Patents

Literature

40results about How to "Avoid stress concentration situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

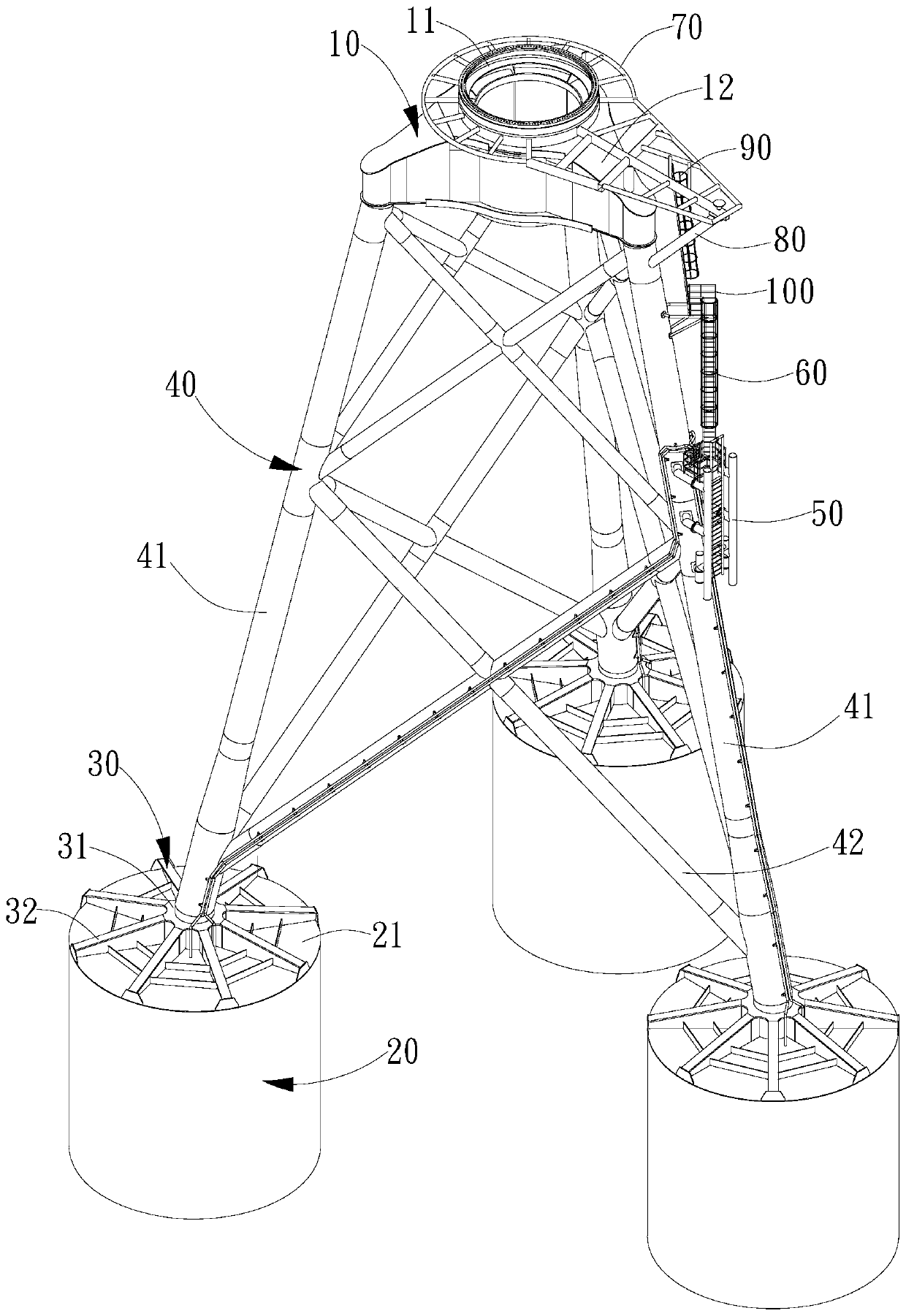

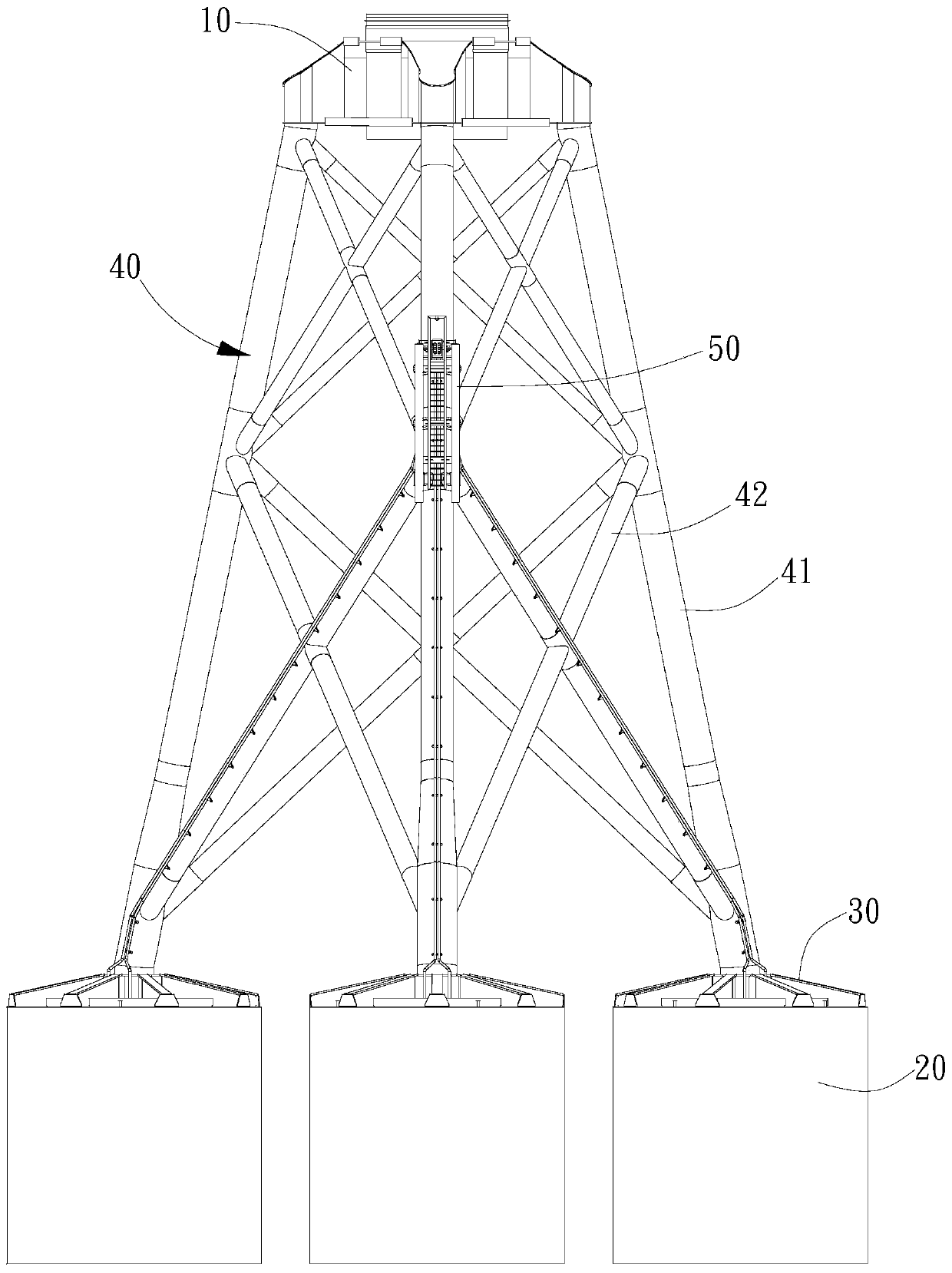

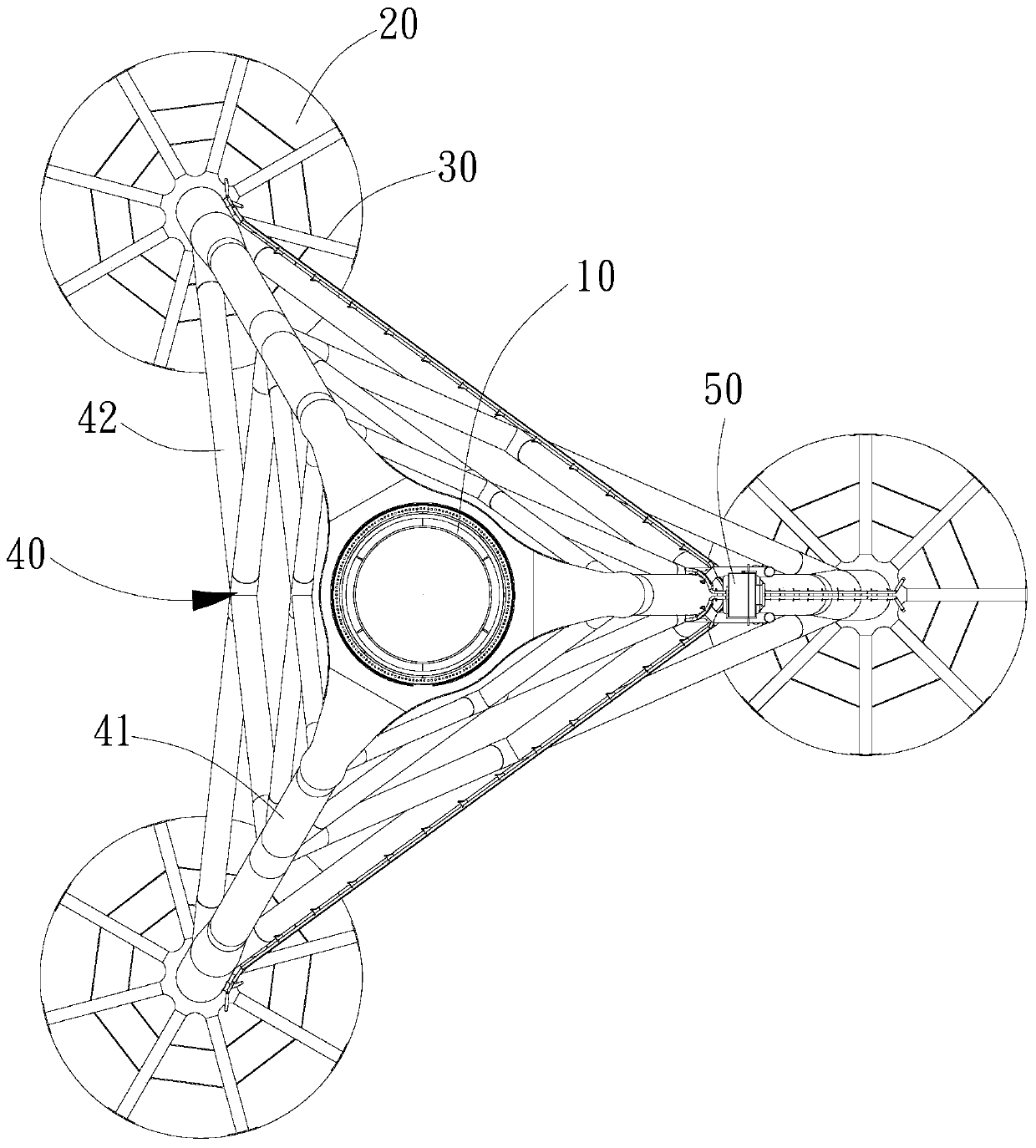

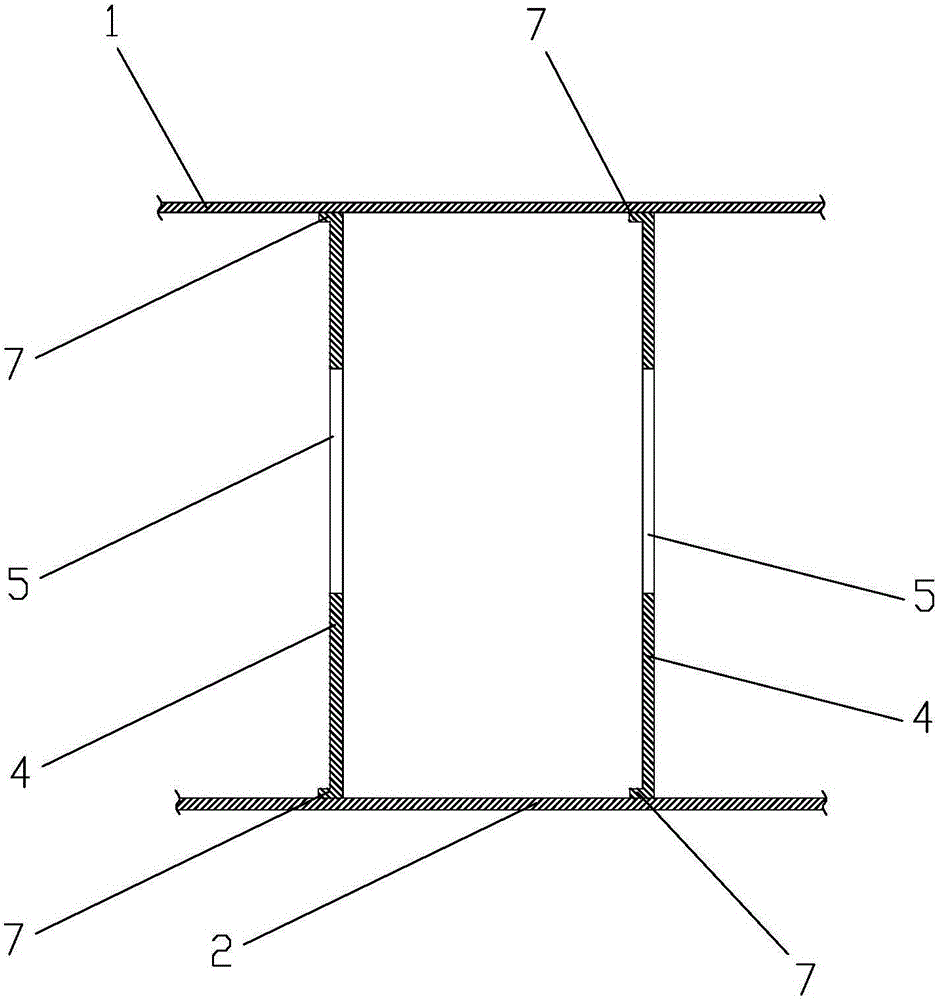

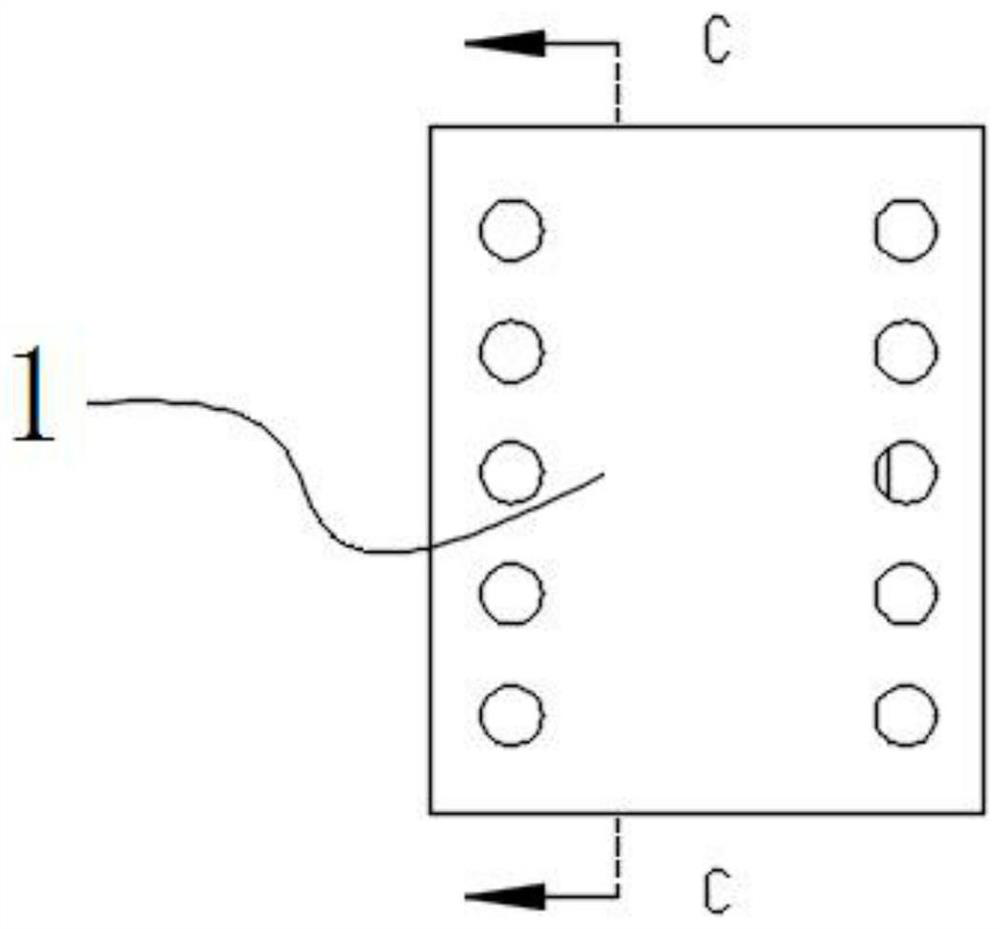

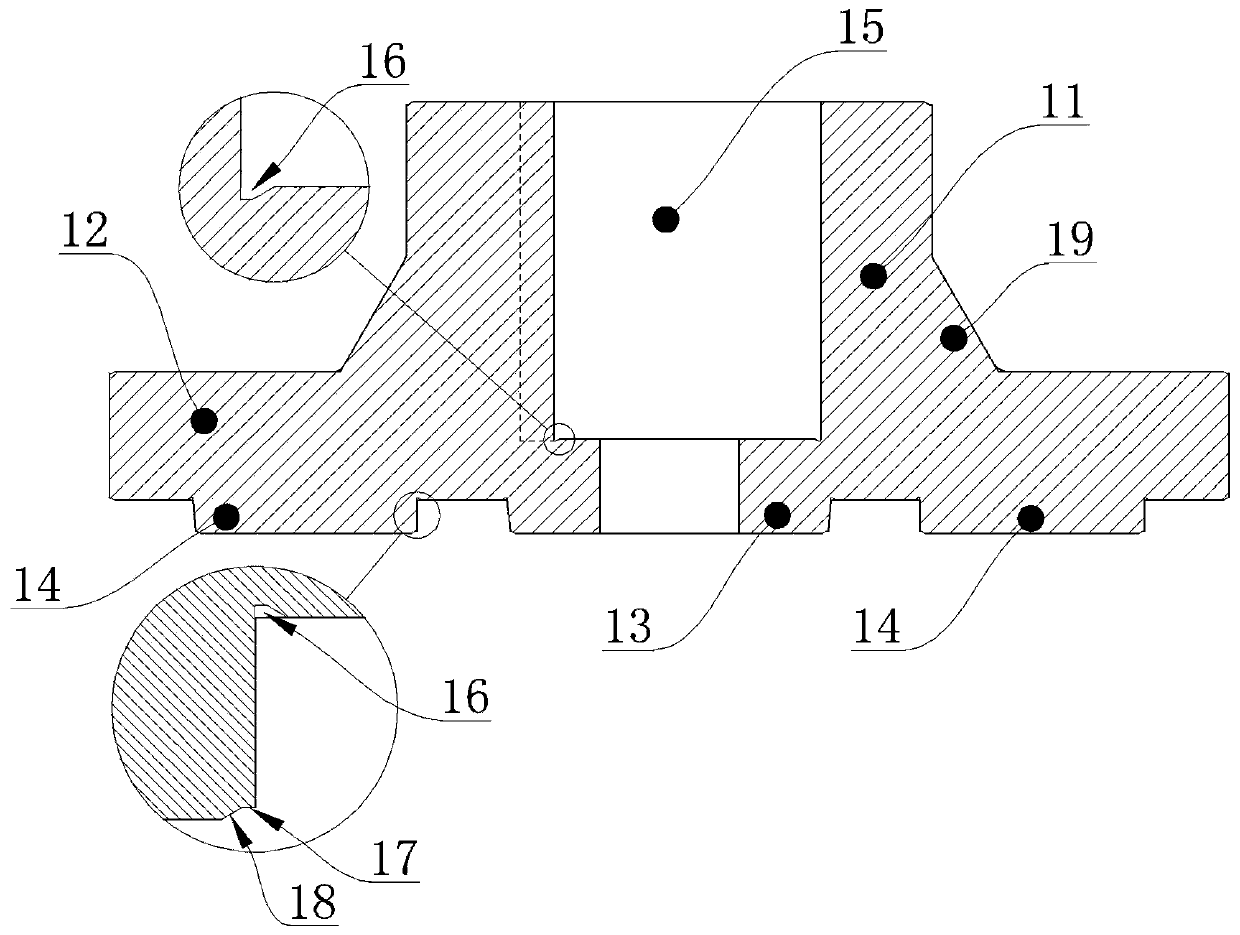

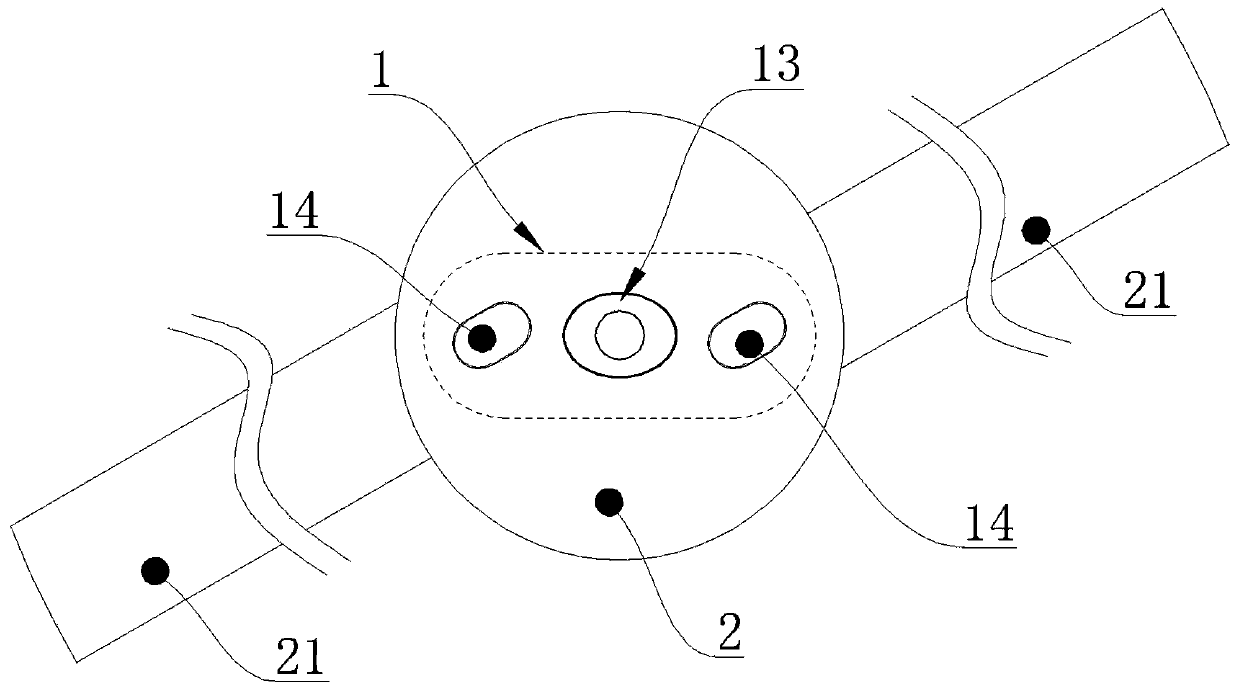

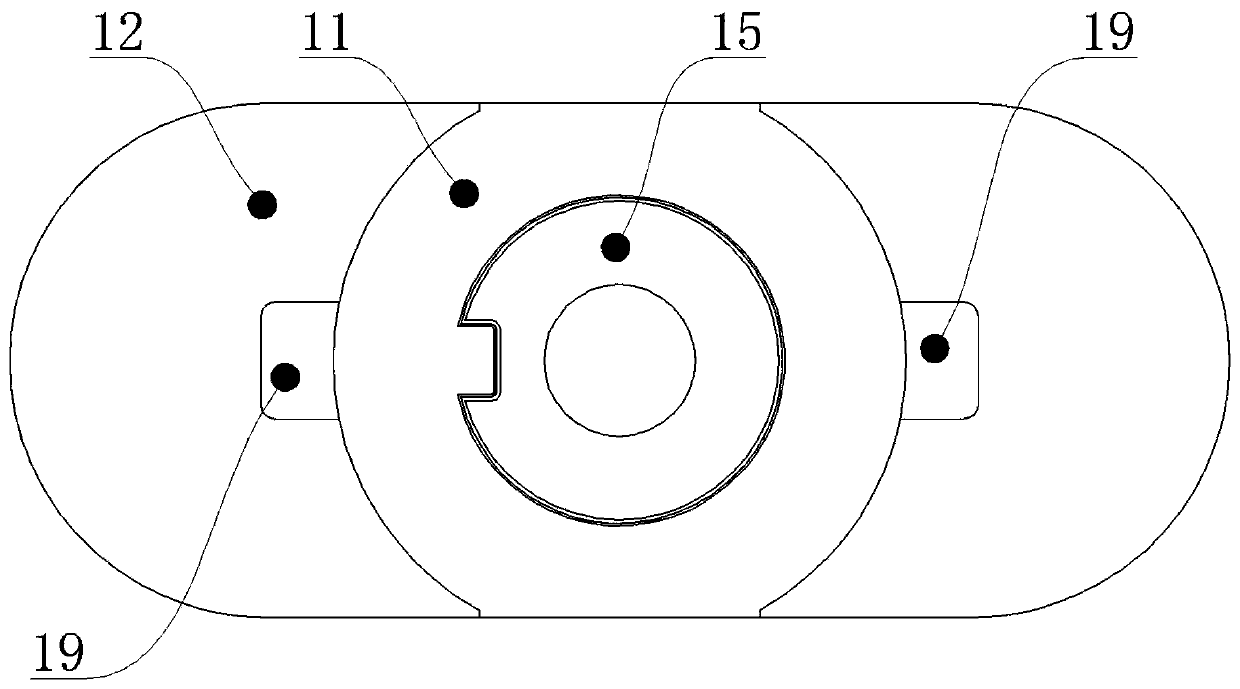

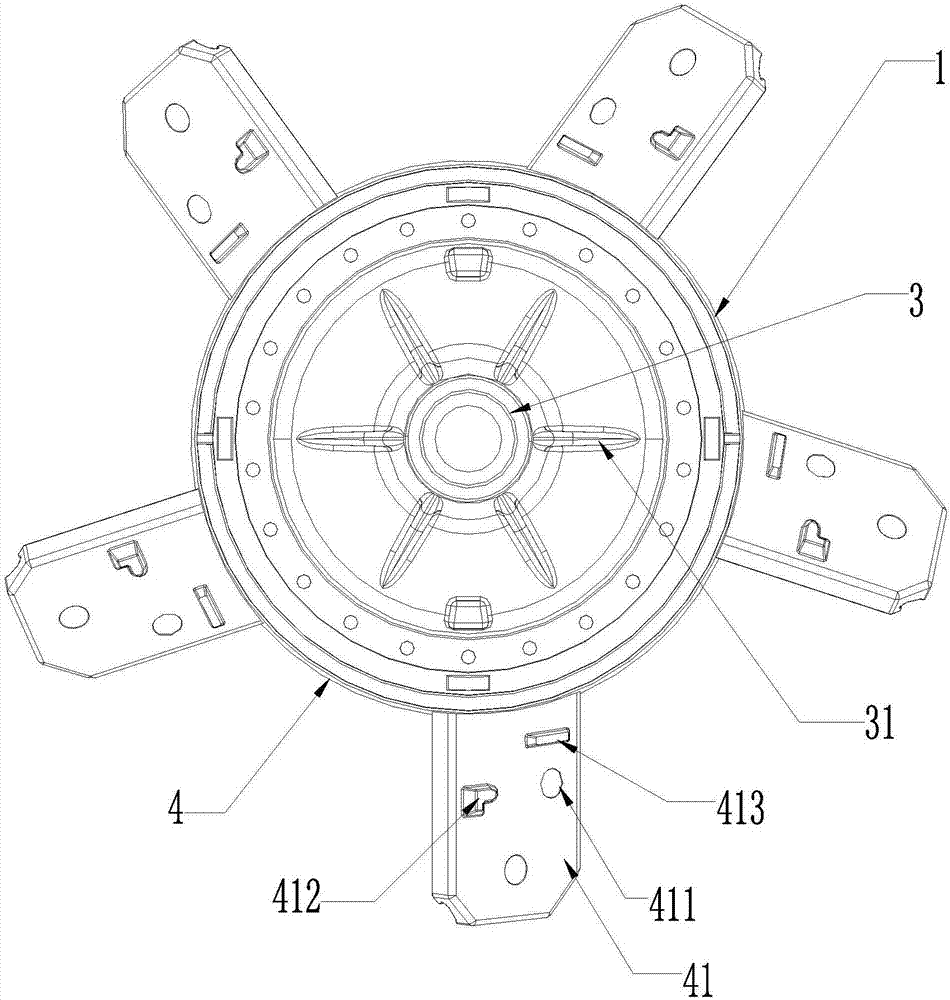

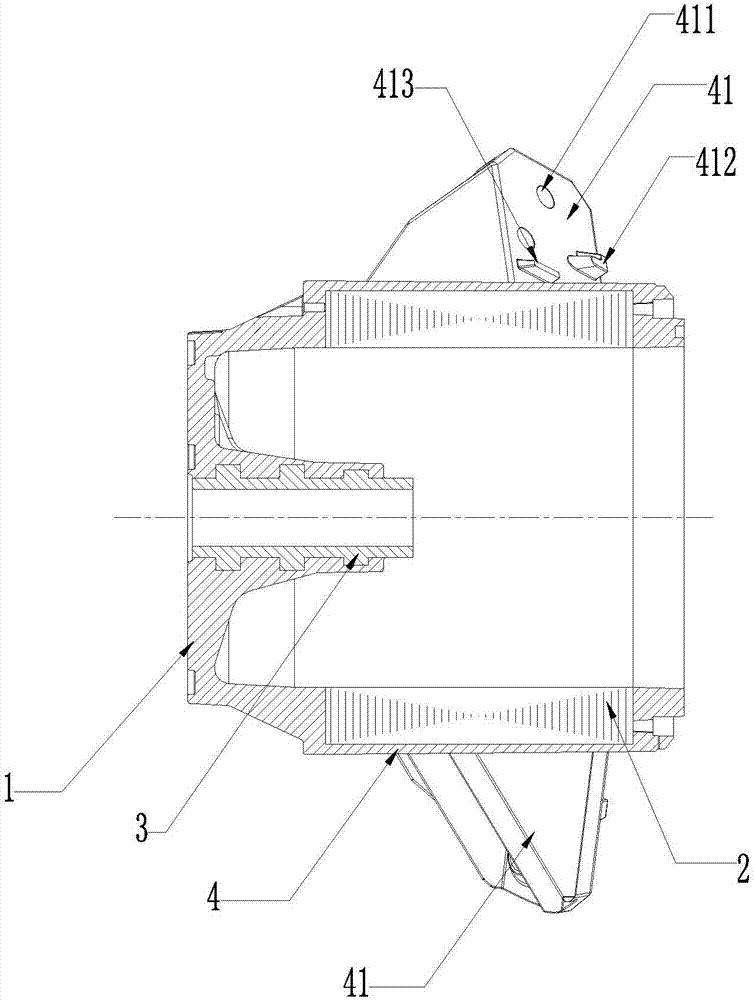

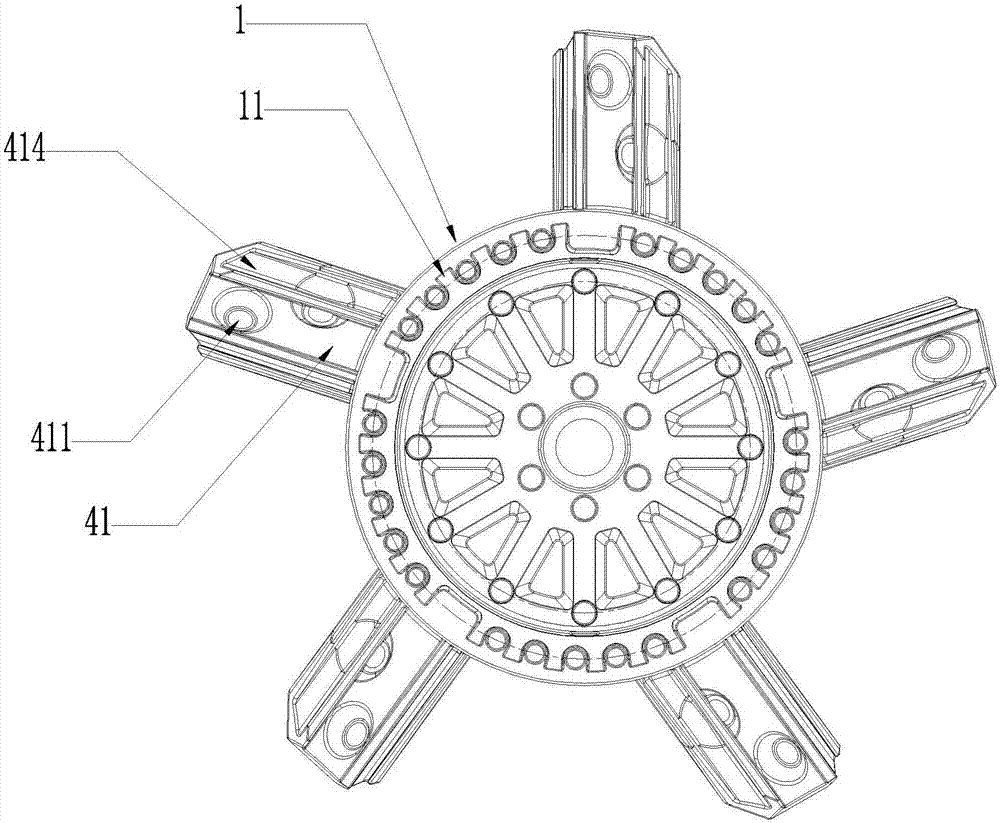

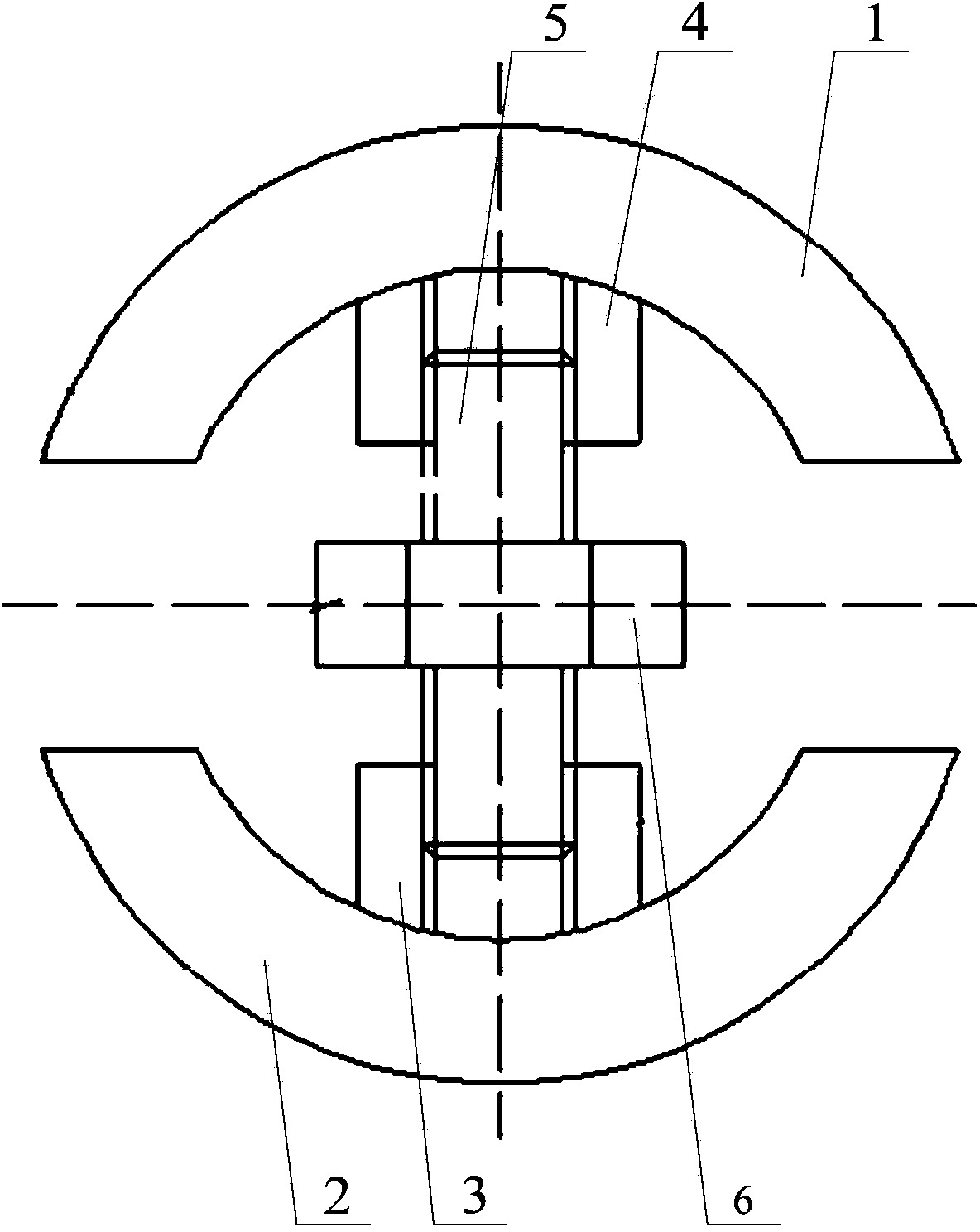

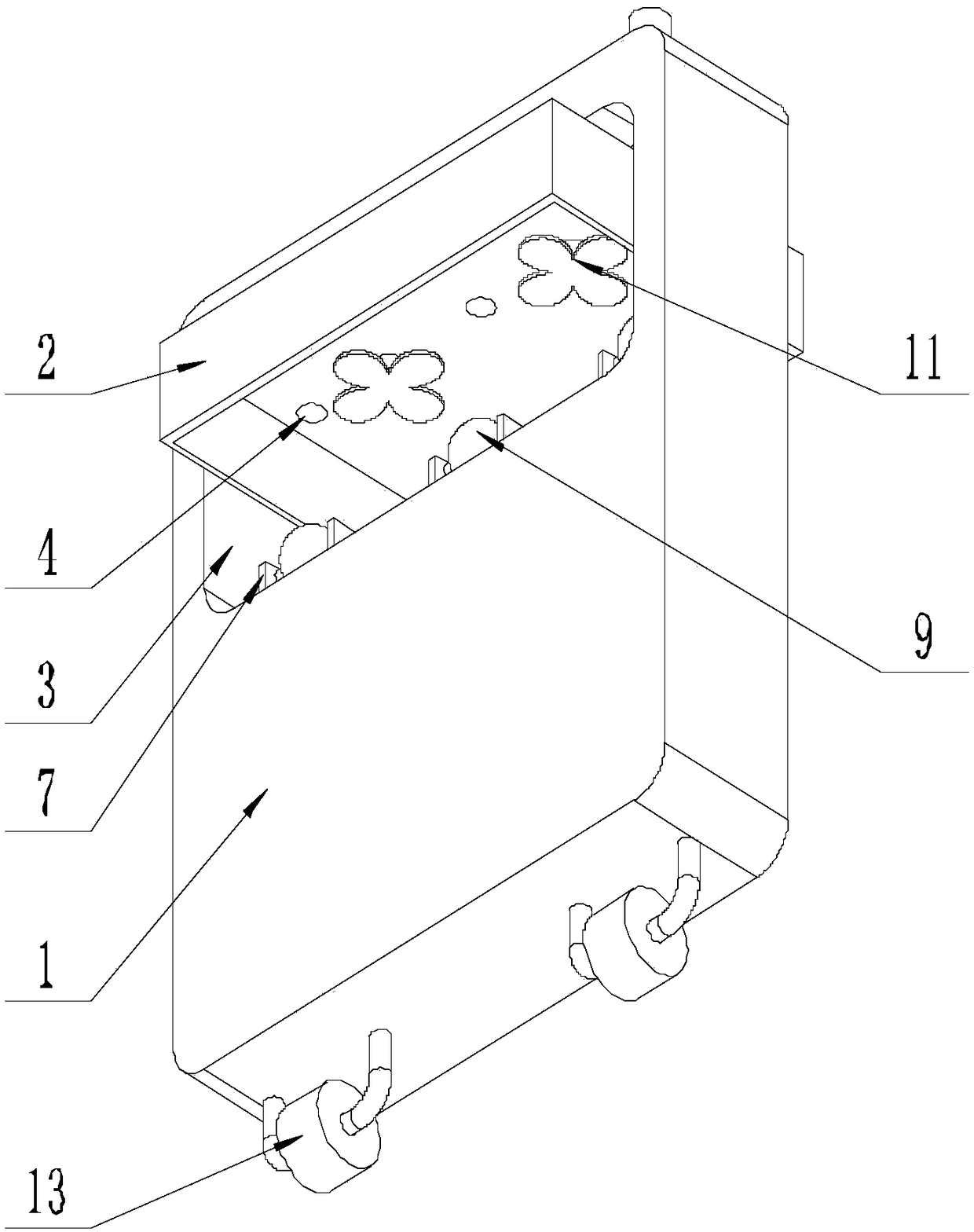

Novel multi-cylinder jacket offshore wind turbine foundation

ActiveCN111021392ANot easy to cause strengthNot easy to cause fatigue damageFoundation engineeringFatigue damageSuction force

The invention relates to a novel multi-cylinder jacket offshore wind turbine foundation which comprises an upper transition section; a plurality of suction cylinders which are arranged below the uppertransition section and are uniformly distributed by taking the upper transition section as the center, wherein the top of each suction cylinder is a cylinder top; a plurality of lower transition sections which are respectively arranged on the top of a plurality of suction cylinders, wherein each lower transition section comprises an annular plate and rib plates which are arranged on the cylindertop, a plurality of rib plates are evenly distributed around the annular plate, and one end of each rib plate is connected with the peripheral side of the annular plate; and a jacket which comprises aplurality of main legs, wherein the top ends of the main legs are connected with the upper transition section, and the bottom ends of the main legs are connected with the annular plates on the corresponding lower transition sections. The wind turbine is mounted on the upper transition section in use and the lower transition sections can effectively and uniformly transmit the load on the main legsof the jacket to the cylinder top area of the suction cylinders so that the cylinder top of the suction cylinders is effectively ensured to be uniformly stressed, the suction cylinder is not liable to be subjected to strength damage and fatigue damage, and the long-term safe and stable operation of the suction cylinder is facilitated.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

