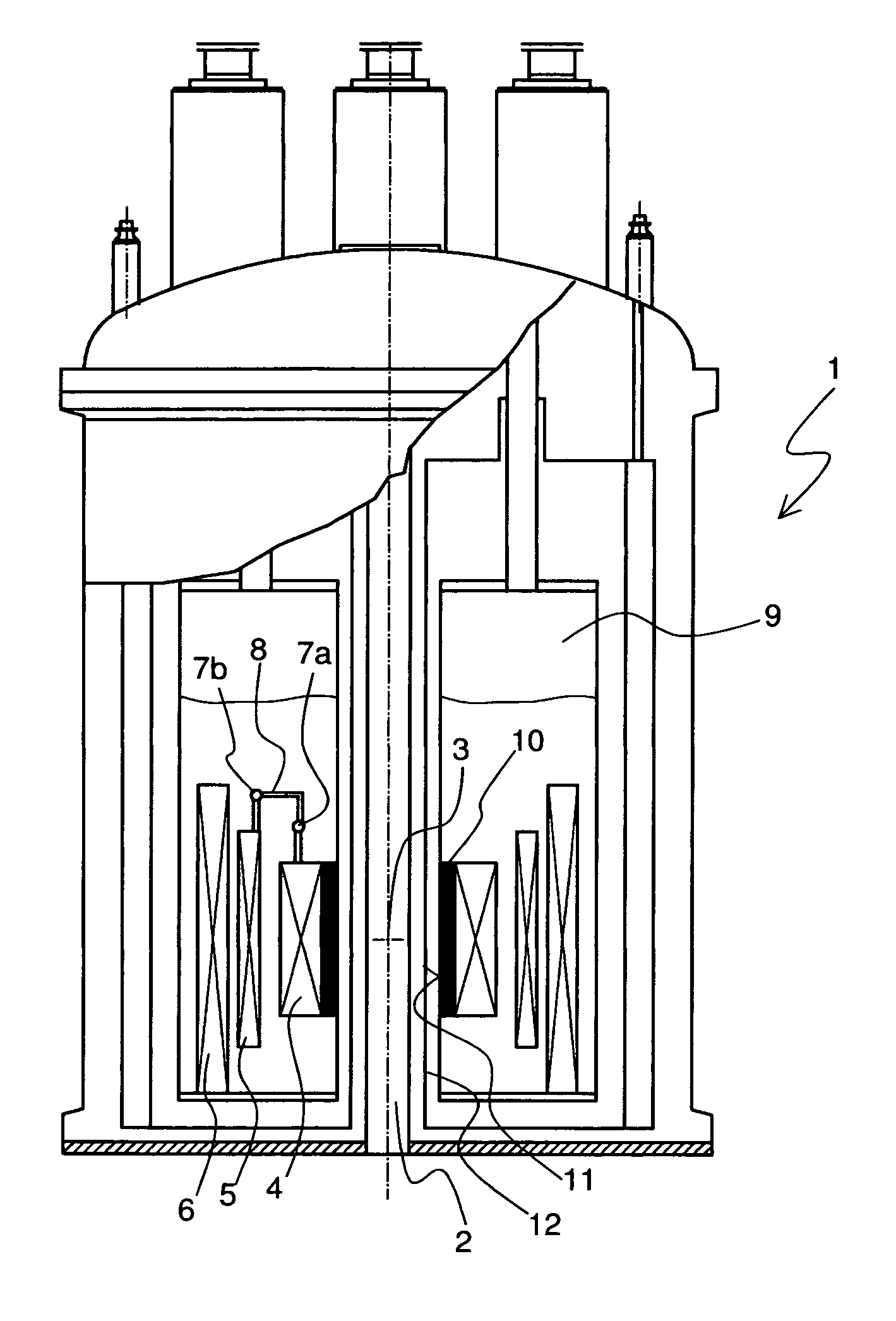

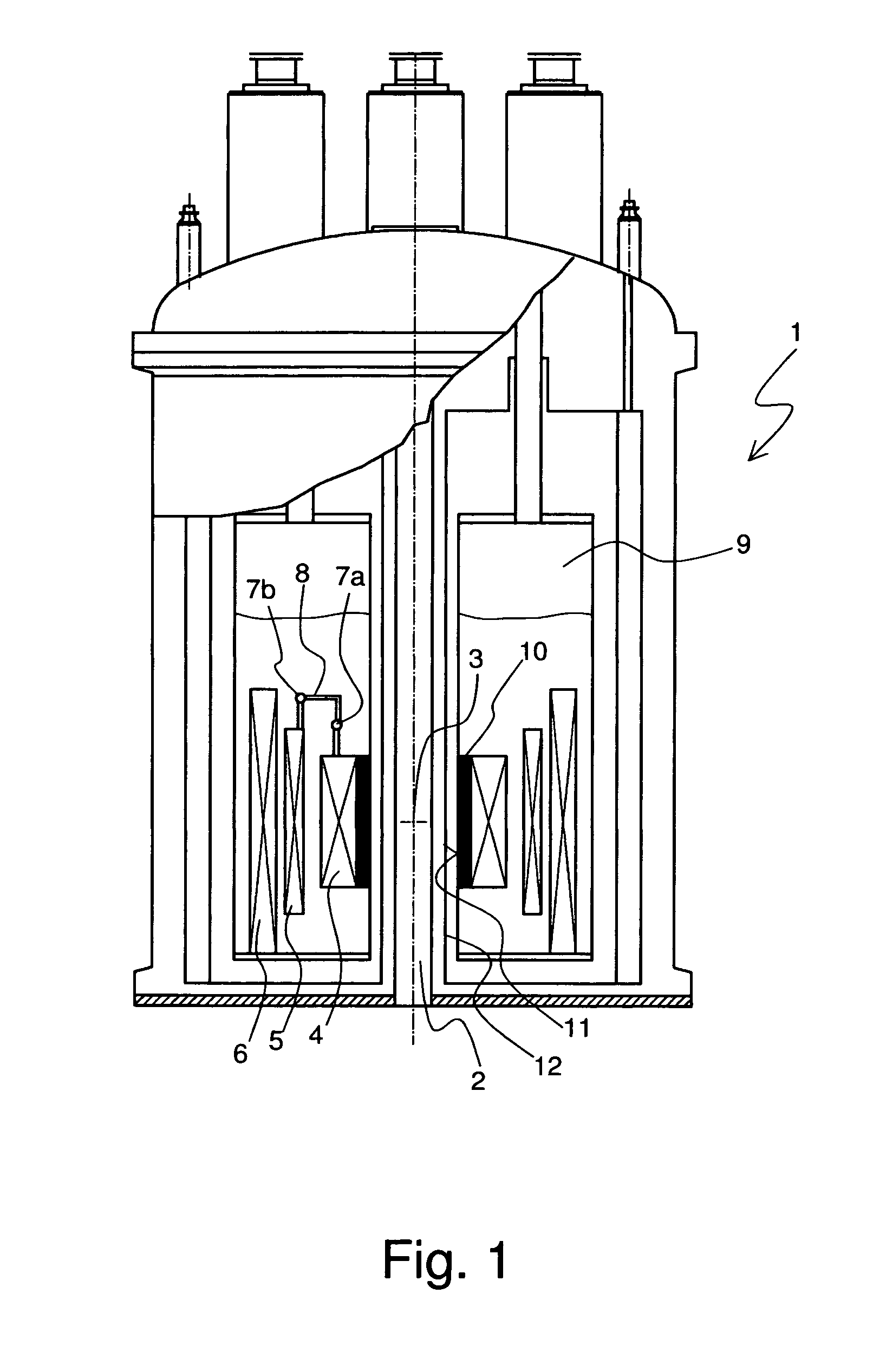

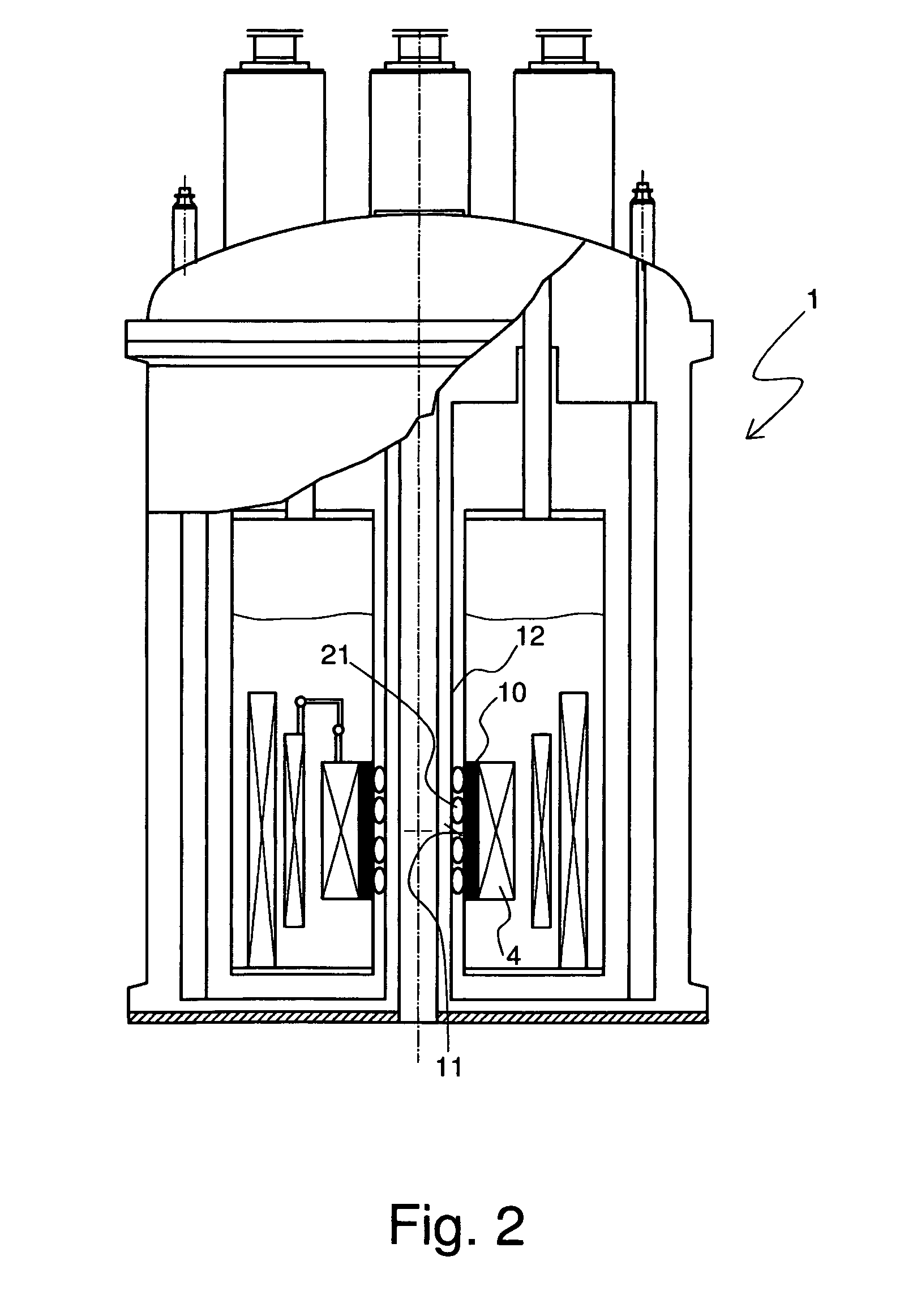

Cryostat having a magnet coil system, which comprises an LTS section and an HTS section, which is arranged in the vacuum part

InactiveUS7982566B2InhibitionPrevent evaporationMagnetic measurementsMagnetsHigh-temperature superconductivityRoom temperature

