Patents

Literature

165 results about "Wafer Product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wafer product and processing method therefor

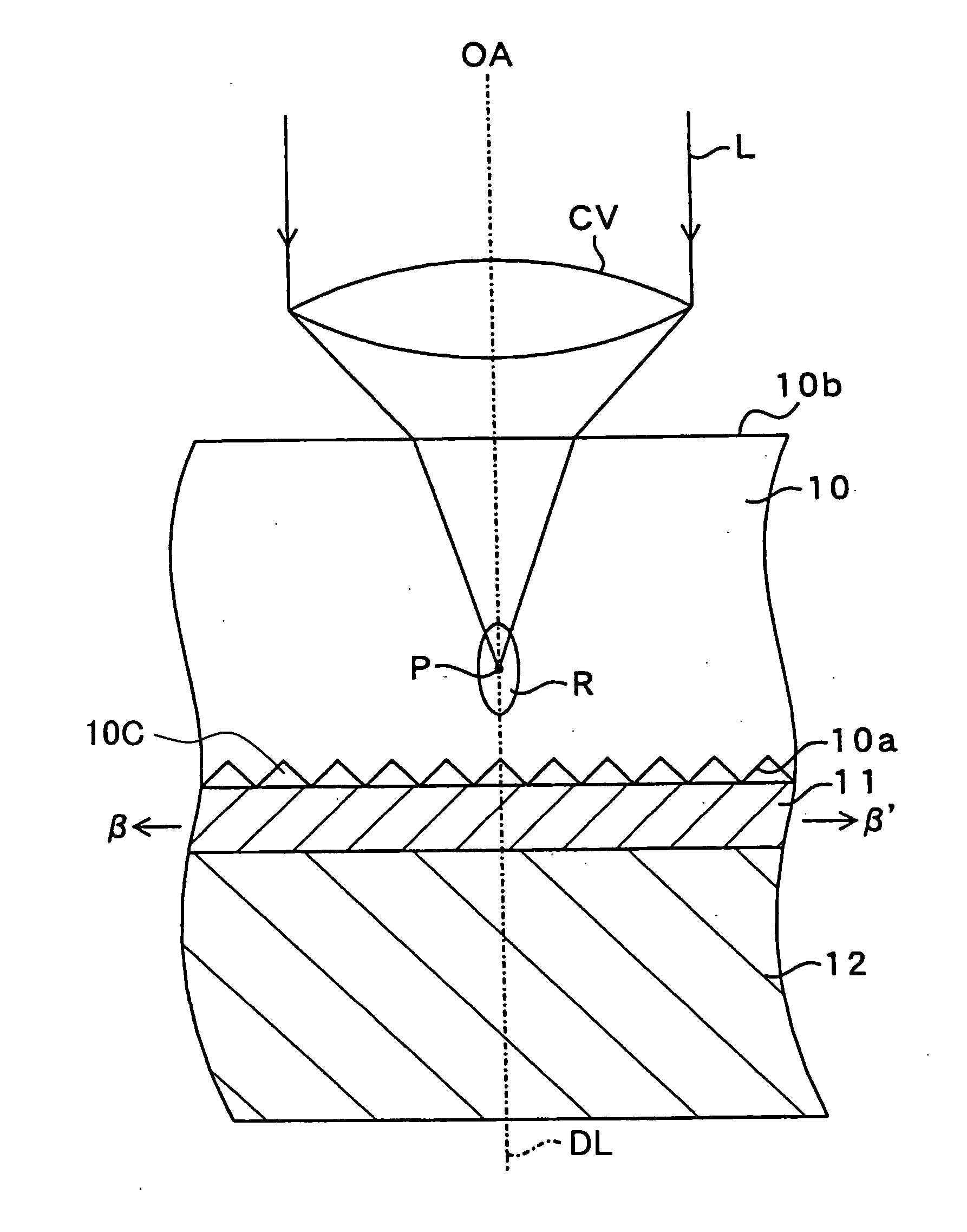

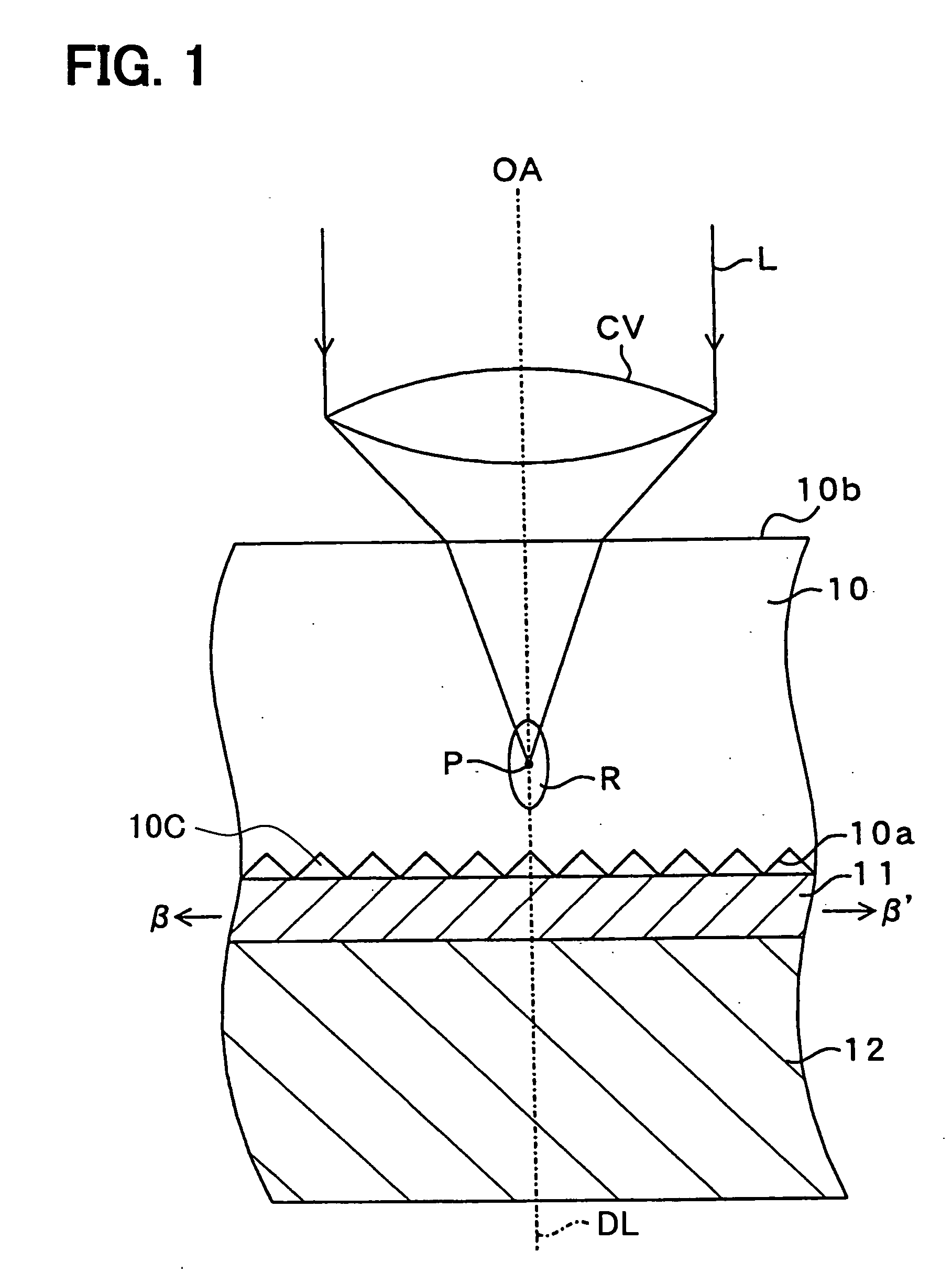

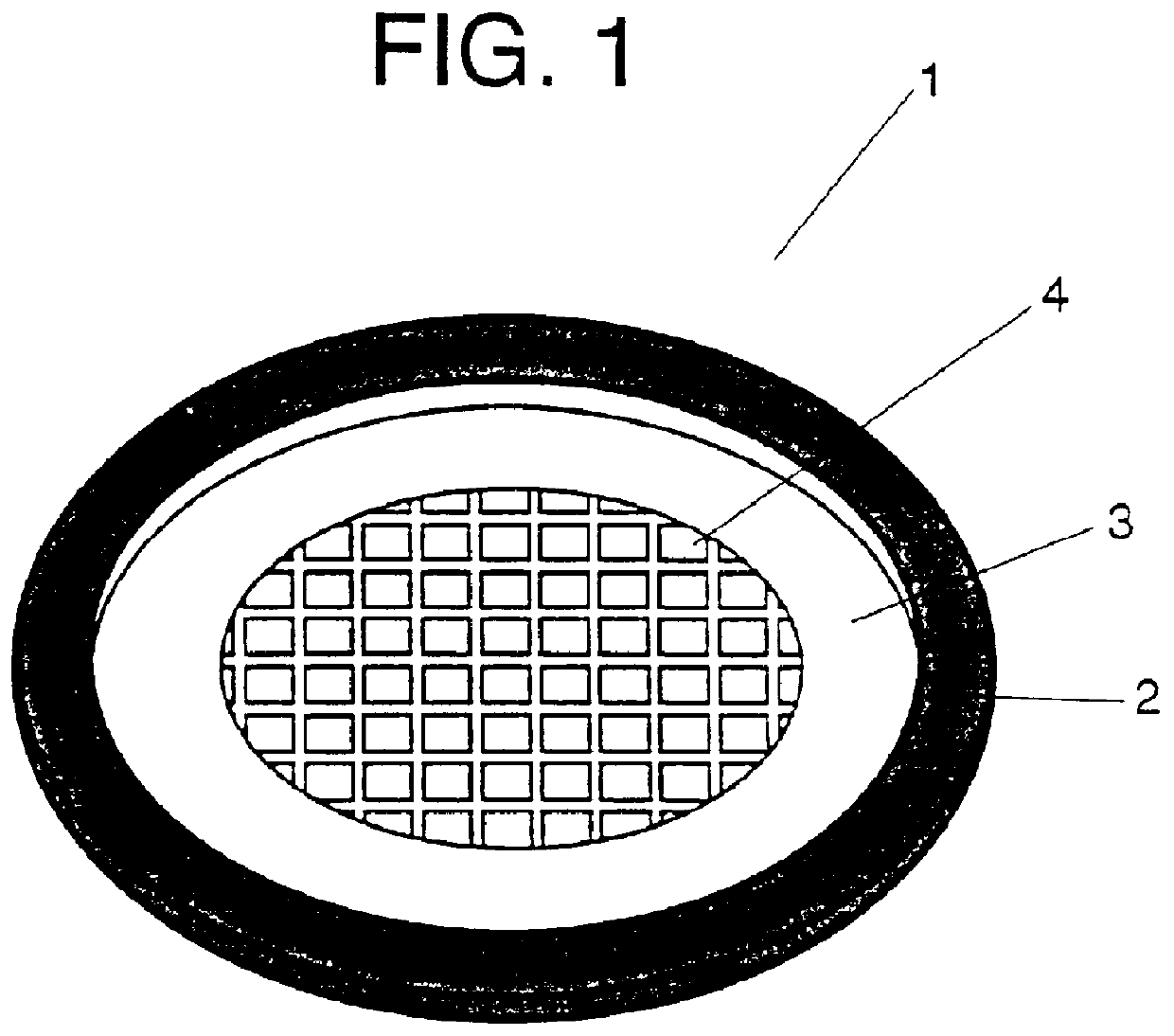

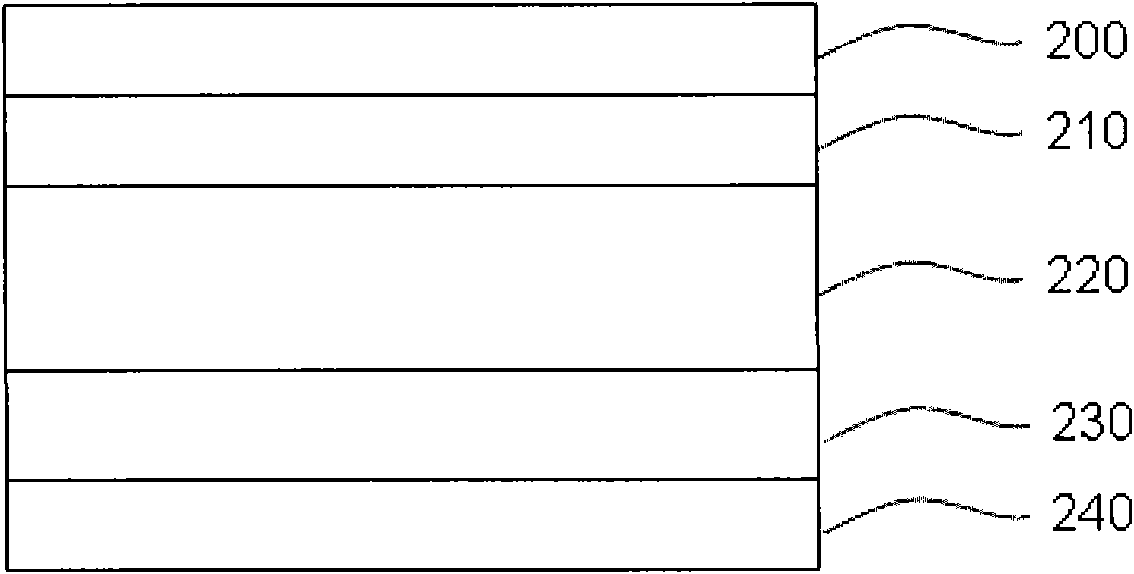

InactiveUS20070111480A1Semiconductor/solid-state device manufacturingFine working devicesLaser lightProtection layer

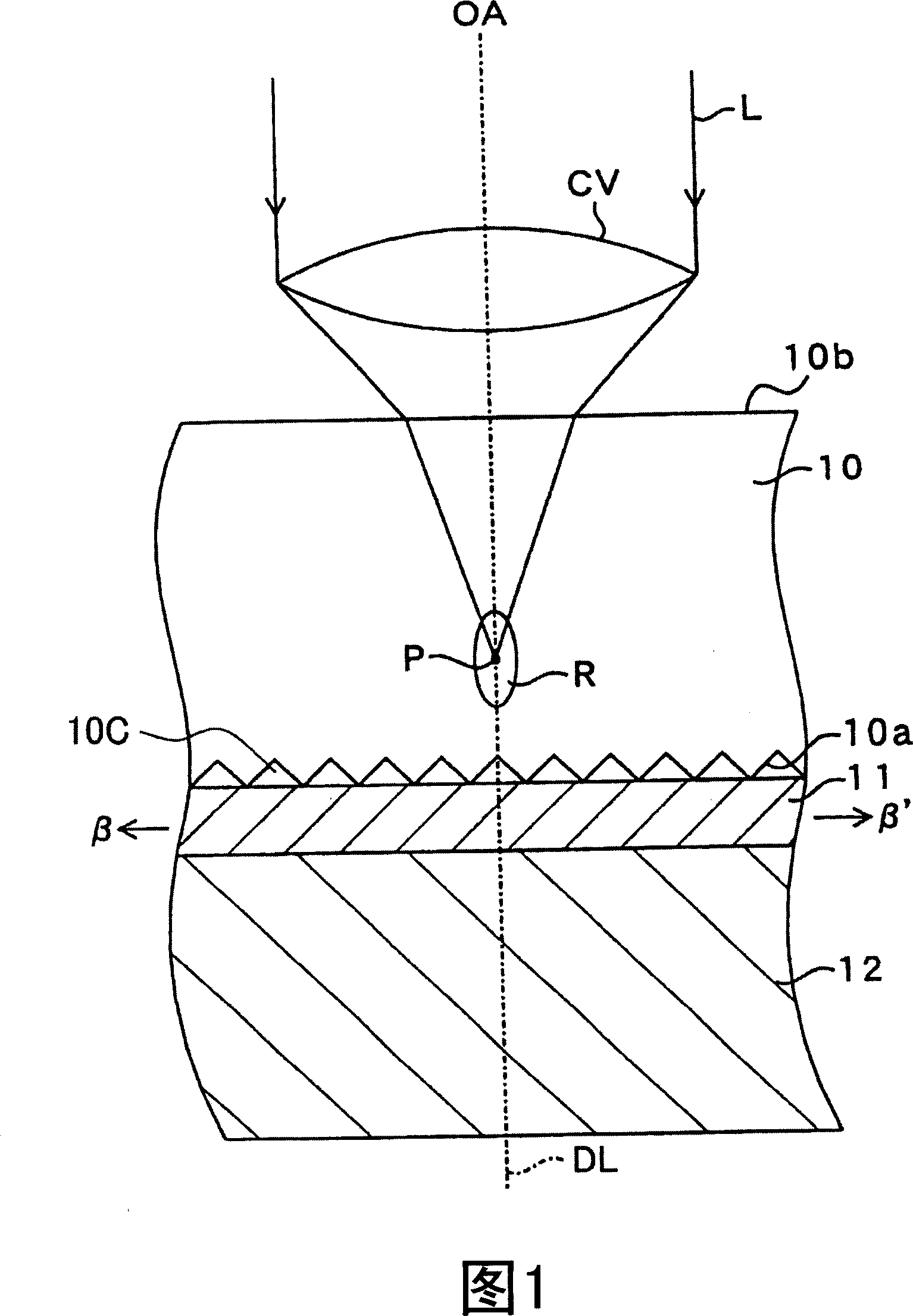

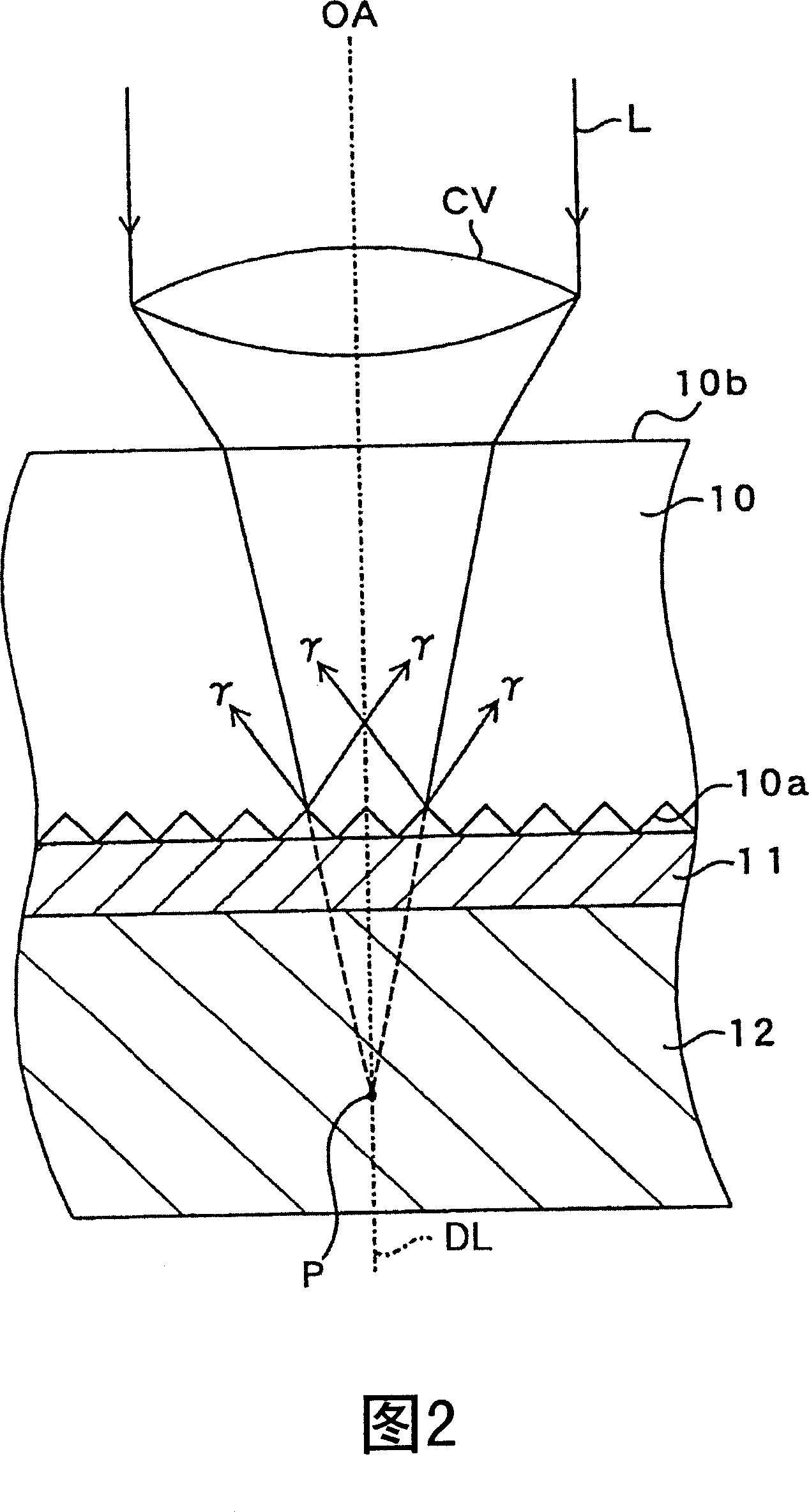

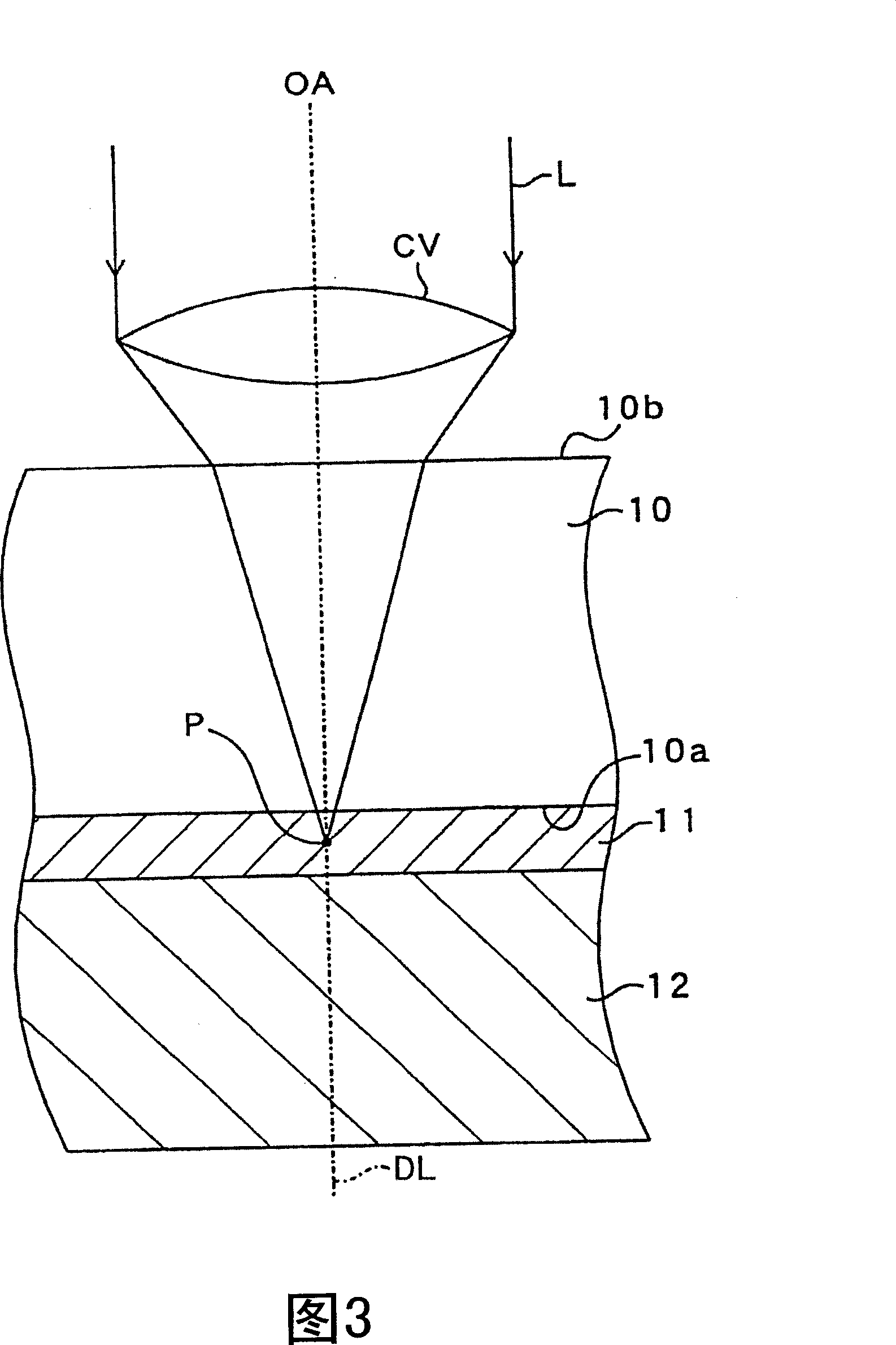

A semiconductor wafer has two faces, one of which is a laser light incident face. A dicing sheet is attached to the other face of the wafer, so that it is stretched to thereby apply tensile stress to a laser-reformed region and cause cutting with the reformed region taken as a starting point for cutting. A protection layer, such as light scattering projections and depressions, a light scattering member or a light reflecting member, is provided between the wafer and the dicing sheet to scatter or reflect the laser light passing through the wafer. Thus, the dicing sheet can be protected from being damaged because the laser light converging point is not formed in the dicing sheet.

Owner:DENSO CORP

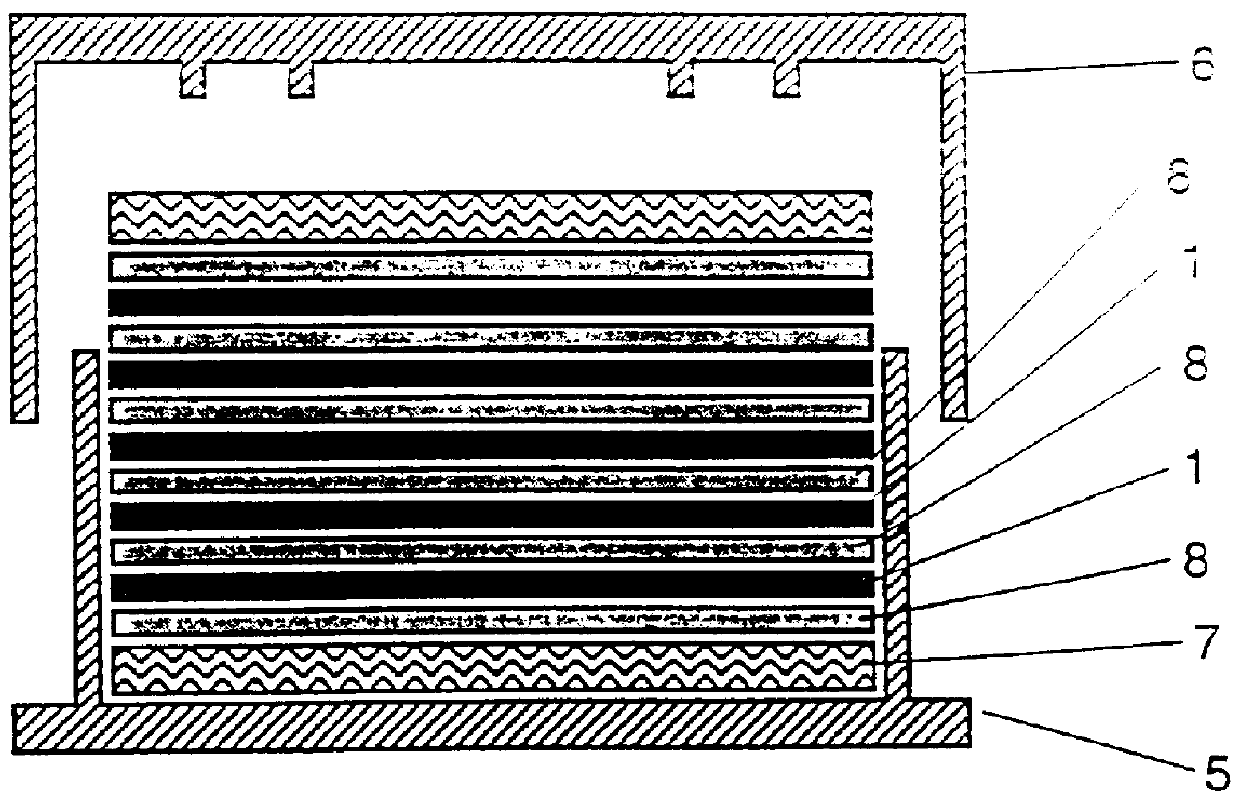

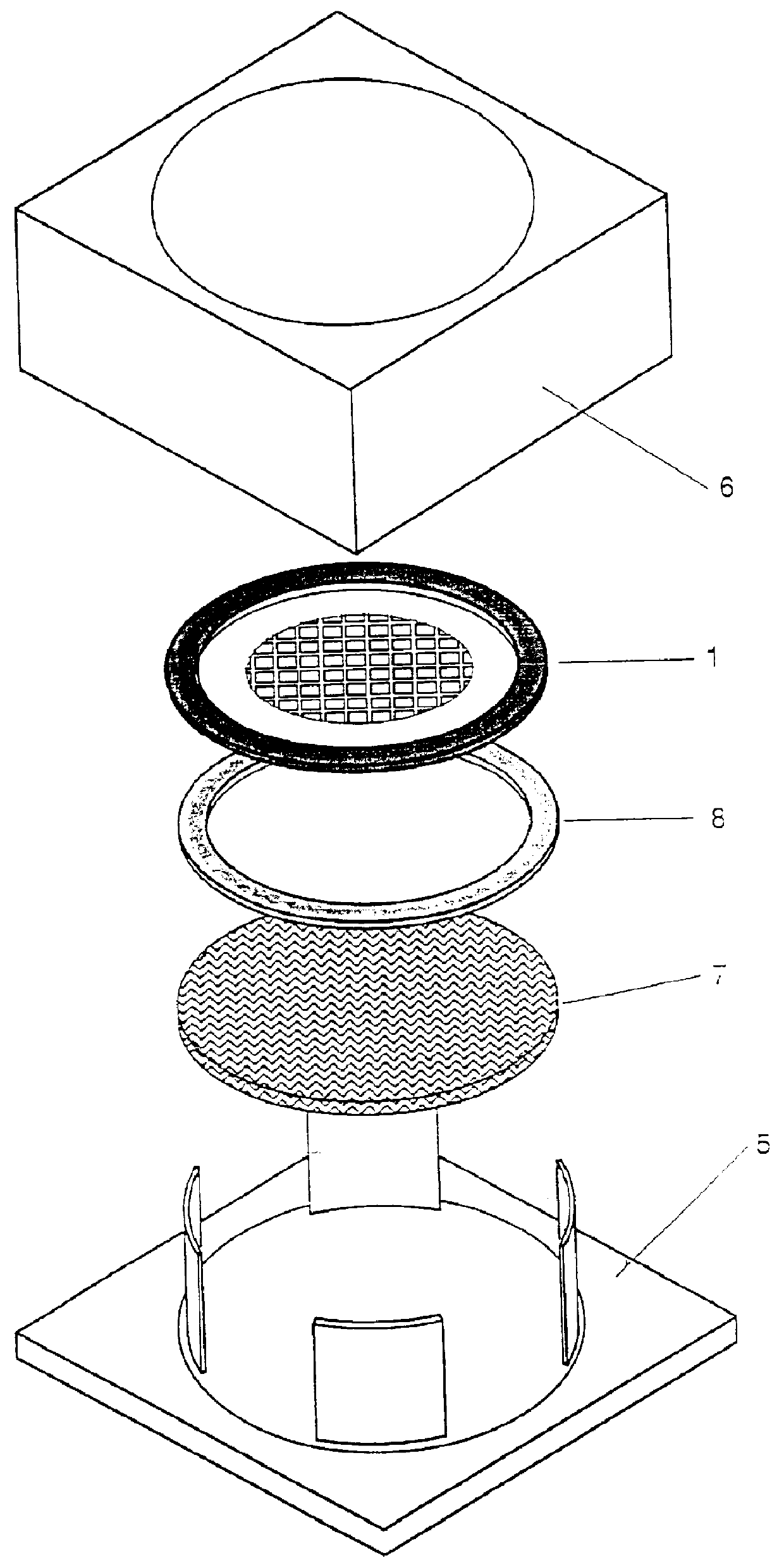

Accommodation container and accommodating method

InactiveUS6119865AContainers for annular articlesSemiconductor/solid-state device manufacturingEngineeringWafer Product

An accommodation container comprises an accommodation container body, a plurality of frames accommodated in the accommodation container body, wherein each frame is composed of a frame body and an adhesive sheet fixed to and disposed inside the frame body, and wherein the plurality frames are disposed so that joining adhesive sheets are spaced at given intervals. With the construction of the accommodation container, it is possible to restrain the adhesive sheets from being bonded to other articles by shock and vibration during the transportation thereof when the plurality of the wafer products each provided with a frame are accommodated in the accommodation container.