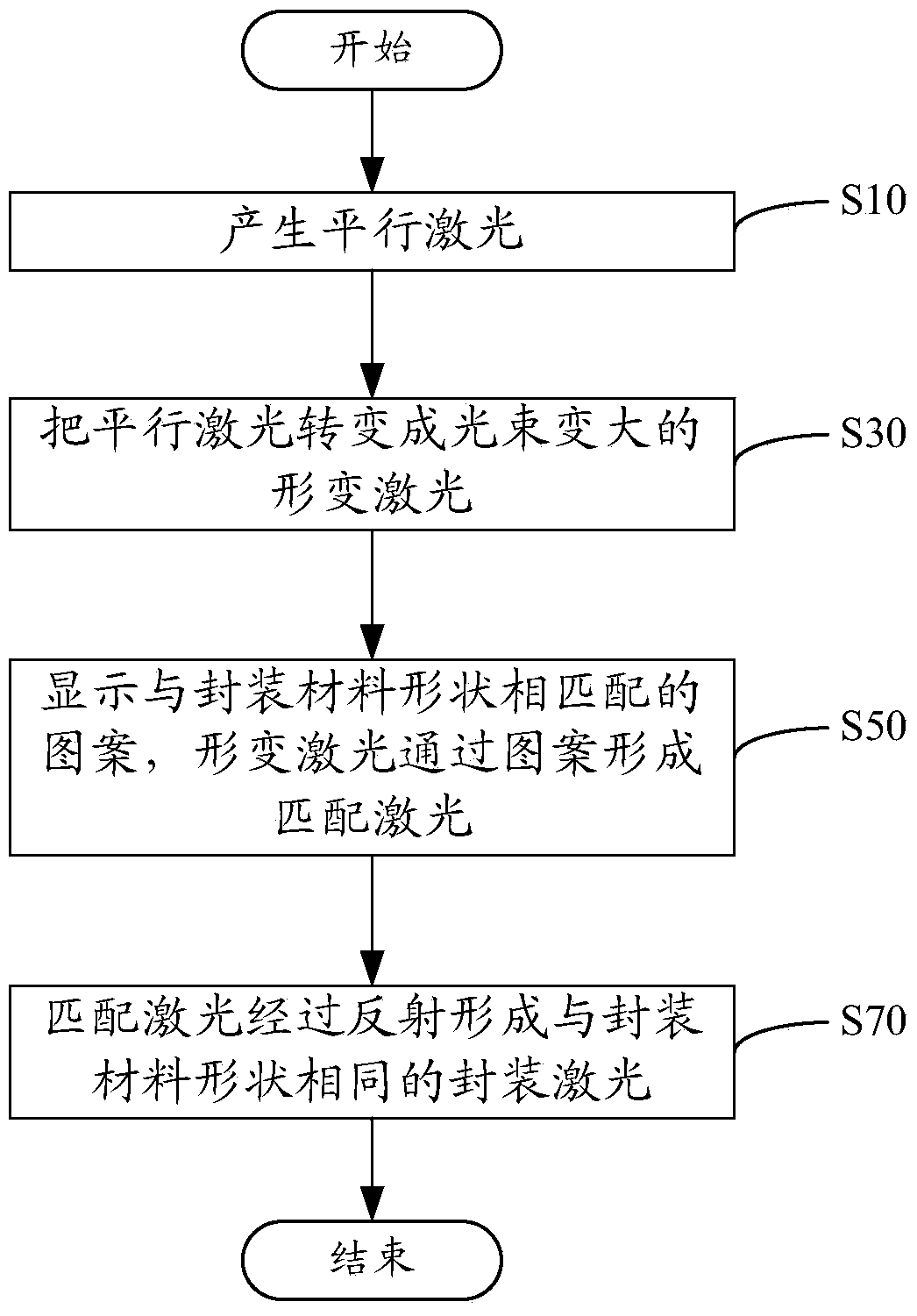

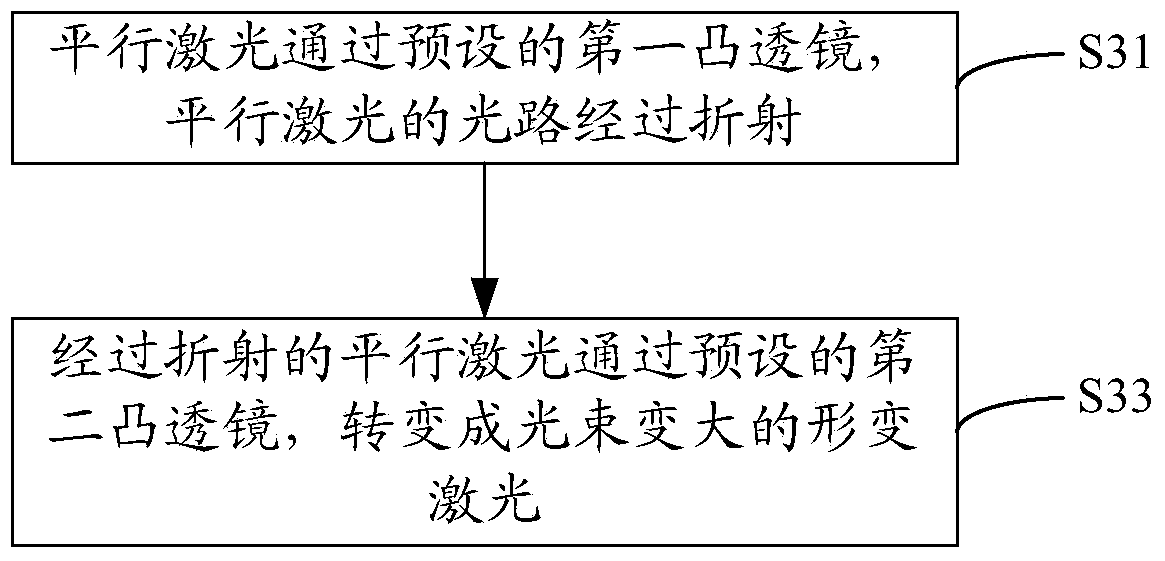

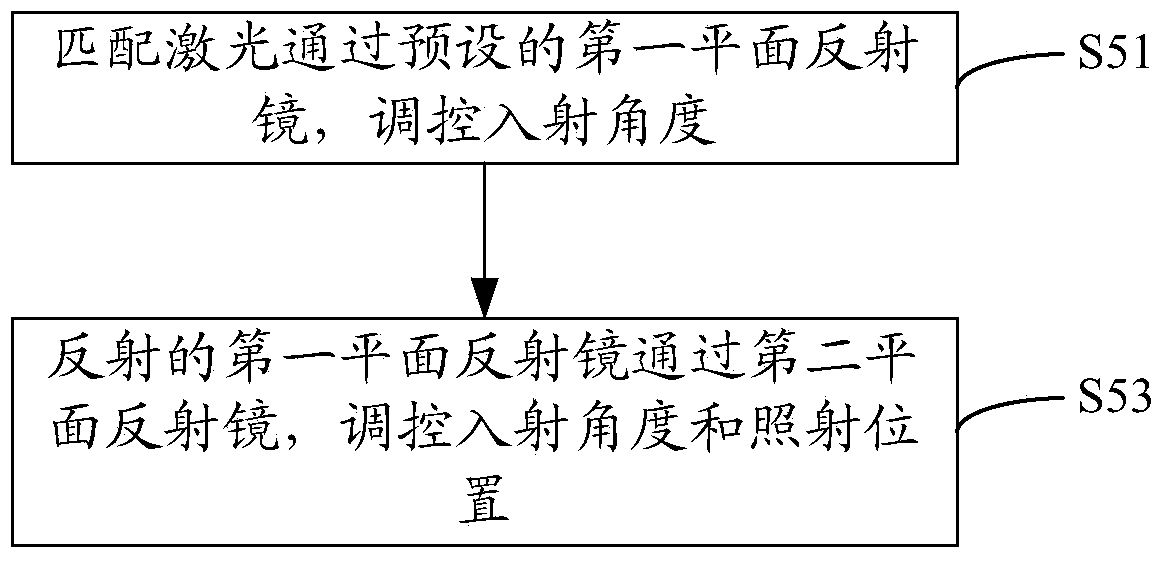

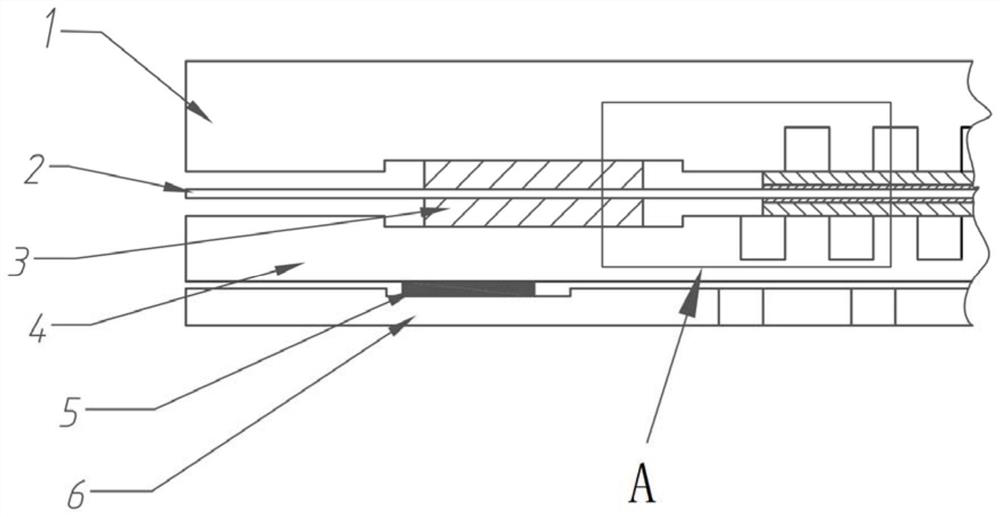

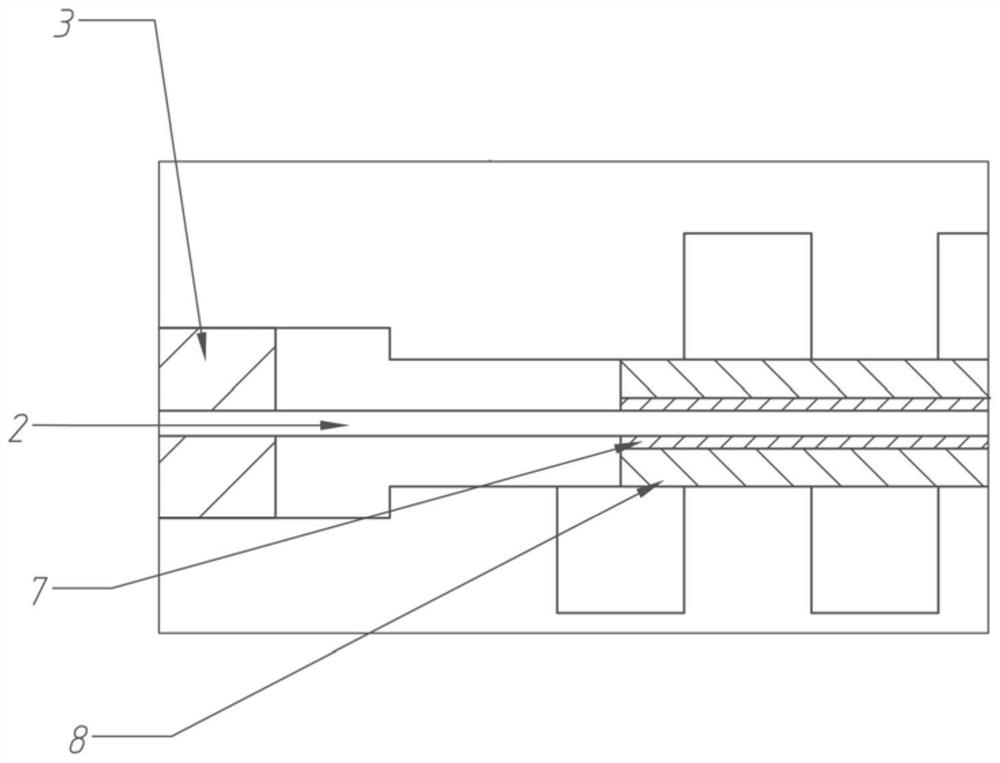

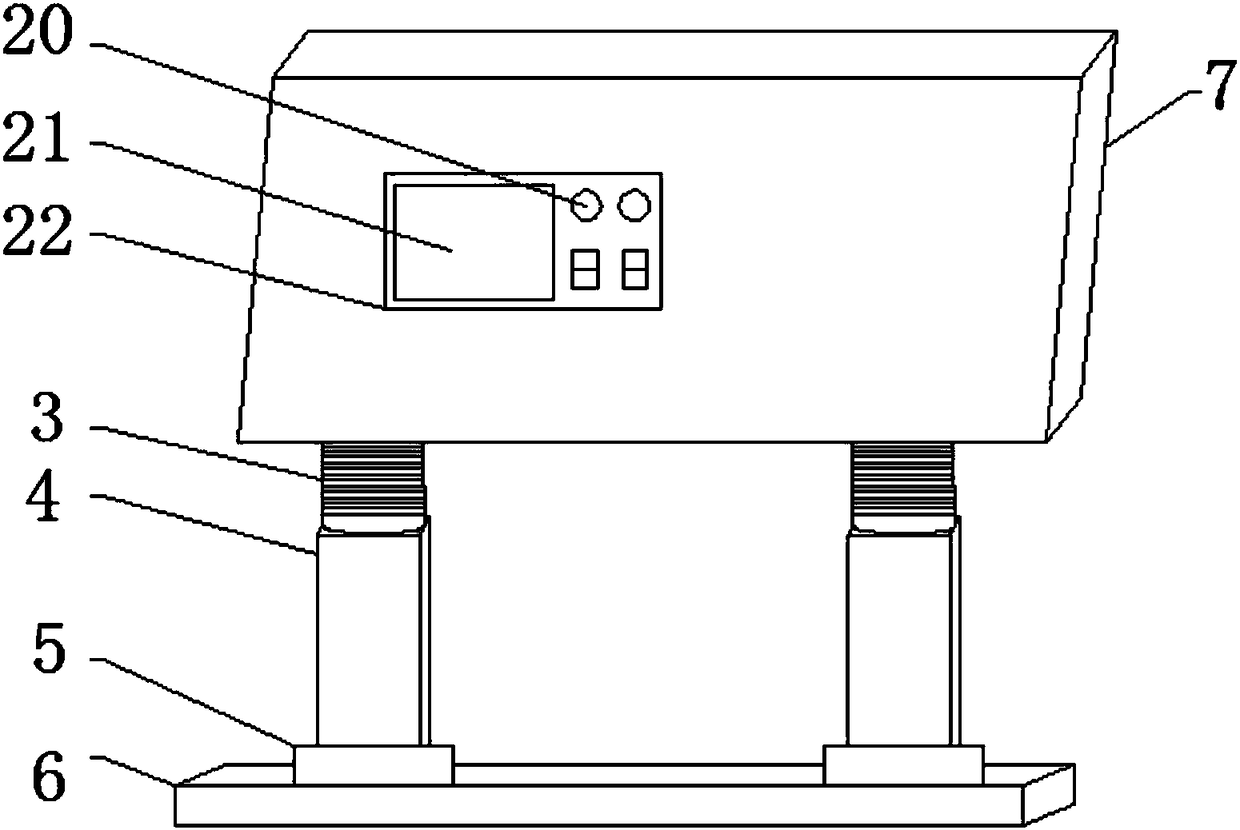

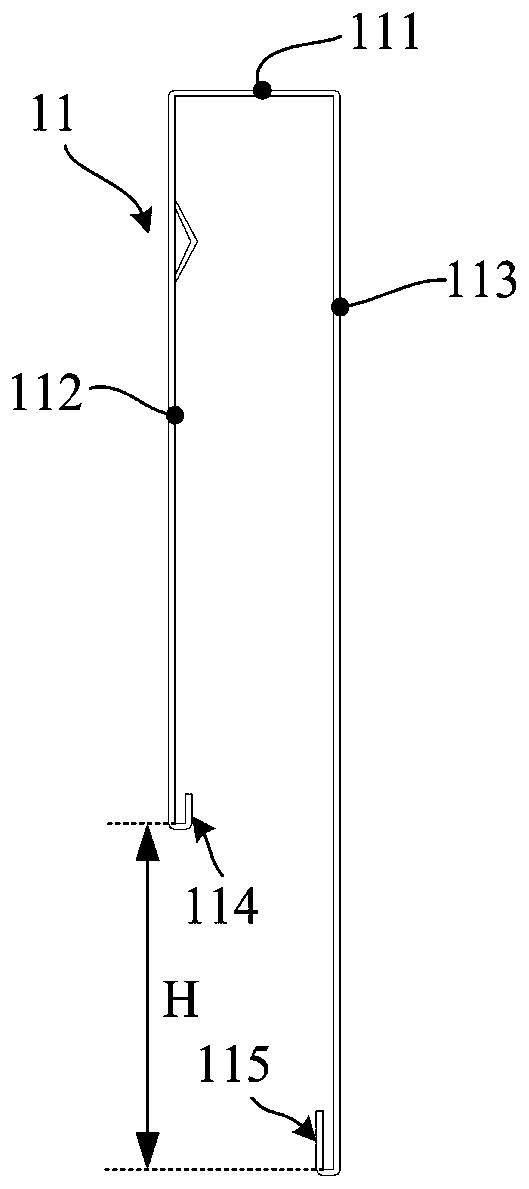

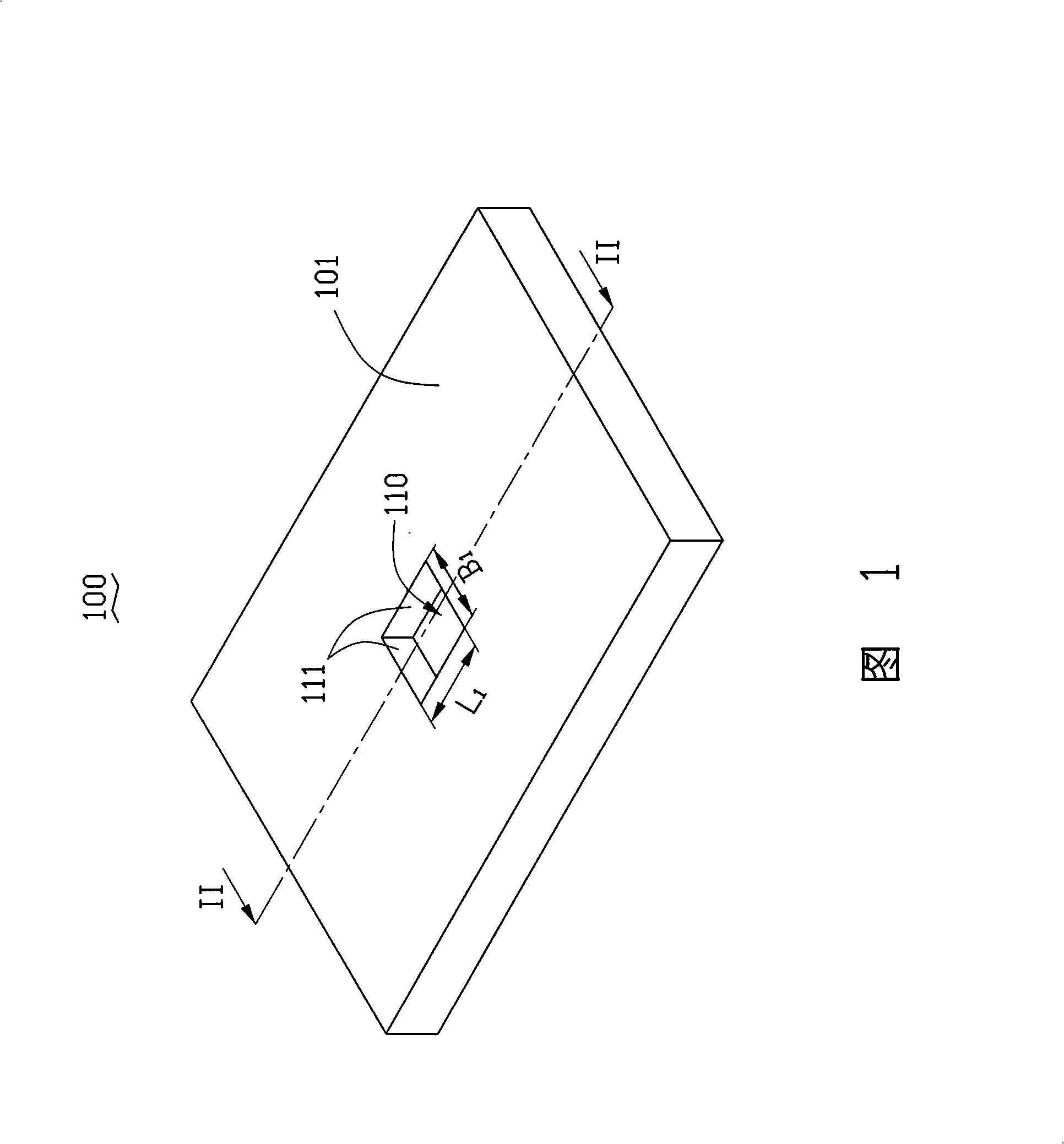

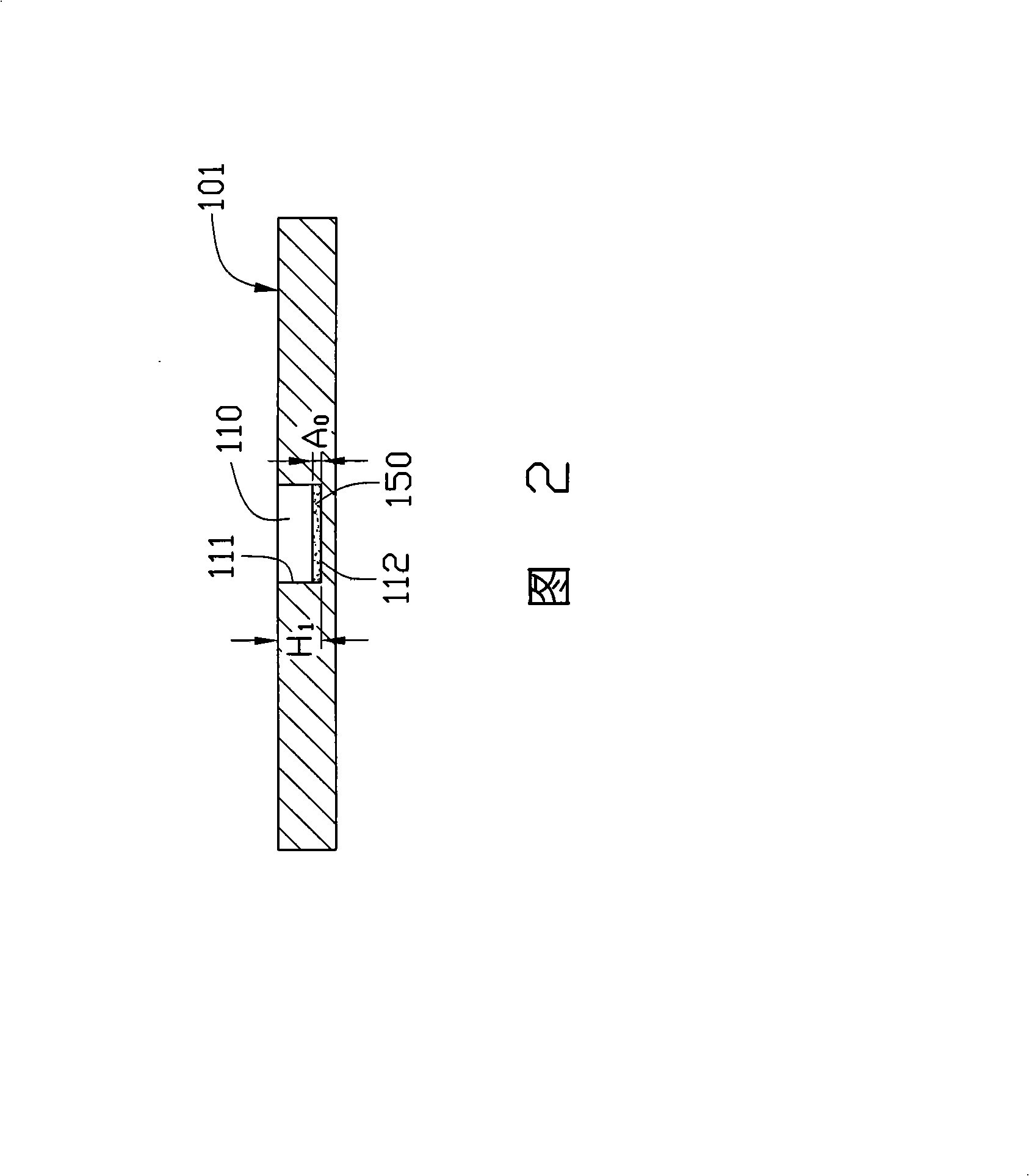

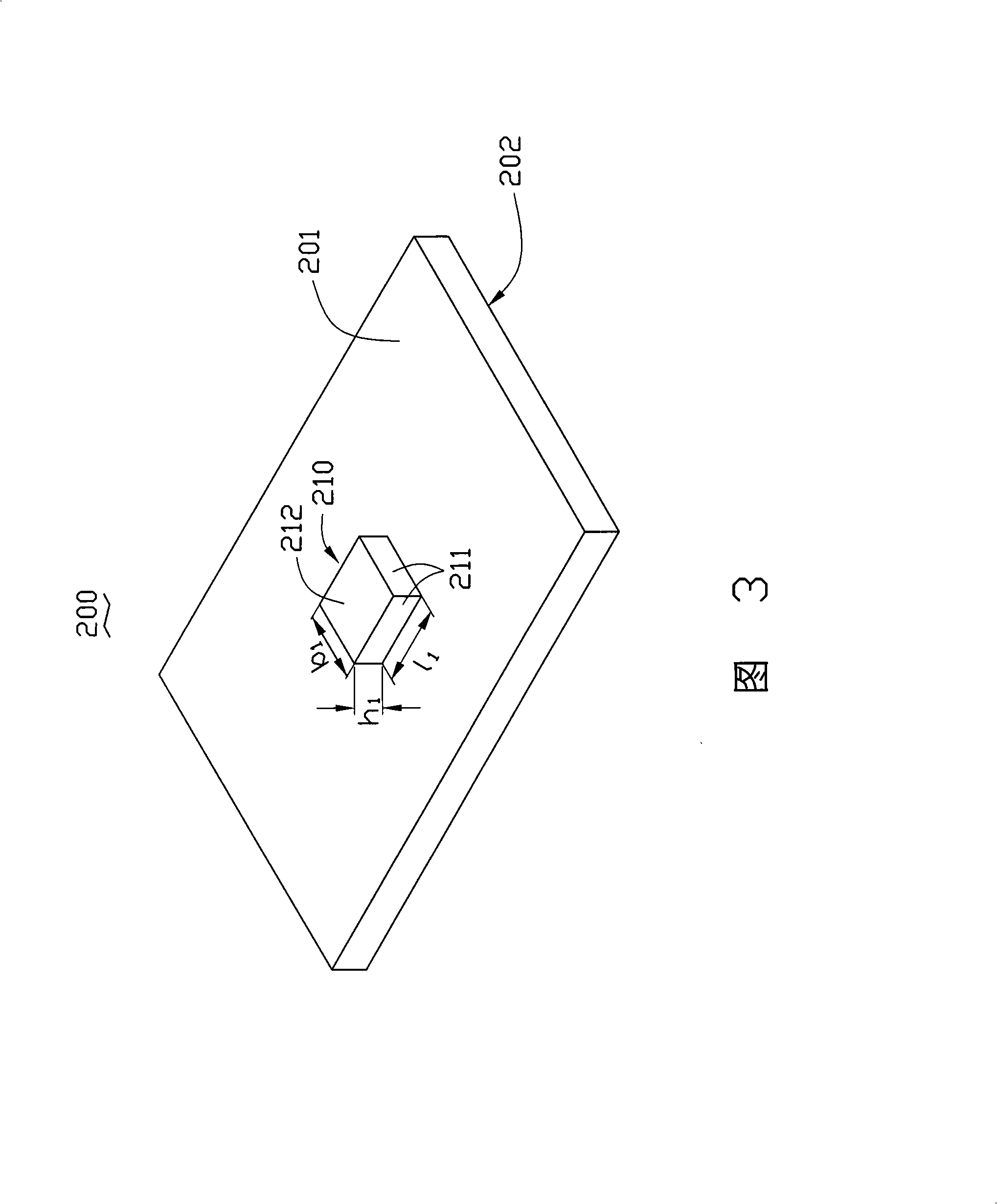

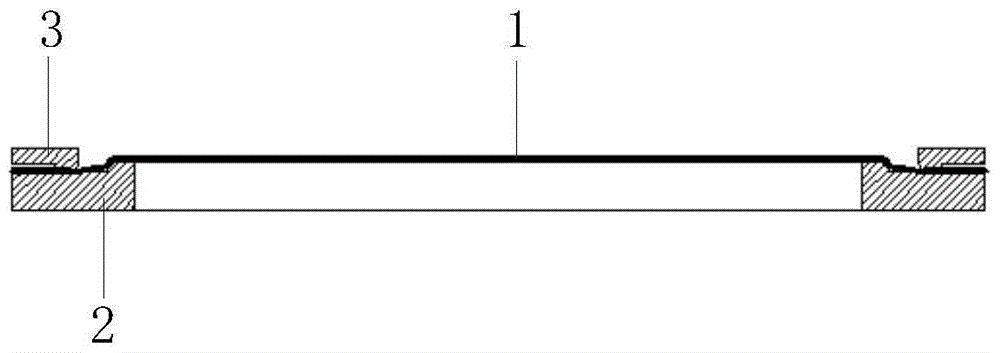

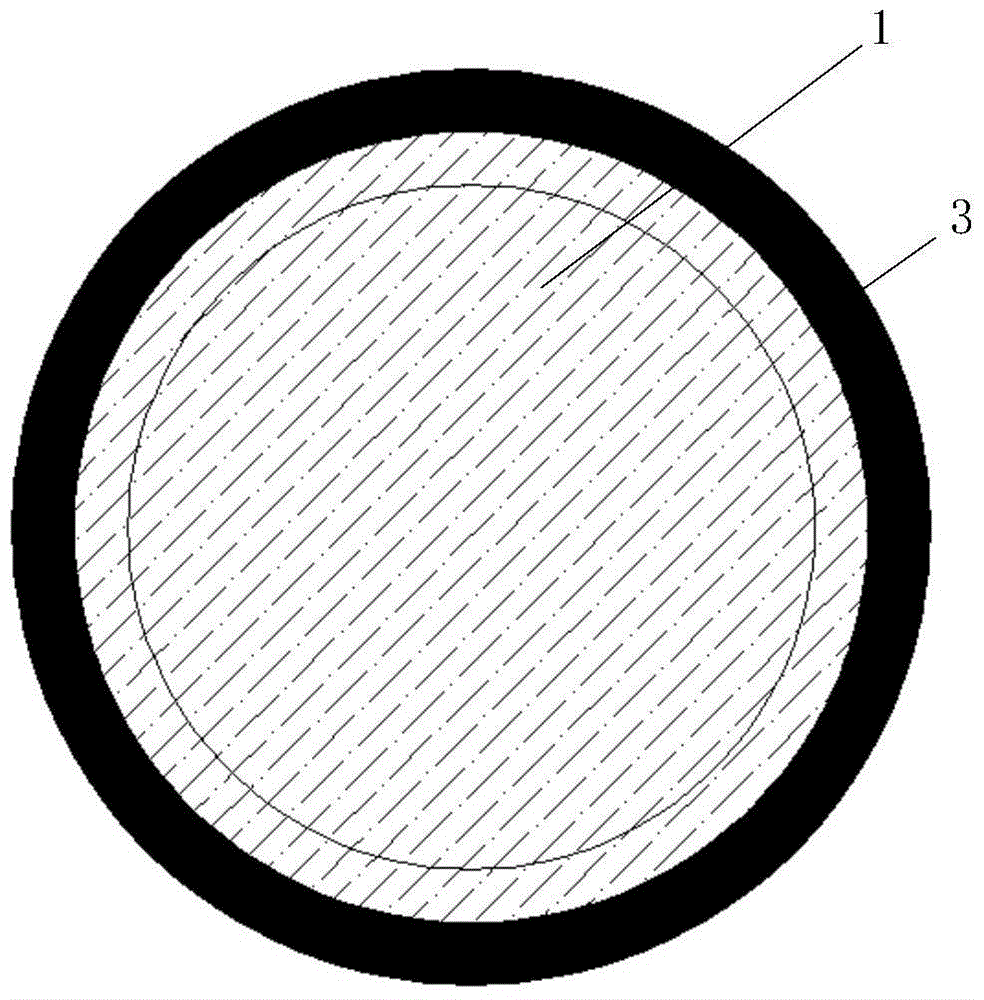

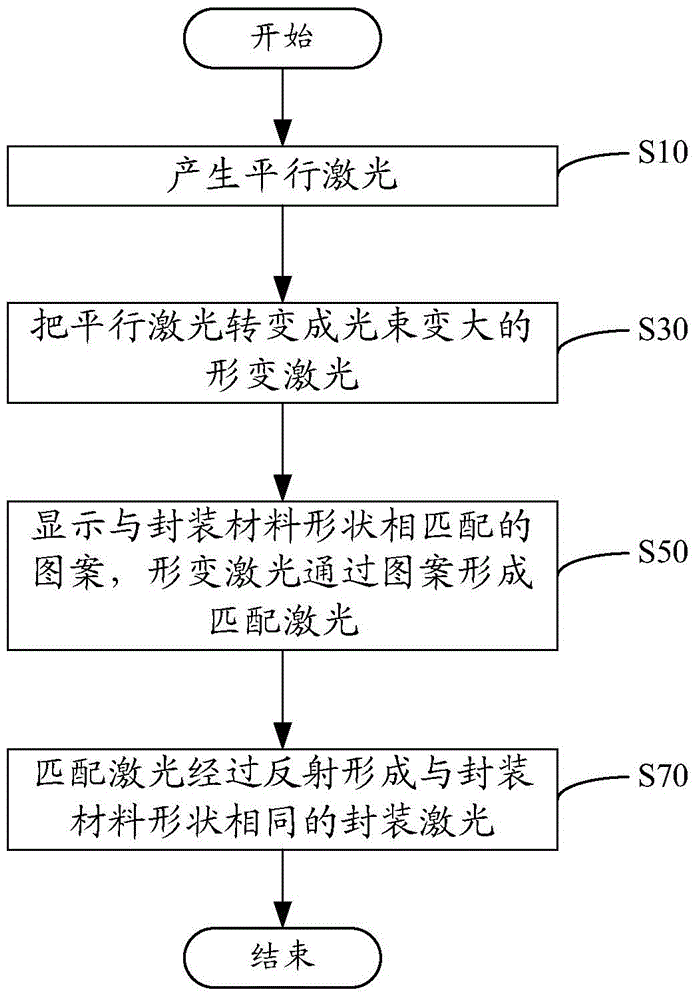

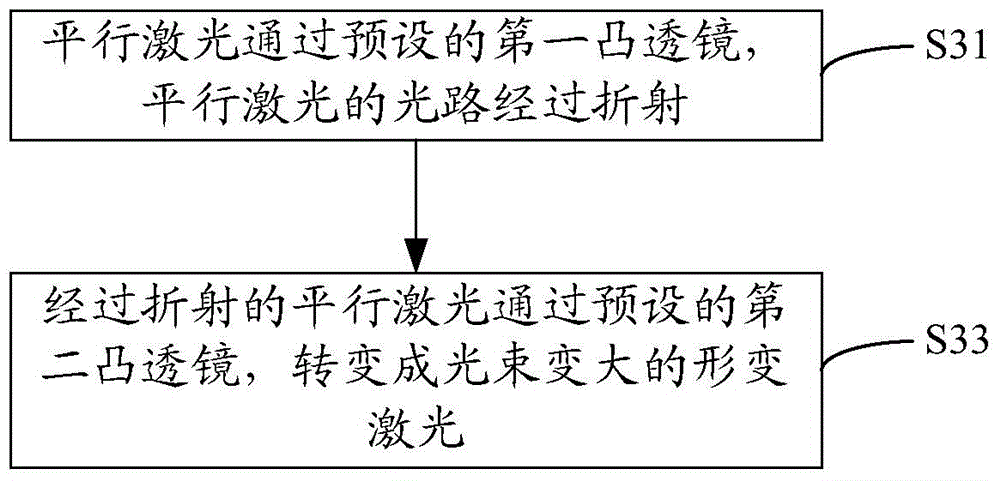

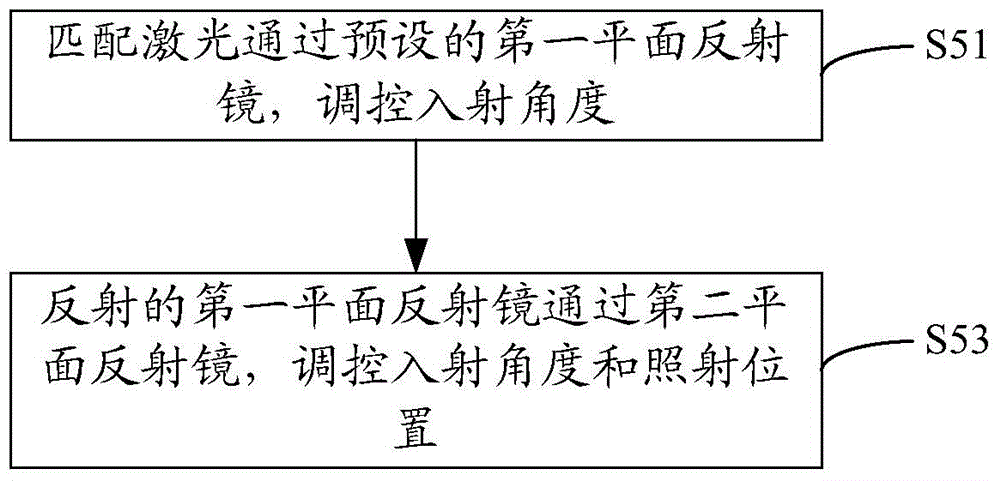

Laser sealing method and system

InactiveCN103464900ASynchronous sealingAvoid Stress Concentration SituationsSolid-state devicesNon-linear opticsLight beamLaser light

The invention discloses a laser sealing method and system. The method comprises the following steps: generating parallel laser light; converting the parallel laser light into deformed laser light of which the light beam is enlarged; displaying a pattern matched with the shape of an encapsulating material, and forming matched laser light by the deformed laser light through the pattern; reflecting the matched laser light to form encapsulating laser light of which the shape is the same as that of the encapsulating material. The light beam of the parallel laser light is enlarged to obtain the deformed laser; the deformed laser light is used for forming the matched laser light through the pattern matched with the shape of the encapsulating material, the matched laser is reflected to form the encapsulating laser light of which the shape is the same as the encapsulating material, and the encapsulating laser light vertically irradiates on the encapsulating material, so that synchronous heating and synchronous laser sealing are realized.

