Vacuum helium filling packaging device and method of nuclear power plant temperature detector

A technology of temperature detector and packaging device, applied in glass molding, glass remolding, glass manufacturing equipment and other directions, can solve the problems of alloy wire melting and helium leakage, achieve uniform heating and softening, prevent helium leakage, Fast sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

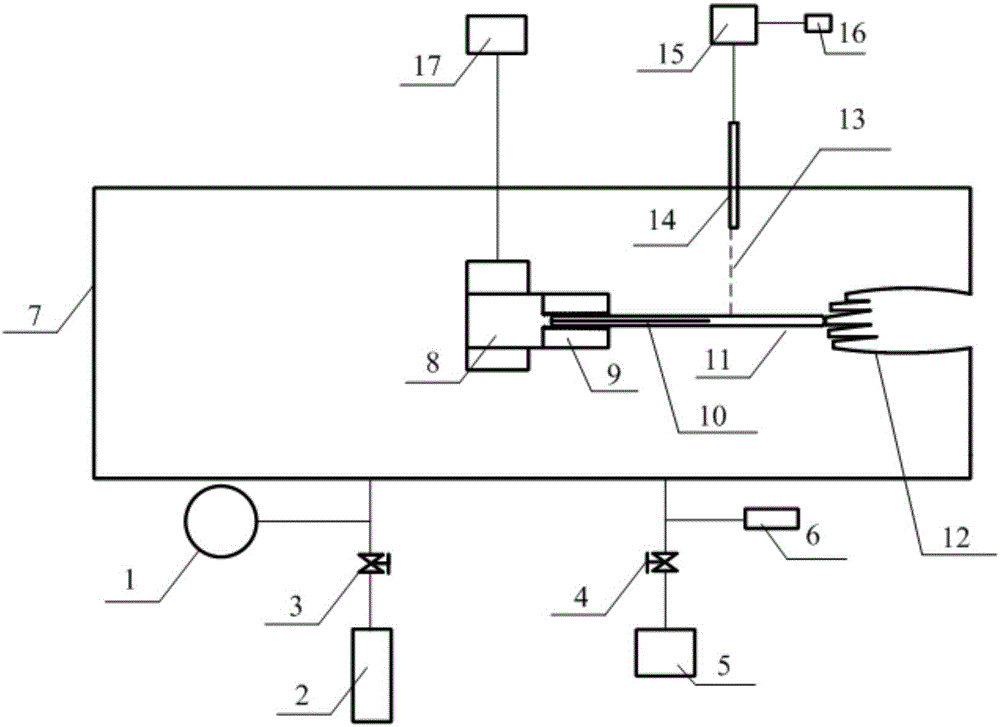

[0034] Such as figure 2 As shown, the vacuum helium-filled packaging device of the nuclear power plant temperature detector in this embodiment includes a glove box 7, a vacuum system for evacuating the glove box 7, a helium filling system for filling helium into the glove box 7, The clamping device 9 for clamping the quartz glass tube 11, and the laser heating system for heating the sealing part of the quartz glass tube 11.

[0035] Glove box 7 is a kind of sealing equipment, the user can operate with hands but without direct contact, it is generally a completely closed box shape, with gloves 12 for users to put their hands in, and users can put gloves 12 in the box operate.

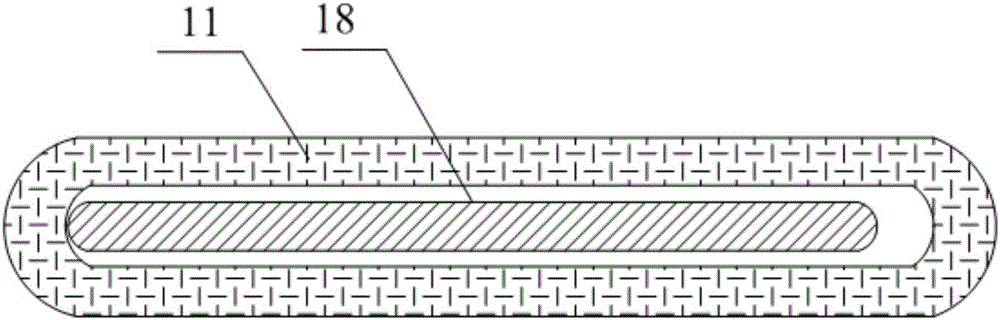

[0036]The clamping device 9 is located in the glove box 7; the quartz glass tube 11 is sealed in the glove box 7, when the quartz glass tube 11 is sealed, one end is close to the glove 11 of the glove box 7, and the other end is fixed on the clamping device 9, and the quartz glass tube 11 is sealed. O...

Embodiment 2

[0049] On the basis of Embodiment 1, the vacuum helium-filled packaging device of the nuclear power plant temperature detector in this embodiment also includes a rotating motor 8 and a rotating motor controller 17, and the clamping device 9 is connected to the output shaft of the rotating motor 8, The rotating motor 8 is connected with the rotating motor controller 17, and the state and the rotating speed of the rotating motor 8 are controlled by the rotating motor controller 17 so as to drive the clamping device 9 and the quartz glass tube 11 to rotate.

[0050] In this embodiment, the vacuum helium-filled packaging device not only has a laser heating system, a clamping device 9, a glove box 7, a vacuum system, and a helium filling system, but the laser heating system emits laser light 13 with highly concentrated energy, which can melt quartz in a short time The glass tube 11 prevents the temperature detection wire 10 in the quartz glass tube 11 from melting; and the rotating ...

Embodiment 3

[0058] On the basis of Embodiment 1 or Embodiment 2, in this embodiment, the vacuum helium-filled packaging method of the temperature detector of the nuclear power plant is further improved:

[0059] The step of "using the vacuum system to vacuum the glove box 7" in step S3 is as in S31-step S32:

[0060] S31, open the vacuum control valve 4, open the vacuum pump 5 to vacuumize the inside of the glove box 7;

[0061] S32. Close the vacuum control valve 4 and the vacuum pump 5 after the reading of the vacuum gauge 6 meets the design requirements. Generally speaking, the design requires that the vacuum degree of the glove box 7 should reach 0.01Pa before the vacuuming can be stopped and filled with nitrogen. Therefore, the vacuum control valve 4 and the vacuum pump 5 should be closed when the reading of the vacuum gauge 1 reaches 0.01Pa.

[0062] In step S3, the step of "filling helium into the glove box 7 by using the helium filling system" is as in S33-step S34:

[0063] S33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com