Method and device for vacuum cavity leakage detection for sensors with vacuum reference cavities

A technology of vacuum chamber and reference chamber, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, can solve the problems of low detection efficiency, missed detection, low detection accuracy, etc., and achieve The effect of improving production efficiency, high detection accuracy, and improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

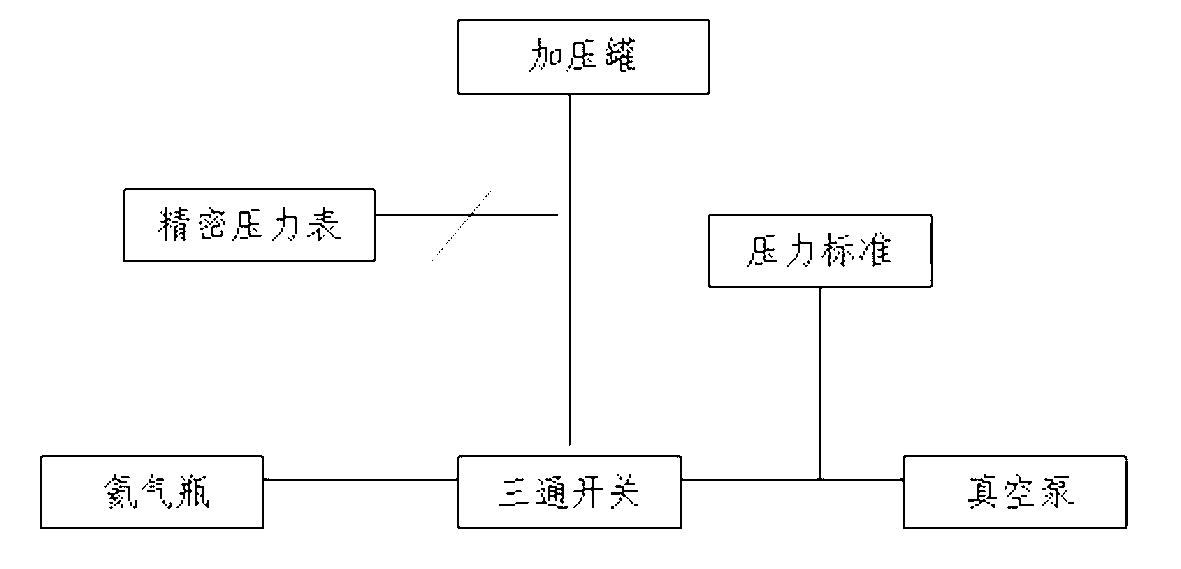

[0039] Embodiment: A method for vacuum chamber leak detection for a vibrating cylinder pressure sensor.

[0040] 1. Purpose of the test

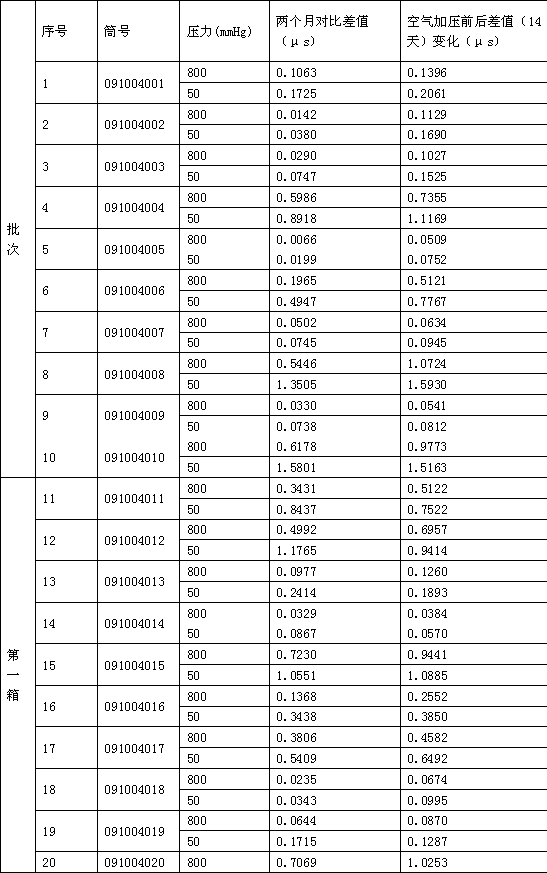

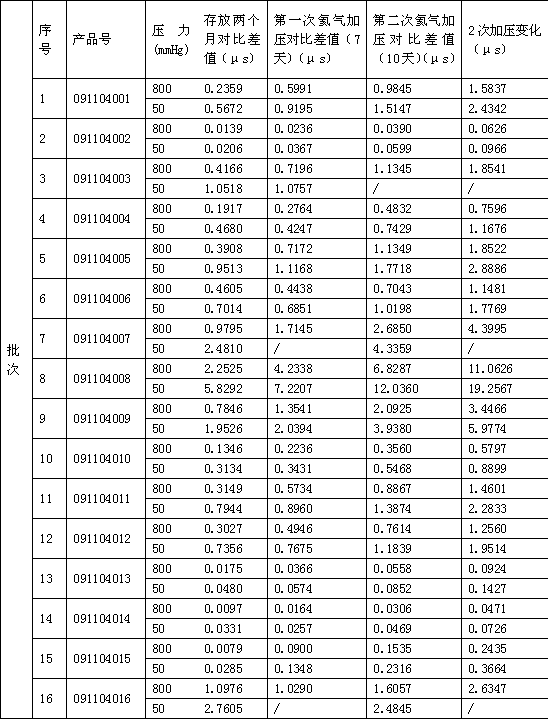

[0041] The high-precision vibrating cylinder sensor is an absolute pressure sensor. The stability of the vacuum degree of its vacuum chamber is one of the important factors determining the stability of the sensor. Therefore, it is necessary to ensure that the vacuum chamber of the sensor does not leak during the manufacturing process. At present, in the production process of the sensor, the sealing of the vacuum chamber depends on 2 months of storage, and the assessment method of measuring the cycle change of the sensor before and after storage is checked. The cycle of this process is about 70 days, which is not conducive to the improvement of production efficiency. Leak rate assessment is not sufficient. Therefore, the purpose of this test is to reduce the time for vacuum chamber leak detection, improve production efficiency, and improve t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com