Patents

Literature

59 results about "Helium pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Helium can be made solid at room temperature if the pressure rises to about 114 thousand atmospheres: that is a pressure of 1.67 million psi, or 834 tons per square inch.

Method and device for evaluating physical parameters of an underground deposit from rock cuttings sampled therein

InactiveUS20050178189A1Short timeLimited spaceElectric/magnetic detection for well-loggingPermeability/surface area analysisMedicinePorous medium

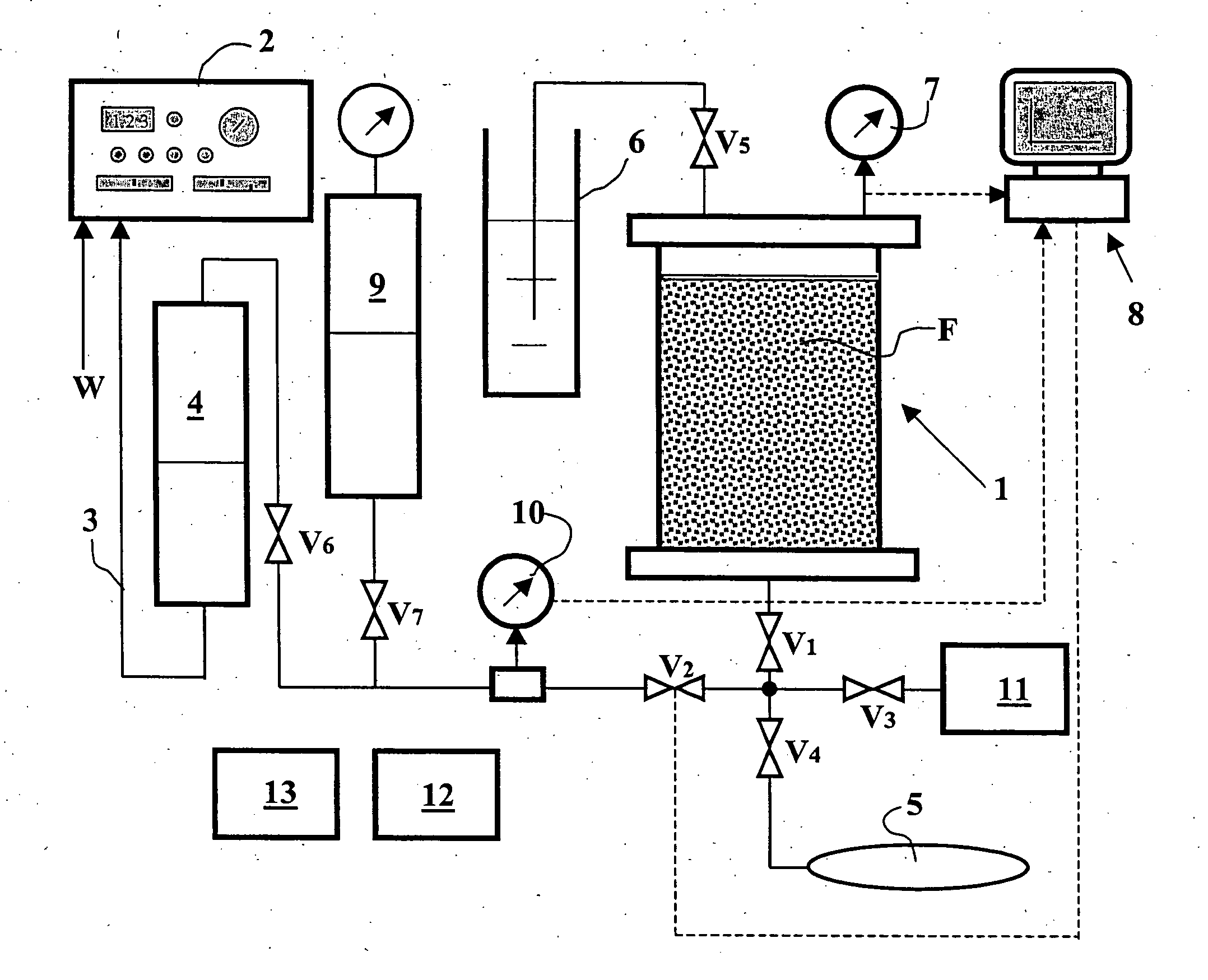

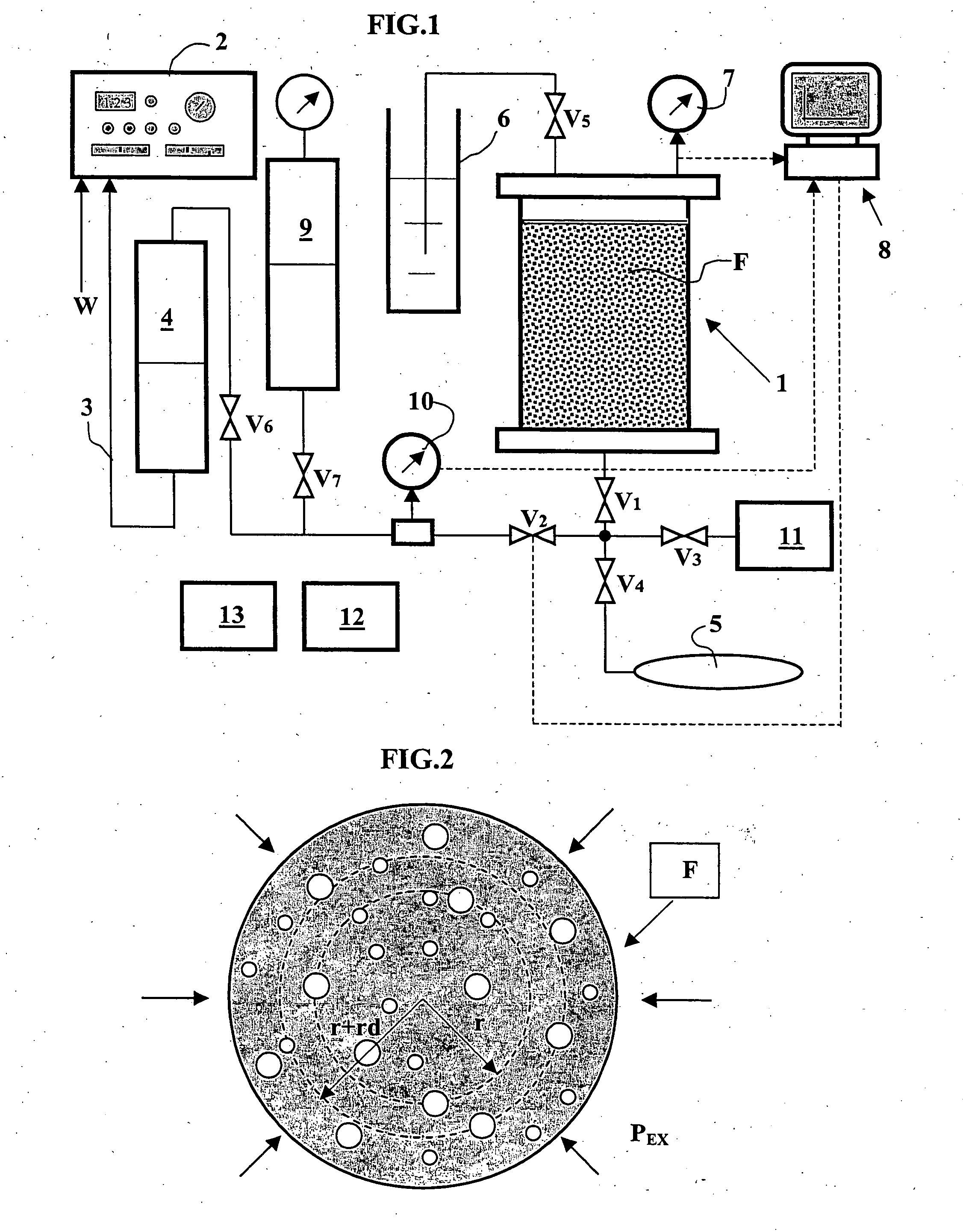

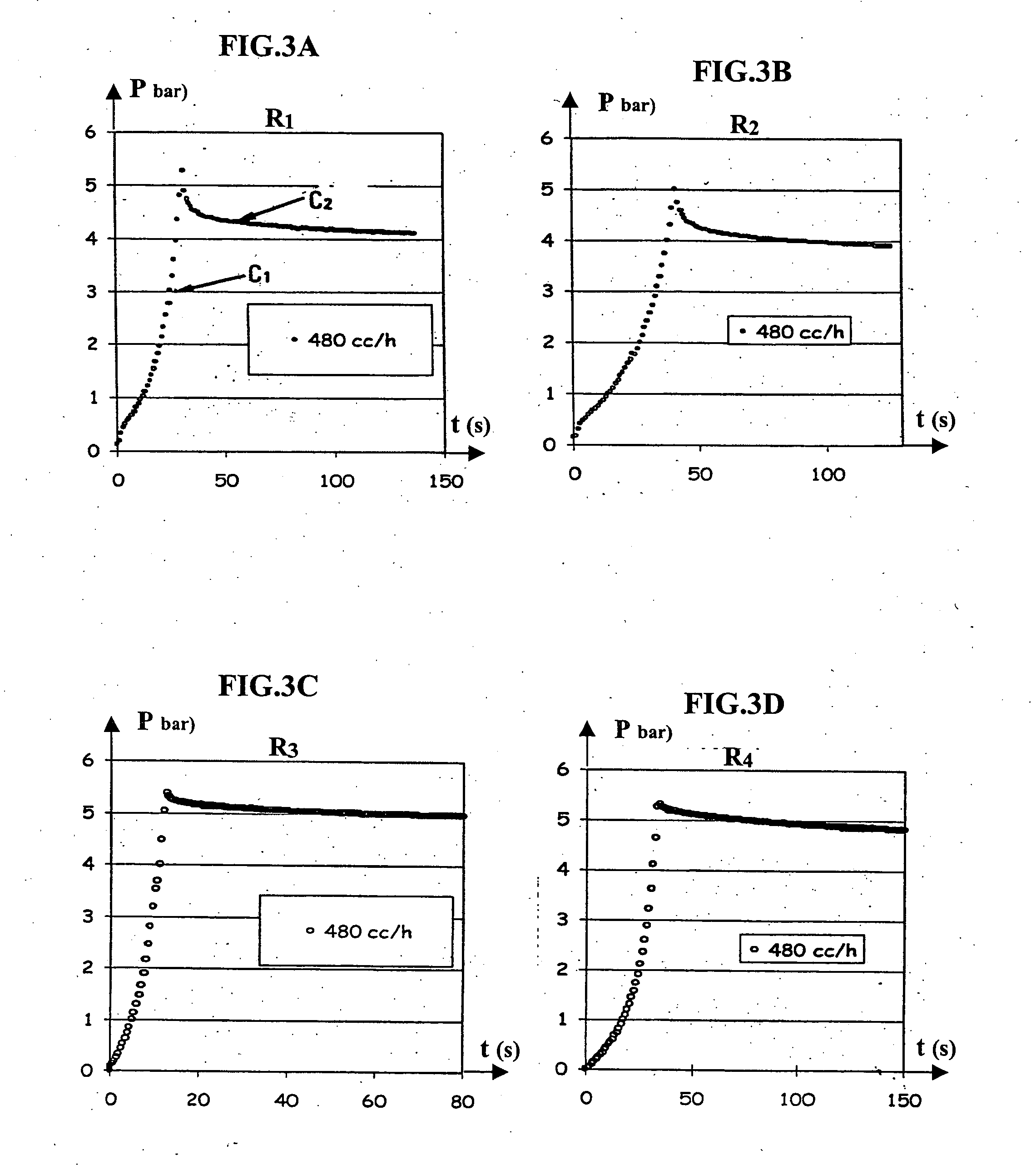

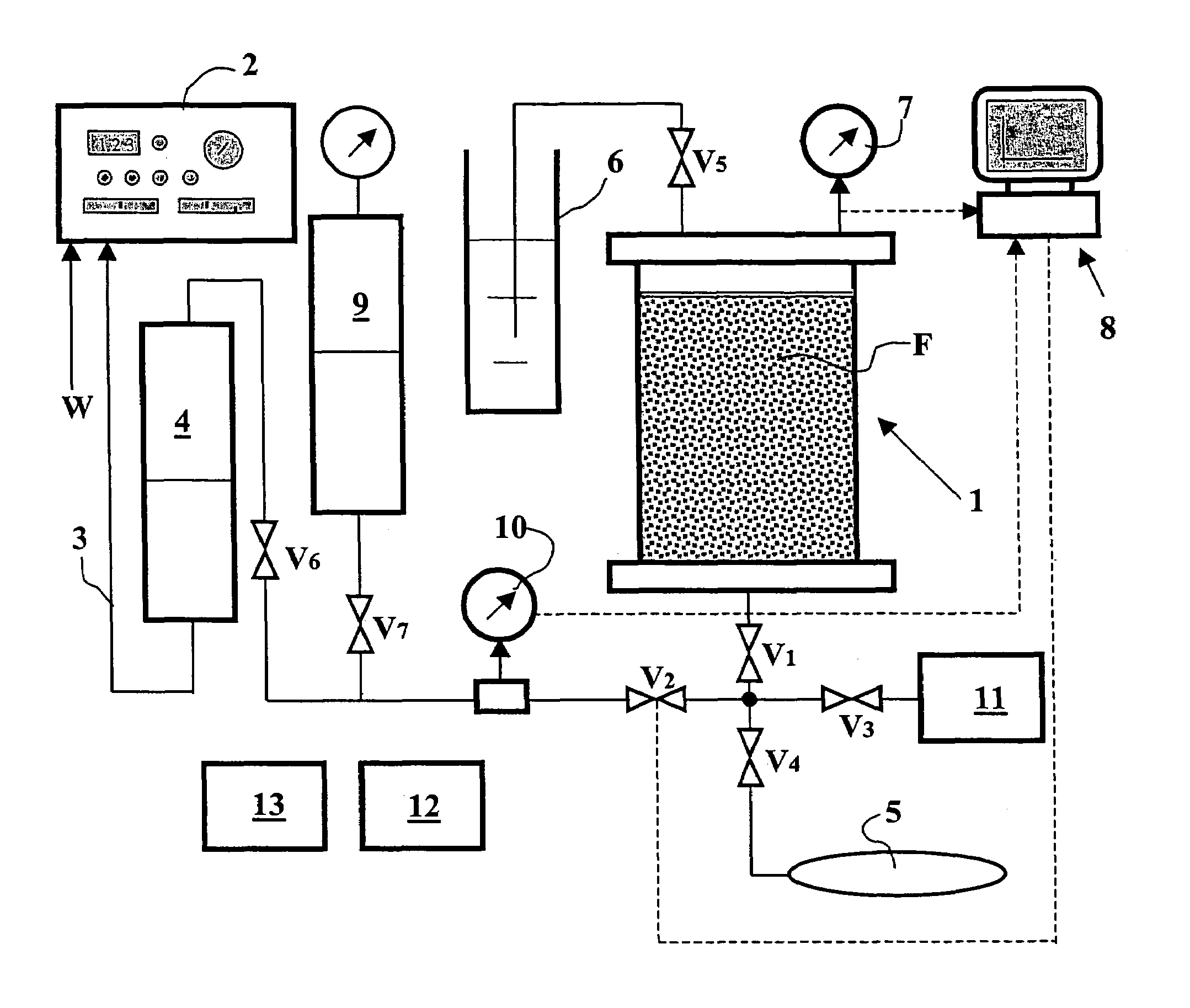

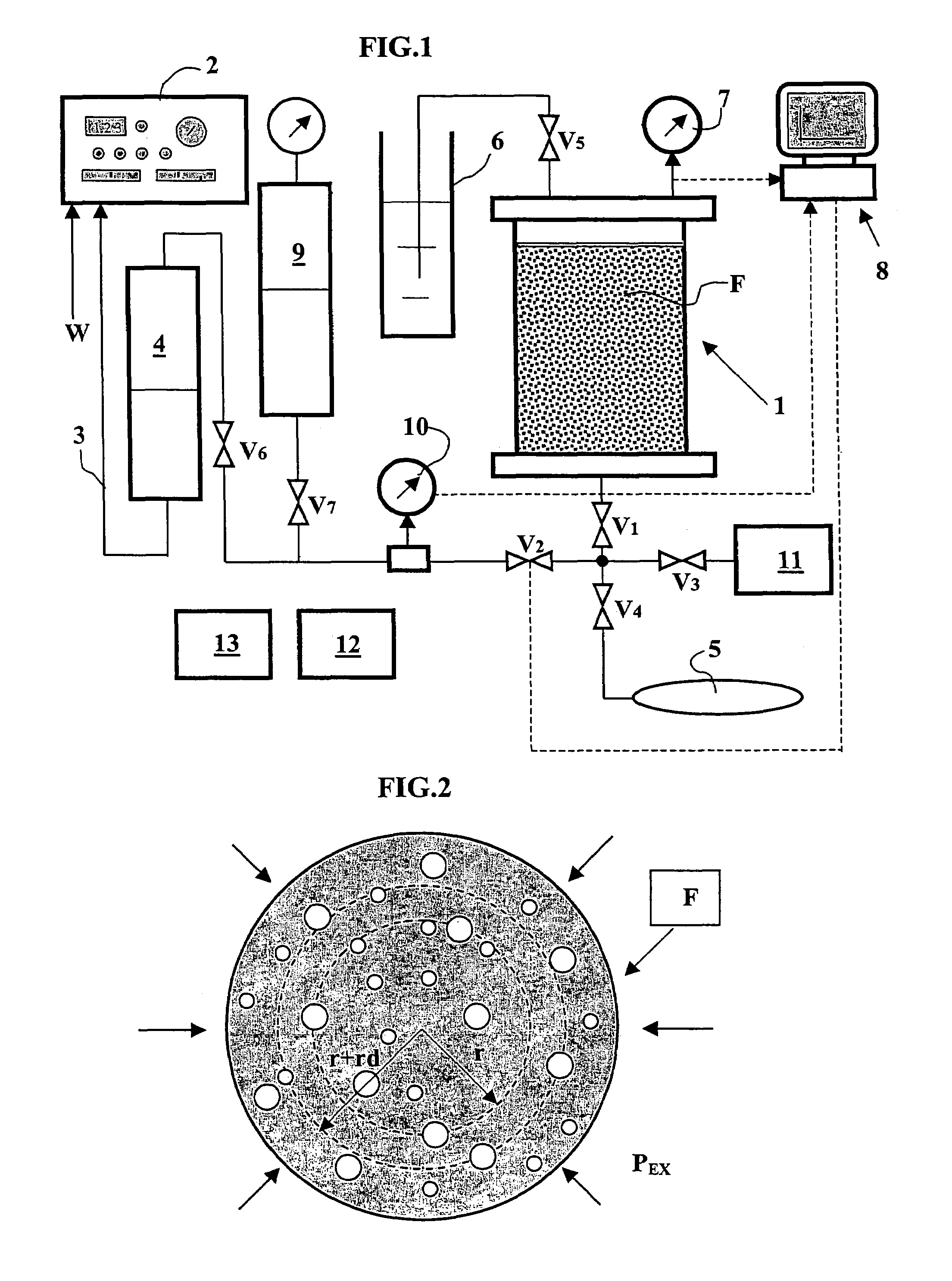

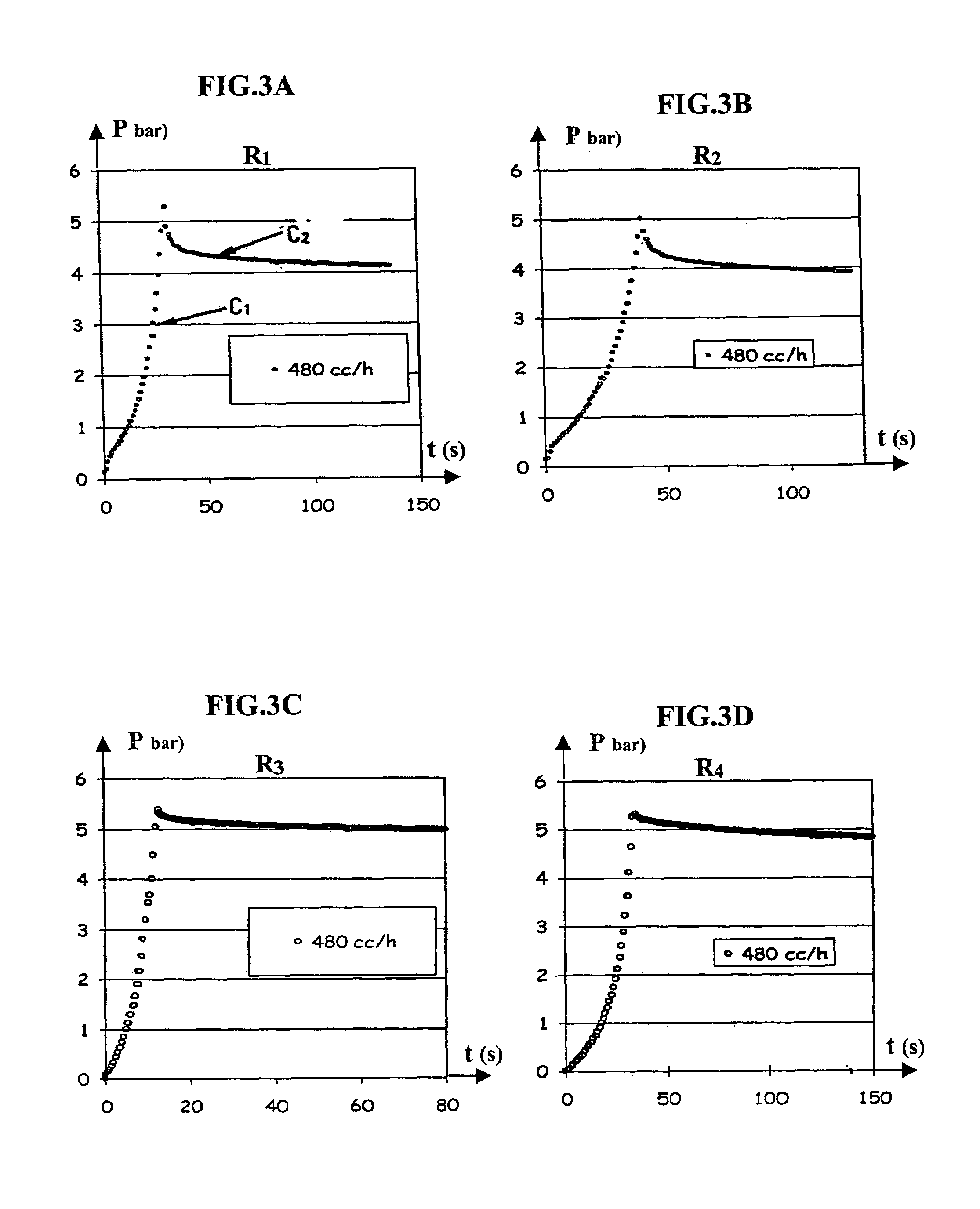

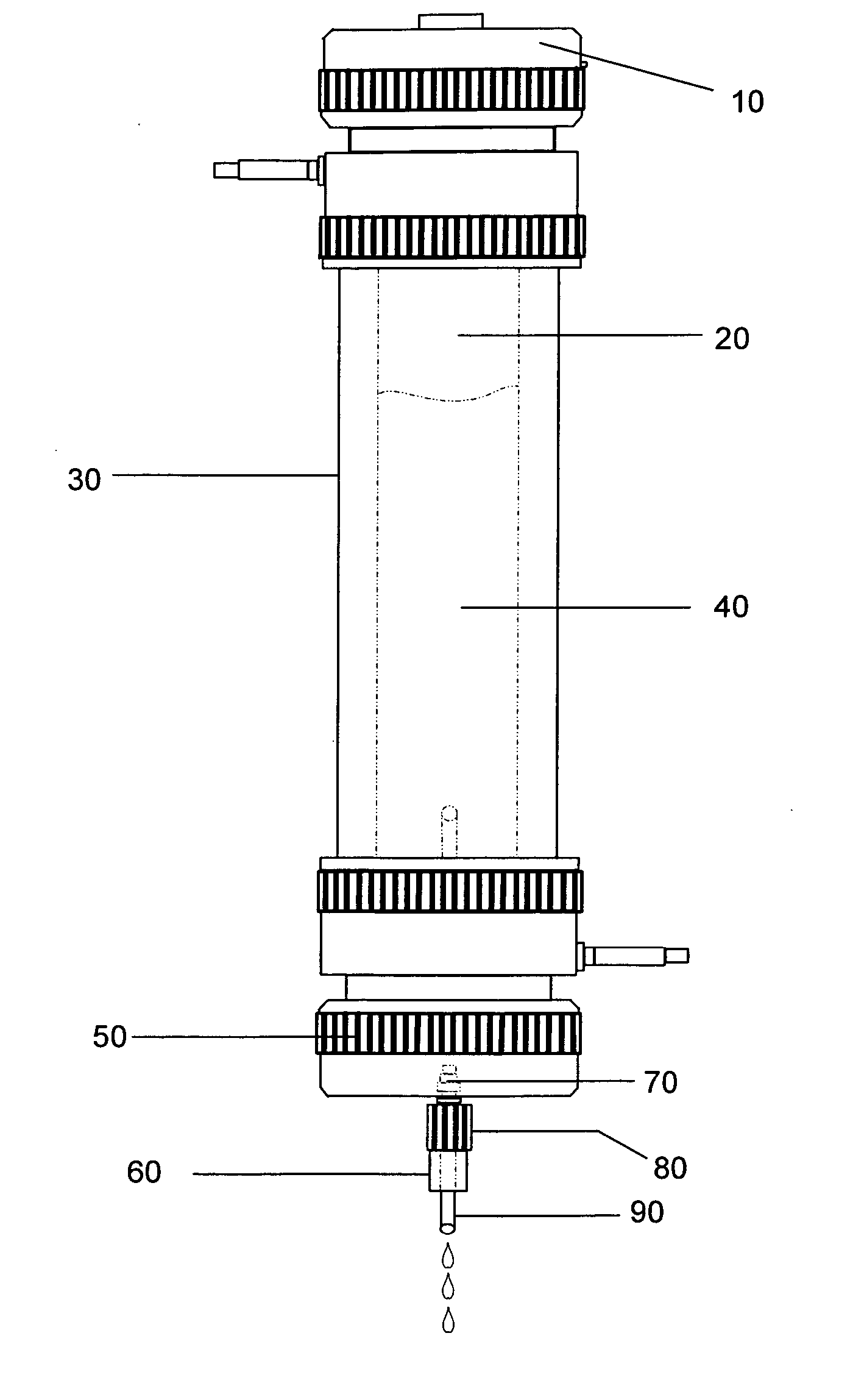

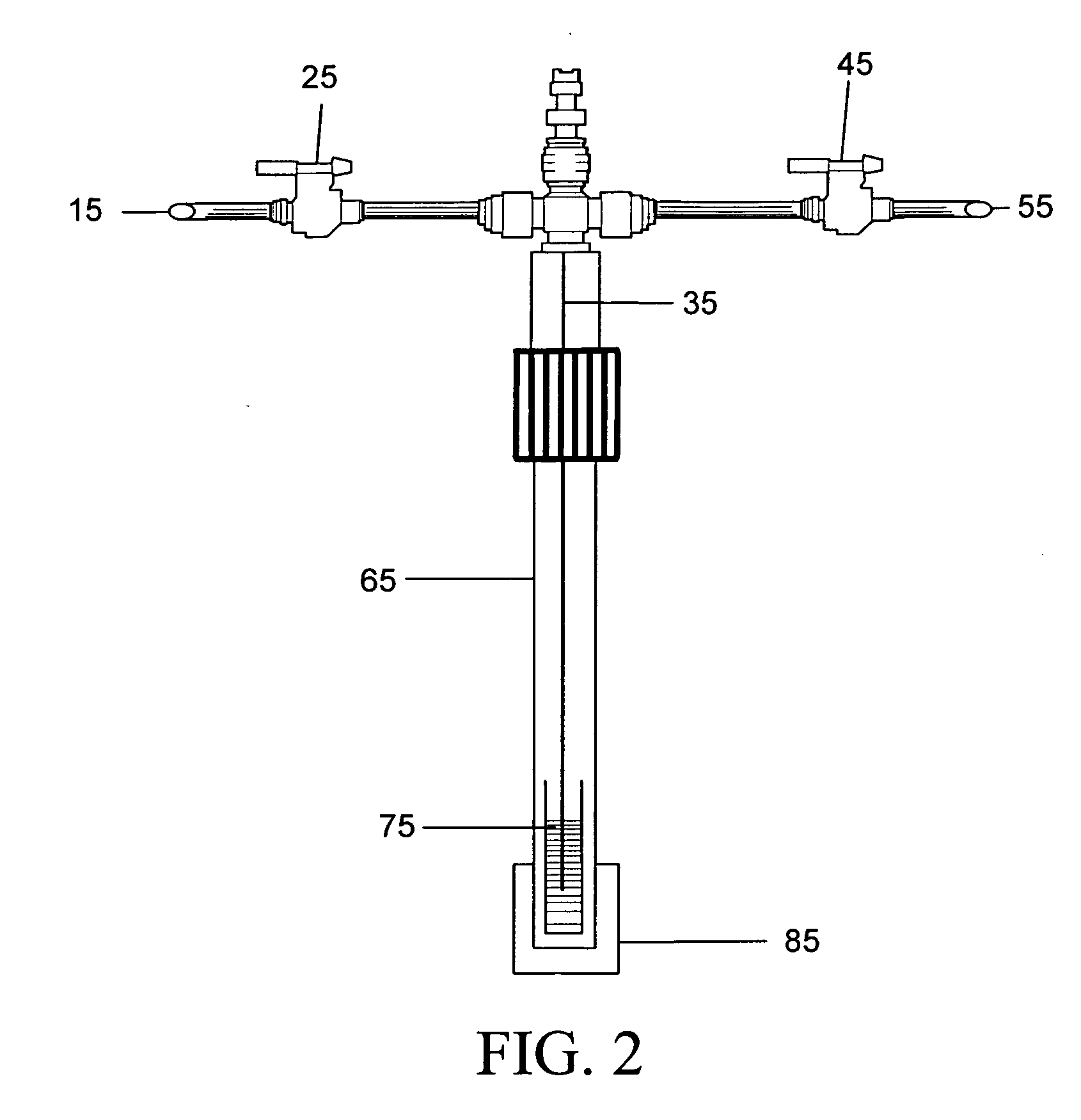

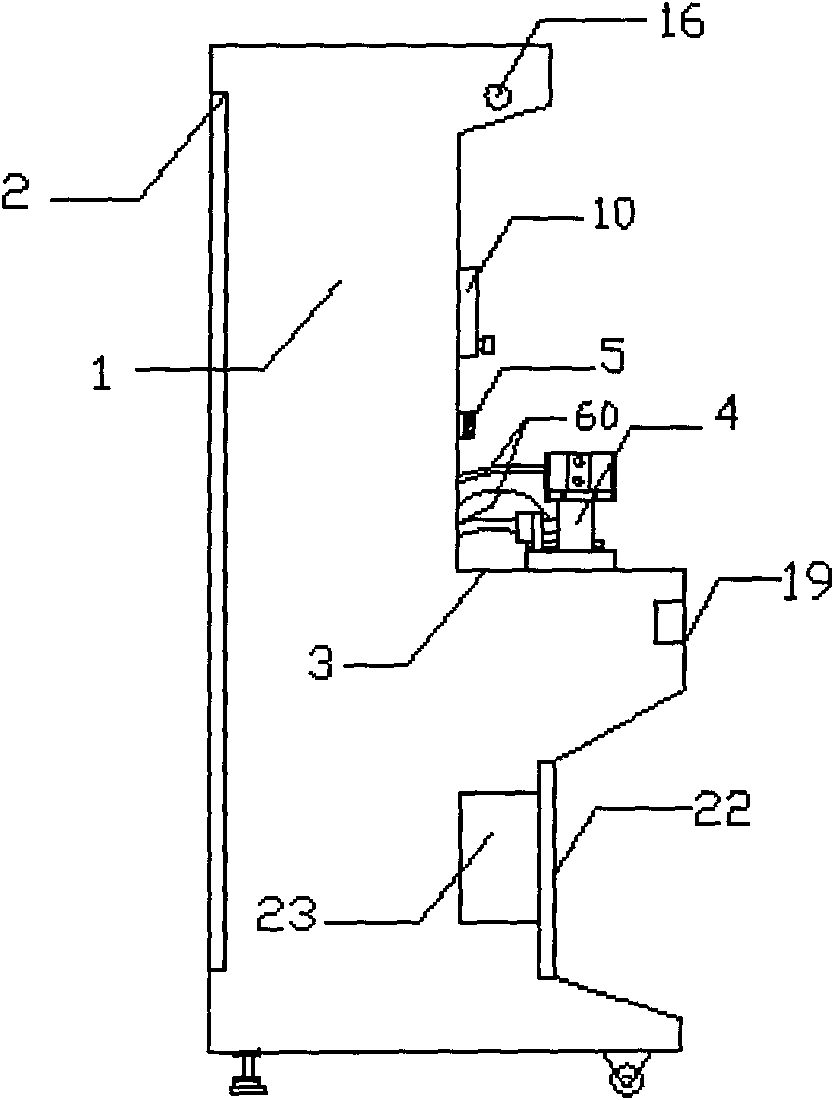

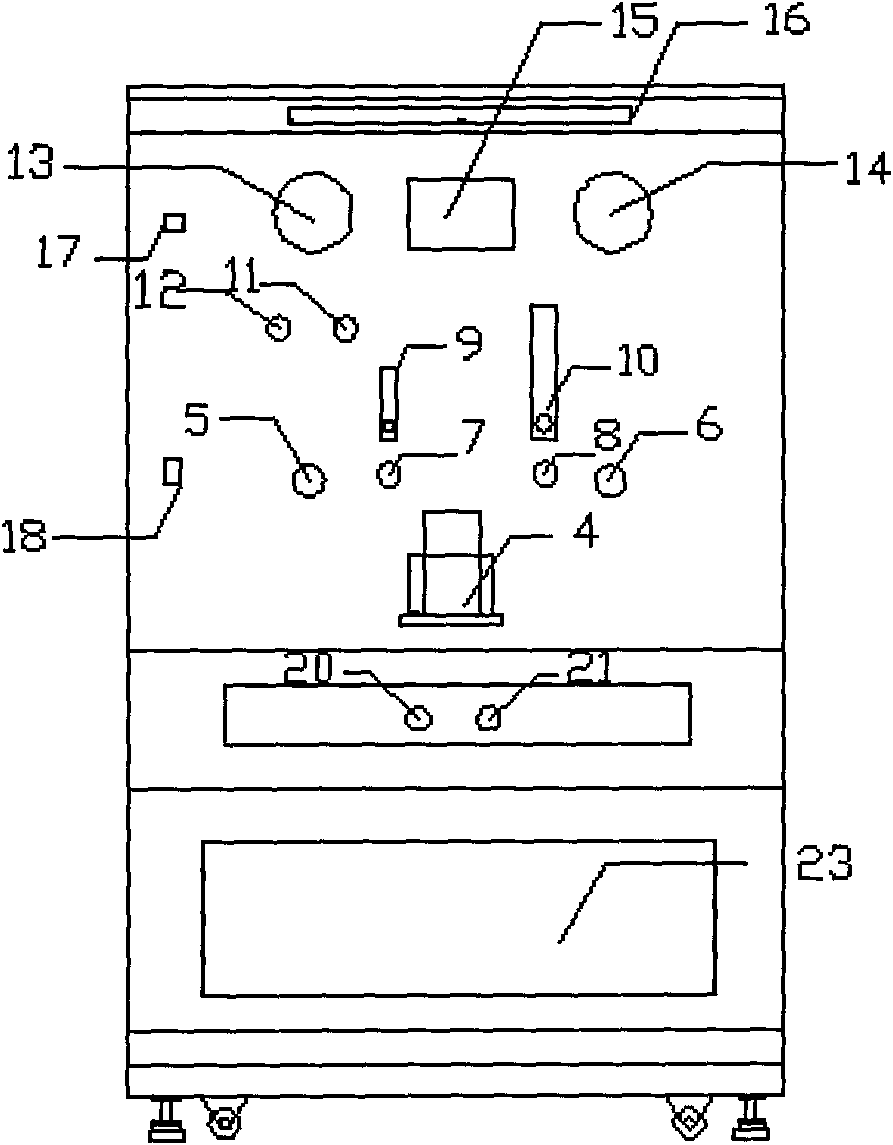

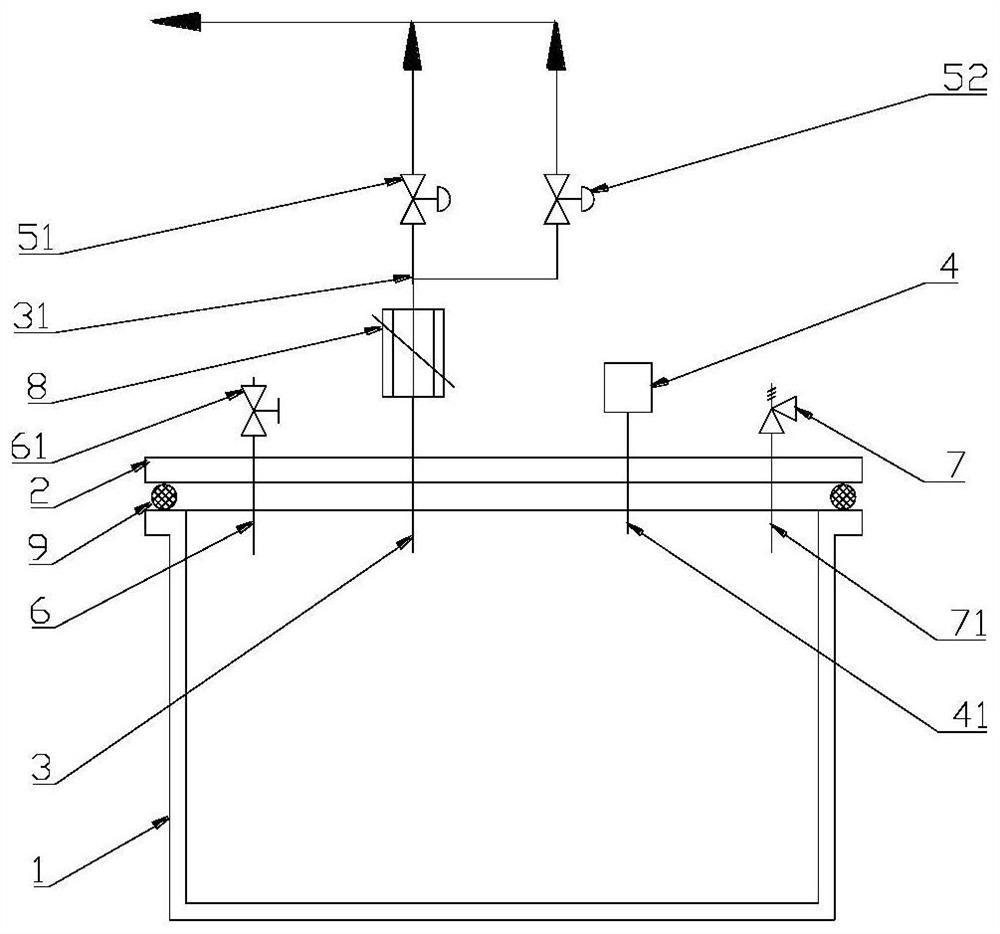

Method and device for evaluating simultaneously, with the same equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented natural or artificial porous medium The porosity of the fragments is measured by means of helium pressure tests according to a protocol known in the art. The chamber (1) containing the fragments is communicated with a tank (11) whose volume is also known and containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the fragments mass are also measured. Combining these measurements allows to determine the porosity of the samples and the density of the rock. Their permeability is then measured by immersing them in a viscous fluid and by communicating the chamber with viscous fluid at a determined pressure contained in a vessel (9) so as to compress the gas trapped in the pores of the rock, according to two different protocols. The values of the physical parameters are determined by modelling the evolution of the pressure or of the volume in the chamber and by means of an iterative adjustment. Applications: petrophysical measurements from drilling cuttings or crushed cores for example.

Owner:INST FR DU PETROLE

Method and device for evaluating physical parameters of an underground deposit from rock cuttings sampled therein

InactiveUS7131317B2Rapid pressure increaseShorten communication timeElectric/magnetic detection for well-loggingPermeability/surface area analysisPorous mediumMedicine