Owner:SHANGHAI UNIV +1

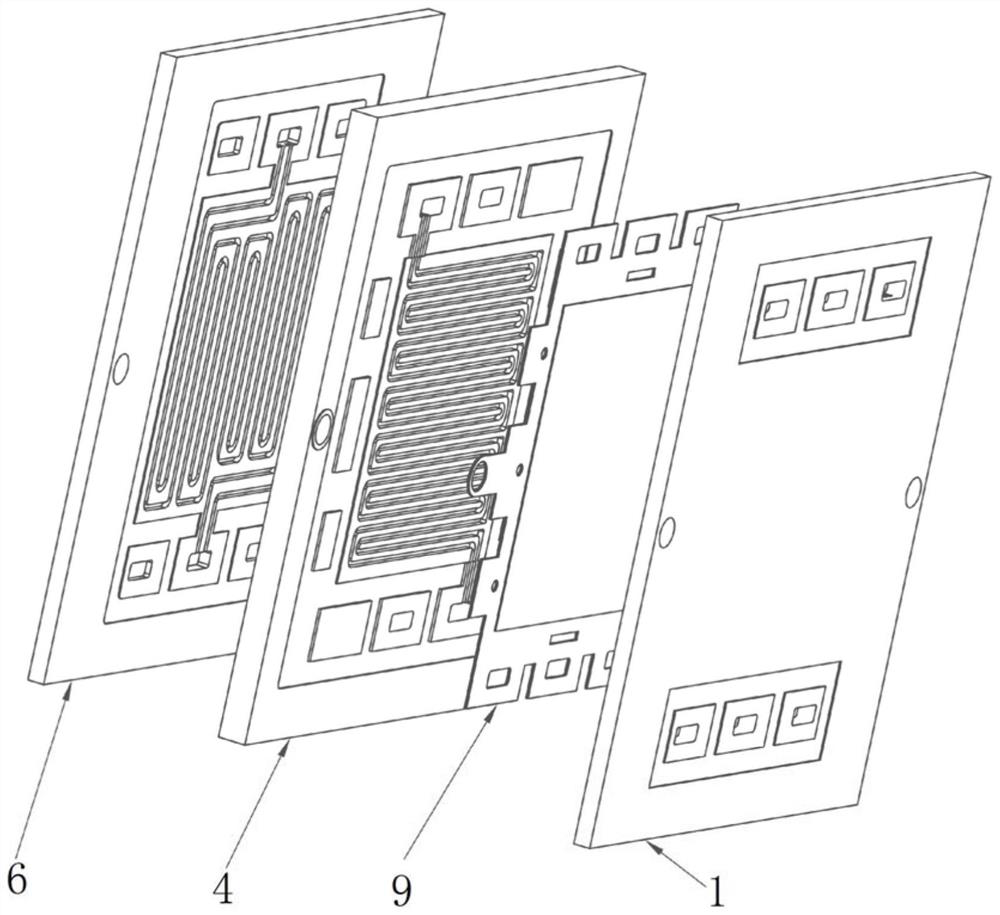

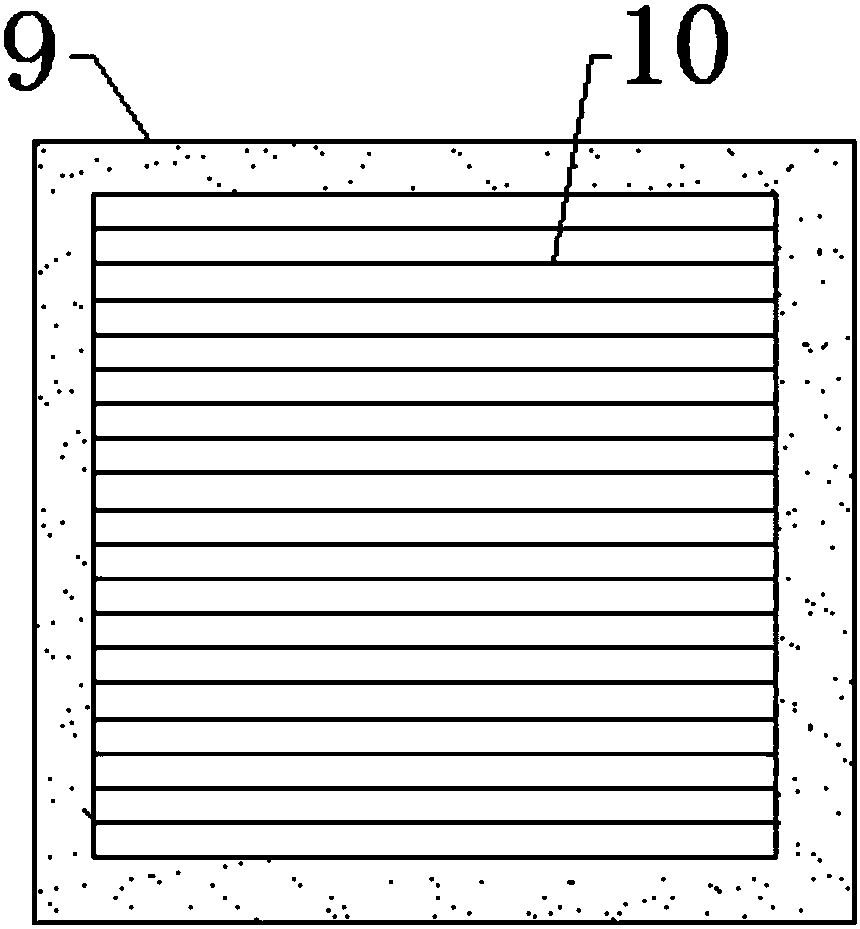

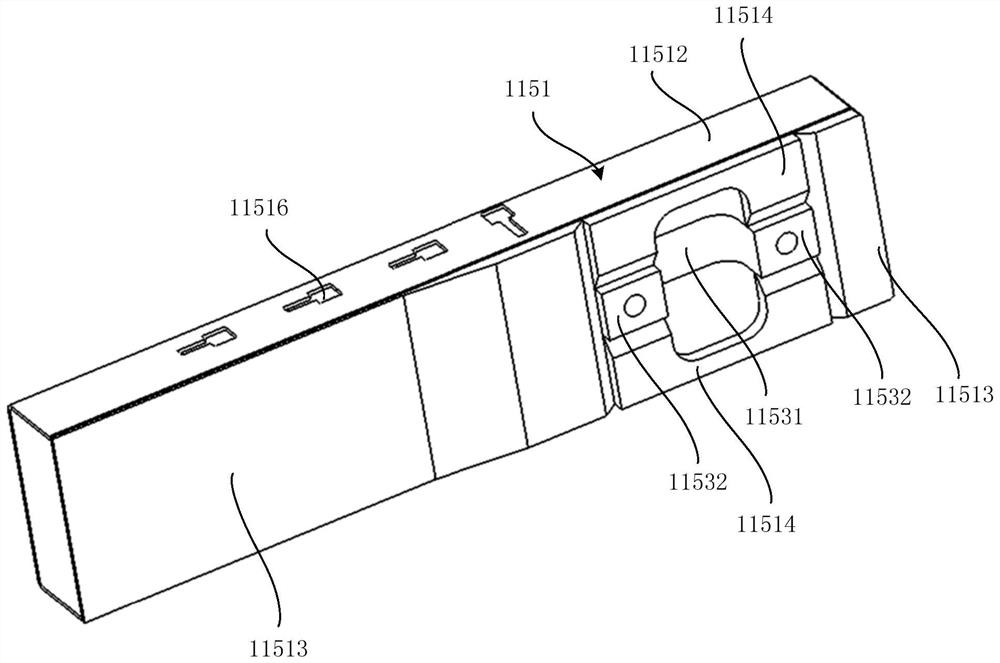

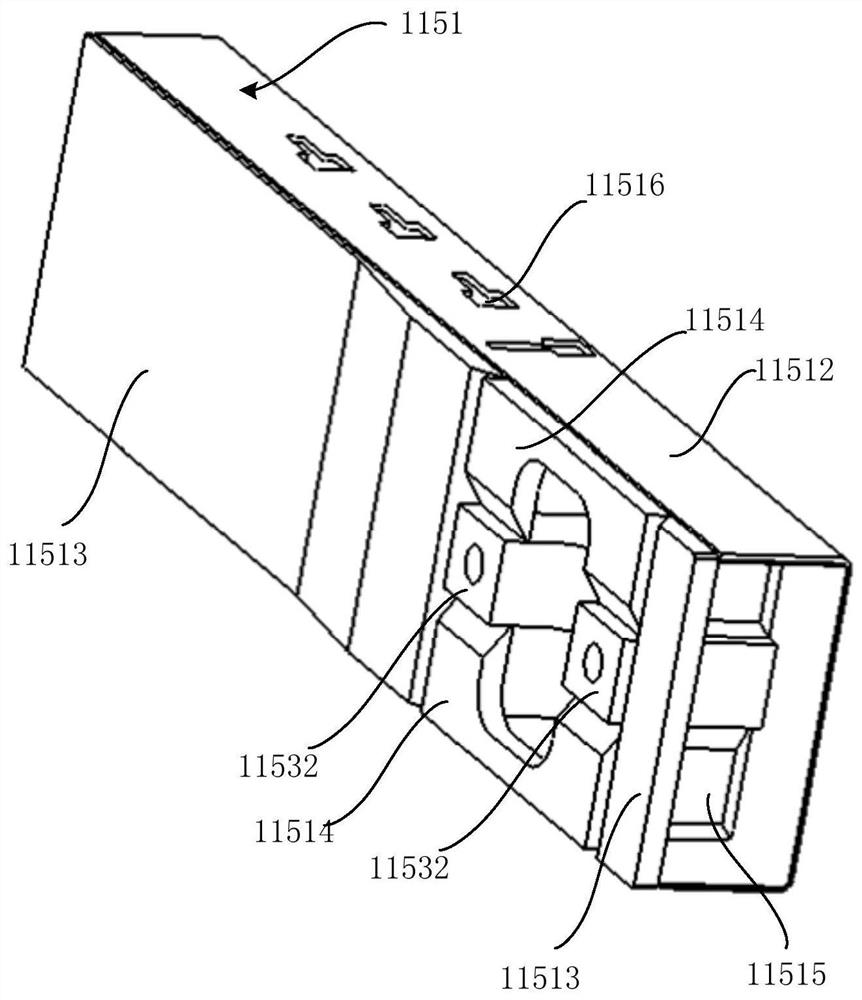

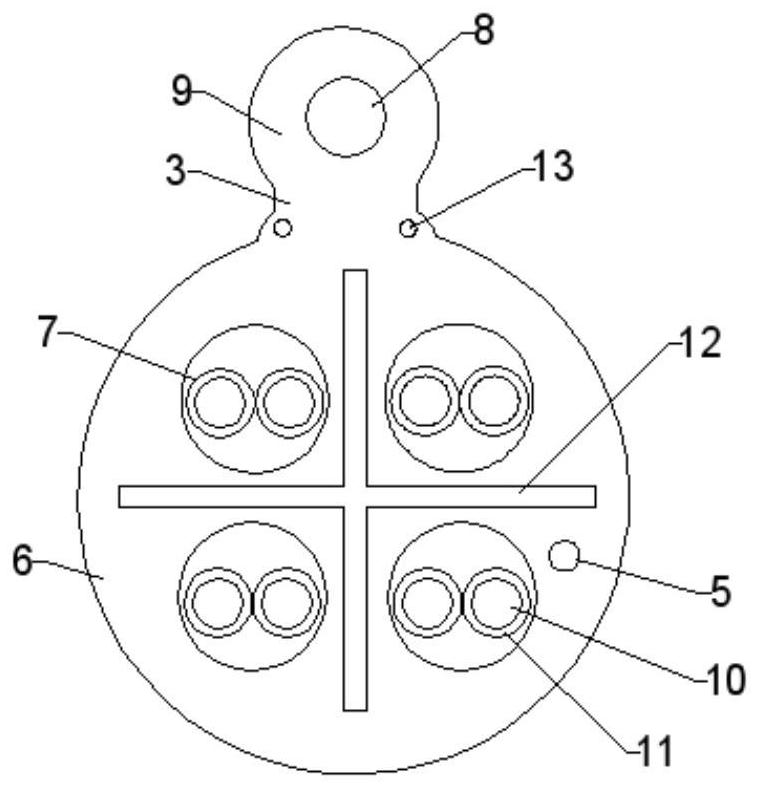

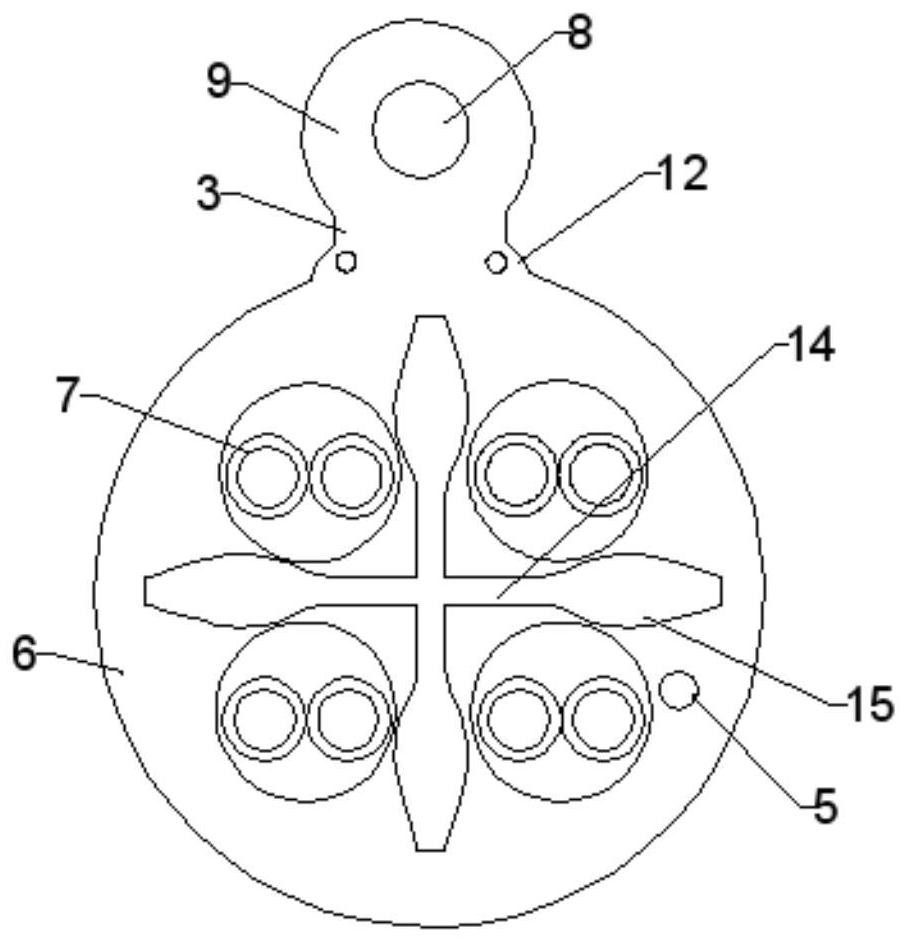

Integrated fuel cell unit cell and fuel cell stack

PendingCN111883797AThere is no problem of thickness size differenceNo compression issuesCollectors/separatorsChemical physicsFuel cells

The invention relates to an integrated fuel cell single cell and a fuel cell stack. The cell stack is formed by stacking and assembling a plurality of single cells, and each single cell comprises a cathode plate, a proton exchange membrane, an anode plate and a water plate which are stacked in sequence, wherein a catalyst layer and a gas diffusion layer are laminated on the front surface and the back surface of the proton exchange membrane at the flow field positions of the cathode plate and the anode plate, the peripheral side of the proton exchange membrane is fixed in the membrane electrodesupport body, and the proton exchange membrane and the membrane electrode support body form a complete plane; the membrane electrode support body, the proton exchange membrane, the catalytic layer and the gas diffusion layer are clamped between the cathode plate and the anode plate as a whole, and the cathode plate and the anode plate are hermetically connected through injected sealant. Comparedwith the prior art, the cell stack has the advantages of stable structure, excellent sealing performance, good durability, high power generation performance and the like.

Owner:TONGJI UNIV

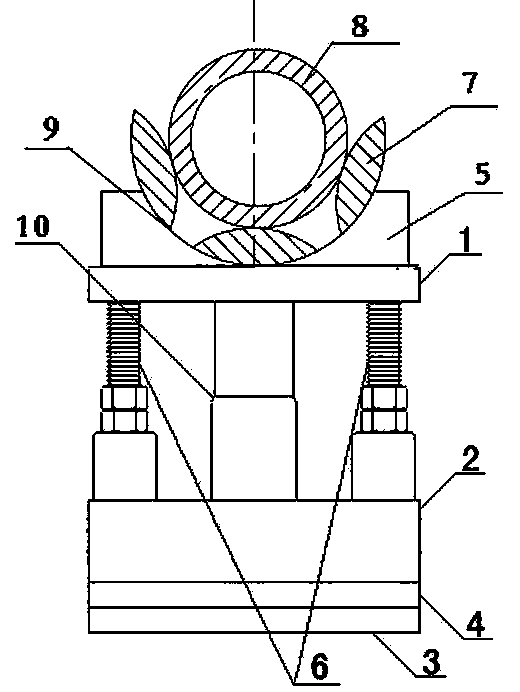

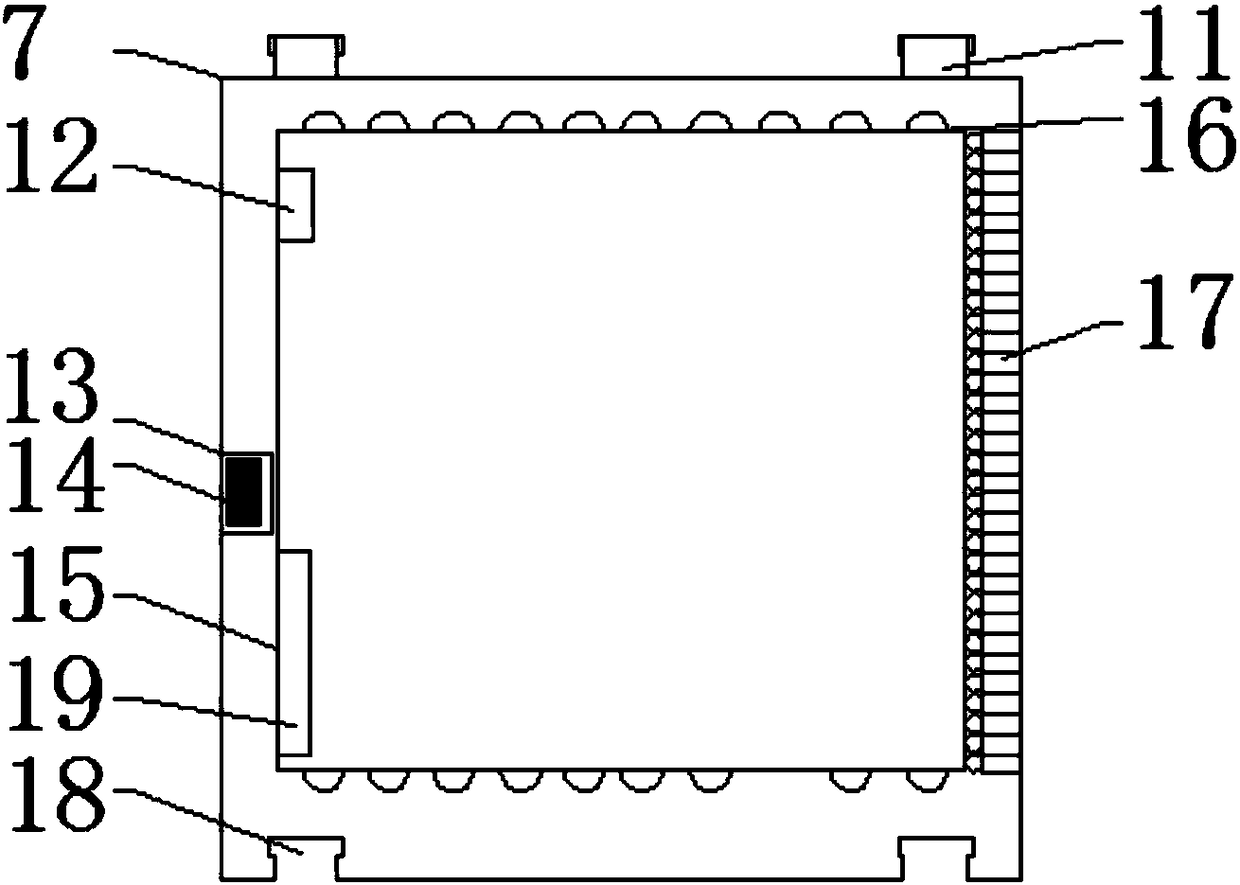

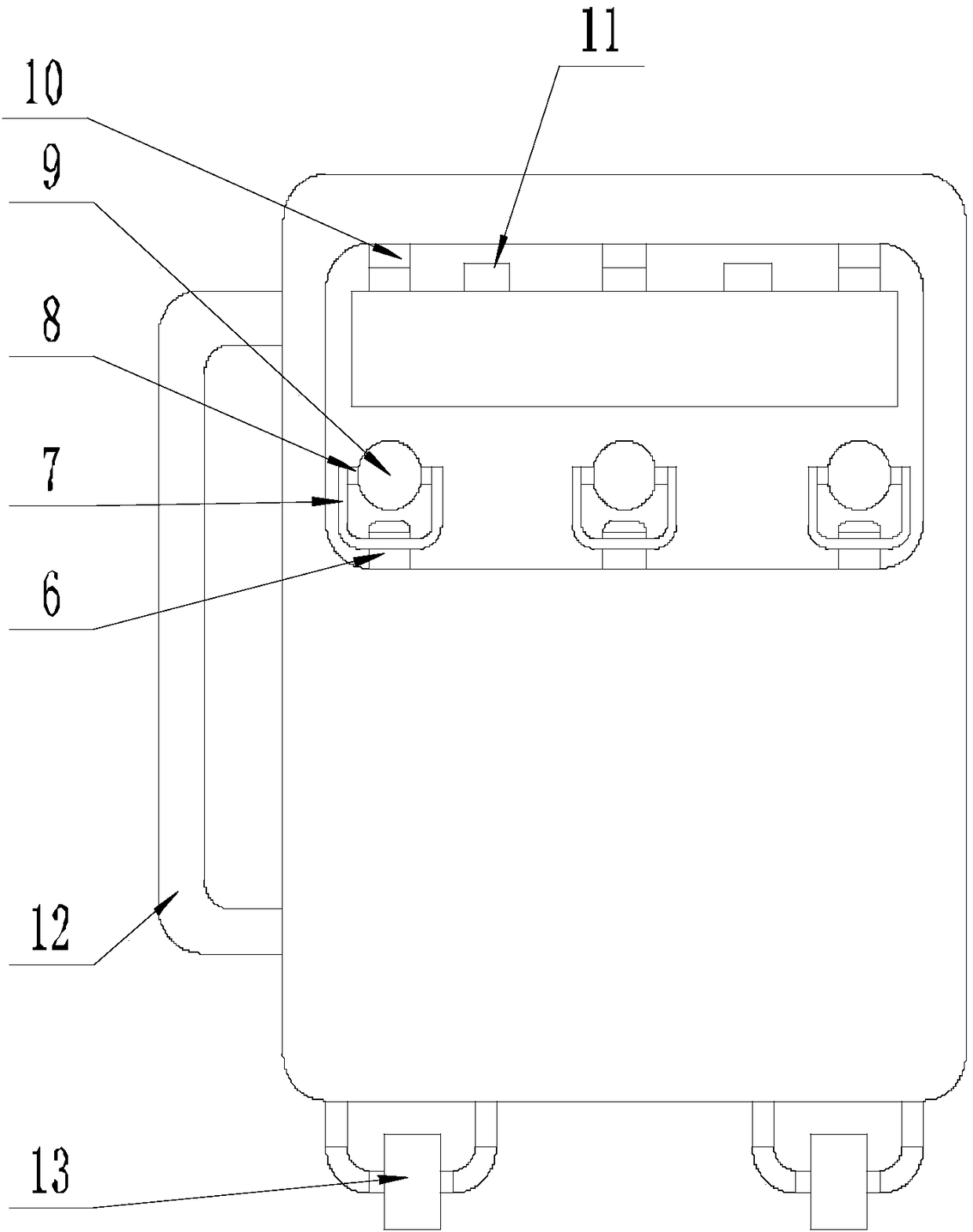

Oil pipeline support

InactiveCN104019283AMeet the needs of regulationAvoid breakingPipe supportsStress concentrationBaseboard

The invention discloses an oil pipeline support which comprises a top plate, a sliding plate, a baseboard and a graphitic layer. The sliding plate is connected with the baseboard through the graphitic layer. The top plate is connected with the sliding plate through an adjustable connecting rod and four vertical adjusting rods. The upper surface of the top plate is provided with a supporting arm, and a pipe slot for placing oil pipelines is formed in the supporting arm. Three cambered surface protrusions are arranged in the pipe slot, the three cambered surface protrusions are arranged at the utter bottom of the pipe slot, on the left side of the pipe slot and on the right side of the pipe slot respectively, and make surface contract with the oil pipelines. According to the oil pipeline support, vertical adjustment of the support is achieved through the vertical adjusting rods, and the requirement for pipeline adjustment can be met; the cambered surface protrusions are arranged in the pipe slot, so that contact between the oil pipelines and the pipe slot is more stable, machining difficulty of the pipe slot is lowered, the situation of stress concentration is avoided, and the oil pipelines are prevented from cracking.

