Vacuum pipeline for transmission cavity of semiconductor dry etching machine and control method thereof

A technology of dry etching and evacuating tubes, used in semiconductor/solid-state device manufacturing, circuits, discharge tubes, etc., can solve problems such as leakage, surface defects of wafer products, and contamination of wafer products by annular particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

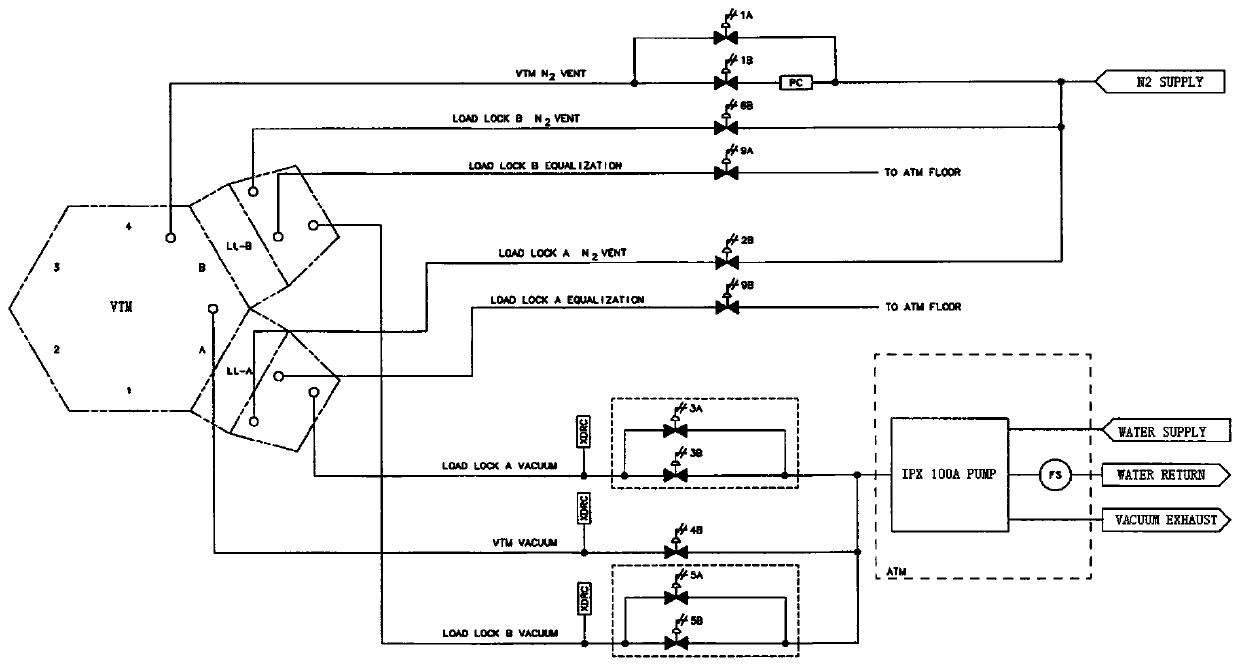

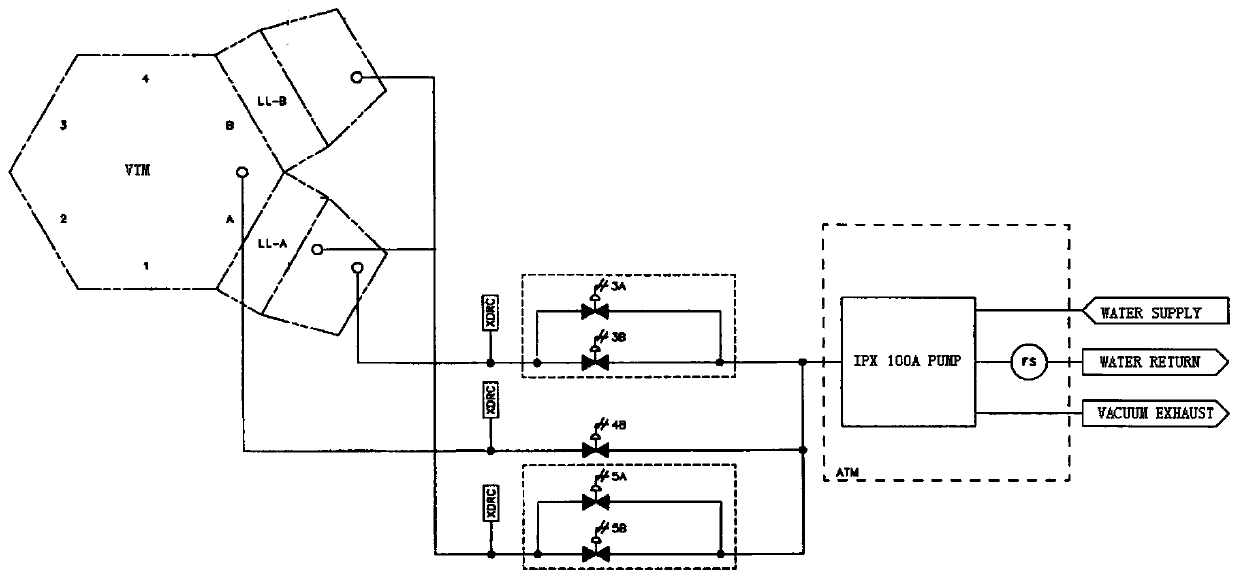

[0042] Vacuum pipeline for the transfer cavity of semiconductor dry etching machine, such as Figure 6 As shown, the vacuum transfer module (VTM) of the semiconductor dry etching machine is connected to the air inlet of the dry pump 1 through a pipeline;

[0043] The buffer chamber 2 is connected to the pipeline between the intake end of the dry pump 1 and the rear end of the helium isolation valve V1;

[0044] The helium front valve V2 is connected to the pipeline between the buffer chamber 2 and the rear end of the helium isolation valve V1;

[0045] The helium post-stage valve V4 is connected to the pipeline between the buffer chamber 2 and the intake end of the dry pump 1;

[0046] The helium pressure gauge 3 is connected to the pipeline between the helium inlet port and the rear end of the helium isolation valve V1;

[0047] The helium supply valve V3 is connected to the pipeline between the helium pressure gauge 3 and the helium inlet port;

[0048] The front end of t...

Embodiment 2