A method and device evaluate simultaneously, with the same equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented natural or artificial porous medium. The porosity of the fragments is measured by means of helium pressure tests according to a protocol known in the art. The chamber (1) containing the fragments is communicated with a tank (11) whose volume is also known and containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the fragments mass are also measured. Combining these measurements allows to determine the porosity of the samples and the density of the rock. Their permeability is then measured by immersing them in a viscous fluid and by communicating the chamber with viscous fluid at a determined pressure contained in a vessel (9) so as to compress the gas trapped in the pores of the rock, according to two different protocols. The values of the physical parameters are determined by modelling the evolution of the pressure or of the volume in the chamber and by means of an iterative adjustment.

Owner:INST FR DU PETROLE

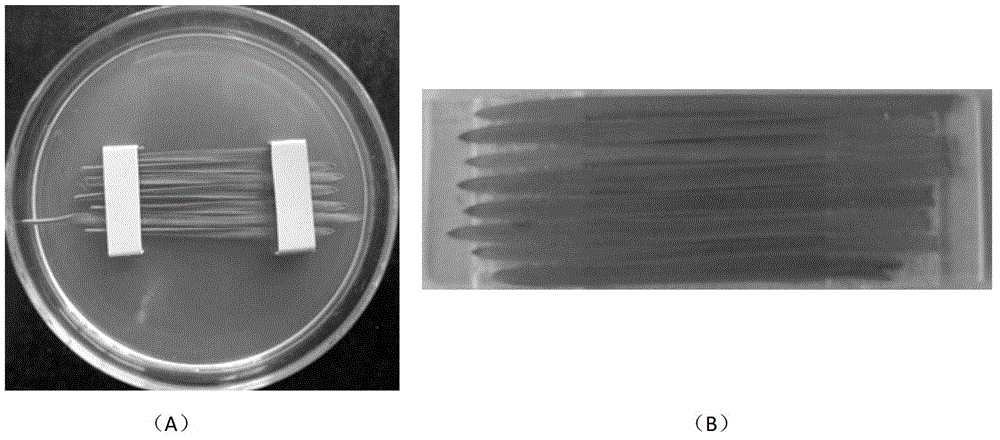

Tube structure with sol-gel zirconia coating

InactiveUS20070095736A1Improve stabilityUnique surface chemistryIon-exchange process apparatusOther chemical processesKetoneHYDROSOL

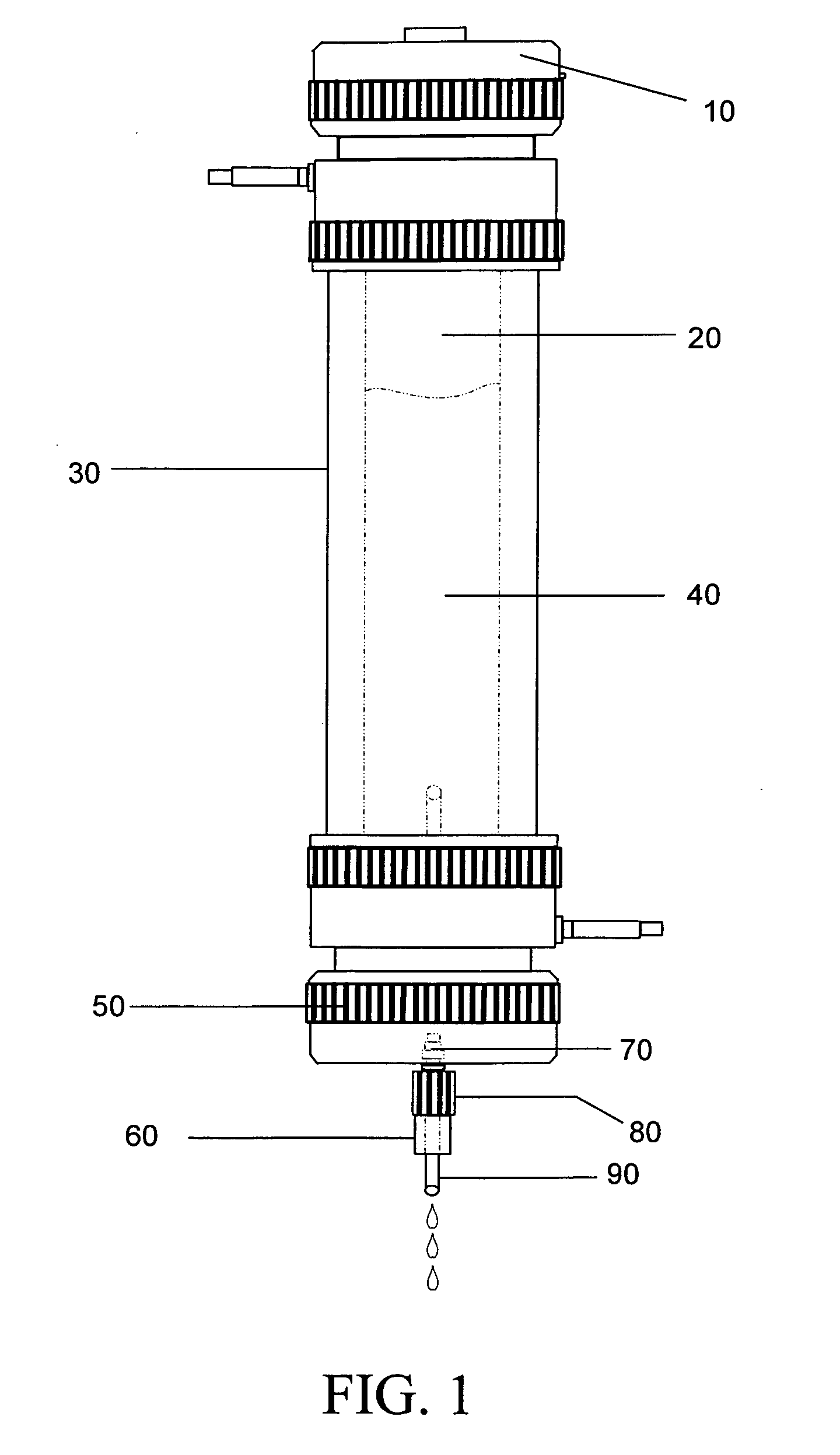

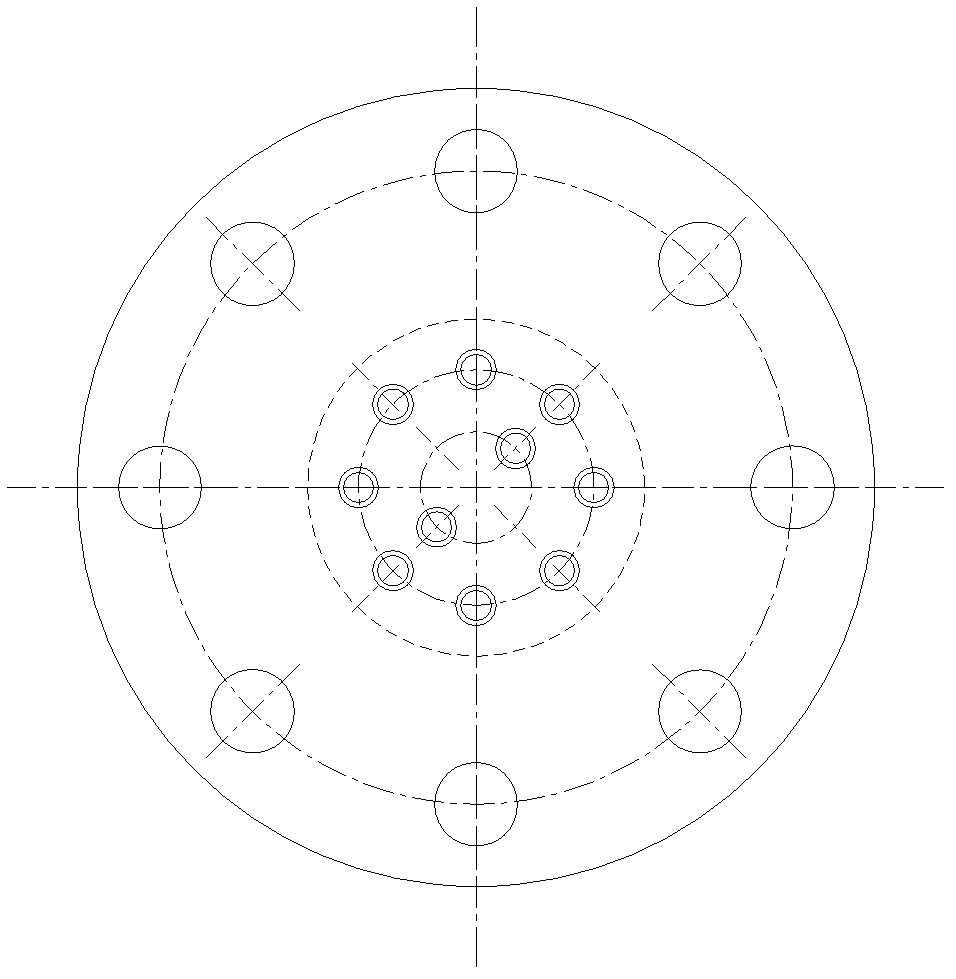

The subject invention concerns zirconia-based hybrid organic-inorganic sol-gel coating for optional use as a stationary phase in capillary microextraction (CME), gas chromatographic (GC), high performance liquid chromatography (HPLC), capillary electrophoresis (CE), capillary electrochromatography (CEC) and related analytical techniques. Sol-gel chemistry is employed to chemically bind a hydroxy-terminated silicone polymer (polydimethyldiphenylsiloxane, PDMDPS) to a sol-gel zirconia network. In one embodiment, a fused silica capillary is filled with a properly designed sol solution to allow for the sol-gel reactions to take place within the capillary. In the course of this process, a layer of the evolving hybrid organic-inorganic sol-gel polymer becomes chemically bonded to the silanol groups on the inner capillary walls. The unbonded part of the sol solution is expelled from the capillary under helium pressure, leaving behind a chemically bonded sol-gel zirconia —PDMDPS coating on the inner walls of the capillary. Polycyclic aromatic hydrocarbons, ketones, and aldehydes are efficiently extracted and preconcentrated from dilute aqueous samples followed by GC separation of the extracted analytes.

