High-pressure-helium obtaining method for liquid-hydrogen temperature zone

A method for obtaining helium and a technology for helium gas, which are applied in the field of low-temperature rocket storage tank pressurization and conveying system testing, can solve the problems of the complex structure of the cold helium pressure regulator, the difficulty in adapting to the high-density launch requirements of rockets, and the difficulty in processing and comprehensive testing. Achieve the effect of saving test funds, saving test costs, improving redundancy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

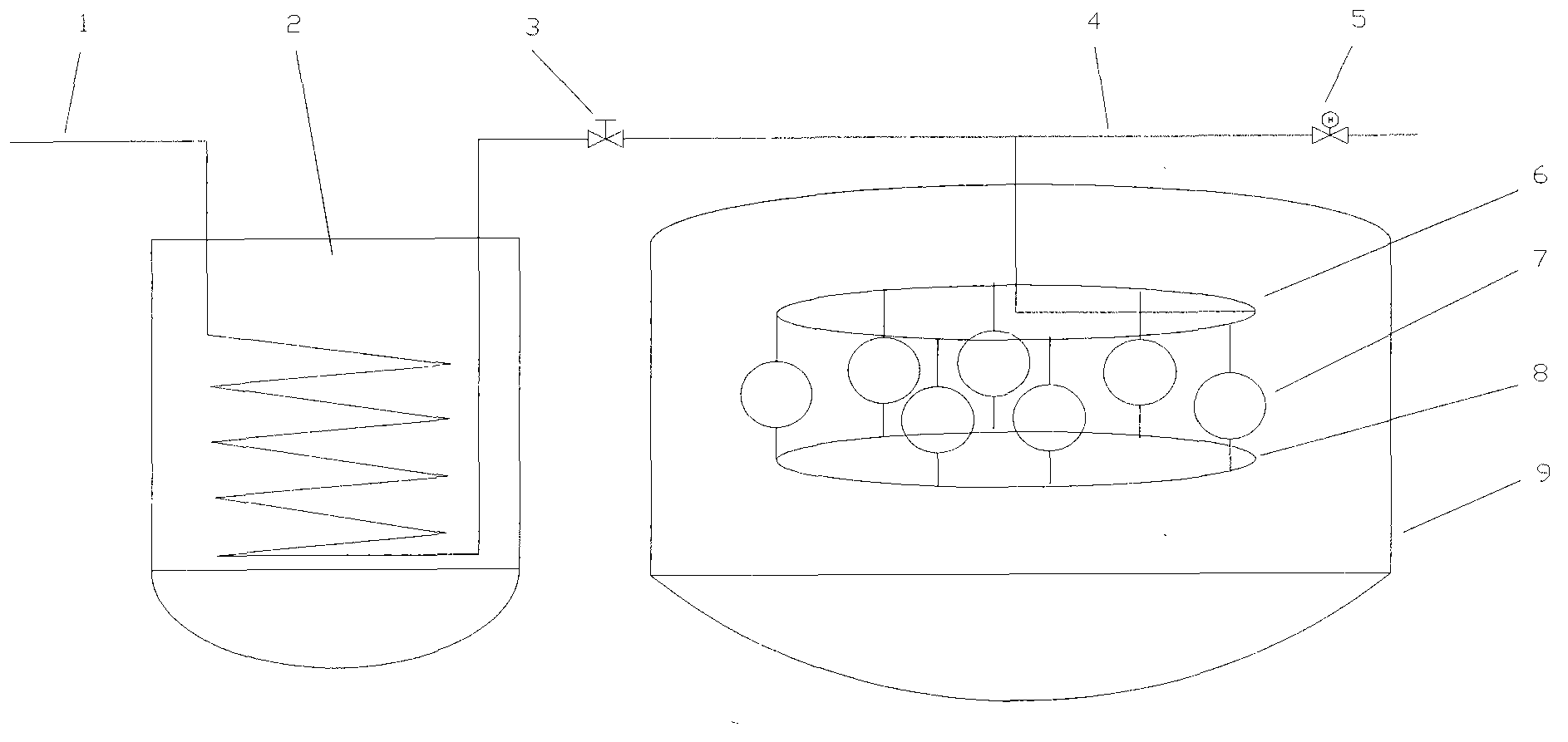

[0012] Such as figure 1 As shown, the device used in the present invention mainly consists of a helium gas inlet pipeline 1, a liquid nitrogen heat exchanger 2, a low-temperature manual valve 3, a helium gas outlet pipeline 4, a low-temperature electromagnetic valve 5, an upper gas collecting ring 6, a titanium Bottle 7, lower gas collecting ring 8, liquid hydrogen Dewar 9 form. The preparation process of helium in the liquid hydrogen temperature zone of the present invention is as follows: firstly, the low-temperature manual valve 3 is opened, and the normal-temperature and high-pressure helium enters the titanium bottle 7 through the helium inlet pipeline 1, the liquid nitrogen heat exchanger 2, and the upper gas collecting ring 6, and increases Press down to 5MPa, then close the low-temperature manual valve 3, fill the liquid nitrogen heat exchanger 2 and the liquid hydrogen Dewar 9 with liquid nitrogen and liquid hydrogen respectively, then open the low-temperature manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com