Owner:WUXI JINDING OIL PIPE FITTINGS

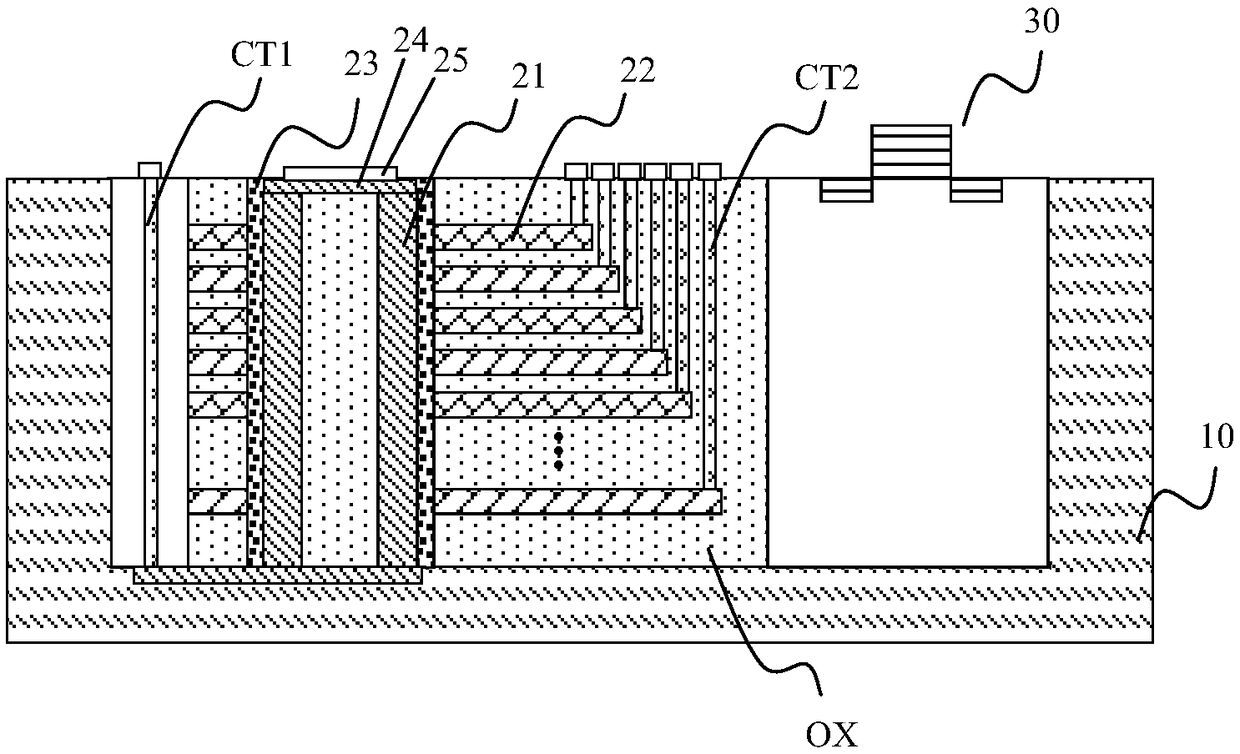

Three-dimensional storage structure

InactiveCN108666320AGuaranteed yieldAvoid stress concentration situationsSolid-state devicesSemiconductor devicesIsolation layerEngineering

The invention relates to the technical field of semiconductors, in particular to a three-dimensional storage structure. The three-dimensional storage structure comprises a substrate, wherein a plurality of grooves are formed in the substrate in an array way, a storage unit structure is formed in each groove, each storage unit structure comprises an annular and vertical columnar channel layer, a plurality of control gate layers and an annular and vertical columnar isolation layer, the annular and vertical columnar channel layer is used for connecting a source and a drain, the plurality of control gate layers are vertically separated, the columnar channel layer is encircled by each control gate layer, the annular and vertical columnar isolation layer is used for separating the columnar channel layer from each control gate layer, a first contact hole and a second contact hole are formed in each storage unit structure, the first contact hole is used for connecting the columnar channel layer, and the second contact hole is used for connecting each control gate layer. By the three-dimensional storage structure, stress contraction can be prevented from being formed in a wafer of the storage structure, and the yield of a wafer product is favorably ensured.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Polishing pad finisher, polishing pad finishing device and polishing system

ActiveCN104209864AReduce frequency of useReduce flakingLapping machinesAbrasive surface conditioning devicesEngineeringFrequency of use

Provided are a polishing pad finisher, a polishing pad finishing device and a polishing system. The finisher comprises abrasive particles and a base body with a grinding face, wherein the abrasive particles firmly solidify on the grinding face, the grinding face comprises an edge grinding face and a central grinding face which are connected, and the edge grinding face surrounds the central grinding face. The central grinding face is a plane and is higher than the edge grinding face. When a polishing pad is finished and due to the fact that the central grinding face of the grinding face is higher than the edge grinding face, the abrasive particles on the edge grinding face are higher than the abrasive particles on the central grinding face. Therefore, when the pressing depth of the polishing pad finisher extending into the polishing pad is small, most of the abrasive particles on the edge grinding face do not perform grinding, the using frequency of the abrasive particles located at the edge position is reduced, and scaling possibility of the abrasive particles located at the edge position is reduced. In addition, the possibility that the abrasive particles located at the edge position bump with the edge of the polishing pad is further reduced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

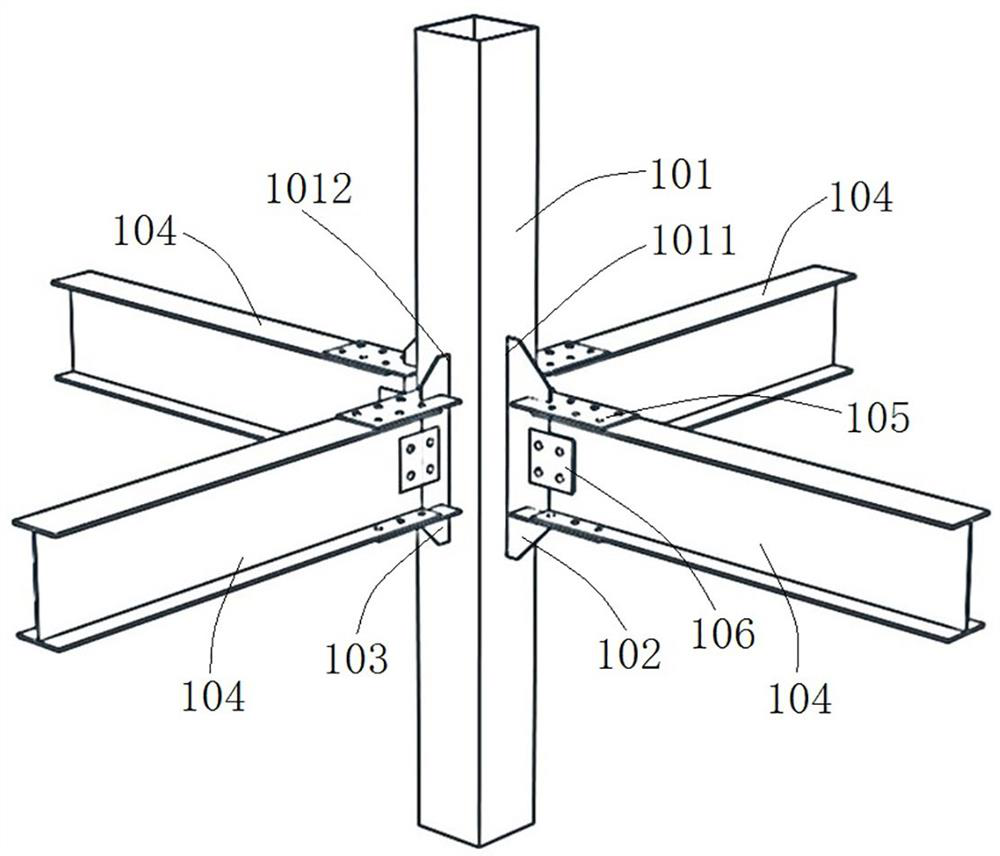

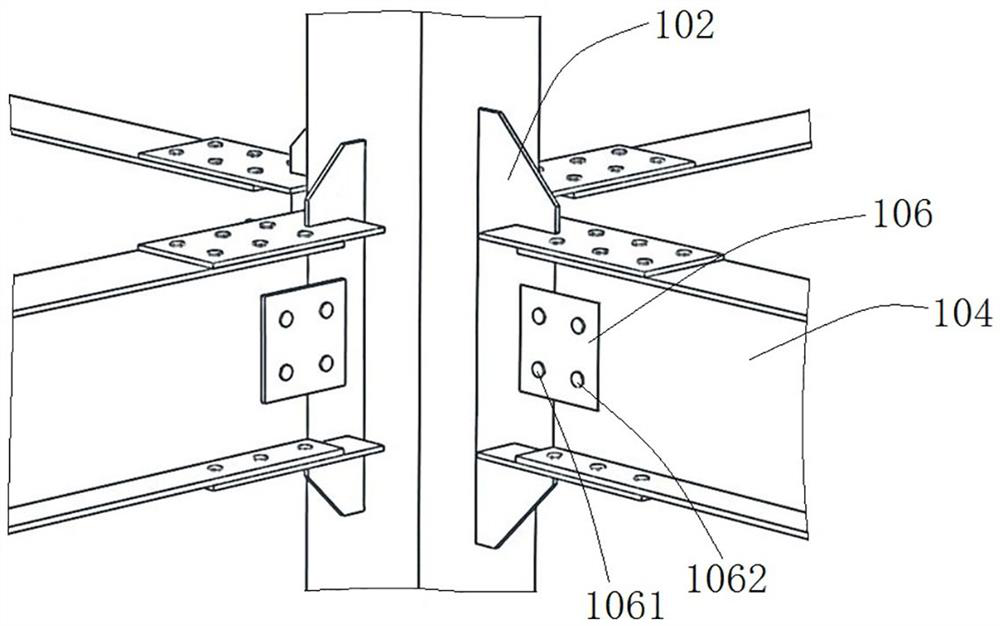

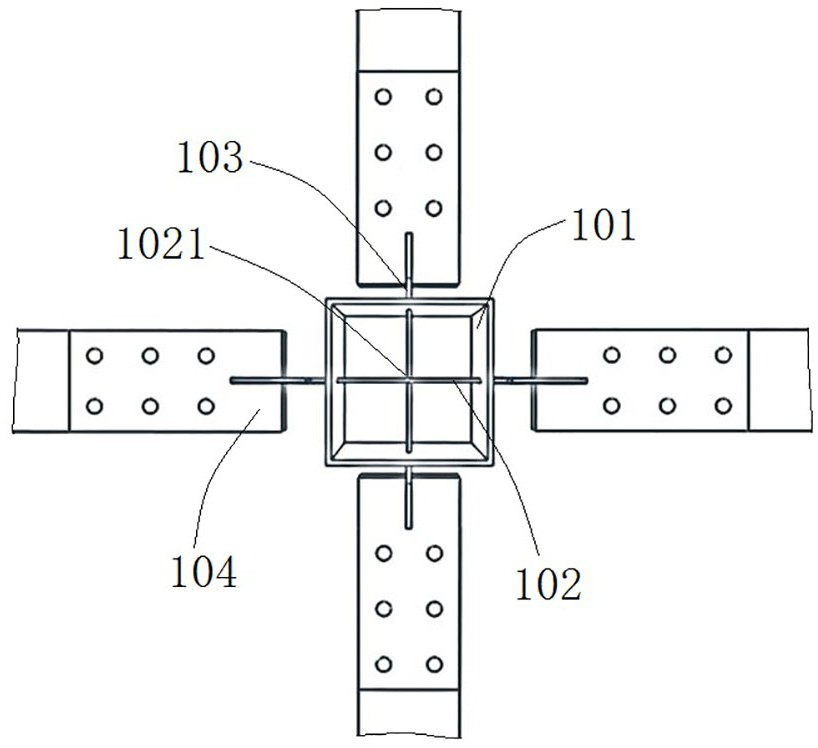

Prefabricated web through type concrete-filled steel tubular column and steel beam connecting joint

InactiveCN112459240AAvoid Weld BreakageGood shock resistanceBuilding constructionsSteel tubeEarthquake resistant

The invention relates to the technical field of building structure engineering, in particular to a prefabricated web through type concrete-filled steel tubular column and steel beam connecting joint.The connecting joint comprises a vertically-extending concrete-filled steel tubular column and four steel beams distributed in a crossed mode; the connecting joint comprises a first joint plate and asecond joint plate; the first joint plate and the second joint plate are distributed in a crossed mode; the first joint plate horizontally penetrates through the concrete-filled steel tubular column;a groove hole allowing the second joint plate to penetrate through is formed in the first joint plate; the second joint plate penetrates through the concrete-filled steel tubular column and the firstjoint plate at the same time; the first joint plate and the second joint plate are both welded to the column wall of the concrete-filled steel tubular column; and the steel beams are fixedly installedat the two ends respectively. The prefabricated web through type concrete-filled steel tubular column and steel beam connecting joint solves the problem of assembly type operation of a closed-sectioncolumn, concrete-filled steel tubes do not need to be disconnected in a joint area, flanges of the steel beams and the column walls are not welded any more, weld joint breakage is avoided, and the anti-seismic property is excellent.

Owner:ZHENGZHOU UNIV

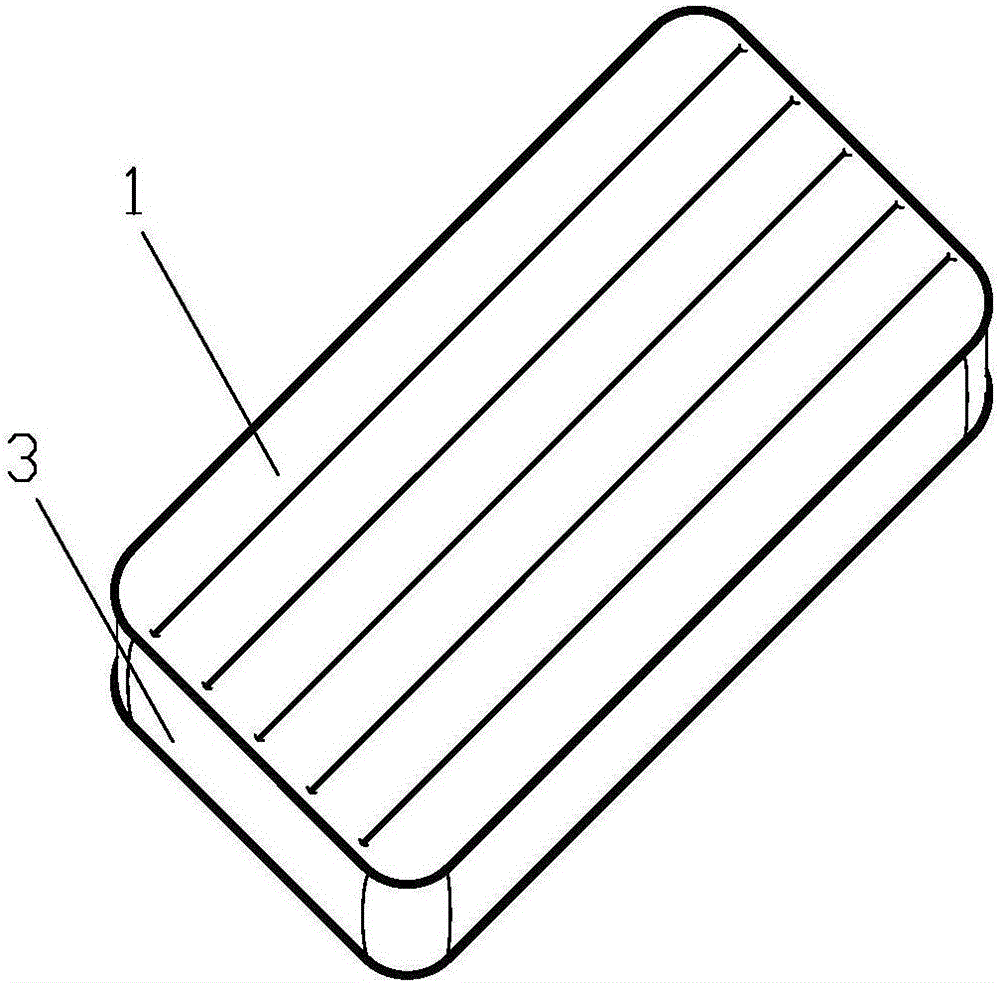

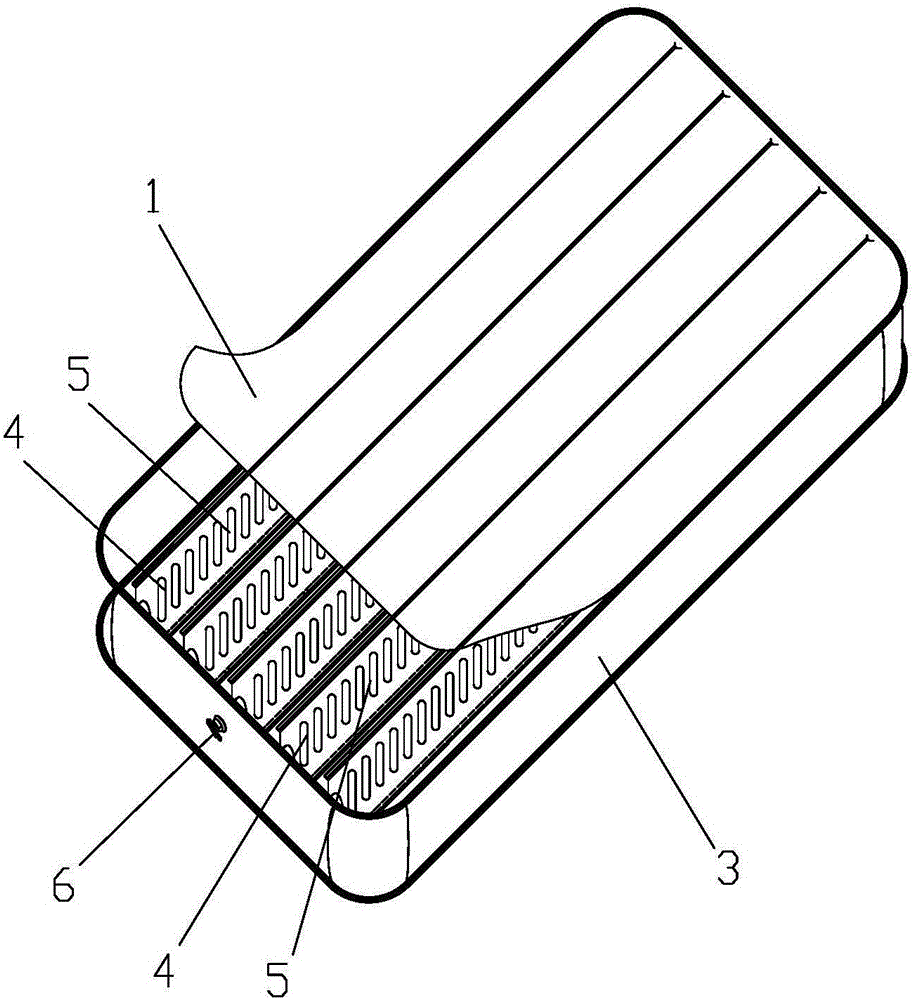

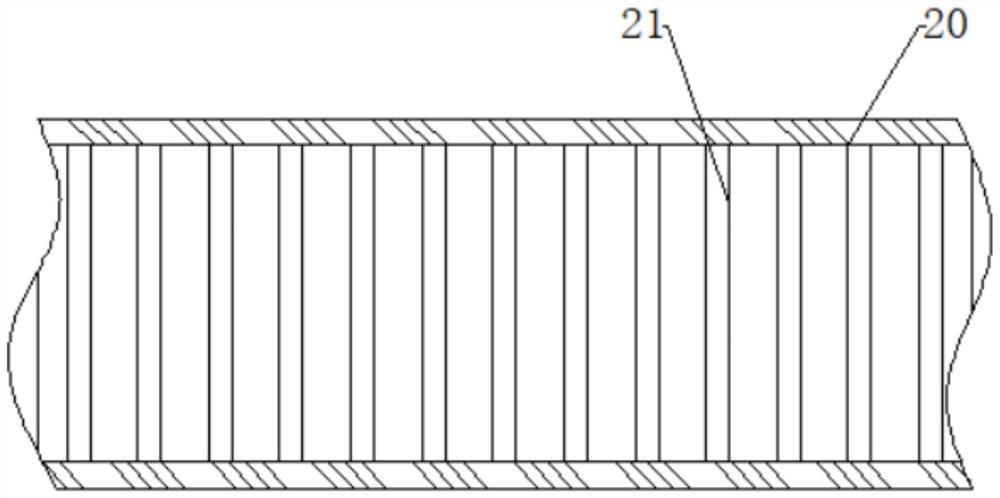

Straight-brace inflatable mattress and manufacture method thereof

The present invention discloses a straight-brace inflatable mattress, characterized in that each straight brace is provided with a plurality of through holes. The inflatable mattress is light in weight, stable in form and good in comfort. The invention also discloses a method of manufacturing the straight-brace inflatable mattress, including: A: manufacturing upper sheeting, lower sheeting, the straight braces and an enclosure; B: punching the straight braces to obtain through holes; C: spreading the lower sheeting on a machine; D: attaching the straight braces to a straight brace die so that the lower ends of the straight braces is abutted to the lower sheeting; E: spreading the upper sheeting on the straight brace die so that the upper sheeting is abutted to the upper ends of the straight braces; F: fusing the upper sheeting and the lower sheeting respectively with the straight braces; G: removing the straight brace die and the fused upper sheeting, straight braces and lower sheeting; H: sleeving an enclosure die with the enclosure, and spreading the upper sheeting and lower sheeting of step G respectively on upper and lower surfaces of the enclosure die; I: fusing the upper sheeting and the lower sheeting with the enclosure; J: cutting off surplus edges; K: obtaining the finished product. The process is simple and low in cost.

