Image sensor from CMOS transistors, and manufacturing method

An oxide semiconductor and image sensor technology, which can be used in semiconductor/solid-state device manufacturing, radiation control devices, electrical components, etc. Improve photosensitive efficiency, save process cost, simple and uncomplicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

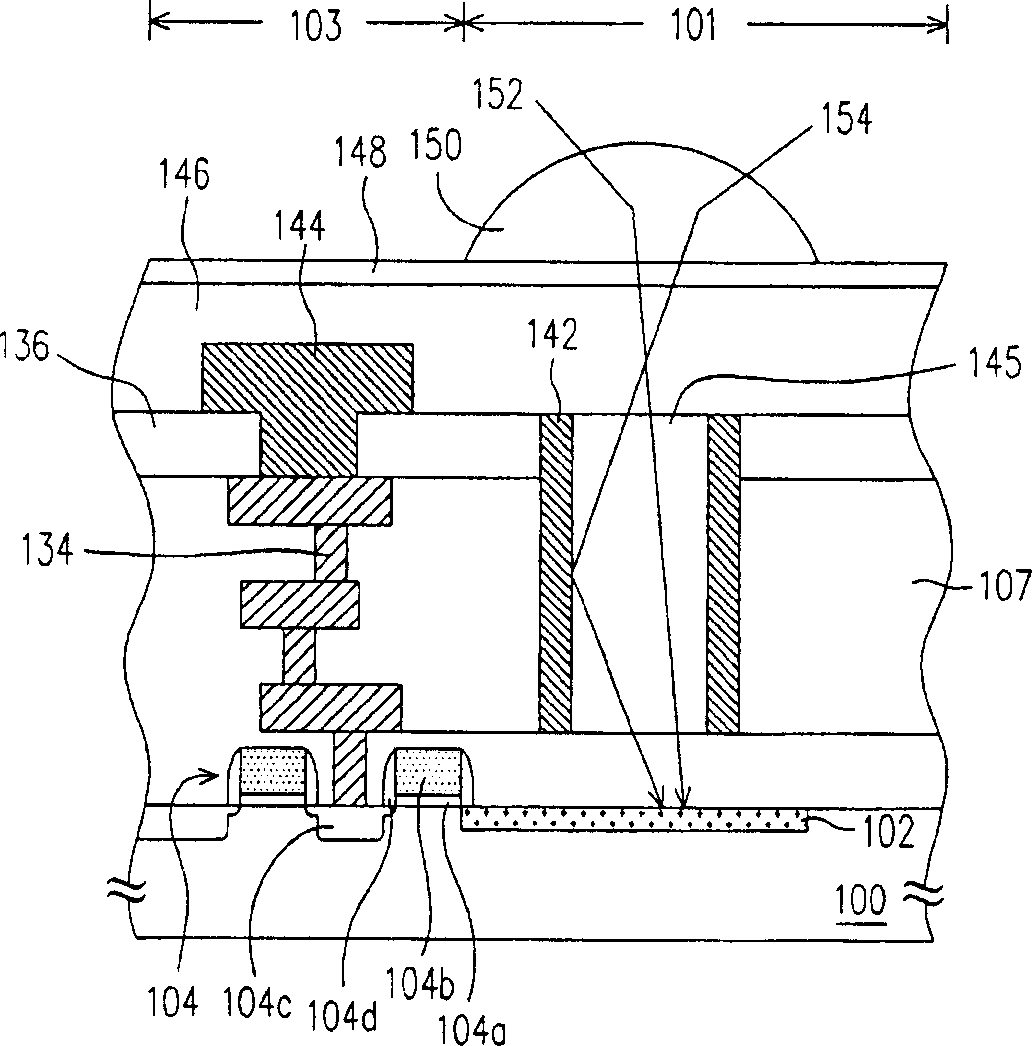

[0062] figure 1 It is a schematic cross-sectional view of a CMOS image sensor according to an embodiment of the present invention.