Owner:MALIK ABDUL +1

Cooling method of low-temperature superconducting magnet and system thereof

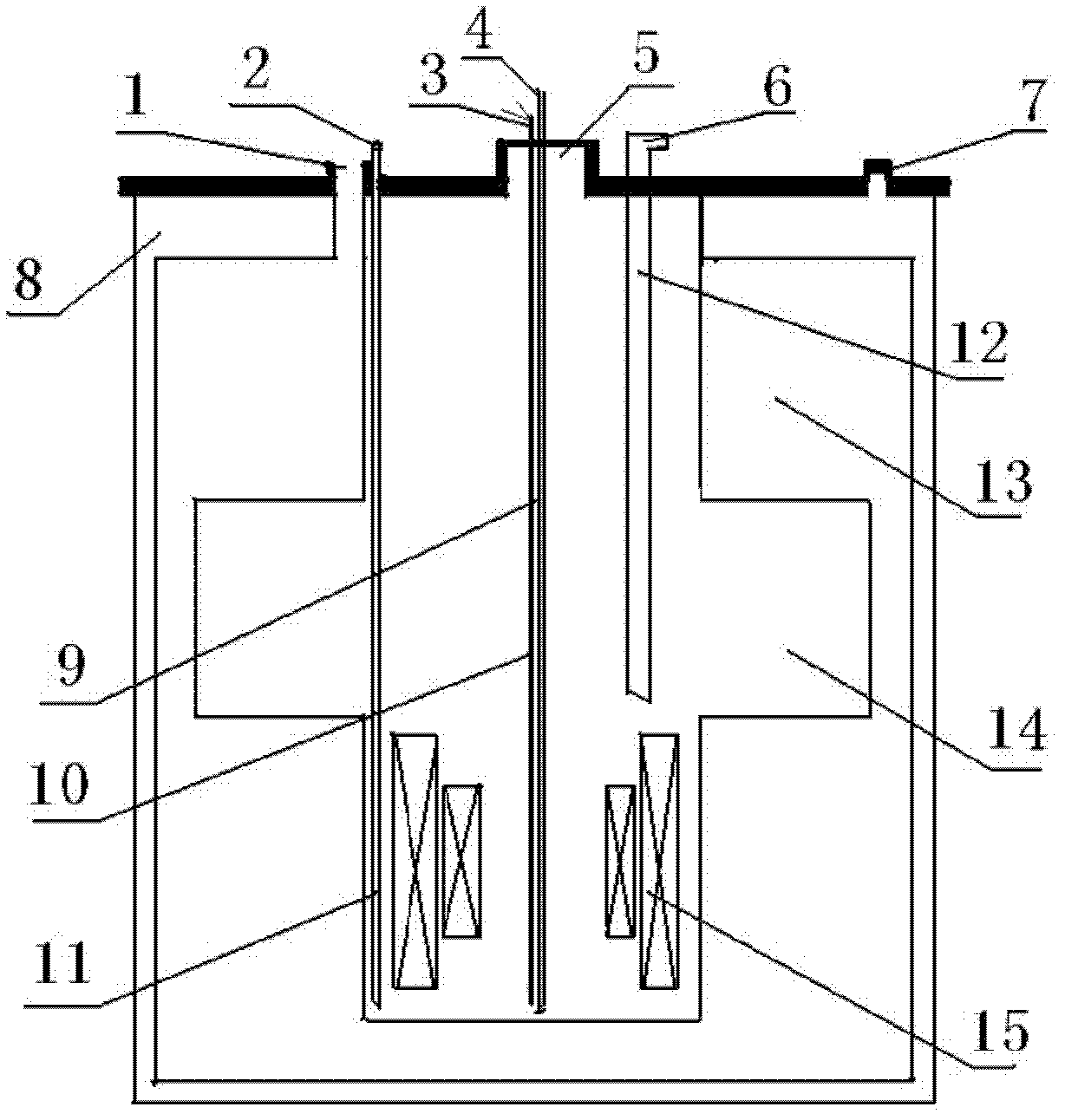

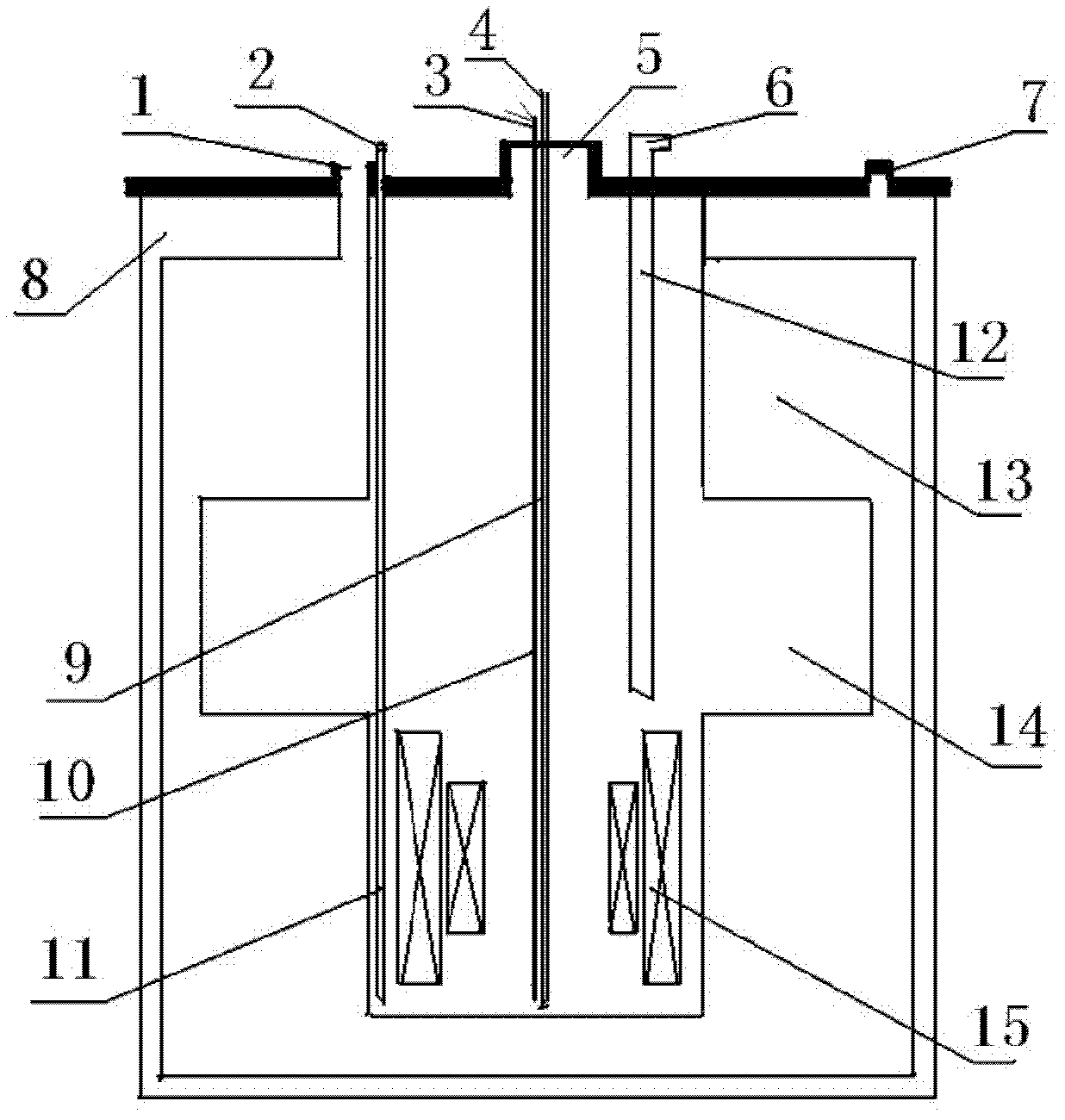

ActiveCN102436898AReduce consumptionSuperconducting magnets/coilsSuperconducting CoilsLiquid nitrogen

The invention relates to a cooling method of a low-temperature superconducting magnet and a system thereof. The characterized is that before cooling the low-temperature superconducting magnet by liquid helium, a superconducting magnet coil is precooled by using liquid nitrogen, and the liquid nitrogen is completely discharged by using the helium pressure method; and then the superconducting magnet coil cooled to the temperature of the liquid nitrogen is cooled to the temperature of the liquid helium by using the liquid helium, thus effectively reducing the consumption of the liquid helium with high price and scarce resources in the process of cooling the existing low-temperature superconducting magnet.

Owner:西部超导材料科技股份有限公司

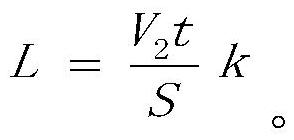

Precision calibrating method of container volume

InactiveCN1673693AVolume Accurate CalibrationContainer/cavity capacity measurementThermodynamicsEngineering

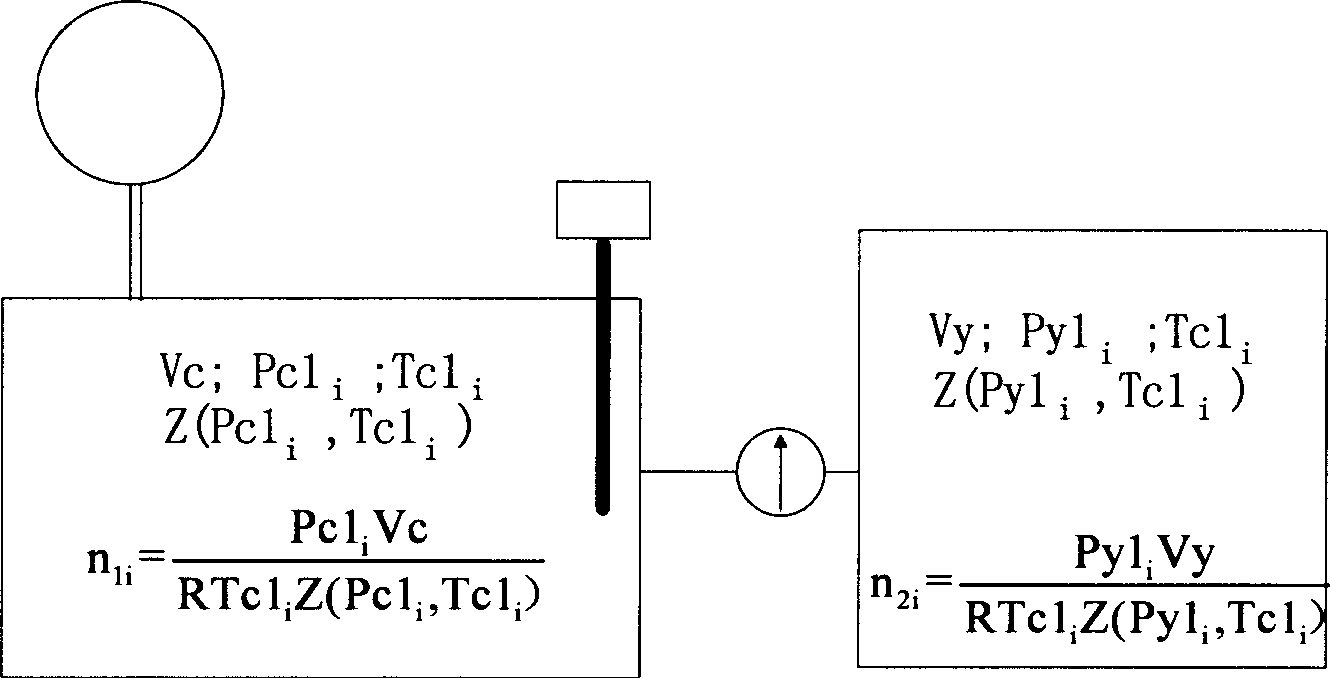

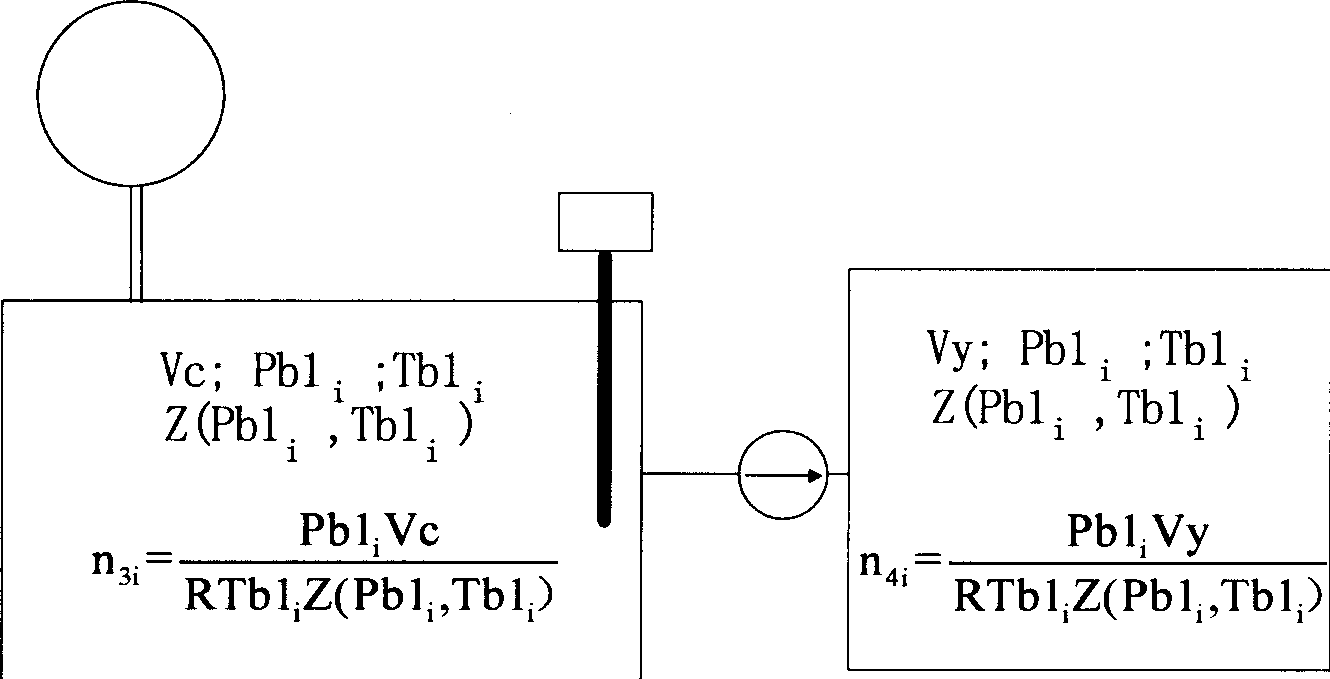

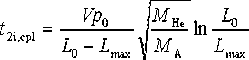

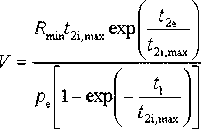

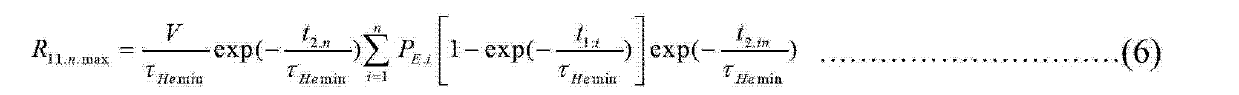

The simple and precise container volume calibrating method adopts helium with stable stability and less wall adsorption as calibrating gas. The calibration includes the following steps: recording the helium pressure and temperature in the operation, establishing dualistic first order equation about the volumes of the first container and the second container based on the MBWR equation and law of conservation of mass; adding steel balls in known volume to alter the volume of the second container; establishing dualistic first order equation about the volumes of the first container and the second container with altered volume similarly; reducing the equation set to obtain several values of the container volumes; calculating the average values and medium values as the final calibrated values optionally. The present invention makes it possible to calibrate the volume of container precisely.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Mass spectrometer leak detection helium pre-filling method capable of prolonging detection waiting time of sealing device

InactiveCN103207050AThe process is simple and not complicatedEasy to masterDetection of fluid at leakage pointEngineeringMass spectrometry

The invention provides a mass spectrometer leak detection helium pre-filling method capable of prolonging the detection waiting time of a sealing device, is applicable to judging whether the leak rate index of a detected helium pre-filling sealing device is qualified, and belongs to the technical field of vacuum leak detection and instruments. The method has the advantages that the problem that a large leak hole in a molecular flow state cannot be identified by coarse detection due to long detection waiting time is solved, so that the dominant position of the helium pre-filling method is maintained; and by taking a redetection and coarse detection helium pressure method as auxiliary measures of the helium pre-filling method, the minimum detectable equivalent standard leak rate of the helium pre-filling method is lower than that of the helium pressure method by a plurality of orders of magnitude. The invention adopts the technical scheme that various types of judgment trend are analyzed and exhausted, corresponding methods are taken one by one, and corresponding criteria are made. The method is characterized in that the redetection and coarse detection helium pressure method which is taken as the auxiliary measures of the helium pre-filling method is endowed with a new important function, so that detectability is remarkably improved.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