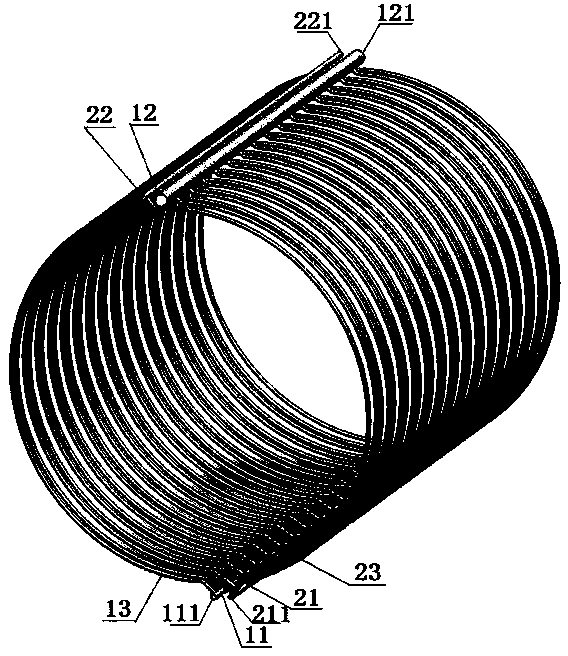

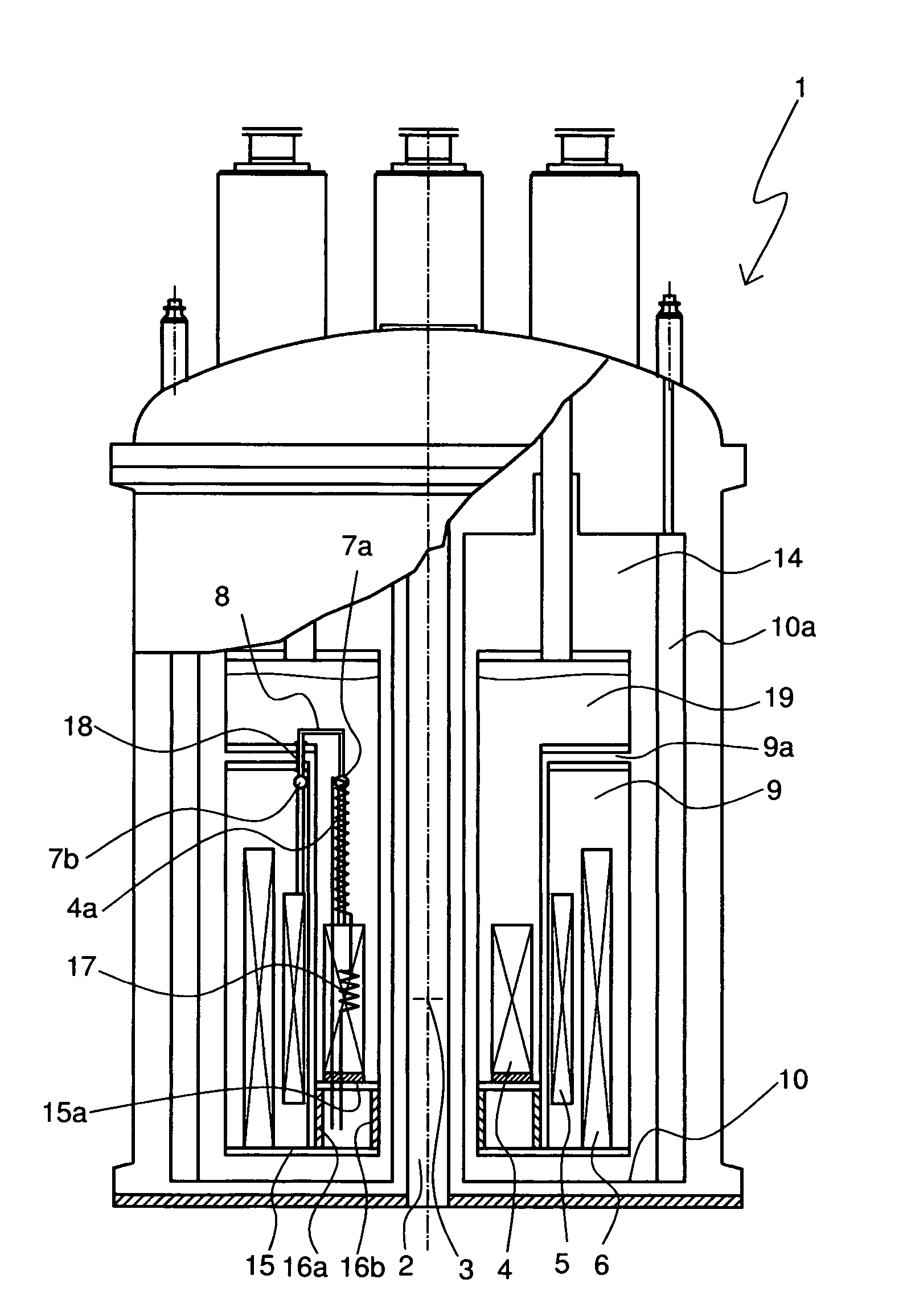

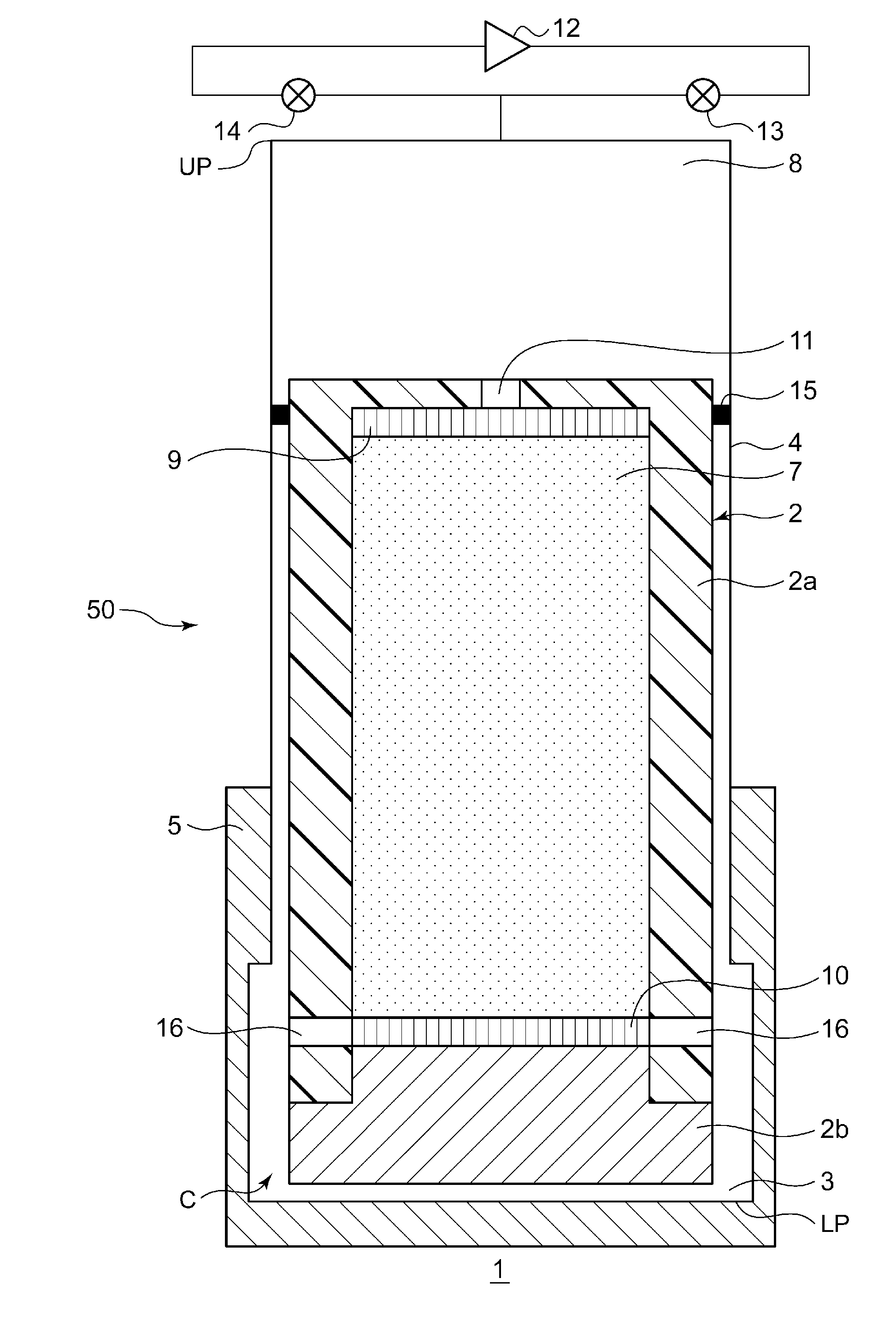

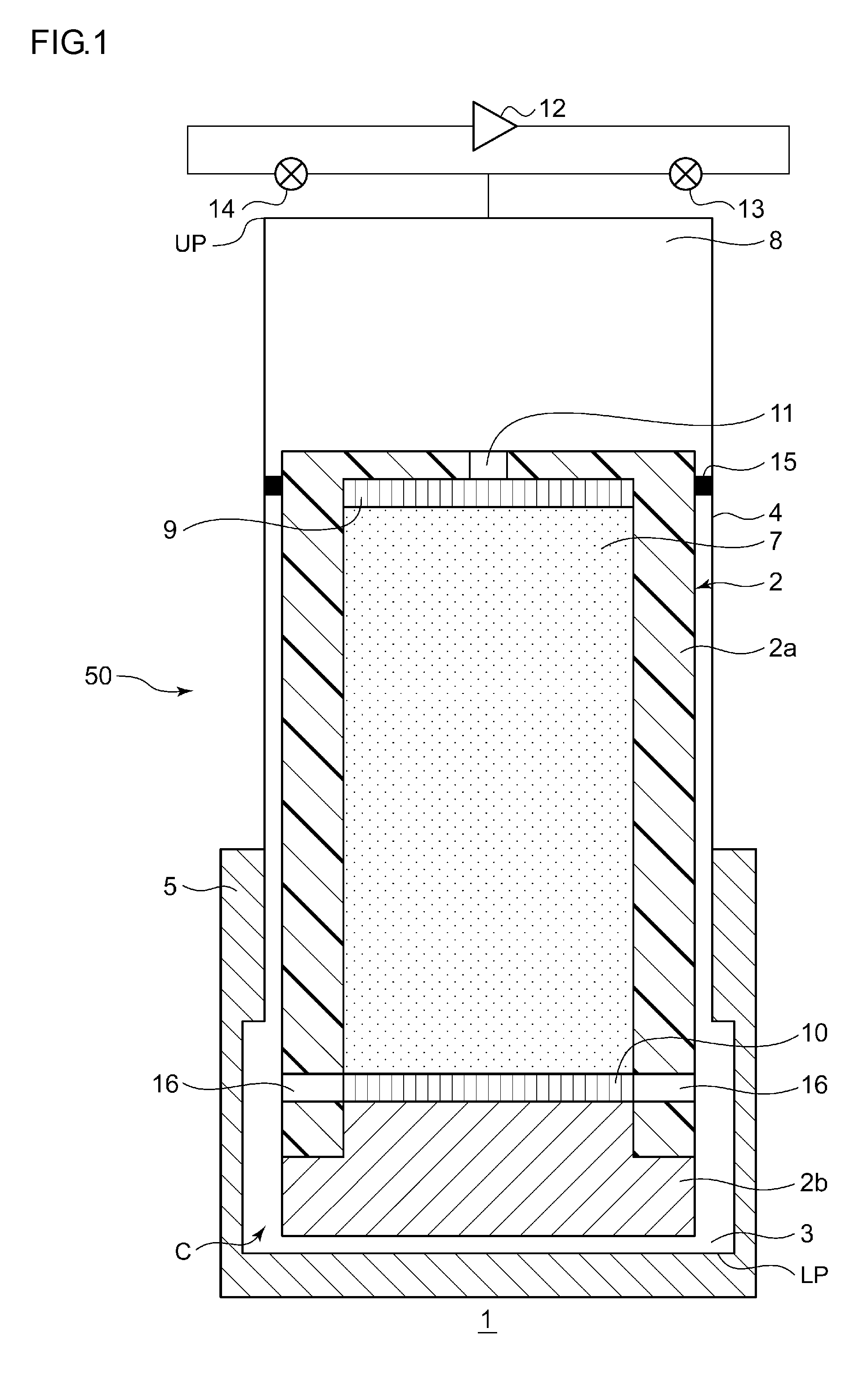

A cryostat (1) with a magnet coil system including superconductors for the production of a magnet field B0 in a measuring volume (3) within a room temperature bore (2) of the cryostat has a plurality of radially nested solenoid-shaped coil sections (4, 5, 6) which surround the room temperature bore and which are electrically connected in series, at least one of which being an LTS section (5, 6) with a conventional low temperature superconductor (LTS) and at least one of which being an HTS section (4) including a high temperature superconductor (HTS), wherein the LTS section (5, 6) is located in a helium tank (9) of the cryostat (1) along with liquid helium at a helium temperature TL. The apparatus is characterized in that the HTS section (4) is disposed radially within the LTS section (5, 6) in a vacuum portion of the cryostat and is separated from the LTS section (5, 6) by the helium tank (9) wall (9a) facing the room temperature bore. The HTS coil section can be reliably used in the cryostat over a long period of time (FIG. 1a).

Owner:BRUKER BIOSPIN

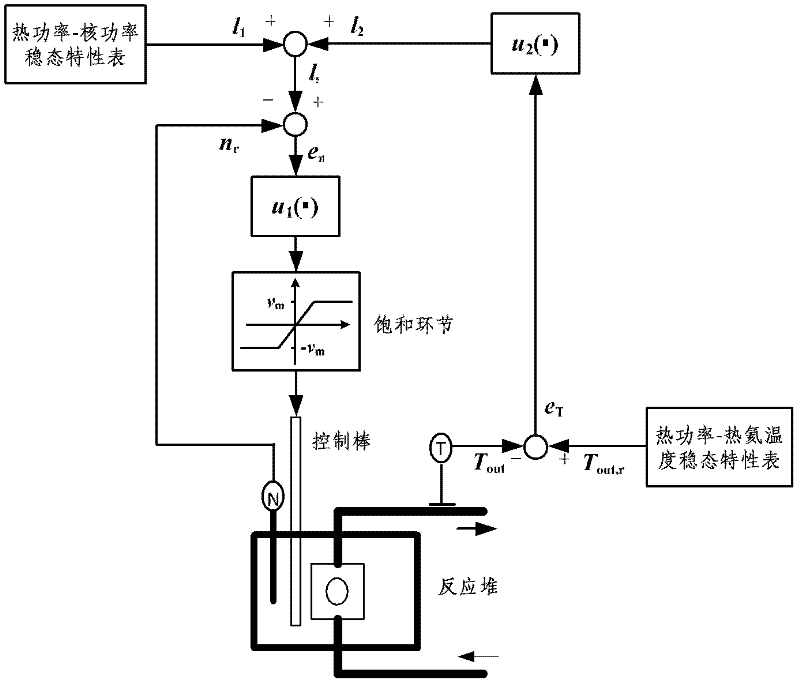

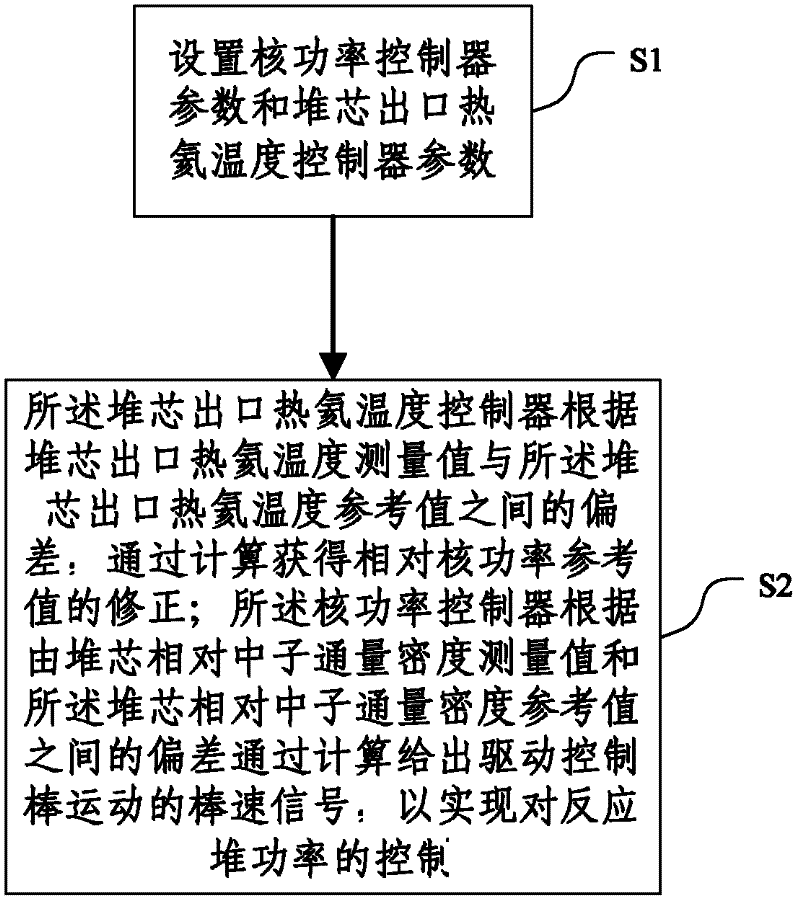

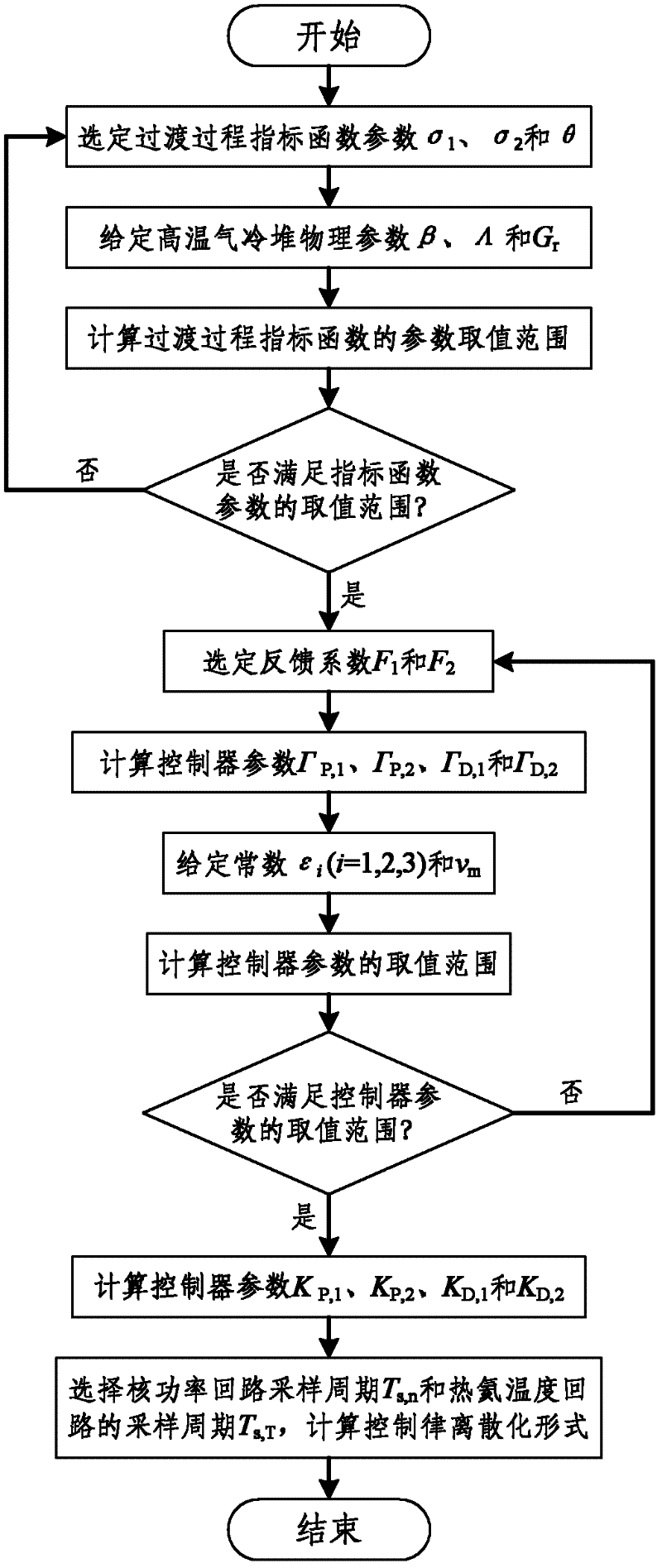

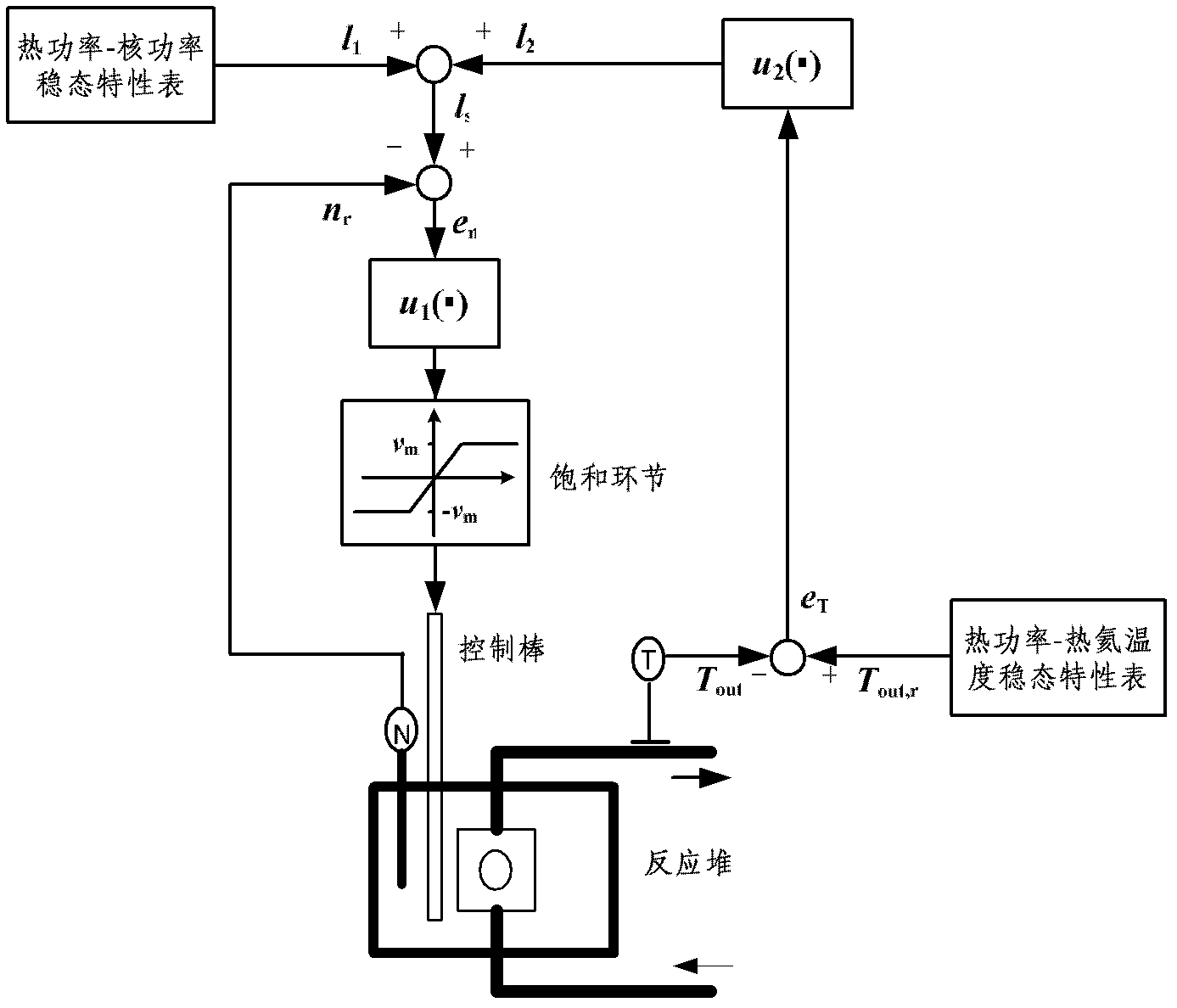

Control method and system of high temperature gas cooled reactor power

ActiveCN102411997AControl thermal powerNuclear energy generationNuclear monitoringNuclear powerNuclear engineering

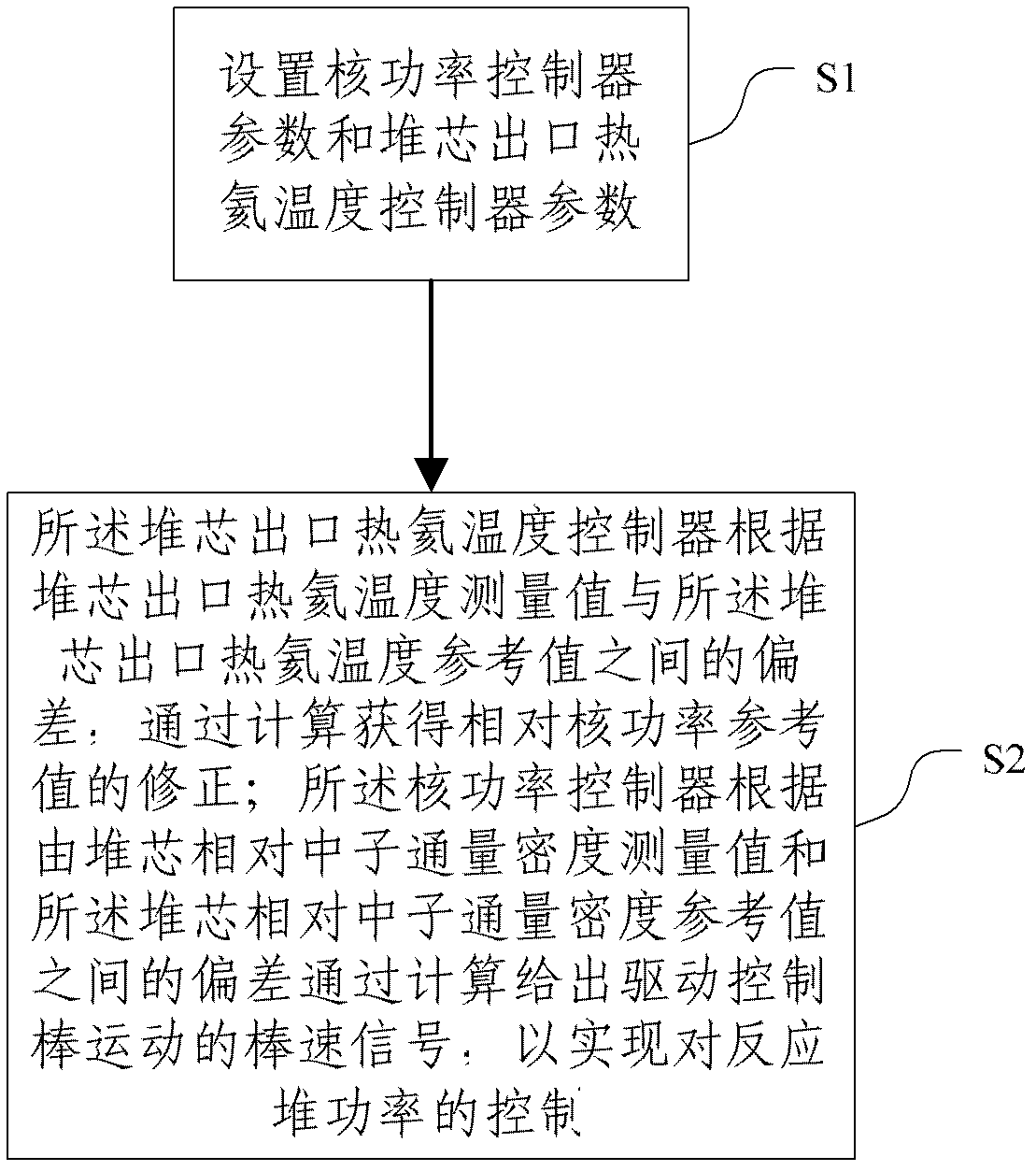

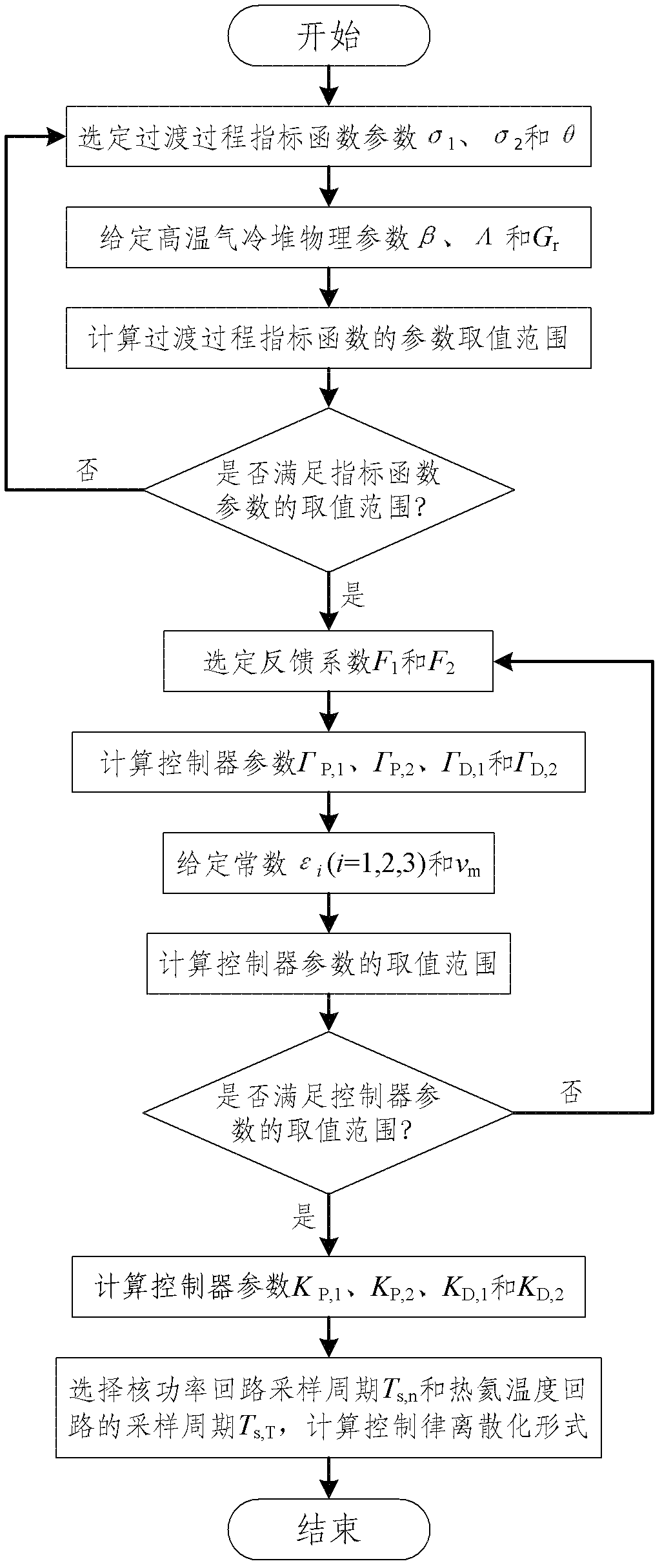

The invention discloses a control method and system of high temperature gas cooled reactor power, relating to the technical field of nuclear energy science and engineering, wherein the method includes the steps as follows: S1, setting a nuclear power controller parameter and a reactor core outlet hot helium temperature controller parameter; S2, the reactor core outlet hot helium temperature controller calculating the deviation between the reactor core outlet hot helium temperature measuring value and the core outlet hot helium temperature reference value to obtain the modification of the relative nuclear power reference value; the nuclear power controller calculating the deviation between the reactor core relative neutron flux density measuring value and the relative neutron flux density reference value and obtaining a rod speed signal that drives the control rod to move. The invention real-time obtains and calculates the core outlet hot helium temperature measuring value and the reactor core relative neutron flux density measuring value of the high temperature gas cooled reactor, obtains the rod speed signal for driving the control rod and controls the high temperature gas cooled reactor power.

