Apparatus for the heat treatment of foodstuffs and feedstuffs, in particular for the production of bakery products

A thermal processing and equipment technology, applied in food ovens, high-frequency/infrared heating baking, forming/molding baked waffles, etc., can solve the problem of inability to increase the diameter of the cylinder, increase the weight, and poor quality of the baking process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

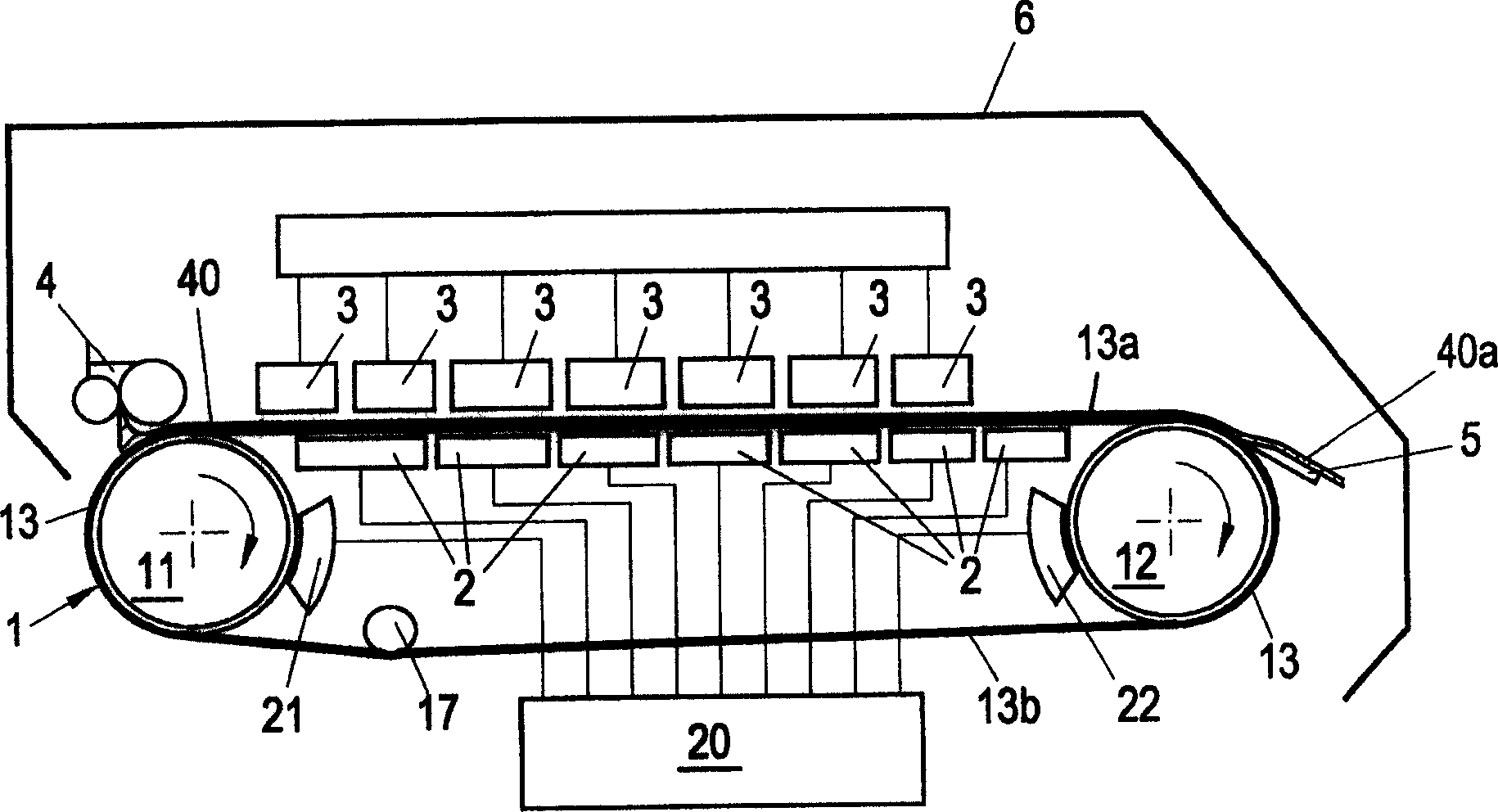

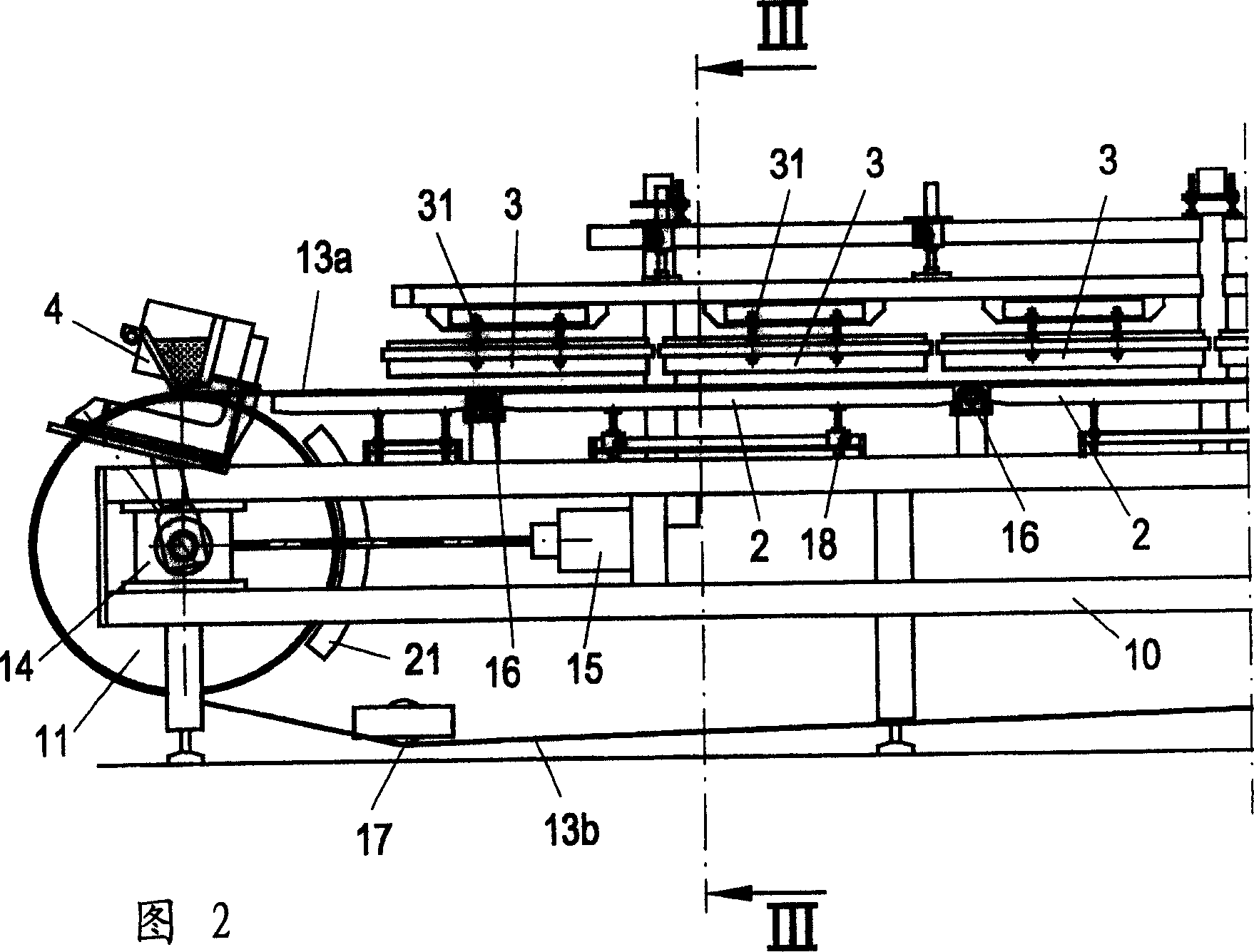