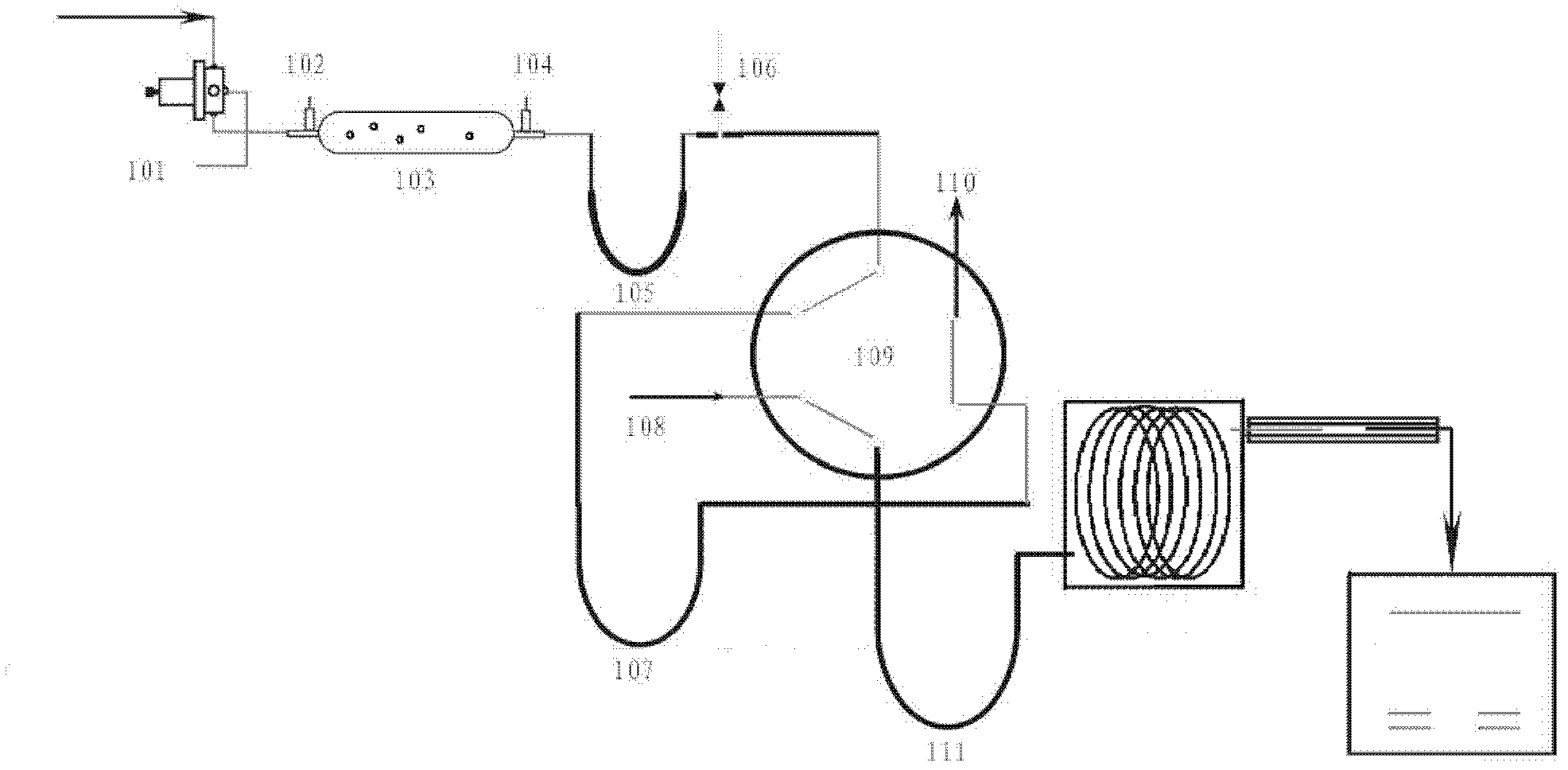

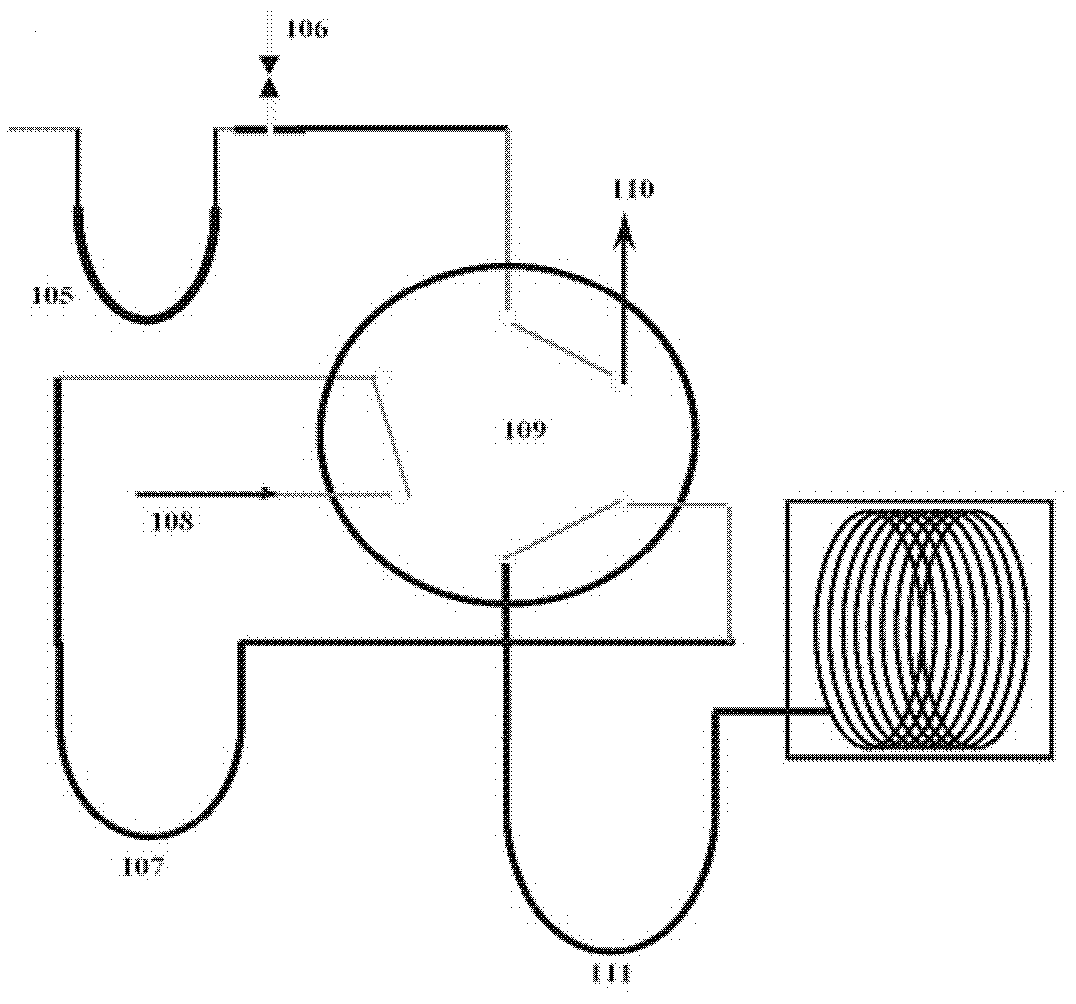

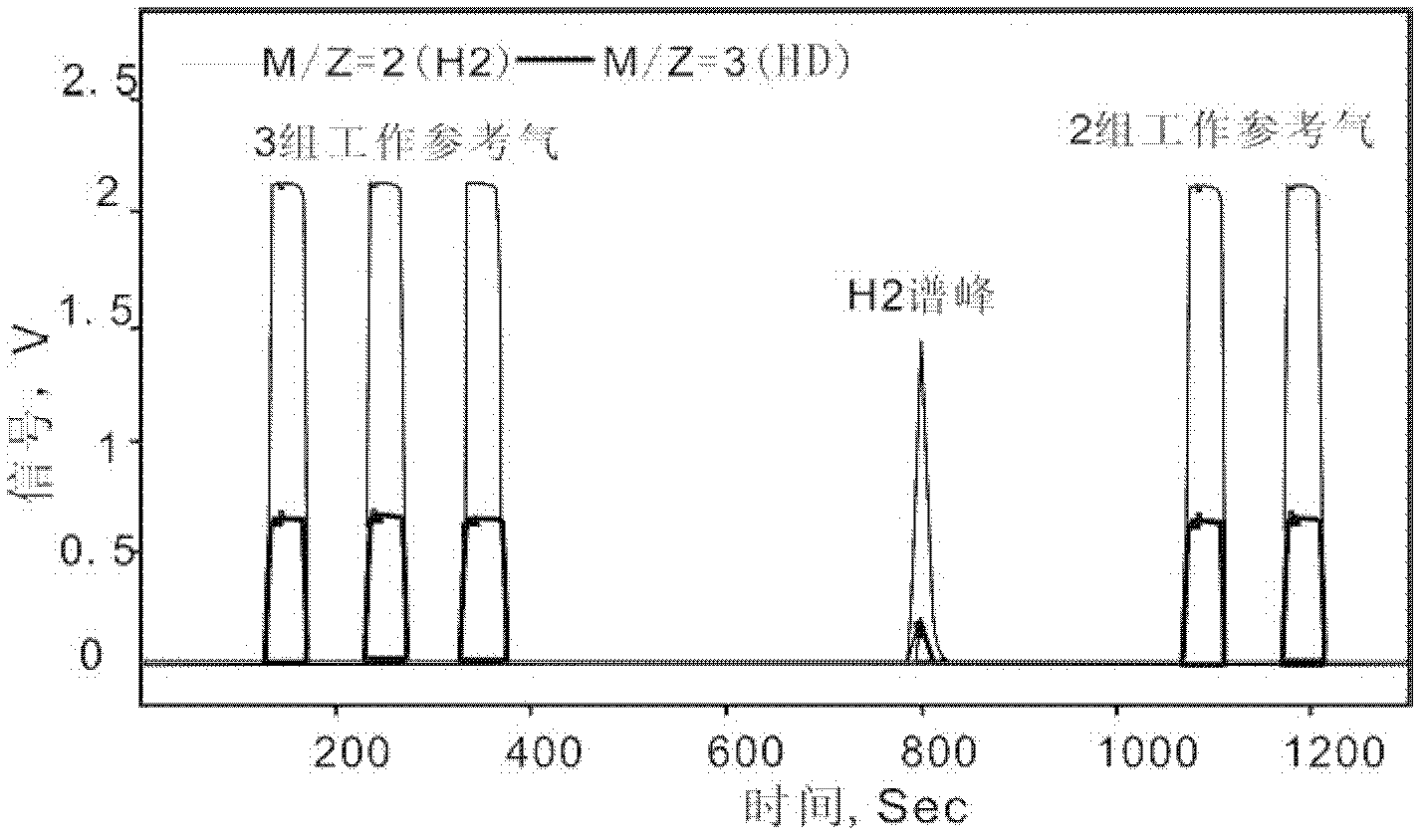

Online analysis pretreatment device for trace hydrogen isotopes in natural gas

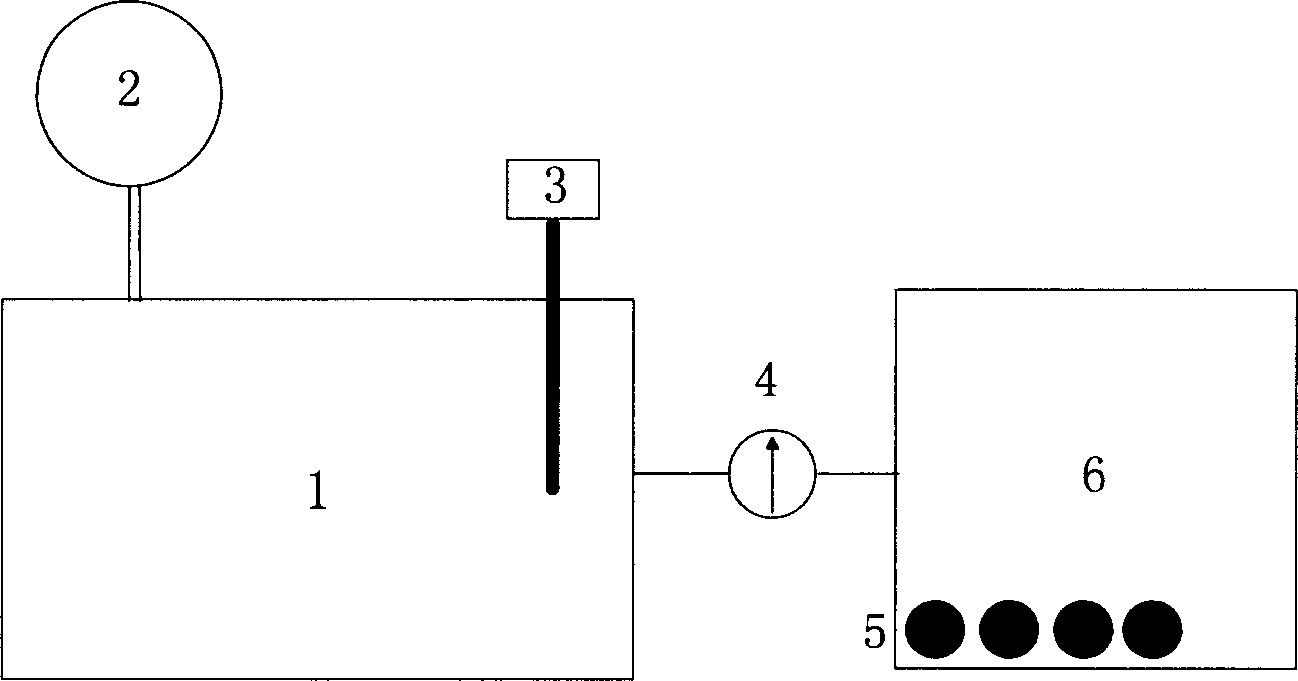

ActiveCN103048412AEnables splitless injectionRealize automatic controlComponent separationPhysical chemistryProduct gas

Owner:CHINA PETROLEUM & CHEM CORP +1

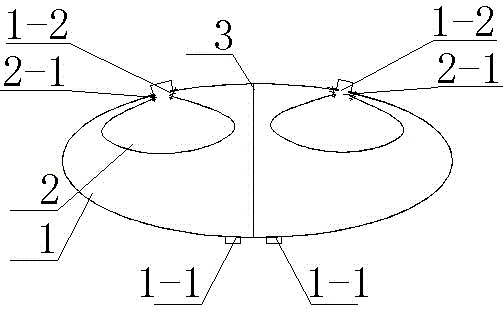

Novel gasbag for airship

InactiveCN104590540AAvoid damageReduce leakageGas-bag arrangementsClassical mechanicsMechanical engineering

The invention relates to a novel gasbag for an airship. An air bag (1) is provided with one or more air openings (1-1) and a pair of helium openings A (1-2). The pair of air opening (1-1) and the pair of helium openings A (1-2) are provided with valves respectively, a pair of helium bags (2) are provided with helium openings B (2-1) respectively and arranged in the air bag (1), the helium openings B (2-1) of the pair of helium bags (2) are located at the helium openings A (1-2) in the air bag (1) respectively and coincide with the helium openings A (1-2), and a bracing wire (3) is installed in the air bag (1) and located between the pair of helium bags (2). The novel gasbag for the airship has the advantages that the pressure of helium in the helium bags and the pressure of air in the air bag are in balance, the pressure difference value is very small, and therefore helium leakage caused by the pressure difference is reduced.

Owner:CHINA SPECIAL TYPE FLIER RES INST

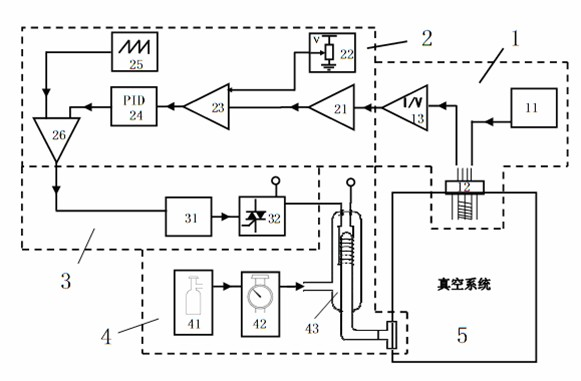

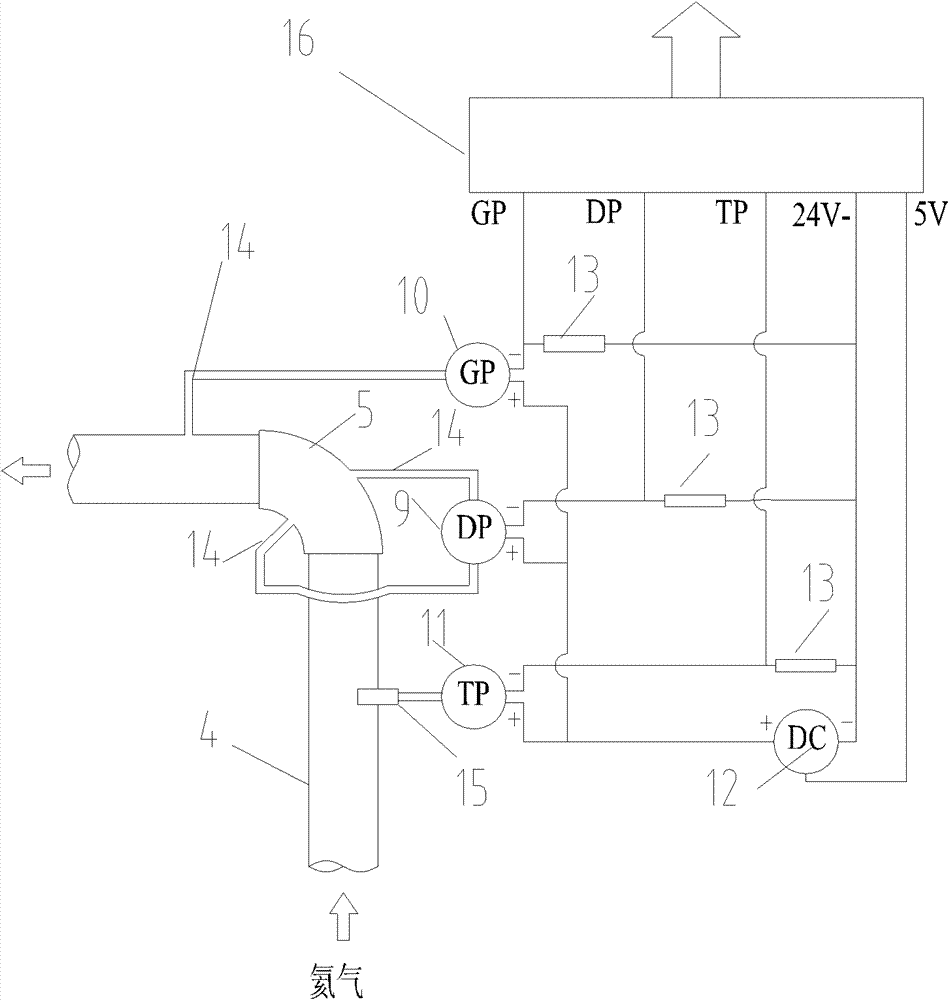

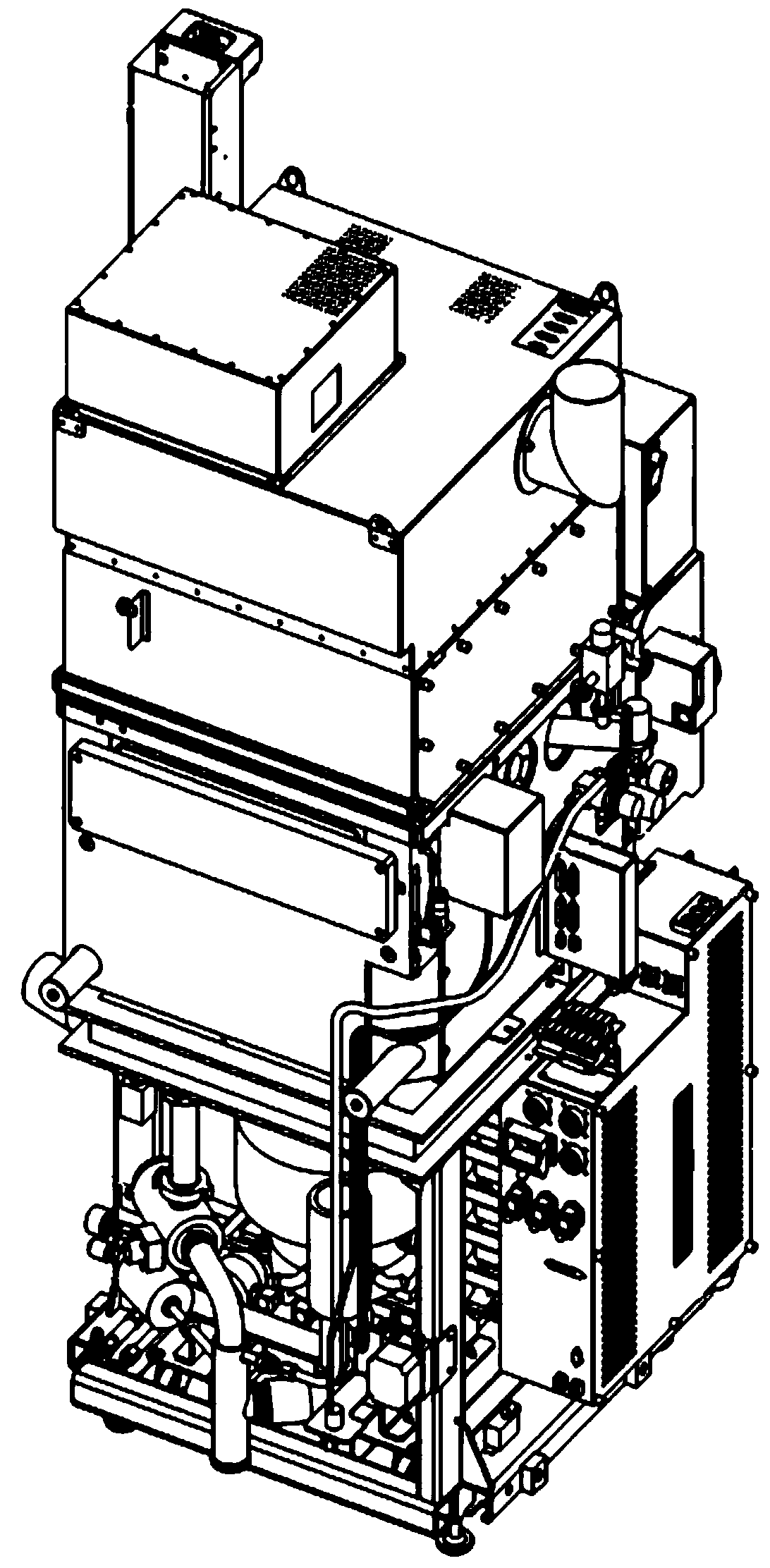

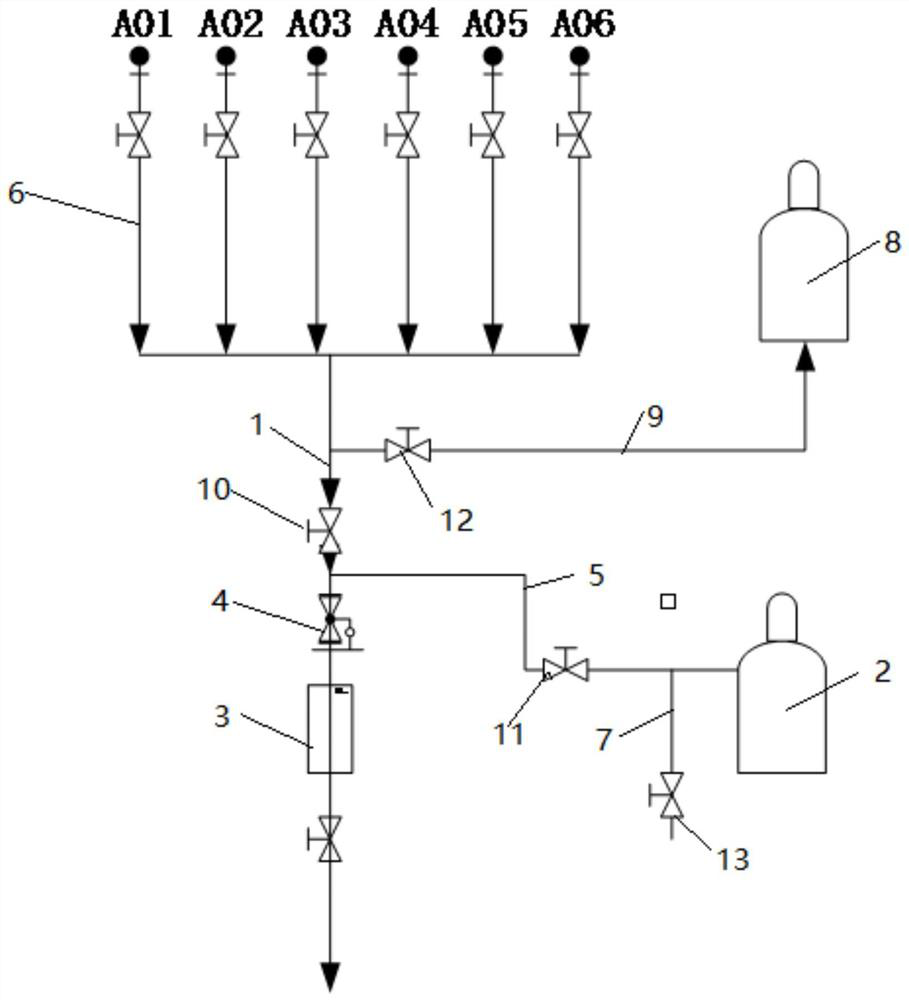

Constant-pressure helium control device of vacuum system and constant-pressure control method

ActiveCN101968661ARegulated permeabilityHigh control sensitivityFluid pressure control using electric meansEngineeringVacuum pump

The invention discloses a constant-pressure helium controller of a vacuum system. In the device, a helium pressure signal in the vacuum system is measured by using a vacuum gauge, the pressure signal is compared with a set value to generate a feedback signal, the heating power of a filter helium micro-leak valve (hereinafter referred to helium leak, see patent CN1479031A) is adjusted through the feedback signal, and finally the helium pressure of the vacuum system reaches the set value. The device and the method have the advantages that: the pressure signal is directly fed back by using the vacuum gauge, the heating power of a helium leak heating wire is controlled through the feedback signal and the permeability of the helium is adjusted so that the device realizes direct control of the helium pressure in the injection vacuum system and is not affected by environmental temperature, pumping rate of a vacuum pump and helium pressure difference change on two sides of the helium leak; and the controller realizes control of the heating power, namely helium permeability of the helium leak by using pulse width modulation, and has high control sensitivity of the helium pressure in the injection vacuum system.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

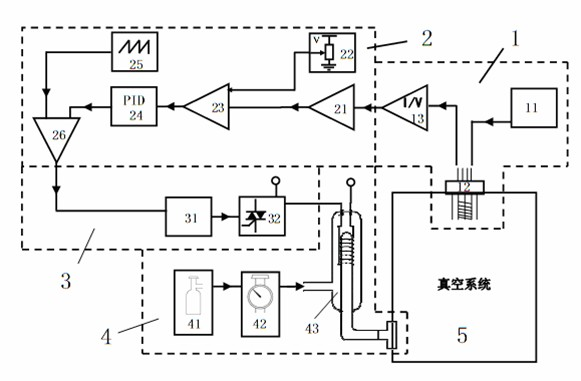

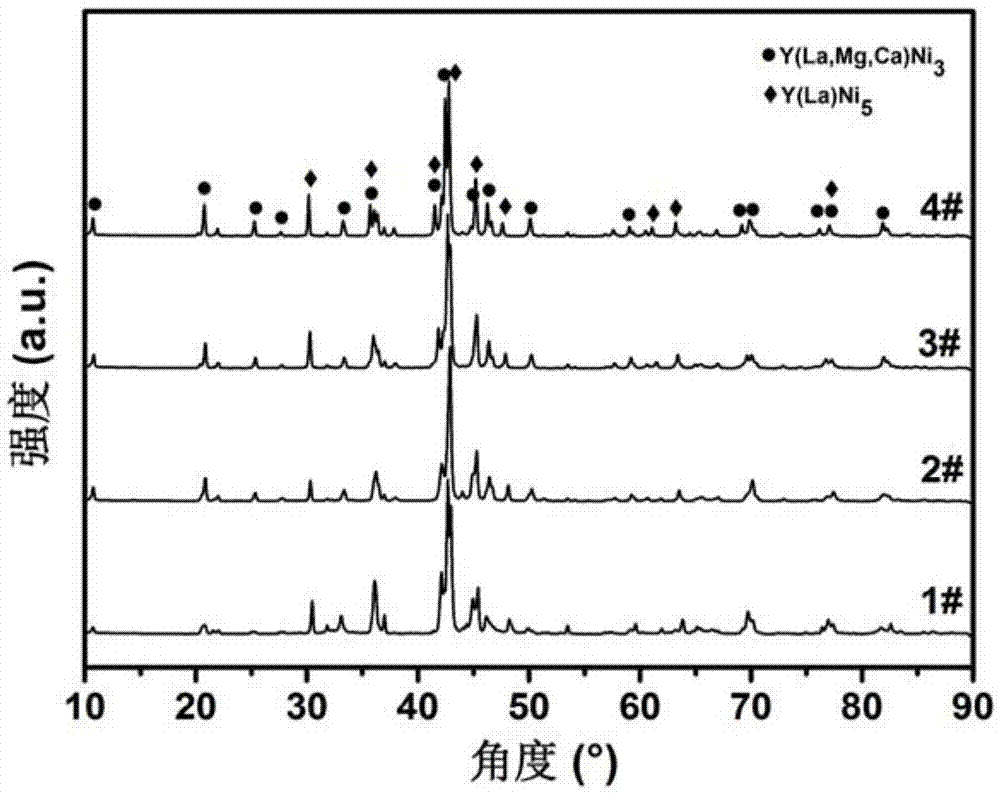

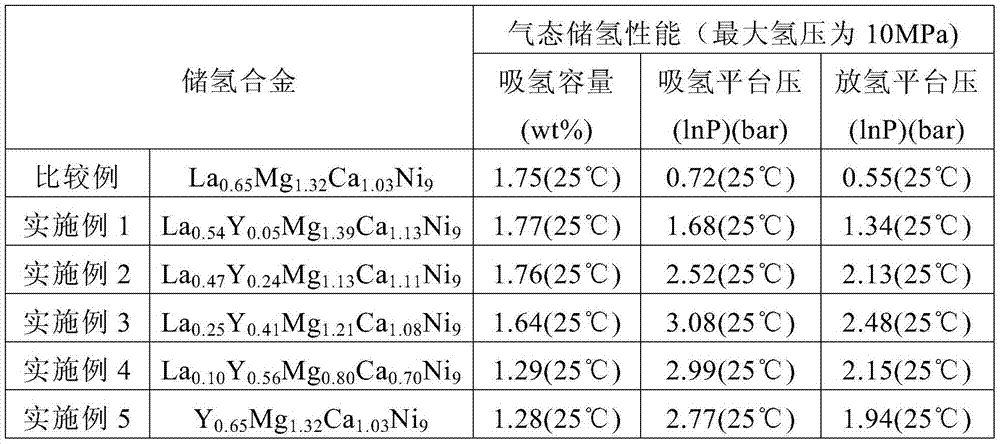

Lanthanum-magnesium-nickel-system AB3 type hydrogen-storage alloy containing elemental yttrium and preparation process thereof

ActiveCN106854715ALow costHigh hydrogen absorption and desorption capacityBiological activationLanthanum

The invention discloses a lanthanum-magnesium-nickel-system AB3 type hydrogen-storage alloy containing elemental yttrium and a preparation process thereof. The hydrogen-storage alloy has a chemical formula of LaYbMg<c>Ca<d>Ni<9>, wherein a, b, c and d represent the atomic ratio of the elements of the alloy; a is more than 0 and no more than 0.65; b is more than 0 and no more than 0.65; c is more than 0; d is more than 0; and the sum of a, b, c and d is no less than 2.5 and no more than 3.5. The preparation process for the hydrogen-storage alloy comprises the following steps: weighing raw materials according to the ratio expressed in the chemical formula; putting metals difficult to volatilize, except elemental Mg and Ca, into a copper crucible, successively carrying out vacuum-pumping, introduction of helium until a pressure is 0.1 MPa, vacuum-pumping and introduction of helium until the pressure is 0.1 MPa, and repeating the successive operations three times for gas washing; turning on a power supply, baking raw materials for 1 min, then allowing the pressure of helium to be fixed at 0.1 MPa, carrying out heating and melting, and after all the metals are completely fused, carrying out cooling to 20 DEG C; and putting metal Mg and Ca easy to volatilize into the crucible, carrying out gas washing three times, baking the raw materials for 1 min and then carrying out melting under the condition of a helium pressure of 0.1 MPa. The hydrogen-storage alloy provided by the invention is low in cost and has high hydrogen absorption and desorption capacity, good activation performance, good cyclic stability and adjustable hydrogen absorption and desorption plateau pressure.