Owner:CHINERGY CO LTD

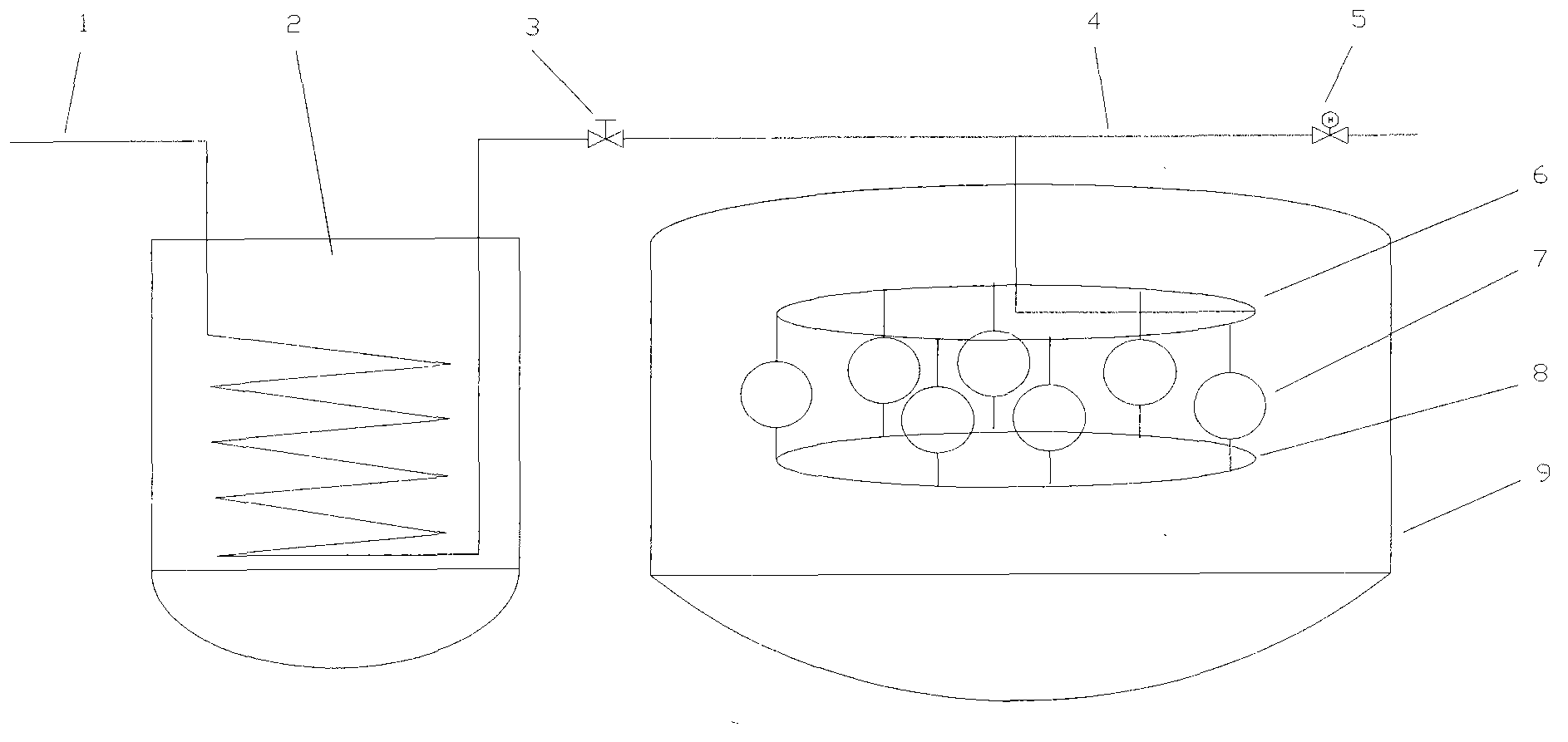

Liquid nitrogen and cold helium double media coupling heat sink for space environment simulation

ActiveCN103388948AEasy to operateGood low temperatureHeating or cooling apparatusGas-turbine engine testingCold airElectricity

The invention discloses a liquid nitrogen and cold helium double media coupling heat sink for space environment simulation. The heat sink is a sealed cylinder which comprises a liquid nitrogen cooling pipe network, a cold air helium cooling pipe network, copper fins and electric heaters, wherein the copper fins are connected with the liquid nitrogen cooling pipe network and the cold air helium cooling pipe network and forms a barrel of the liquid nitrogen and cold helium double media coupling heat sink with the liquid nitrogen cooling pipe network and the cold air helium cooling pipe network. The electric heaters are uniformly distributed on the copper fins. According to the heat sink disclosed by the invention, the liquid nitrogen cooling pipe network and the cold air helium cooling pipe network are embedded and coupled, so that refrigerating media liquid nitrogen and cold helium work independently to switch in function smoothly, thereby, realizing transition from a liquid nitrogen temperature area to a low temperature gas helium temperature area. In addition, according to design of two parallel and staggered medium pipelines with two runners, conditions of complex flow, reduced safety, discontinuous transition of the temperature area and waste of cooling capacity caused by emptying switch of a single runner can be avoided. The heat sink disclosed by the invention is simple in operational flow and safe and reliable.

Owner:SHANGHAI JIAO TONG UNIV +1

Liquid helium and superflow helium temperature zone insulating material high-voltage electric appliance performance test platform

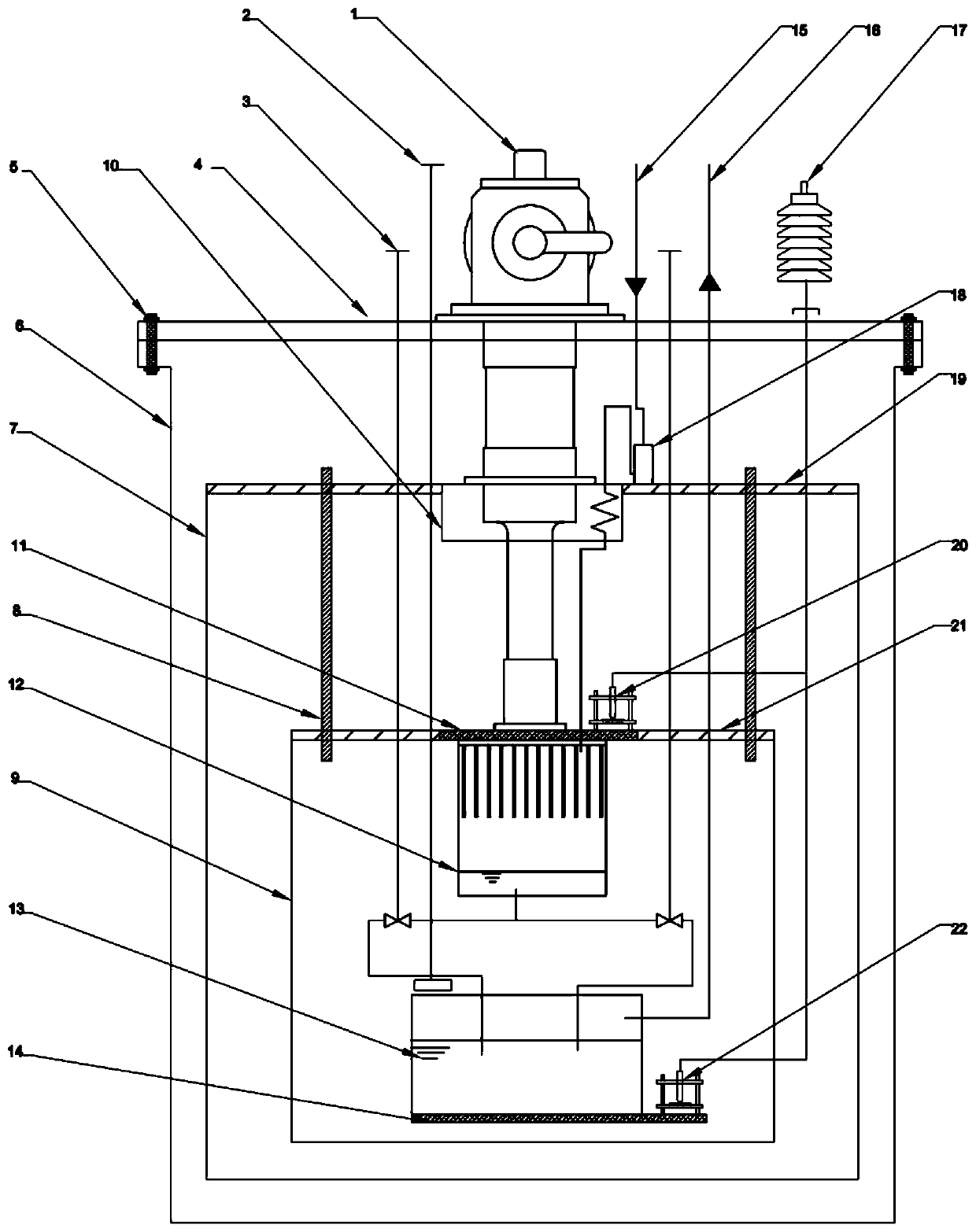

PendingCN111257411AGuaranteed vacuumReduce consumptionMaterial breakdown voltageTesting dielectric strengthEngineeringTest chamber

The invention provides a liquid helium and superflow helium temperature zone insulating material high-voltage electrical performance test experiment platform. The platform comprises a vacuum chamber,a first-stage test chamber and a second-stage test chamber which are nested layer by layer from outside to inside. A refrigerator is used for providing cold energy for a liquid helium temperature zonetest platform in the first-stage test chamber, so that the test requirement of the insulating material under the 4.2 K temperature zone use condition can be met; and the second-stage test chamber isin contact with a liquid helium temperature zone test platform, helium is introduced, and the cooling capacity is provided for the liquid helium temperature zone test platform by adopting the refrigerator, helium introduced into the helium condensation cavity is liquefied under the action of the refrigerator; liquefied helium is converted into superfluid helium through a throttle valve and an airexhaust pressure reduction pipeline, and the superfluid helium is output into the superfluid helium cavity to provide cold energy for a superfluid helium zone test platform in the secondary test chamber, so that the test requirement of the insulating material under the 1.8 K temperature area use condition can be met.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

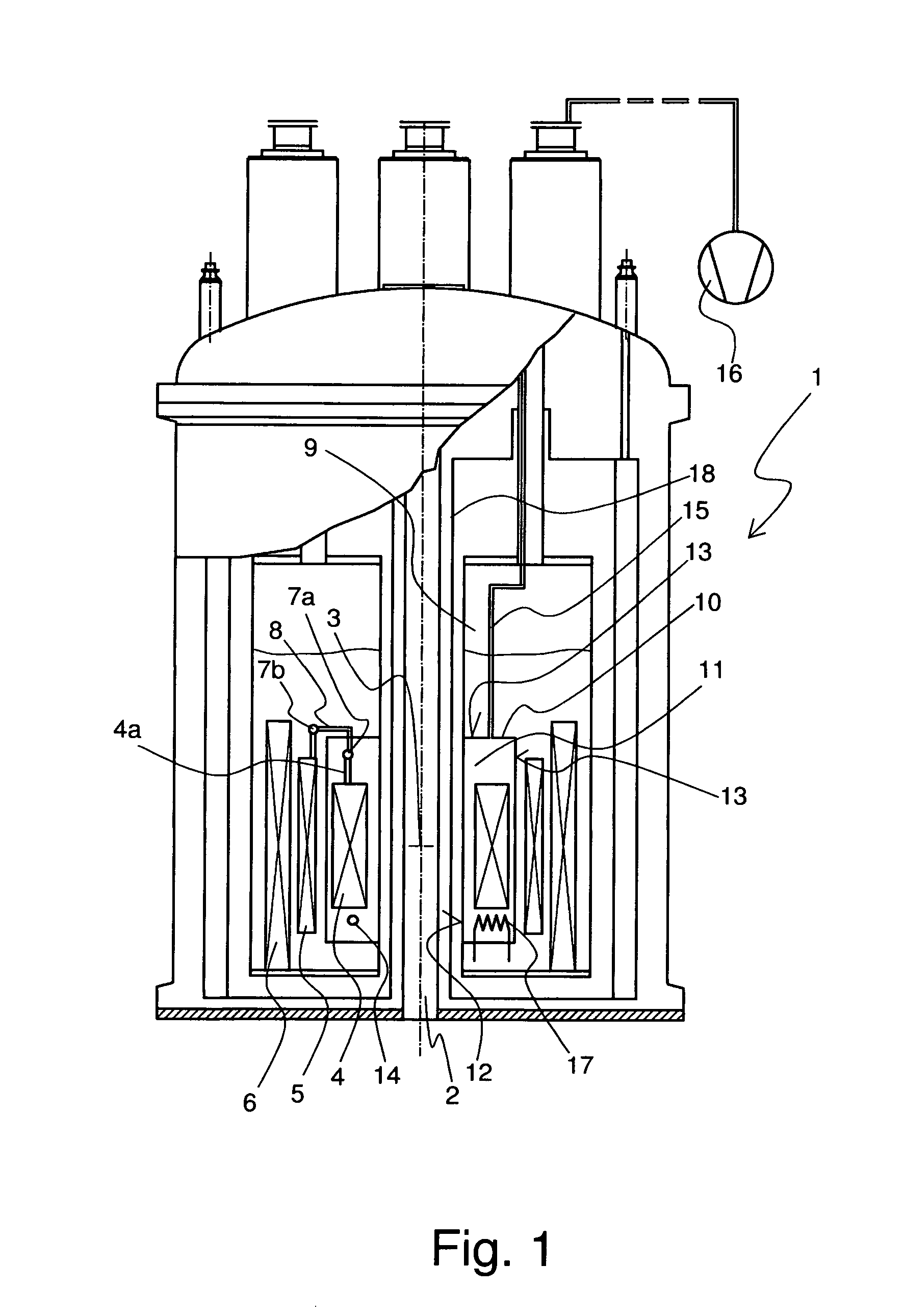

Cryostat having a magnet coil system, which comprises an LTS section and an encapsulated HTS section

ActiveUS8255023B2InhibitionSmall amountSuperconductors/hyperconductorsMagnetic measurementsHigh-temperature superconductivityMagnet coil

A cryostat (1) with a magnet coil system including superconductors for the production of a magnet field B0 in a measuring volume (3) has a plurality of radially nested solenoid-shaped coil sections (4, 5, 6) and which are electrically connected in series, at least one of which being an LTS section (5, 6) with a conventional low temperature superconductor (LTS) and at least one of which being an HTS section (4) including a high temperature superconductor (HTS), wherein the magnet coil system is located in a helium tank (9) of the cryostat (1) along with liquid helium at a helium temperature TL. The apparatus is characterized in that a chamber (11) is provided within which the HTS sections (4) are held having an internal portion with a sufficiently low pressure such that helium located therein at a temperature of TL is gaseous. The cryostat in accordance with the invention can be utilized to maintain HTS coil sections over a long period of time in a reliable fashion.

Owner:BRUKER BIOSPIN +1

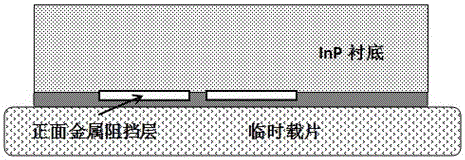

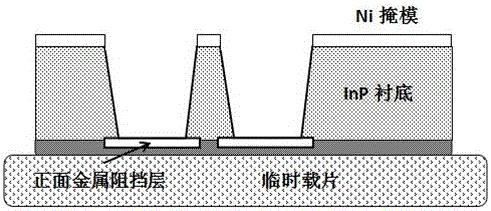

Method for producing indium phosphide back hole

ActiveCN106684061AGood effectSimple processSemiconductor/solid-state device detailsSolid-state devicesEngineeringThinning

The invention provides a method for producing an indium phosphide back hole. The method comprises the following steps: step (1), producing a metal barrier layer at a position of the front of a indium phosphide wafer where the back hole needs to be configured, and finishing a front process; step (2), bonding the front of the wafer to a temporary slide sapphire, and thinning and polishing the back of the wafer; step (3), photoetching a back hole figure at the back of the wafer, ensuring that the back hole position is consistent with the front metal barrier layer, and forming an etching mask; step (4), rising the back helium temperature of an STS ICP dry etching machine to 190 DEG C, using the combined gas of chlorine (C12) and argon Ar to perform dry etching, until etching to the front metal barrier layer; step (5), removing the etching mask; and step (6), sputtering a seed layer at the back, electroplating a back gold and filling the back hole, and then finishing the back hole production. The method for producing the indium phosphide back hole provided by the invention has the following advantages that the problem of etching an indium phosphide deep hole has been solved; the back hole morphology, the etching repeatability and the coherence are all very good; and meanwhile, the process is simple and can be compatible with the GaAs process, thus the method is suitable for large-scale popularization and application.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

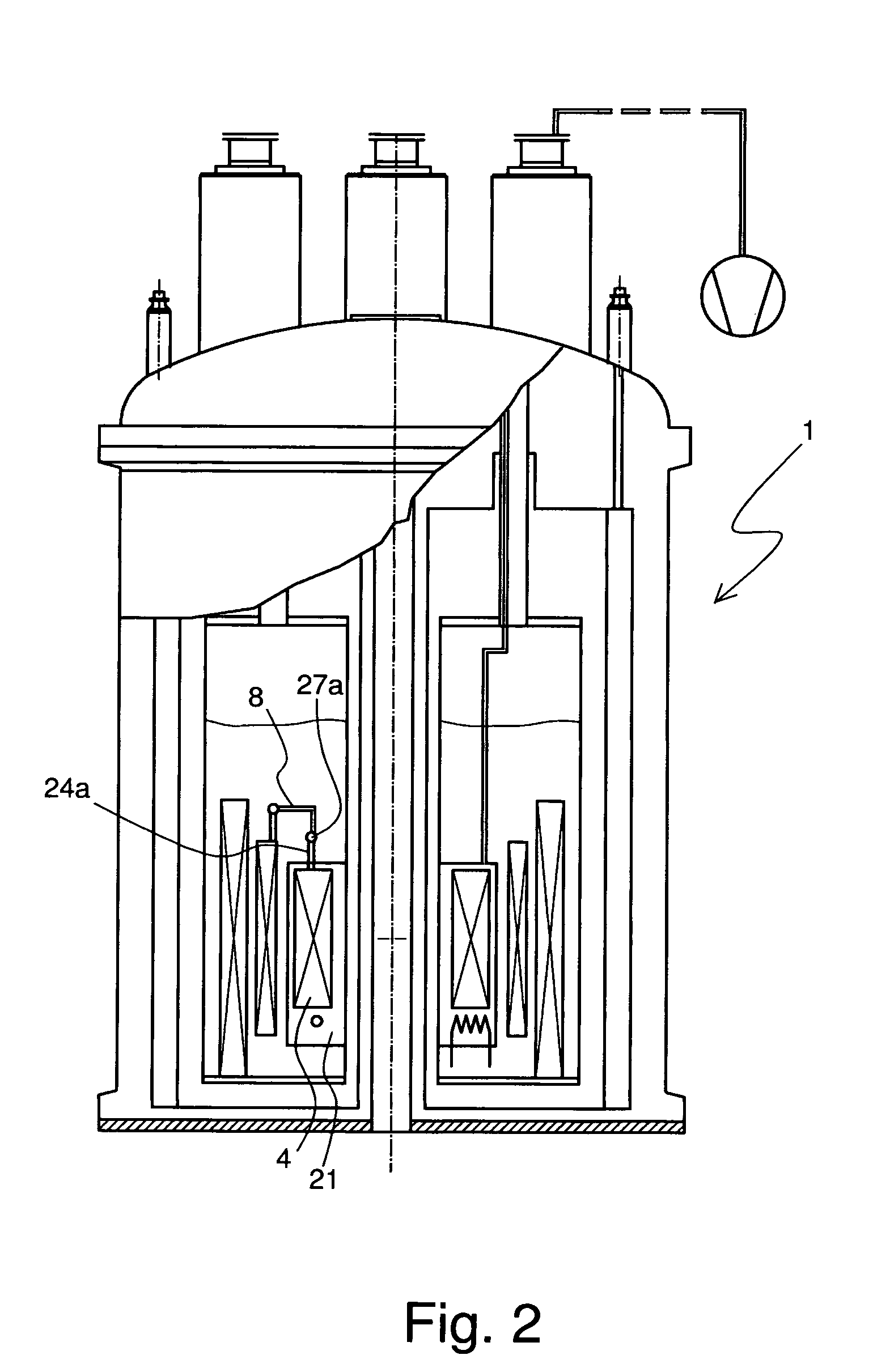

Cryostat having a magnet coil system, which comprises an under-cooled LTS section and an HTS section arranged in a separate helium tank

ActiveUS8255022B2Simple and safe processMagnetsMagnetic field measurement using superconductive devicesHigh-temperature superconductivityMagnet coil

A cryostat (1) with a magnet coil system including superconductors for the production of a magnet field B0 in a measuring volume (3) has a plurality of radially nested solenoid-shaped coil sections (4, 5, 6) which are electrically connected in series, at least one of which being an LTS section (5, 6) with a conventional low temperature superconductor (LTS) and at least one of which being an HTS section (4) including a high temperature superconductor (HTS), wherein the LTS section (5, 6) is located in a first helium tank (9) of the cryostat (1) along with liquid helium at a helium temperature TL<4 K. The apparatus is characterized in that the HTS section (4) is disposed radially within the LTS section (5, 6) in a separate helium tank (19) of the cryostat (1) having normal liquid helium and is separated from the LTS section (5, 6) by means of at least one wall disposed between the two helium tanks. An HTS coil section can be maintained in the cryostat in accordance with the invention over a long period of time and in a reliable fashion.