Owner:OKI ELECTRIC IND CO LTD

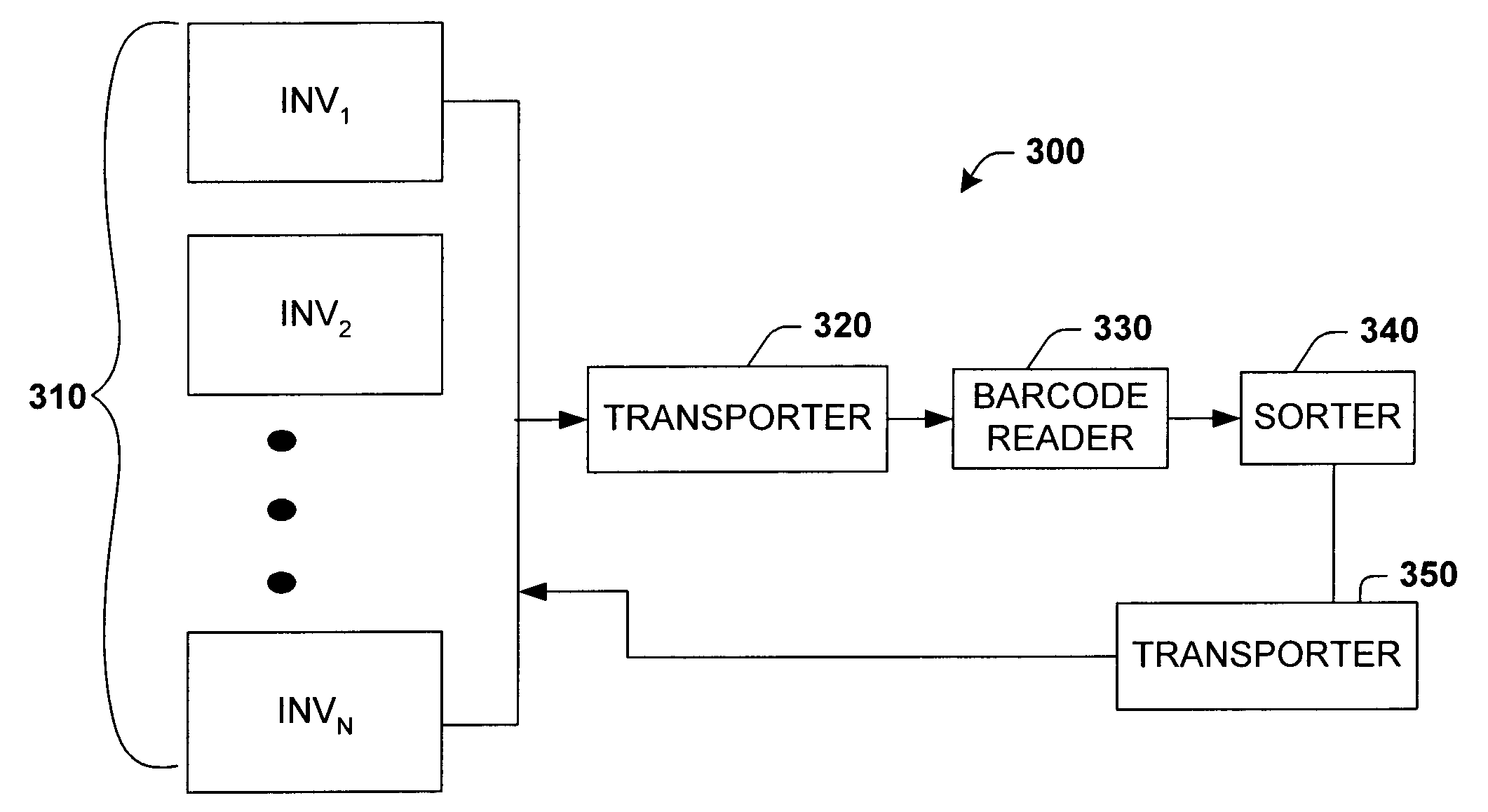

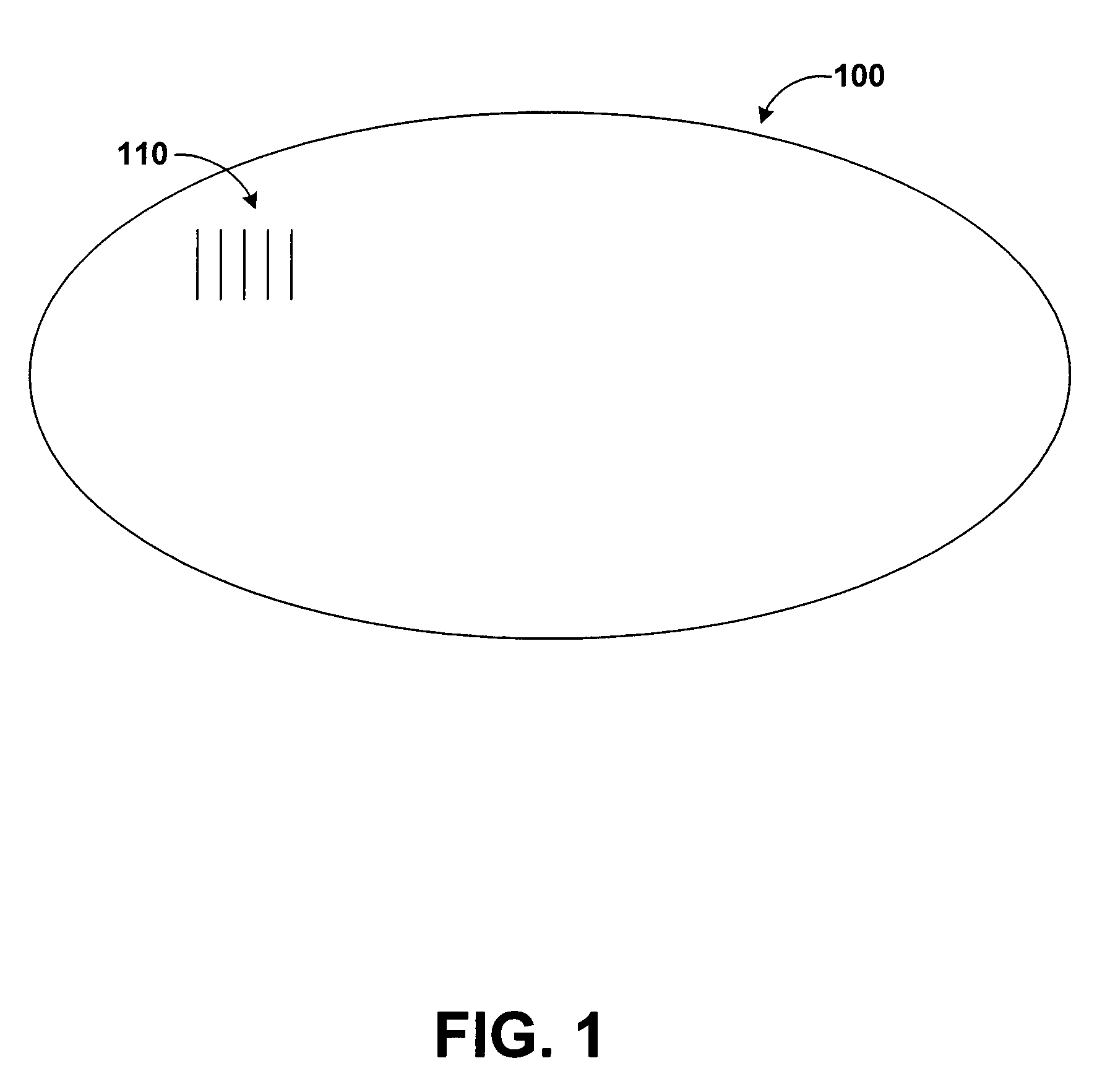

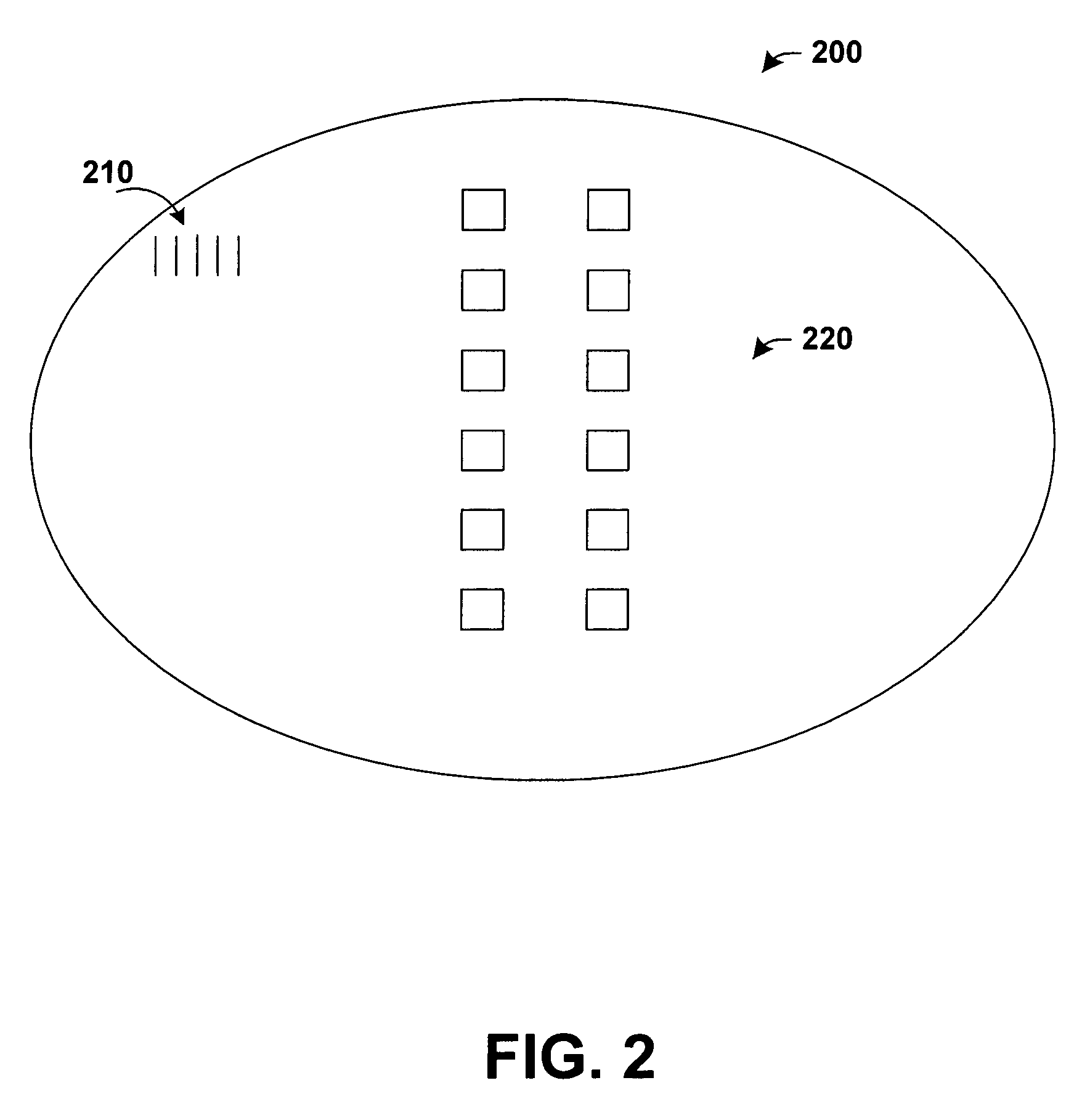

Barcode marking of wafer products for inventory control

InactiveUS7100826B1Improve performanceImprove production efficiencyDigital data processing detailsCharacter and pattern recognitionEngineeringBarcode reader

A system for performing inventory control for wafers, unpackaged integrated circuits and packaged integrated circuits is provided. The system includes barcode readers, sorters and transporters operable to locate and relocate wafers, unpackaged circuits and packaged circuits. The system further includes a feedback system for feeding back information generated by the barcode readers, sorters, transporters and / or manufacturing devices associated with the wafers, unpackaged circuits and packaged circuits. The system further provides for generating Electronic Data Interchange (EDI) data that can be transmitted to wafer suppliers and employed in controlling wafer ordering, purchasing, processing and returning.

Owner:ADVANCED MICRO DEVICES INC

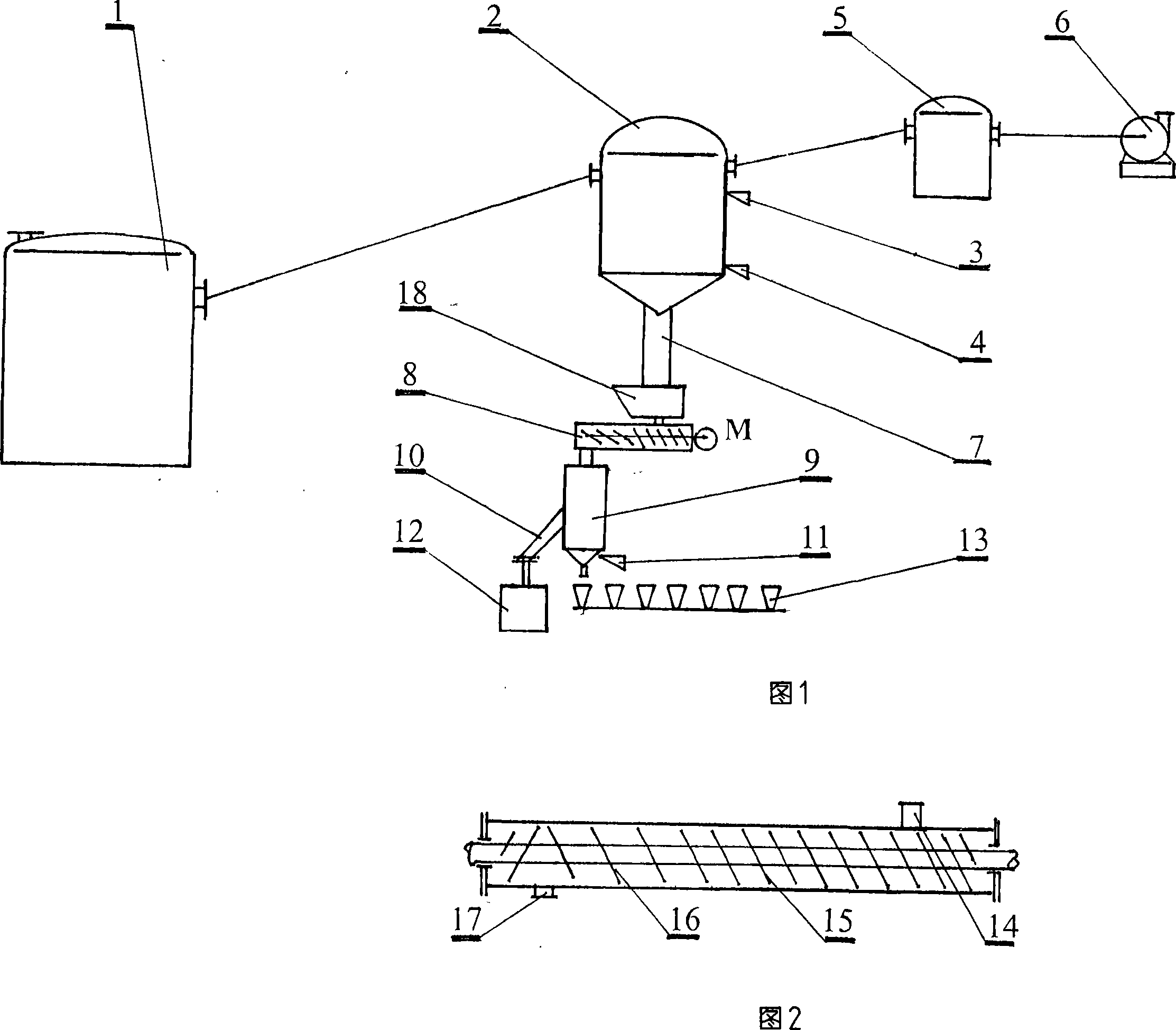

Automatic accurate weighing device for powdery material

InactiveCN101105409ANo leakageNo pollution in the processWeighing apparatus with automatic feed/dischargeMotor speedGrating

The invention discloses a powdery material accurate weighing device, which comprises a raw material tank and a weighing cup. The invention is characterized in that the feeding process is operated under vacuum, a high-level switch and a low-level switch are disposed above a vacuum intake tank, an auger conveying mechanism is disposed below the vacuum intake tank, the spiral pitch has two classes, the motor speed has two classes, a optical fiber grating pressure sensor is disposed below a weighing bunker, an automatic reverse turning bed is disposed in the weighing bunker, the signal from a material level switch and the optical fiber grating pressure sensor is transmitted to PLC, and the PLC outputs control signal to a motor of a vacuum pump, vacuum air passages and material control valves. The invention remarkably improves the weighing accuracy from above plus or minus 10 g error of the existing automatic weighing to within plus or minus 1 g error, even lower. It has the advantages of whole sealing operation under vacuum condition, no dust pollution, improved operating environment, accurate weighing, and good consistency. The invention is helpful for further improving the production quality of friction wafer product; and has high spreading and application values, and good market prospect.

Owner:李红

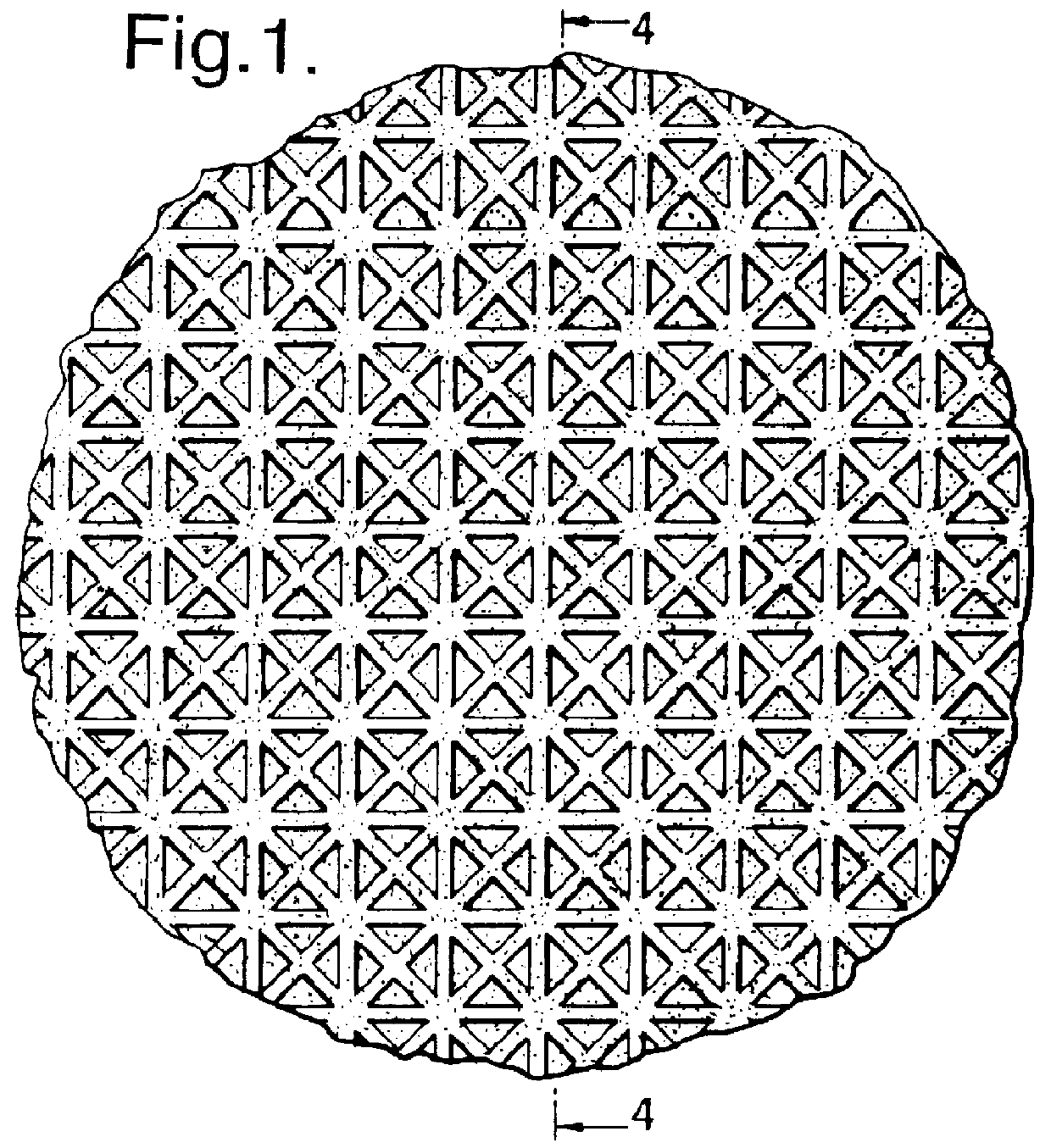

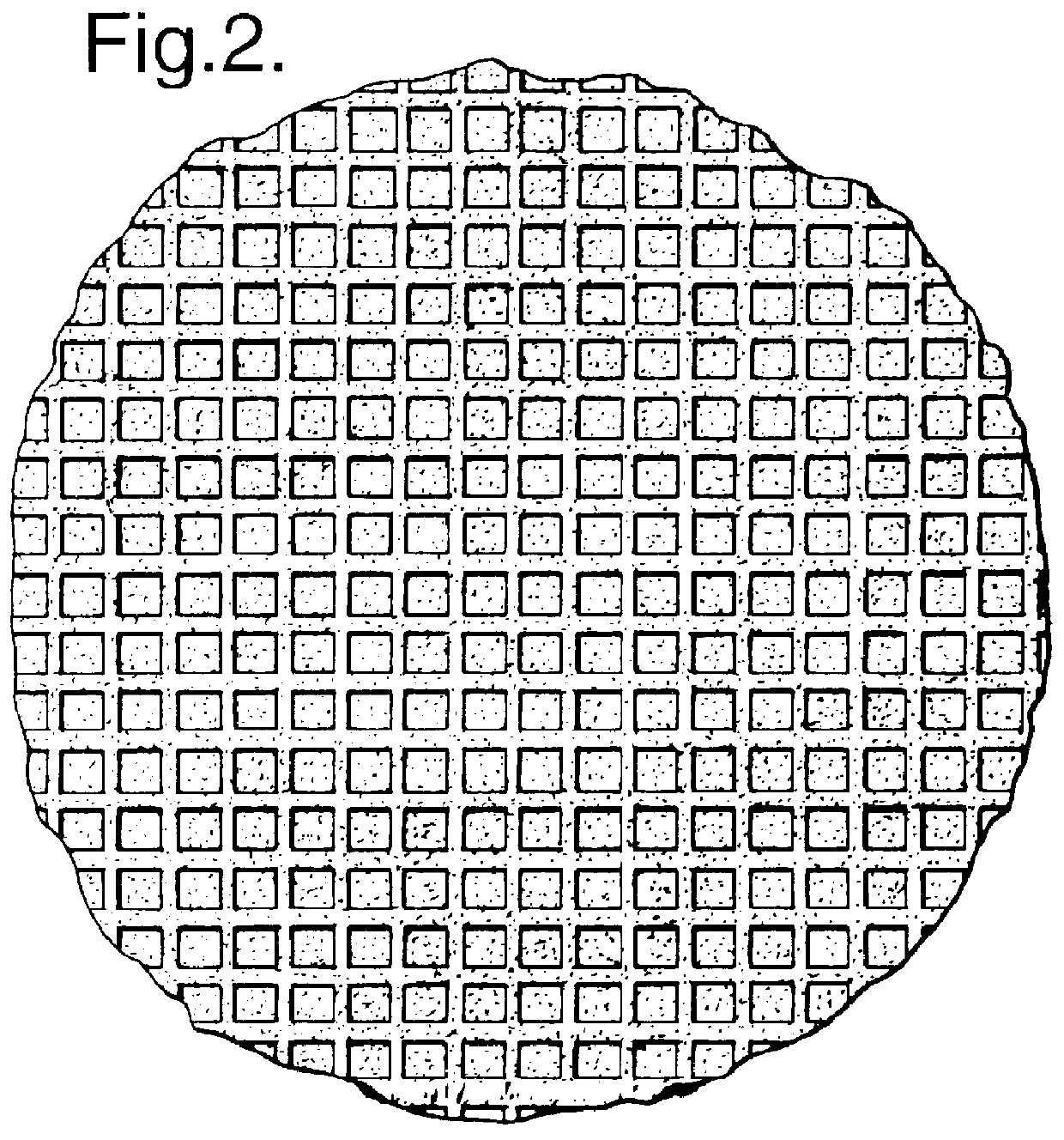

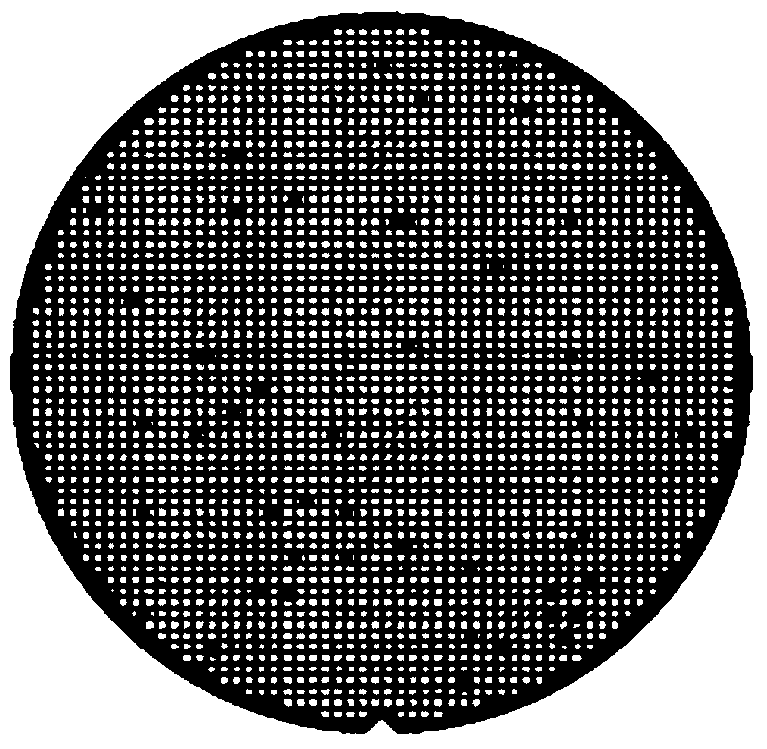

Wafer product and process of manufacture

A crisp, approximately circular wafer product is provided whereby the two surfaces of the wafer each have a pattern formed by ridges, the first surface having a pattern comprising at least two grid patterns superimposed on each other, one grid being at an angle of approximately 45 DEG to the other, the second surface having a single grid pattern, the pattern being at 45 DEG to the lower grid on the first surface.

