Capillary tube thermostatic expansion valve mixing and filling device based on PLC (programmable logic controller)

A technology of thermal expansion valve and capillary tube, which is applied to equipment, mechanical equipment, container filling method, etc. into pressure vessels, can solve the problems of time-consuming adjustment of fixtures, inaccurate filling results, and difficulty in installation of filling parts, etc. High degree of automation, solving mixing and charging accuracy, easy maintenance and improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

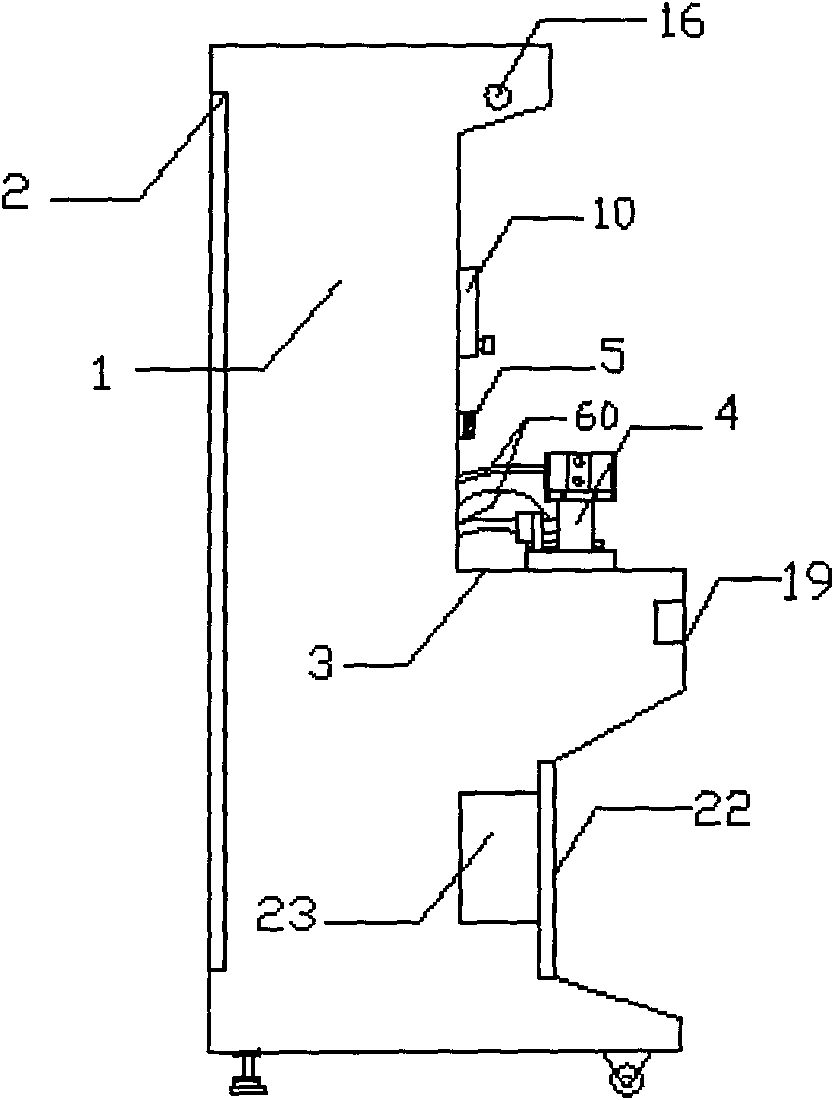

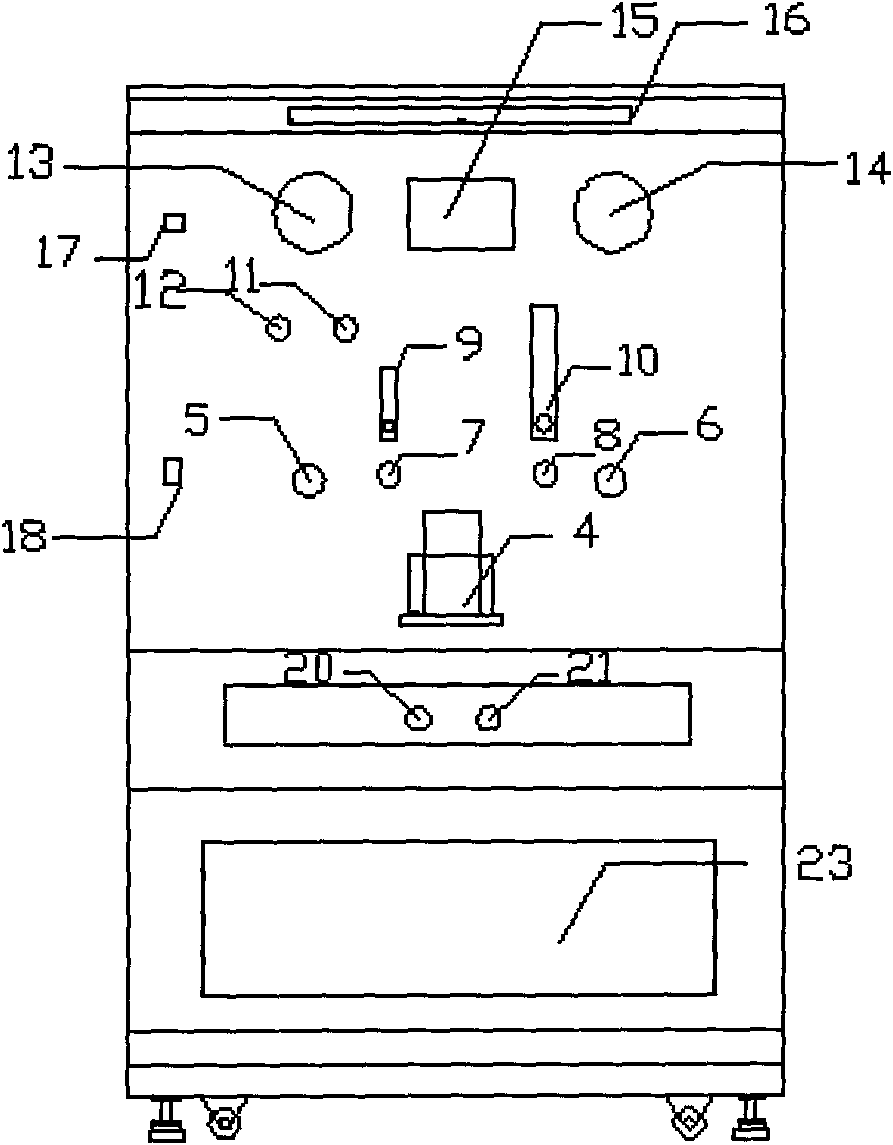

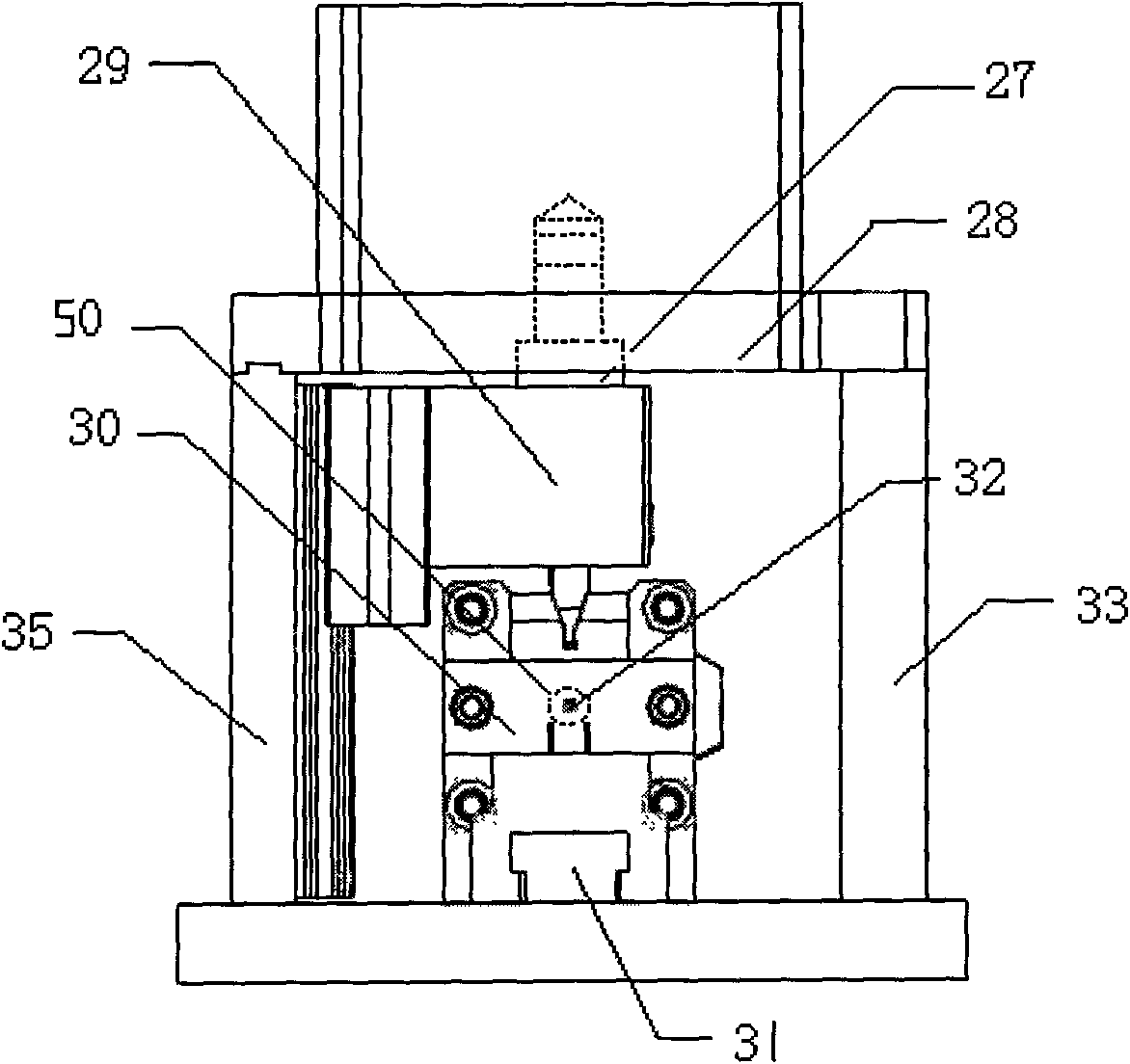

[0035] Before operation, according to the needs of different types of thermal expansion valves, adjust the position of the lower knife seat 43 on the slide rail 31 to adapt to different capillary lengths, adjust the refrigerant pressure reducing valve 5 and helium pressure reducing valve 6 to the specified pressure, and fine-tune the first Throttle valve 7 and second throttle valve 8, insert the thermal expansion valve capillary tube to be charged into the air inlet port 32 on the charging tool 5 during operation, and the PLC control system controls the rear cylinder 26 to push the charging connecting plate 34 to press O The ring 50 compresses the capillary tube of the thermal expansion valve, and sequentially opens and closes the vacuum solenoid valve 46, the helium gas inlet solenoid valve 44, the first refrigerant inlet solenoid valve 45, the second refrigerant inlet solenoid valve 48, and the deflation solenoid valve. The valve 47 is filled, if the qualified indicator light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com