Owner:刘炜舜

Pipeline support for technical services

InactiveCN108087633AContact stabilityReduce processing difficultyPipe supportsPipe heating/coolingProtective relayPetroleum

The invention provides a pipeline support for technical services. The pipeline support comprises a protective shell; a supporting frame table is mounted on the inner surface wall of the protective shell; a bracket is mounted on the upper portion of the supporting frame table; a pipeline is mounted on the lower portion of the bracket; dampers are mounted on the lower portion of the protective shell; support bodies made of aluminum alloys are mounted on the lower portions of the dampers; bases are arranged on the lower portions of fixing nuts; sun-blocking paper is arranged outside the protective shell; a solar cell panel is mounted on the top of the protective shell; bulged grooves are formed in the front portion of the protective shell; a protective box is mounted on the inner surface wallof the protective shell; a single chip microcomputer is mounted inside the protective box; and a liner is arranged inside the protective shell. Up-down adjustment of the support bodies is achieved through the dampers, meanwhile, the pipeline is also prevented from being damaged, by arranging bulged groove protrusions in the bracket, contact between the petroleum pipeline and the bracket is more stable, the machining difficulty of the bracket is reduced, and the situation of stress concentration is avoided.

Owner:天津欧津汇溢市场调查有限公司

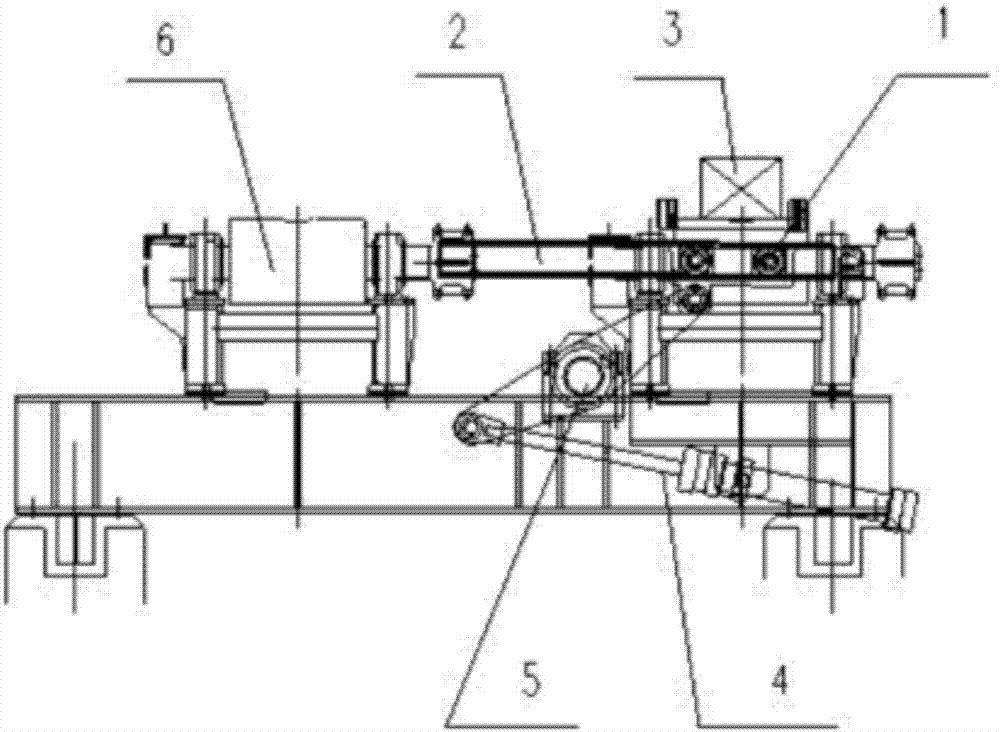

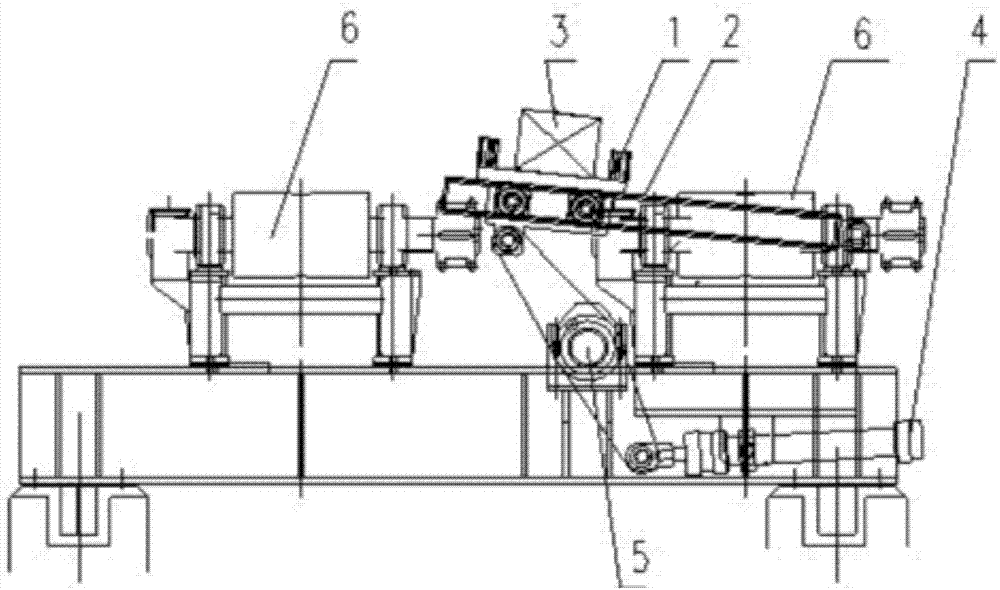

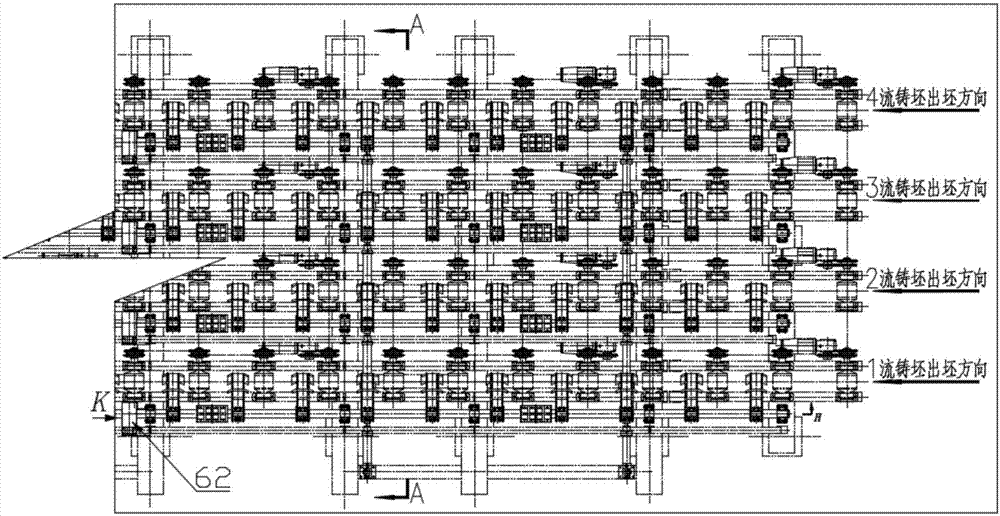

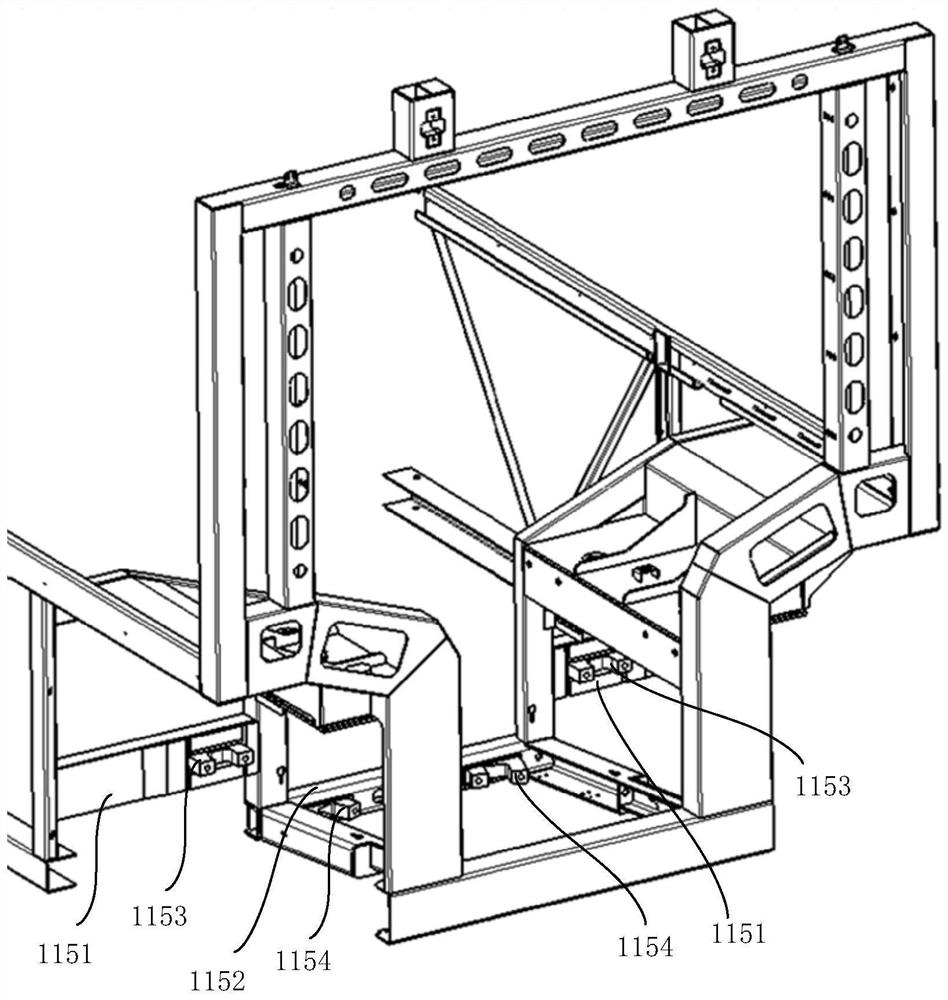

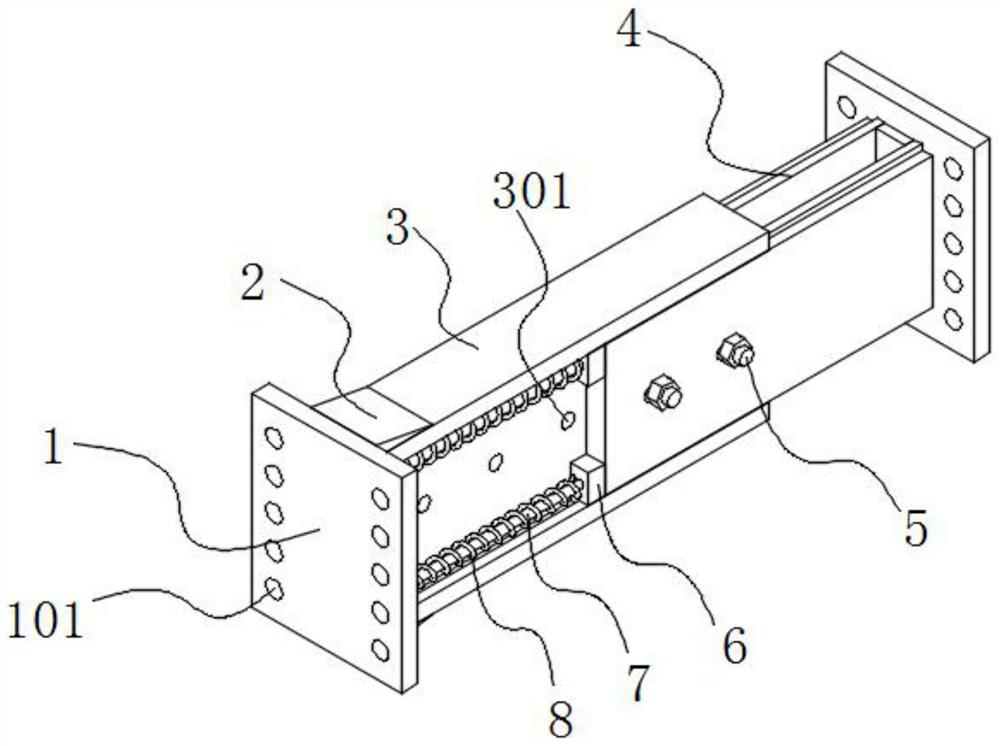

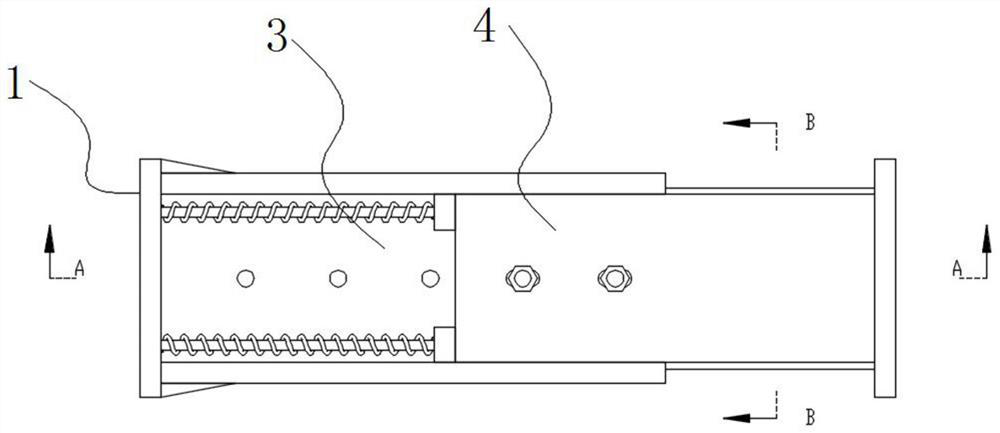

Dummy bar storage method for square billet continuous-casting machine

ActiveCN107234219ADurable, stable and reliable operationPlay the role of deviationMechanical engineeringContinuous casting

The invention discloses a dummy bar storage method for a square billet continuous-casting machine. The dummy bar storage method for the square billet continuous-casting machine comprises the following step that A, a dummy bar storage device for the square billet continuous-casting machine is obtained for storing dummy bars. The dummy bar storage method is characterized in that the dummy bar storage device for the square billet continuous-casting machine comprises a pushing mechanism, a turning mechanism and a supporting mechanism, the pushing mechanism is controlled to drive the turning mechanism to drive the supporting mechanism to turn, and thus the dummy bar storage operation can be achieved through the supporting mechanism; and in addition, side baffles of a roller bed of the square billet continuous-casting machine can be formed after the supporting mechanism turns. By adoption of the dummy bar storage method for the square billet continuous-casting machine, the dummy bar storage efficiency can be ensured, and the function of the side baffles of the roller bed is achieved.

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

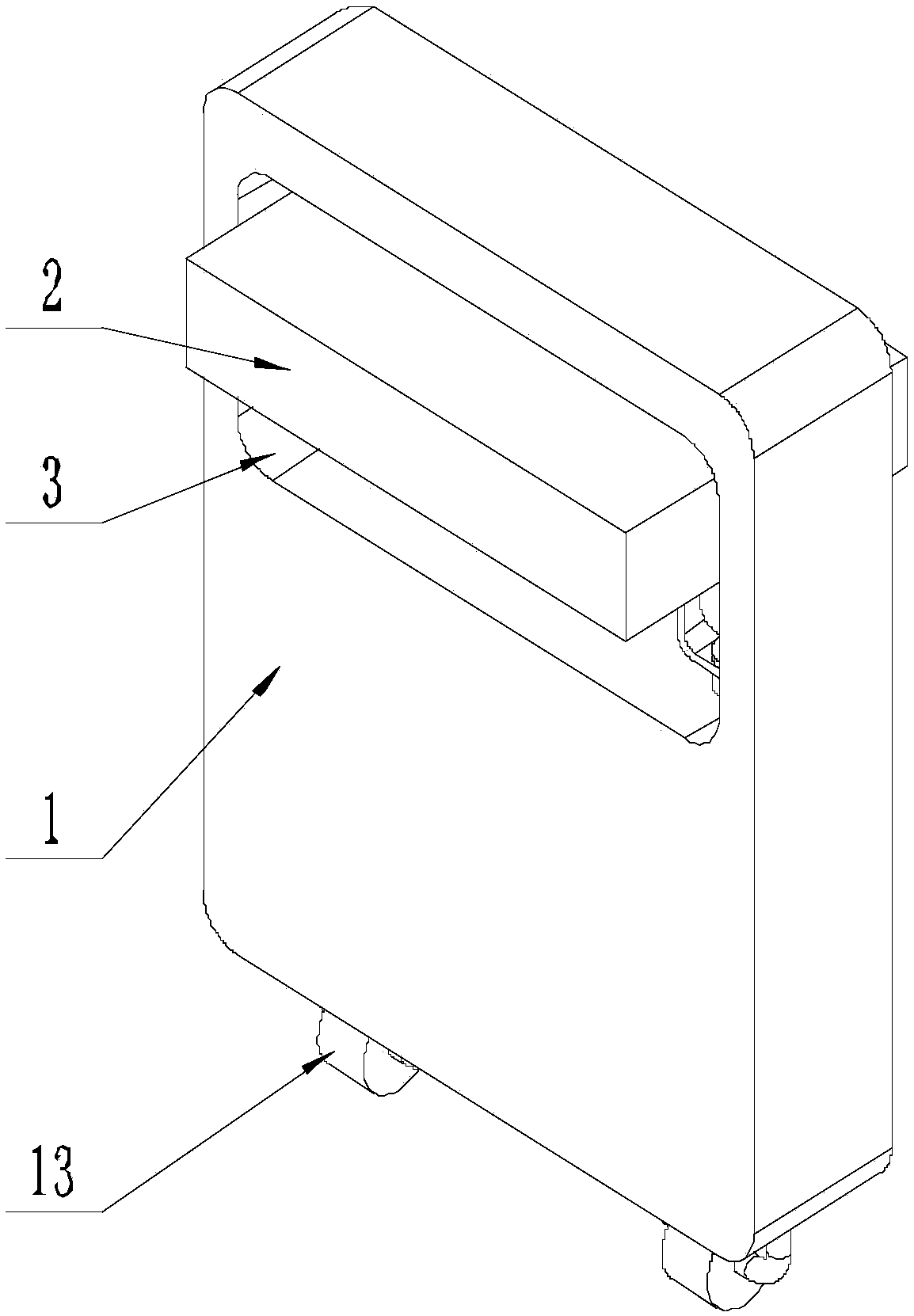

Vehicle body and rubber-tired train

ActiveCN112550486AReduce loadAvoid stress concentration situationsRailway transportTowing devicesBogieControl theory

The embodiment provides a train body and a rubber-tired train, the train body comprises a bottom frame and a top plate which are oppositely arranged, and a train body side wall and a train body end wall which are connected with the bottom frame and the top plate, the train body end wall comprises two train end outer side cross beams and a train end inner side cross beam, and in the width directionof the train body, the train end inner side cross beam is located between the two train end outer side cross beams; a first vehicle body traction rod seat is arranged on each vehicle end outer side cross beam and is perpendicular to the vehicle body end wall; two second vehicle body traction rod seats are arranged on the vehicle end inner side cross beam, and the second vehicle body traction rodseats are obliquely arranged away from the adjacent first vehicle body traction rod seats. The vehicle body end wall is connected with the two first traction assemblies and the two second traction assemblies at the same time so as to transmit traction force and braking force between the trailer bogie and the vehicle body together, the load on each traction assembly is reduced, meanwhile, the traction force and the braking force are evenly distributed to the whole vehicle body end wall, and the situation of stress concentration is avoided.

