Helium mass spectrum fine leakage detecting method of multiple helium pressing and prefilled helium pressing

A technology of pre-filling helium and helium mass spectrometry, which is applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., which can solve the problem of complex judgment procedures and methods, missed detection, and loss of detection sensitivity. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0145] 5. Embodiment 2 The method for fine leak detection by helium mass spectrometry using pre-filled helium pressurized helium method

[0146] The detection procedure for pre-filled helium pressure helium helium mass spectrometry fine leak detection for pre-filled helium components is as follows:

[0147] Step S0 pre-filled with helium and sealed: Put the unsealed test piece into the pre-filled helium device, fill the helium-nitrogen mixed gas with a pressure of 1.05Pa to 1.10Pa according to the selected pre-filled helium ratio k, and in this gas To seal the inspected part, the k value and sealing time should be recorded and saved. Step S0 is a helium prefilling step before implementing the helium prefilling procedure.

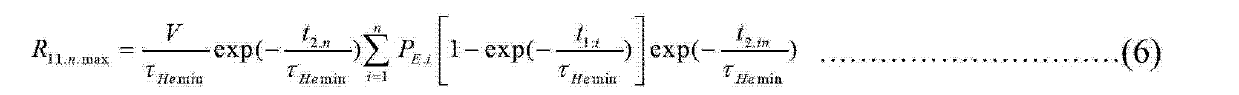

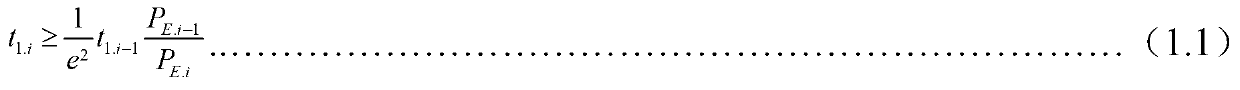

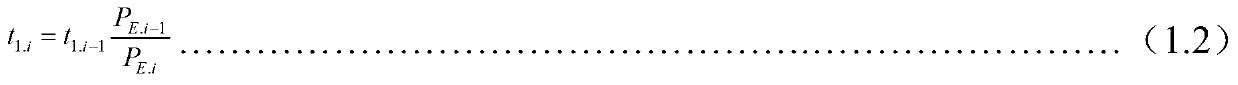

[0148] Step S1 Pressing helium: For the i-th (i=1~n) pressing of helium, put the inspected part into the helium pressing box, evacuate the helium pressing box to within 100Pa, press the selected helium pressing pressure P E.i and duration t 1.i , fill the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com