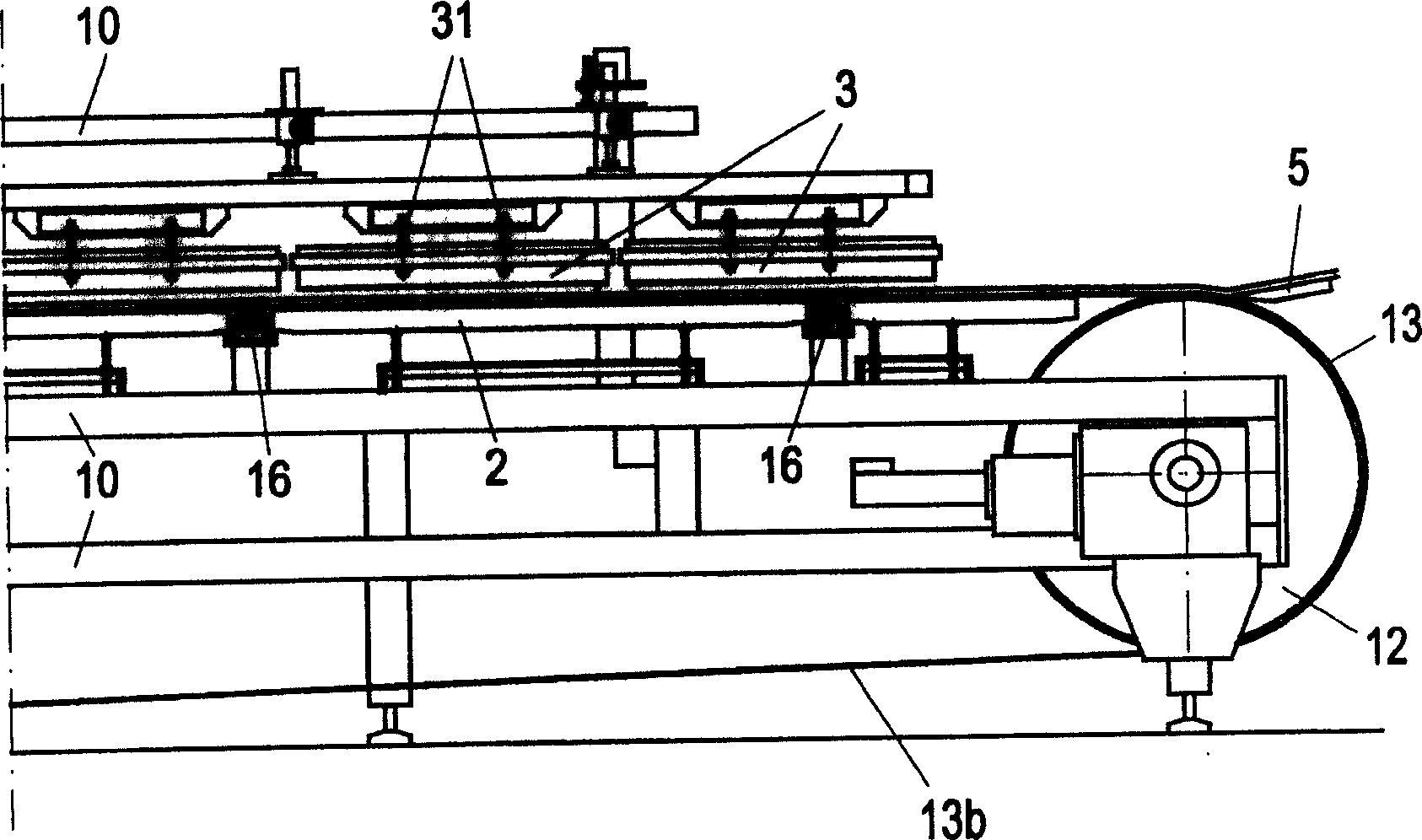

[0038] Referring now to the drawings shown in detail, first in particular figure 1 . This figure shows a novel plant with a conveyor 1 consisting of a conveyor belt 13 guided by two deflection rollers 11 and 12 . The conveyor belt 13 is made of ferromagnetic sheet metal, in particular steel. A set of induction heaters 2 is arranged below the upper run 13a of the conveyor belt 13 . The induction heater 2 is connected to a controllable power supply unit 20 . The induction heater 2 is located on the side of the conveyor belt 13 facing away from the side where the baked products are placed. A set of infrared heaters 3 is arranged above the upper run 13a of the conveyor belt 13 . The IR heater 3 is located on that side of the baked product. The placing device 4 (ie, the feeding device 4 ) is arranged at the left end of the conveying device 1 , and the removing device 5 (ie, the discharging device) is arranged at the right end of the conveying device 1 . The whole device is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com