Roller brush unit concentric snapping structure for cleaning wafers

A joint structure and rolling brush technology, which is applied in the field of concentric clamping structure of rolling brush units, can solve the problems of waste, poor sealing effect of O-ring, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

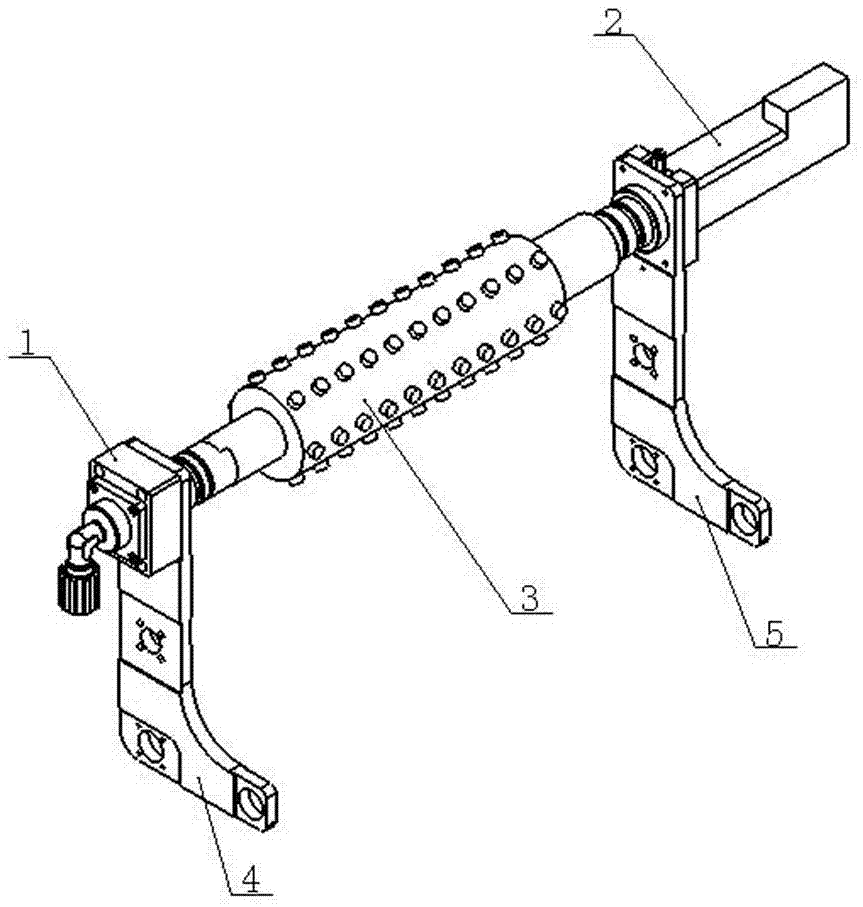

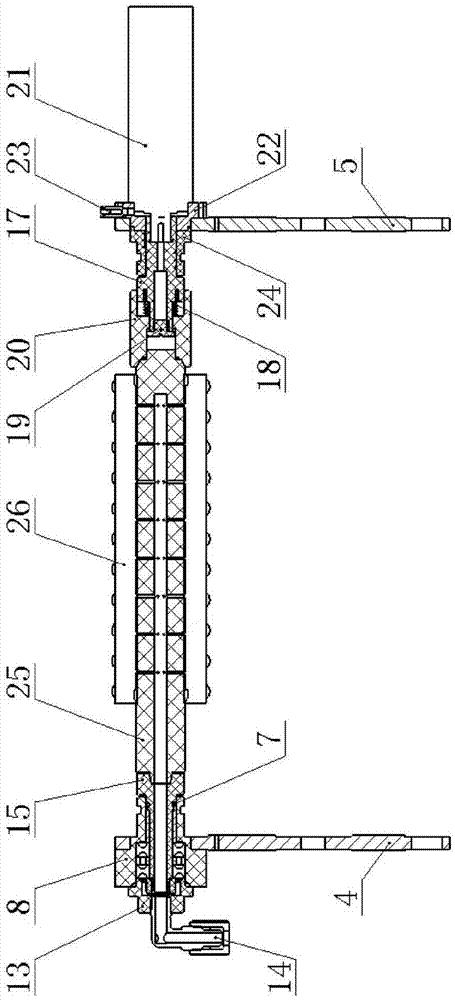

[0025] Such as figure 1 , figure 2 As shown, the concentric clamping structure of the rolling brush unit for cleaning wafers of the present invention includes a left swing frame 4, an inertia unit 1 fixed on the left swing frame 4, a right swing frame 5, a drive unit 2 fixed on the right swing frame 5, an inertia unit A roller brush unit 3 with a PVA roller brush 26 is clamped between the unit 1 and the drive unit 2 .

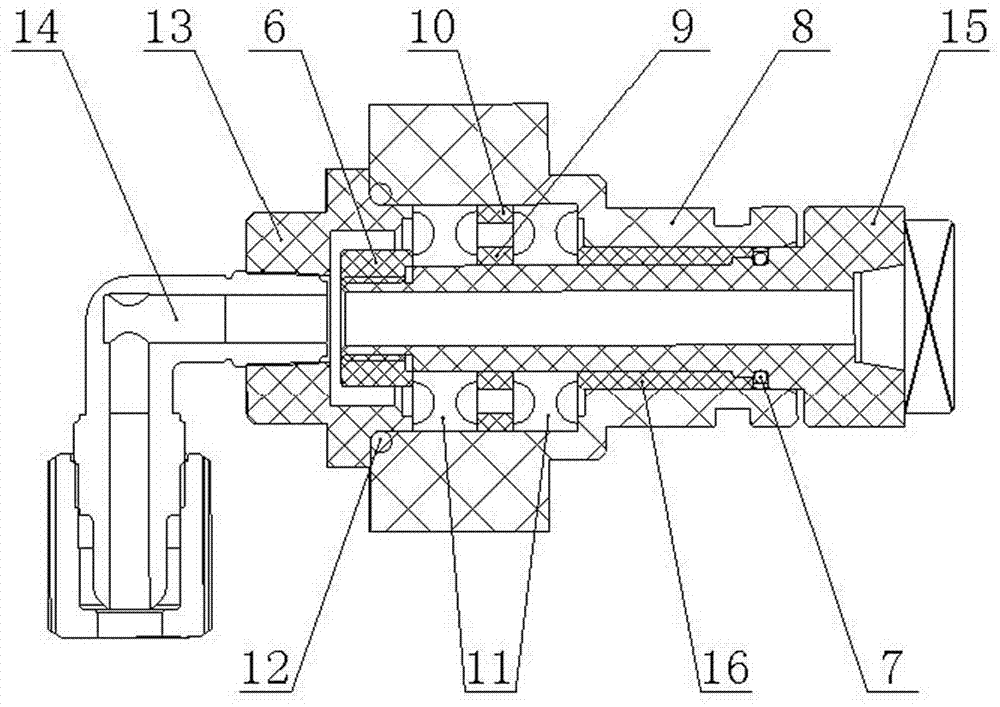

[0026] Such as figure 2 , image 3 , Figure 4 As shown, the inert unit 1 includes a mounting seat 8 whose central hole is a two-step round hole, and a bearing group composed of an inner spacer 9, an outer spacer 10 and a bearing 11 is installed in the large hole at the left end of the second-step round hole. A spacer 16 is installed in the small hole at the right end of the round hole. The spacer 16, the bearing 11 and the mounting seat 8 are jointly installed with a central hole as a water supply channel and a three-step idler shaft 15 on the outside. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com