High-precision numerical control phase shifter for K wave band and phase shifting method of high-precision numerical control phase shifter

A digitally controlled phase shifting, high-precision technology, applied in the field of phase shifters, can solve problems such as poor amplitude modulation, discontinuous phase shifting, and large phase shifting steps, and achieve system cost reduction, easy integration, and phase shifting steps small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

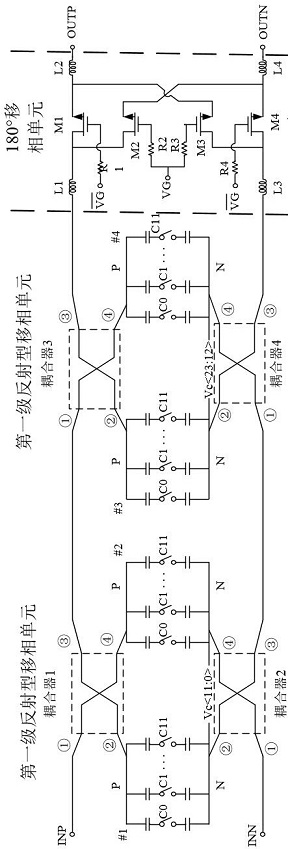

[0055] This embodiment proposes a high precision numerical control phase for k-band, connected to the INN input signal and the INP input signal, such as figure 1 , figure 2 As shown, a reflective phase shift module, a 180 ° phase shift unit, and a logic control circuit are shown.

[0056] The reflective phase shifting module includes two reflective phase shift units, respectively, a first stage reflective phase shift unit and a second-stage reflective phase shift unit, respectively;

[0057] The first stage reflective phase shift unit, the second stage reflective phase shift unit, and the 180 ° phase shift unit are sequentially connected; the first stage reflective phase shift unit is connected to the INN input signal and the INP input signal, respectively;

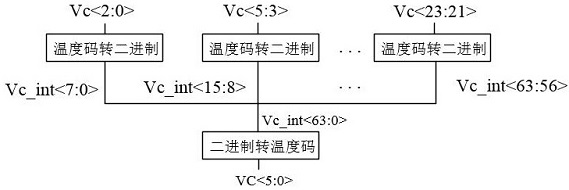

[0058] The logic control circuit includes a first stage control unit, a second level control unit, and a third level control unit;

[0059] The first stage control unit is a binary bit control code output unit, respectively, ...

Embodiment 2

[0064] This embodiment also proposes a phase shift method for a high-precision numerical control phase using a K-band, based on a high-precision numerical control phase in which the K band is used, including the following steps:

[0065] Step 1: Divide the binary bit control code output from the first stage control unit into two parts, partially output to the 180 ° phase shift unit for phase control, and the other part is transmitted to the second level control unit;

[0066] Step 2: Convert the received binary bit control code to a temperature code at the second stage control unit, and then split the converted temperature code and corresponding to the temperature code transfer module unit transmitted to the third stage control unit;

[0067] Step 3: Both the temperature code transfer module unit in the third stage control unit is divided into two groups, respectively, respectively, and the first-stage reflective phase shift unit and the second stage reflective phase shift unit ar...

Embodiment 3

[0071] In addition to the above-described embodiment 1, in order to better achieve the present invention, figure 1 , figure 2 As shown, the first stage reflective phase shift unit includes a first coupler, a second coupler, a first capacitive switch array, and a second capacitor switch array; the second stage reflective phase shift unit includes a third coupling. A fourth coupler, a third capacitive switch array and a fourth capacitor switch array; the first coupler, the second coupler, the third coupler, the fourth coupler are four coupler, the first A capacitor switch array, the second capacitance switch array third capacitor switch array and the fourth capacitive switch array contain 12 parallel switching capacitors;

[0072] The 1-coupled 1 interface connection of the INP input signal, 2 connecting the P end of the first capacitance switch array, 4 interface connects the P end of the second capacitor switch array;

[0073] The 1 interface of the second coupler is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com