Owner:BRUKER BIOSPIN +1

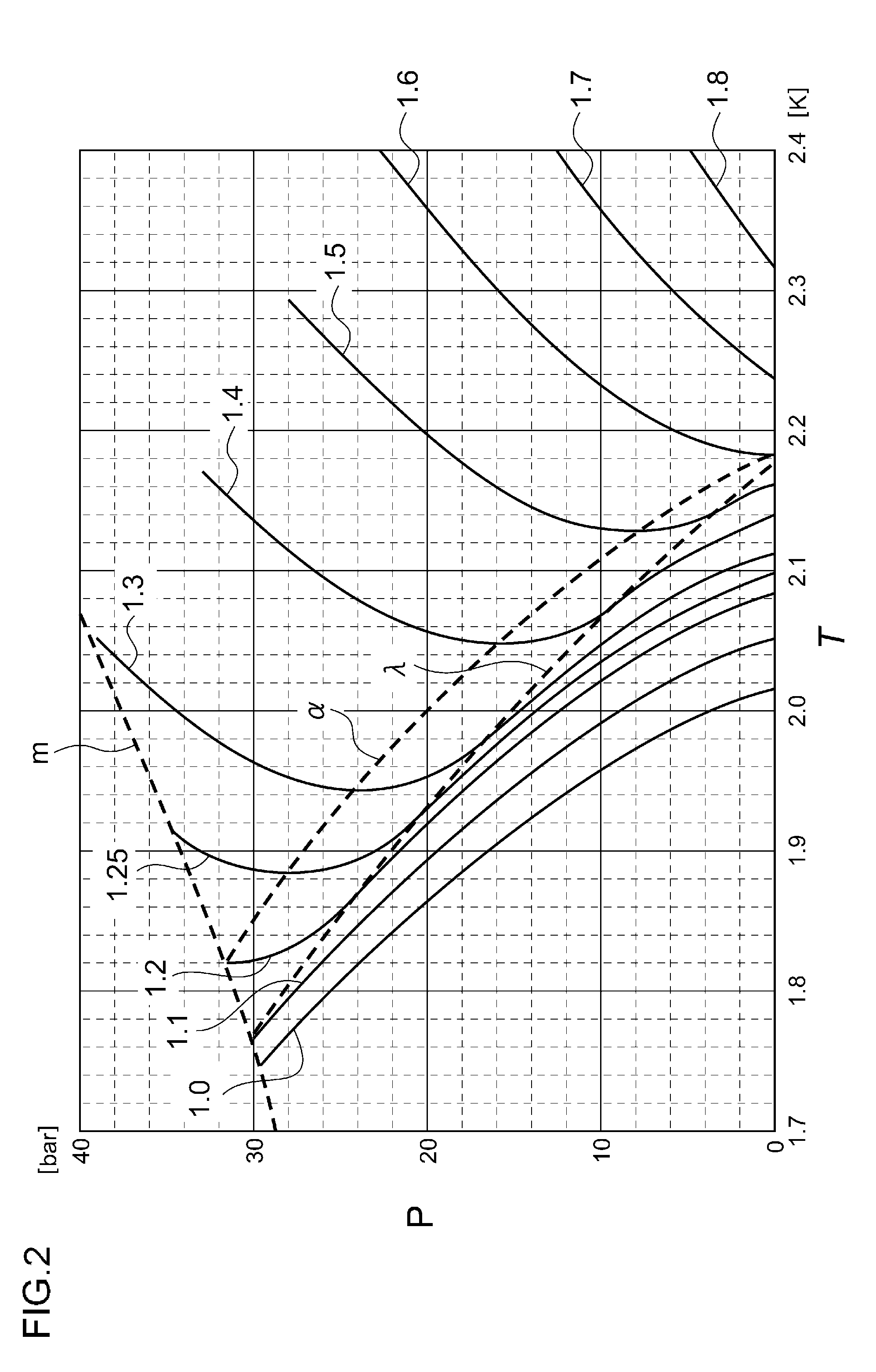

Cryocooler and cryocooler operation method

ActiveUS20160178247A1Reduce the temperatureCompression machinesGas cycle refrigeration machinesHorizontal axisThermal expansion

In a cryocooler for developing coldness of 4 K or lower by expanding helium, an expander expands high-pressure helium. A compressor compresses low-pressure helium returned from the expander, to generate high-pressure helium, and supplies the high-pressure helium to the expander. When helium temperature in the expander is 2.17 K or lower, the pressure of the low-pressure helium is equal to or higher than pressure given by a curve, in a helium state diagram in which the horizontal axis is temperature and the vertical axis is pressure, along which helium's volumetric thermal expansion coefficient is 0.

