Method for comprehensively utilizing distillation raffinate produced in production of alpha-pyrrolidone and N-vinyl pyrrolidone

A technology of vinylpyrrolidone and pyrrolidone, which is applied in the field of waste treatment, can solve the problems of non-recycling, high cost, and difficult separation of enterprises, and achieve the effect of simple and uncomplicated process, improving production efficiency, and meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

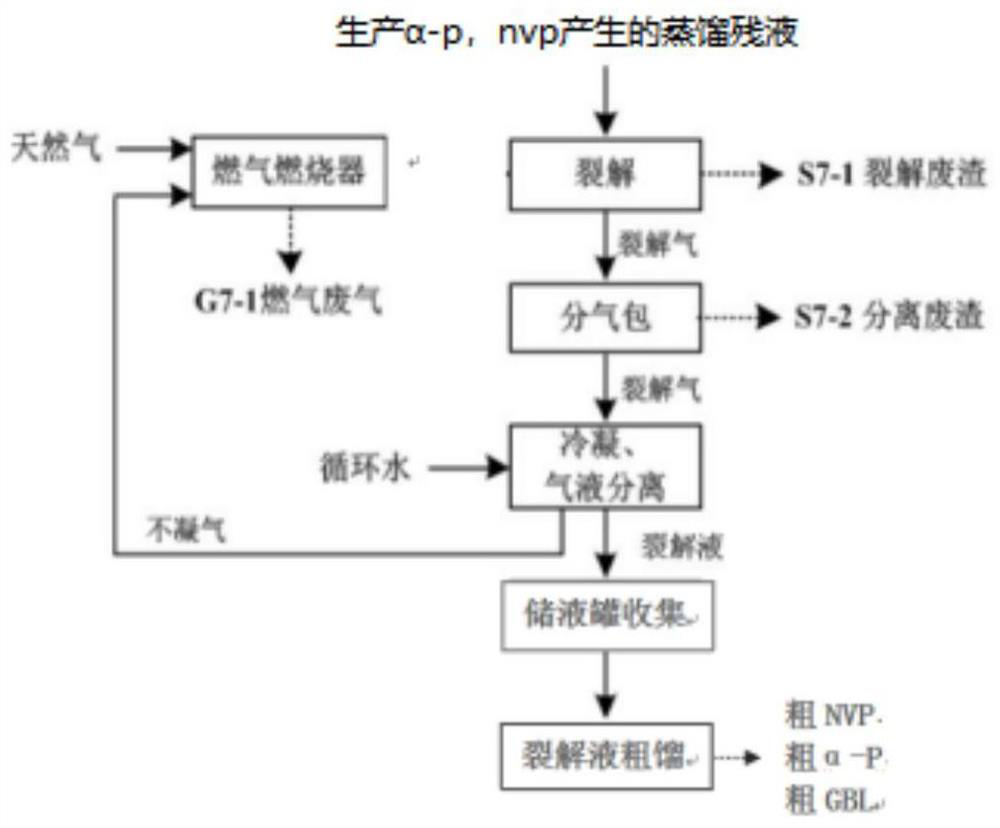

[0012] like figure 1 As shown, a method for the comprehensive utilization of the distillation raffinate for the production of α-pyrrolidone and N-vinylpyrrolidone. After the α-P and NVP distillation raffinate is released, it becomes a block solid at room temperature and pressure, and is packaged and temporarily stored in hazardous waste. The warehouse is ready for use. When in use, it is manually fed to the cracking furnace, and 5 tons are fed at a time. Close the furnace door, replace with N2 gas for 20 minutes, turn on the motor of the cracking furnace, roll the cracking furnace slowly, turn on the gas burner to start heating, under the condition of 480-500°C (cracking room temperature), the preferred temperature is 485°C, small molecular polyethylene Pyrrolidone generates NVP gas through the reverse reaction of pyrolysis, and a small amount of NVP undergoes a reverse reaction under this condition to finally generate α-P gas; based on the above principle, the raw material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com