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

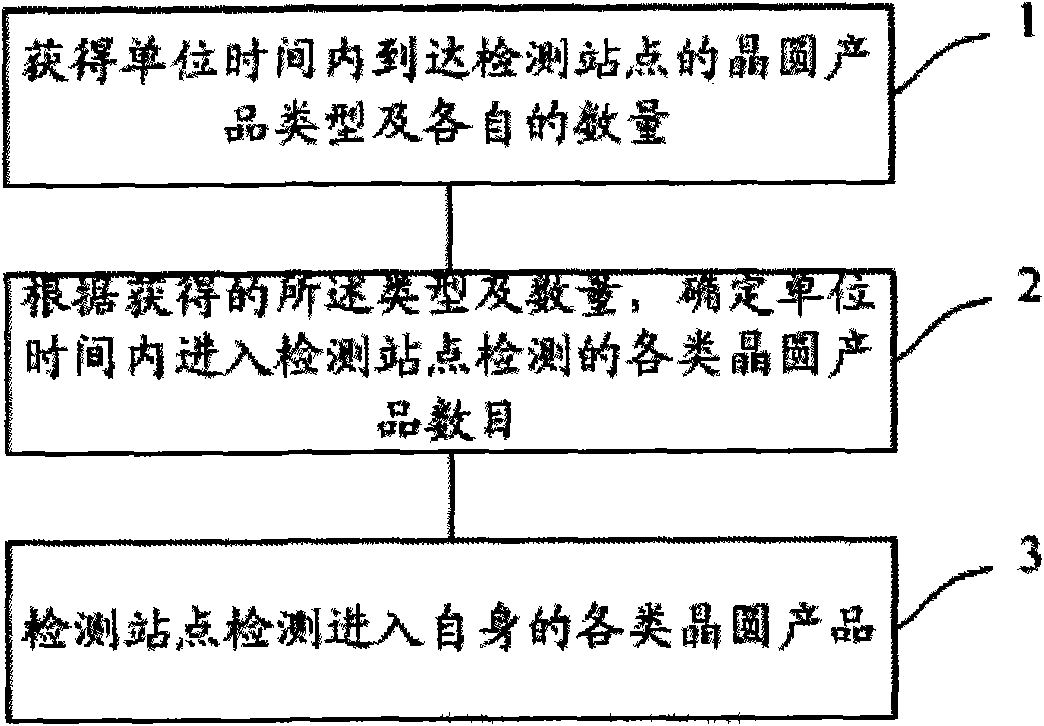

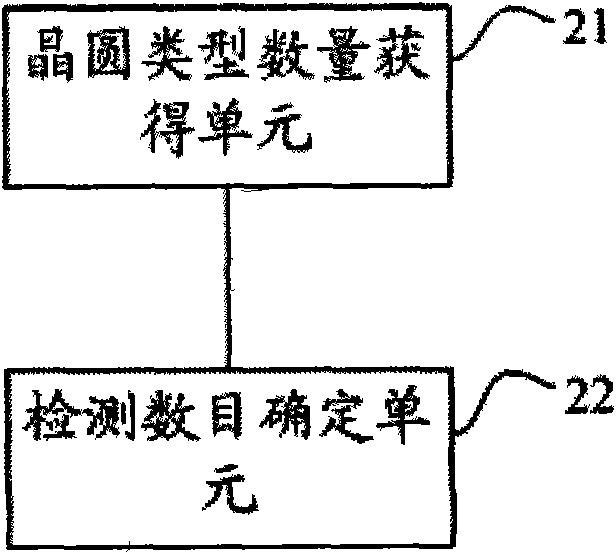

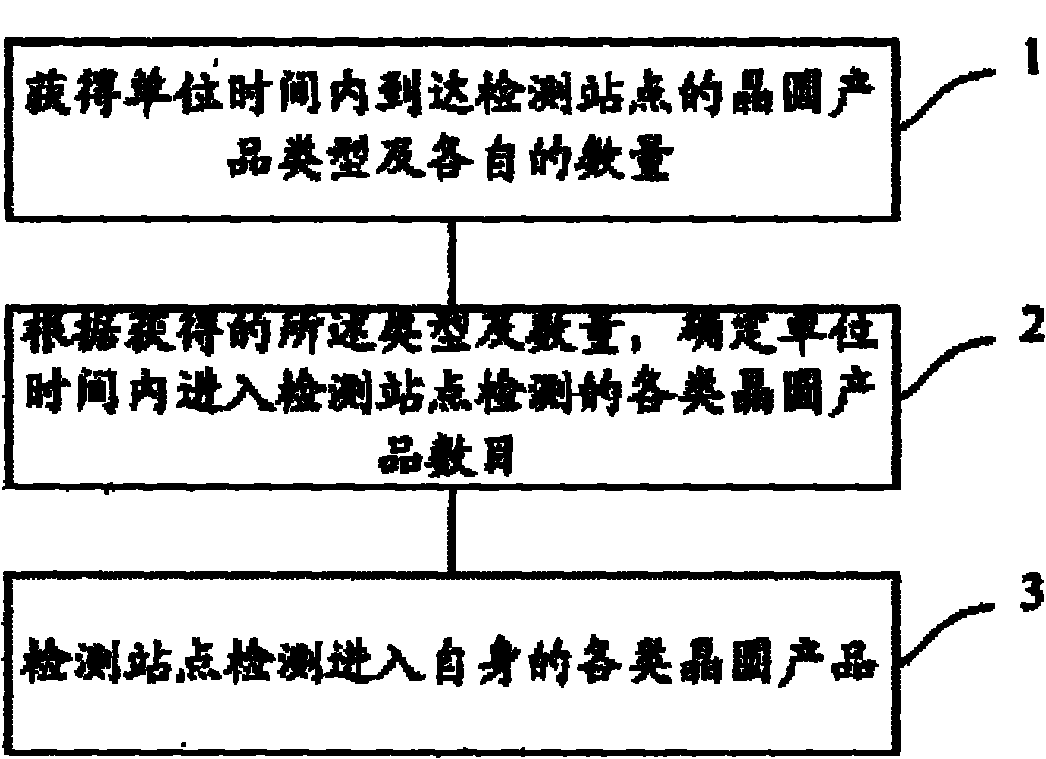

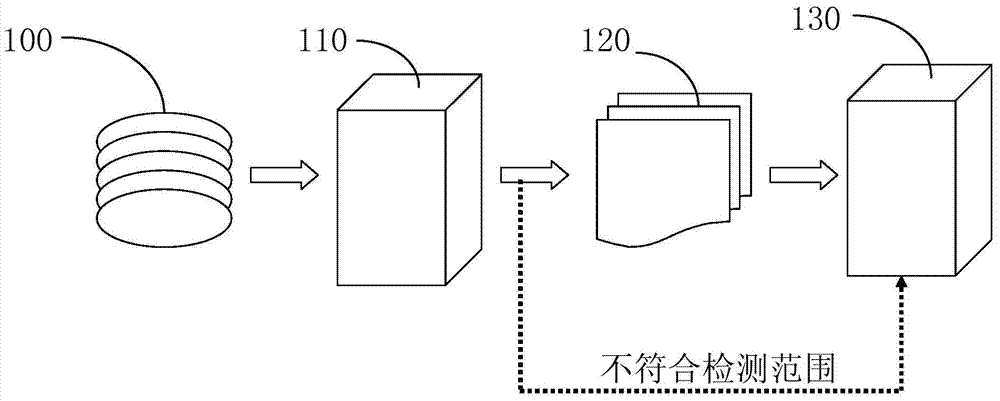

On-line detection method and system for wafer

ActiveCN101872714AImprove rationalityPrevent production delaysSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringWafer Product

The invention provides an on-line detection method and an on-line detection system for a wafer, which avoid the problems that the conventional detection scheme possibly delays product time, reduces the detection effect and cannot make full use of the detection capability of a detection site. The method comprises the following steps of: acquiring types and numbers of wafer products reaching the detection site in unit time; determining the number of various wafer products detected in the detection site in unit time according to the acquired types and the acquired numbers; and detecting the various wafer products entering the detection site by the detection site.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Wafer product and processing method therefor

InactiveCN1967815ASemiconductor/solid-state device detailsSolid-state devicesLight reflexLaser light

A semiconductor wafer has two faces, one of which is a laser light incident face. A dicing sheet is attached to the other face of the wafer, so that it is stretched to thereby apply tensile stress to a laser-reformed region and cause cutting with the reformed region taken as a starting point for cutting. A protection layer, such as light scattering projections and depressions, a light scattering member or a light reflecting member, is provided between the wafer and the dicing sheet to scatter or reflect the laser light passing through the wafer. Thus, the dicing sheet can be protected from being damaged because the laser light converging point is not formed in the dicing sheet.

Owner:DENSO CORP

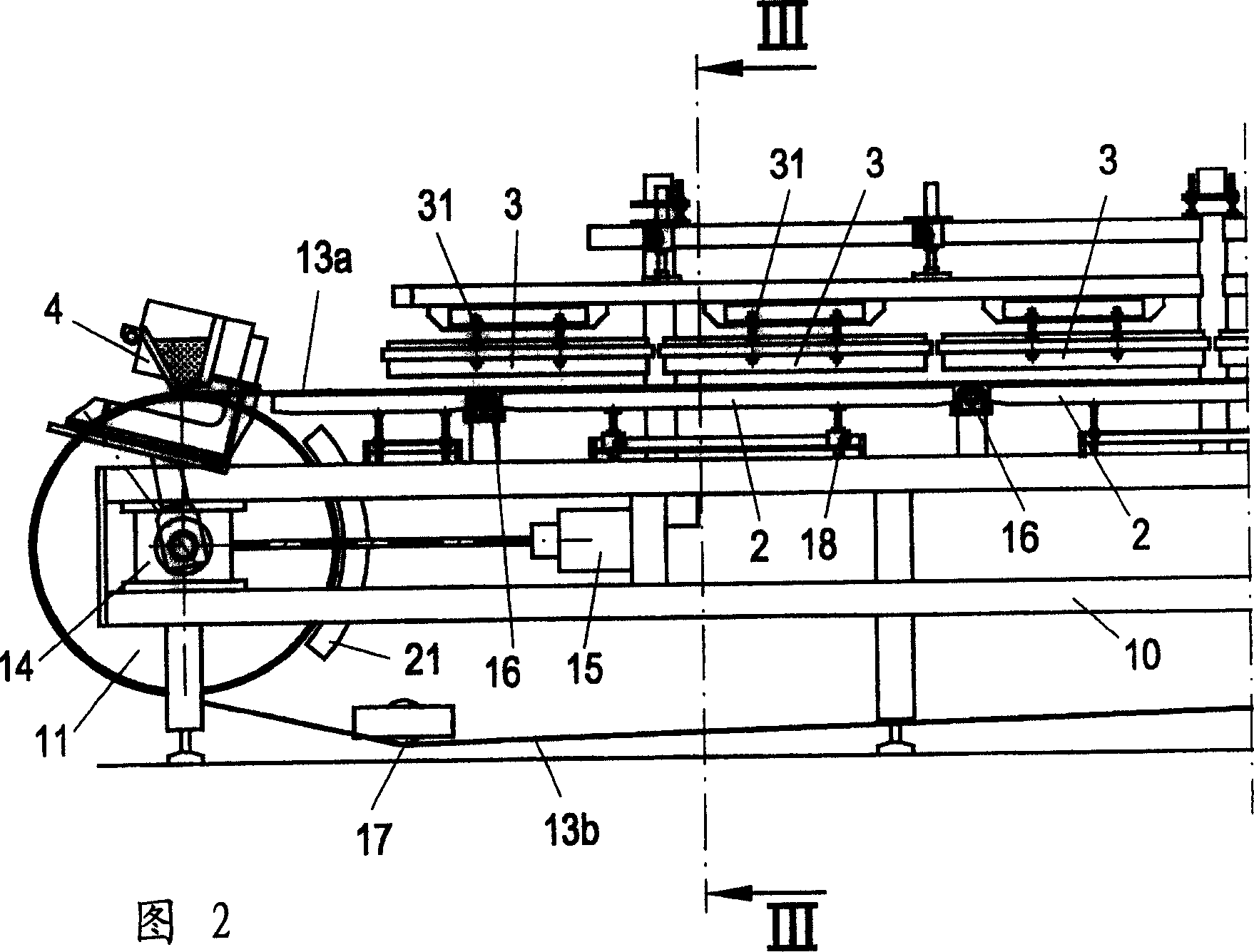

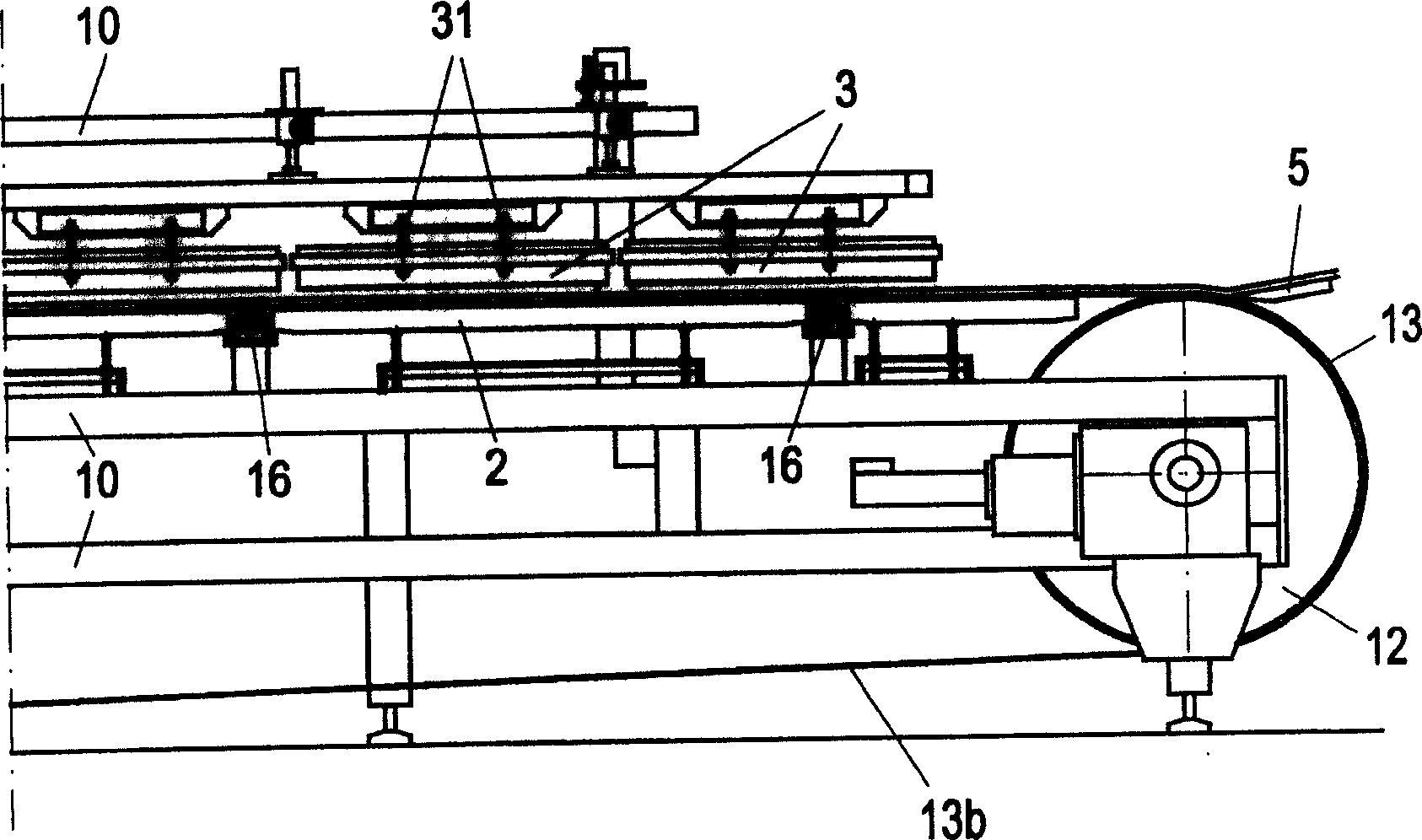

Apparatus for the heat treatment of foodstuffs and feedstuffs, in particular for the production of bakery products

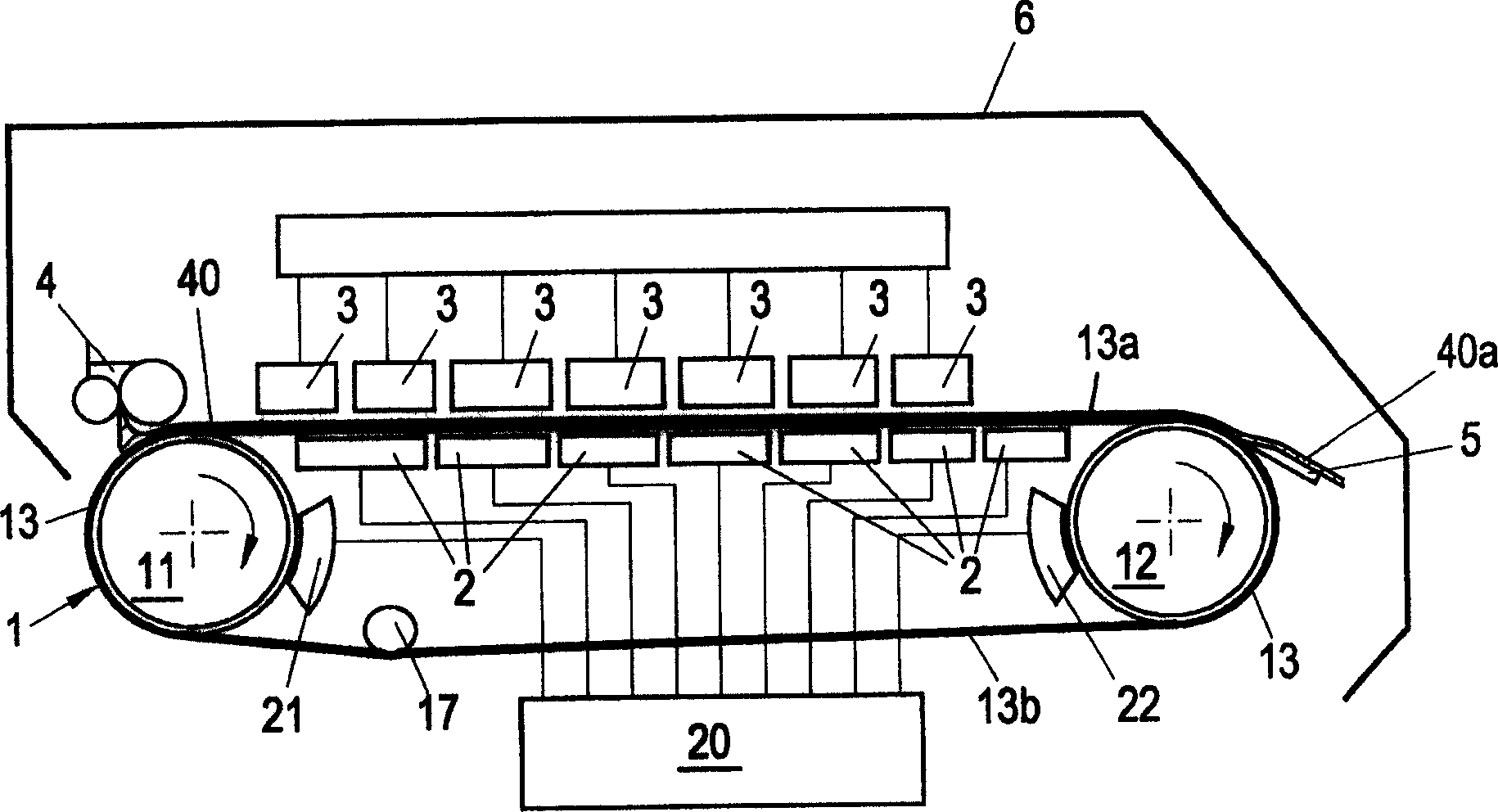

An apparatus for the heat treatment of foodstuffs and feedstuffs, in particular for the production of bakery products, such as wafer products, has a continuously moving conveying device, a device for depositing the product on the conveying device, and a device for removing the heat-treated product from the conveying device. The conveying device is formed by an endless conveyor belt that can be circulated between two return rollers and which is formed by a ferromagnetic metal strip, in particular by a steel strip. A heating device is provided on one side of the conveyor belt and includes a group of induction heaters.

Owner:MASTERFOODS AUSTRIA

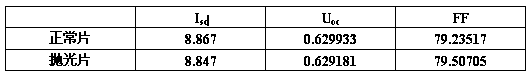

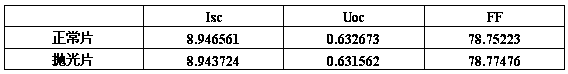

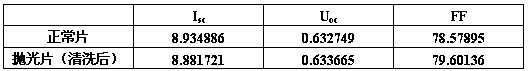

Method for cleaning solar cell silicon wafer after polishing

InactiveCN103441187AIncrease the open circuit voltageGood effectAfter-treatment detailsFinal product manufacturePotassium hydroxideSolar cell

The invention provides a method for cleaning a solar cell silicon wafer after polishing. The method includes the following steps that (1) the solar cell silicon wafer after polishing is subjected to acid cleaning, and (2) the solar cell silicon wafer after acid cleaning is subjected to mixed acid cleaning, alkali cleaning and acid cleaning. In the step (2), mixed acid of hydrofluoric acid and nitric acid is used for the mixed acid cleaning, sodium hydroxide solutions or potassium hydroxide solutions are used for the alkali cleaning, and mixed acid of hydrofluoric acid and hydrochloric acid is used for the acid cleaning. The method is simple and convenient to operate, capable of efficiently eliminating various pollutions, generated in the polishing process, of the solar cell silicon wafer, and capable of obviously improving open-circuit voltages of silicon wafer products, and good technological support is provided for mass production of back polishing cells and back passivating cells.

Owner:昊诚光电(太仓)有限公司

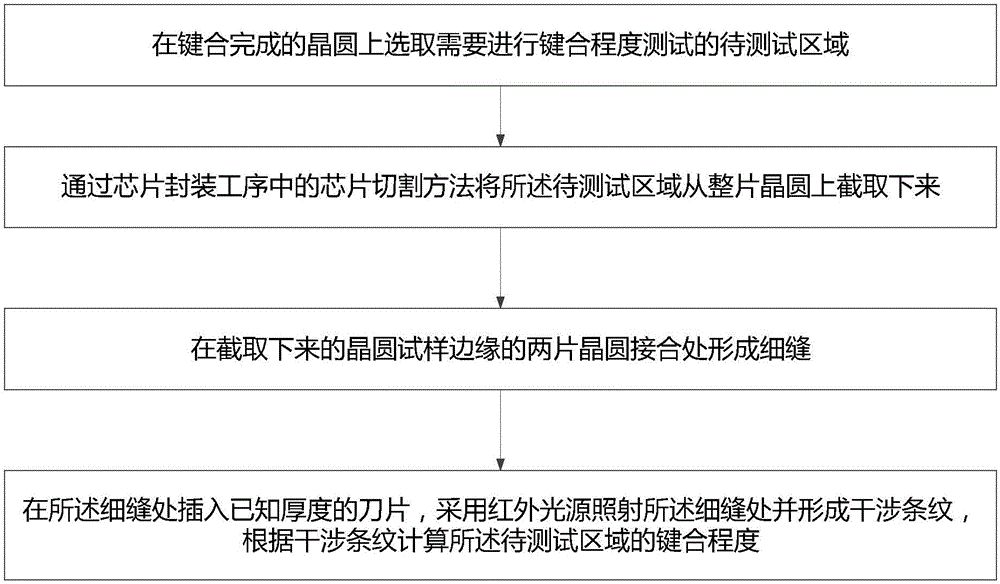

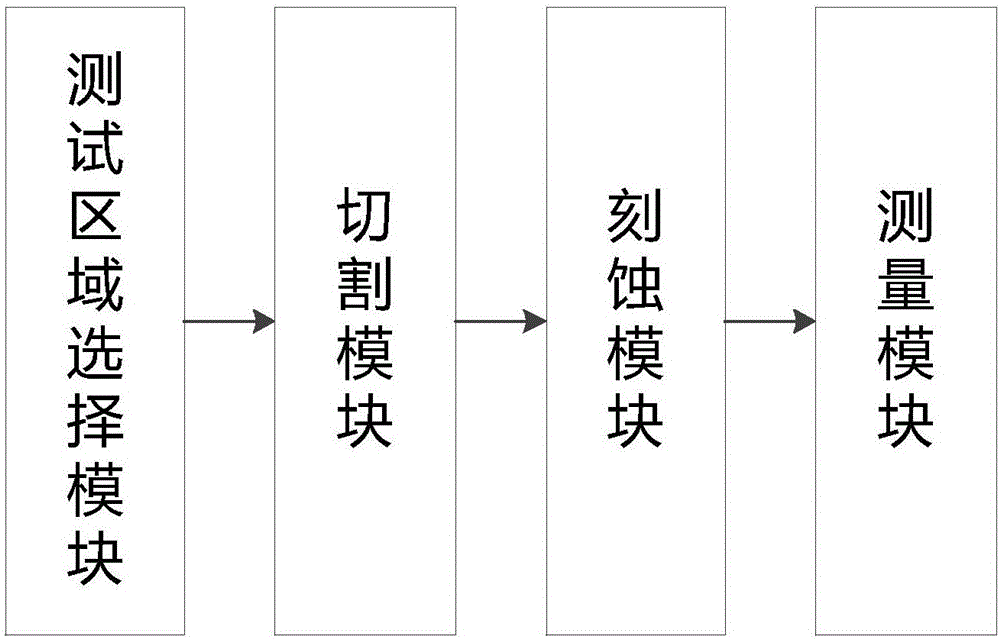

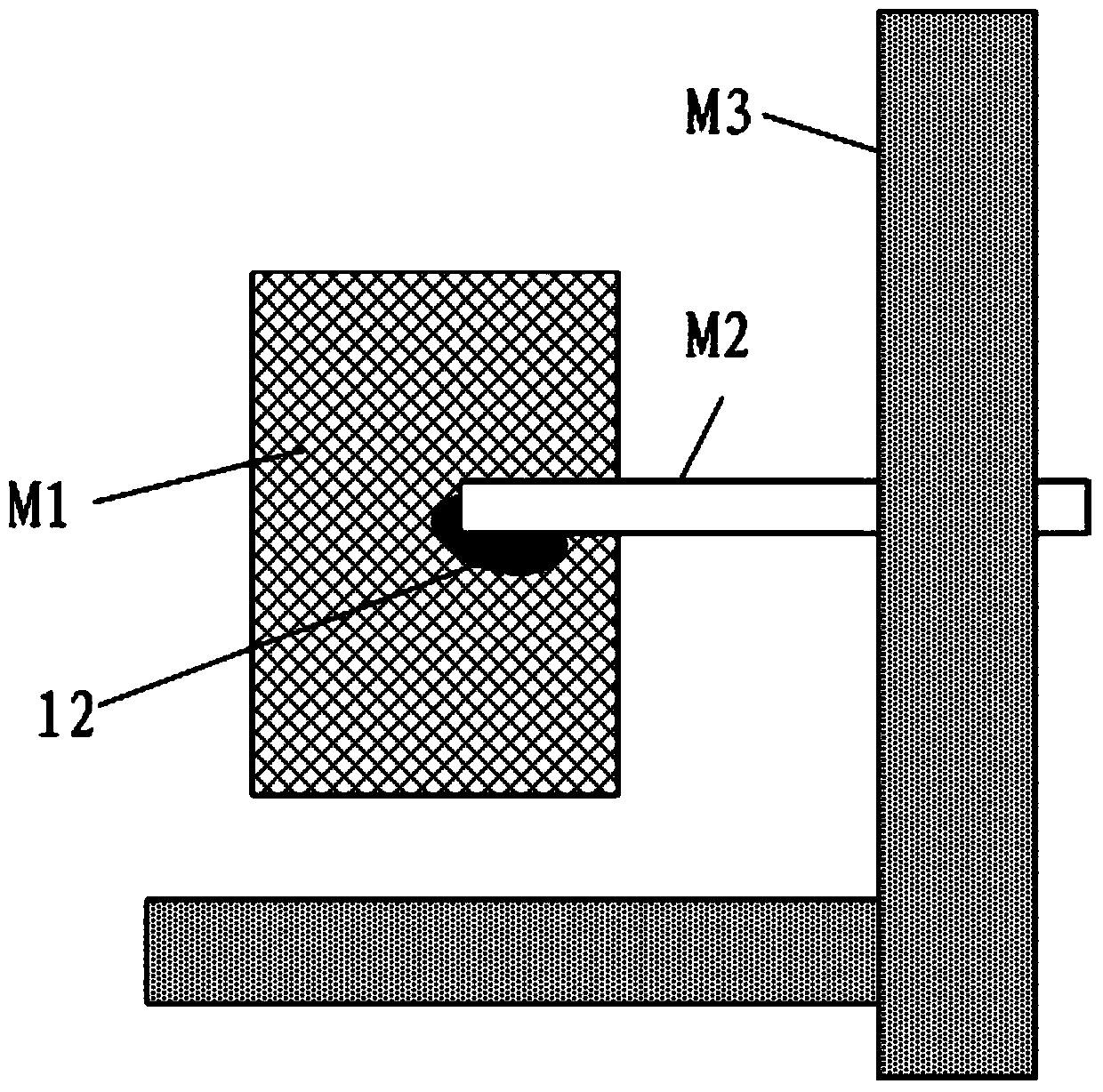

Method and system for testing bonding degree at any position of wafer product

ActiveCN106206350ADoes not reduce the efficiency of bond testingInterception implementationSemiconductor/solid-state device testing/measurementThree-dimensional integrated circuitWafer Product

The invention particularly relates to a method and a system for testing the bonding degree at any position of a wafer product. The method comprises the following steps: selecting an area to be tested on a wafer after bonding; cutting out the area to be tested from the whole piece of wafer through a chip cutting method; forming a fine slit at the joint of two pieces of wafers on the edge of the cut wafer sample; inserting a blade at the fine slit, using an infrared source to irradiate at the position of the fine slit and forming interference fringes, and calculating the bonding degree of the area to be tested according to the interference fringes. The method and the system for testing the bonding degree at any position of the wafer provided by the invention can be commonly applied to three-dimensional chip products, the area to be tested of the wafer is cut in virtue of a chip cutting technology, so that the bonding degree at any position of the wafer is tested, and the restriction that the bonding degree at the pole edge position of the wafer can be tested only in a traditional method is overcome; and moreover, the introduction of new working procedures is not needed, so that the efficiency of testing the bonding degree of the wafer cannot be reduced.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

