Continuous drilling machine

A threaded connection and spindle technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of slipping and wear, reducing the service life of the drill bit, and small elastic deformation of the drill string.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

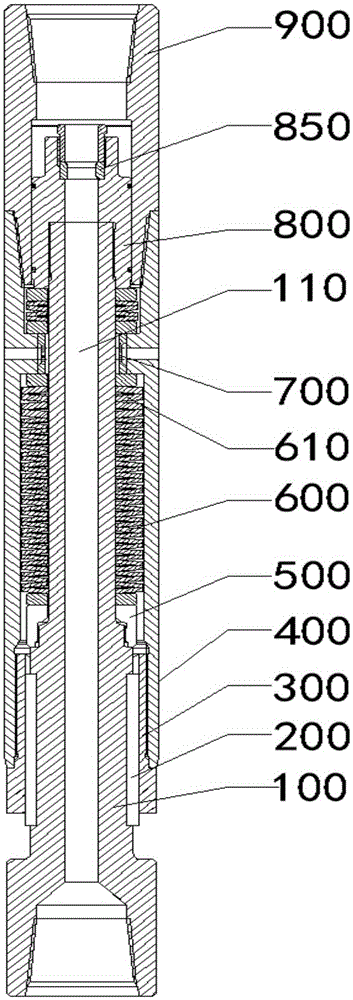

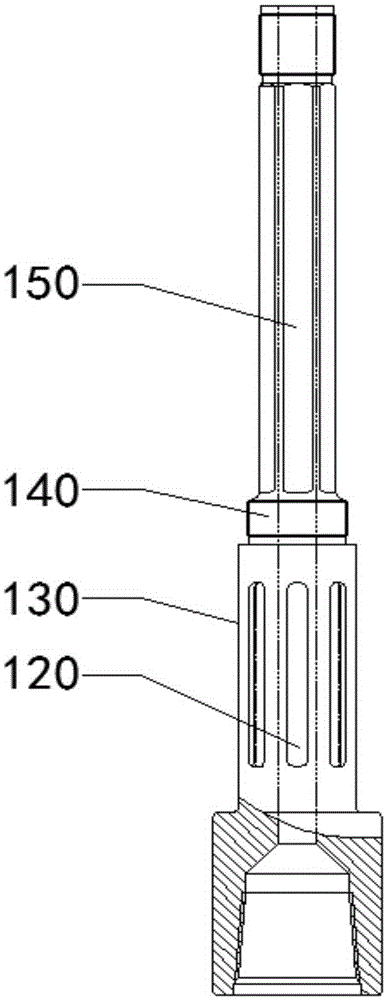

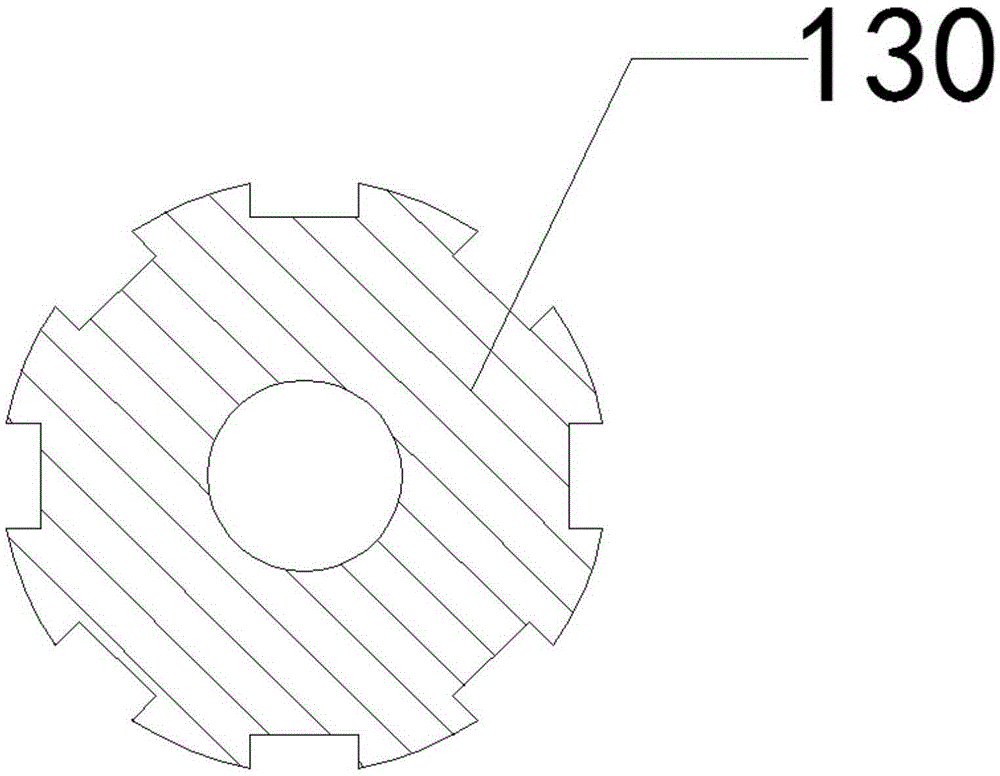

[0040] For the first embodiment, refer to Figure 1-8, the continuous drilling device includes a housing 400 and a main shaft 100, the bottom of the inner wall of the housing 400 is threaded with a first sliding sleeve 300, and a spline hole is arranged in the first sliding sleeve 300, and the spline hole The inner wall of the main shaft 100 is provided with a spline groove 120, and the outer wall of the main shaft 100 is provided with a plurality of key grooves 120, and the plurality of key grooves 120 are arranged at intervals along the circumferential direction of the main shaft 100, and the length direction of each key groove 120 is consistent with that of the main shaft 100. The length direction is the same, the keyway 120 is provided with a sliding key 200 matching the spline groove 120, the inner wall of the housing 400 is also provided with an annular boss, and the outer wall of the main shaft 100 is also provided with an anti-drop Nut 500, the outer diameter of the an...

no. 2 example

[0082] For the second embodiment, refer to Figure 9-10 , the implementation principle and technical effect of the device provided by the embodiment of the present invention are the same as those of the foregoing embodiment. For brief description, for the parts not mentioned in the device embodiment, reference may be made to the corresponding content in the foregoing embodiment.

[0083] In this embodiment, a pressure-assisting adjustment core 910 and an adjustment core mounting seat 920 for fixing the pressure-assisting adjustment core 910 are arranged in the installation cavity. into the inner hole of the pressure-assist adjusting sleeve 850, and the adjusting core mounting base 920 is detachably connected in the mounting cavity.

[0084] Wherein, the inner wall of the installation cavity is provided with a step surface, the bottom edge of the adjustment core mounting seat 920 is supported on the step surface, and the top is pressed against by a snap spring, thereby ensuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com