'Helium hood method' long-distance pipeline leakage point troubleshooting and positioning device and troubleshooting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

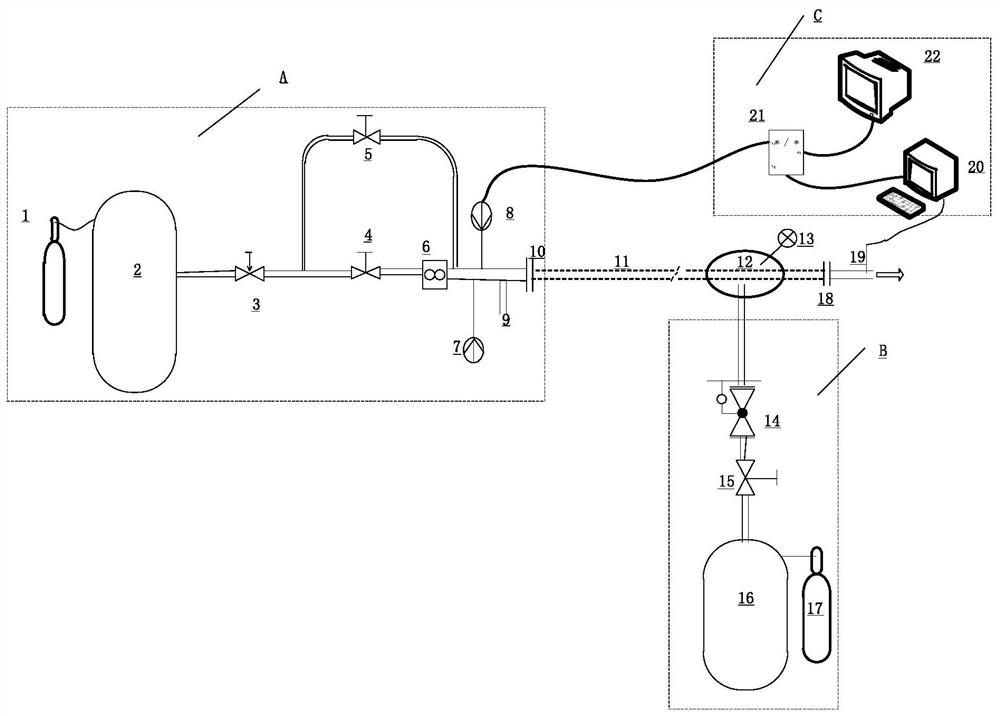

[0041] Such as figure 1 As shown, the long-distance pipeline leak detection and location device based on the "helium hood method" includes upstream flow supply and control block A, helium hood and helium application block B, and downstream measurement and data acquisition and analysis block C.

[0042] Among them, the upstream flow supply and control board A is composed of compressed air source 1, air pressure tank 2, flow regulating valve 3, air switch 4, bypass switch 5, flow sensor 6, dew point thermometer 7, temperature sensor 8, reference drain Point 9 and the upstream connecting flange 10 are formed (shown in plate A in the figure).

[0043] The compressed air source 1 is connected to the air surge tank 2, the gas outlet of the air surge tank 2 is connected to the pipeline through a hose joint, and the flow regulating valve 3, the air switch 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com