Owner:SUMITOMO HEAVY IND LTD

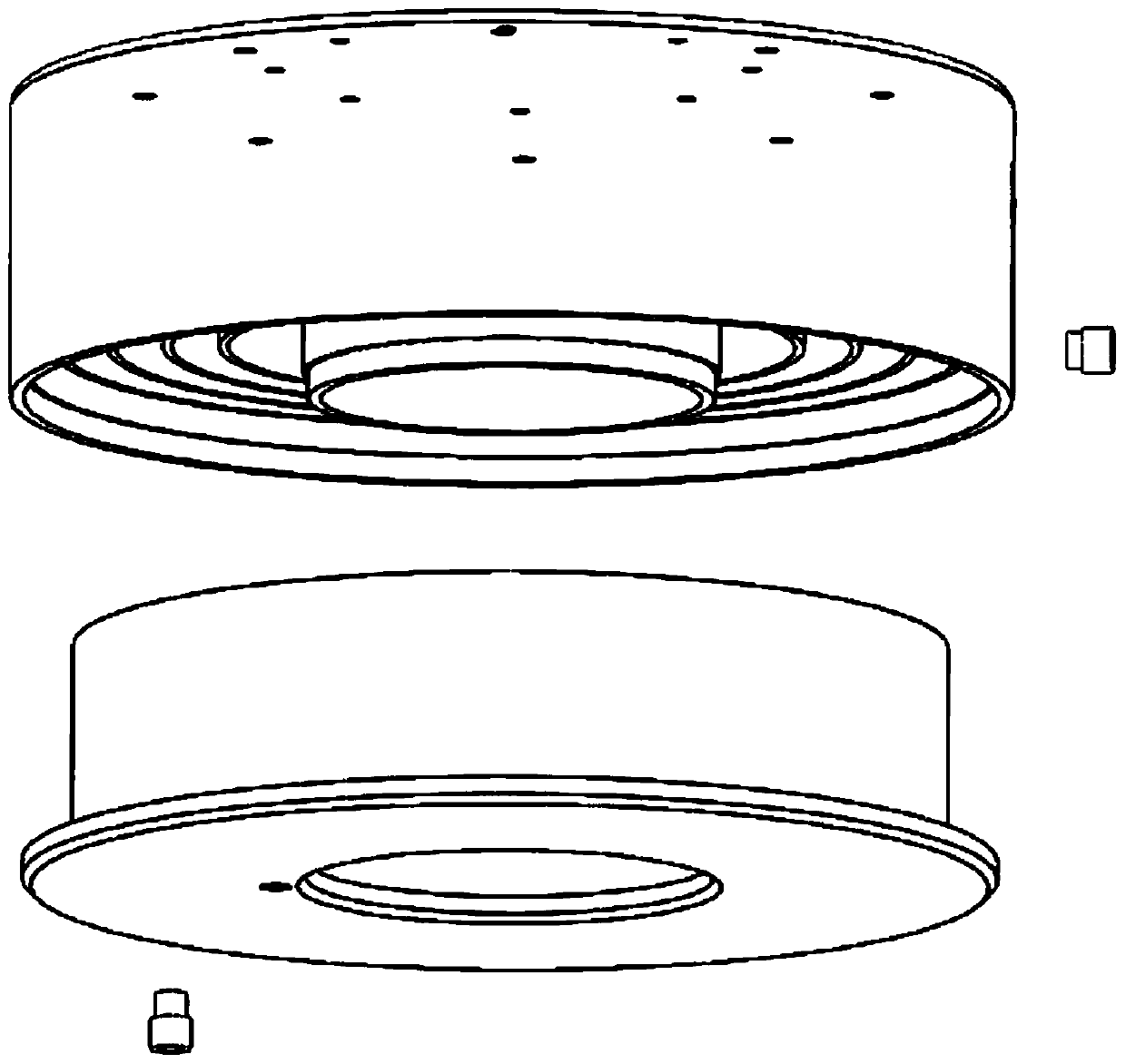

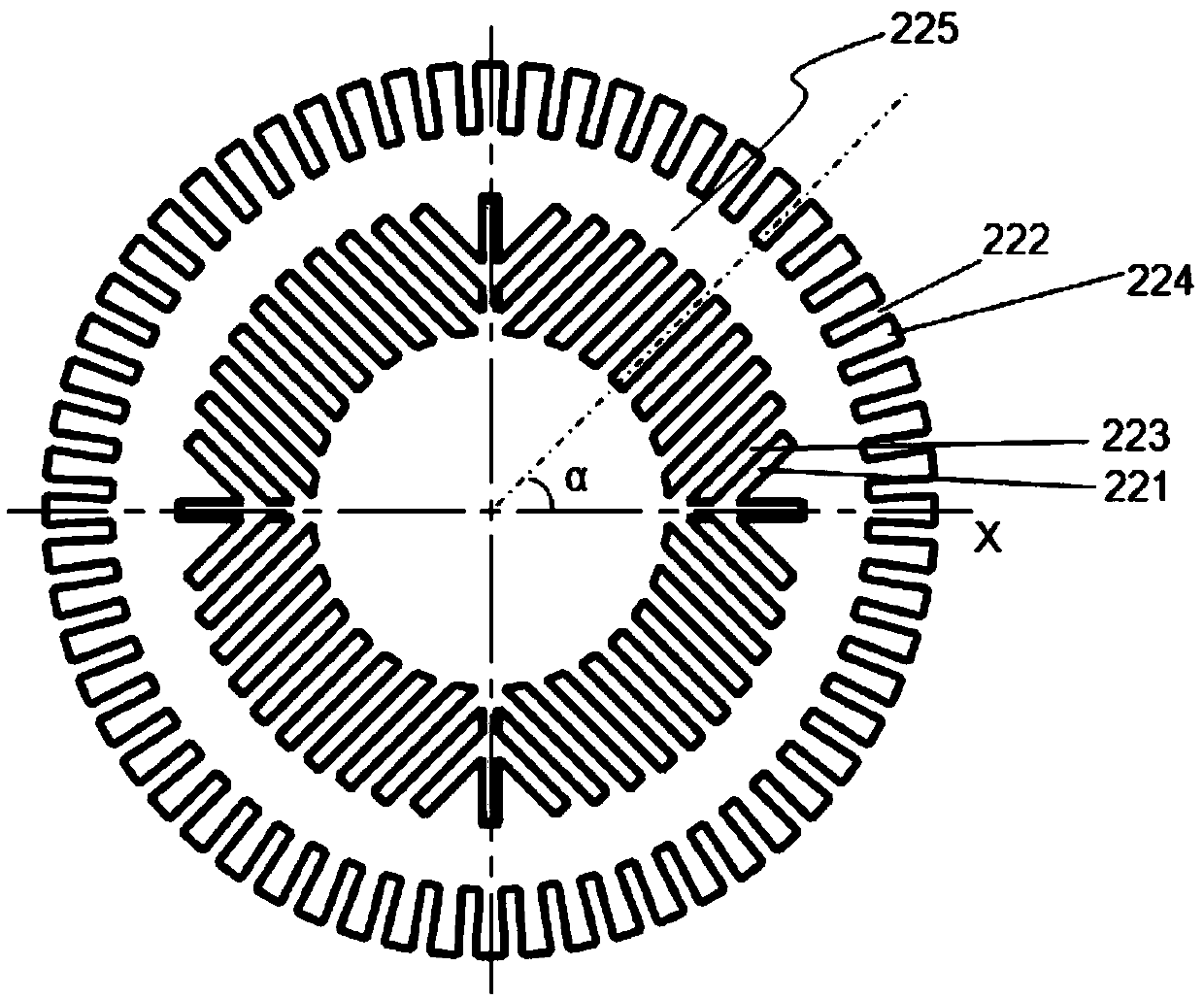

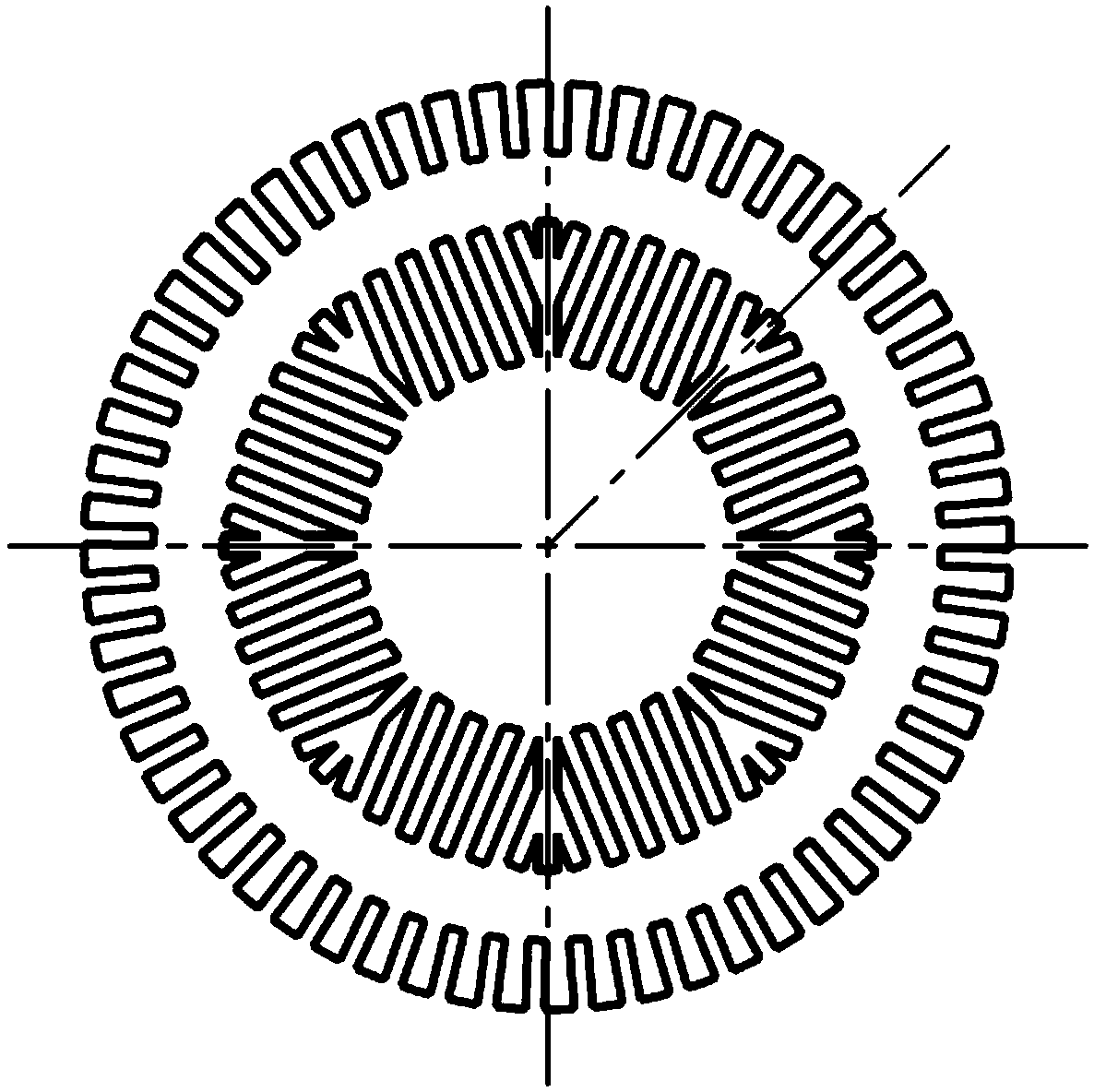

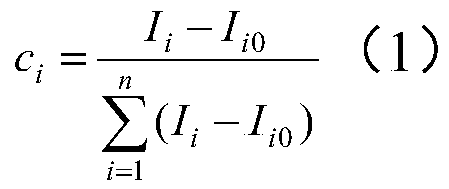

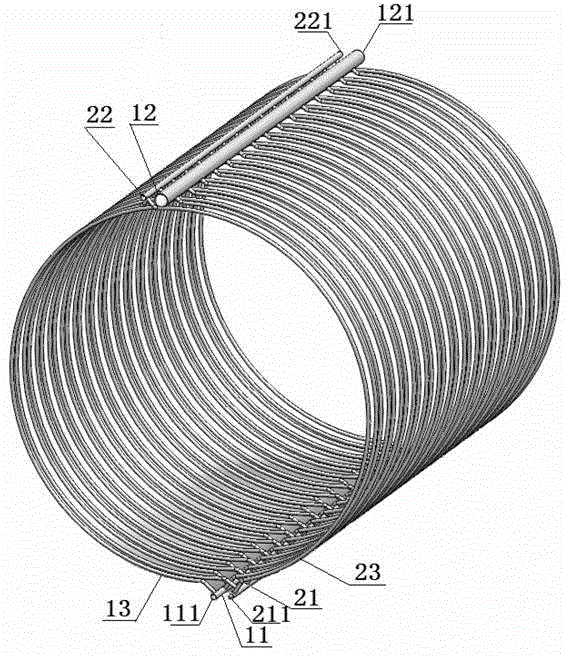

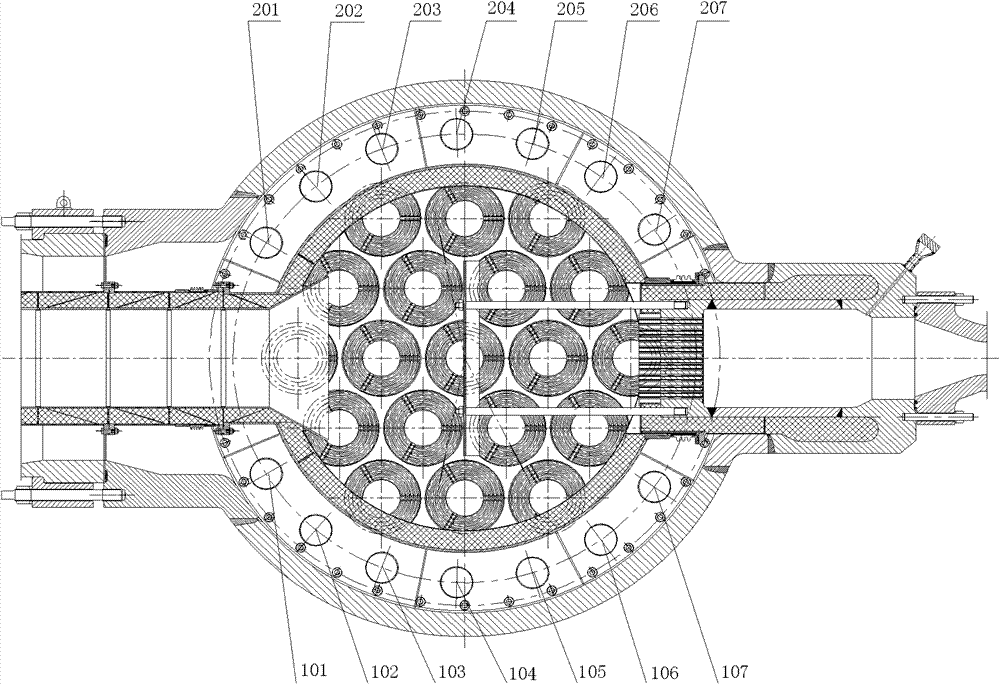

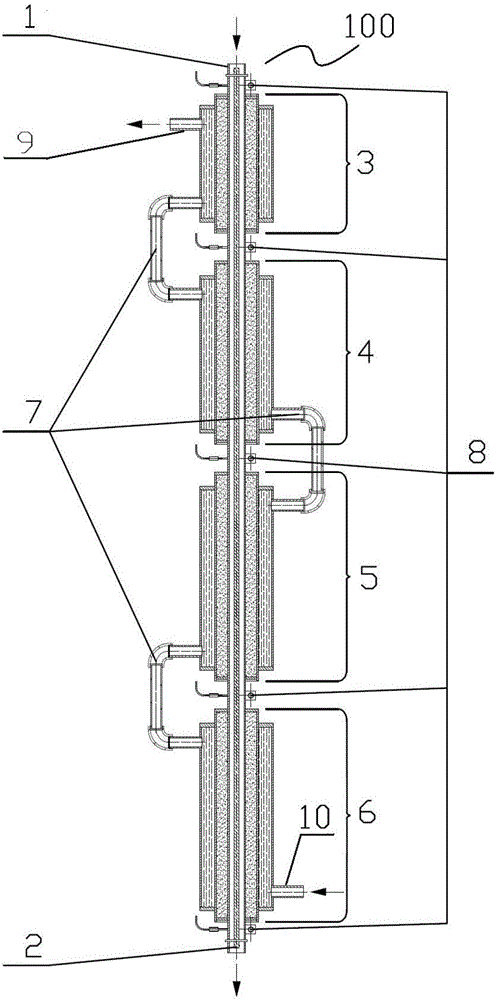

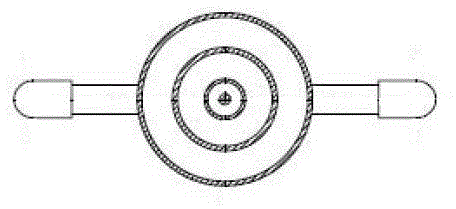

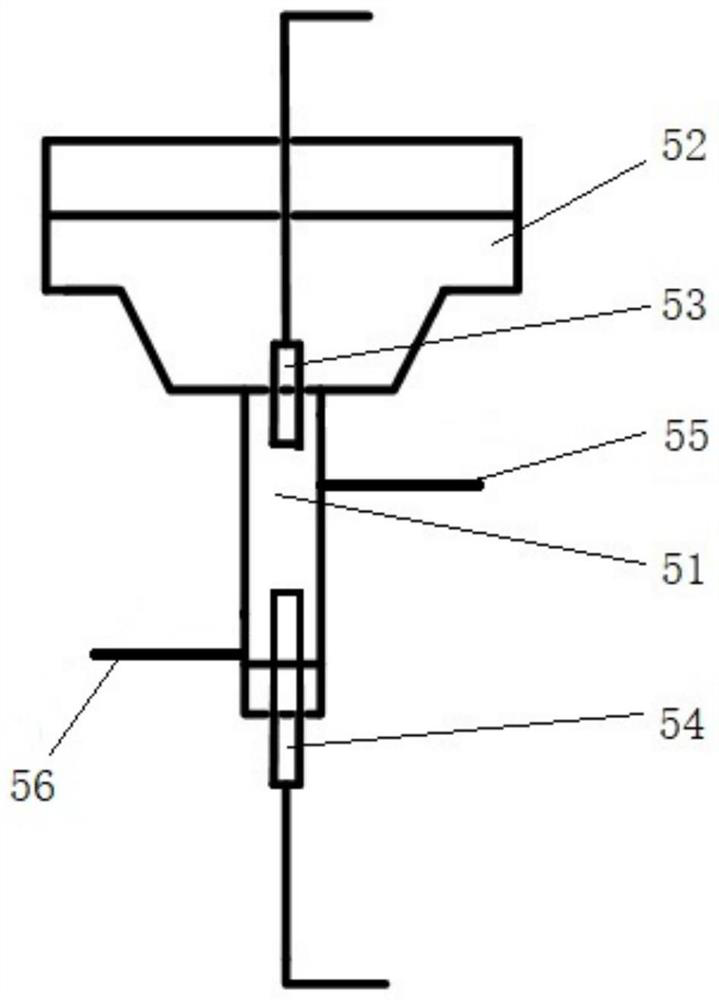

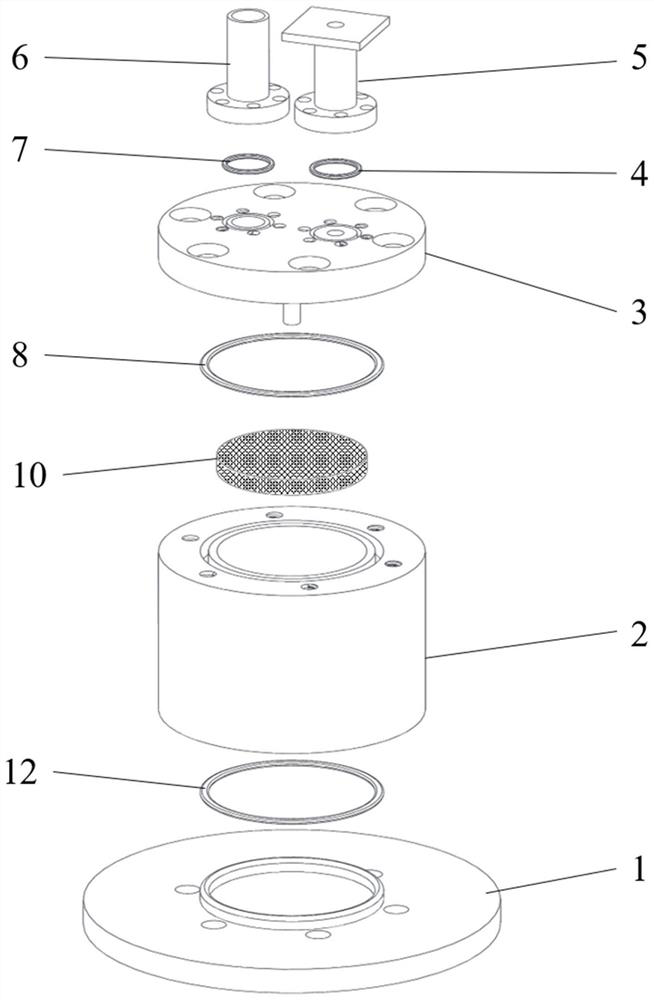

Heat exchanger and pulse tube refrigeration machine with heat exchanger

ActiveCN110579035ASame total areaSolve the problem of uneven radial airflowCompression machinesGas cycle refrigeration machinesEngineeringProduct gas

The invention relates to a heat exchanger and a pulse tube refrigeration machine with the heat exchanger. The heat exchanger comprises a heat exchange body, wherein multiple sector areas are arrangedalong circumferences inside the heat exchange body; and multiple inner fins in mutual parallel and multiple inner flow ways of the heat exchanger in mutual parallel are disposed in each of the sectorareas. In comparison with the prior art, the heat exchanger disclosed by the invention has the beneficial effects that the multiple sector areas are divided inside the heat exchange body, and the inner flow ways of the heat exchanger in each of the sector areas are made to be mutually parallel, so a total area of airflow channels in a unit area from the outer side to the inner side is same, and the problem that radial airflows are non-uniform when gas reaches a heat regenerator can be solved; and outer fins are disposed along the axial direction of the wall outer side of the heat exchange body, and a flow inlet groove and a flow outlet groove are formed in the outer side of a flow collection device respectively, so the flow collection device is communicated with an outer flow way of the heat exchanger, a fluid is uniformly distributed via a flow groove and then flows axially for heat suction, circumferential uniformity of the helium temperature is ensured, and the problem that the temperature of gas at an inlet of the heat regenerator is not uniform circumferentially because the axial length of the heat exchanger is short and axial cooling can hardly be arranged can be solved.

Owner:TONGJI UNIV

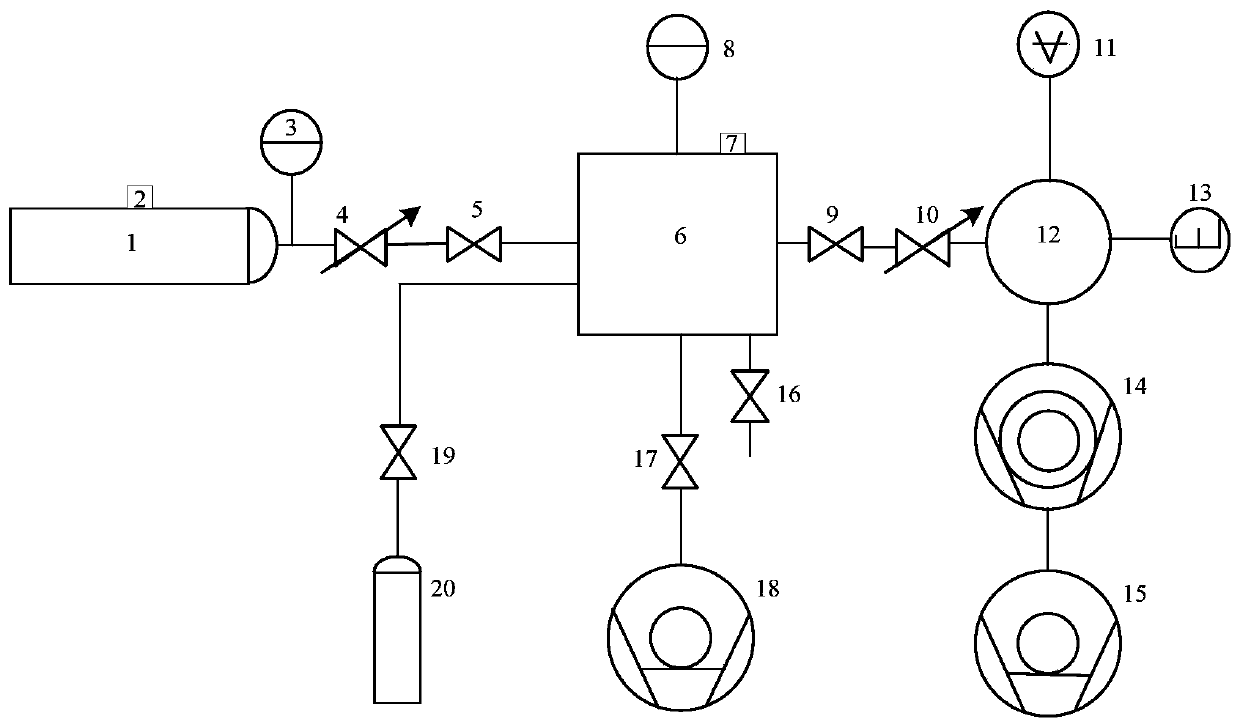

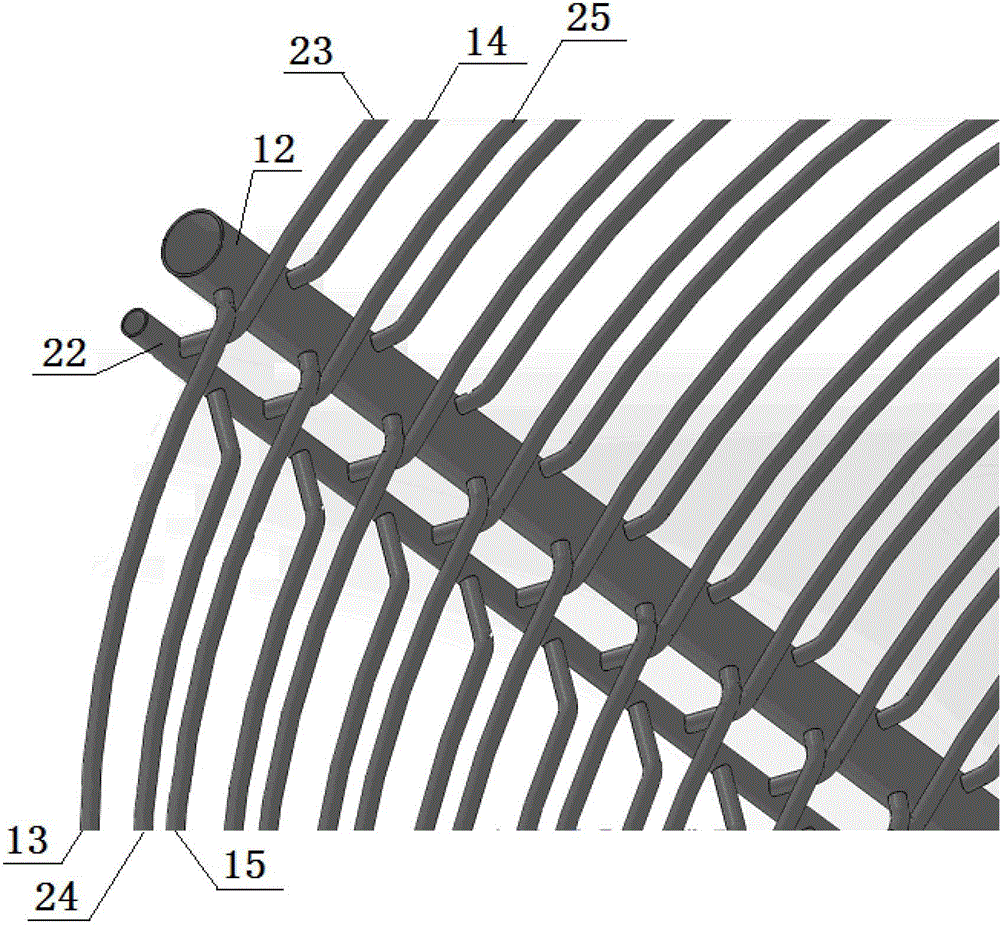

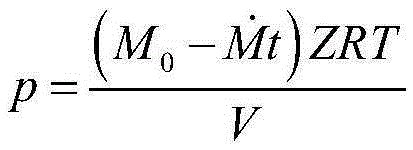

Helium recovery device and method for leakage detection of high-pressure gas cylinder

ActiveCN111141458AHigh puritySatisfied for repeated useDetection of fluid at leakage pointMaterial analysis by electric/magnetic meansGas cylinderMeasuring instrument

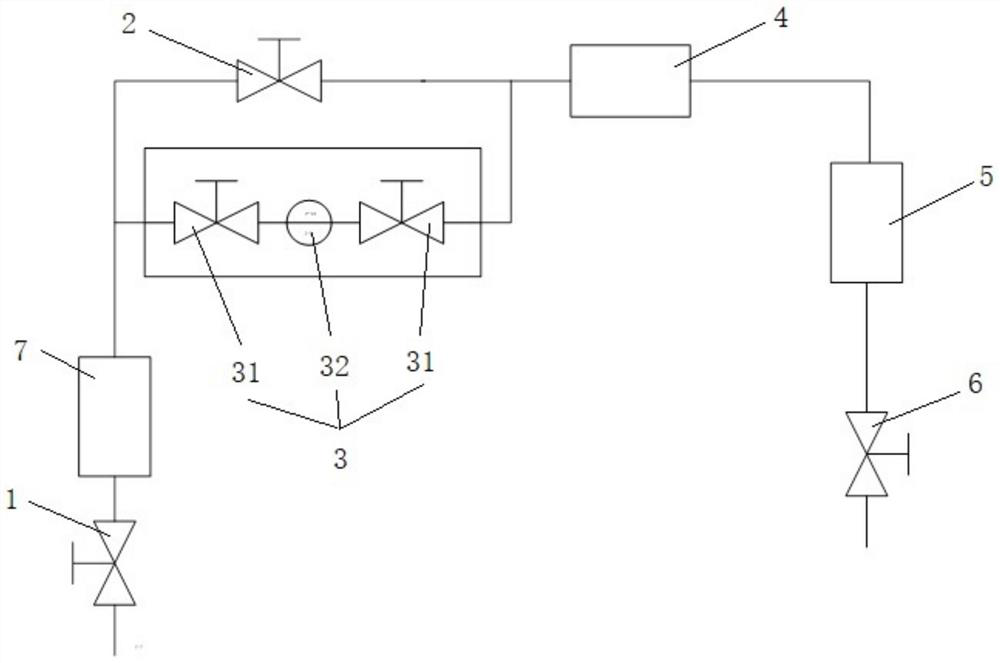

The invention discloses a helium recovery device and method for the leakage detection of a high-pressure gas cylinder. The helium recovery device comprises a gas storage container, a temperature and pressure monitoring unit, a measuring instrument, a replacement system, a pressure relief controller and a vacuumizing unit; the gas storage container is used for storing helium recovered from a detected high-pressure gas cylinder; the temperature and pressure monitoring unit is used for monitoring the temperature and pressure of the high-pressure gas cylinder and the gas storage container in a recycling process; the measuring instrument is used for measuring the concentration of the recycled helium in the gas storage container; the replacement system is used for replacing air in the gas storage container before helium recovery to ensure the purity of the recovered helium; the pressure relief controller is used for adjusting the rate of the relief of pressure from the high-pressure gas cylinder to the gas storage container; and the vacuumizing unit is used for vacuumizing the gas storage container. The helium recovery device can recover helium after the leakage detection of the high-pressure gas cylinder is completed, meanwhile, it is guaranteed that the recovered helium has certain purity, and the use requirement of next leakage detection can be met.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Liquid nitrogen-cooled helium dual-medium coupled heat sink for space environment simulation

ActiveCN103388948BEasy to operateGood low temperatureHeating or cooling apparatusGas-turbine engine testingElectricityCold air

Owner:SHANGHAI JIAO TONG UNIV +1

Pressure monitor, superconducting magnet and MRI (Magnetic Resonance Imaging) system

InactiveCN106033016APrecise pressure controlLow costApparatus for force/torque/work measurementMeasurements using magnetic resonanceElectricitySuperconducting Coils

The invention discloses a pressure monitor, a superconducting magnet and an MRI system. The pressure monitor comprises a temperature sensing unit for sensing the helium temperature of the superconducting magnet and providing representative data, a determining unit for comparing the representative data with a threshold and obtaining a determination result, and a control unit for controlling a refrigeration part of the superconducting magnet according to the determination result, wherein the determining unit is electrically connected with the temperature sensing unit and the control unit. The pressure monitoring monitor of the superconducting magnet can control the pressure of the superconducting magnet accurately and greatly reduces the cost of an absolute pressure sensor.

Owner:SIEMENS SHENZHEN MAGNETIC RESONANCE

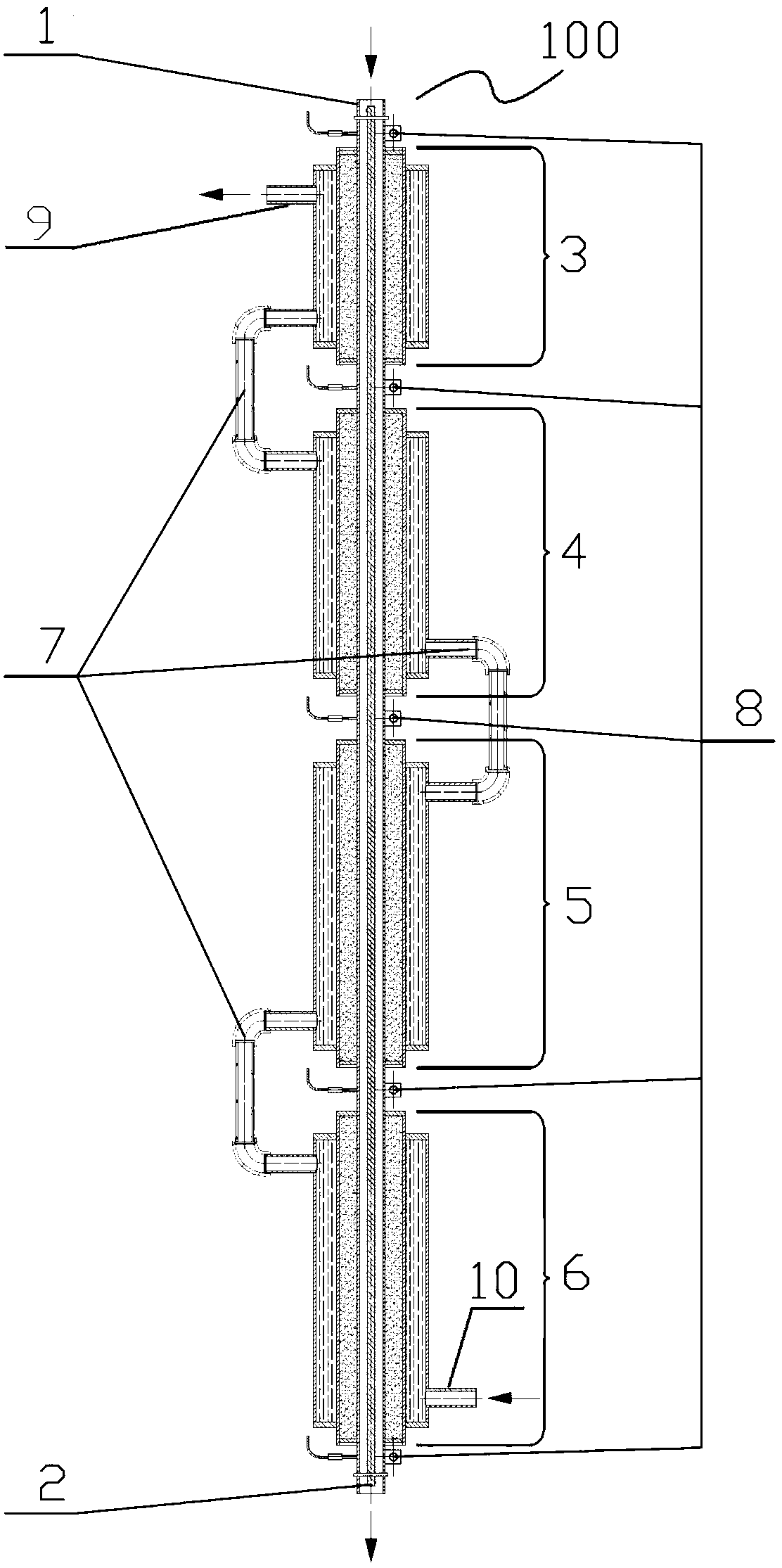

High-pressure-helium obtaining method for liquid-hydrogen temperature zone

InactiveCN104062102AReduce evaporationReduce consumptionMachine part testingStructural reliabilityLiquid hydrogen

