Solar silicon wafer surface defect detection device

A solar silicon wafer and defect detection technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of silicon wafer damage, large mechanical loss, and low long-term efficiency, so as to facilitate mechanical control and facilitate The effect of short control and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

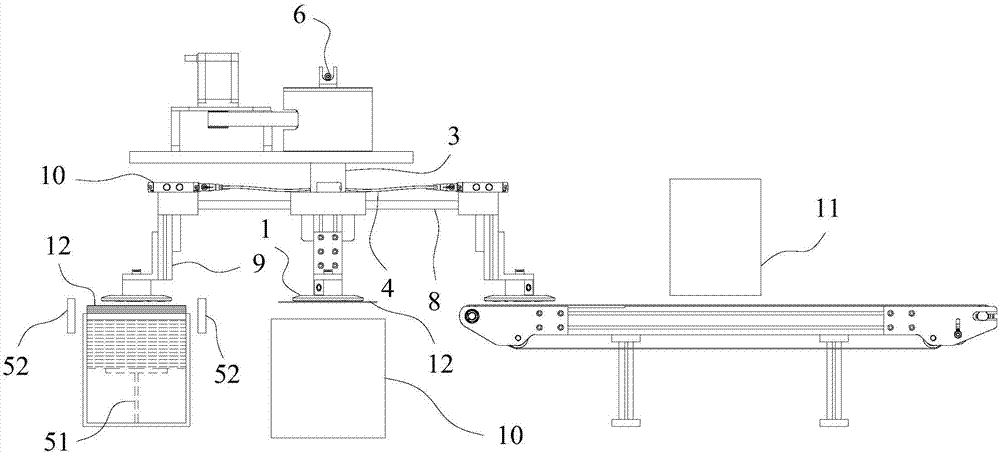

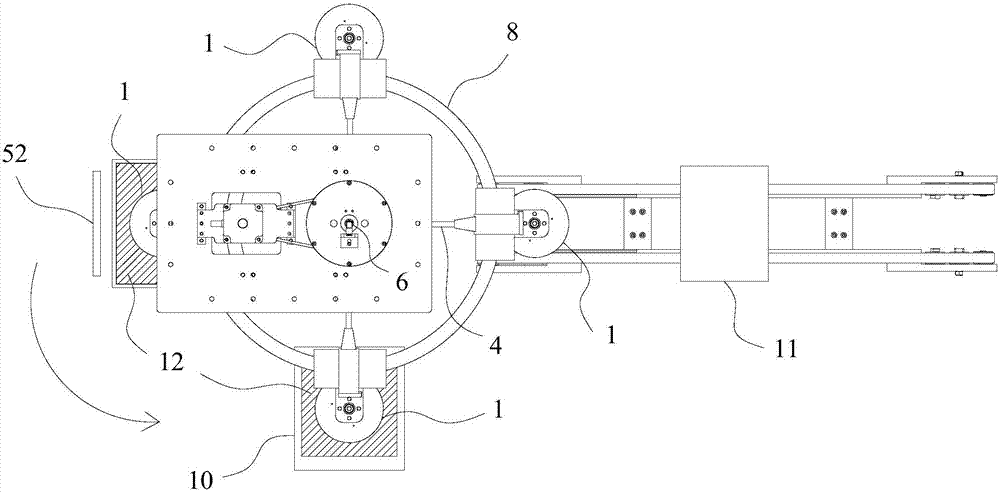

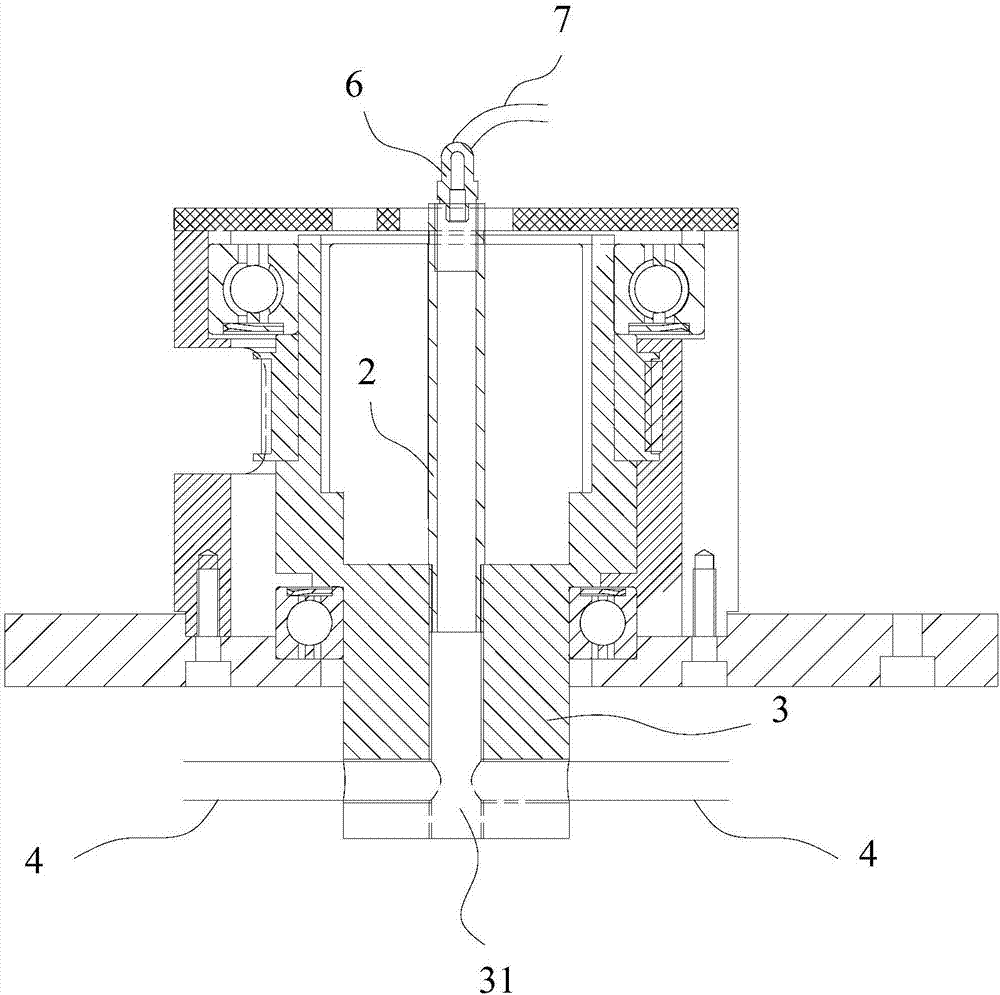

[0050] Such as Figure 1-3 , a surface defect detection device for solar silicon wafers according to the present invention, comprising a grabbing component, a circular track 8, a detection component, a gas distribution component, a display component, a feeding device, a feeding device, a drive system and a control system , the control system controls the driving system to drive the grabbing part, detection part, display part, feeding device and unloading device, the control system includes a processing module, and the grabbing part includes four suction cups 1, The gas distribution assembly includes an air guide tube 2 and a sleeve 3, the air guide tube 2 is a hollow copper tube, the sleeve 3 is provided with an inner hole 31, and the lower end of the air guide tube 2 is connected to the inner hole 31. The upper end of the air guide tube 2 is provided with an opening one, the opening one is connected to the air pipe two 7 through the rotary joint 6, the air pipe two 7 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com