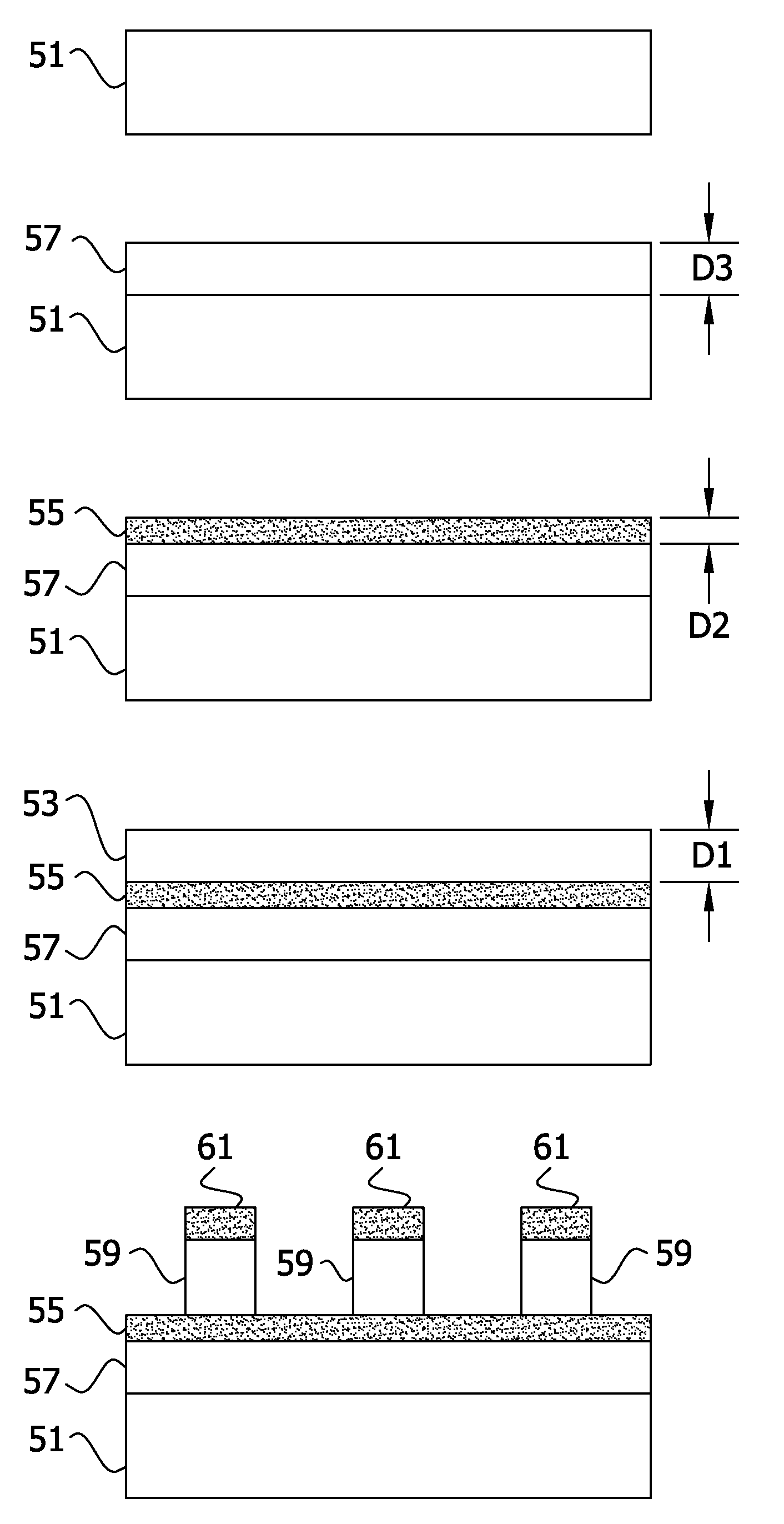

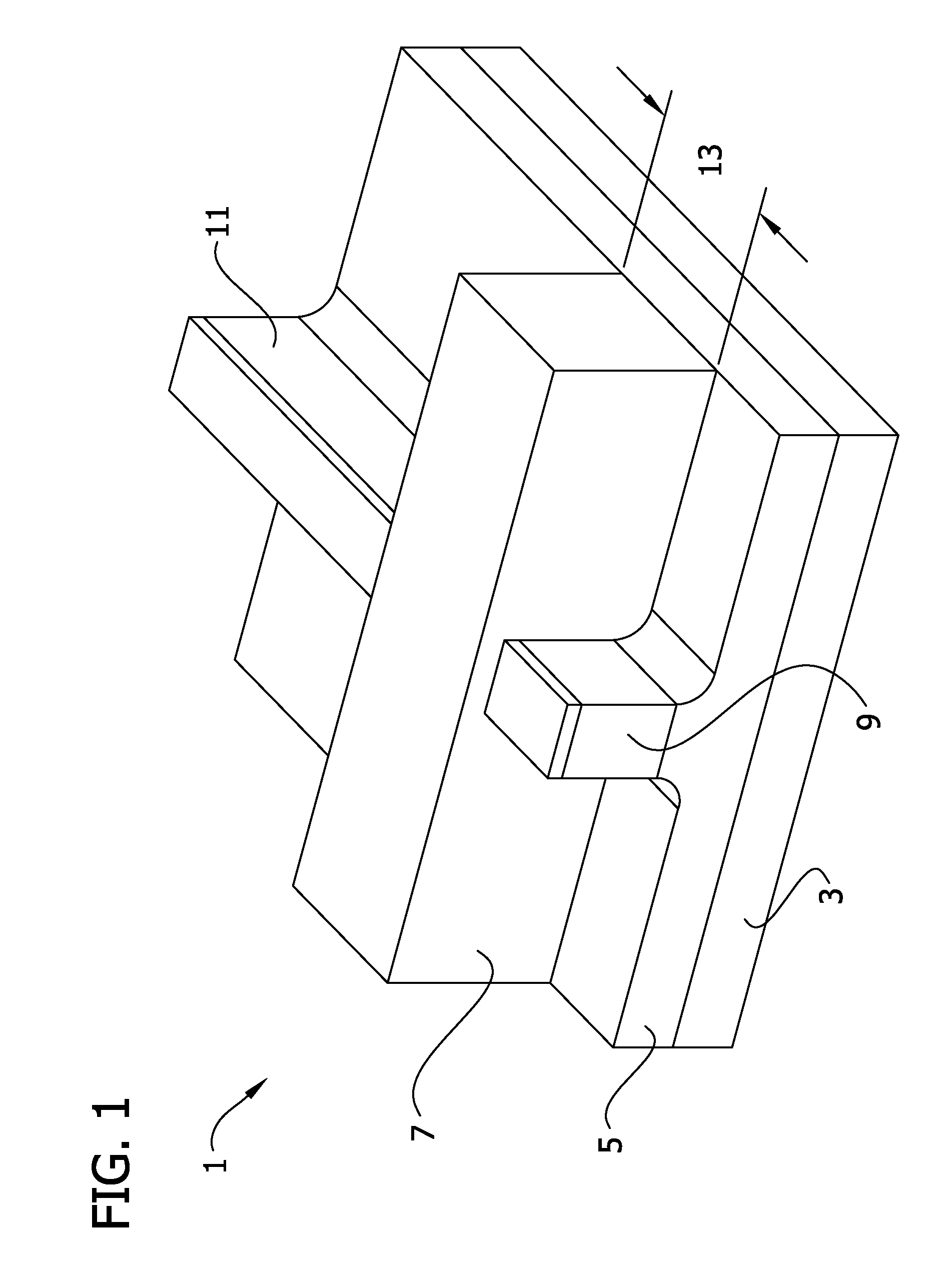

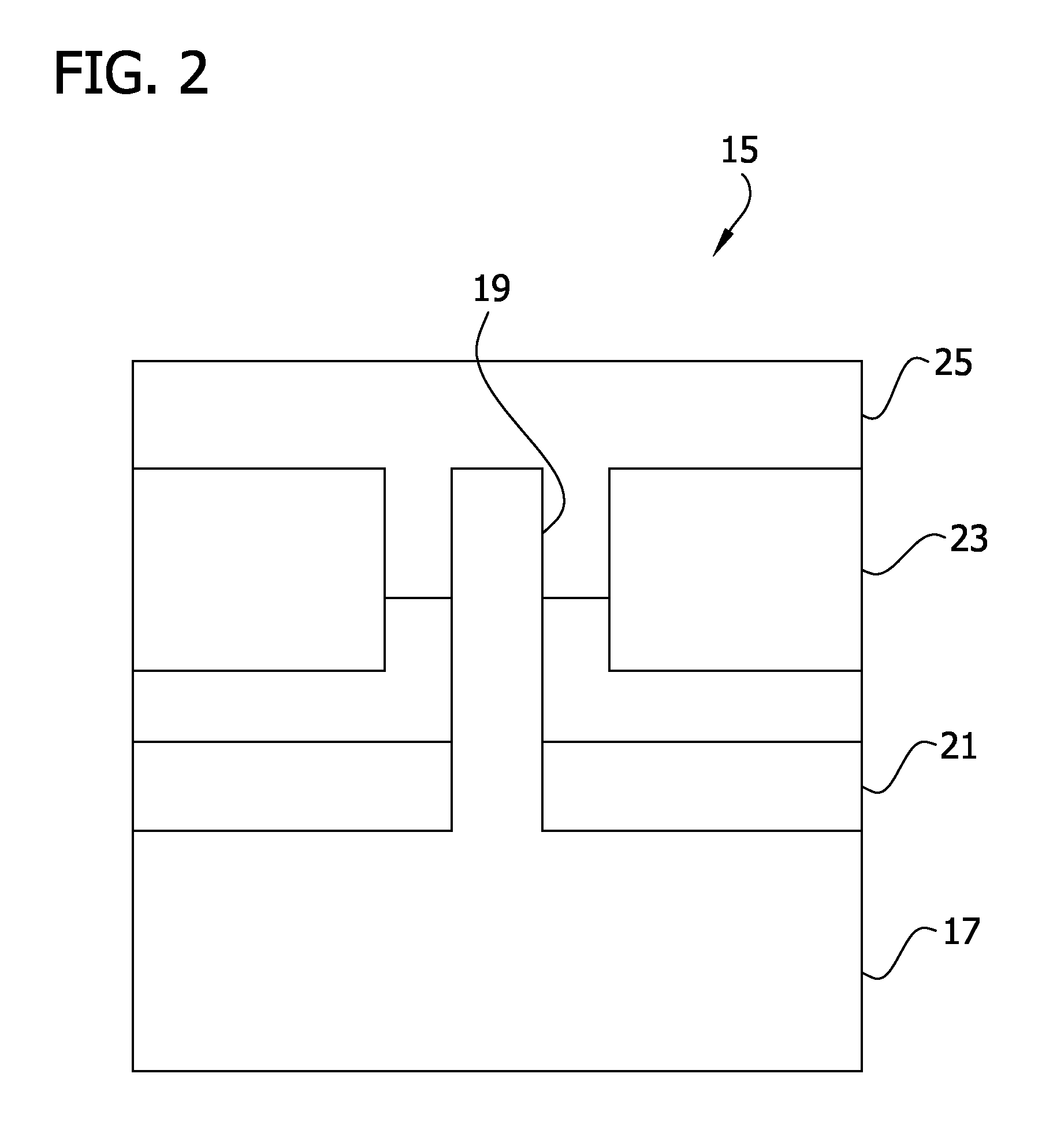

Bulk silicon wafer product useful in the manufacture of three dimensional multigate mosfets

ActiveUS20110163313A1Avoid damaging effectsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMOSFETSemiconductor structure

A method for preparing a semiconductor structure for use in the manufacture of three dimensional transistors, the structure comprising a silicon substrate and an epitaxial layer, the epitaxial layer comprising an endpoint detection epitaxial region comprising an endpoint detection impurity selected from the group consisting of carbon, germanium, or a combination.

Owner:GLOBALWAFERS CO LTD

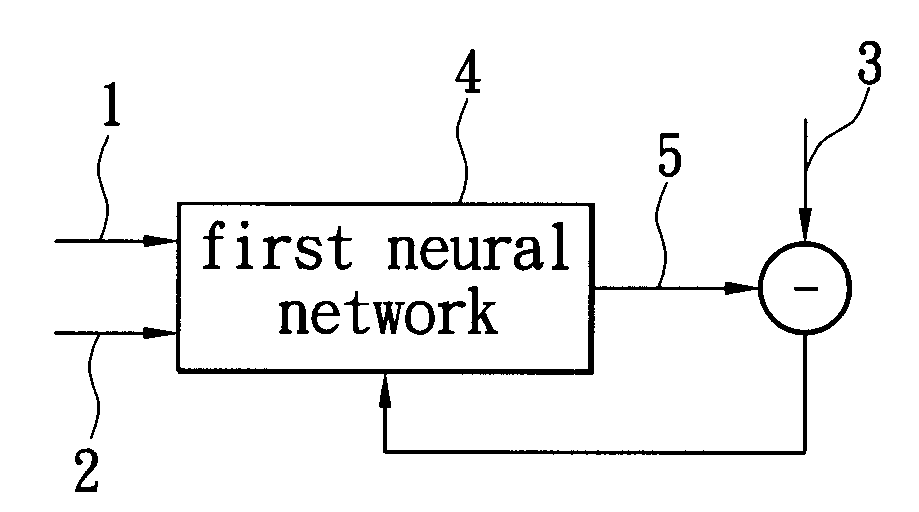

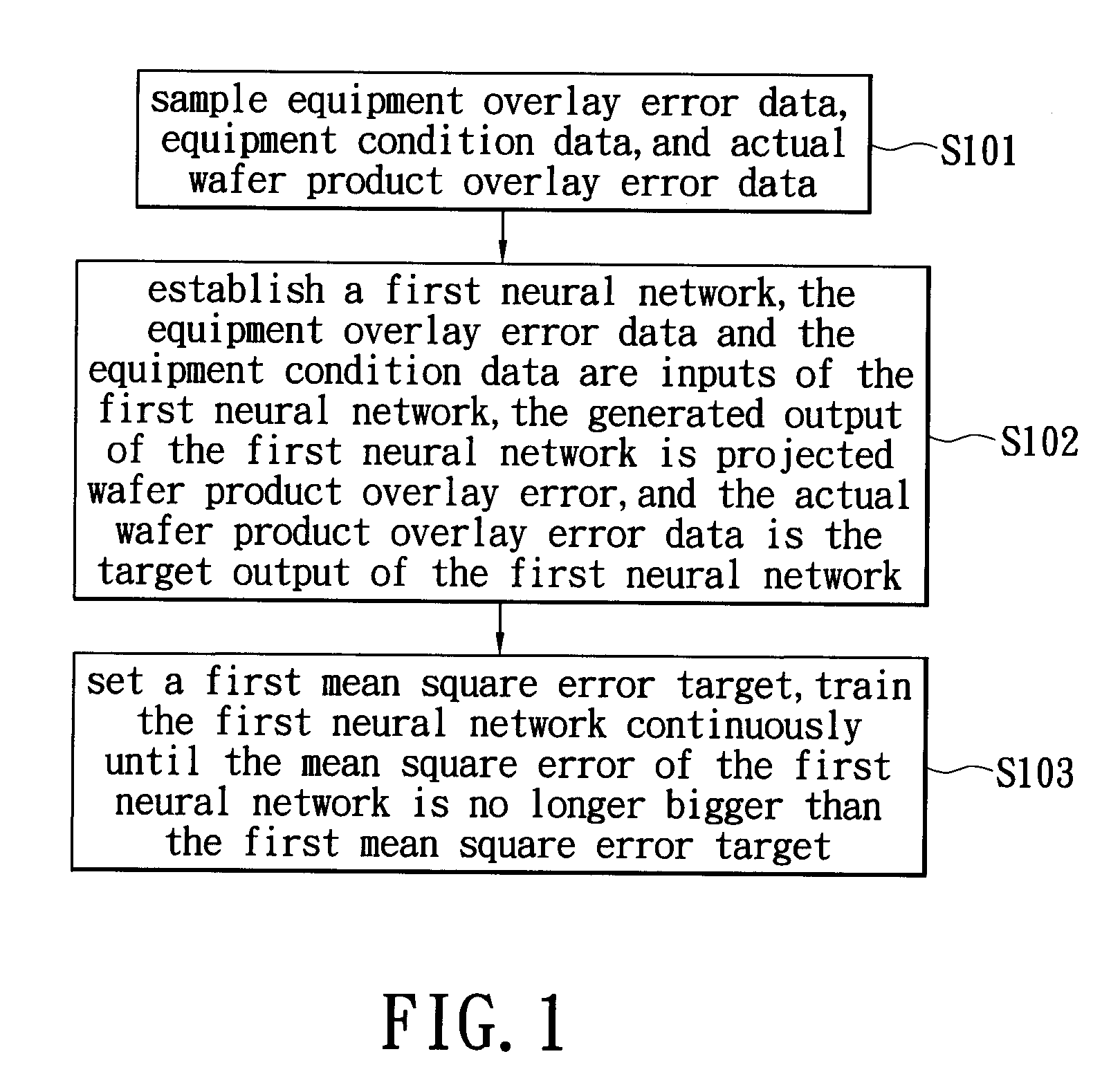

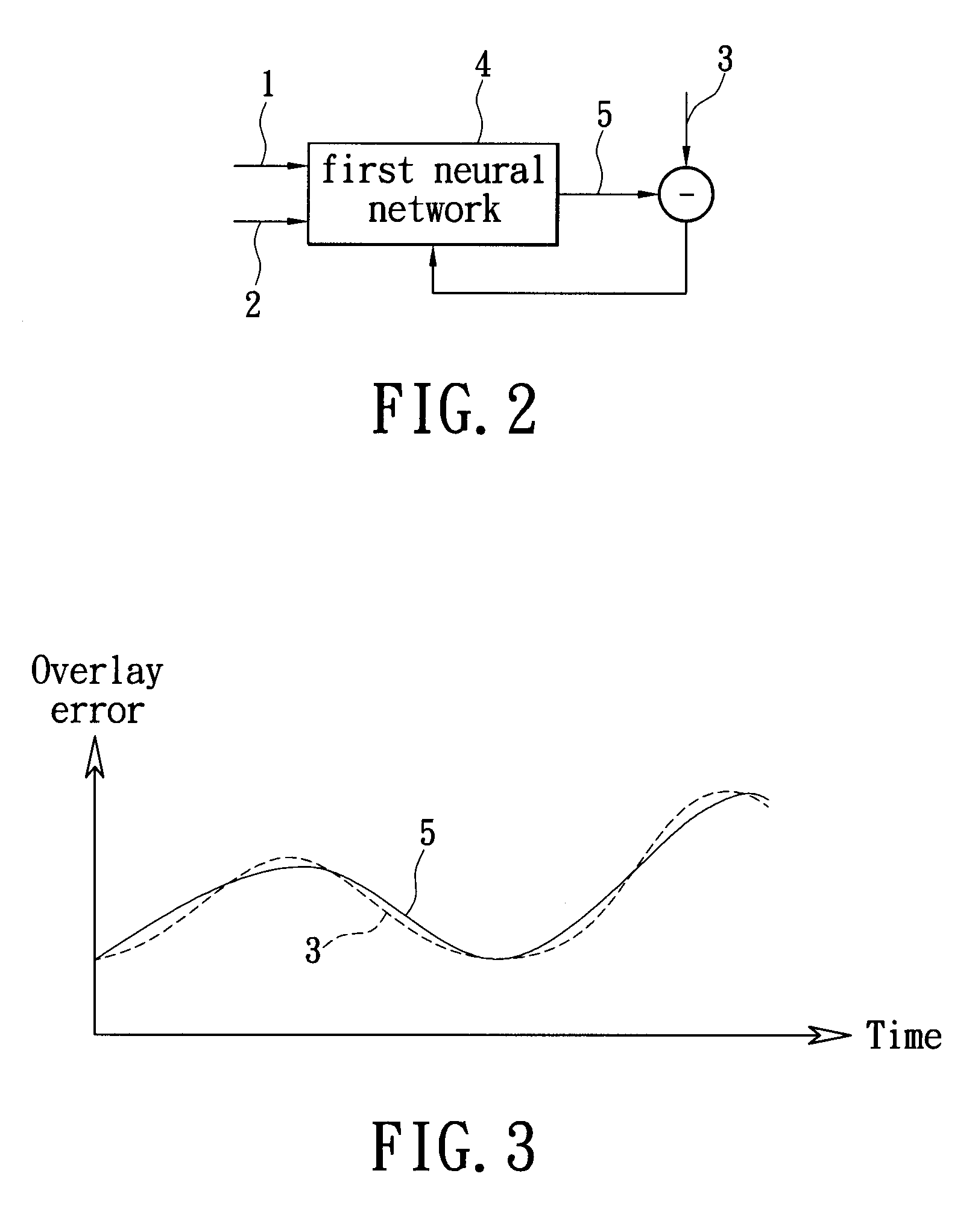

Method for projecting wafer product overlay error and wafer product critical dimension

InactiveUS20100049680A1Improve efficiencySemiconductor/solid-state device testing/measurementPhotomechanical apparatusMean squareNerve network