Owner:GRIMAT ENG INST CO LTD

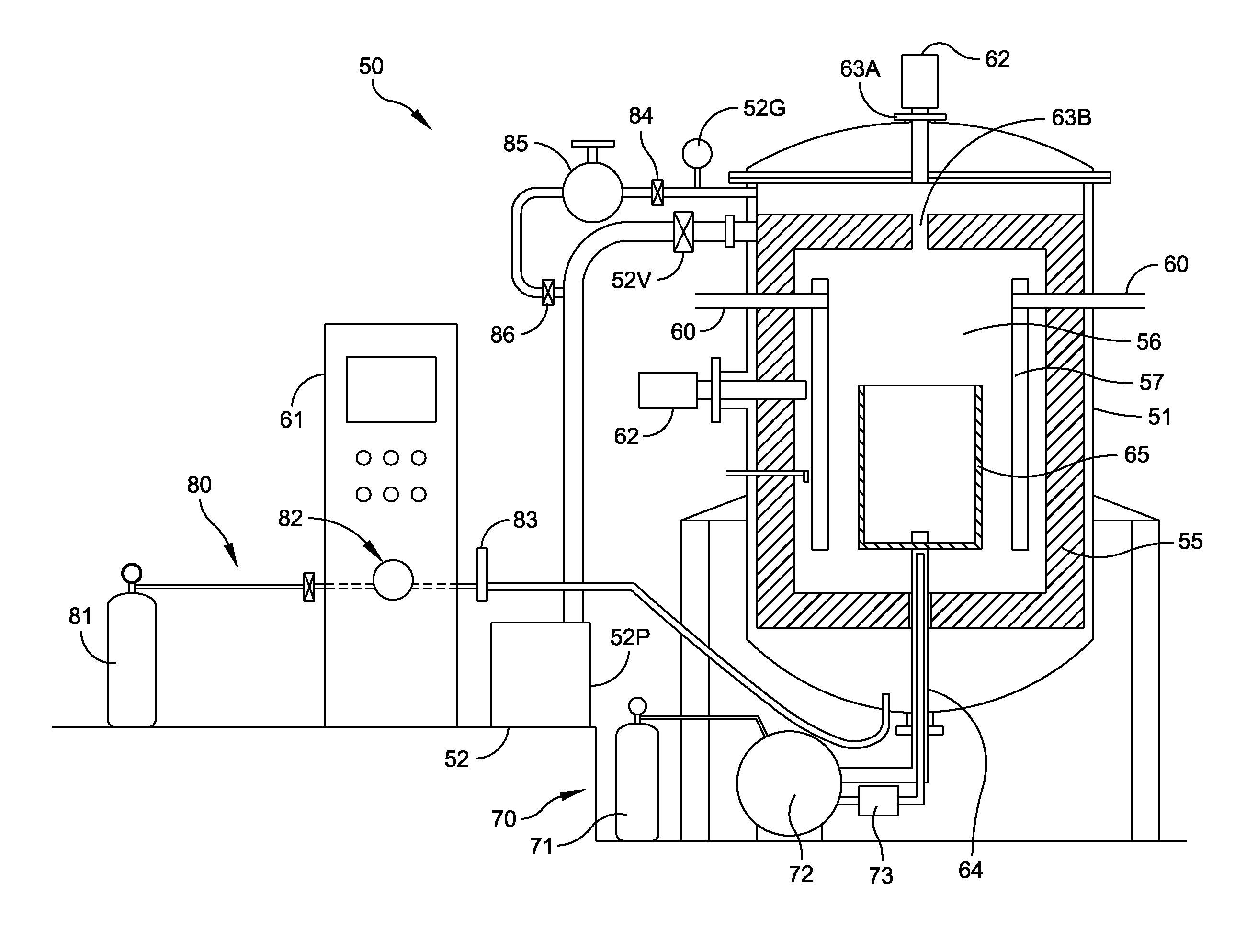

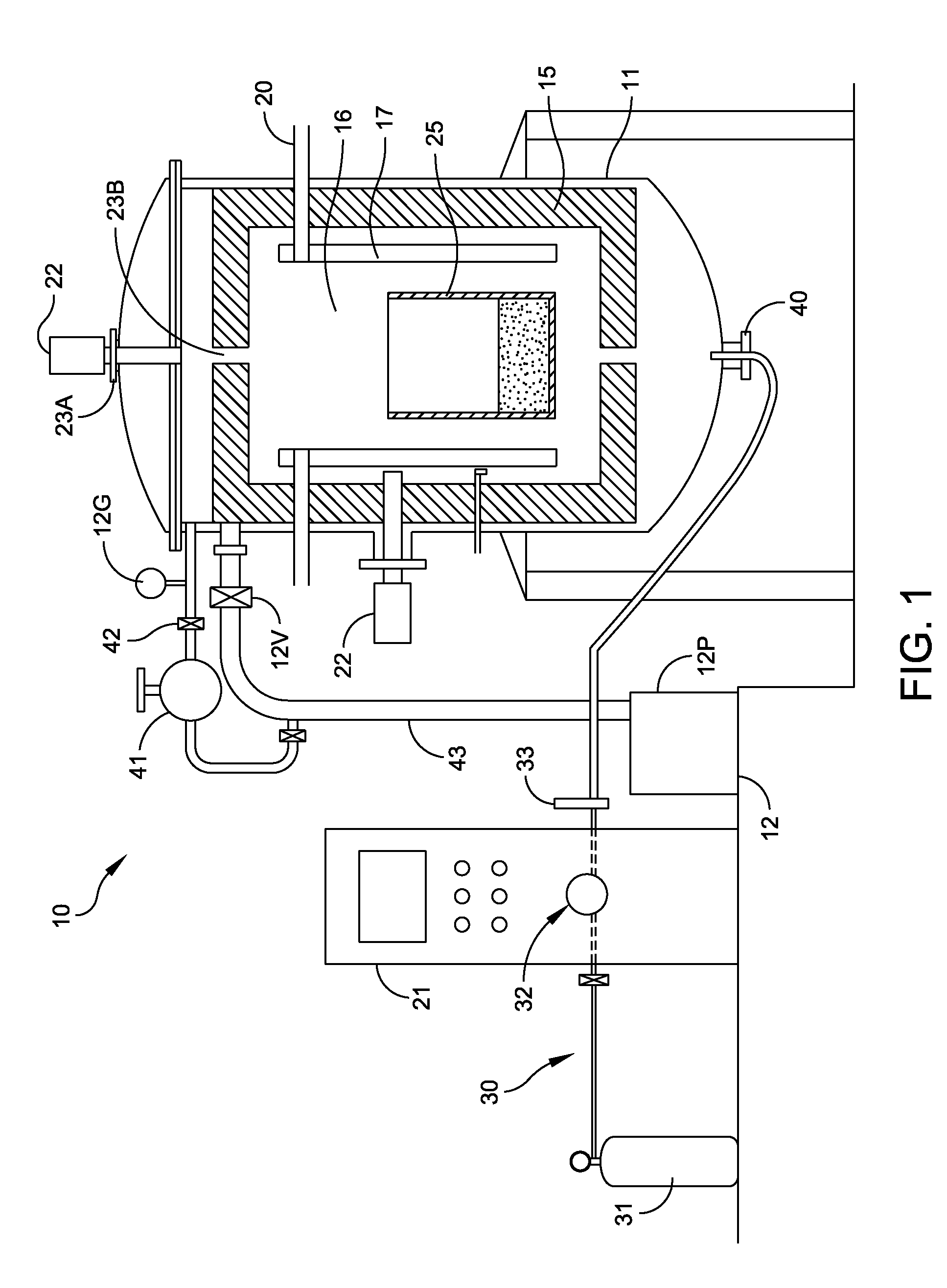

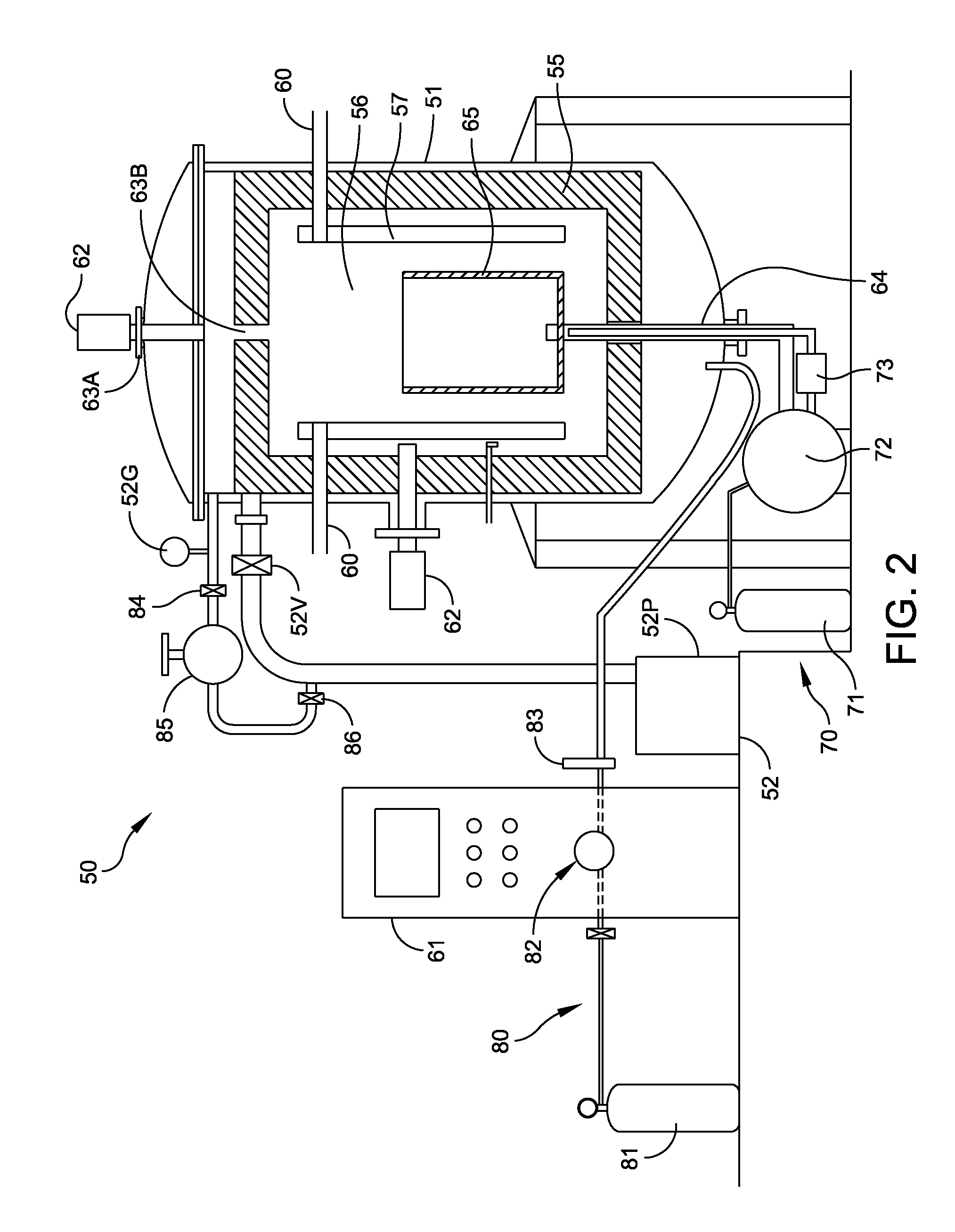

High-Temperature Process Improvements Using Helium Under Regulated Pressure

ActiveUS20110048316A1Increase heatHigh heat conductivityPolycrystalline material growthFrom normal temperature solutionsHeat flowEngineering

A method for minimizing unwanted ancillary reactions in a vacuum furnace used to process a material, such as growing a crystal. The process is conducted in a furnace chamber environment in which helium is admitted to the furnace chamber at a flow rate to flush out impurities and at a predetermined pressure to achieve thermal stability in a heat zone, to minimize heat flow variations and to minimize temperature gradients in the heat zone. During cooldown helium pressure is used to reduce thermal gradients in order to increase cooldown rates.

Owner:GTAT CORPORATION

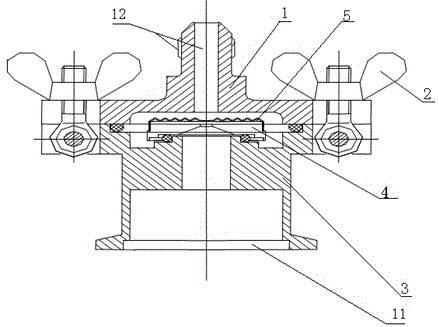

Capillary tube thermostatic expansion valve mixing and filling device based on PLC (programmable logic controller)

InactiveCN102174984AEasy maintenanceEasy to improveEfficient regulation technologiesContainer filling under pressureDisplay deviceEngineering

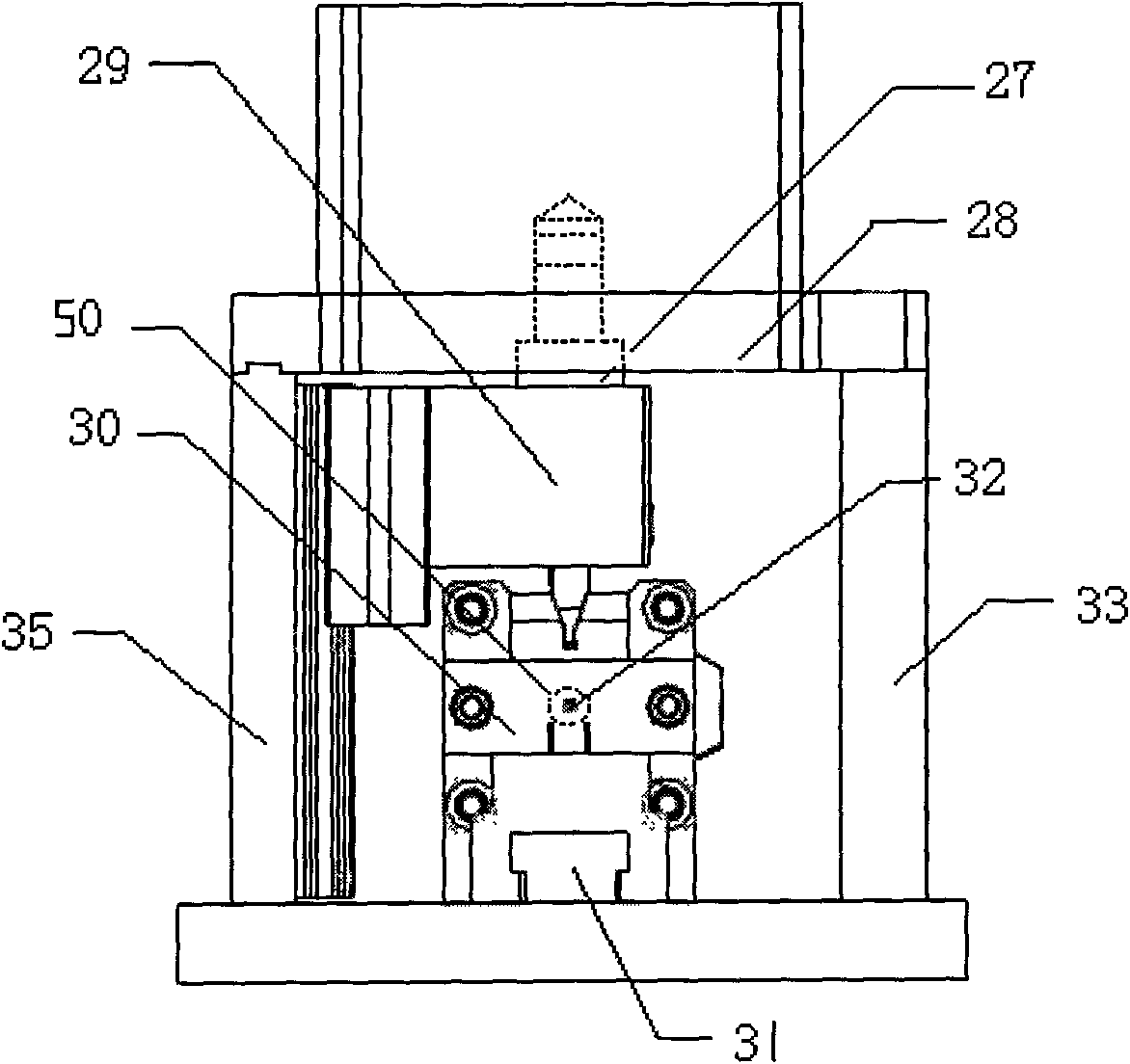

The invention discloses a capillary tube thermostatic expansion valve mixing and filling device based on a PLC (programmable logic controller). The front end fixture table surface of a vertical operating table is provided with a thermostatic expansion valve filling fixture; a panel on the upper part of the fixture table surface is provided with a refrigerant reducing valve, a helium reducing valve, two throttling valves, two glass rotor flow meters, a qualification indicating lamp, a disqualification indicating lamp, a refrigerant pressure meter, a helium pressure meter, a touch screen display, a fluorescent lamp and a power supply switch; a panel at the lower part of the fixture table surface is an operating key region, and is provided with a scram starting button and a front door; the upper part of the vertical operating table is provided with gas circuit pipe fittings, such as a pressure sensor, an electromagnetic valve and the like, and the bottom of the vertical operating table is provided with an electric wiring board; and a PLC control system is adopted as an electric control device, and is respectively connected with the touch screen display, the pressure sensor, the scram starting switch, the qualification indicating lamp, the disqualification indicating lamp and the electromagnetic valve. The device provided by the invention has the advantages of being convenient to install, high in filling accuracy of two types of media and high in automatic degree, and being used for the difficulties of mixing and filling accuracy of the existing thermostatic expansion valve.

Owner:杭州中久自控系统有限公司

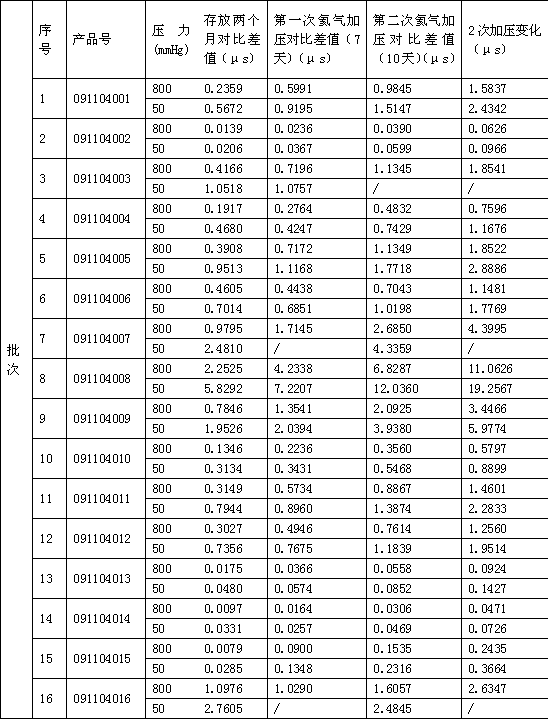

Helium mass spectrum fine leakage detecting method of multiple helium pressing and prefilled helium pressing

ActiveCN103278295AAvoid missing detectionReduce the fine leak detection process of helium mass spectrometryDetection of fluid at leakage pointEngineeringMass spectrometry

The invention discloses a helium mass spectrum fine leakage detecting method of multiple helium pressing and prefilled helium pressing. According to the method, the procedure for helium mass spectrum fine leakage detection by a multiple helium pressing method or a prefilled helium pressing method in a pressed helium or prefilled helium sealing device is given, and the helium pressing duration, the longest detection waiting duration and the measurement leakage rate criterion are particularly given. The method has the beneficial effects that compared with the secondary fine leakage detection by a single helium pressing method, the method is simpler, faster and more precise, and in addition, the error judgment of fine leakage and the leakage detection of large leakage near the rough leakage can be avoided; compared with the twice detection of the first fine leakage detection and the second fine leakage detection after the helium pressing, the method has the advantages that once fine leakage detection is reduced, the testing deviation is reduced, and in addition, the pressure of helium gas pressed by the helium pressing or the pressure of the prefilled helium gas attenuated inside an element to be detected before the helium pressing can be utilized, so the detection is more sensitive; and compared with a method for comparing the measuring leakage rate and the detection waiting time of the first fine leakage detection and the second fine leakage detection after the helium pressing through multiple factors, the method is simpler, more convenient and feasible.

Owner:BEIJING KEYTONE ELECTRONICS RELAY

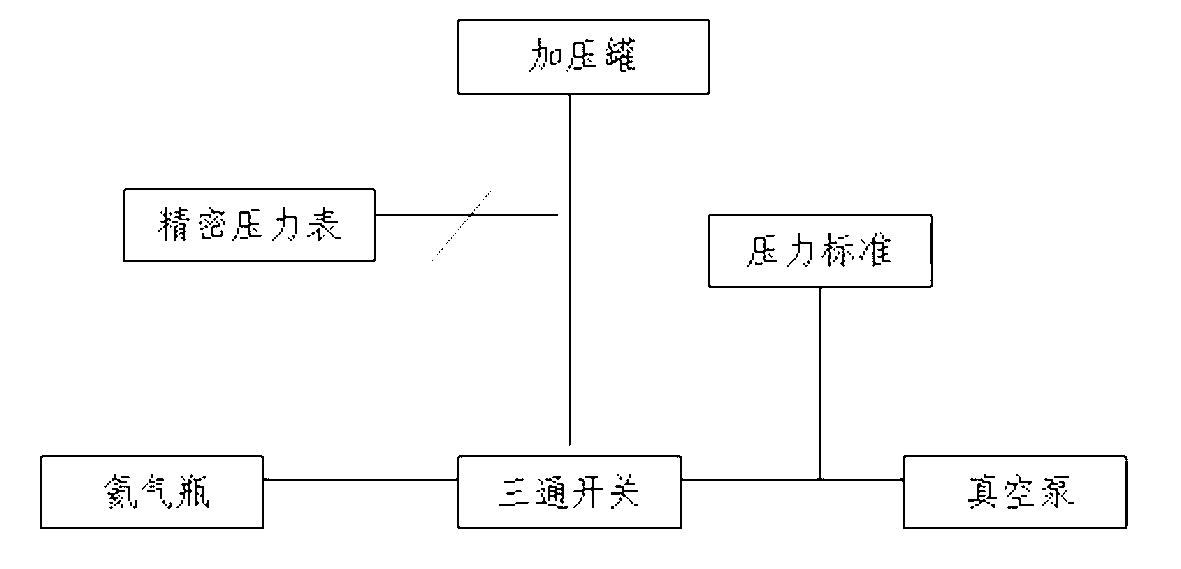

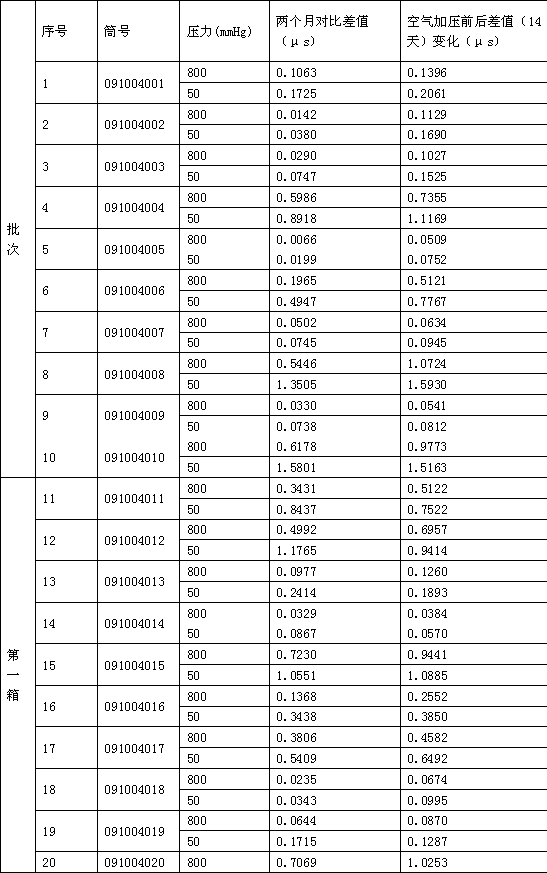

Method and device for vacuum cavity leakage detection for sensors with vacuum reference cavities

InactiveCN103063381APreserve accuracyOutput cycle shortenedMeasurement of fluid loss/gain rateMeasuring outputEngineering

The invention belongs to the technical field of a detecting method for sensors, and particularly relates to a method and a device for vacuum cavity leakage detection for sensors with vacuum reference cavities. The method solves the problems that an existing leakage detecting method for the sensors with the vacuum reference cavities is low in detection accuracy and not free of missed detection, and only capable of detecting a single product and low in detection efficiency. The detecting method comprises the following steps: measuring output signals for products needing to be detected; and placing a plurality of the products into a pressuring tank, sealing the pressuring tank, evacuating air in the pressuring tank, filling helium into the pressuring tank, maintaining the pressure, evacuating the helium, measuring output signals of the products, and then comparing the output signals before and after the pressuring. The device comprises the pressuring tank capable of containing the plurality of the products to be detected, wherein the pressuring tank is provided with pipelines to be connected with a helium tank, a pressure instrument, a pressure switch and a vacuum pump. The device for the vacuum cavity leakage detection for the sensors with the vacuum reference cavities has the advantages of being high in detection accuracy rate, shortening the period of technical processes and being suitable for mass production.