The invention discloses a high-pressure-helium obtaining method for a liquid-hydrogen temperature zone and the method is mainly used for providing low-temperature helium for a ground test system of a carrier-rocket cold-helium pressurization system. An applied device mainly includes a liquid-nitrogen heat exchanger, an upper volute, titanium bottles, a lower volute and a liquid-hydrogen dewar. Each titanium bottle is provided with an upper opening and a lower opening, which are connected to the upper and lower volute respectively. The liquid-hydrogen dewar is a vacuum powder heat insulation structure. A preparation process of the low-temperature helium is as follows: firstly, the titanium bottles are filled with normal-temperature helium to XMPa and then liquid nitrogen and liquid hydrogen are injected to the liquid-nitrogen heat exchanger and the liquid-hydrogen dewar and then the titanium bottles are filled with helium which undergoes temperature reduction by the liquid-nitrogen heat exchanger so that the pressures of the titanium bottles rise to be slightly higher than XXMPa; the inflation is stopped and the helium is made to stand so as to reduce temperature and reduce pressure and then the titanium bottle inflation and standing processes are repeated until the pressures in the titanium bottles are stabilized to XXMPa without an obvious lowering trend; and if a needed helium temperature is lower than 21K, deflation of the titanium bottles can be carried out firstly after preparation of the XXMPa helium is completed and the helium can be used after the temperature is reduced to a needed value. The titanium bottle inflation and deflation structure is high in reliability and the titanium bottles can be used for a plurality of times and consumption of liquid hydrogen and helium in a test process is reduced so that an objective of reducing test cost and improving test security is achieved.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

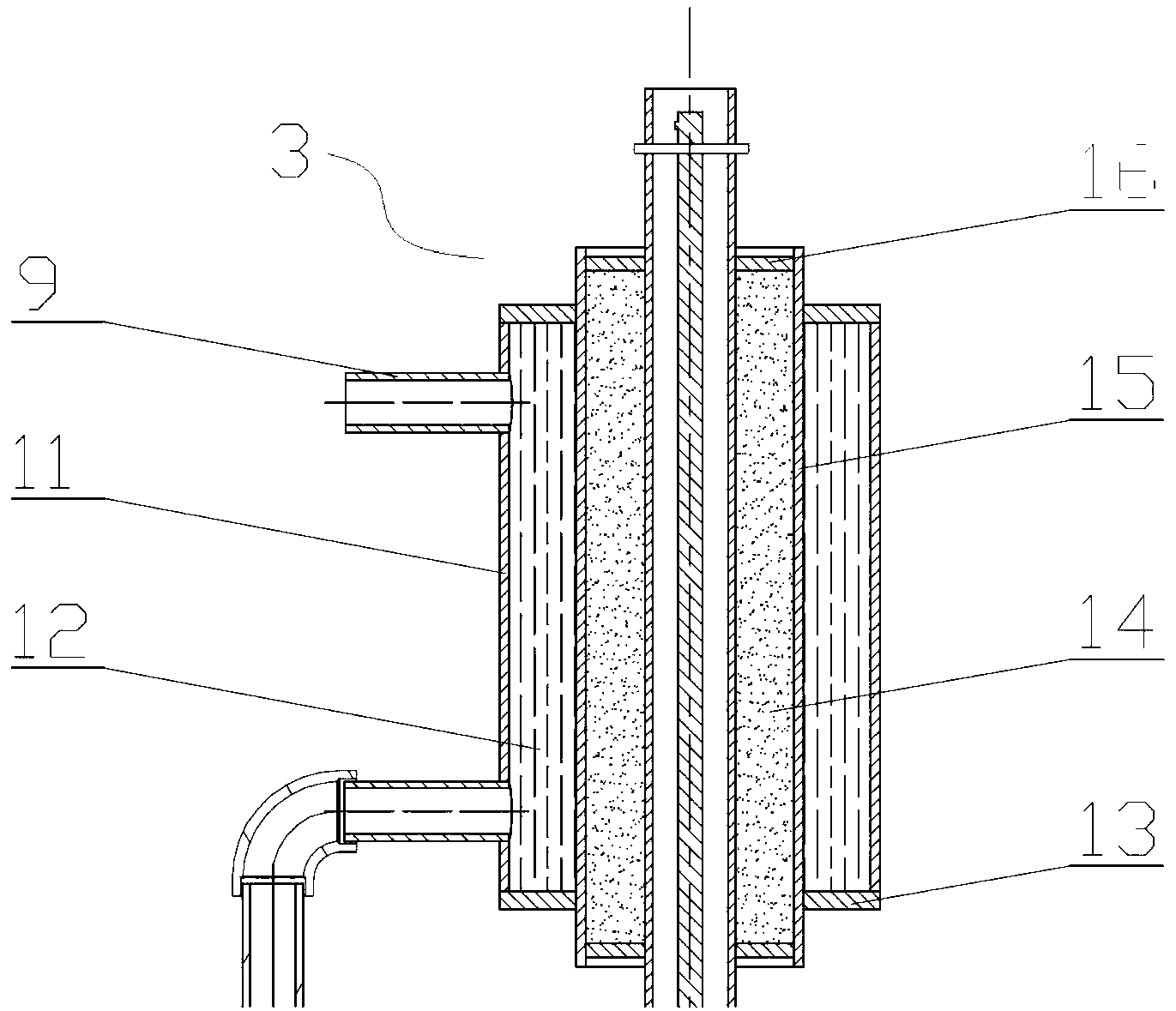

Sleeve type helium temperature-control sediment sampling device applied to high-temperature gas cooled reactor

ActiveCN103236277AValid follow-up measurementEfficient analysisNuclear energy generationNuclear monitoringTemperature controlTwo temperature

Owner:TSINGHUA UNIV

System and method for directly measuring total helium mass flow rate of primary loop of high-temperature gas cooled reactor

ActiveCN102252723BMeets the requirement for redundant direct measurementsImprove reproduction accuracyIndirect mass flowmetersData acquisitionMechanical engineering

Owner:TSINGHUA UNIV

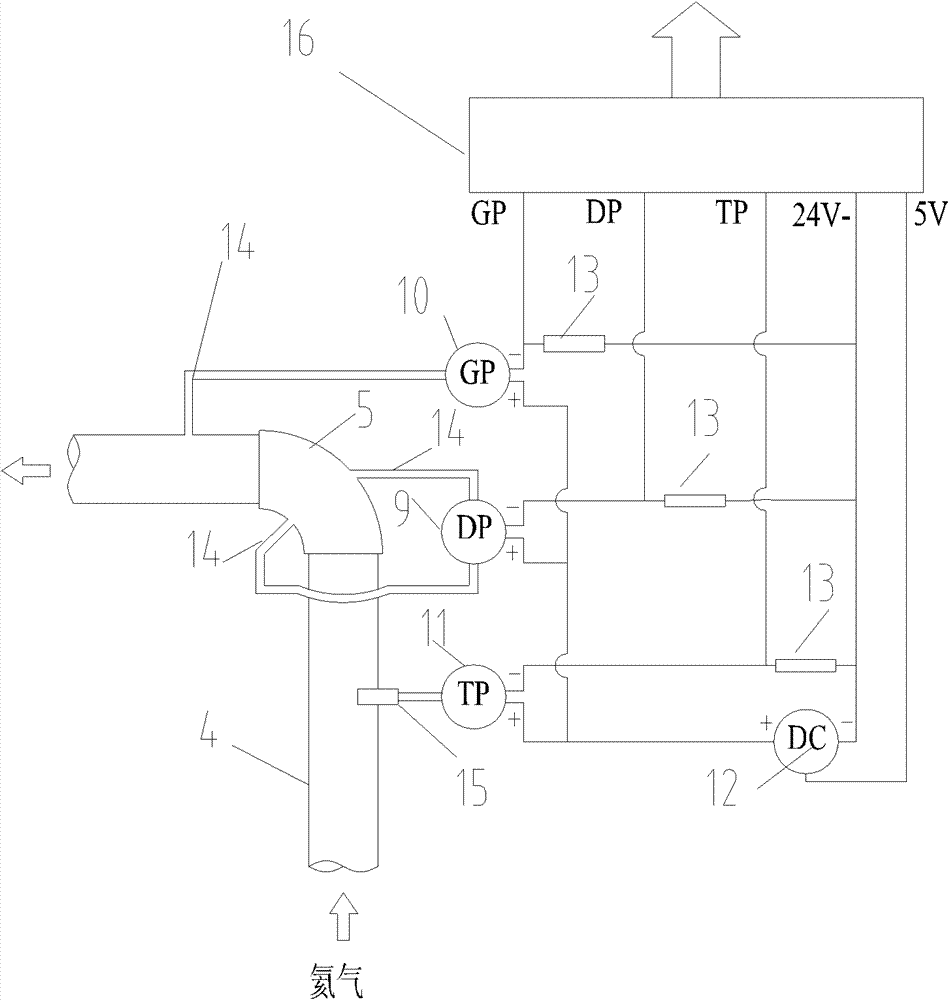

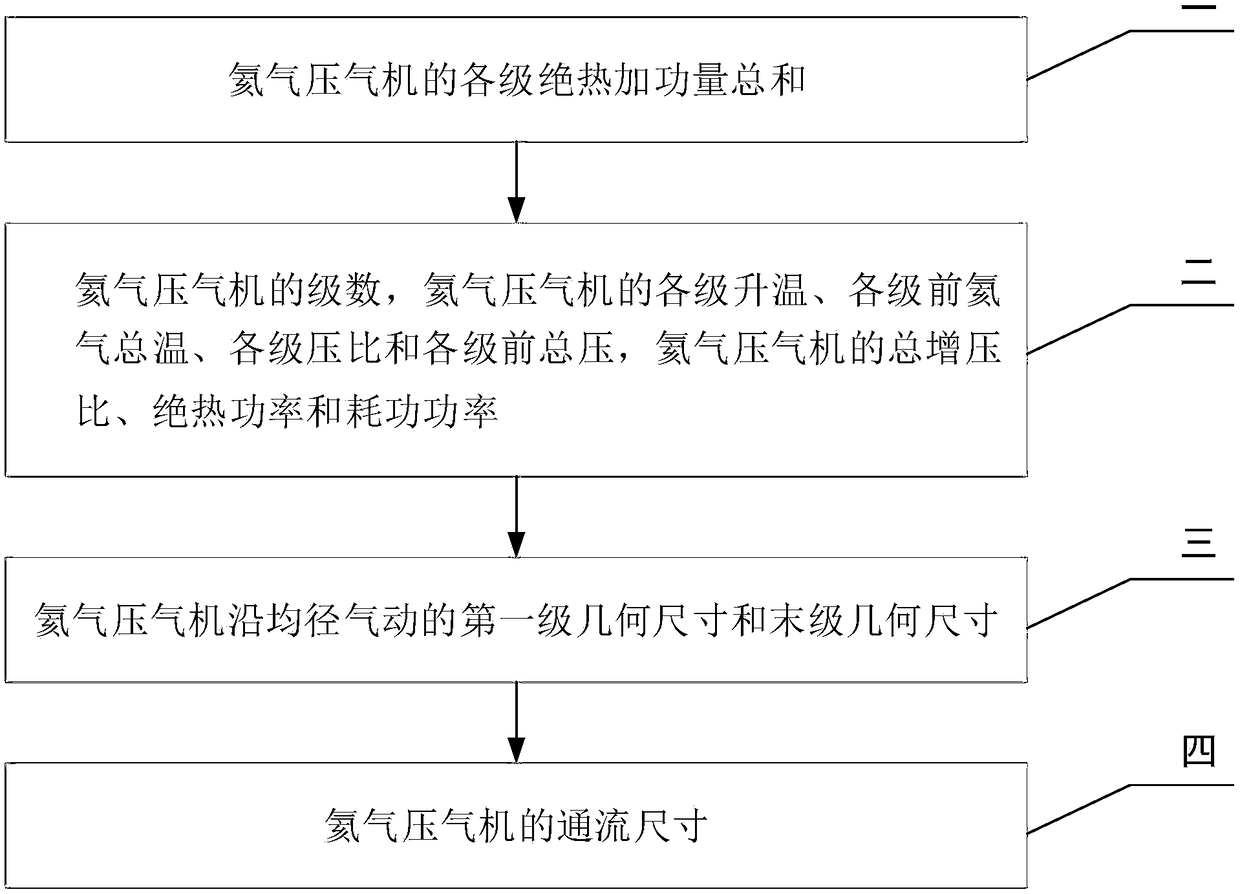

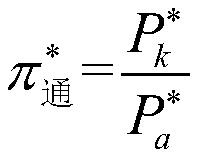

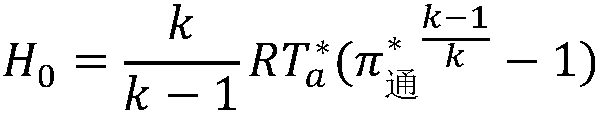

A one-dimensional pneumatic design method for a helium compressor

ActiveCN109446745AImprove efficiencyGeometric CADSustainable transportationEngineeringDesign methods

The invention discloses a one-dimensional pneumatic design method for a helium compressor, and belongs to the technical field of pneumatic design of compressors. The problem that the pneumatic designof an existing helium compressor cannot meet the requirement for the design efficiency of the helium compressor is solved. According to the invention, the sum of the adiabatic work amounts of all stages of the helium compressor is reasonably designed and reasonably distributed; the temperature rise of each stage of a helium compressor, the total helium temperature before each stage, the pressure ratio of each stage and the front total pressure of each stage are calculated to obtain the total supercharging ratio, the adiabatic power and the power consumption power of the helium compressor, thefirst-stage geometric dimension and the last-stage geometric dimension of the helium compressor along the uniform-diameter pneumatic direction are determined, and further the through-flow dimension ofthe helium compressor is solved, so that the design of the one-dimensional pneumatic direction of the helium compressor is completed. Compared with the prior art, the method has the advantages that the efficiency of the helium compressor designed by the aid of the method can be improved by 2%-3%, and the method can be applied to the technical field of helium compressor pneumatic design.

Owner:中国船舶重工集团公司第七0三研究所

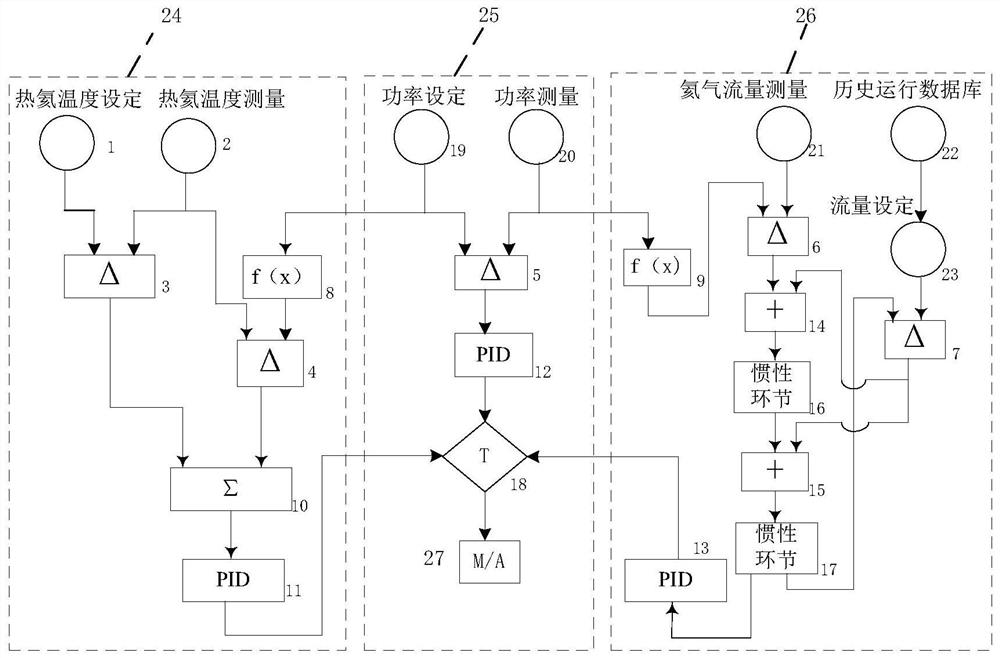

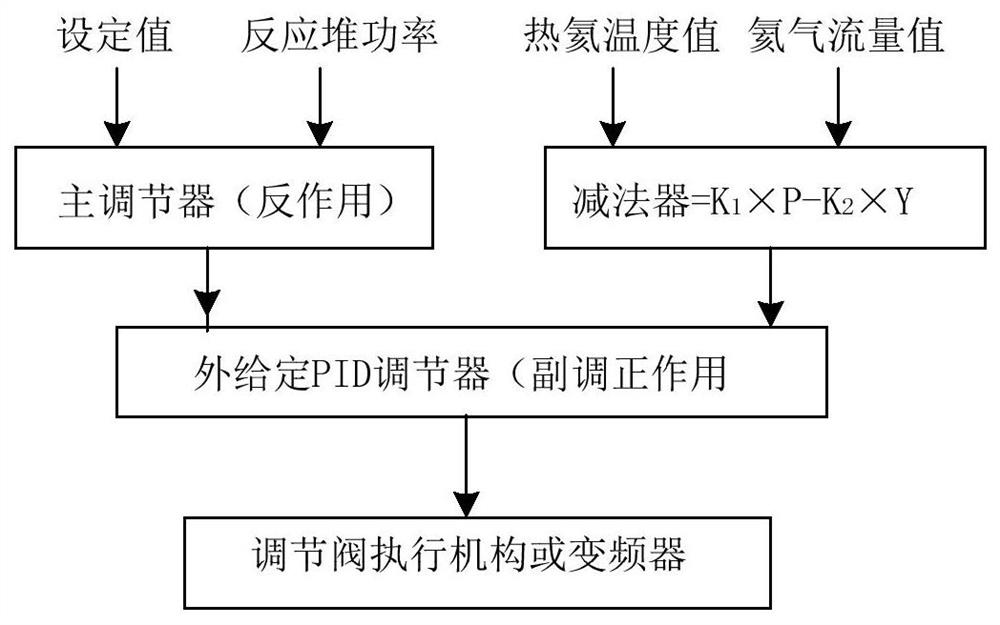

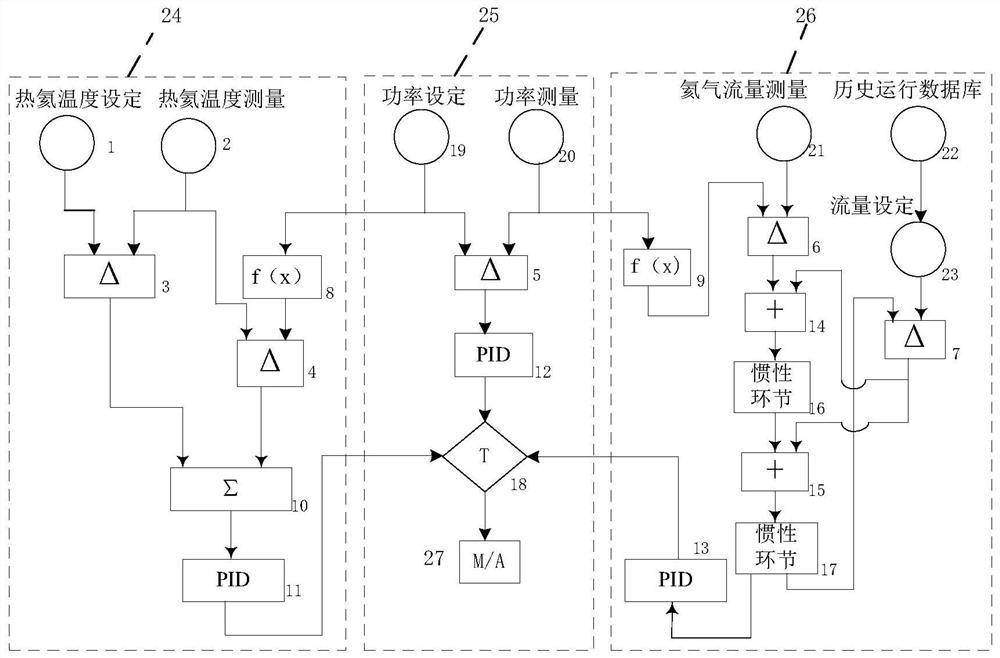

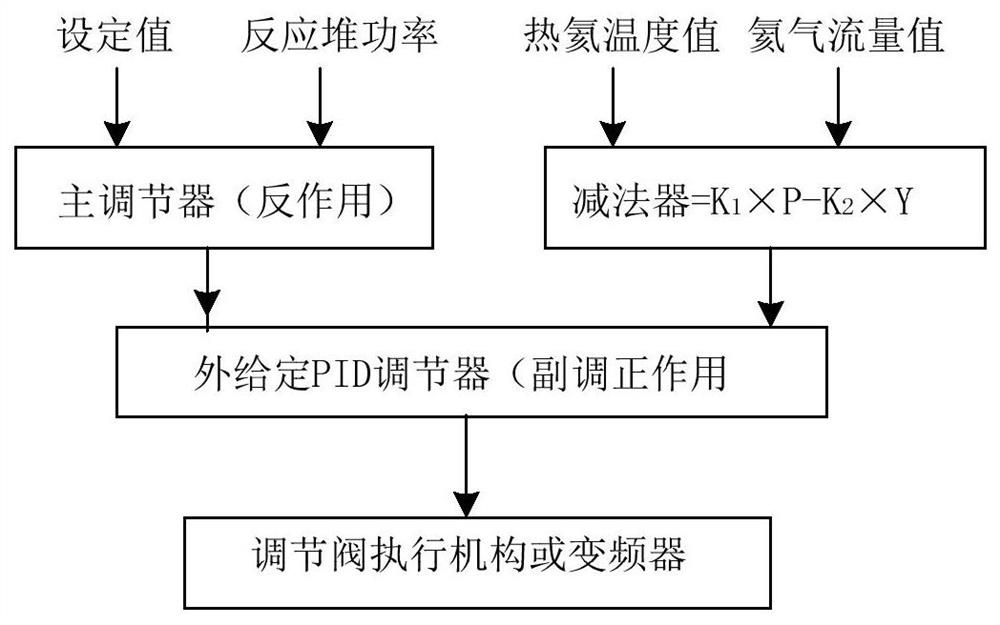

High-temperature gas cooled reactor helium flow control system and method with incremental adjusting function

ActiveCN112382418AImprove robustnessCorrected outputNuclear energy generationFlow control using electric meansThermodynamicsControl system

The invention discloses a high-temperature gas cooled reactor helium flow control system and method with an incremental adjusting function. The high-temperature gas cooled reactor helium flow controlmethod comprises the following steps: 1) calculating a hot helium temperature correction value for hot helium temperature PID adjustment; 2) calculating a power correction value for power PID adjustment of a unit; 3) calculating a helium flow correction value for helium flow PID adjustment; and 4) performing three-impulse control according to the hot helium temperature correction value for hot helium temperature PID adjustment, the power correction value for unit power PID adjustment and the helium flow correction value for helium flow PID adjustment, and then controlling the reactor accordingto the result of the three-impulse control. The system and method can rapidly tract and control the change trend of a variable, correct and control the output of the variable to meet the functional requirements of peak regulation and frequency modulation of the reactor tracking power grid load.