Owner:INOTERA MEMORIES INC

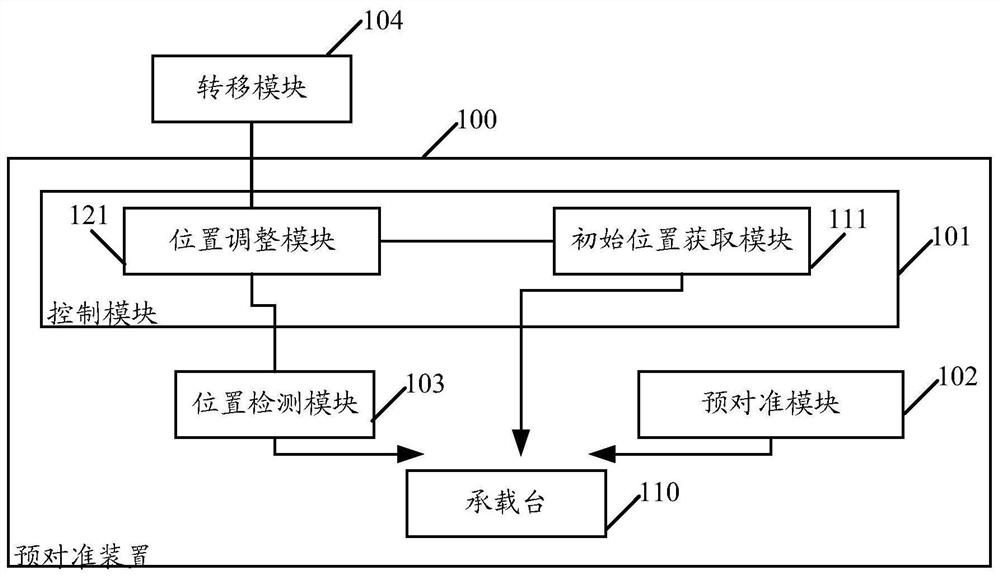

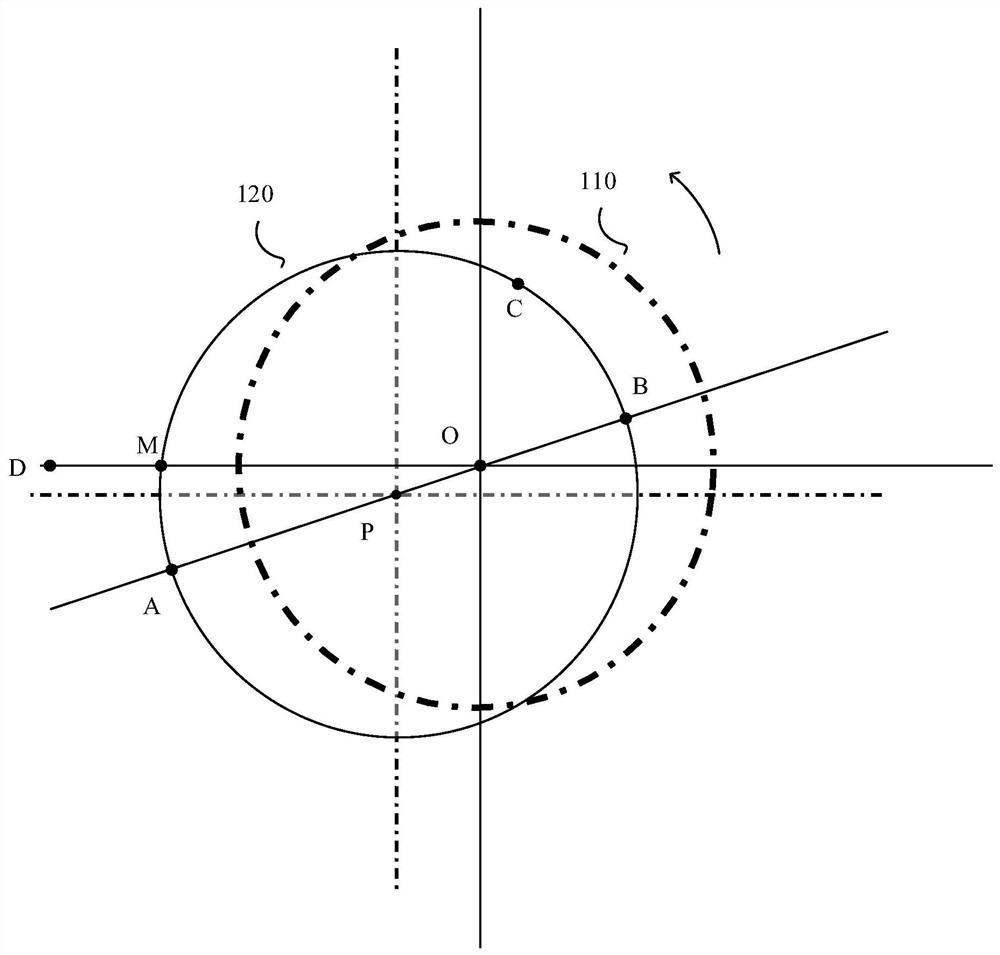

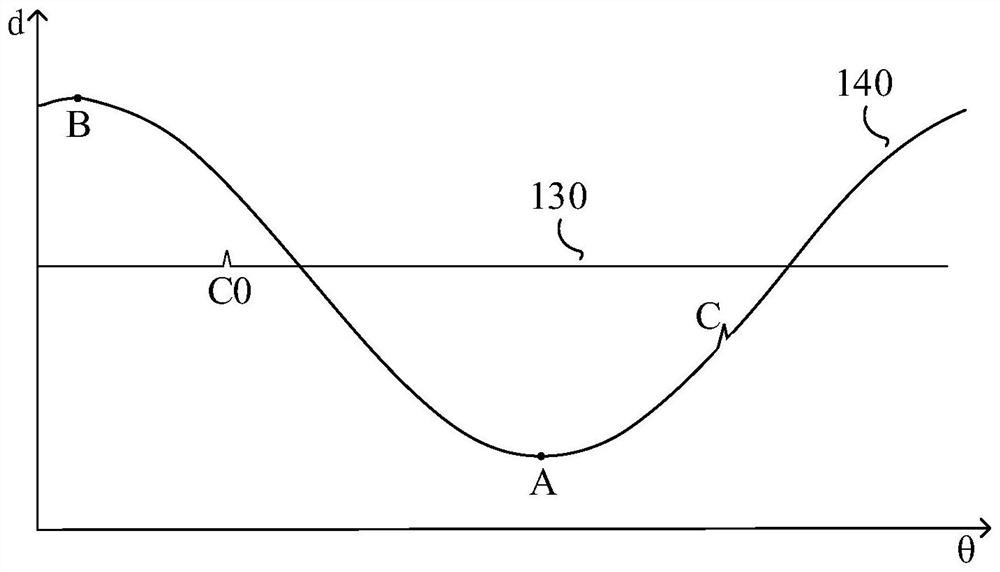

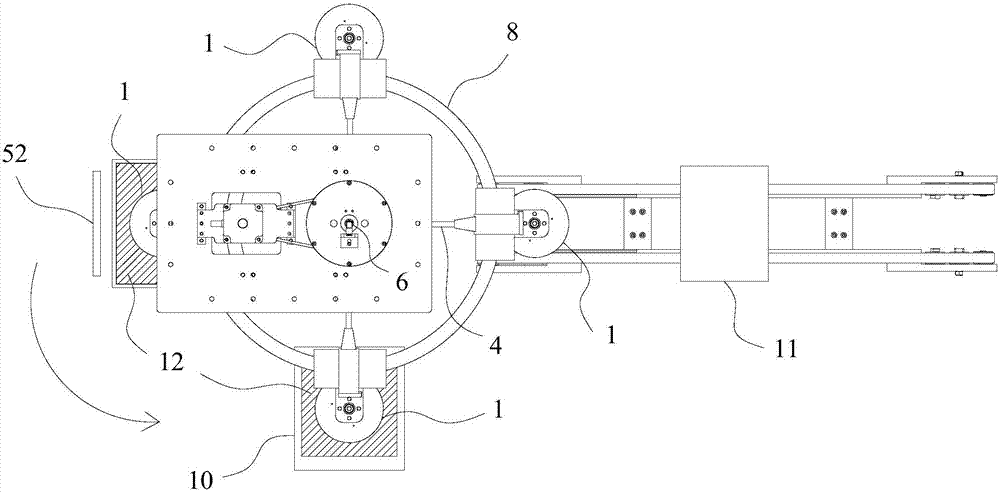

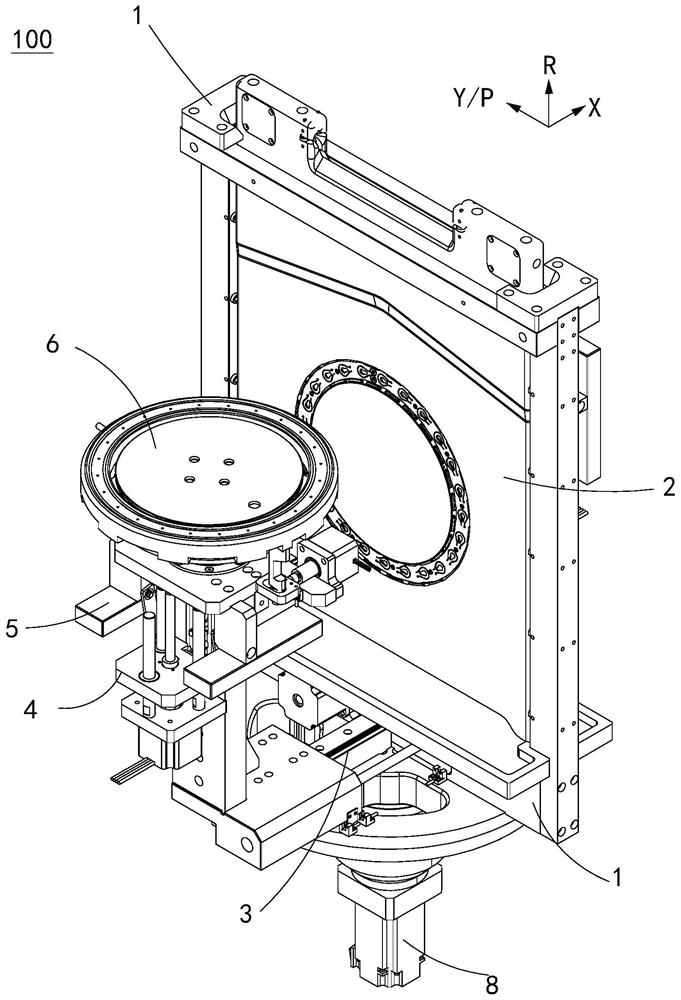

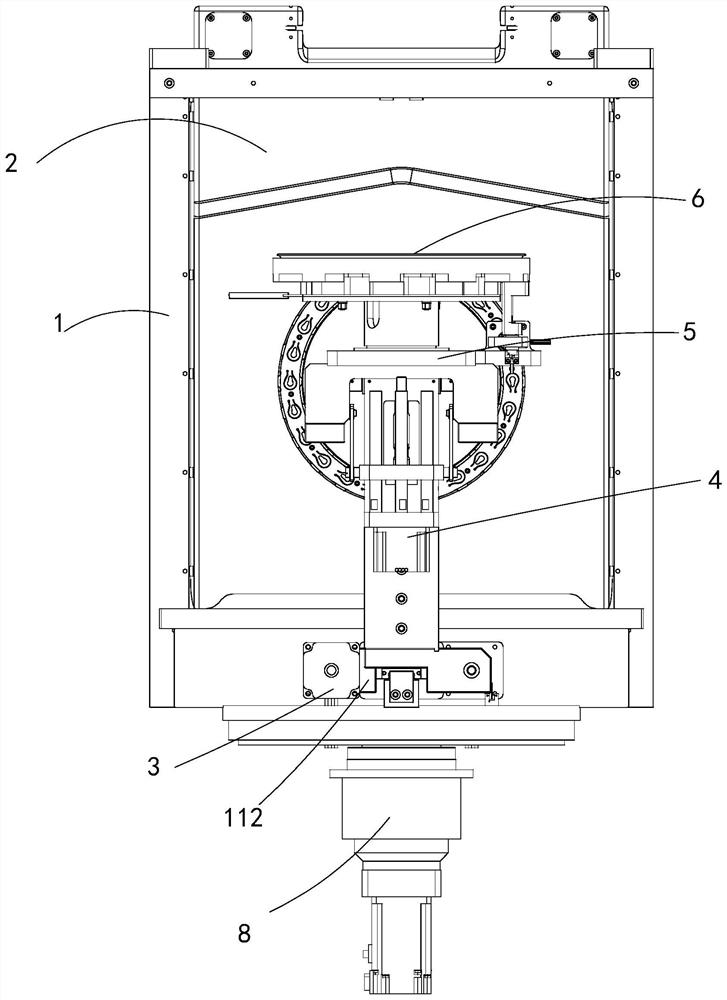

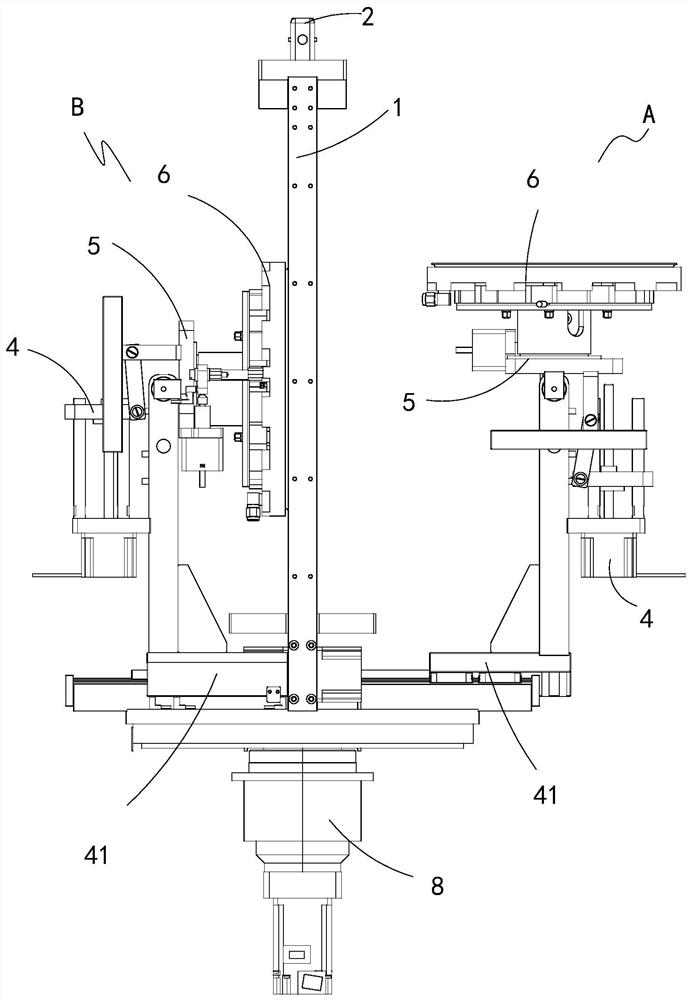

Pre-alignment device and pre-alignment method applied to same

ActiveCN113066746AImprove detection efficiencyAvoid downtimeSemiconductor/solid-state device detailsSolid-state devicesMachineVector control

The embodiment of the invention provides a pre-alignment device and a pre-alignment method applied to the device, and the pre-alignment device comprises a bearing platform which is provided with a central axis and is used for bearing a wafer and driving the wafer to rotate around the central axis of the bearing platform; a position detection module which is used for detecting an offset vector of the central axis of the wafer relative to the central axis of the bearing table; a control module which is used for adjusting the position of the next wafer on the bearing table based on the offset vector; and a pre-alignment module which is used for detecting the gap position of the wafer adjusted by the control module. Through continuous detection and compensation, it is ensured that the position where the wafer is placed does not have too large deviation, so that it is ensured that the pre-alignment module can detect the notch of the wafer, the phenomenon that a machine is shut down due to the fact that the pre-alignment module cannot find the notch of the wafer is prevented, and the detection efficiency of the pre-alignment module is improved; therefore, the yield of wafer products is improved.

Owner:CHANGXIN MEMORY TECH INC

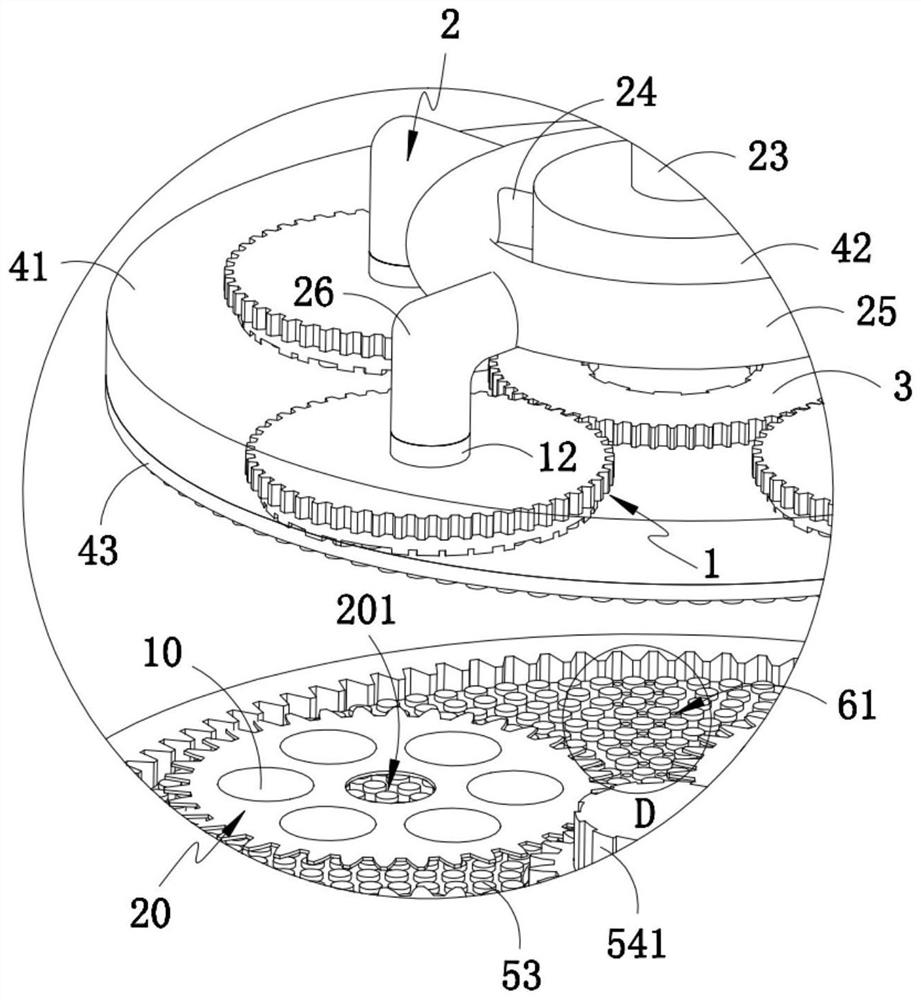

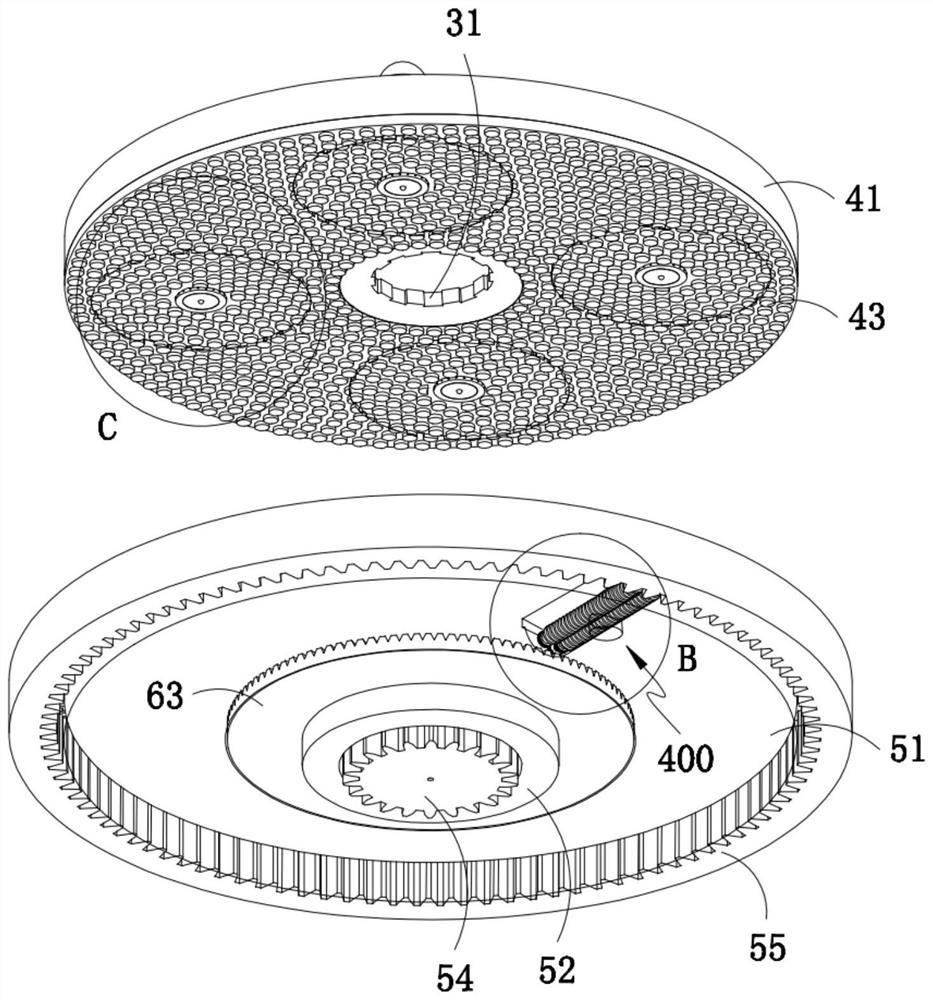

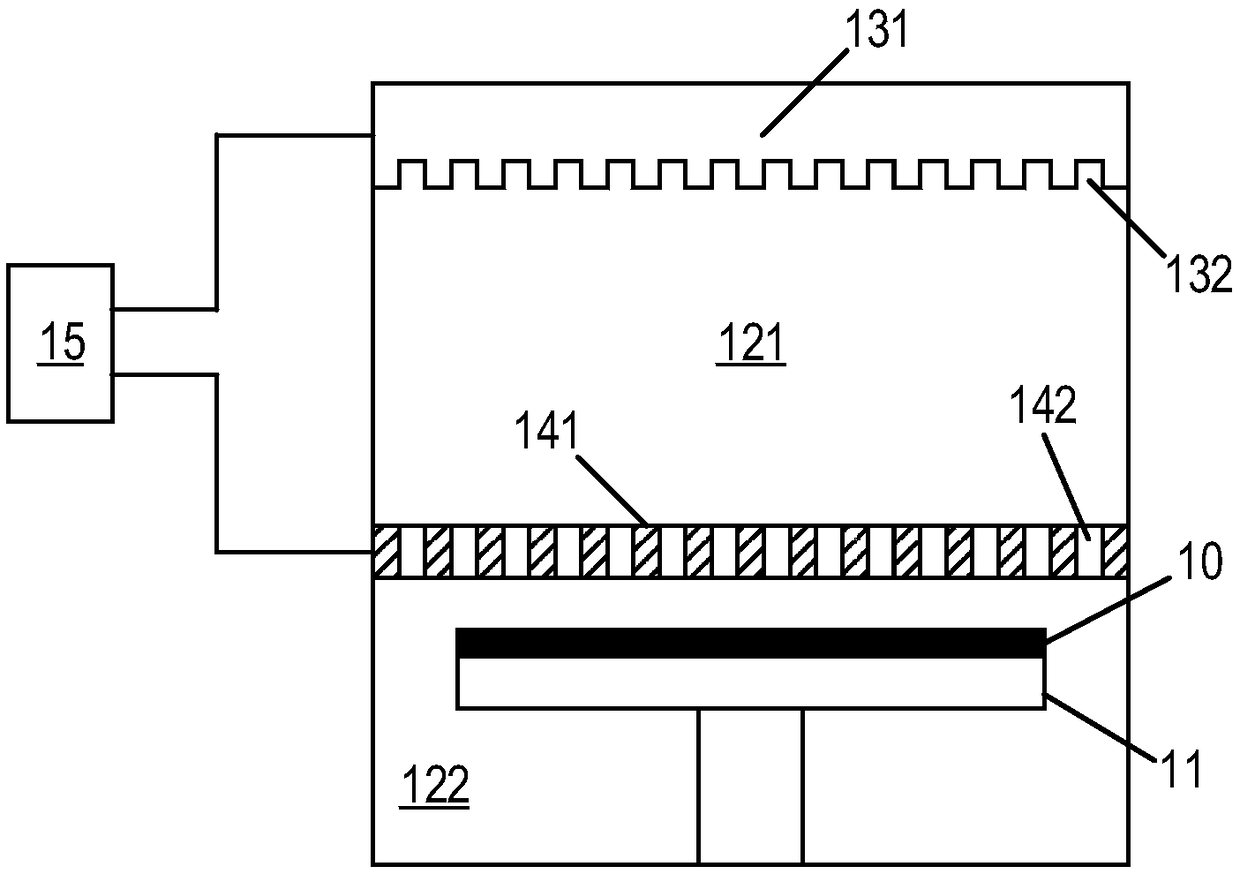

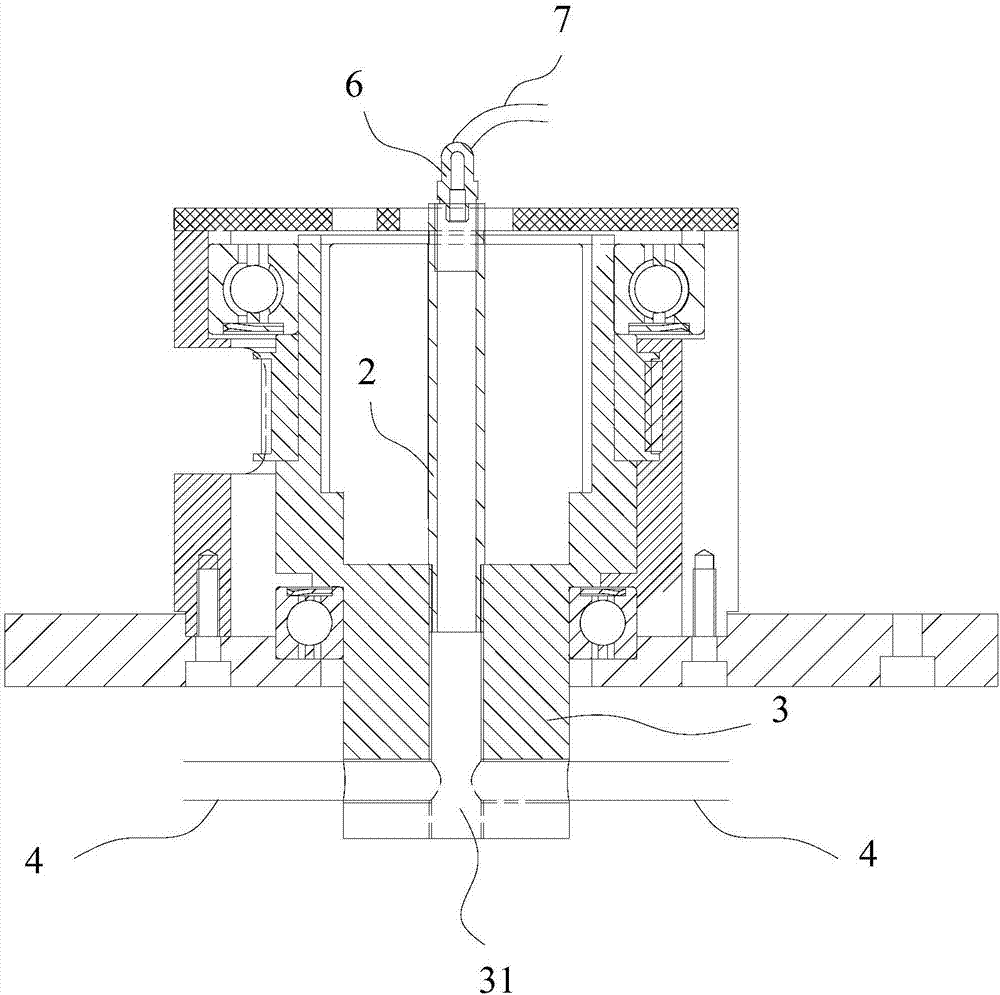

Silicon wafer dual-face grinding equipment and production process thereof

ActiveCN111761505AAffects high-quality grindingIngenious structural designLapping machinesWork carriersEngineeringSilicon chip

The invention provides silicon wafer dual-face grinding equipment and a production process thereof. The equipment comprises an up and down grinding disc system, a lower plane disc for loading a silicon wafer to be ground and a spraying sweeping chip removal system mounted on the upper grinding disc system, the spraying sweeping chip removal system comprises an upper plane disc mechanism corresponding to the lower plane disc, a liquid supply device communicating with the upper plane disc mechanism, and an upper transmission assembly for driving the upper plane disc mechanism to rotate, when theupper plane disc mechanism rotates to the position above the corresponding lower plane disc, trigger liquid outlet is achieved, cleaning liquid is sprayed out under the rotation centrifugal effect ina sprinkler manner, grinding impurities are removed in a spraying manner from the center of the lower plane disc to the center and are swept, in cooperation with a chip removal extrusion system mounted on the lower grinding disc system, impurity mixed liquid is extruded, transferred, filtered and recycled, the liquid outlet manner is ingeniously designed while the automatic liquid supply is achieved to synchronously remove the grinding impurities in time, and the technical problems that in the prior art, the grinding impurities cannot be removed in time, and a silicon wafer product is poor inquality and low in yield can be solved.

Owner:ZHEJIANG COWIN ELECTRONICS

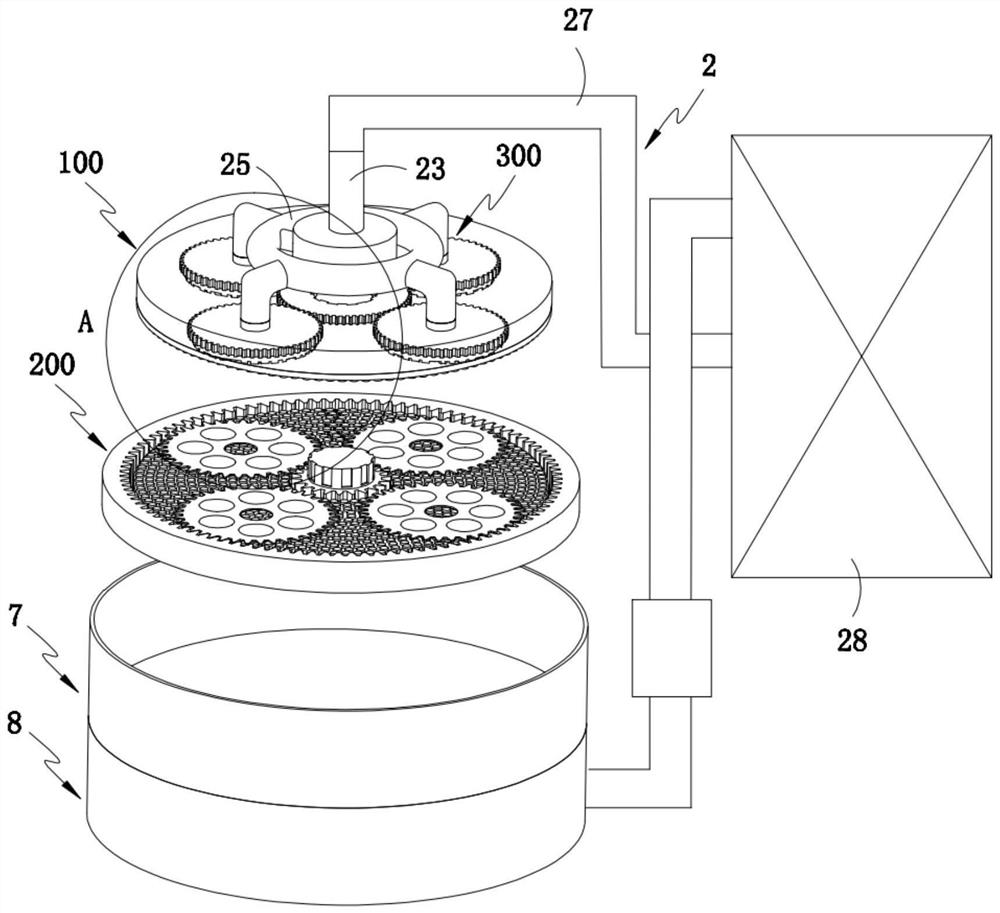

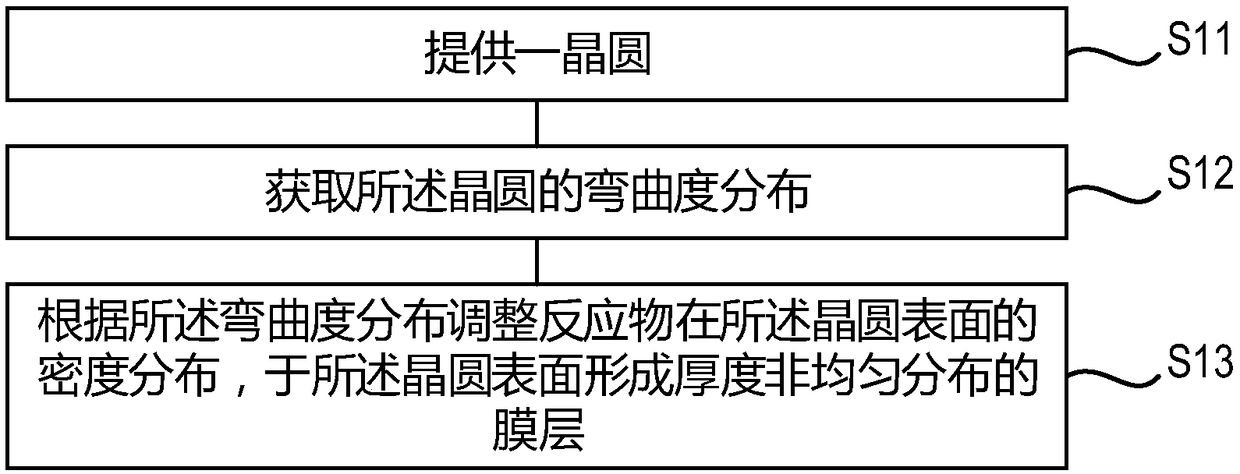

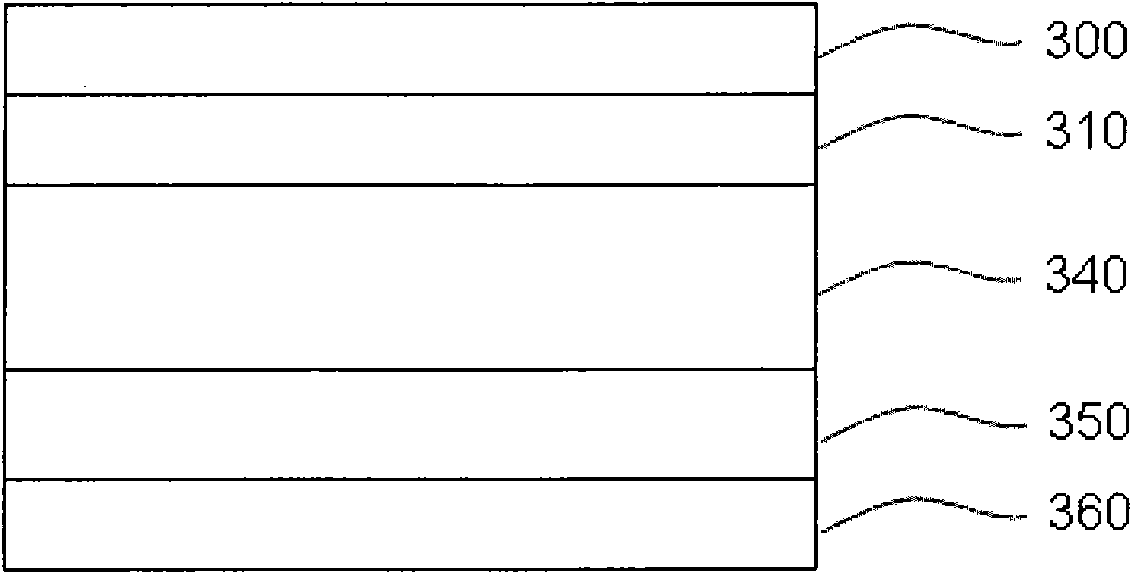

A method for balancing distribution of wafer curvature

ActiveCN109273378ABalanced Curvature DistributionQuality improvementSemiconductor/solid-state device testing/measurementChemical vapor deposition coatingWafer curvatureDensity distribution

The invention relates to the technical field of semiconductor manufacturing, in particular to a method for balancing distribution of wafer curvature. The method for balancing the wafer bending distribution comprises the following steps: providing a wafer; Acquiring a curvature distribution of the wafer; Adjusting the density distribution of the reactant on the wafer surface according to the curvature distribution, and forming a film layer with a thickness non-uniformly distributed on the wafer surface. The invention can form a film layer with non-uniform thickness distribution on the wafer surface, realizes the balance of wafer curvature distribution, is suitable for wafers with various shapes, and effectively improves the quality of wafer products.

Owner:YANGTZE MEMORY TECH CO LTD

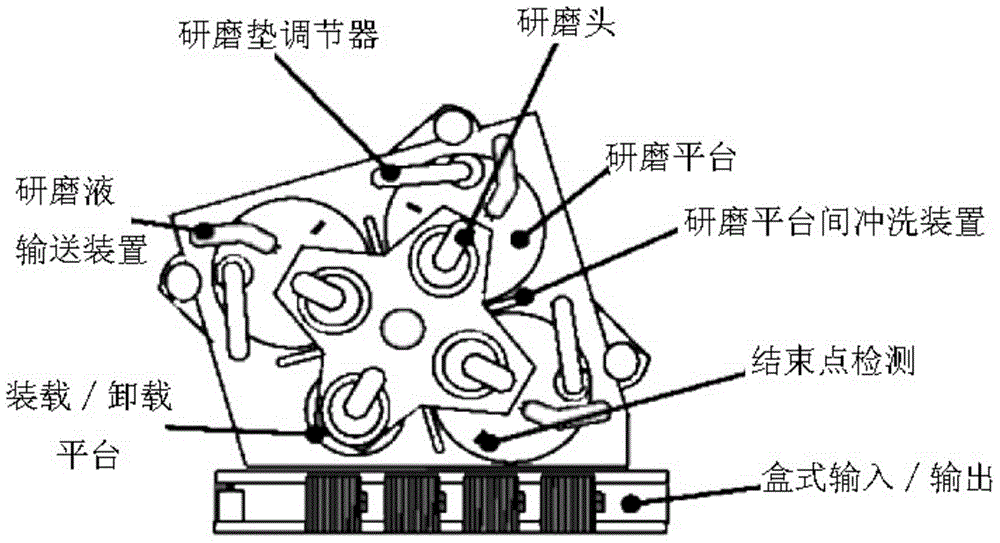

Chemical mechanical polishing method for wafer planarization production

InactiveCN105081957AIncrease productivityGuarantee product qualitySemiconductor/solid-state device manufacturingLapping machinesProcess engineeringWafer Product

The invention relates to a chemical mechanical polishing method for wafer planarization production. The method comprises the following steps of providing a chemical mechanical polishing machine; putting a wafer to be polished into a loading platform; when the wafer enters into a first polishing platform, using first selection ratio polishing fluid to polish according to scheduled polishing time and polishing amount; when the wafer enters into a second polishing platform, using second selection ratio polishing fluid to polish according to scheduled polishing time and polishing amount, wherein the second selection ratio is larger than the first selection ratio; when the wafer enters into a third polishing platform, using high selection ratio polishing fluid to polish according to scheduled polishing time and polishing amount; washing; conveying the wafer to an unloading platform. Two batches of wafer products are pre-produced, and a corresponding polishing amount is established in an advanced process control system according to the corresponding relation between front amount and rear amount. According to the chemical mechanical polishing method for wafer planarization production provided by the invention, on the premise of ensuring the product quality, the production efficiency of CMP (Chemical Mechanical Polishing) is greatly improved.