Owner:TAIYUAN AERO INSTR

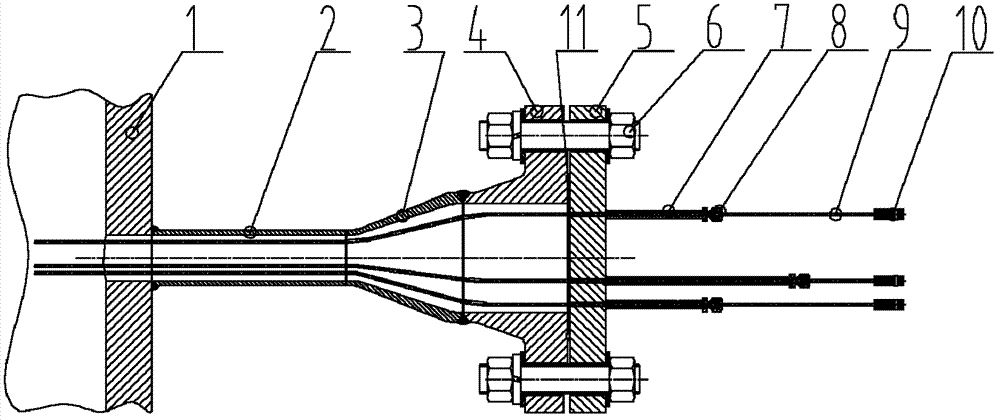

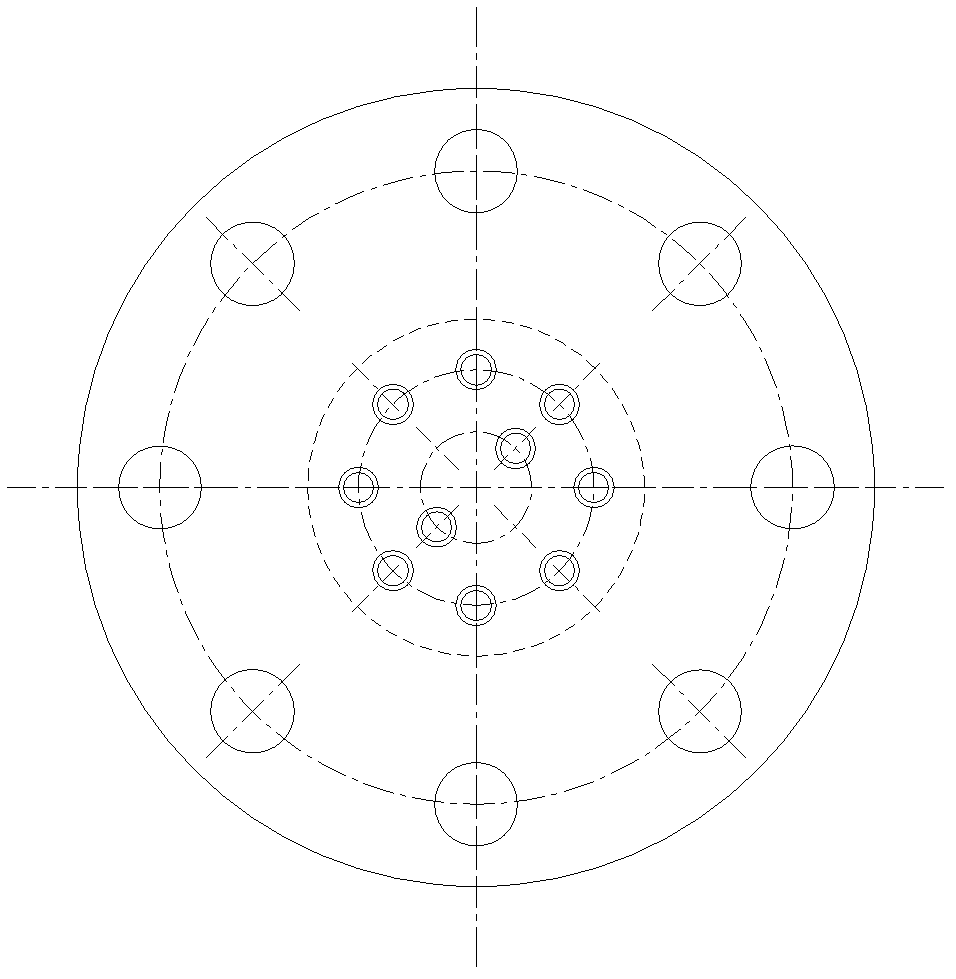

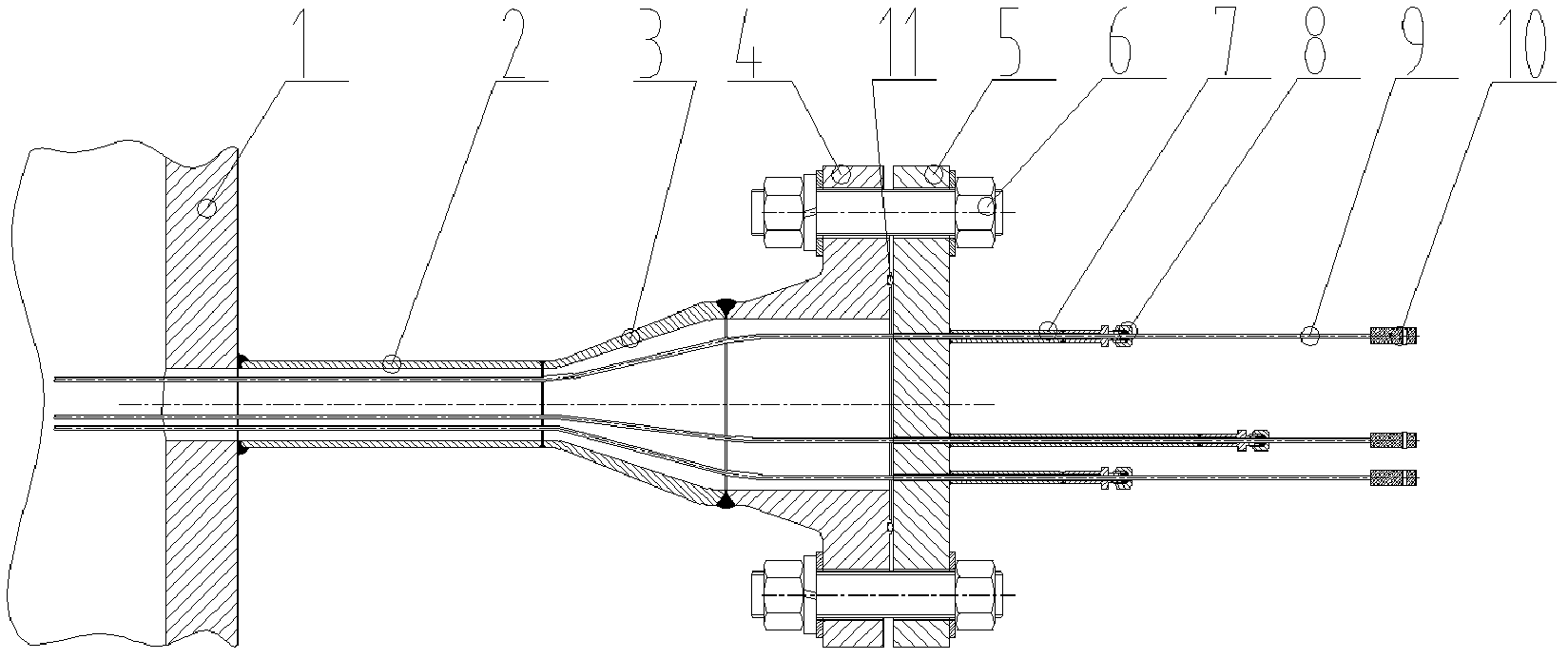

Sheathed thermocouple component penetrating high-temperature high-pressure helium pressure shell

ActiveCN103090985AHigh strengthGuaranteed air tightnessThermometer detailsThermometers using electric/magnetic elementsThermal engineeringEngineering

The invention discloses a sheathed thermocouple component penetrating a high-temperature high-pressure helium pressure shell, and relates to the field of reactor thermal engineering test temperature measurement. The sheathed thermocouple component comprises a penetrating part which is used forleading out and seals at least one sheathed thermocouple from the pressure shell. The penetrating part further comprises a barrel body and a sealing flange, wherein the barrel body is used for leading out at least one sheathed thermocouple from the pressure shell, the sealing flange is arranged at one end of the barrel body and is used for sealing one end of the barrel body of the penetrating part, and the sheathed thermocouple penetrates through the sealing flange. The sheathed thermocouple component is used for leading out a plurality of sheathed thermocouples from the high-temperature high-pressure helium pressure shell, is capable of basically not reducing the strength of the pressure shell and guaranteeing the air tightness, is capable of leading out an electric lead-out end from the pressure shell under the condition that a sheathed thermocouple measurement end is installed well in the pressure shell, and is convenient to detach and install. The sheathed thermocouple component penetrating the high-temperature high-pressure helium pressure shell is simple in structure, good in reliability, and high-temperature-resistant.

Owner:TSINGHUA UNIV

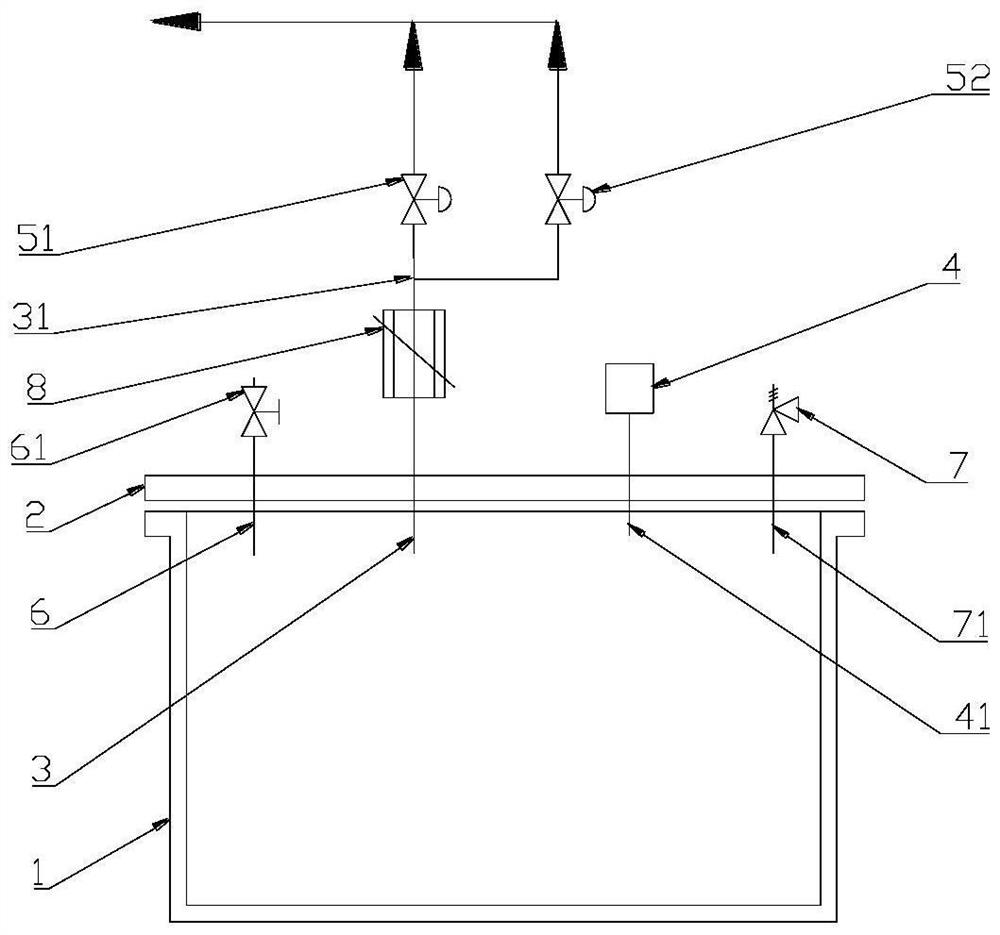

Testing device for functional verification of steam generator accident emission system

ActiveCN112489831AImprove reliabilityNuclear energy generationNuclear monitoringHuman–machine interfaceIsolation valve

The invention discloses a testing device for functional verification of a steam generator accident emission system. The testing device comprises a main water supply pipeline, a main water supply isolation valve, a steam generator, a main steam isolation valve, a main steam pipeline, a first discharge valve, a second discharge valve, a discharge tank, a primary loop helium pressure measuring device, a secondary loop water supply pressure measuring device, a primary loop humidity detecting device, a man-machine interface display. a Labview data acquisition cabinet and a steam generator accidentemission DCS cabinet. The system can realize advanced verification of actual functions of the steam generator accident emission system.

Owner:XIAN THERMAL POWER RES INST CO LTD

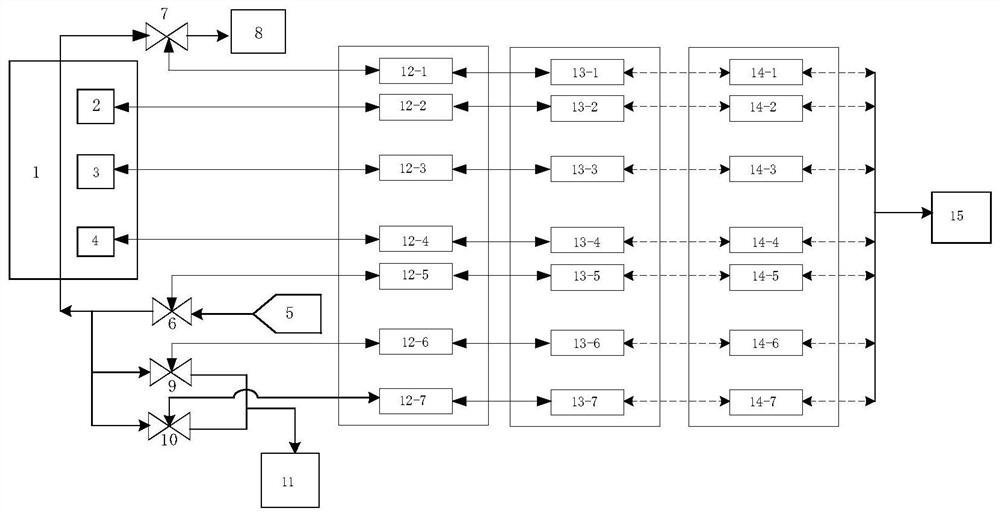

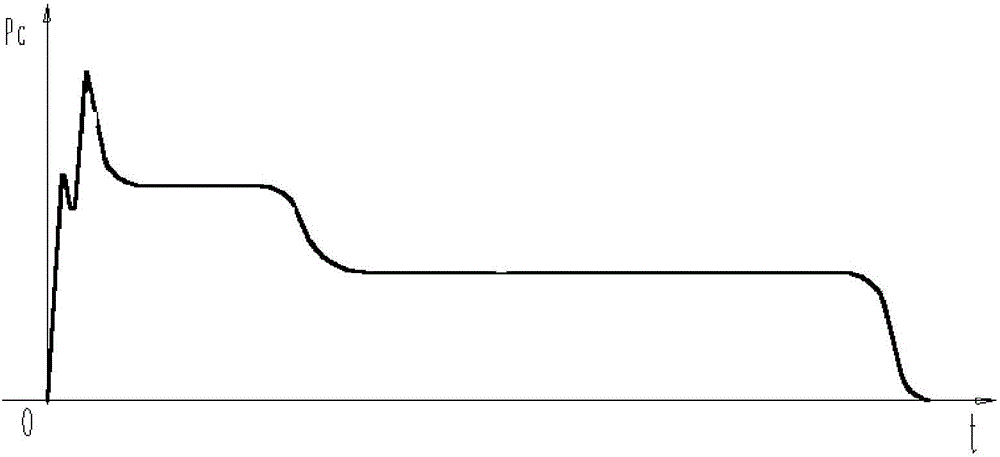

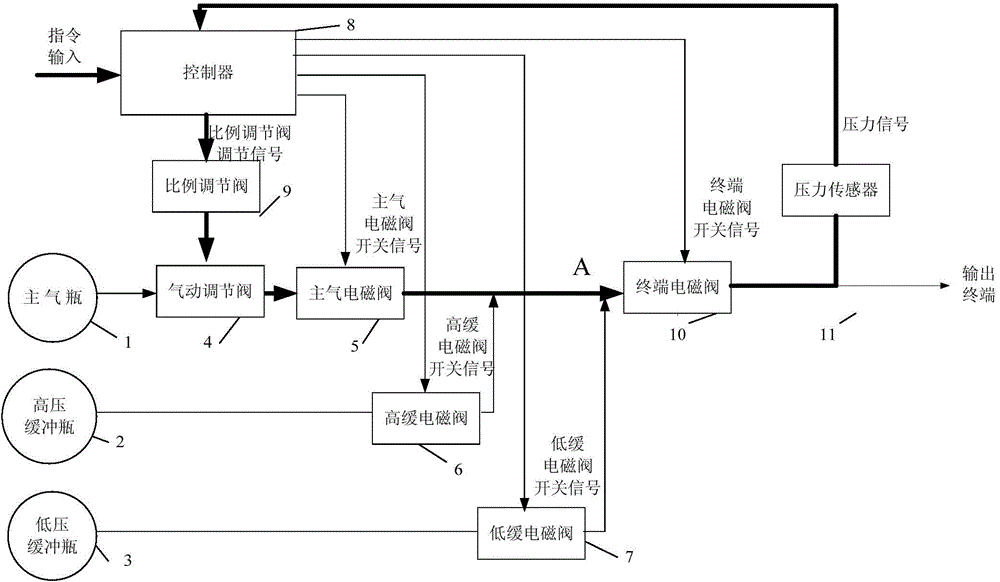

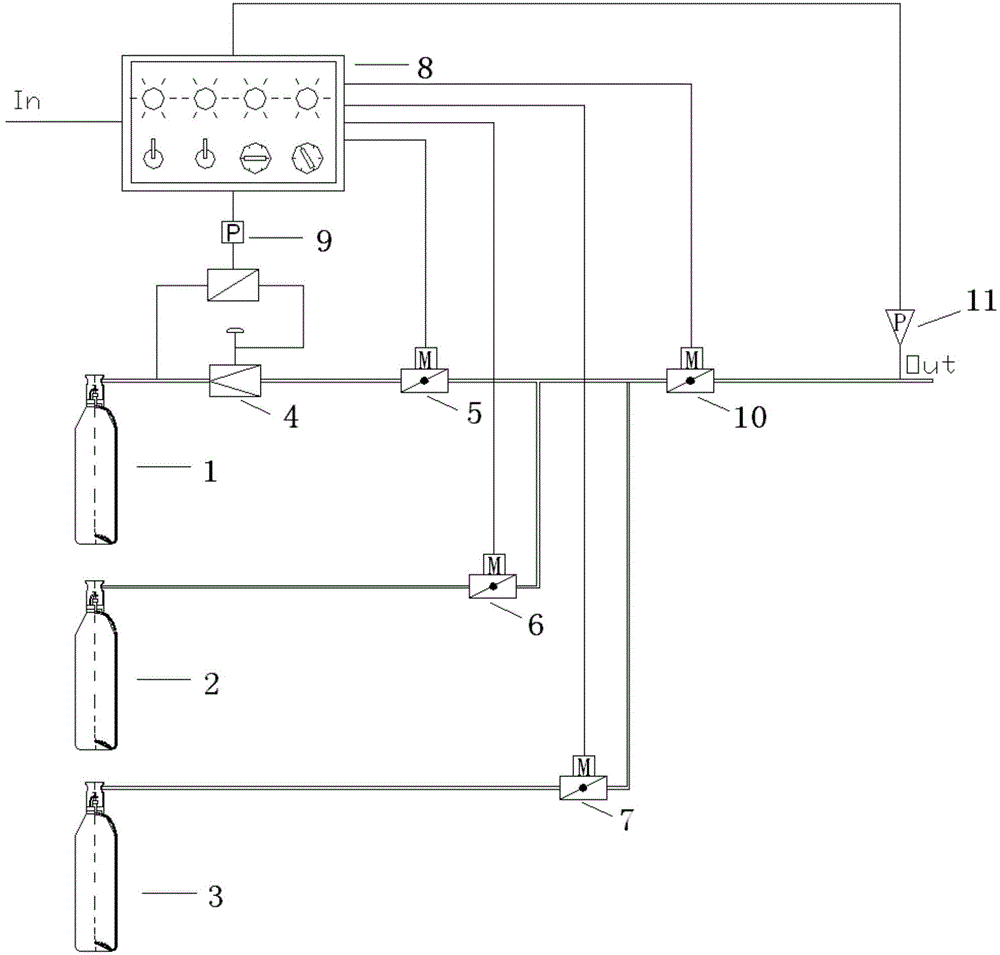

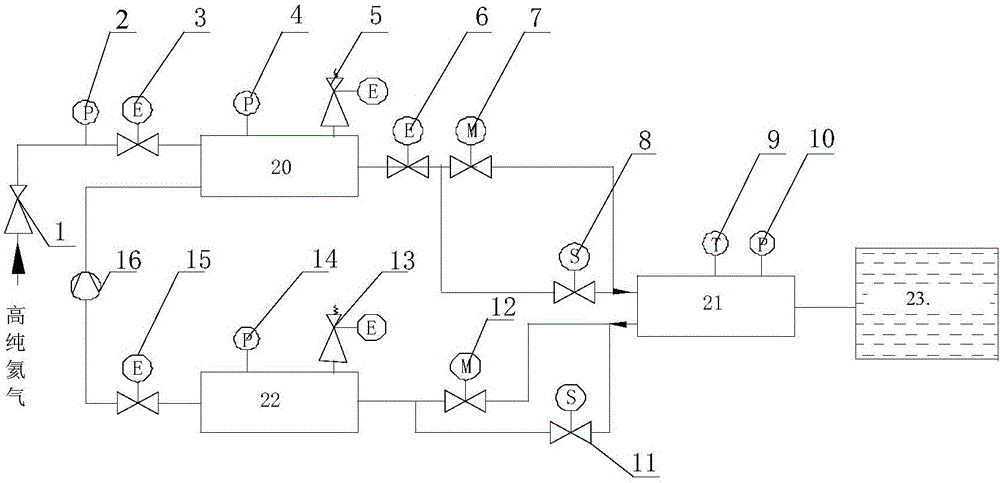

Automatic pressure regulating type high-pressure helium control system

ActiveCN104317322AImprove speedGuaranteed stabilityFluid pressure control using electric meansControl systemHigh pressure

