Tube structure with sol-gel zirconia coating

a technology of sol-gel zirconia and tube structure, which is applied in the direction of liquid/solution decomposition chemical coating, other chemical processes, separation processes, etc., can solve the problems of narrow range of ph stability, affecting the stability of the stationary phase, and difficult to achieve using either purely organic or purely, etc., to achieve excellent chemical and ph stability and unique surface chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

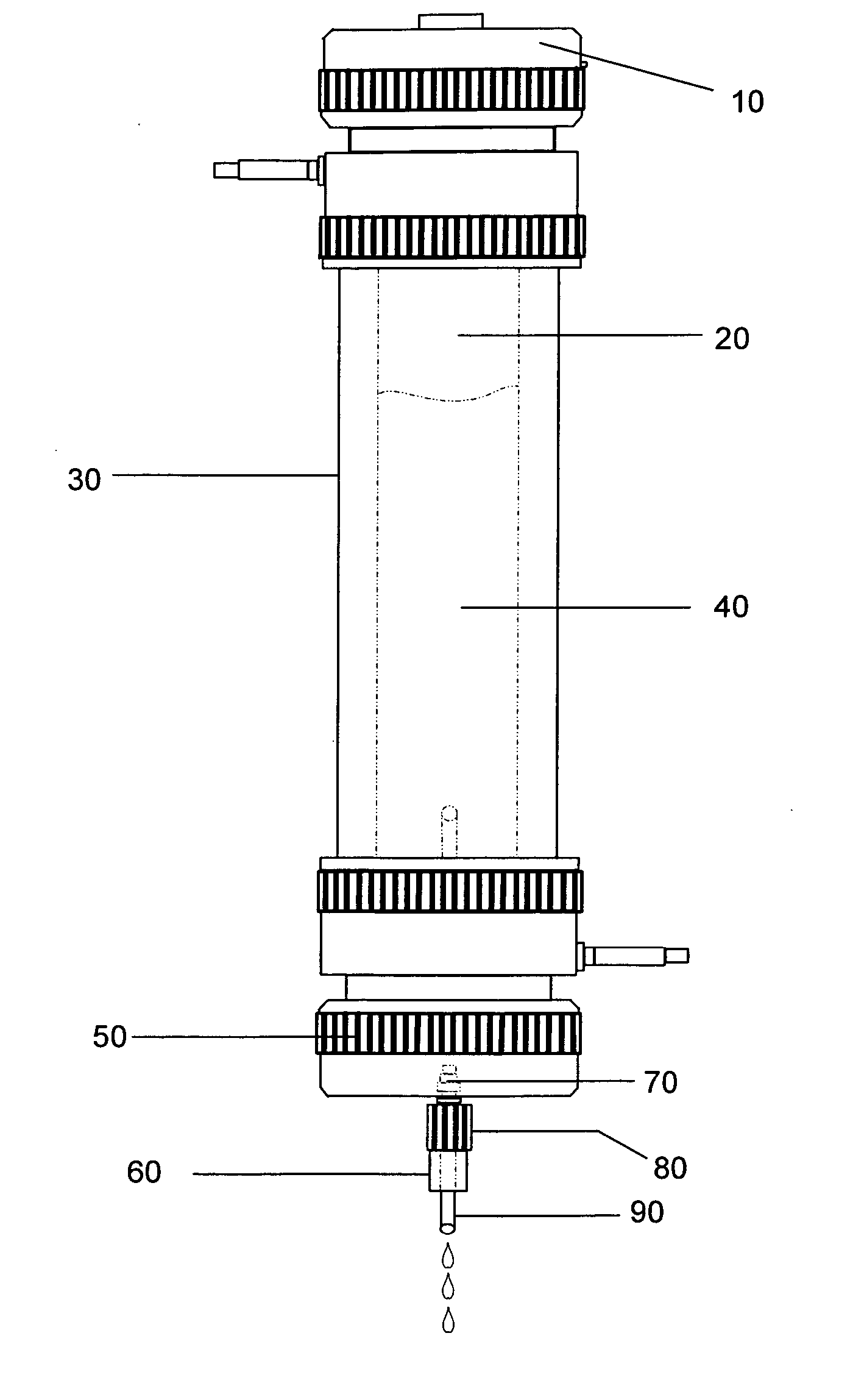