Owner:HEJIAN TECH SUZHOU

Solar silicon wafer surface defect detection device

InactiveCN106992128AHigh precisionReduce contactSemiconductor/solid-state device testing/measurementControl systemEngineering

Owner:CHENGDU FUYU TECH

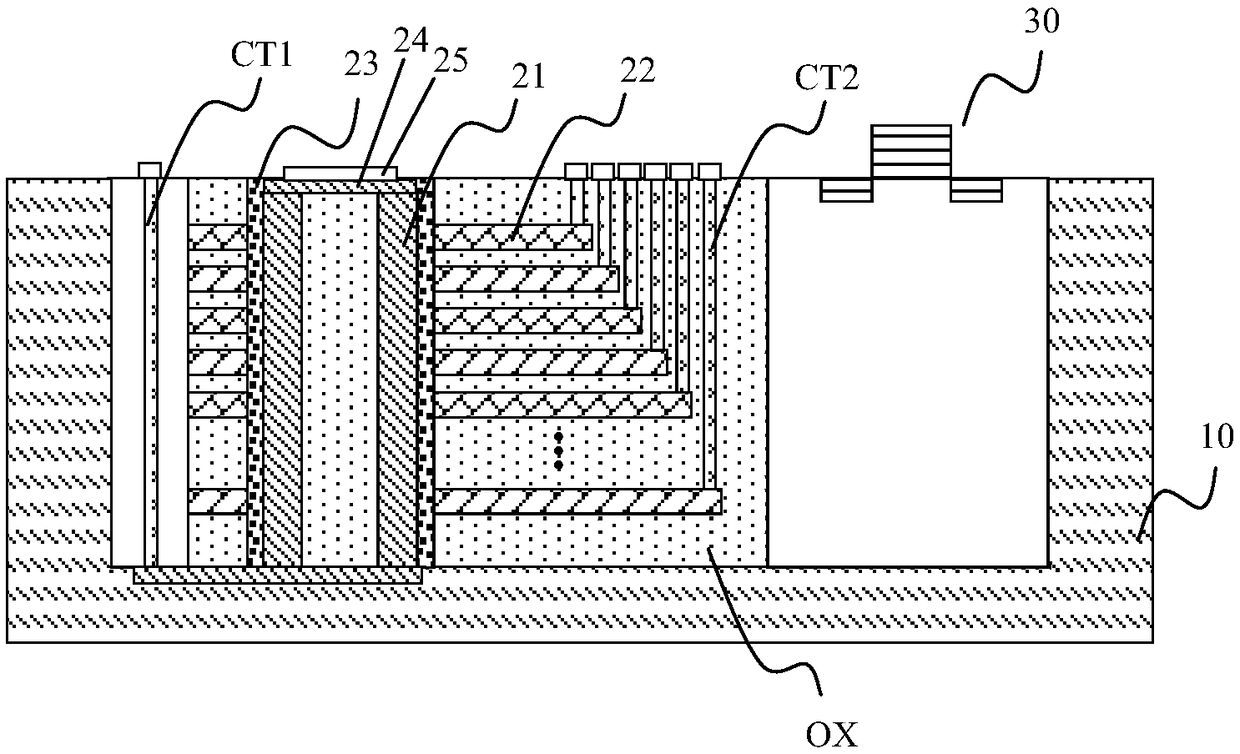

Three-dimensional storage structure

InactiveCN108666320AGuaranteed yieldAvoid stress concentration situationsSolid-state devicesSemiconductor devicesIsolation layerEngineering

The invention relates to the technical field of semiconductors, in particular to a three-dimensional storage structure. The three-dimensional storage structure comprises a substrate, wherein a plurality of grooves are formed in the substrate in an array way, a storage unit structure is formed in each groove, each storage unit structure comprises an annular and vertical columnar channel layer, a plurality of control gate layers and an annular and vertical columnar isolation layer, the annular and vertical columnar channel layer is used for connecting a source and a drain, the plurality of control gate layers are vertically separated, the columnar channel layer is encircled by each control gate layer, the annular and vertical columnar isolation layer is used for separating the columnar channel layer from each control gate layer, a first contact hole and a second contact hole are formed in each storage unit structure, the first contact hole is used for connecting the columnar channel layer, and the second contact hole is used for connecting each control gate layer. By the three-dimensional storage structure, stress contraction can be prevented from being formed in a wafer of the storage structure, and the yield of a wafer product is favorably ensured.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

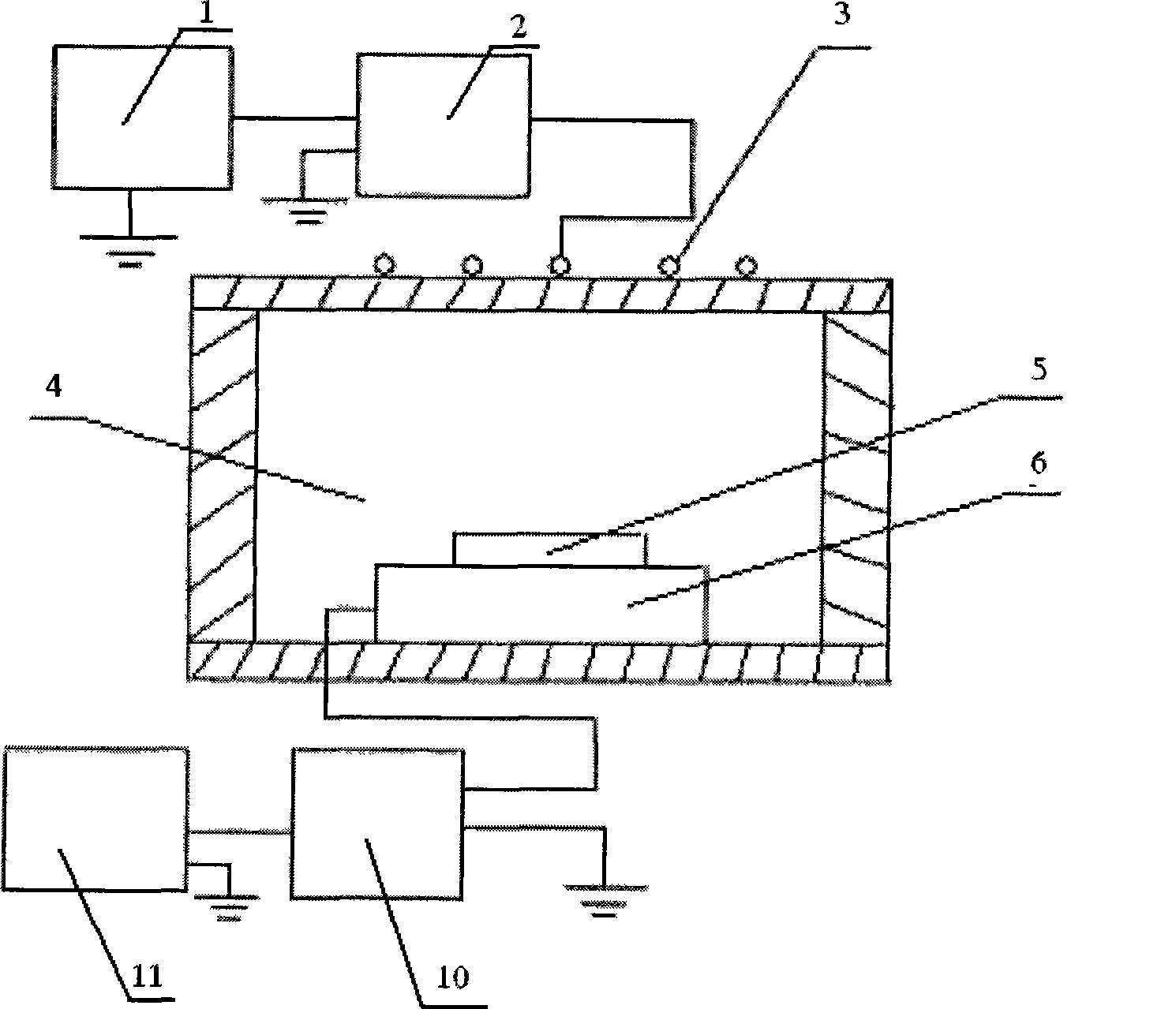

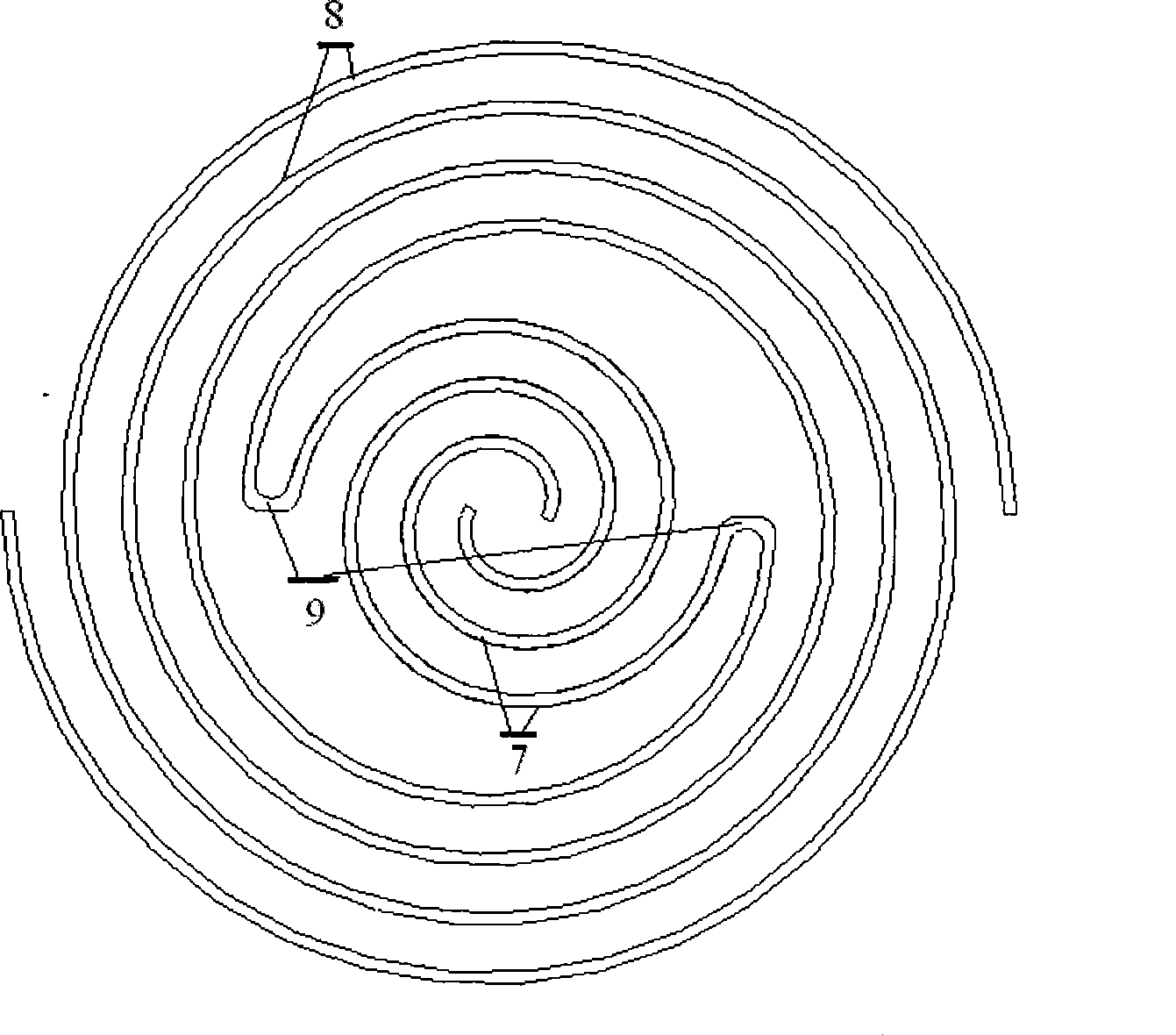

Inductance coupling coil and plasma device

ActiveCN101465189AReduce intensityUniform radial distributionTransformersSemiconductor/solid-state device manufacturingChemical reactionReaction rate

The invention relates to an inductively coupled coil used in the semiconductor machining process, and a plasma device which uses the inductively coupled coil. The key design points lie in that the inductively coupled coil at least comprises two identical branches, and each branch comprises an inner coil (7) and an outer coil (8); the coiling directions of the inner and outer coils are opposite; the tail end of the inner coil (7) is connected with the initial end of the outer coil (8) in series through a connecting segment (9); and the inner and outer coils of each branch are symmetrically nested respectively and are coplanar. When in work, the RF current flowing through the inner coil and the RF current flowing through the outer coil are opposite in direction, so that uniformly distributed electromagnetic fields are generated in a reaction chamber so as to obtain uniformly distributed plasmas; according to the wafer size, a large area of plasmas can be easily obtained through the increase of coil length and number to improve the uniformity of plasmas in the large-area process, so as to achieve less chemical reaction rate differences on the wafer surface and improve the quality of wafer products.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

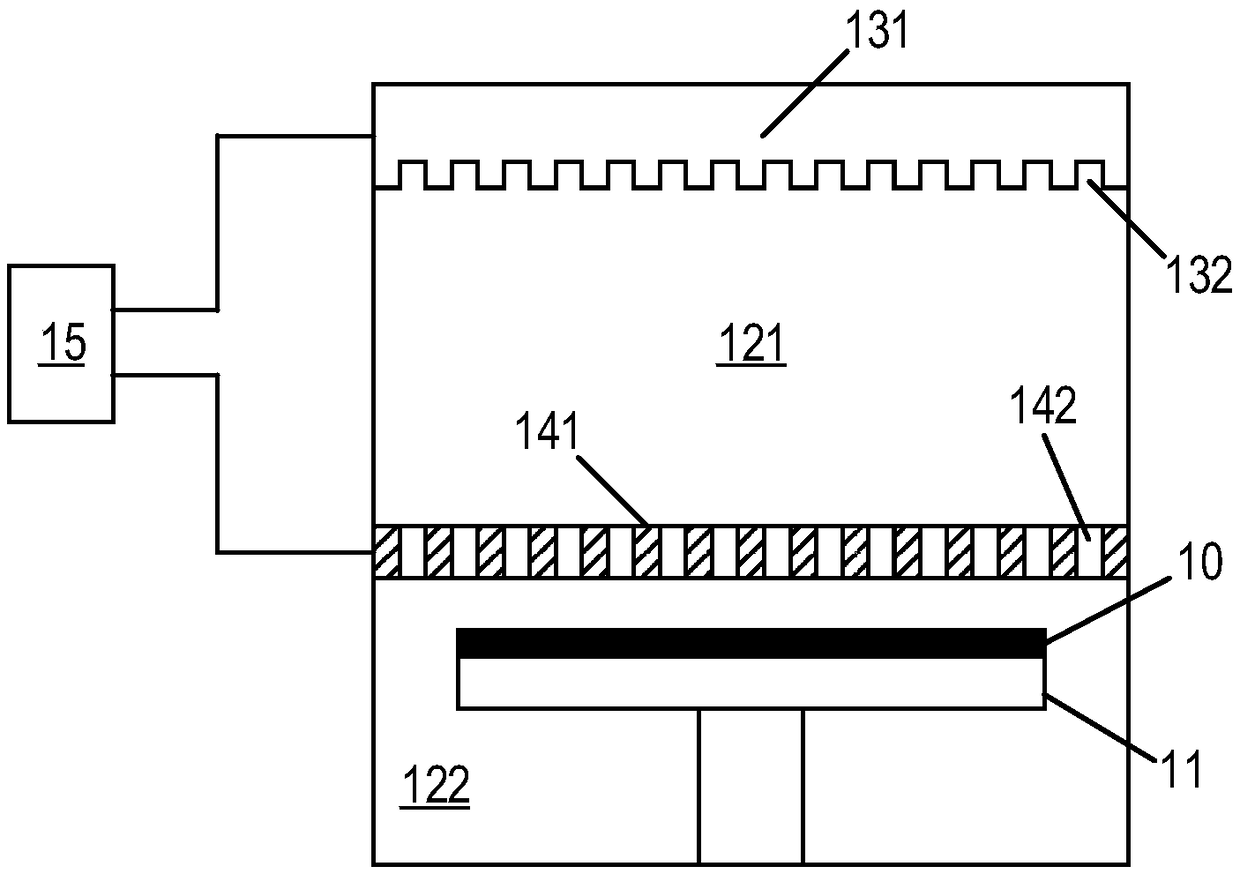

Film deposition apparatus

PendingCN109037120AQuality improvementTortuosity distribution balanceSemiconductor/solid-state device manufacturingWafer curvatureEngineering

The invention relates to the technical field of semiconductor manufacturing, in particular to a film deposition device. The film deposition apparatus includes an adjusting portion including a partition surface disposed toward a wafer surface and a plurality of nozzles disposed on the partition surface for transferring reactants to the wafer surface; A control unit for controlling whether each of the nozzles is opened or not to realize the non-uniform distribution of the reactant density on the surface of the wafer. The invention can form a film layer with non-uniform thickness distribution onthe wafer surface, realizes the balance of wafer curvature distribution, is suitable for wafers with various shapes, and effectively improves the quality of wafer products.

Owner:YANGTZE MEMORY TECH CO LTD

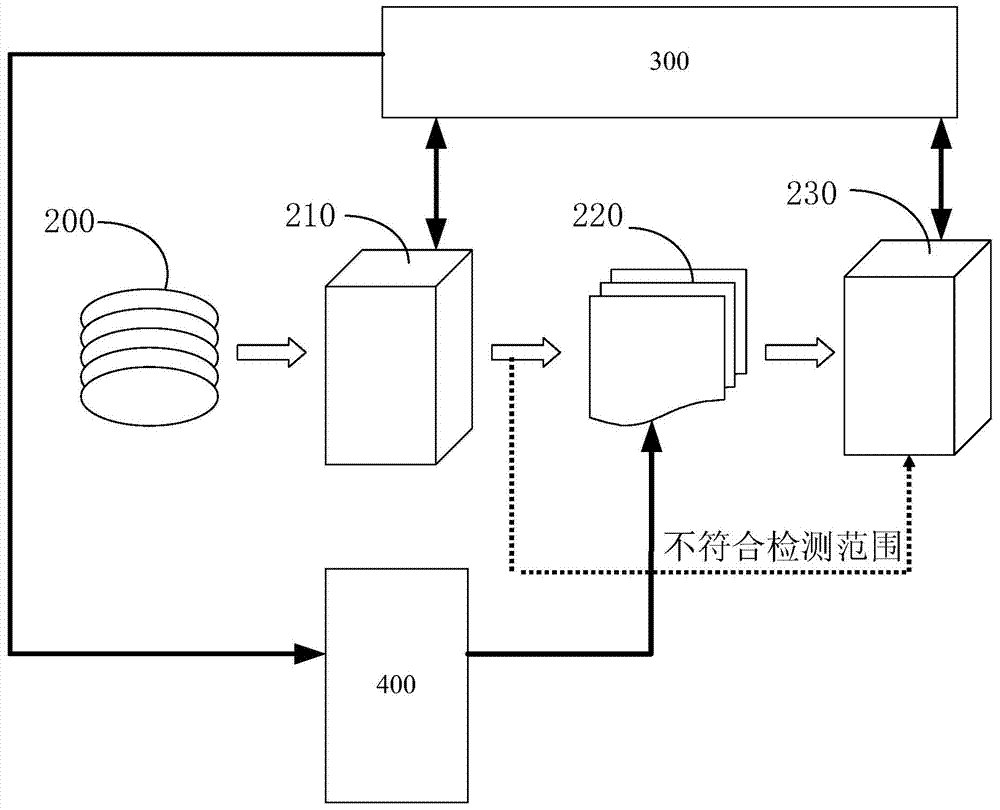

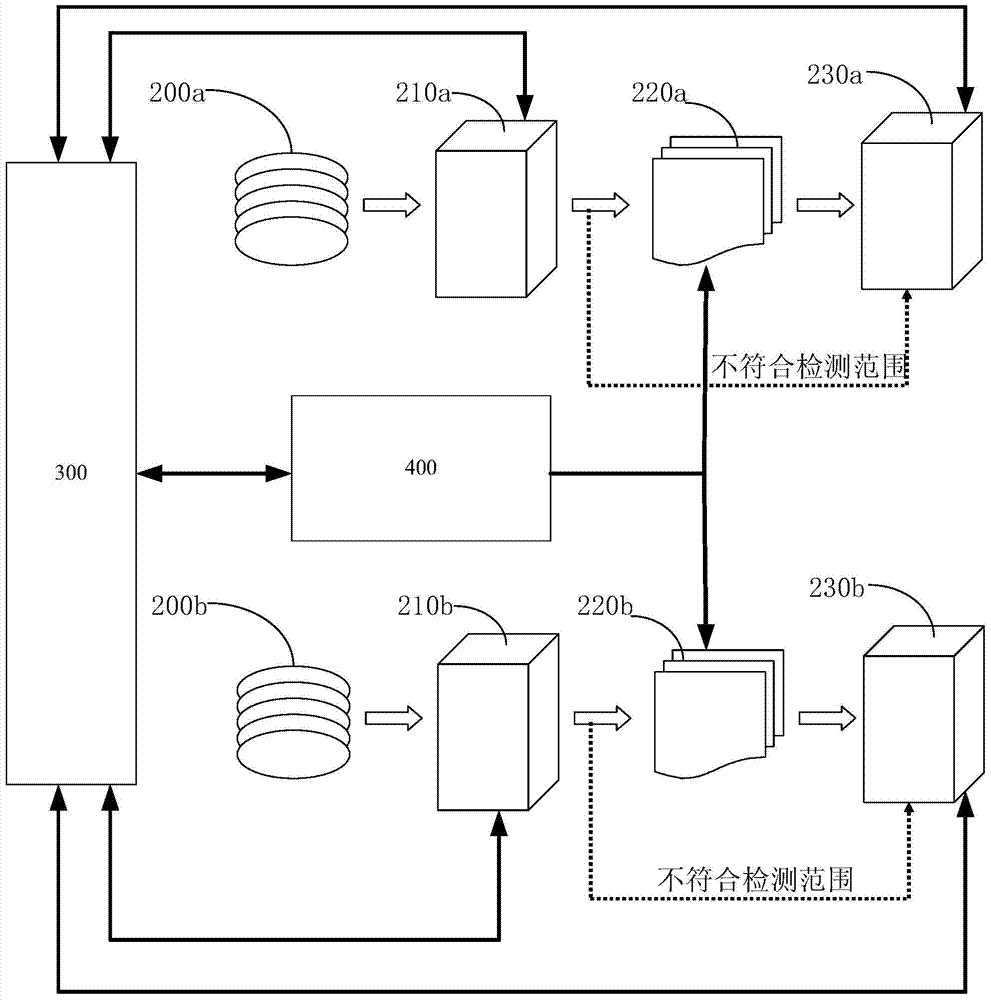

Defect detecting system and method

ActiveCN103489817AImprove operational efficiencySave testing resourcesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComputer scienceWafer Product

The invention relates to the technical field of semiconductors, and discloses a defect detecting system and method. According to the method, a process device operation information database connected with a production management system is established, information of operation cavities of all process devices is collected and stored in the database, meanwhile, the database is further connected with all the defect detecting devices, the number of wafers for defect detection is defined according to the number of operation cavities of process devices of wafer products, and the number of the wafers is transmitted to the defect detection devices. Compared with the prior art, when a certain or a set of cavities of the process devices can not normally work due to various reasons of the process devices, the process device operation information database defines the number of wafer products for defect detection according to the number of actual operation cavities of the process devices, spot check rules of the defect detecting devices are timely regulated, defect detection operation efficiency is effectively improved, detection resources are saved, and dynamic and self-adjustable effective defect detection is achieved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for detecting semiconductor polish wafer surface scratches

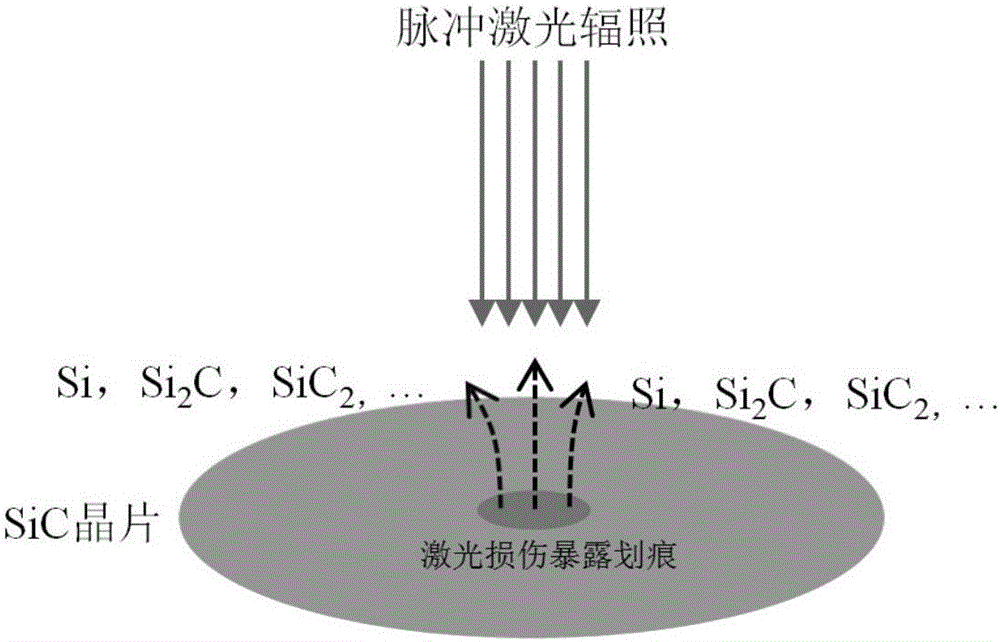

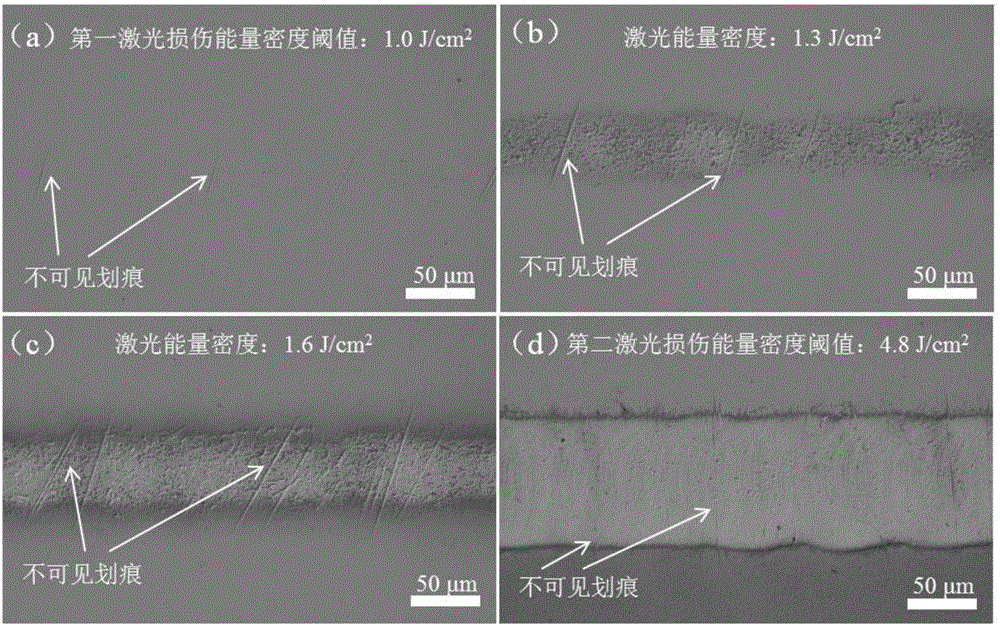

ActiveCN105870033AQuick checkEfficient detectionSemiconductor/solid-state device testing/measurementMicroscopic observationPulsed laser irradiation

The invention provides a method for detecting semiconductor polish wafer surface scratches. The detection method comprises the following steps that 1, a semiconductor polish wafer is irradiated by means of a pulse laser; 2, the semiconductor polish wafer surface subjected to pulse laser irradiation is observed with a microscope, wherein the total irradiation energy density of the pulse laser is between a first damage energy density threshold value and a second damage energy density threshold value. The detection method is high in speed, low in cost, small in damage to the wafer, free of pollution and capable of being widely applied to rapid detection on the surface scratches of semiconductor polish wafer products.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