The invention relates to a helium pressure regulating system, in particular to an automatic pressure regulating type high-pressure helium control system. The automatic pressure regulating type high-pressure helium control system comprises a main gas bottle, a high-pressure buffer bottle, a low-pressure buffer bottle, a pneumatic regulating valve, a main gas electromagnetic valve, a high-slow electromagnetic valve, a low-slow electromagnetic valve and a terminal electromagnetic valve, the output port of the main gas bottle is communicated with the input end of the pneumatic regulating valve, the output end of the pneumatic regulating valve is communicated with the input end of the main gas electromagnetic valve, the output port of the high-pressure buffer bottle is communicated with the input end of the high-slow electromagnetic valve, the output port of the low-pressure buffer bottle is connected with the input end of the low-slow electromagnetic valve, and the output ends of the main gas electromagnetic valve, the high-slow electromagnetic valve and the low-slow electromagnetic valve are communicated with the input end of the terminal electromagnetic valve. The automatic pressure regulating type high-pressure helium control system is capable of improving the pressure regulating speed and precision so as to realize the quick, precise and stable pressure output of a high-pressure gas source terminal.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

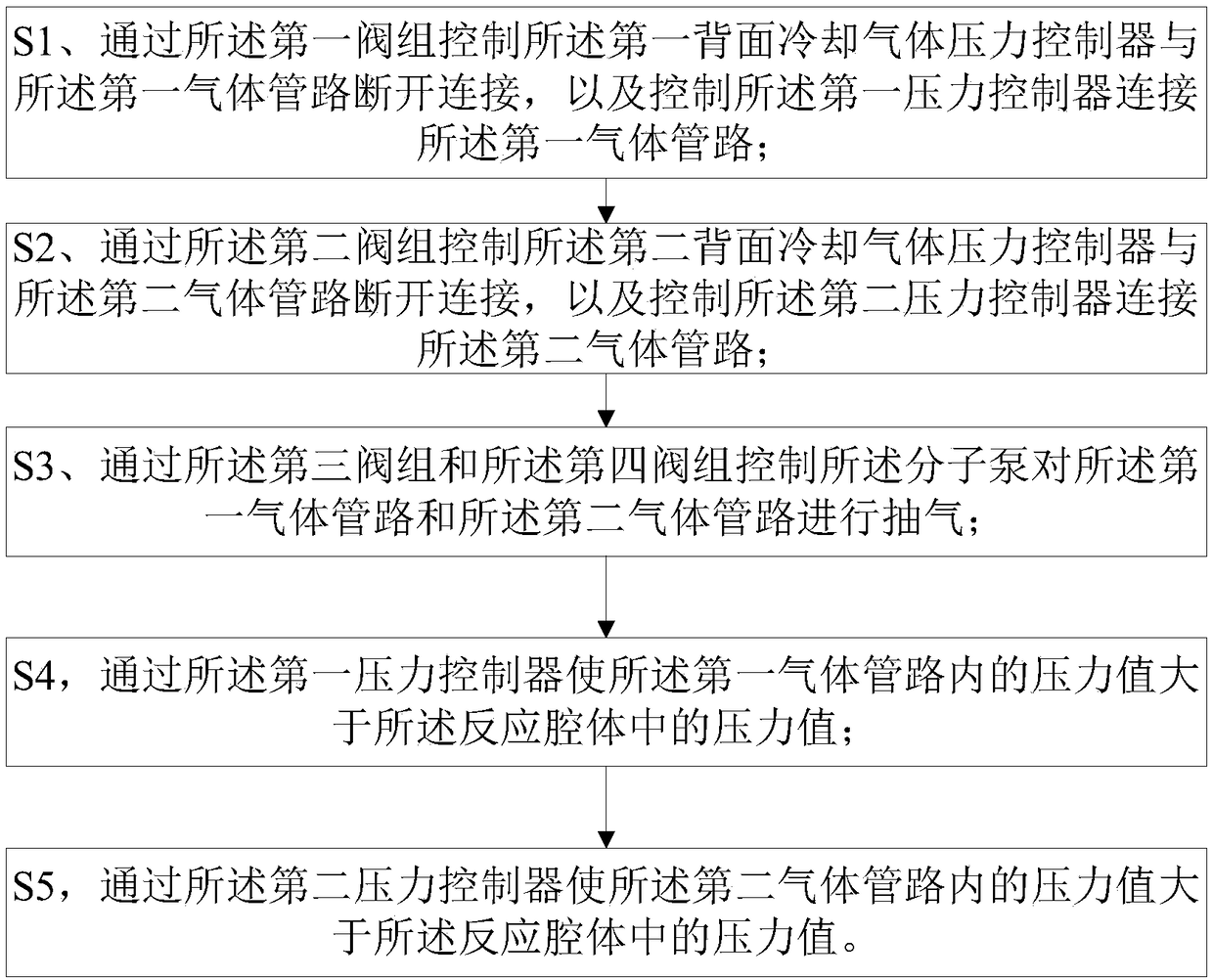

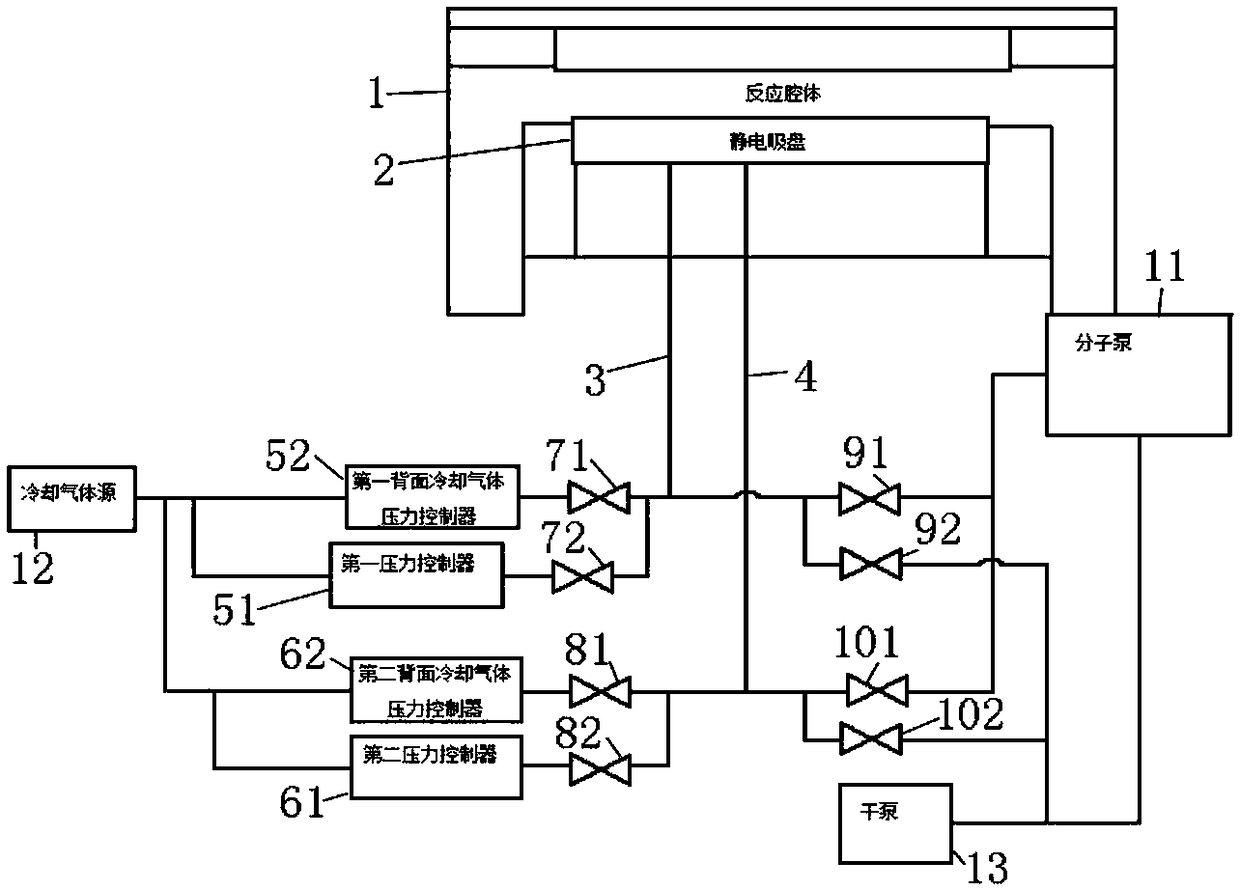

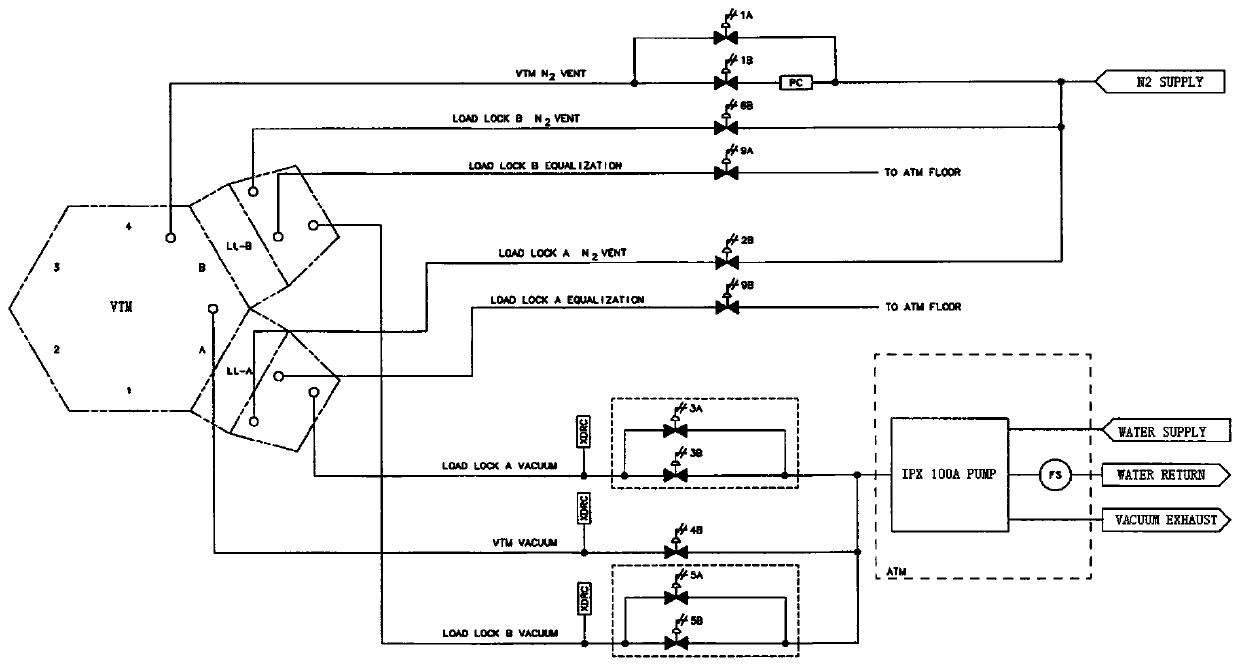

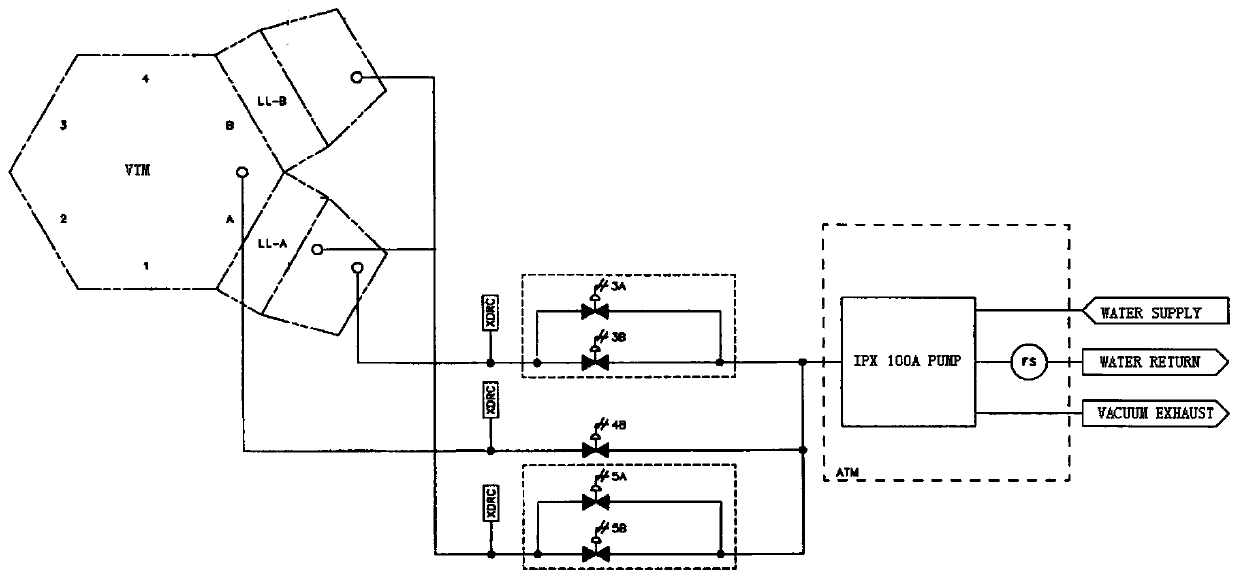

Helium pressure control system and method in electrostatic chuck destaticizing

ActiveCN108376659AAvoid contactReduce defectsSemiconductor/solid-state device manufacturingControl systemPollution

The invention provides a helium pressure control system and method in electrostatic chuck destaticizing; the method comprises the following steps: using a first valve set to control a first backside cooling air pressure controller to be disconnected from a first air pipe, and controlling a first pressure controller to be connected with the first air pipe; using a second valve set to control a second backside cooling air pressure controller to be disconnected from a second air pipe, and controlling a second pressure controller to be connected with the second air pipe; using a third valve set and a fourth valve set to control a molecular pump to extract air from the two air pipes; using two pressure controllers to control the pressure in the two air pipes. The advantages are that the methodcan balance the pressure in a reaction cavity and the pressure in the air pipes, thus preventing reaction resultant from contacting the surface of the electrostatic chuck, reducing pollution sources,reducing wafer defects, and prolonging the vacuum cavity maintenance period.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

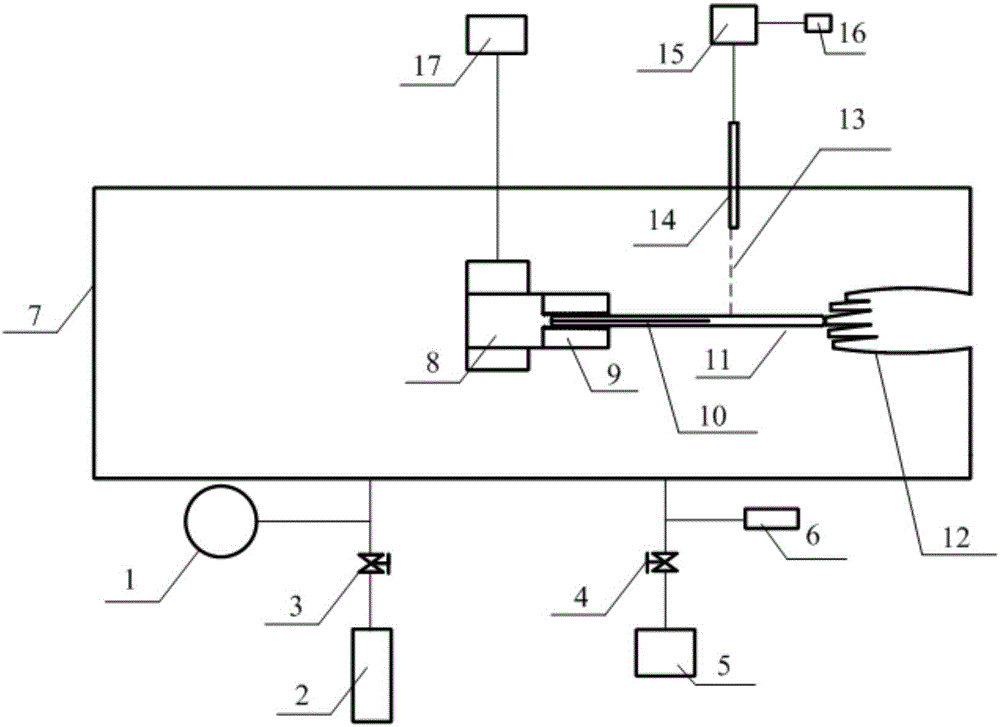

Vacuum helium filling packaging device and method of nuclear power plant temperature detector

InactiveCN106737878AAvoid meltingOvercome the problem of melting phenomenonGlass reforming apparatusManipulatorAlloyLaser heating

The invention discloses a vacuum helium filling packaging device and method of a nuclear power plant temperature detector. The device comprises a glove box, a vacuum system, a helium filing system, a clamping device for clamping a quartz glass tube, and a laser heating system for heating the sealing part of the quartz glass tube. The vacuum system and the helium filling system both communicate with the interior of the glove box. The clamping device is located in the glove box. The laser heating system partly extends into the glove box. By means of the vacuum helium filling packaging device, the quartz glass tube is heated and molten through lasers with highly-centralized energy on the premise that it is ensured that a temperature detection wire is not molten, and the problem that in a conventional sealing method, an alloy wire can melt is solved. By means of the vacuum system, the helium filling system and the glove box, the vacuum degree in the quartz glass tube before helium filling and the helium pressure in the quartz glass tube after helium filling can be ensured, and helium leakage can be prevented during quartz glass tube sealing.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

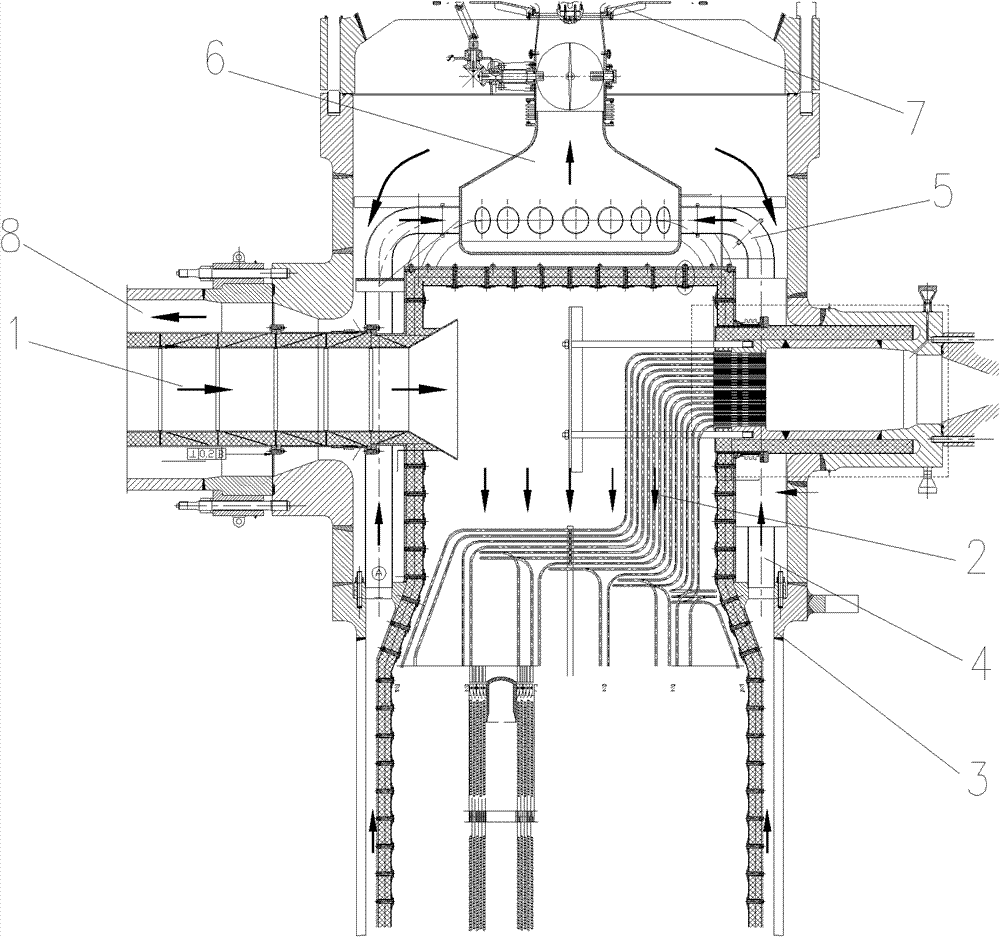

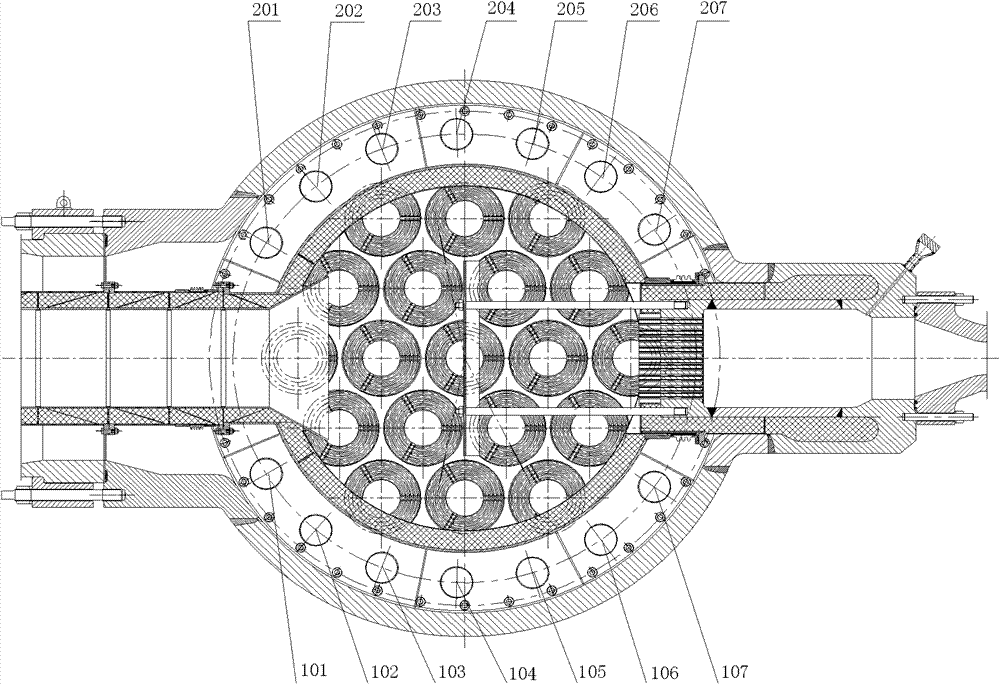

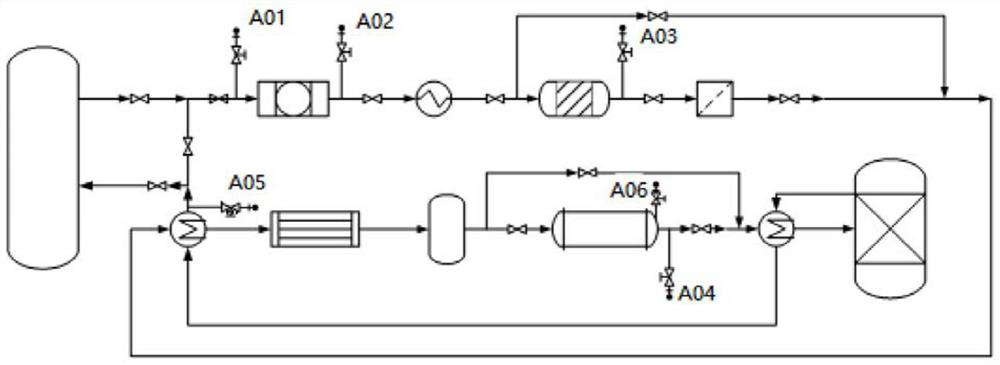

System and method for directly measuring total helium mass flow rate of primary loop of high-temperature gas cooled reactor

ActiveCN102252723BMeets the requirement for redundant direct measurementsImprove reproduction accuracyIndirect mass flowmetersData acquisitionMechanical engineering

Owner:TSINGHUA UNIV

Special helium detection method and special helium detection device of sensing element

InactiveCN104483074AImprove detection efficiencyEasy to pressurizeDetection of fluid at leakage pointEngineeringHigh pressure

The invention discloses a special helium detection method and a special helium detection device of a sensing element. The sensing element (5) is placed on a seal ring (4) to be connected with a tooling base (3); the tooling base (3) is connected to a pressurization cover (1); the pressurization cover (1) is connected to a high-pressure air source (9), a pressure release valve (8) and a helium source (7); a helium detection instrument port (11) on the tooling base (3) is connected with a helium detection instrument; vacuumization and detection are carried out through the helium detection instrument; the helium detection instrument is used for applying specified helium pressure in the front of the sensing element (5) after switching to a fine detection state; the sealing property of the sensing element (5) is detected; once detection is completed, air is used for blowing and clearing a pressurization helium pipeline for carrying out the next detection. The helium pressure of about 1.8 MPa is applied to the front of the sensing element, and meanwhile the requirement that the leakage amount of components cannot be greater than 10<-10> mbar.l / s is detected, and the detection efficiency is high.

