Helium pressure tuner pressure precision control apparatus and method

A precision control and tuner technology, applied in fluid pressure control, electric fluid pressure control, non-electric variable control and other directions, can solve the problems of reducing feedback speed, long cycle, mechanical mechanism failure, etc., and achieve accurate displacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

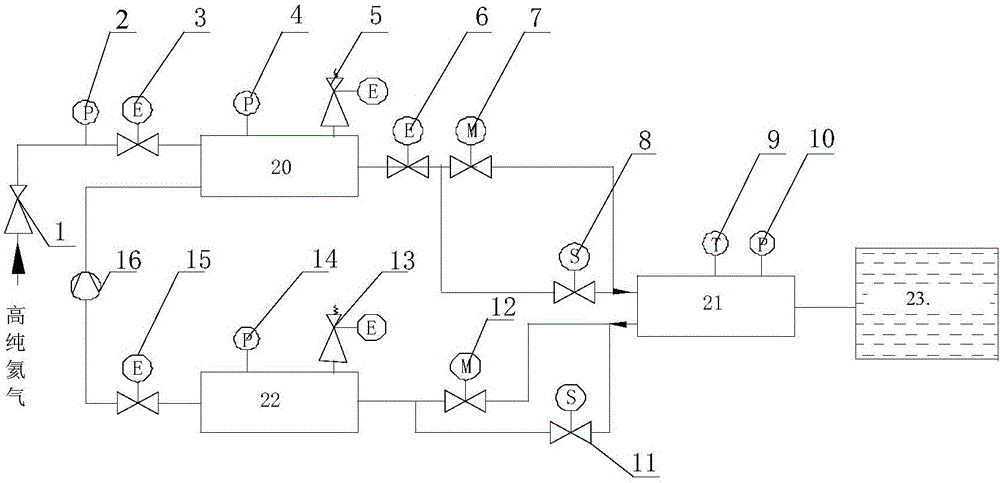

[0024] Embodiment 1, referring to the accompanying drawings, a helium pressure tuner pressure precision control device, it includes: decompression gas supply system, buffer system, adjustment system, pressure stabilization system and gas collection system;

[0025] The decompression and air supply system includes: the first decompression valve 1, the first pressure sensor 2 and the first electromagnetic isolation valve 3 connected in sequence through stainless steel pipelines;

[0026] The buffer system includes: a buffer tank 20 connected to the first electromagnetic isolating valve 3, a second pressure sensor 4 for monitoring the helium pressure in the buffer tank 20, a first automatic exhaust valve 5 for controlling the pressure range of the helium in the buffer tank 20, connecting The second electromagnetic isolating valve 6 at the output end of the buffer tank 20;

[0027] The adjustment system includes: a first high-precision mass flow controller 7 and a first electromag...

Embodiment 2

[0031] Embodiment 2, a helium pressure tuner pressure precision control method, it uses the helium pressure tuner pressure precision control device as described in embodiment 1, and comprises the following steps:

[0032] A. The pressure precision control device of the helium pressure tuner starts the initialization process after starting up, that is: according to the pressure conditions in the buffer tank 20, the surge tank 21 and the gas collection tank 22, by controlling the first electromagnetic isolation valve 3 and the first automatic exhaust The gas valve 5, the second electromagnetic isolation valve 6, the first electromagnetic regulating valve 8, the second electromagnetic regulating valve 11, and the second automatic exhaust valve 13 are switched off to achieve the initial pressure value in each tank;

[0033] B. After 2 seconds of initialization, the pressure precision control device of the helium pressure tuner automatically enters the running state, monitors the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com