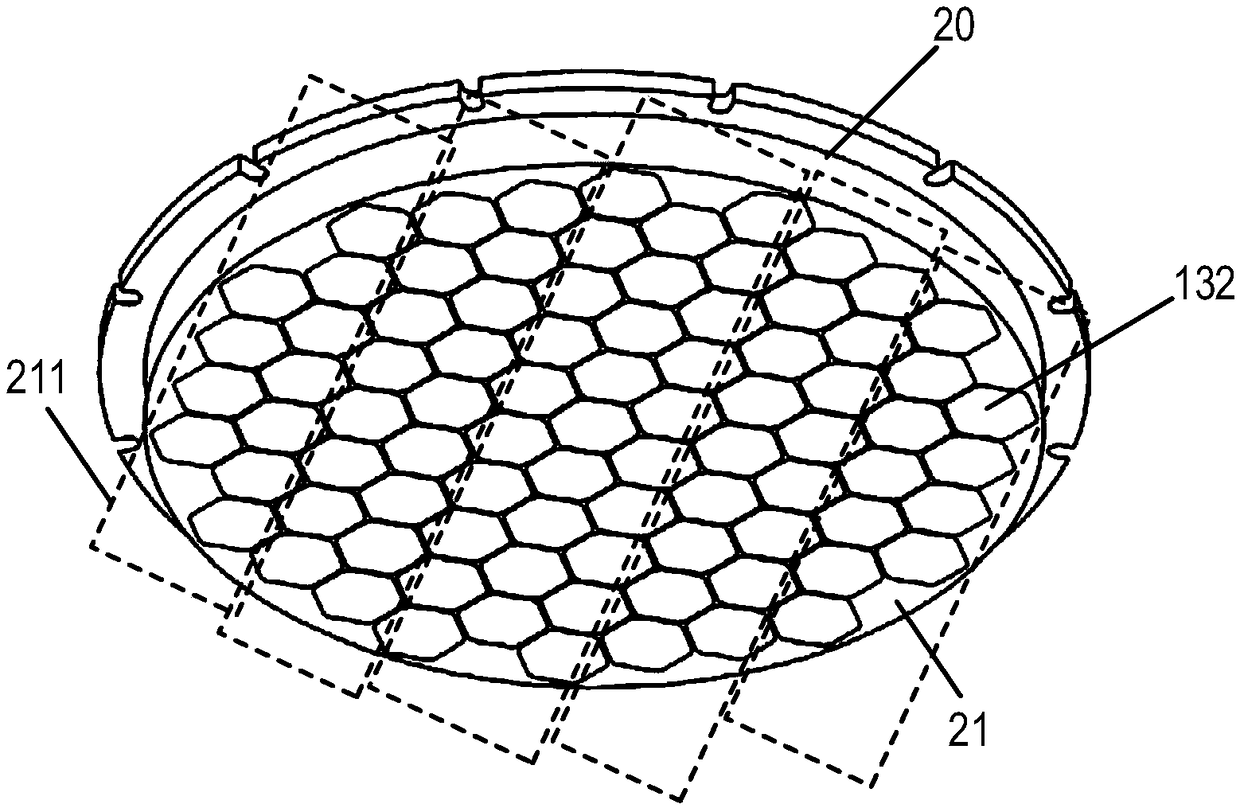

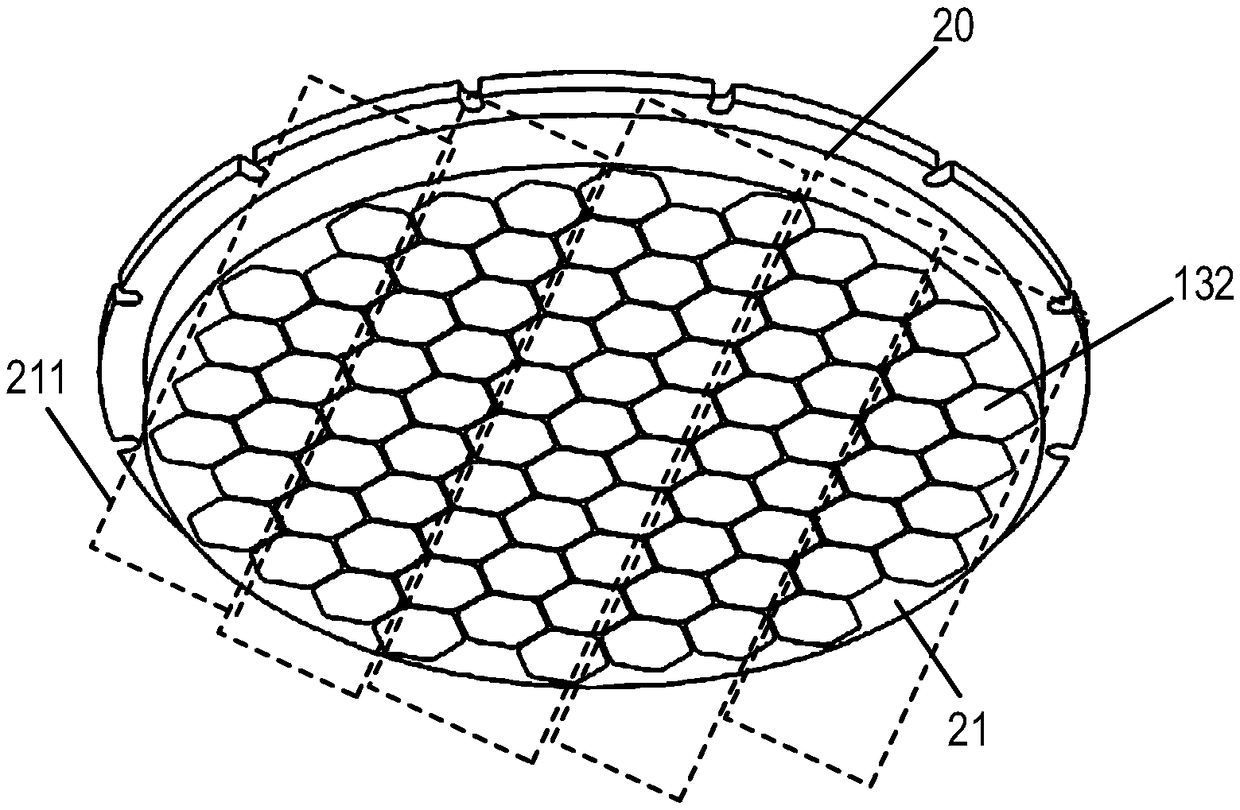

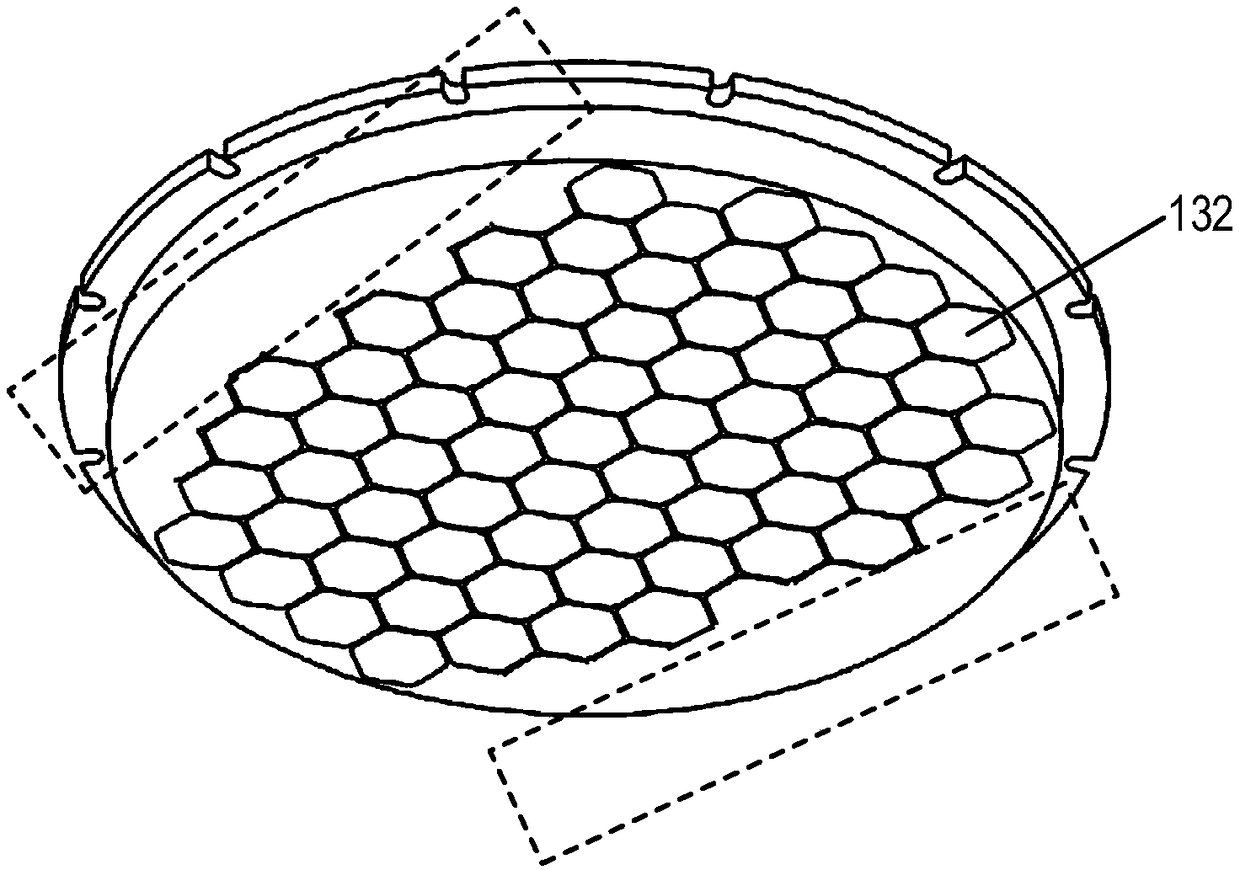

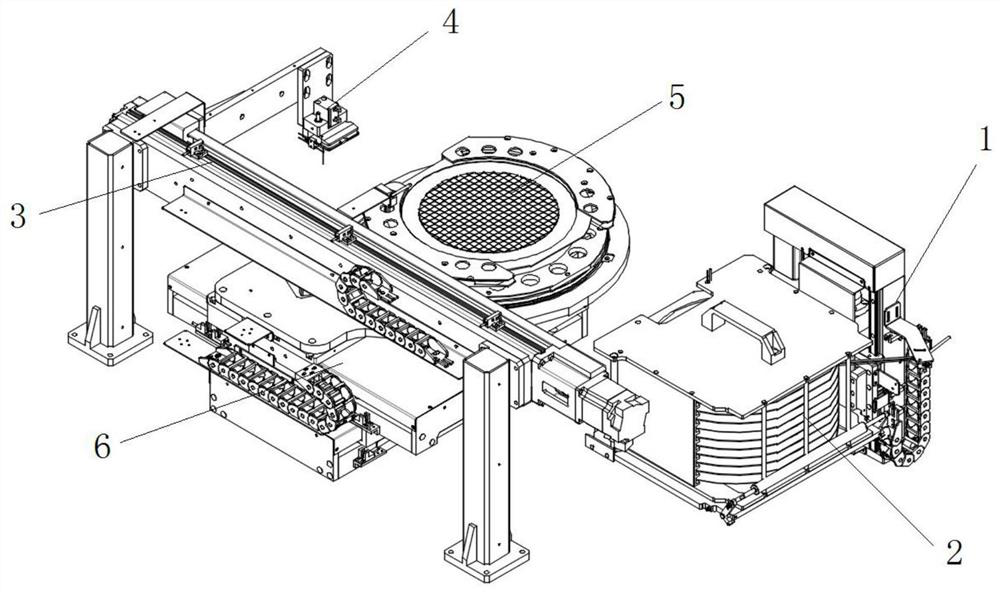

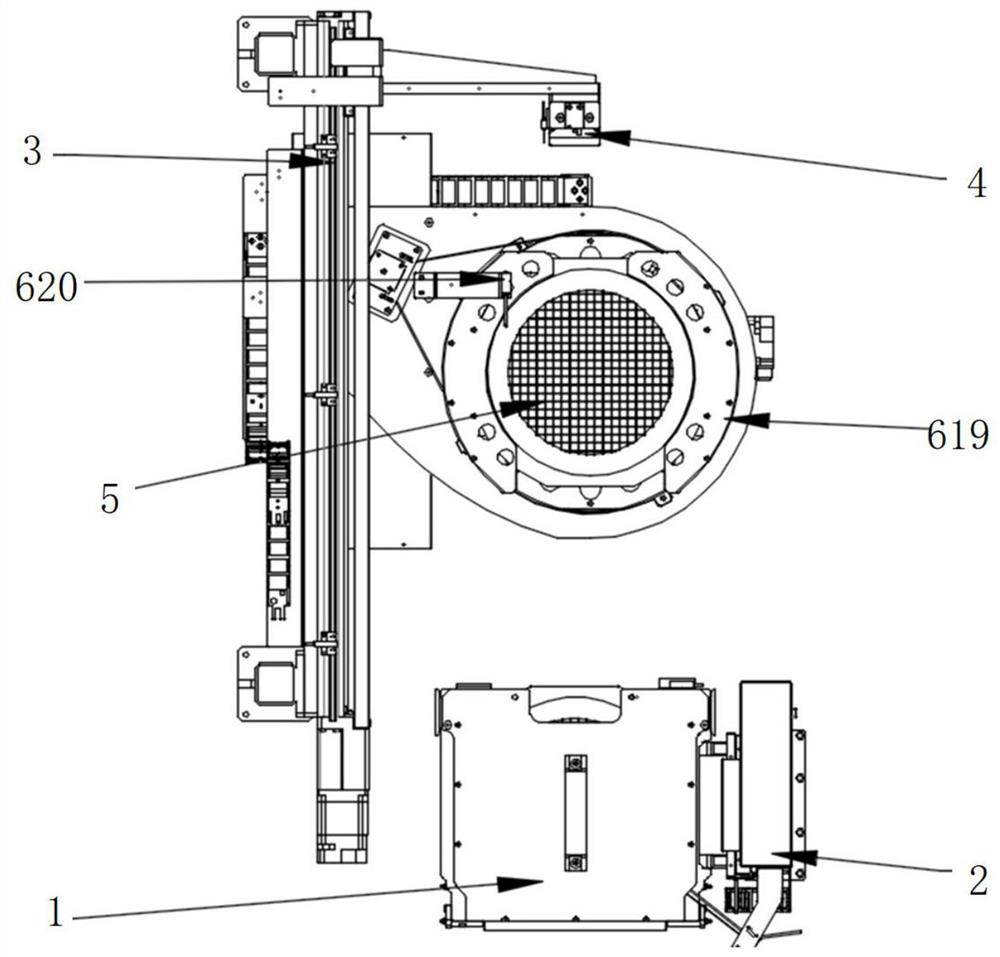

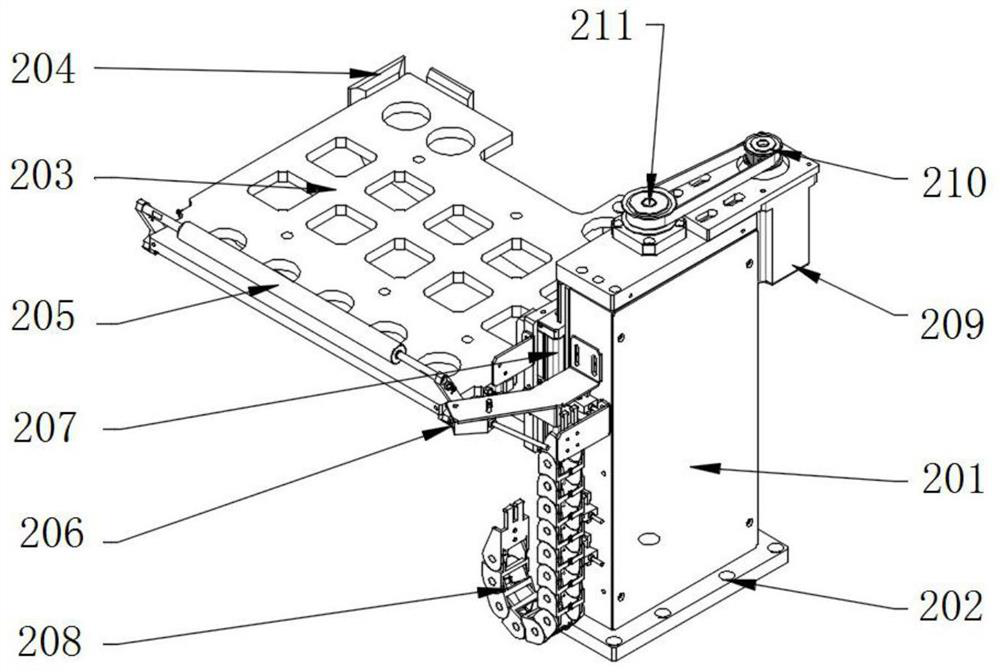

Automatic loading and film expanding equipment for wafer discs

PendingCN113510610ARapid mass productionStable quality and performanceLapping machinesWork carriersCircular discDevice material

The invention discloses automatic loading and film expanding equipment for wafer discs. The automatic loading and film expanding equipment for the wafer discs comprises a wafer disc lifting basket device, a lifting basket lifting platform mechanism, a clamping jaw movement mechanism, a wafer clamping jaw mechanism, a wafer mold expanding workbench and an XY-axis linear module. According to the invention, rapid and mass production for blue wafer film discs in a production process for semiconductor devices can be achieved, a manual operation mode is replaced, high efficiency, high quality and stable performance are achieved, middle film expanding machine equipment is reduced, manual operation and production management costs are reduced, unstable quality caused by the fact that product quality changes along with human factors is avoided, meanwhile, production operation is convenient and rapid, wafer products are convenient to store and use, environment protection for the wafer products is facilitated, quality problems such as wafer smudginess are effectively solved, and high production efficiency and stable product quality are achieved.

Owner:NORTECH AUTOMATION SHENZHEN CO LTD

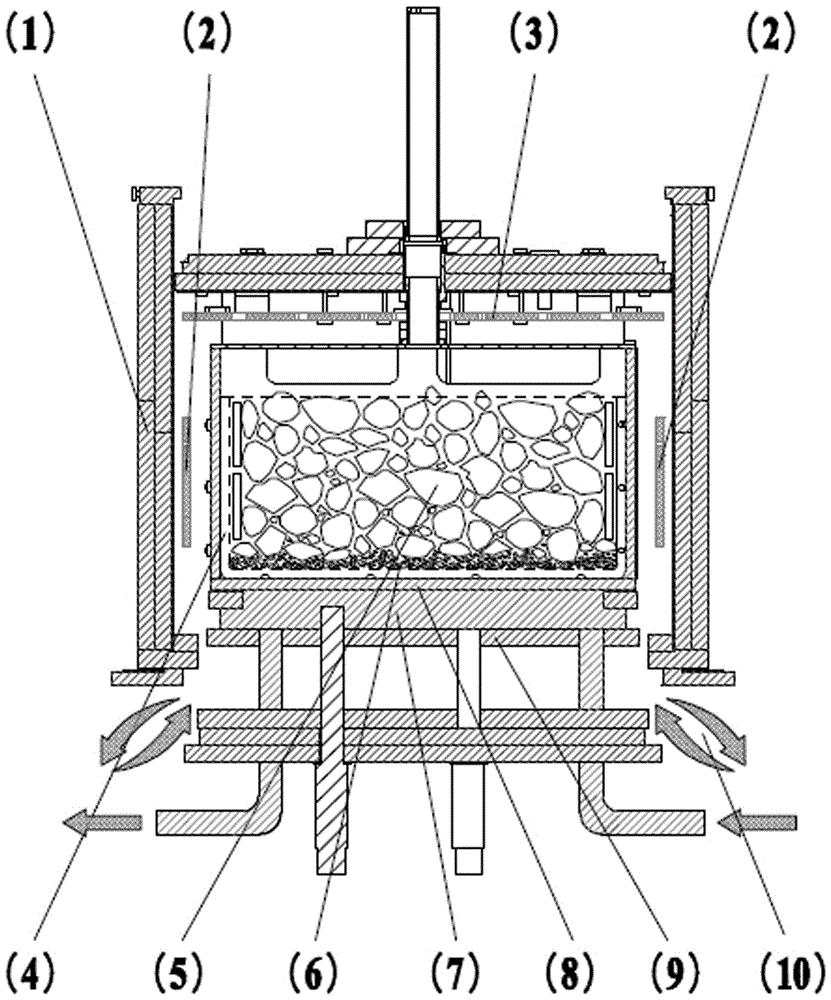

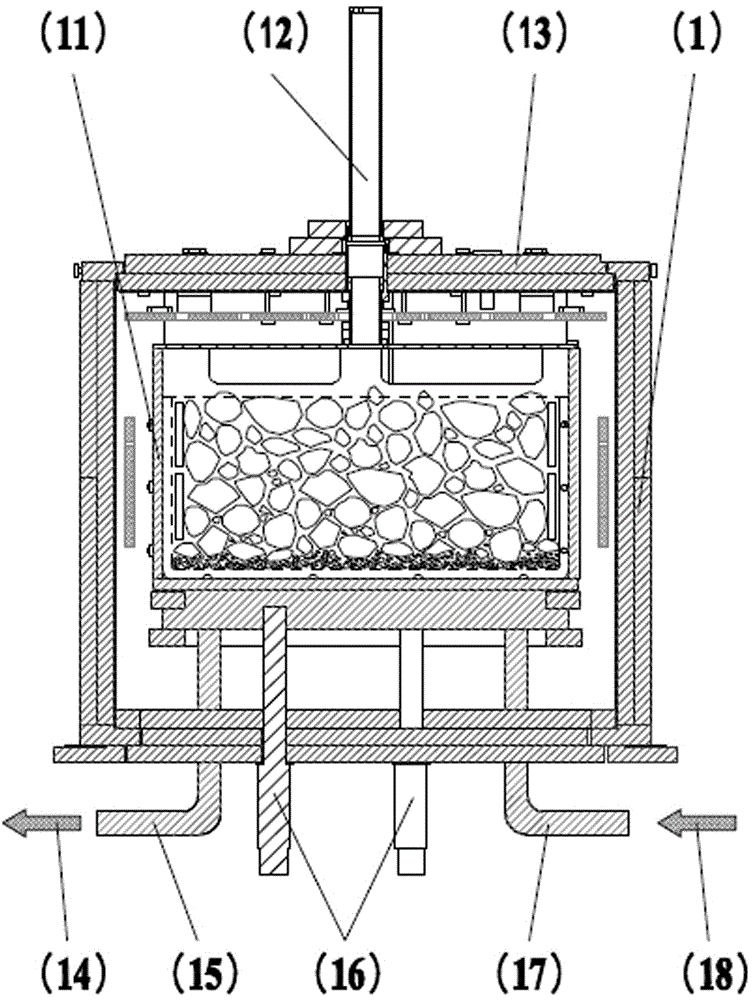

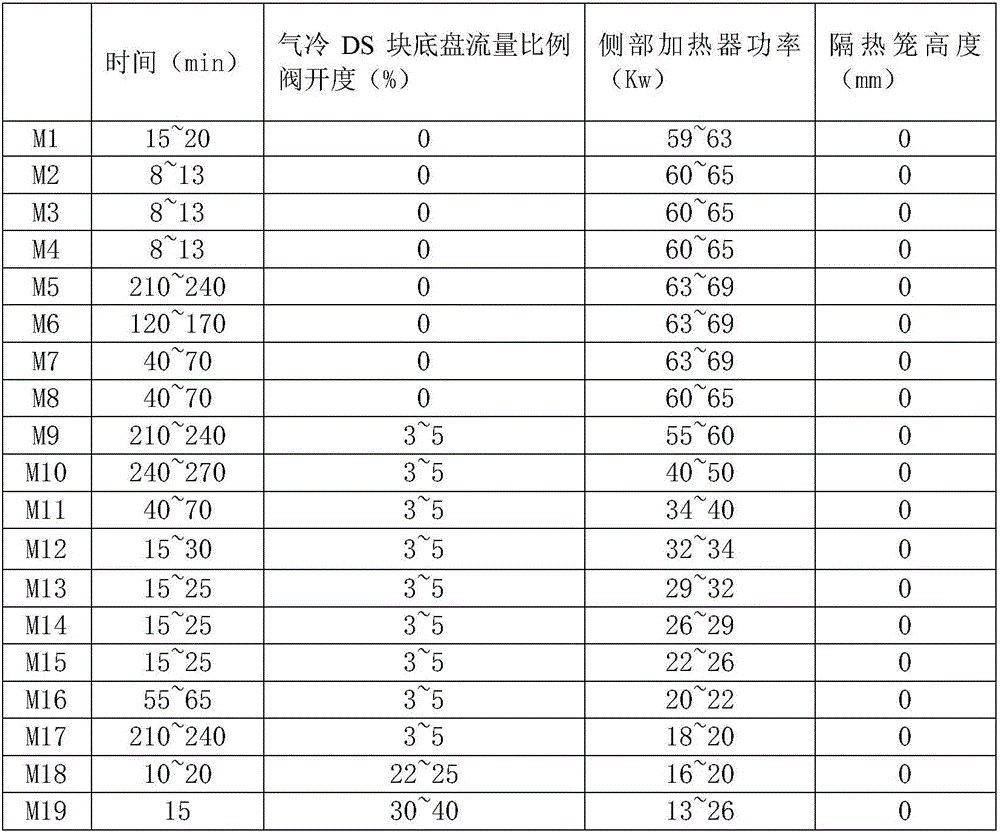

Opening-free heat insulation cage ingot casting device and method

InactiveCN106222741AReduce shockStable retention heightPolycrystalline material growthSingle crystal growth detailsIngot castingEngineering

The invention relates to field of polycrystalline silicon ingot casting, in particular to an opening-free heat insulation cage ingot casting device and method. The device comprises a heat insulation cage, wherein a lateral heater is arranged on the inner side face of the heat insulation cage, a top heater is arranged at the top in the heat insulation cage, and the lateral heater and the top heater are separately controlled by double power supplies. In a melting step, the temperature of an air cooling DS block is controlled not to be higher than 1400 DEG C. In astep of change from melting to crystal growth, the temperature of an air cooling DS block is 1300-1360 DEG C, the temperature of the top heater is 1530-1545 DEG C. In a crystal growth step, the temperature of the top heater is reduced from 1430 DEG C to 1400 DEG C, and the temperature of the air cooling DS block is reduced from 1300 DEG C to 1000 DEG C. By the adoption of the opening-free heat insulation cage ingot casting device, the heat insulation cage cannot be needed to be opened, the subfissurescrap ratio of cut silicon wafers is reduced by about 15%, the dislocation number of silicon ingots in growth is effectively controlled, the photoelectric conversion efficiency of silicon wafer products is high, and the stability is good.