Owner:GUIZHOU HONGLIN MACHINERY

Multipurpose fish catching lamp

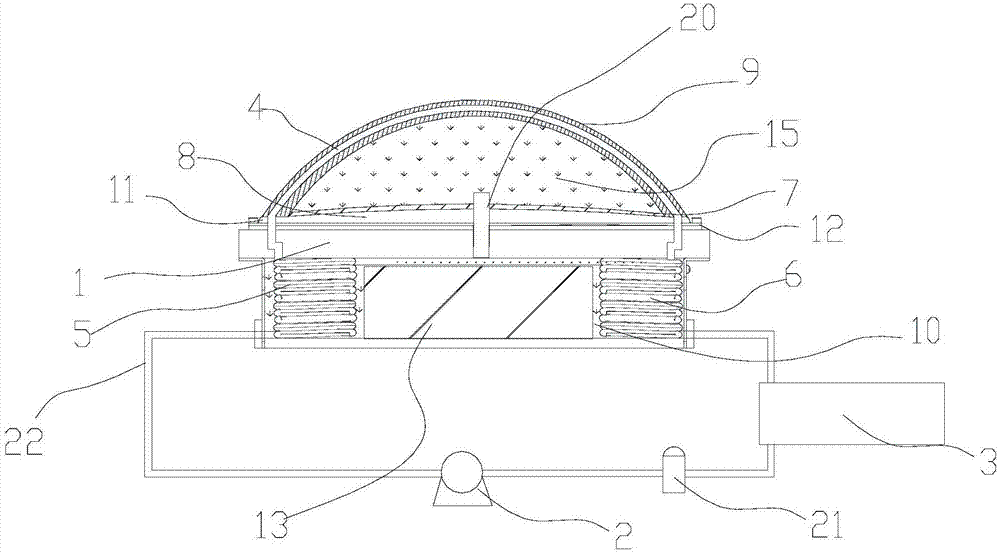

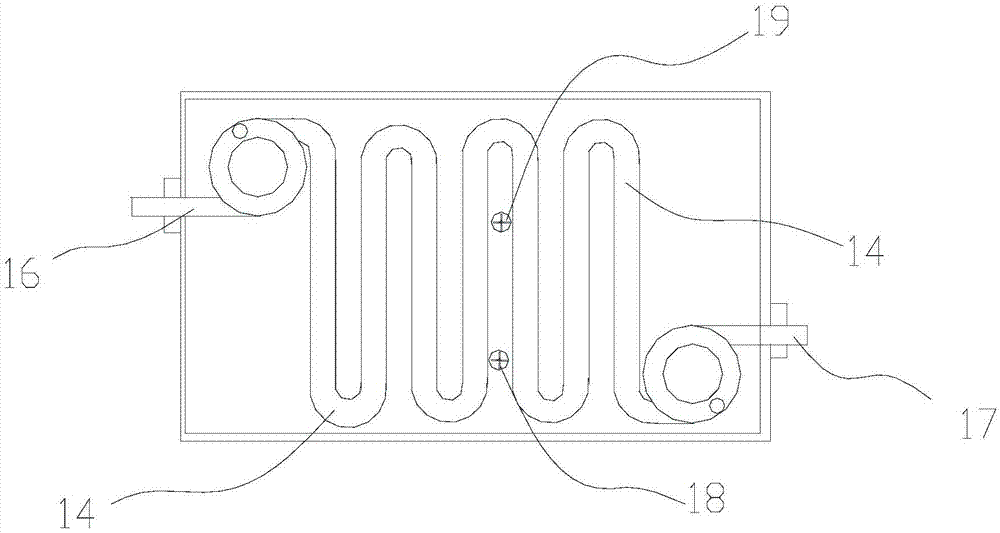

InactiveCN106989318AReduce weightAvoid burst damageLighting heating/cooling arrangementsGas-tight/water-tight arrangementsWater flowEngineering

The invention discloses a multipurpose fish catching lamp which comprises a fixed plate, a driving pump and a water receiver. A circuit board is arranged on the front face of the fixed plate. The circuit board is provided with an arc face protruding outwards, and a plurality of sets of LED lamp belts are mounted on the circuit board. A double-layer transparent lamp shell protruding outwards is fixed to the fixed plate. A hollow mounting cavity is formed in the fixed plate, and a cooling device is arranged in the mounting cavity. The cooling device comprises a pair of hollow spiral elastic pipes and a coil pipe. The spiral elastic pipes are used for providing tension. The coil pipe mounted at the top of the mounting cavity in a closely attached manner. The transparent lamp shell on the innermost layer is filled with a helium protection layer, and the helium protection layer communicates with the mounting cavity through a gas pipe. The helium pressure is larger than 1.2 standard atmospheric pressures. The driving pump communicates with the water receiver, the cooling device and a cooling cavity through a water pipe. The driving pump is used for driving water flow to cyclically flow in the water receiver, the cooling device and the cooling cavity. The defects that an existing fish catching lamp is high in electric energy consumption, high in heat and single in purpose are overcome.

Owner:ZHEJIANG CHANGLUX LIGHTING

System and method for controlling helium pressure during superconducting test piece testing

PendingCN111857200AImprove control accuracyReduce lossesFluid pressure control using electric meansThermodynamicsControl system

The invention provides a system and method for controlling helium pressure in a Dewar during superconducting test piece testing. The Dewar comprises an inner cavity for accommodating liquid helium, and the inner cavity is provided with a liquid helium gasification area. The control system comprises a pressure sensor, a controller, a first pressure release valve and a second pressure release valve,wherein the pressure sensor detects helium pressure in the gasification area in the Dewar, and the first pressure release valve and the second pressure release valve are communicated with the gasification area through pressure release pipelines; the controller controls the first pressure release valve or the second pressure release valve to be opened and closed according to a pressure signal sentby the pressure sensor; and the aperture of the first pressure release valve is larger than that of the second pressure release valve. The two pressure release valves with different apertures are adopted, the pressure release valves with the corresponding apertures are opened according to the current helium pressure value, when the current helium pressure is large, the large-aperture pressure release valve is opened, pressure is released quickly, after the helium pressure is reduced to a certain degree, the small-aperture pressure release valve is adopted for pressure release, the small-aperture pressure release valve is more beneficial to control over the pressure release speed, and helium pressure precision is controlled conveniently.

Owner:VACREE TECH +1

Vacuum pipeline for transmission cavity of semiconductor dry etching machine and control method thereof

ActiveCN109727898ANo pollutionExtended maintenance cycleElectric discharge tubesSemiconductor/solid-state device manufacturingIsolation valveEngineering

The invention discloses a vacuum pipeline for a transmission cavity of a semiconductor dry etching machine. The vacuum transmission module of the semiconductor dry etching machine is connected to theair inlet end of a dry pump through a pipeline. A buffer chamber is connected to a pipeline between the air inlet end of the dry pump and the rear end of a helium isolation valve. A helium front stagevalve is connected to a pipeline between the buffer chamber and the rear end of the helium isolation valve. A helium rear stage valve is connected to a pipeline between the buffer chamber and the airinlet end of the dry pump. A helium pressure gauge is connected to a pipeline between a helium inlet end and the rear end of the helium isolation valve. A helium supply valve is connected to a pipeline between the helium pressure gauge and the helium inlet end. The front end of the helium isolation valve is connected to an electrostatic adsorption disk through a pipeline. The invention also discloses a control method of the vacuum pipeline for the transmission cavity of the semiconductor dry etching machine. The vacuum pipeline can prevent a process reaction product from contacting the surface of a wafer product through a helium passage, reduces the defects of the wafer, improves the process stability, prolongs a cavity maintenance period, and increases the workshop productivity.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Helium pressure tuner pressure precision control apparatus and method

ActiveCN106249771AAccurate displacementPrecise control of displacementNuclear energy generationFluid pressure control using electric meansPressure stabilizationBuffer tank

The invention belongs to the technical field of nuclear energy utilization and especially relates to a helium pressure tuner. The technical scheme is as follows: the helium pressure tuner pressure precision control apparatus comprises a pressure reduction energy invigorating system, a buffer system, an adjustment system, a pressure stabilization system and a gas collection system. The control method is as follows: first of all, after high-purity high-pressure helium goes into the buffer system through the pressure reduction energy invigorating system, low-pressure helium is formed; when the apparatus runs, the helium in a buffer tank goes into the pressure stabilization system through the adjustment system, the pressure stabilization system is connected in series with a helium pressure tuner, accurate control of the displacement amount of the helium pressure tuner is realized through controlling the helium flows of an air inlet system and an exhaust system, and accordingly, the cavity center frequency is stable. According to the invention, through accurate control of pressure in the voltage stabilization tank, accurate control of the displacement amount of the helium pressure tuner is realized, the cavity frequency can be rapidly and accurately adjusted nearby the center frequency, and final relative errors do not exceed 0.03%.

Owner:WUXI HONGRUI AEROSPACE MECHANICAL & ELECTRICAL EQUIP CO LTD

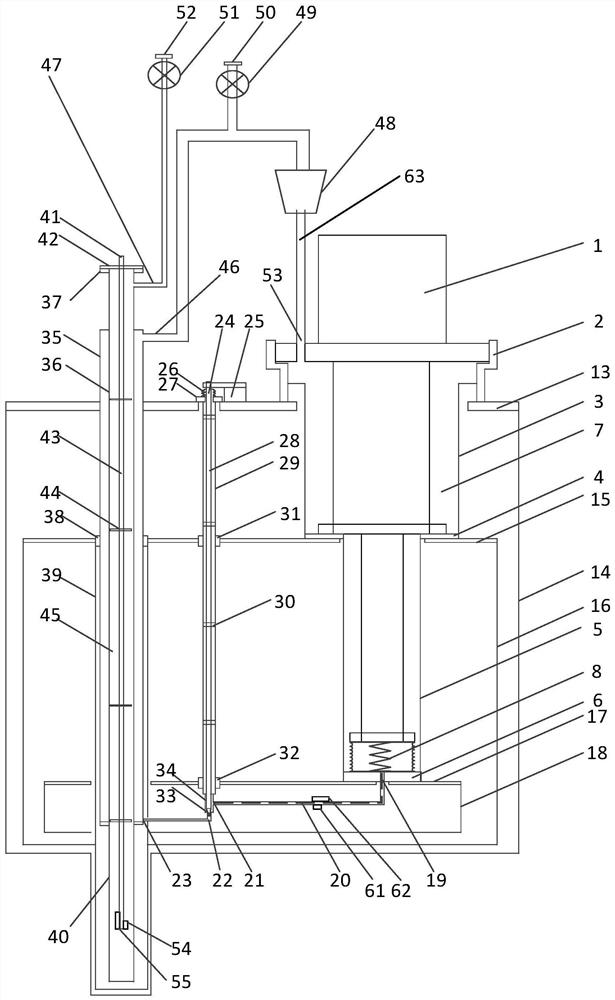

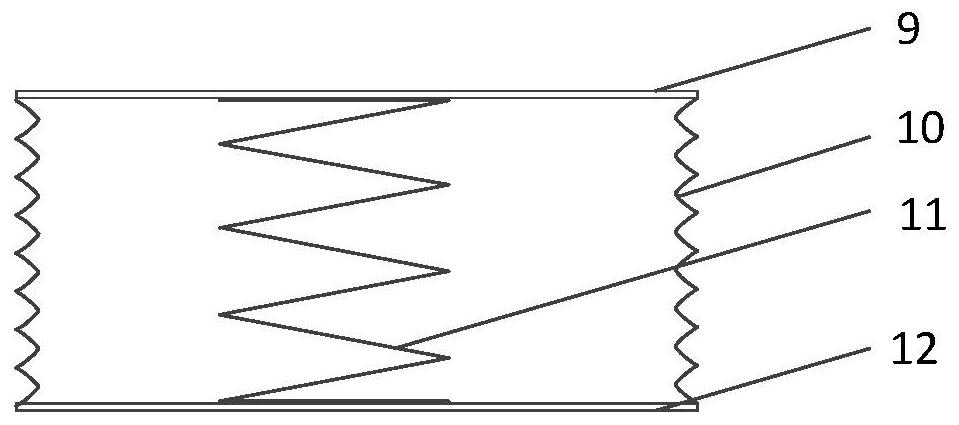

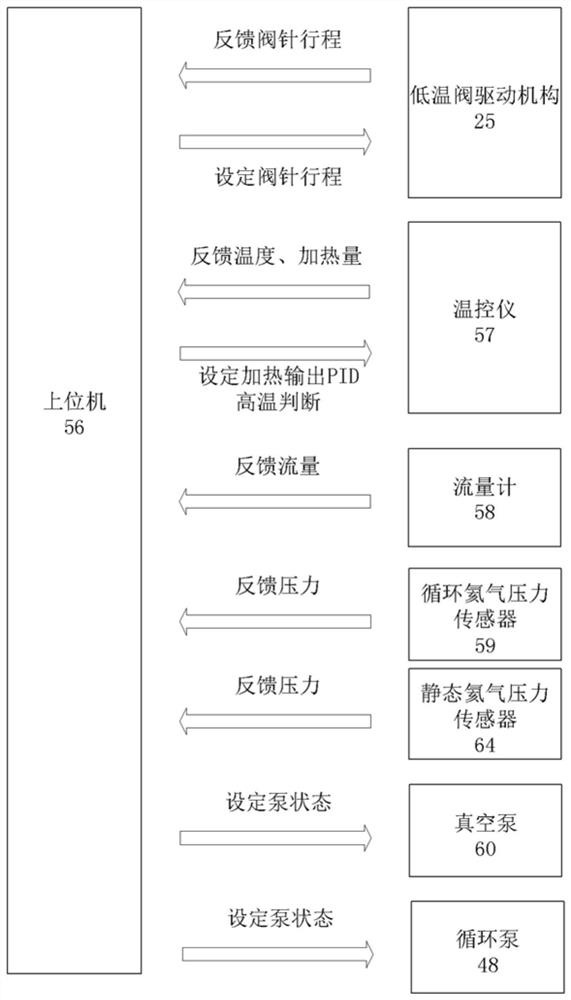

Thermostat device capable of performing continuous variable temperature control in wide temperature zone

PendingCN113778149ATemperature does not need to change drasticallyRealize regulationTemperatue controlTemperature controlLoop control

The invention discloses a thermostat device capable of performing continuous variable temperature control in a wide temperature zone, which comprises a low-temperature refrigerating system, a sample cavity assembly, a heat insulation assembly and a sample temperature control system. A sample rod body (43) in the sample cavity assembly is provided with a sample temperature sensor (54) and a sample heater (55) which are respectively connected with a temperature controller (57) in the sample temperature control system, the temperature controller (57) is connected with an upper computer (56) through a circuit, and the upper computer (56) performs PID closed-loop control on the sample temperature sensor (54) and the sample heater (55) through the temperature controller (57). A static helium pressure sensor (64) connected with the upper computer (56) is arranged on a static helium pipeline communicated with a static helium interface (47) in the sample cavity assembly. The device disclosed by the invention can realize continuous variable temperature control in a wide temperature zone of 2-800K, and meets the requirements of the current high-end physical property measurement field.

Owner:CSIC PRIDE (NANJING) CRYOGENIC TECHNOLOGY CO LTD

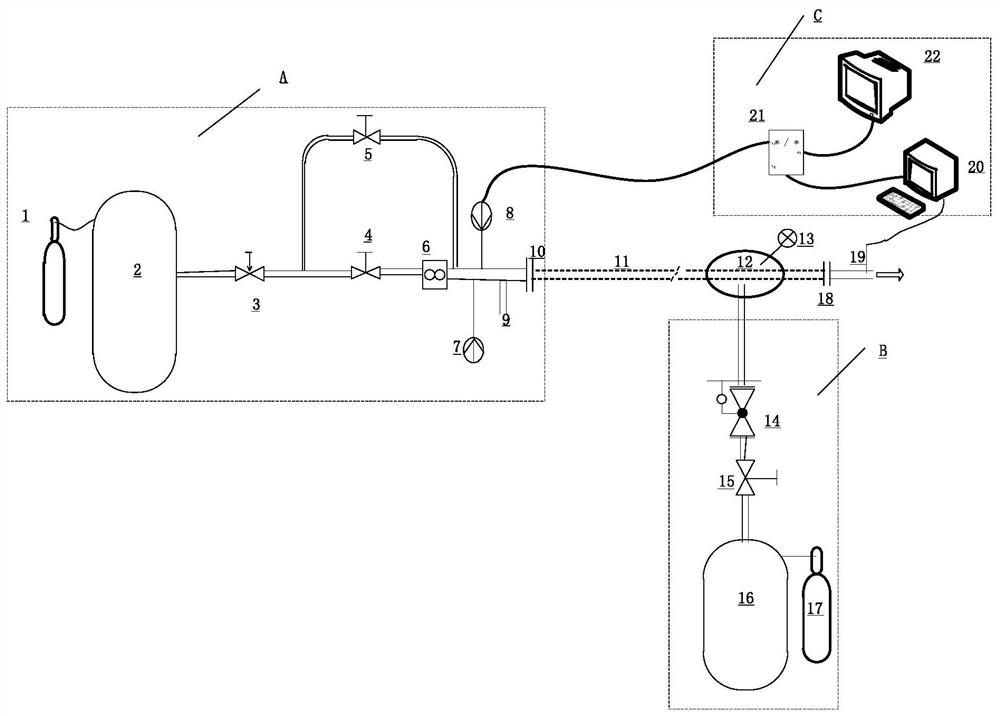

Method and system for detecting trace amount of water in helium

PendingCN114136721AReduce dosageReduce wasteWithdrawing sample devicesGas analyser construction detailsThermodynamicsStream flow

The invention discloses a method for detecting trace water in helium, which comprises the following detection steps: pretreatment: firstly purging a sampling pipeline by using helium to be detected, then purging a gas inlet pipeline by using reference gas, and finally putting into operation; wherein after the pretreatment, the gas pressure in the sampling pipeline is set to be 1.5-2.5 bar; the pressure of helium to be measured and the pressure of reference gas in the analyzer are kept at 1-2 bar, and the gas flow is smaller than or equal to 200 mL / min; the reference gas is inert gas of which the water content is less than 0.001%; and detection: conveying the helium to be detected into the analyzer for detection through the sampling pipeline and the gas inlet pipeline in sequence. The invention further discloses a system for detecting the trace amount of the water in the helium. The system is suitable for detecting the trace amount of the water in the helium by using the method for detecting the trace amount of the water in the helium. On the premise of ensuring the accuracy of the test value of the trace water in the helium, the use amount of the helium during the measurement of the trace water in the helium is reduced, and the waste of the helium is reduced.

Owner:HUANENG NUCLEAR ENERGY TECH RES INST CO LTD +1

'Helium hood method' long-distance pipeline leakage point troubleshooting and positioning device and troubleshooting method

PendingCN112414630ANot destroyedImprove detection efficiencyDetection of fluid at leakage pointPipeline systemsThermodynamicsEngineering

The invention belongs to the nondestructive testing technology, and particularly relates to a 'helium hood method' long-distance pipeline leakage point troubleshooting and positioning device and troubleshooting method. The device comprises a flow supply and control plate A arranged at the upstream of a detected pipeline, and a helium hood and a helium applying plate B connected with the detected pipeline. The helium hood and helium applying plate B is composed of a helium hood, a helium concentration detector, a pressure reducing valve, a helium supply switch, a helium pressure stabilizing tank, a helium cylinder and a pressure gauge. The method comprises the following steps of: purging the pipeline to remove residual working gas, installing the helium hood on the detected pipe section, inflating the detected pipe with helium, checking leakage points, taking flange opening positions at the two ends of an inlet and an outlet of the pipeline as detection interfaces, applying a long-distance helium hood to the pipeline in the process, checking and positioning the leakage points of the pipeline by stages so as to determine the number and positions of leakage points of the buried pipeline. The method is safe and reliable, and can carry out leakage detection in flammable, explosive, high-temperature and other high-risk places.

Owner:JIANGSU NUCLEAR POWER CORP

Sheathed thermocouple component penetrating high-temperature high-pressure helium pressure shell

ActiveCN103090985BHigh strengthGuaranteed air tightnessThermometer detailsThermometers using electric/magnetic elementsThermal engineeringEngineering

The invention discloses a sheathed thermocouple component penetrating a high-temperature high-pressure helium pressure shell, and relates to the field of reactor thermal engineering test temperature measurement. The sheathed thermocouple component comprises a penetrating part which is used forleading out and seals at least one sheathed thermocouple from the pressure shell. The penetrating part further comprises a barrel body and a sealing flange, wherein the barrel body is used for leading out at least one sheathed thermocouple from the pressure shell, the sealing flange is arranged at one end of the barrel body and is used for sealing one end of the barrel body of the penetrating part, and the sheathed thermocouple penetrates through the sealing flange. The sheathed thermocouple component is used for leading out a plurality of sheathed thermocouples from the high-temperature high-pressure helium pressure shell, is capable of basically not reducing the strength of the pressure shell and guaranteeing the air tightness, is capable of leading out an electric lead-out end from the pressure shell under the condition that a sheathed thermocouple measurement end is installed well in the pressure shell, and is convenient to detach and install. The sheathed thermocouple component penetrating the high-temperature high-pressure helium pressure shell is simple in structure, good in reliability, and high-temperature-resistant.

Owner:TSINGHUA UNIV

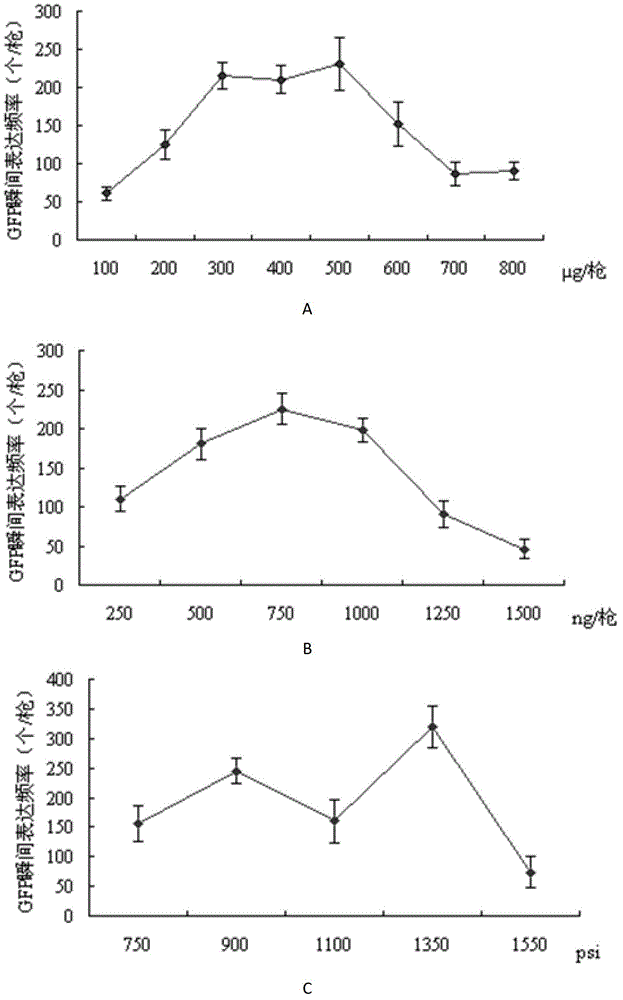

Method for transient expression of wheat leaf single cell based on efficient gene gun conversion and application of method

InactiveCN102978230AOptimize bombardment parametersEfficient conversion systemMicrobiological testing/measurementVector-based foreign material introductionDiseaseCuticle

The invention discloses a method for transient expression of a wheat leaf single cell based on efficient gene gun conversion and application of the method. The method for transient expression of the wheat leaf single cell based on the efficient gene gun conversion comprises the following steps of: performing gene gun conversion by using a green fluorescent protein gene as a report gene and a detached leaf of a first wheat leaf as a conversion receptor; immobilizing the wheat leaf by a solid fresh-keeping culture medium, wherein tungsten powder with the diameter of 1 micron is used for gene gun conversion, the using amount is 300ug / gun and the using amount of plasmid is 750ng / gun; and an attacking distance is measured based on 1350psi of cracking membrane helium pressure, a distance between the cracking film and a receptor film is 6 mm, and a distance between the receptor and a stopping net is 6 cm. By the method, haynaldia villosa SGT1 genes are expressed excessively in the detached leaf epidermis cells of the Yangmai 158 of the disease-sensing wheat categories; and a result shows that the index of powdery mildew haustorium in interaction cells can be reduced by the gene transient expression and the invasion of powdery mildew and the formation of the haustorium can be inhibited by the gene so as to increase the resistance of the powdery mildew.

Owner:NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com