[0053] Based on the evacuation pipeline of the transport chamber of the semiconductor dry etching machine in Embodiment 1, a filter 4 is also provided on the pipeline between the helium supply valve V3 and the helium pressure gauge 3 .

[0054] Preferably, a working valve V5 is provided on the pipeline from the vacuum transfer module (VTM) to the intake end of the dry pump.

[0055] Preferably, the semiconductor dry etching machine is Lam 2300VersysTM Metal / Silicon System.

[0056] Preferably, the dry pump 1 is an iPX 100 type.

[0057] Preferably, the dry pump 1 is installed at the position of the atmospheric transfer module (ATM).

Embodiment 3

[0059] Based on the control method of the silicon etching system transmission chamber vacuum pumping pipeline in the first embodiment, the dry pump 1 uses the vacuum transfer module and the airlock (used as a transfer between the vacuum transfer module (VTM) and the atmospheric transfer module (ATM) Station) vacuuming, usually the vacuum transfer module (VTM) works together with the dry pump through N2purge (N2 purge) to maintain the transmission working pressure at a pressure of 85 mTorr to 95 mTorr (eg 90 mTorr);

[0060] When the transmission is waiting, the helium post-stage valve V4 remains open, and a dry pump is used to evacuate the buffer chamber 2 to 85 mTorr to 95 mTorr (for example, 90 mTorr);

[0061] When removing static electricity, the helium supply valve V3 and the helium back-stage valve V4 are closed, and the helium isolation valve V1 and the helium front-stage valve V2 are opened. The gas in the back helium pipeline is discharged into the buffer chamber, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com