Owner:YICHANG CSG POLYSILICON CO LTD

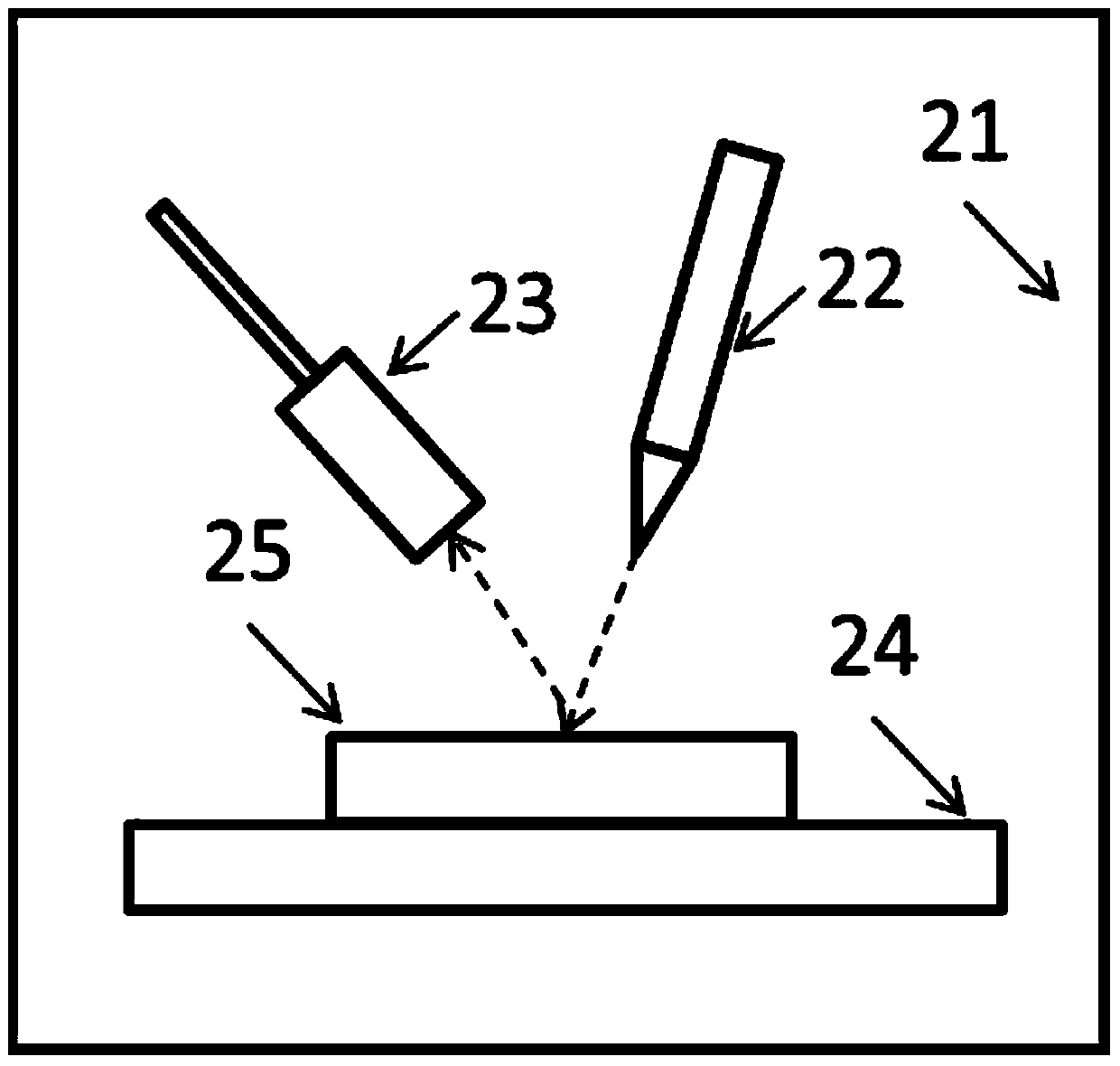

Focused ion beam sample preparation method for precisely positioning front-layer defects

ActiveCN104198247ASolve the problem of difficult location of defects in the front layerSave defect location timePreparing sample for investigationMaterial analysis by measuring secondary emissionMicroscopic observationScanning tunneling microscope

The invention provides a focused ion beam sample preparation method for precisely positioning front-layer defects. The method comprises the following steps: carrying out online defect detection on a wafer to find out the defects and observing the specific features of the defects by using a scanning electron microscope or an optical microscope; if the scanning electron microscope cannot observe the defects or judge the reasons of the defects and the reasons of the defects cannot be judged according to the observation result of the optical microscope, firstly obtaining the microscopic observation result by using the optical microscope and then carrying our defect positioning by means of the microscopic observation result and the information of different layers of photo masks, obtained a wafer product design process.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

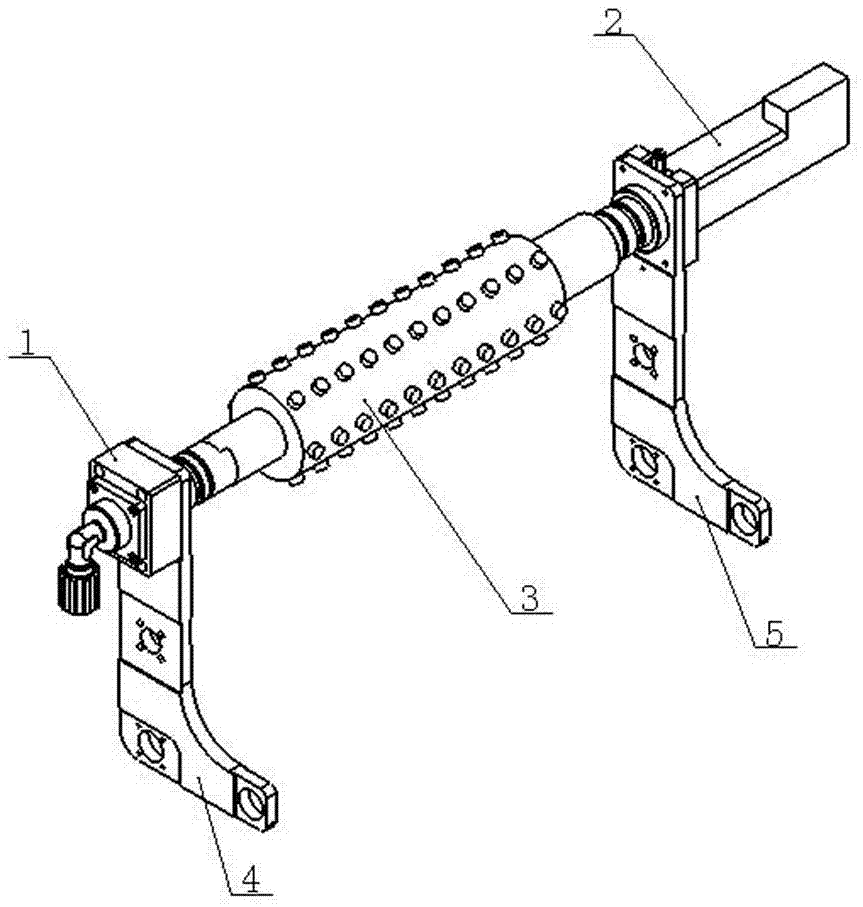

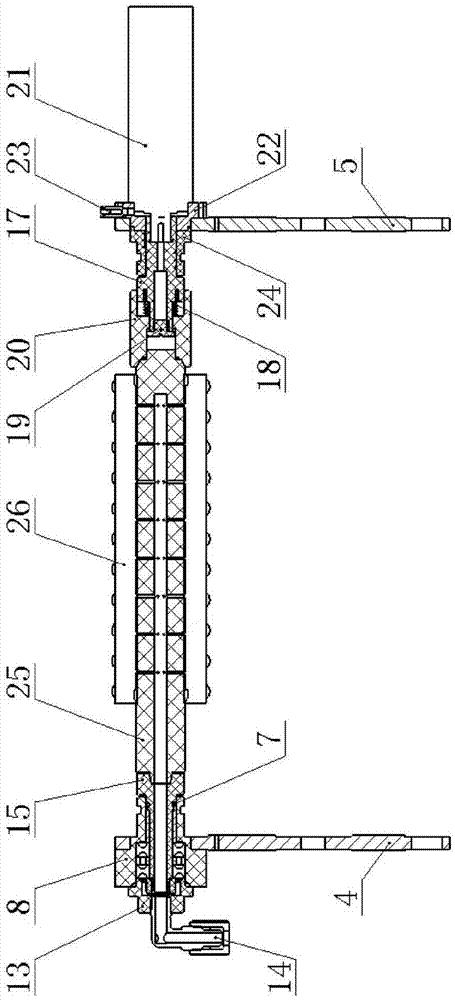

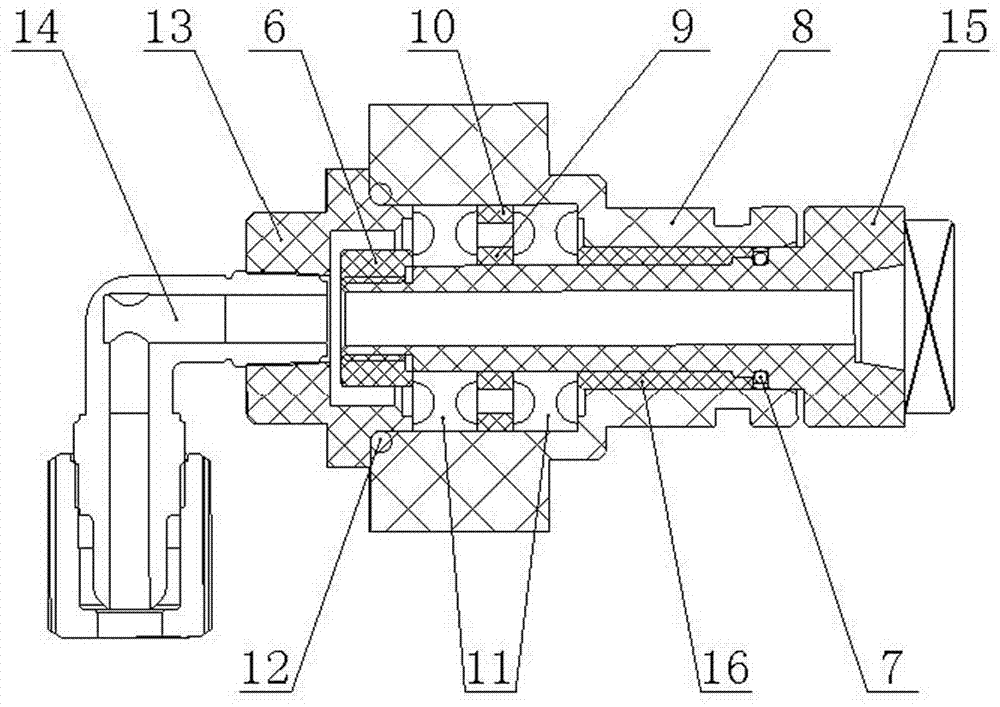

Roller brush unit concentric snapping structure for cleaning wafers

InactiveCN107275262AEliminate impact damageQuick releaseSemiconductor/solid-state device manufacturingCleaning using toolsDrive shaftWafer Product

The invention provides a roller brush unit concentric snapping structure for cleaning wafers. An elastic telescopic snapping structure is arranged on a driving unit for realizing quick snapping and changing. The roller brush unit concentric snapping structure reduces a non-coaxiality manufacturing tolerance between a driving shaft and an idle shaft. The rotating shaft and the driving shaft or the idle shaft of the roller brush utilize a structure form in which a conical hole and a conical shaft are connected in a flexible concentric positioning manner and a square hole and a square shaft are connected in a rigid engaging force transmission manner, thereby reducing a rigid connection degree and the rotating shaft, the driving shaft and the idle shaft of the roller brush, attenuating rotation bounce of the rotating shaft of the roller brush, and eliminating impact of roller brush bounce to a wafer. A glyd ring is arranged for realizing bidirectional sealing. Not only is bidirectional leakage of the idle shaft is settled, but also a function of supporting the idle shaft in concentric rotation is performed. The roller brush unit concentric snapping structure for cleaning the wafers is used for a cleaning system after chemically mechanical polishing (CMP) of the wafer, thereby preventing impact damage of the wafer by the roller brush, improving wafer product quality, reducing sealing gasket changing frequency and prolonging maintenance period of the cleaning equipment.

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

Tube core chip mounting method for ultrathin wafer process

ActiveCN102237286AHigh mechanical strengthImprove yield rateSemiconductor/solid-state device manufacturingSilver pasteBonding process

The invention discloses a tube core chip mounting method for an ultrathin wafer process. The method is characterized by comprising the following steps of: providing a wafer and forming an integrated circuit on the front of the wafer; providing a bonding layer; providing a supporting substrate and bonding the supporting substrate on the front of the wafer by using the bonding layer; thinning the back of the wafer; carrying out a back technique on the back of the wafer to form a device electrode; bonding the back of the wafer with the supporting substrate on a cutting film and cutting the wafer and the supporting substrate so as to form a plurality of wafer particles with supporting substrate particles; bonding the plurality of wafer particles on corresponding lead frames; stripping the supporting substrate particles from the wafer particles so as to complete the tube core chip mounting. According to the invention, since a supporting substrate is bound on the wafer and the wafer particles with the supporting substrate are all placed on the lead frames, the mechanical strength of the wafer product can be enhanced, and the electrical property of a circuit on the wafer can be prevented from being affected by conductive silver paste in the chip mounting and bonding process.

Owner:重庆万国半导体科技有限公司

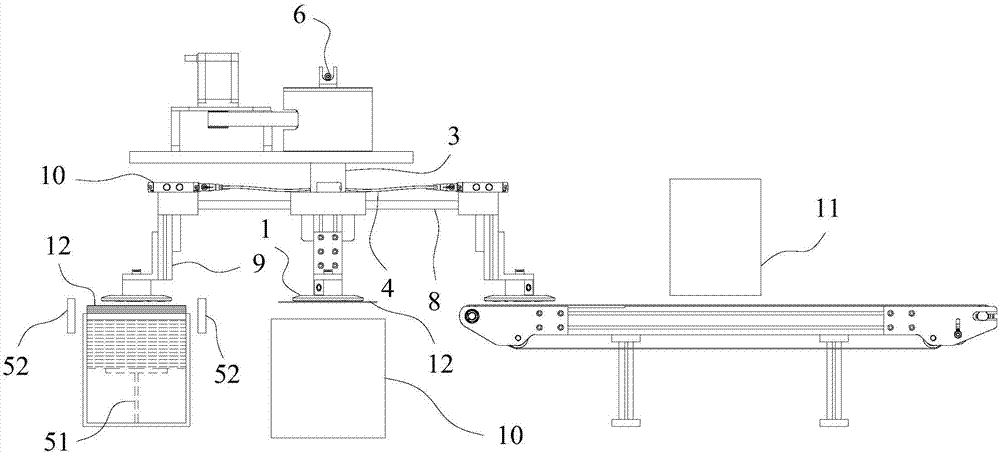

Automatic feeding and discharging mechanism for wafer product electroplating hanger

PendingCN113249774AFlexible operationFlexible controlCellsSemiconductor devicesStructural engineeringMechanical engineering

The invention discloses an automatic feeding and discharging mechanism for a wafer product electroplating hanger. The automatic feeding and discharging mechanism comprises a Y-direction hanger socket, an electroplating hanger, an X-direction sliding assembly, a P-axis overturning driving assembly, an overturning supporting assembly and a feeding and discharging suction cup assembly. The electroplating hanger is inserted into the Y-direction hanger socket, and at least one side surface of the electroplating hanger is provided with a trough; and the P-axis overturning driving assembly is located on the trough side of the electroplating hanger and is driven by the X-direction sliding assembly to be close to or away from the electroplating hanger in the X-direction. The feeding and discharging suction cup assembly is connected to the P-axis overturning driving assembly through the overturning supporting assembly, and when the P-axis overturning driving assembly drives the overturning supporting assembly to overturn along the P-axis and move in the X-direction, the feeding and discharging suction cup assembly can be driven to be aligned with the trough to complete feeding or discharging of wafer type products. Automatic feeding and discharging operation of products can be achieved, equipment operation and control are more flexible, and efficiency is high.

Owner:厦门柔性电子研究院有限公司 +1

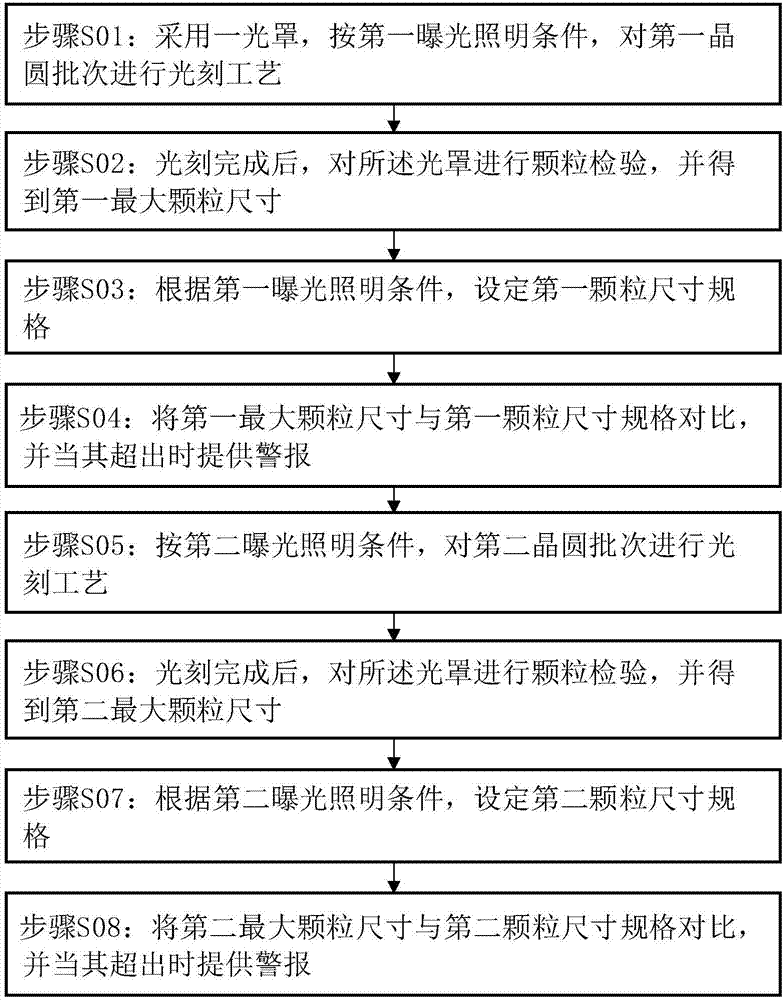

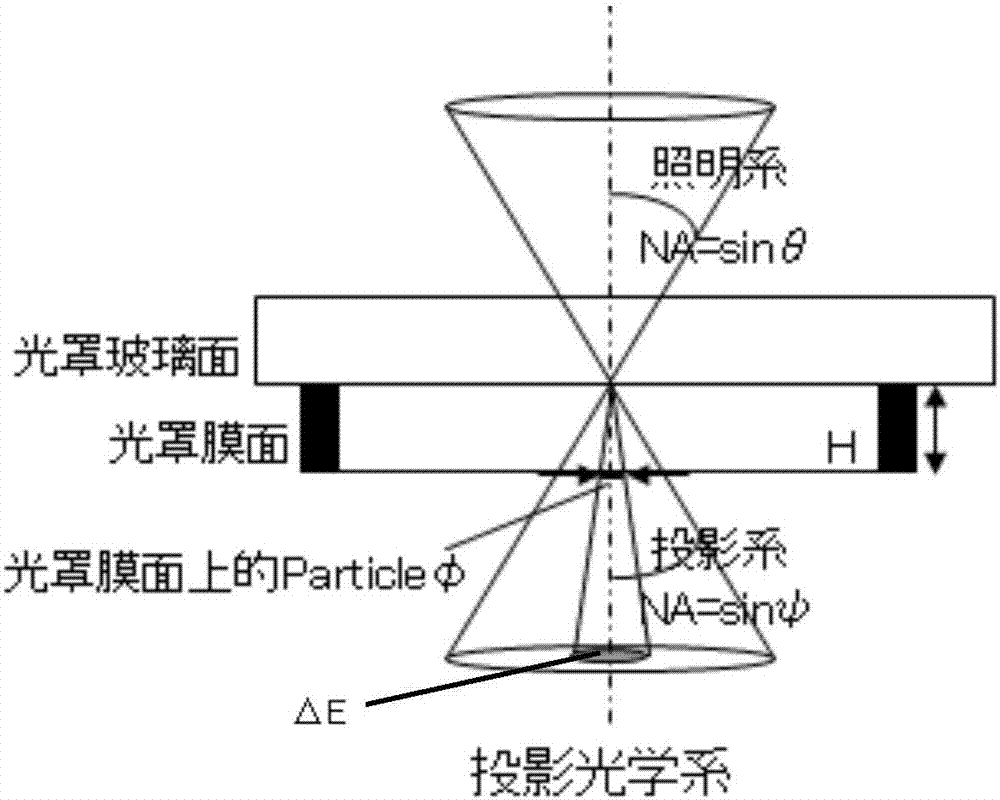

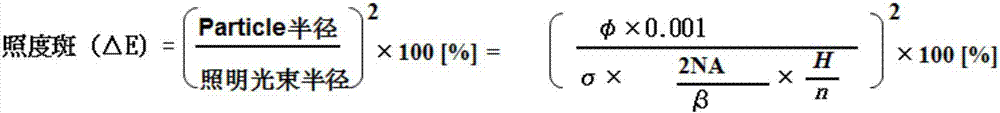

Photomask particle size assessment method

ActiveCN106933062AReduce unnecessary reworkLow costPhotomechanical exposure apparatusMicrolithography exposure apparatusComputational physicsWafer Product

The invention discloses a photomask particle size assessment method. After a photomask is subjected to particle detection in each time, corresponding particle size specification is set according to the current exposure illumination condition; the particle size specification is dynamically adjusted, and whether the photomask particle size exceeds standard or not is assessed based on the particle size specification, so that the problems of unnecessary rework and increasing of cost of wafer products caused by over tightness of the particle size specification can be obviously reduced; and a condition that the particle size affects the product in certain exposure conditions while the product is wrongly judged to be qualified can be avoided, so that risk of wrong outgoing of certain products can be prevented.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

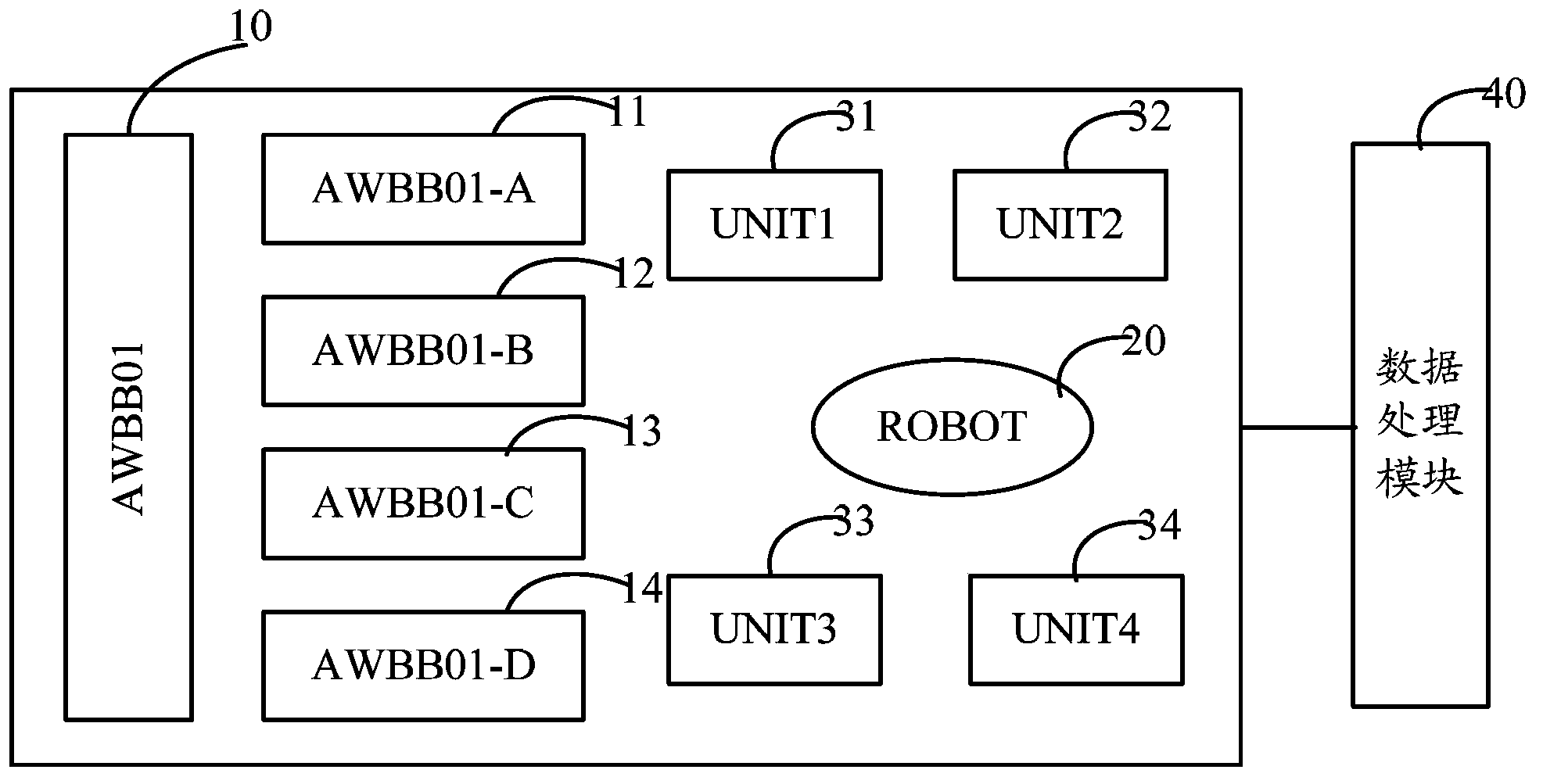

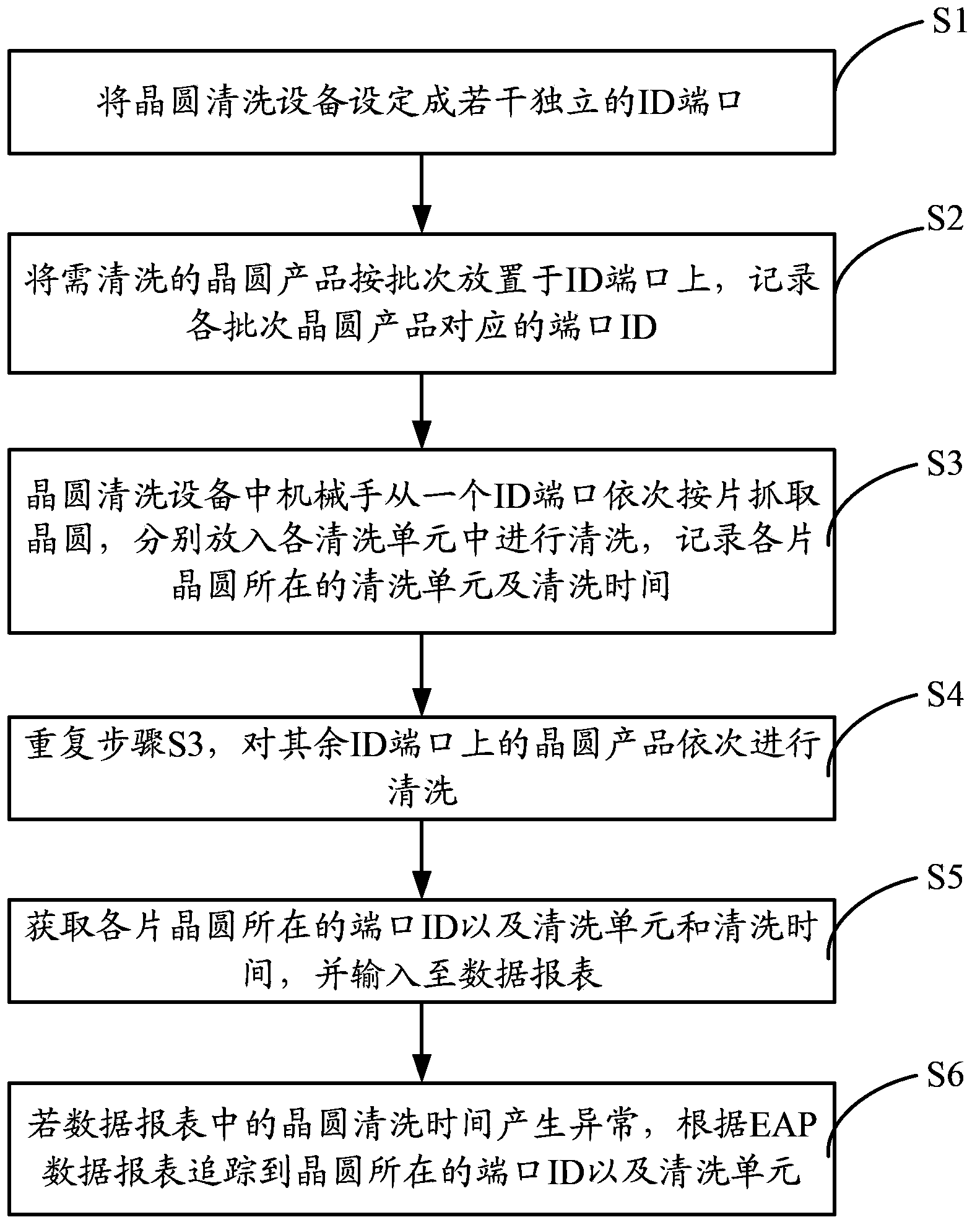

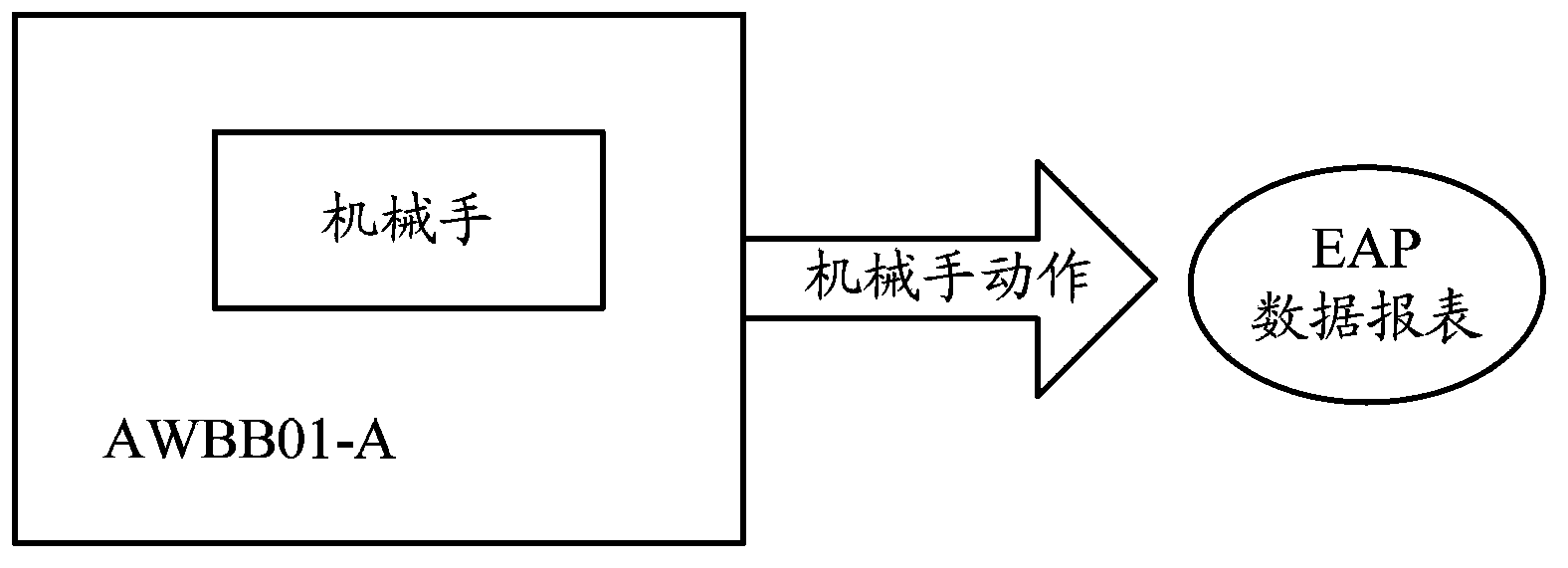

Wafer cleaning equipment-based product tracking method and system

InactiveCN103854963AAccurate queryImprove yieldSemiconductor/solid-state device manufacturingEngineeringManipulator

The invention discloses a wafer cleaning equipment-based product tracking method and system. The method comprises the steps that: wafer cleaning equipment is set into a plurality of independent ID ports; wafer products that need to be cleaned are placed by batch at the ID ports; a mechanical arm of the wafer cleaning equipment grabs the wafers by sheet successively from one ID port and the wafers are respectively placed into all cleaning units for cleaning; the wafer products at the rest of ID ports are successively cleaned; port IDs where all wafers are located as well as cleaning units and cleaning times are obtained and the information is inputted into a data report; and if the wafer cleaning time in the data report is abnormal, the port IDs where the wafers are located at and the cleaning units are tracked according to the data report. According to the invention, the machine is set into independent ID ports and the process as well as the state of the product of each ID port is recorded in real time. Therefore, when the process is abnormal or the equipment works abnormally, inquiring can be carried out timely and accurately and the abnormal product can be tracked, thereby improving the yield.

Owner:CSMC TECH FAB2 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com