Wafer cleaning equipment-based product tracking method and system

A technology for product tracking and cleaning equipment, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as inability to process products, record and query the operation process and status of wafer products, and inability to track wafer products , to achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

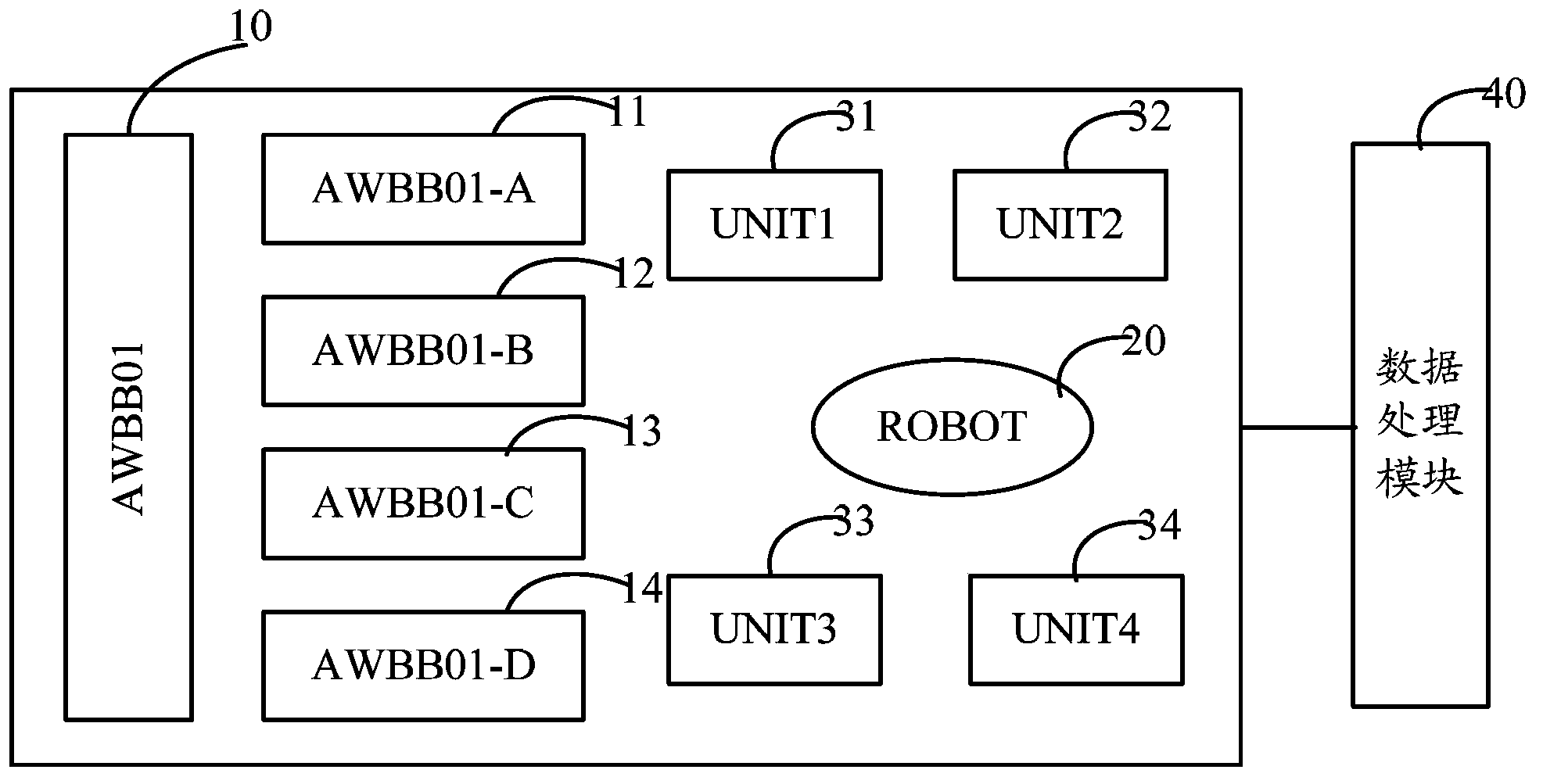

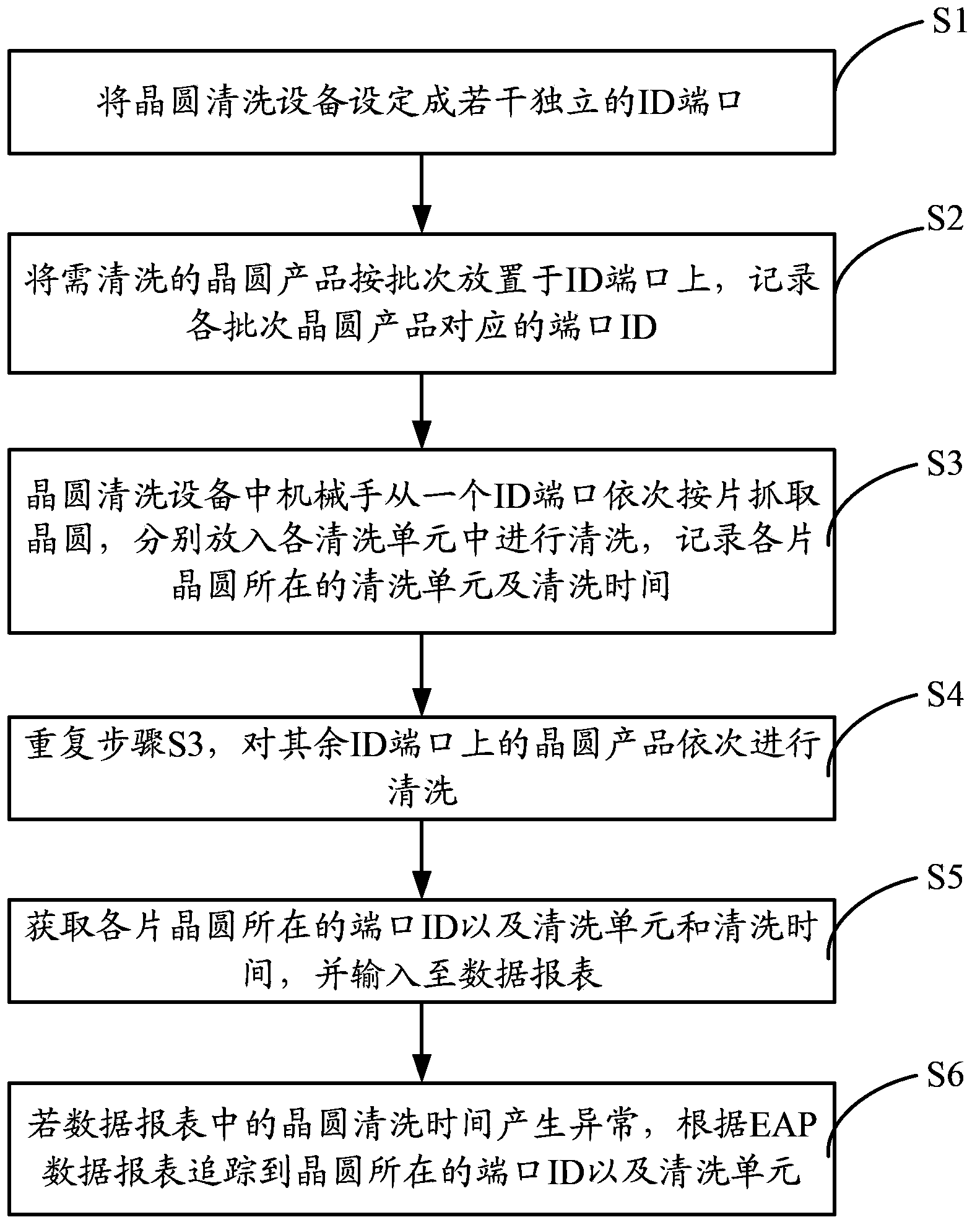

[0038] The invention discloses a product tracking method based on wafer cleaning equipment. The tracking method specifically includes:

