Precision calibrating method of container volume

A calibration method and container technology, applied in the direction of volume measuring instruments/methods, container/cavity capacity measurement, instruments, etc., can solve the problems of high container volume error, cumbersome operation, limited reading accuracy, etc., and achieve the effect of accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

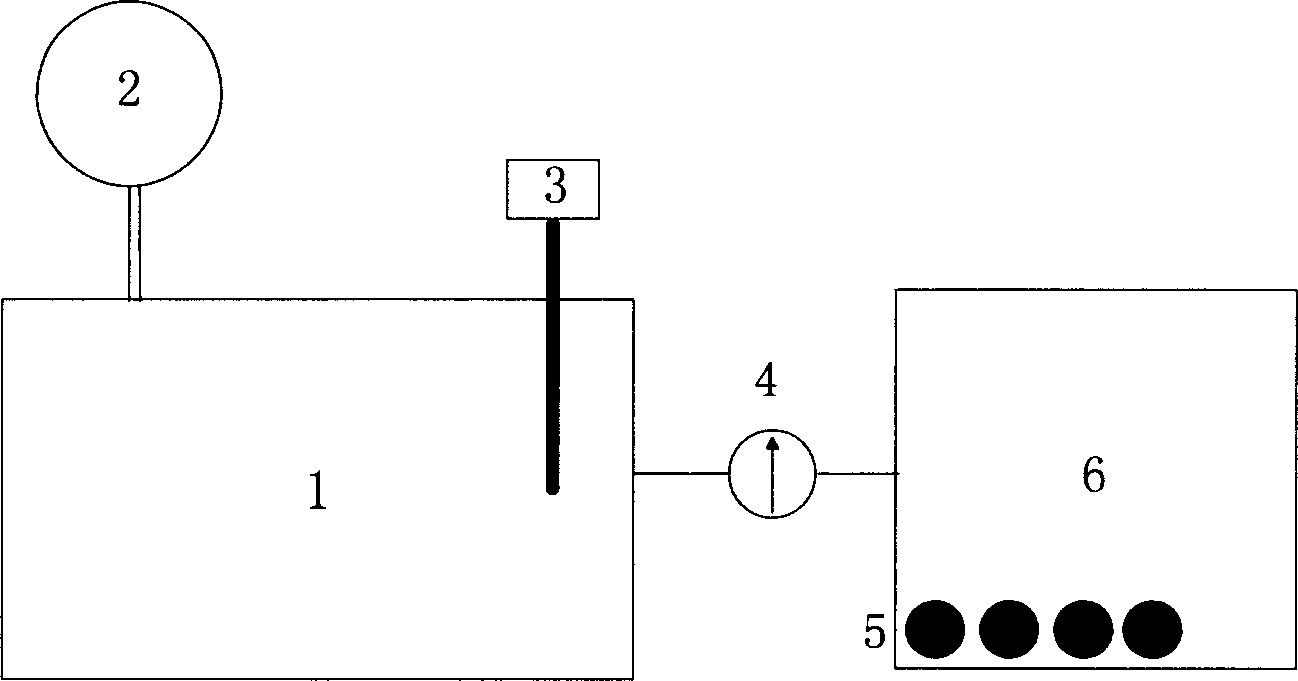

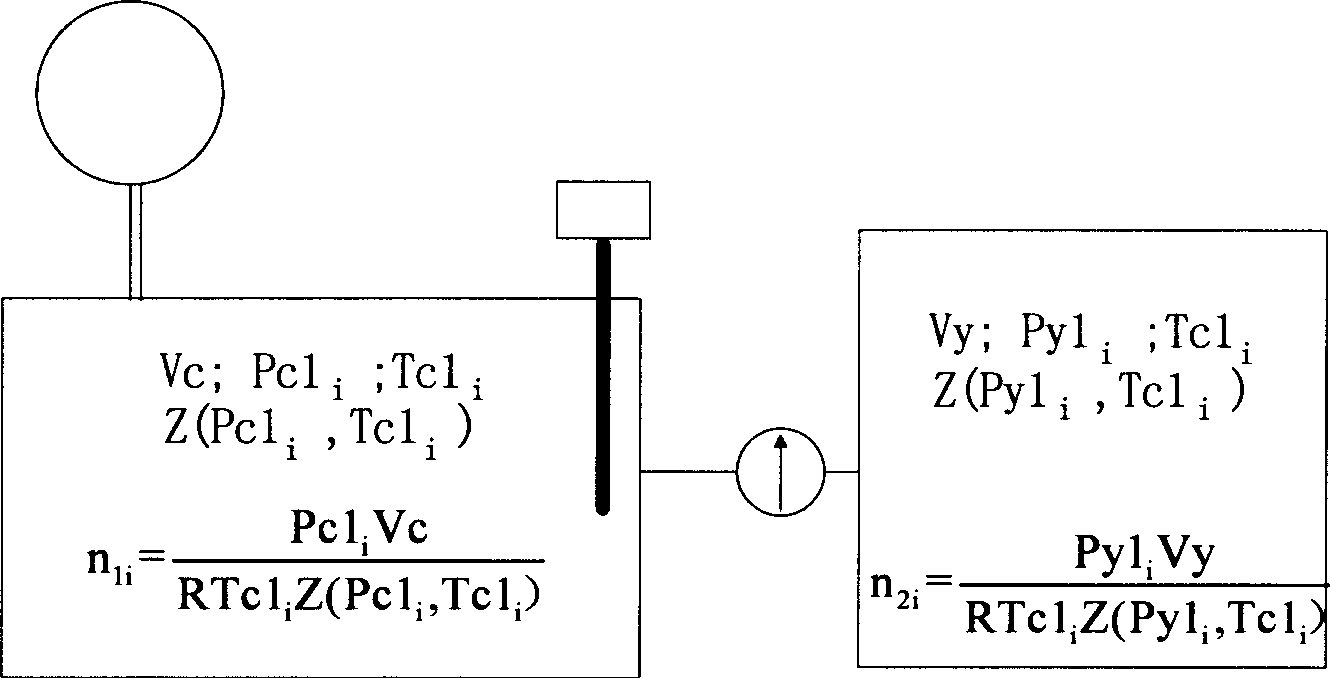

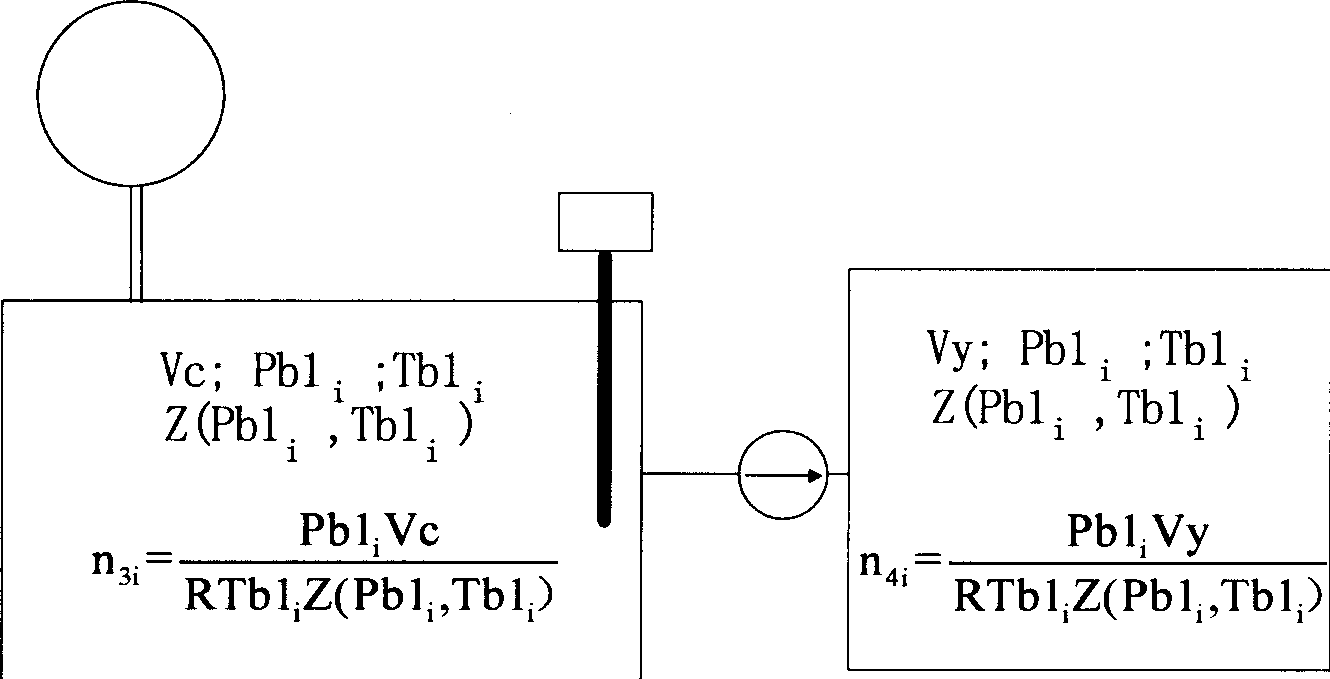

[0028] The method of the present invention uses a device such as figure 1 As shown, the device includes a first container 1, a temperature transmitter 2, a pressure transmitter 3, a valve 4, a steel ball 5, and a second container 6. The first container 1 is equipped with a temperature transmitter 2, a pressure transmitter Container 3, steel ball 5 is housed in the second container 6, the first container 1 and the second container 6 are connected by pipeline, and valve 4 is arranged on the pipeline.

[0029] The invention provides a simple and accurate method for calibrating the volume of a container, which includes the following steps:

[0030] 1) With stable properties and small helium adsorbed on the wall as the calibration gas.

[0031] 2) The temperature of the test environment is measured by the temperature transmitter 3 , and the pressure transmitter 2 is used to measure the experimental pressures of the first container 1 and the second container 6 .

[0032] 3) First,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com