Three-dimensional storage structure

A technology of three-dimensional storage and storage unit, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of wafer cracking, affecting the deposition and etching process, and large bending stress of the wafer, so as to achieve the effect of ensuring the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

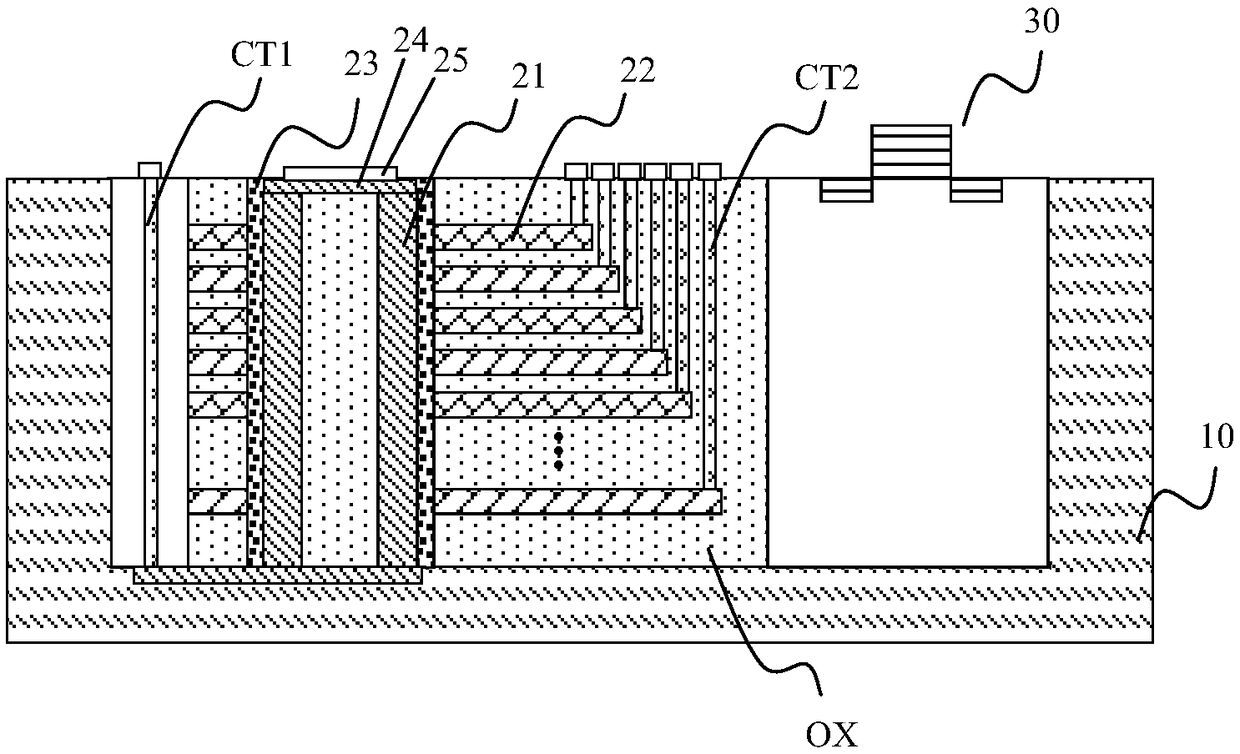

[0024] In a preferred embodiment, as figure 1 As shown, a three-dimensional memory structure is proposed, which may include a substrate 10; a plurality of grooves in an array are formed on the substrate 10; a memory cell structure is formed in each groove:

[0025] Each memory cell structure can include:

[0026] An annular and vertical columnar channel layer 21 for connecting a source and a drain;

[0027] a plurality of control gate layers 22 spaced from each other up and down, and each control gate layer 22 surrounds the columnar channel layer 21;

[0028] An annular and vertical columnar isolation layer 23, used to isolate the columnar channel layer 21 from each control gate layer 22;

[0029] Wherein, each memory cell structure is formed with a first contact hole CT1 for connecting the columnar channel layer 21 , and each second contact hole CT2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com