Owner:XIAN THERMAL POWER RES INST CO LTD

Cryostat having a magnet coil system, which comprises an LTS section and a heatable HTS section

InactiveUS8406833B2Guaranteed uptimeIncrease capacitySuperconductors/hyperconductorsCompression machinesMagnet coilHelium temperature

A cryostat (1) with a magnet coil system including superconductors for the production of a magnet field B0 in a measuring volume (3) has a plurality of radically nested solenoid-shaped coil sections (4, 5, 6) and which are electrically connected in series, at least one of which being an LTS section (5, 6) with a conventional low temperature superconductor (LTS) and at least one of which being an HTS section (4) including a high temperature superconductor (HTS), wherein the magnet coil system is located in a helium tank (9) of the cryostat (1) along with liquid helium at a helium temperature TL<4 K. The apparatus is characterized in that heating means are provided which always keep the HTS at an increased temperature TH>TL and TH>2.2 K. The cryostat in accordance with the invention can maintain the HTS section over a long period of time in a reliable manner.

Owner:BRUKER BIOSPIN

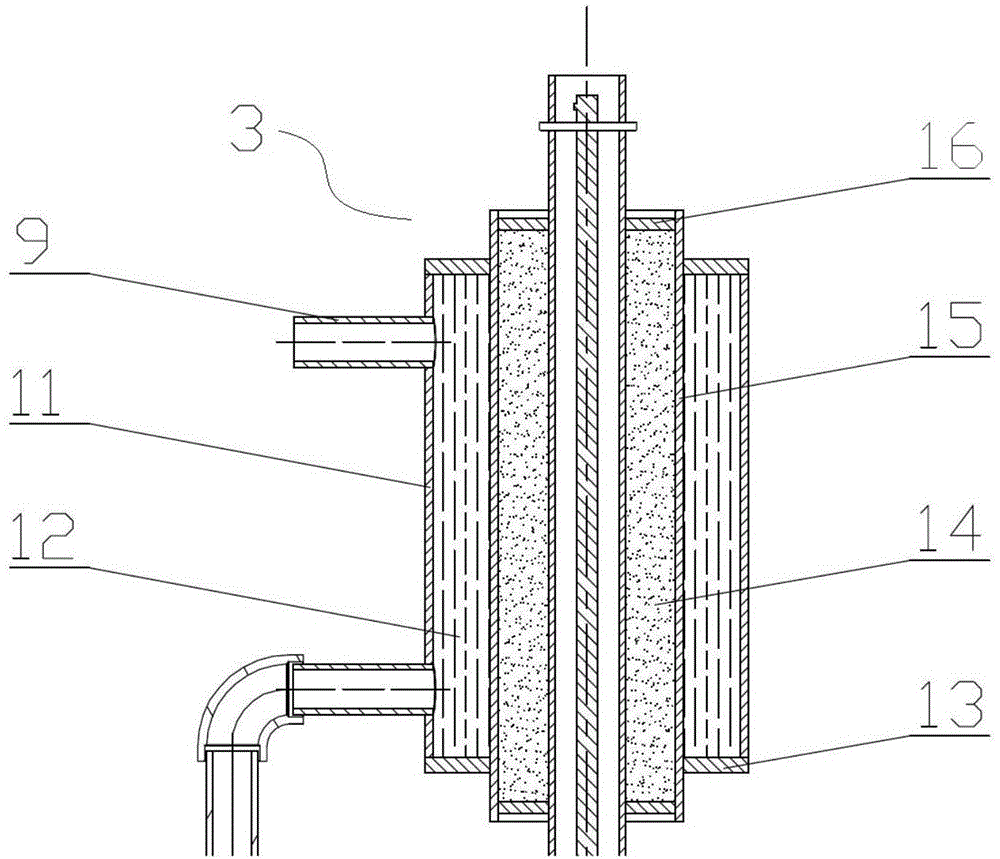

A sleeve-type helium temperature-controlled deposition sampling device for high-temperature gas-cooled reactors

ActiveCN103236277BEfficient analysisNuclear energy generationNuclear monitoringTemperature controlDeposition temperature

The invention relates to a sleeve type helium temperature-control sediment sampling device applied to a high-temperature gas cooled reactor. The sampling device is characterized by comprising a sleeve, a core rod which is fixed inside the sleeve and extends along the axial direction, a plurality of temperature control units which are sequentially fixed on the outer wall of the sleeve at intervals along the axial direction, a plurality of water delivery pipe sections for communicating every two adjacent temperature control units, as well as a water inlet and a water outlet which are respectively connected with the two temperature control units at the outmost sides. The temperature-control sediment sampling device is capable of implementing the certain temperature control on a high-temperature helium environment generated by a steam generator in the whole sedimentation length, so that during the continuous cooling process of high-temperature helium, sedimentable fission product particles with different types, and graphite dust within different particle size ranges, which are carried in the high temperature helium, are gradually sedimented and adsorbed onto the sleeve and the core rod through a certain temperature gradient, and therefore, the follow-up measurement and analysis can be effectively implemented.

Owner:TSINGHUA UNIV

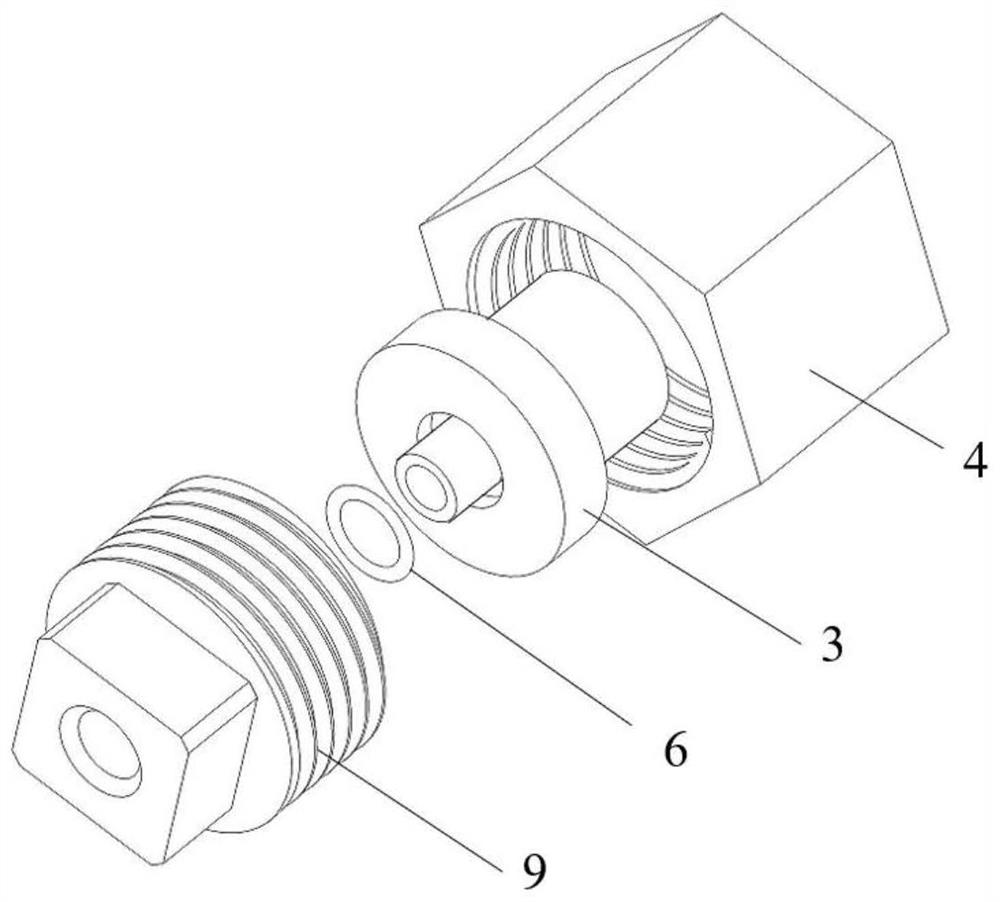

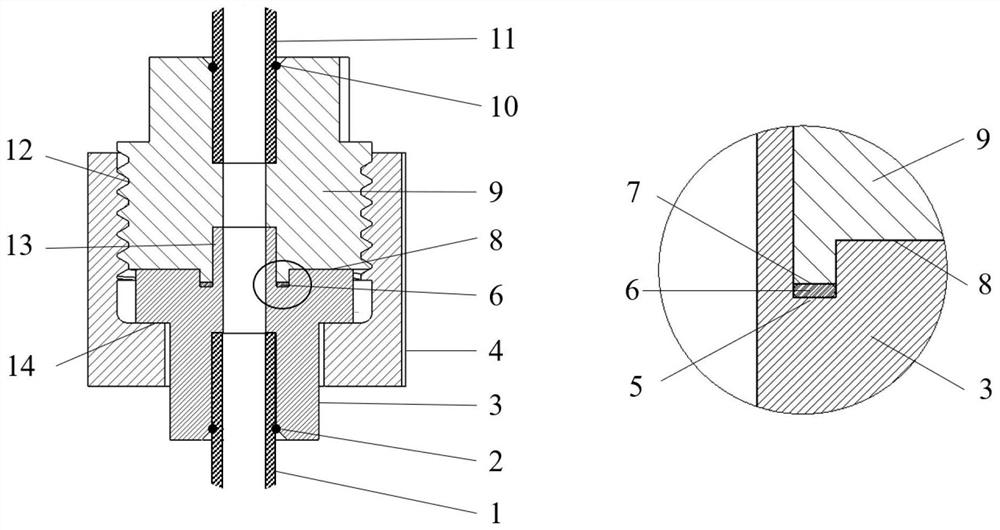

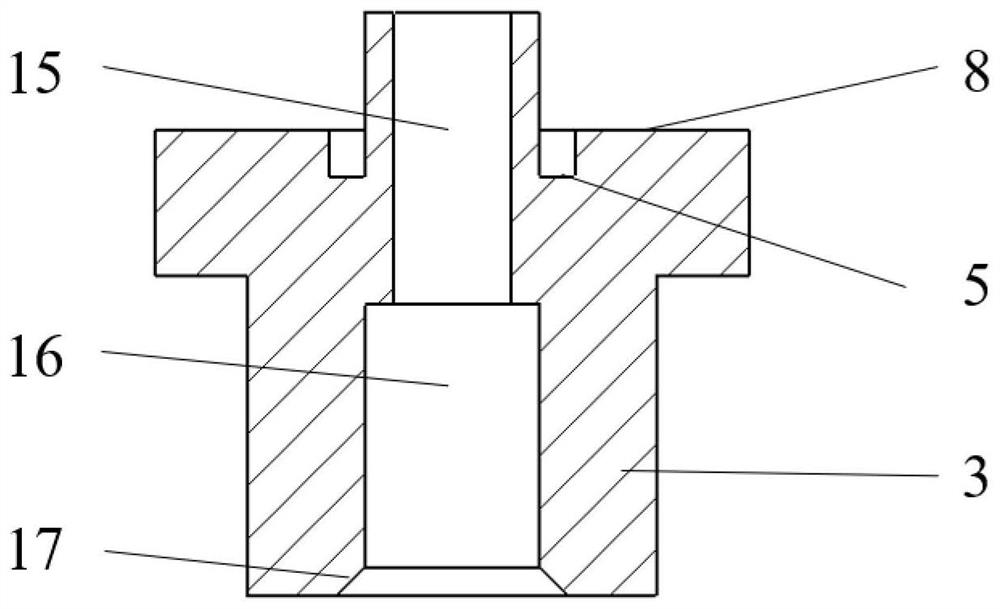

Freely-detachable gold wire sealing connection device for superfluid helium temperature zone and implementation method

ActiveCN112944066AImprove sealingWon't leakJoints with sealing surfacesCompression machinesEngineeringMechanical engineering

The invention discloses a freely-detachable gold wire sealing connection device for a superfluid helium temperature zone and an implementation method. The freely-detachable gold wire sealing connection device is composed of a sealing connection base, a sealing connection nut, a gold wire sealing ring and a sealing connection screw. The sealing of a fluid working medium in the superfluid helium temperature zone is realized in a gold wire sealing manner, and a gas inlet pipe and a gas outlet pipe can be freely separated by designing three independent components, namely the base, the nut and the screw, so that the mounting and dismounting of a low-temperature fluid pipeline are greatly simplified, and the device and the implementation method have very positive significance in application of a low-temperature throttling refrigerating machine working in the superfluid helium temperature zone in the special fields of aerospace and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Control method and system of high temperature gas cooled reactor power

ActiveCN102411997BControl thermal powerNuclear energy generationNuclear monitoringNuclear powerNuclear engineering

The invention discloses a control method and system of high temperature gas cooled reactor power, relating to the technical field of nuclear energy science and engineering, wherein the method includes the steps as follows: S1, setting a nuclear power controller parameter and a reactor core outlet hot helium temperature controller parameter; S2, the reactor core outlet hot helium temperature controller calculating the deviation between the reactor core outlet hot helium temperature measuring value and the core outlet hot helium temperature reference value to obtain the modification of the relative nuclear power reference value; the nuclear power controller calculating the deviation between the reactor core relative neutron flux density measuring value and the relative neutron flux density reference value and obtaining a rod speed signal that drives the control rod to move. The invention real-time obtains and calculates the core outlet hot helium temperature measuring value and the reactor core relative neutron flux density measuring value of the high temperature gas cooled reactor, obtains the rod speed signal for driving the control rod and controls the high temperature gas cooled reactor power.

Owner:CHINERGY CO LTD

Primary loop humidity measuring device for high-temperature gas cooled reactor

PendingCN114199303AAutomatic temperature adjustmentNo pressure testMeasurement devicesNuclear energy generationCooling coilProcess engineering

The invention provides a primary loop humidity measuring device for a high temperature gas cooled reactor, which comprises a sampling chamber, an air cooling temperature adjusting device, a filter assembly and a flow adjusting assembly, a temperature sensor and a hygrograph sensor are arranged in the sampling chamber, and the air cooling temperature adjusting device is used for adjusting the temperature of gas entering the sampling chamber; the flow adjusting assembly adjusts the flow of gas entering the sampling chamber. The device has the beneficial effects that the efficiency of the heat exchanger does not need to be manually adjusted and controlled, and the temperature of helium entering the sampling chamber can be automatically adjusted; and a water-cooling coil pipe is omitted, so that a pressure test is not needed.