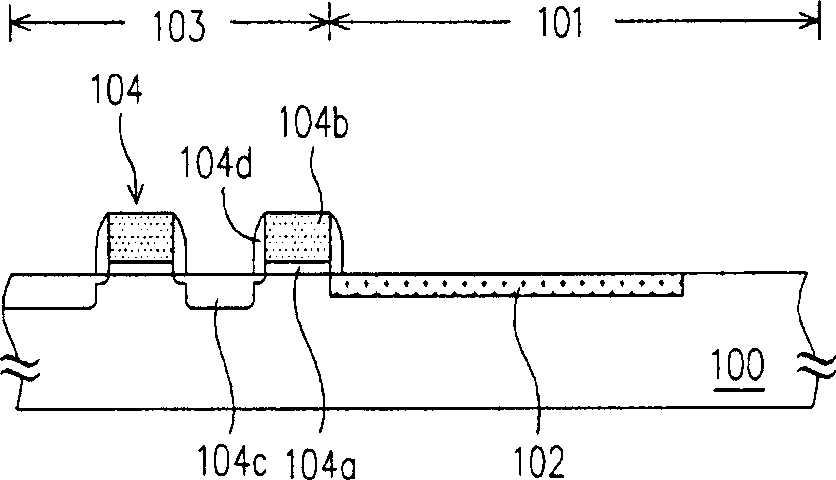

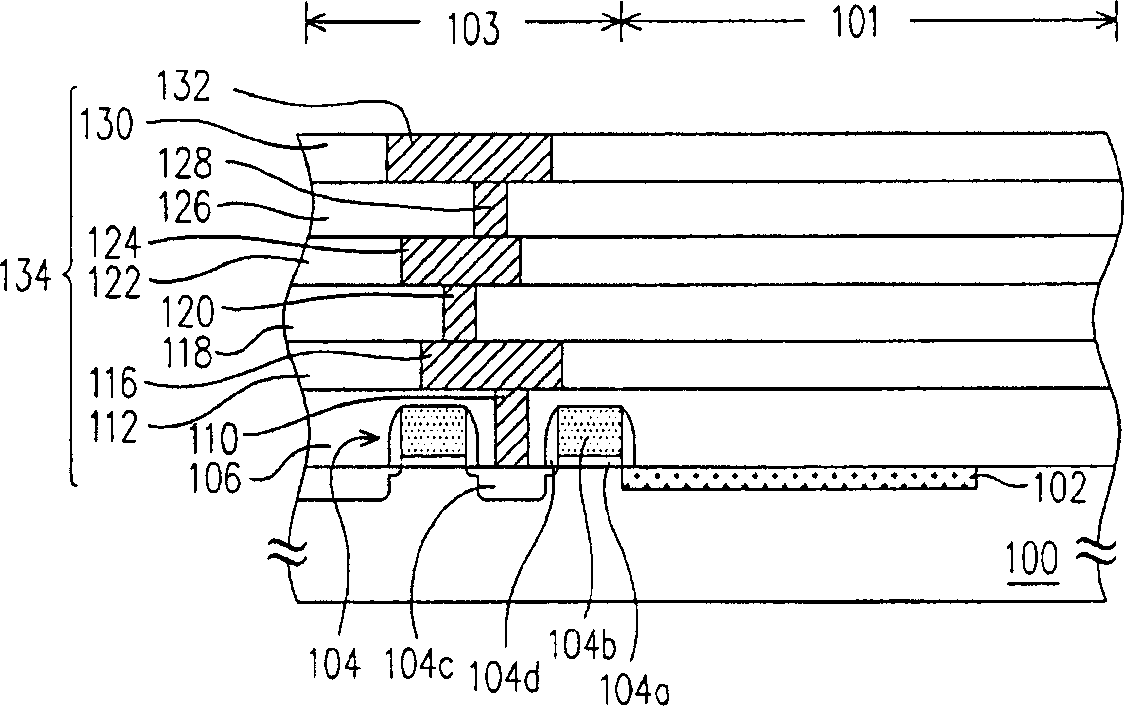

[0063] Please refer to figure 1 , the CMOS image sensor of the present invention comprises a light sensing element 102, a transistor 104, a ring post reflection layer 142, a protective layer 136, a transparent material layer 146, a material layer 145, a filter film 148, a light concentrating Component 150 and dielectric layers 106, 107. Wherein, the light sensing element 102 is disposed in the light sensing region 101 of the substrate 100, the light sensing element 102 is, for example, a photodiode; and the transistor 104 is disposed on the transistor region 103 of the substrate 100, and the transistor 104 and the light sensing The measuring element 102 is electrically connected. The transistor 104 includes a gate dielectric layer 104a, a gate 104b, a source / drain region 104c and a spacer 104d. The dielectric layer 106 is disposed on the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com