[0039] S1. Set the wafer cleaning equipment to several independent ID ports;

[0040] S2. Place the wafer products to be cleaned on the ID port in batches, and record the port ID corresponding to each batch of wafer products;

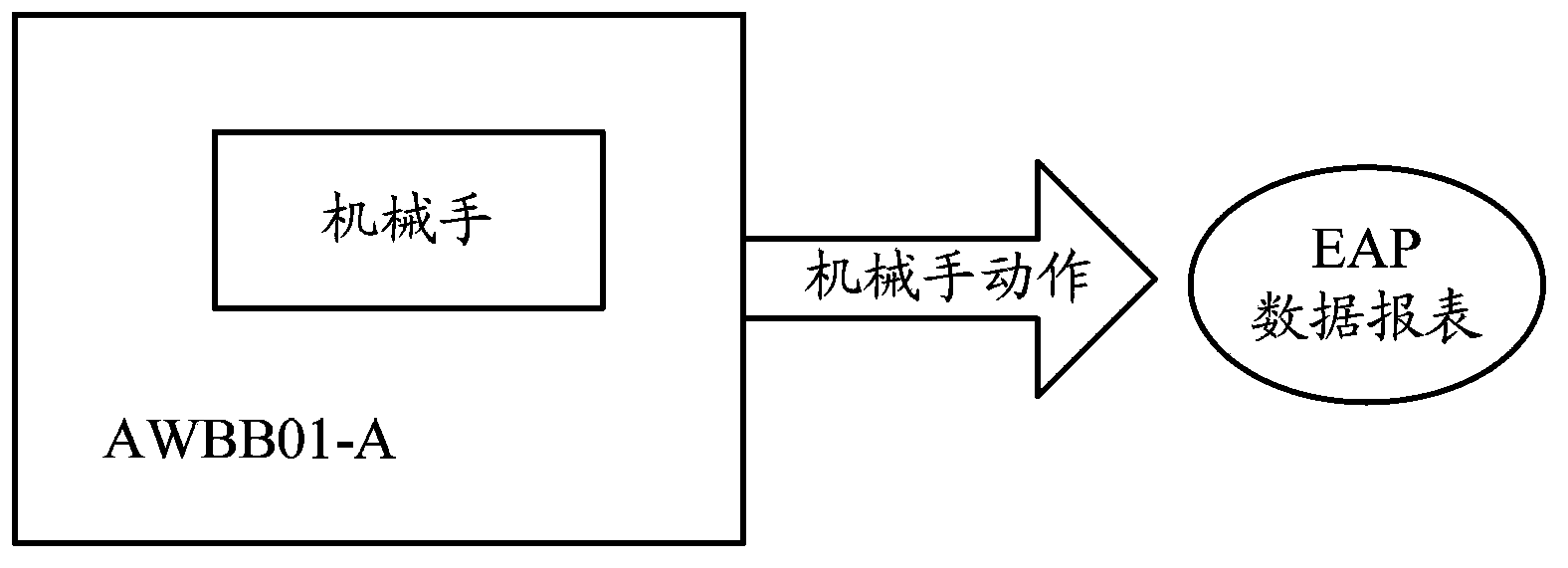

[0041] S3. The robotic arm in the wafer cleaning equipment sequentially grabs the wafers from an ID port, puts them into each cleaning unit for cleaning, and records the cleaning unit where each wafer is located and the cleaning time;

[0042] S4. Repeat step S3 to sequentially clean the wafer products on the remaining ID ports;

[0043] S5, obtain the port ID where each wafer is located, the cleaning unit and the cleaning time, and input them into the data report;

[0044] S6. If the wafer cleaning time in the data report is abnormal, track the port ID and cleaning unit where the wafer is located according to the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com