Mass spectrometer leak detection helium pre-filling method capable of prolonging detection waiting time of sealing device

A technology of waiting time for inspection and pre-filling with helium, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, which can solve the problem that large leaks cannot be identified by rough inspection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

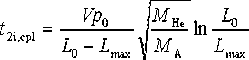

[0242] Example 1 (see Figure 12 ): marked in the figure t 2i / V = 3 h / cm 3 or 30 h / cm 3 , L max = 1×10 -3 Pa×cm 3 / s, p i = 1.01×10 5 Pa. By formula (7) get t 2i, cp1 / V = 54.19 h / cm 3 ,so t 2i t 2i, cp1 , belonging to step S31 of "Content of the invention". As described in this step, the L max, H ≥ L 0 , L max ≤ L i, M . And when R i > R i, Lmax When , the leak rate is unqualified; and when R i ≤ R i, Lmax When the minimum detectable leak rate is less than L 0 The crude inspection method is used for leak detection of the tested device to confirm or exclude L H The existence of the leakage rate is judged to be unqualified or qualified. The statements in step S31 of "Summary of the Invention" are the same as those seen in the figure.

Embodiment 2

[0243] Example 2 (see Figure 13 ): marked in the figure t 2i / V = 100 h / cm 3 , L max = 1×10 -2 Pa×cm 3 / s, p i = 1.01×10 5 Pa. By formula (7) get t 2i, cp1 / V = 37.20 h / cm 3 , get from formula (8) t 2i, cp2 / V = 1046 h / cm 3 ,so t 2i, cp1 t 2i ≤ t 2i, cp2 . It can be seen from the figure R i > R i, Lmax , so it belongs to step S321 of "Content of the invention". As described in this step, the L max, H L 0 , L max ≤ L i, M , and when R i > R i, Lmax The hourly leak rate is unqualified. It can be seen from the figure L > L max , so the leakage rate is unqualified. Therefore, the statements in step S321 of "Summary of the Invention" are the same as those seen in the figure.

Embodiment 3

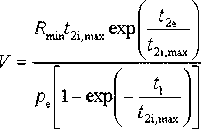

[0244] Example 3 (see Figure 14 ): marked in the figure V = 1cm 3 , L max = 1×10 -2 Pa×cm 3 / s, p i = 1.01×10 5 Pa, t 2i = 100 h; p e = 4×10 5 Pa, t 1 = 40min, t 2e = 60 min. By formula (7) get t 2i, cp1 = 37.20 h, obtained from formula (8) t 2i, cp2 = 1046 h, so t 2i, cp1 t 2i ≤ t 2i, cp2 . By formula (9) get t 2i, max = 8605 h, so t 2i t 2i, max . It can be seen from the figure R i R i, Lmax , R e > R e_Li, M , so it belongs to step S32221 of "Content of the invention". According to the description of this step, re-examination and rough inspection by helium pressure method should be used to judge whether R e ≤ R e_Li, M , from which it is judged whether L ≤ L i, M ,and t 2e cannot exceed the value expressed by equation (10) t 2e, max . like R e > R e_Li, M ,but L > L i, M , the leak rate is unqualified. And from formula (6) and formula (10) get t 2e, max = 2494 min, so fits t 2e Does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com