Owner:华能核能技术研究院有限公司 +1

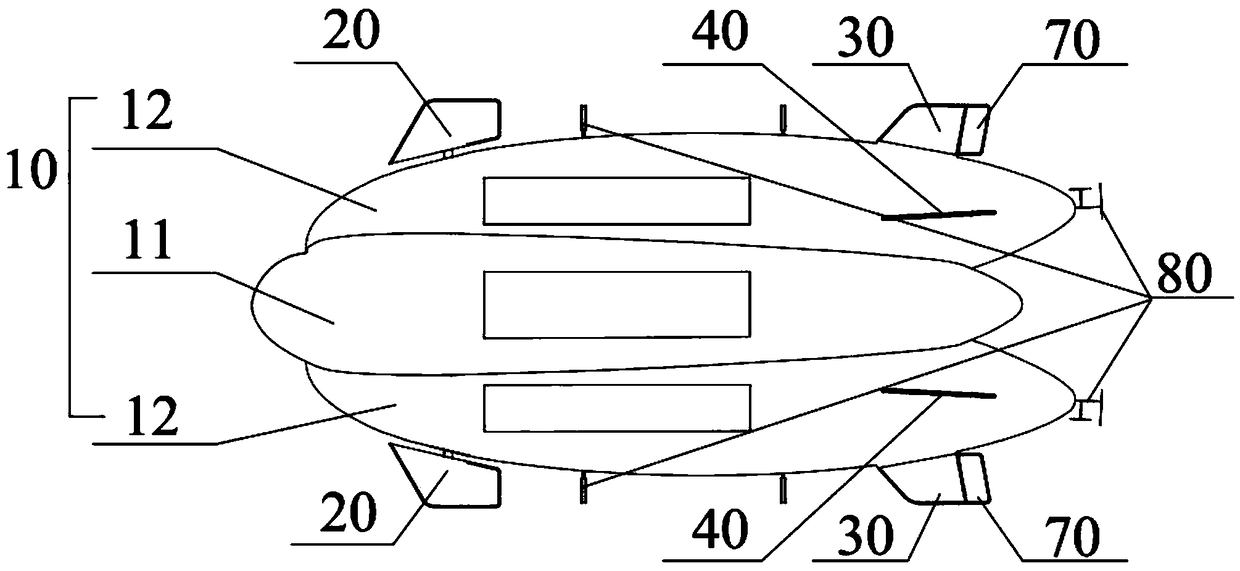

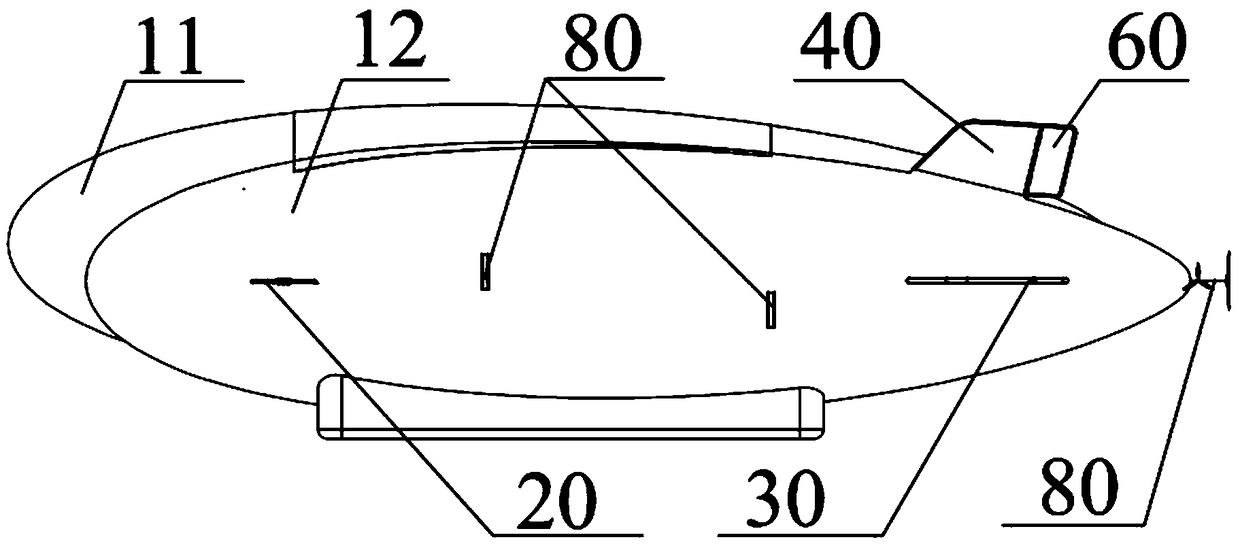

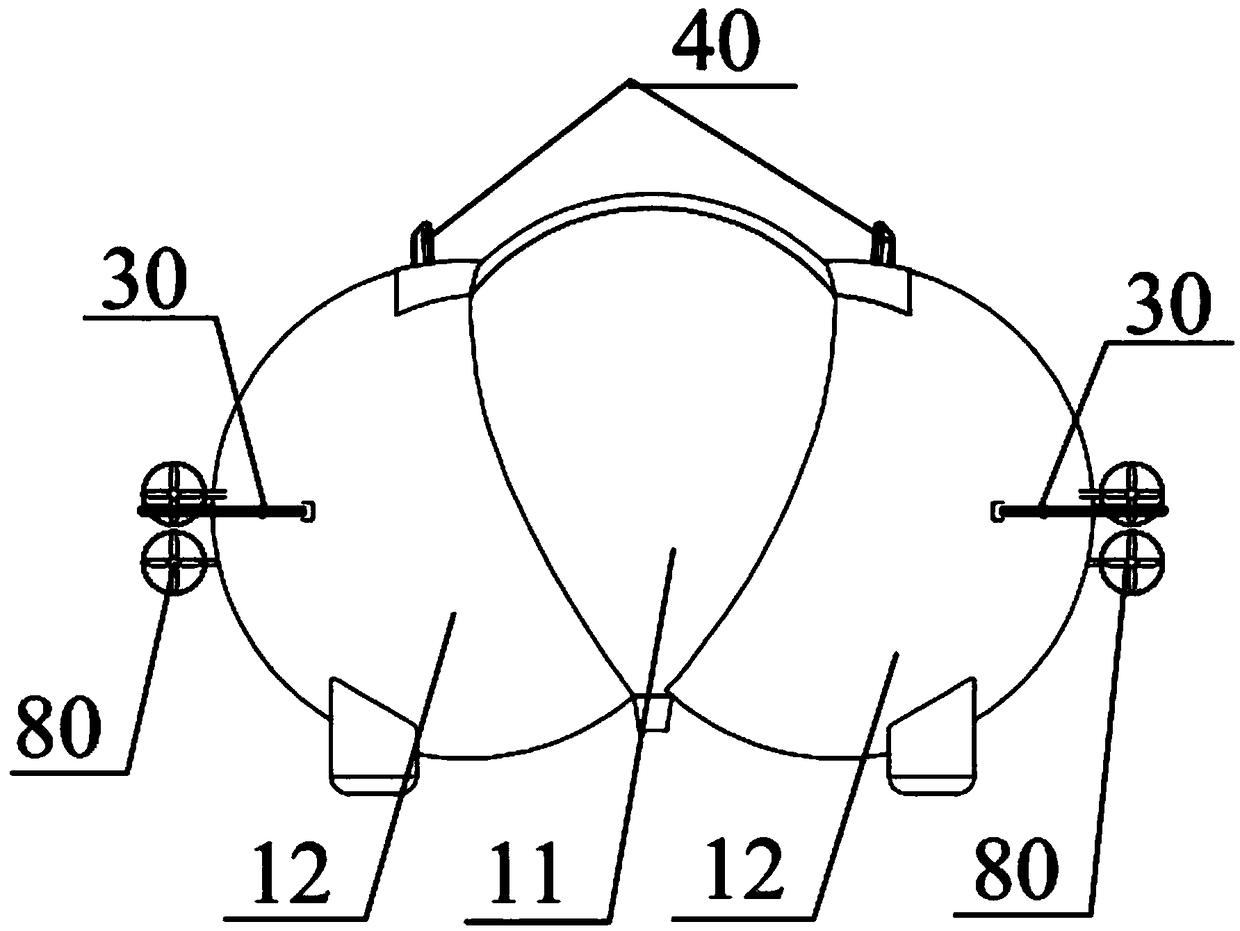

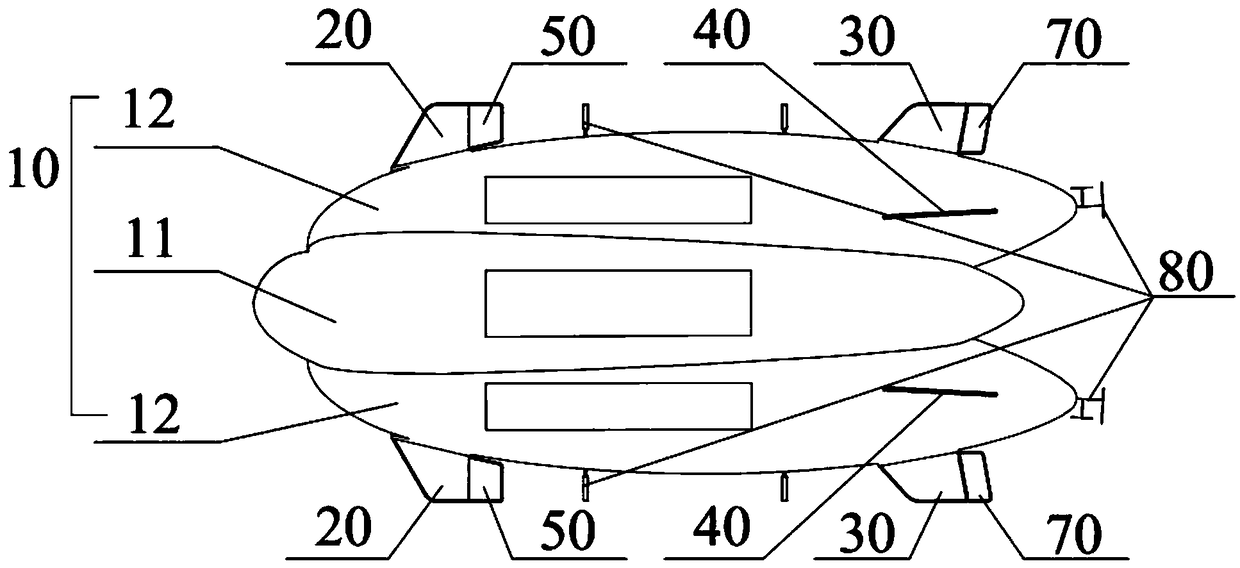

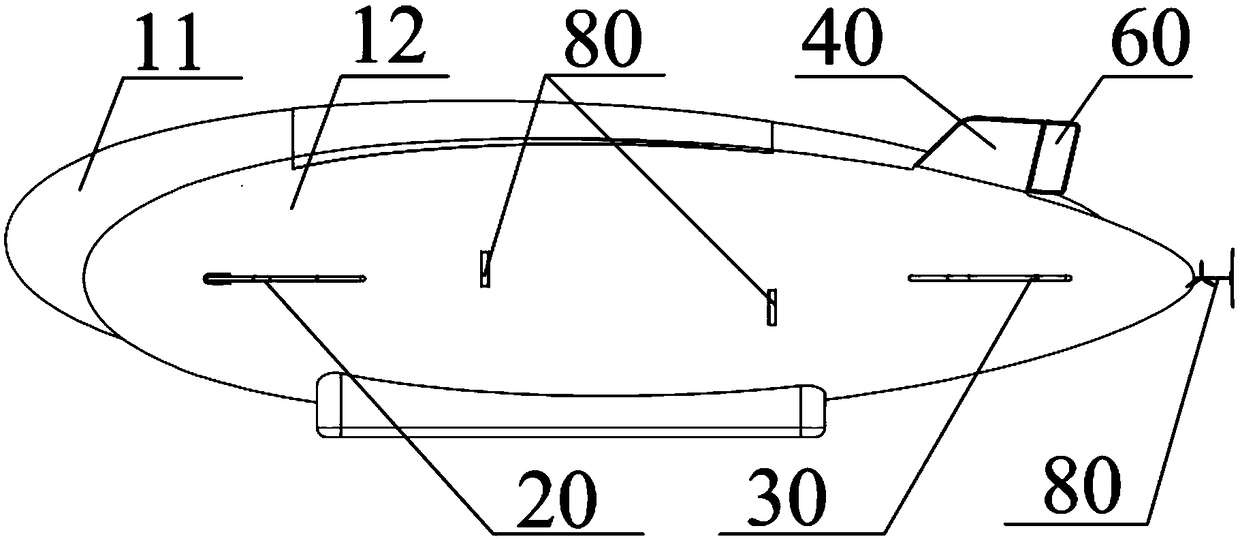

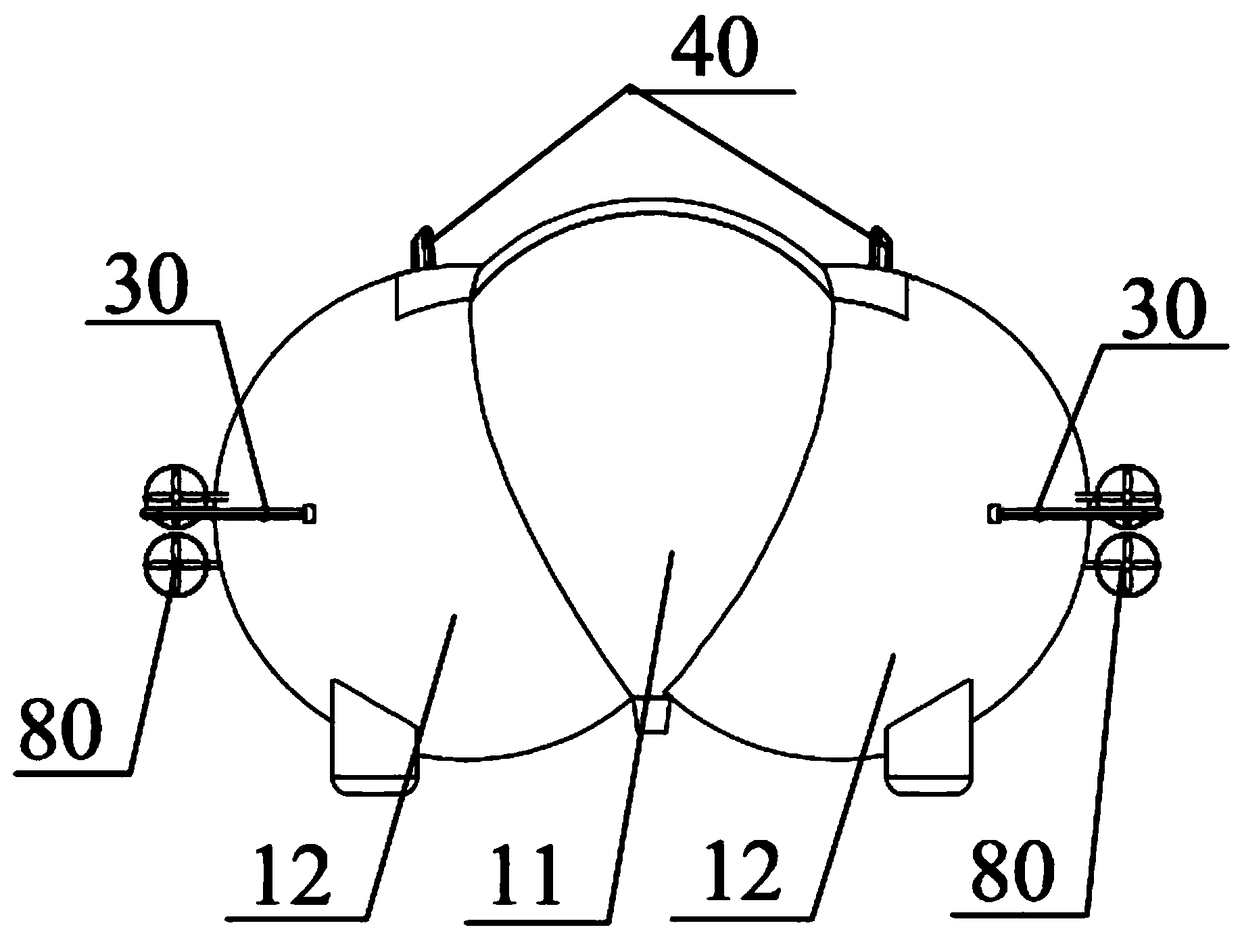

Stratospheric airship with full-motion front wings and mobile counterweight

InactiveCN108639305AIncrease pitch performanceSolve the buoyancy balance problemRigid airshipsGas-bag arrangementsStratosphereEngineering

The invention discloses a stratospheric airship with full-motion front wings and a mobile counterweight. The front wings are symmetrically arranged on both sides of the front portion of a hull, and the front wings can be rotated relative to the hull. Horizontal tails are symmetrically disposed on both sides of the rear portion of the hull. The hull includes a main capsule and two side capsules, and the main capsule is disposed in the middle of the two side capsules. The head portion of the main capsule protrudes from the head portions of the side capsules on both sides, and the horizontal position of the main capsule is higher than the side capsules on both sides. Vertical tails are arranged on the upper portions of the tail portions of the side capsules, and the front wings and the horizontal tails are symmetrically disposed on both sides of the longest weft of the side capsules. The full-motion front wings have more remarkable adjustment effect on the airship, and the buoyant weightbalance problem caused by the helium temperature difference of the stratospheric airship is comprehensively and effectively solved by adjusting the pitch angle of the airship, controlling a power device in a vector mode and the like.

Owner:达天飞艇(宁夏)有限公司

Stratospheric airship with front wings and working method thereof

InactiveCN108639304ASolve the buoyancy balance problemLong cruise timeRigid airshipsEngineeringVector mode

The invention discloses an airship with front wings and a mobile counterweight. The airship includes a hull, the front wings, horizontal tails and vertical tails. The front wings are symmetrically arranged on both sides of the front portion of the hull, and the horizontal tails are symmetrically disposed on both sides of the rear portion of the hull. The hull includes a main capsule and two side capsules, and the main capsule is disposed in the middle of the two side capsules. The head portion of the main capsule protrudes from the head portions of the side capsules on both sides, and the horizontal position of the main capsule is higher than the side capsules on both sides. The vertical tails are arranged on the upper portions of the tail portions of the side capsules, and the front wingsand the horizontal tails are symmetrically disposed on both sides of the horizontal meridians of the side capsules. According to the buoyancy variation of the airship, the rudder yaw-angles of the front wings are controlled, and the buoyant weight balance problem caused by the helium temperature difference of a stratospheric airship is comprehensively and effectively solved by adjusting the pitchangle of the airship, controlling a power device in a vector mode and the like.

Owner:达天飞艇(宁夏)有限公司

Extremely low temperature cold head evaporator capable of inhibiting anti-gravity climbing of superfluid helium liquid film

PendingCN114754508AIncrease distanceInhibit anti-gravity climbCompression machinesEvaporators/condensersEngineeringHelium cryogenics

The invention relates to the technical field of superfluid helium low-temperature throttling refrigerators, and discloses an extremely-low-temperature cold head evaporator capable of inhibiting anti-gravity climbing of a superfluid helium liquid film, which comprises a base, an evaporator main body, a top cover, a first connecting pipe, a second connecting pipe and a porous sintering interlayer, according to the ultra-low-temperature cold head evaporator, conventional liquid helium and super-flow liquid helium are separated through the porous sintering interlayer, the temperature before throttling can be effectively controlled through the top cover with the good heat insulation effect and the special structural design of the top cover, anti-gravity climbing of a super-flow helium liquid film can be restrained, and therefore the stability of the pressure and the temperature in the ultra-low-temperature cold head evaporator is guaranteed, and the service life of the ultra-low-temperature cold head evaporator is prolonged. And the device has very positive significance in practical application of the extremely low temperature throttling refrigerating machine working in the superfluid helium temperature region.

Owner:上海铂钺制冷科技有限公司

High temperature gas-cooled reactor helium flow control system and method with incremental adjustment function

ActiveCN112382418BImprove robustnessCorrected outputNuclear energy generationFlow control using electric meansThermodynamicsControl system

The invention discloses a high-temperature gas-cooled reactor helium flow control system and method with an incremental adjustment function, comprising the following steps: 1) calculating the thermal helium temperature correction value used for thermal helium temperature PID adjustment; 2) calculating The power correction value used for the power PID adjustment of the unit; 3) Calculate the helium flow correction value for the helium flow PID adjustment; 4) According to the hot helium temperature correction value for the hot helium temperature PID adjustment, for the unit The power correction value for power PID adjustment and the helium flow correction value for helium flow PID adjustment are used for three-impulse control, and then the reactor is controlled according to the results of the three-impulse control. The system and method can quickly track the change trend of the control variable , to modify the output of the control variable to meet the functional requirements of the reactor tracking the grid load for peak regulation and frequency regulation.

Owner:XIAN THERMAL POWER RES INST CO LTD

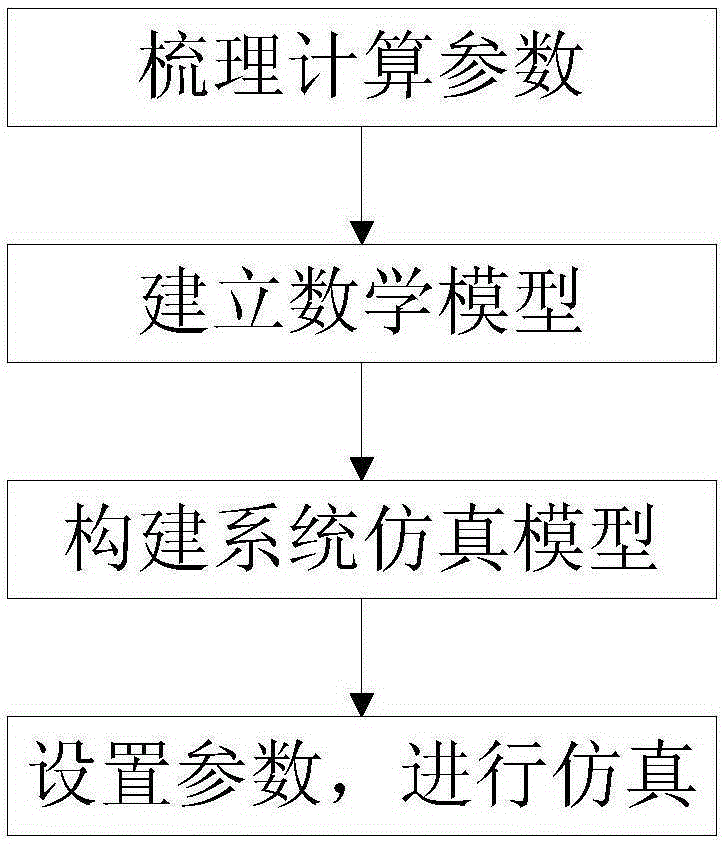

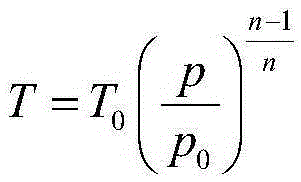

A simulation method for heat transfer process of cold helium cylinder deflation

ActiveCN103473399BImprove calculation accuracySpecial data processing applicationsSolid wallGas cylinder

Disclosed is a simulation method of a cold helium bottle venting and heat transferring process. A cold-helium-bottle inner convective heat transfer mathematical model, an outer convective heat transfer mathematical model, a metal bottle wall heat conduct mathematical model and a cold helium pressure and temperature calculate mathematical module are established by the lumped parameter method through establishing a helium bottle solid wall heat capacity unit, a simulated module is established in system simulating software, influences on helium temperature in the helium bottle by medium convection, metal wall heat capacity and heat conduction are considered, and simulation accuracy of temperature changes in the filling and venting process of a cold helium bottle is improved.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

A superconducting magnet cooling device

A superconducting magnet cooling device. The superconducting magnet (1) is hoisted on the lower surface of the upper end plate of the gas helium container (4) through the pull rod (6), and the superconducting magnet (1) passes through the cold conducting belt (12) and the second stage (11) of the refrigerator (9). connected, and the superconducting magnet (1) is wrapped with multiple layers of heat insulating layers (2). The gas helium container (4) is a closed container, and the neck tube (8) is positioned at the top of the gas helium container (4) and communicates with it. The gas helium container (4) is hoisted on the lower surface of the upper cover plate of the vacuum container (5) through the pull rod (7). The upper cover plate of the gas helium container (4) and the primary cold head (10) of the refrigerator (9) are sealed with indium wire. The outer periphery of the gas helium container (4) is wrapped with multiple layers of heat insulating layers (3). When the temperature of the gas helium container (4) is lower than the temperature of the superconducting magnet (1), helium is filled, and at this time, the superconducting magnet (1) is cooled by solid heat conduction and gas convection. When the temperature of the gas helium container (4) is higher than that of the superconducting magnet (1), the helium is extracted.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

A Fusion Reactor Breeding Cladding Pebble Bed Blowing Tritium Helium Thermal Hydraulic Characteristics Experimental Device and Method

An experimental device for the thermal and hydraulic characteristics of tritium-helium blown in a fusion reactor breeding blanket pebble bed is mainly used to study the flow and heat transfer characteristics of the fusion reactor solid-state breeding blanket blowing tritium-helium gas between the pebble bed breeder pellets. Use a non-contact high-frequency induction power supply to heat the quasi-breeder metal balls to simulate the high power density nuclear heat generated by the breeder balls in the pebble bed, carry out the temperature, speed, and pressure changes of tritium-helium blowing, and arrange the breeder balls Experimental research on the thermal-hydraulic characteristics of the pebble bed under the conditions of mode, size, and power density changes, measuring the temperature distribution of the proliferator pellets and the wall surface of the pebble bed, and obtaining the relational expression of the convective heat transfer criterion and the flow resistance relational expression, which is the laboratory condition The experiment demonstrates the nuclear heat transfer of neutrons deposited on the breeder pellets in the pebble bed and the flow and heat transfer characteristics of tritium-helium blowing, and verifies the feasibility of the solid-state breeder envelope design scheme, the correctness of the numerical method and the data, for Provide support for the research and development of ITER China's solid-state experimental cladding module.

Owner:中国人民解放军陆军军官学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com