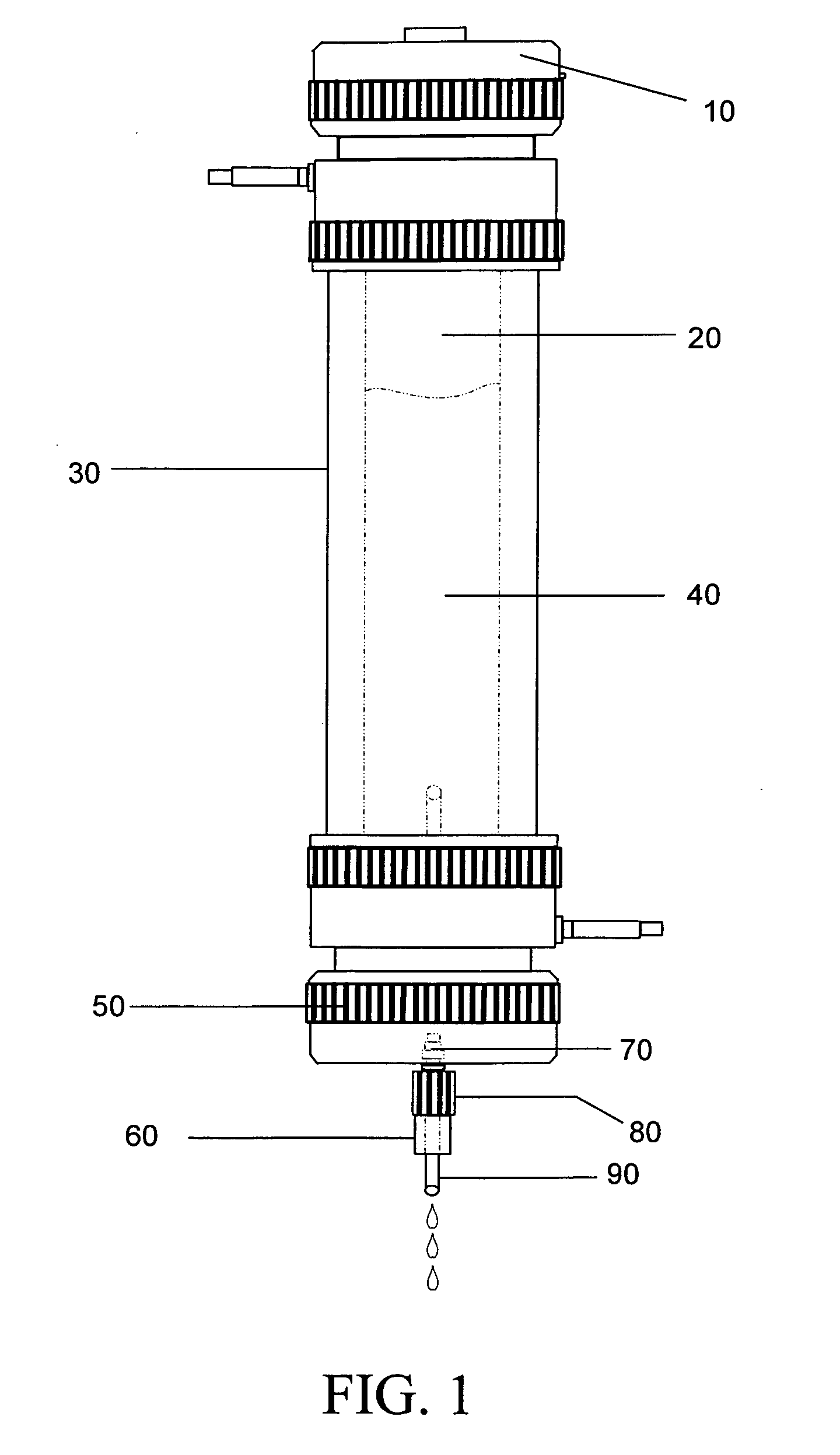

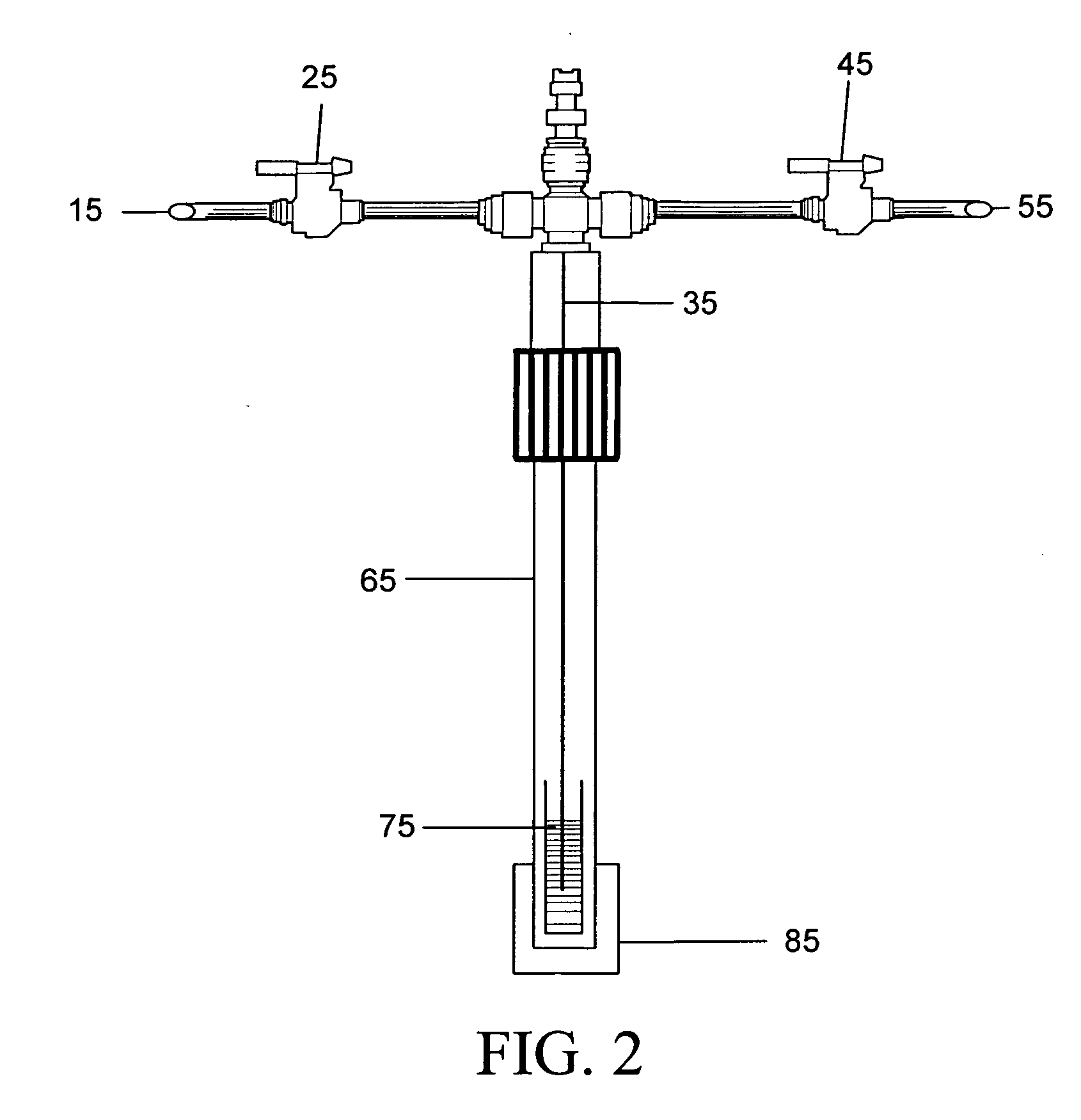

[0020] For the preparation of sol-gel-coated capillaries according to this invention, a cleaned and hydrothermally treated fused-silica capillary is filled with a specially designed sol solution using a helium pressure-operated filling / purging device. The key ingredients of the sol solution include appropriate amounts of: sol-gel precursor such as zirconium (IV) butoxide; a stationary phase coating such as silanol-terminated poly copolymer (dimethyldiphenylsiloxane); a solvent such as methylene chloride; a chelating reagent such as acetic acid; a deactivating reagent such as poly(methylhydrosiloxane); or a deactivating reagent such as hexamethyldisilazane. After filling, the sol solution is allowed to stay inside the capillary for 10-15 minutes. During this time, an organic- inorganic hybrid sol-gel network evolves in the sol solution within the confined environment of the fused-silica capillary, and a thin layer of the evolving sol-gel stationary phase chemically bonds to the capil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com