Novel gasbag for airship

An airbag and a new type of technology, applied in the field of airships, can solve the problems of indeterminate positions of internal equipment and devices, difficult manufacturing, and increased leakage of helium, and achieve easy debugging and maintenance, reduce leakage of helium, and reduce sealing requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

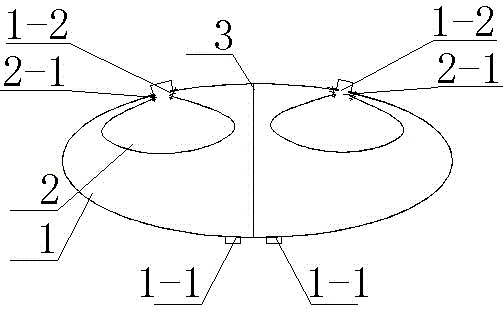

[0015] Such as figure 1 As shown, a new type of airbag for airship is characterized in that it includes an airbag (1), a pair of helium airbags (2) and a tension line (3), and one or more airbags are arranged on the airbag (1). A pair of helium ports (1-1) and a pair of A helium ports (1-2), a pair of air ports (1-1) and a pair of A helium ports (1-2) are respectively provided with valves, and a pair of helium bladders (2 ) are respectively provided with B helium ports (2-1), a pair of helium air bags (2) are respectively installed in the air bag (1), and the B helium ports (2-1) of a pair of helium air bags (2) are respectively The pair of A helium ports (1-2) on the air bag (1) are overlapped, and the tension wire (3) is installed in the air bag (1) and between the pair of helium bags (2).

[0016] Working principle: when in use, use a blower to fill the air chamber with air through one of the air ports 1-1, and stop the blower when the pressure difference between the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com