Owner:CRRC NANJING PUZHEN CO LTD

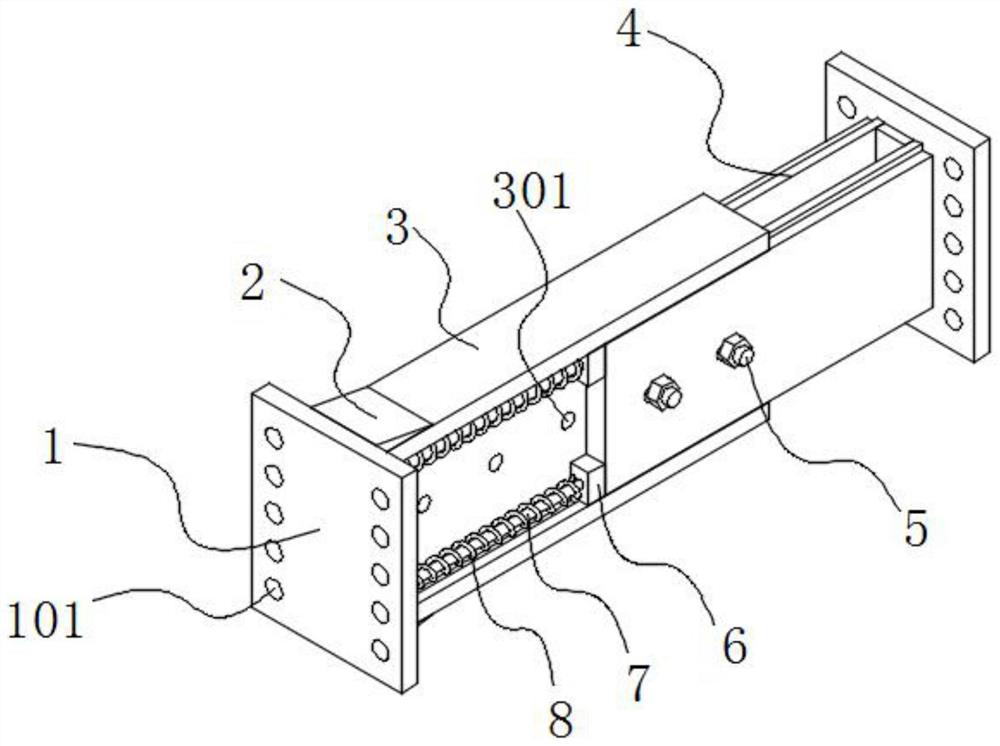

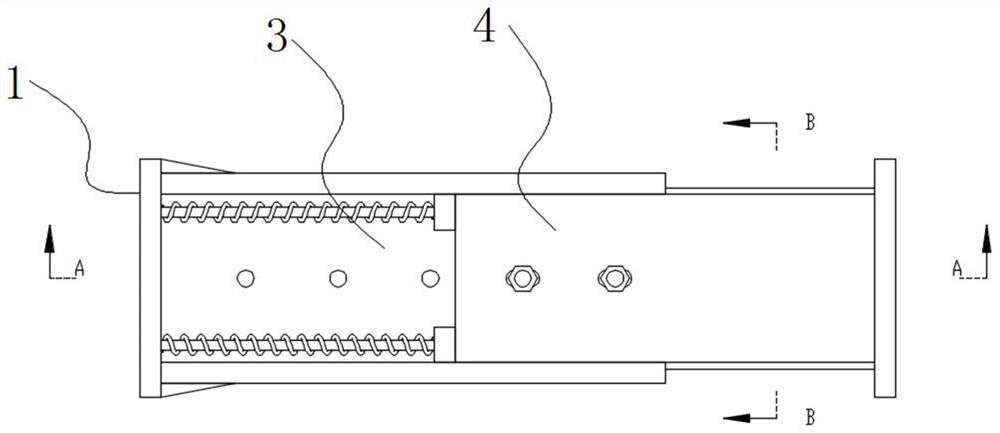

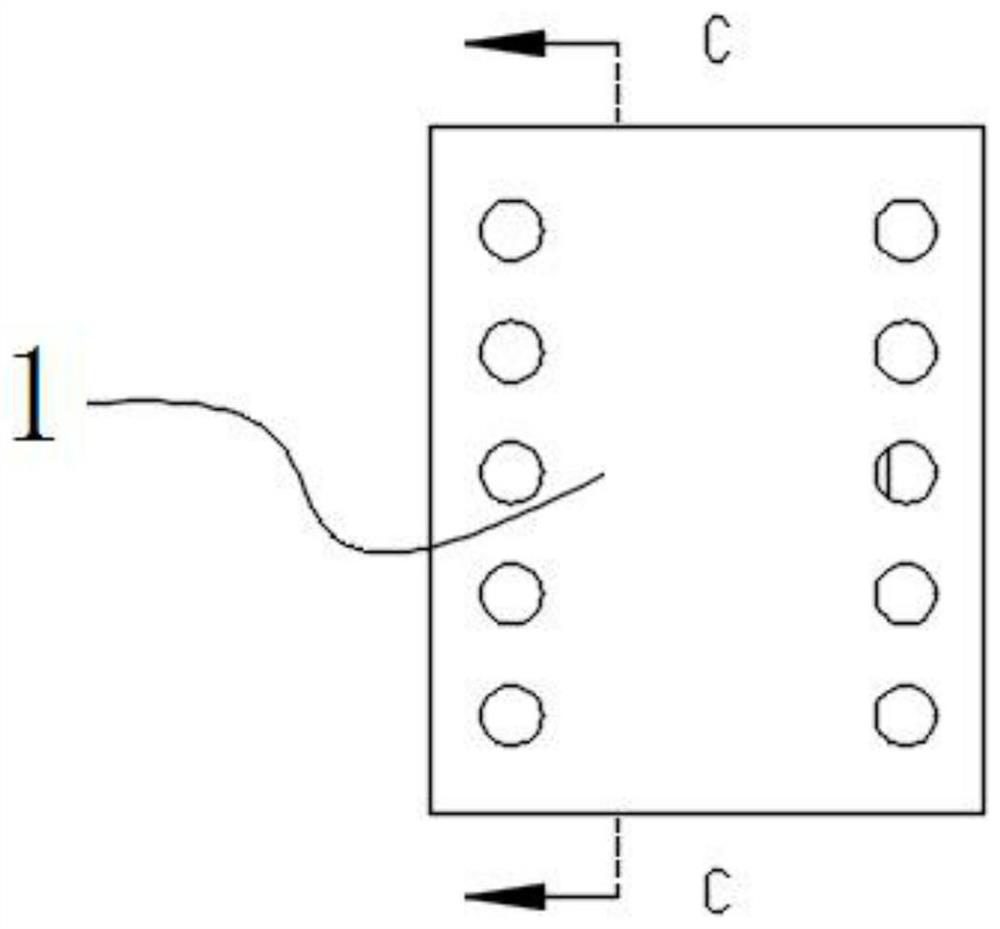

Telescopic building steel structural connecting part

ActiveCN112459253AImprove buffering effectExtended service lifeShock proofingArchitectural engineeringBuilding construction

The invention discloses a telescopic building steel structural connecting part, and relates to the technical field of building construction. The telescopic building steel structural connecting part comprises I-shaped steel and a plurality of T-shaped sliding blocks, a connecting plate is fixedly connected to one end surface of the I-shaped steel and one end surfaces of the T-shaped sliding blocks,the T-shaped sliding blocks are connected to the surfaces of the two sides of the I-shaped steel in a sliding mode, and a plurality of sliding grooves are formed in the T-shaped sliding blocks. According to the telescopic building steel structural connecting part, by using kidney-shaped holes, threaded holes and fastening screws, when the connecting part is impacted by external force after beingfixed, fixing bolts keep still, the kidney-shaped holes slightly slide left and right relative to the fixing bolts, so that the T-shaped sliding blocks slightly swing, the buffering effect is improved, the situation of stress concentration is avoided, and therefore the fixing bolts are protected, and the service life of the fixing bolts is prolonged; and by using air bags, sliding rods, air inletchannels and air outlet channels, when the T-shaped sliding blocks slide left and right, the sliding rods can extrude the air bags, the air bags can blow air into the kidney-shaped holes through air blowing channels, and the overheating fatigue of fastening bolts and other structural parts under severe friction can be avoided.

Owner:国舜绿建科技有限公司

Tool apron and processing method thereof

PendingCN110651587AOutstanding and Beneficial Technical EffectsReduce stressMowersStructural engineeringInternal stress

The invention belongs to the technical field of mowers and particularly relates to a tool apron. The tool apron comprises a mounting seat and is characterized in that the mounting seat is produced bydie casting through a powder metallurgy process, a connecting seat is arranged at one end of the mounting seat, a mounting protrusion and positioning protrusions for tool mounting are arranged at theother end of the mounting seat, a plurality of annular stress grooves are formed in the mounting seat, and the annular stress grooves are arranged around the periphery of the mounting protrusion / positioning protrusions. The tool apron is simple in structure, convenient to produce and small in internal stress during production.

Owner:JINHUA YUCHEN POWDER METALLURGY

A telescopic building steel structure connector

ActiveCN112459253BImprove buffering effectExtended service lifeShock proofingArchitectural engineeringAirbag

Owner:国舜绿建科技有限公司

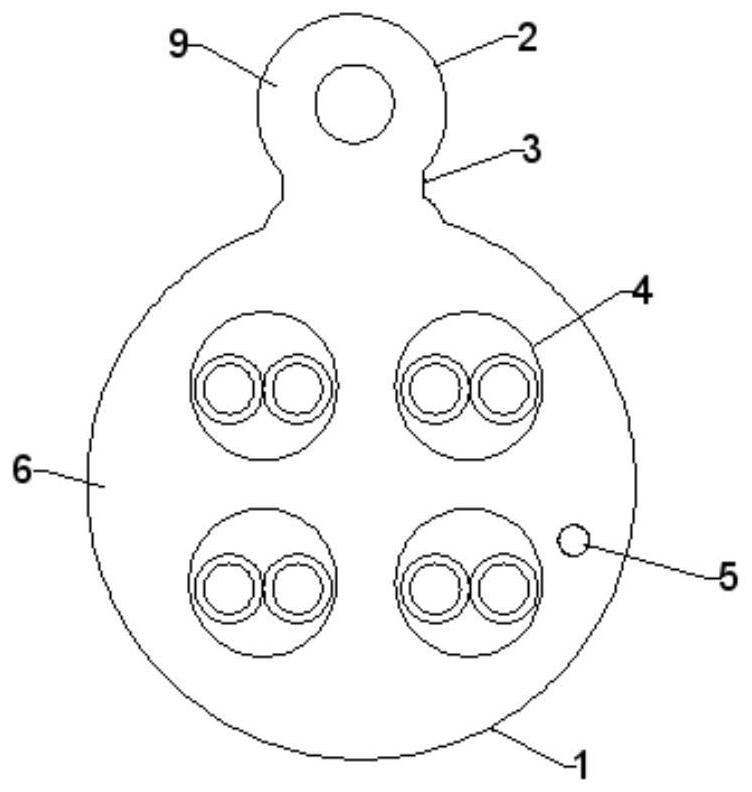

Reinforced high-strength paired cable for outdoor digital communication

ActiveCN113707375AImprove connection strengthHigh tensile strengthClimate change adaptationInsulated cablesArchitectural engineeringElectric cables

The invention provides a reinforced high-strength paired cable for outdoor digital communication. The cable comprises a cable main body part and at least one reinforcing structure arranged on the outer side of the cable main body part, and the reinforcing structure is connected with the cable main body part through a sling; the cable main body part comprises a cable core, a cable tearing rope and a cable outer sheath outside the cable core, and the cable tearing rope is arranged between the cable core and the cable outer sheath or arranged in the cable outer sheath; and the reinforcing structure comprises a reinforcing member and a reinforcing structure outer sheath on the outer side of the reinforcing member. The cable is reasonable in structural design, and the reinforcing structure can effectively improve the tensile strength and the bearing capacity of the cable.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

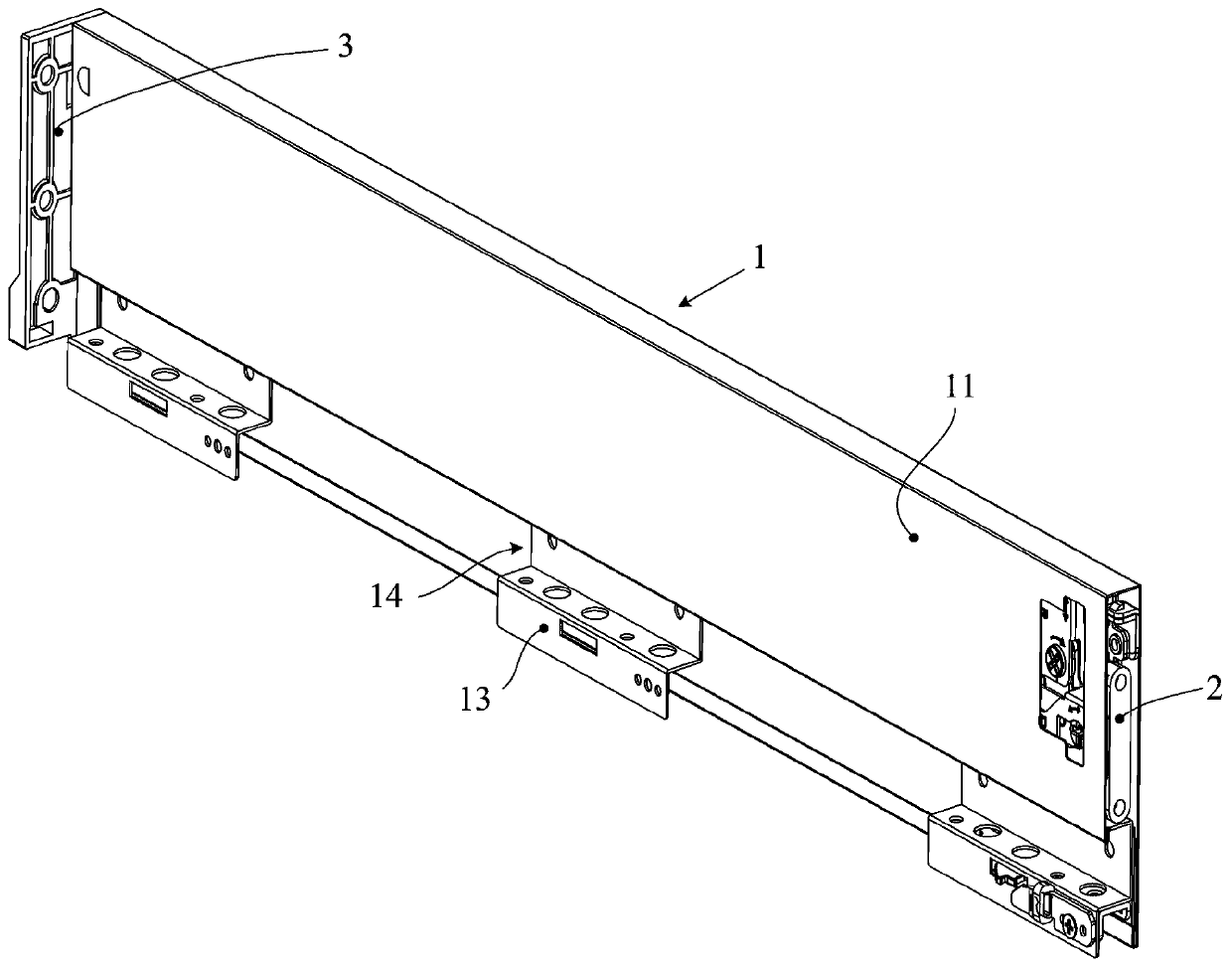

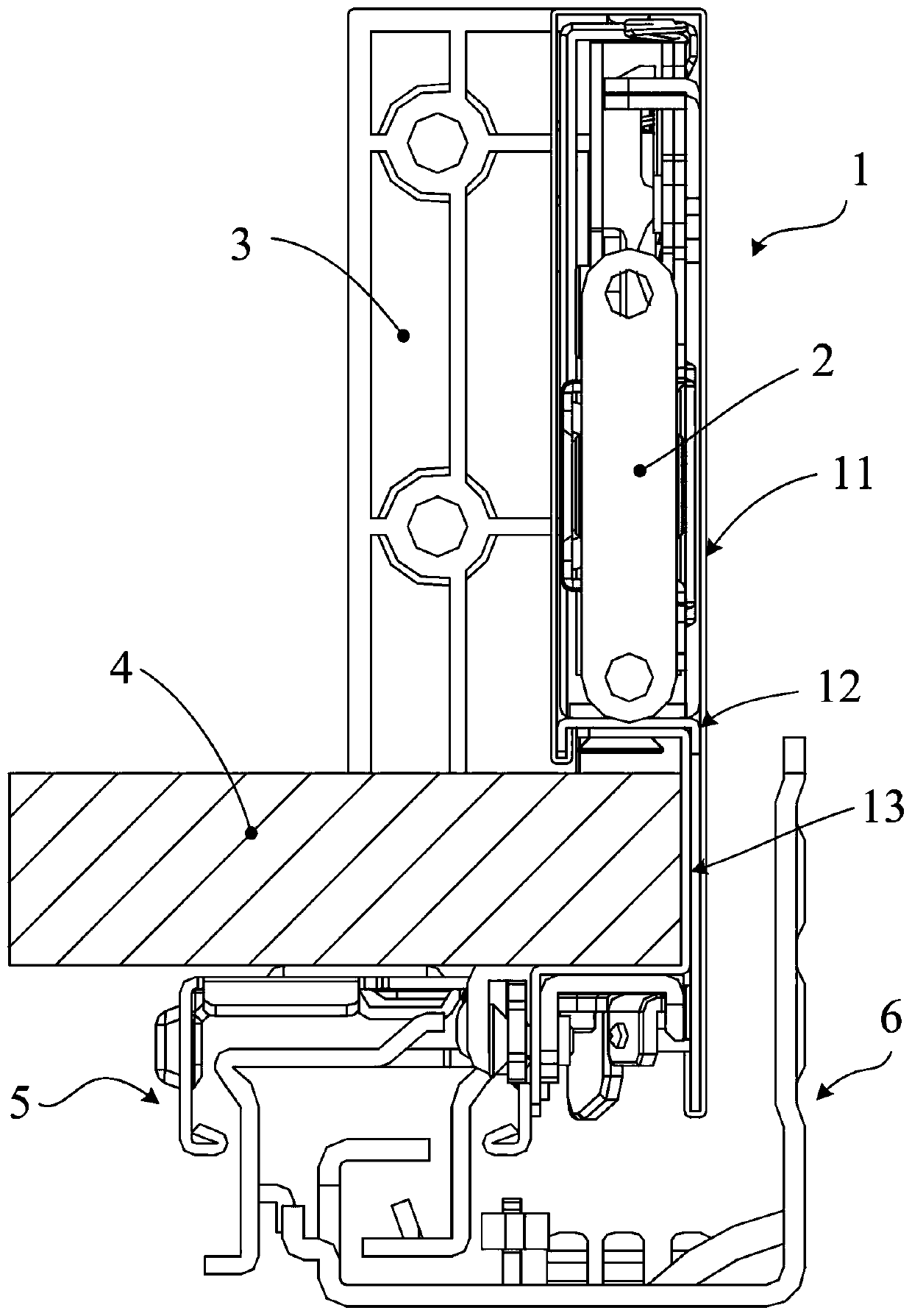

Side plate structure of novel drawer slide rail

The invention discloses a side plate structure of a novel drawer slide rail. The side plate structure comprises a slide plate arranged along the drawing direction of a drawer, wherein a front connecting component is arranged at the front part of the side plate and is connected with a front panel, a rear connecting component is arranged at the rear part of the side plate and is connected with a rear back plate; the side plate is formed by connecting a slide plate shell, an upper side plate frame and a lower side plate frame; an inner bending part is at least arranged at the lower part of the side plate shell and is connected with the bending part of the upper side plate frame through insertion, a horizontal part is at least arranged at the lower side plate frame to form a mounting slot formounting a drawer base plate with the upper side plate frame, and the lower side plate frame is detachably connected with a movable slide rail of the slide rail. Compared with the prior art, the technical scheme of the invention has the advantages of reliable structure, safety in use and the like, the use reliability of the side plate structure of the drawer can be effectively improved, the structure is simplified, and the production cost is lowered.

Owner:DONGGUAN GERUISI PRECISION HARDWARE TECH CO LTD

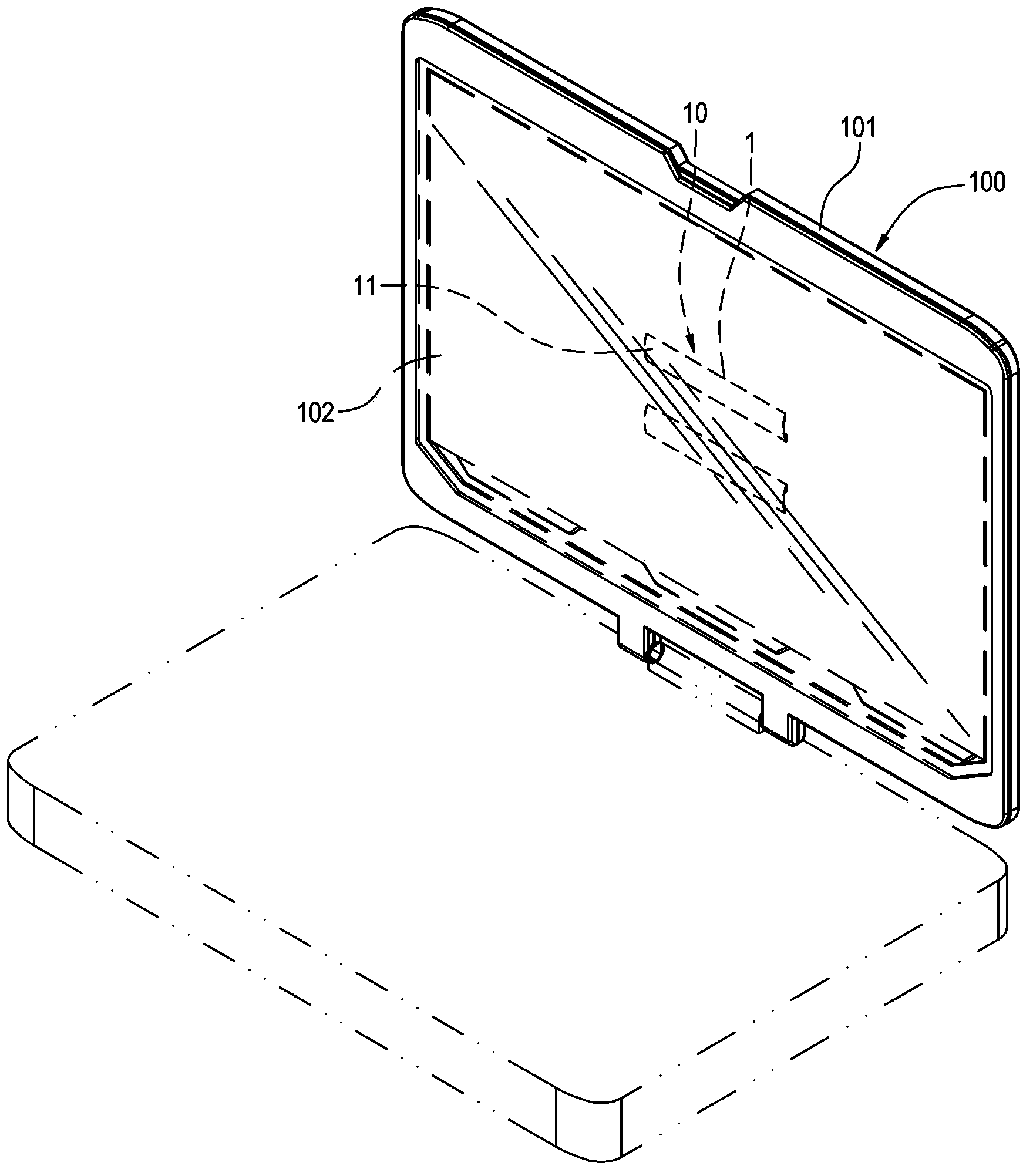

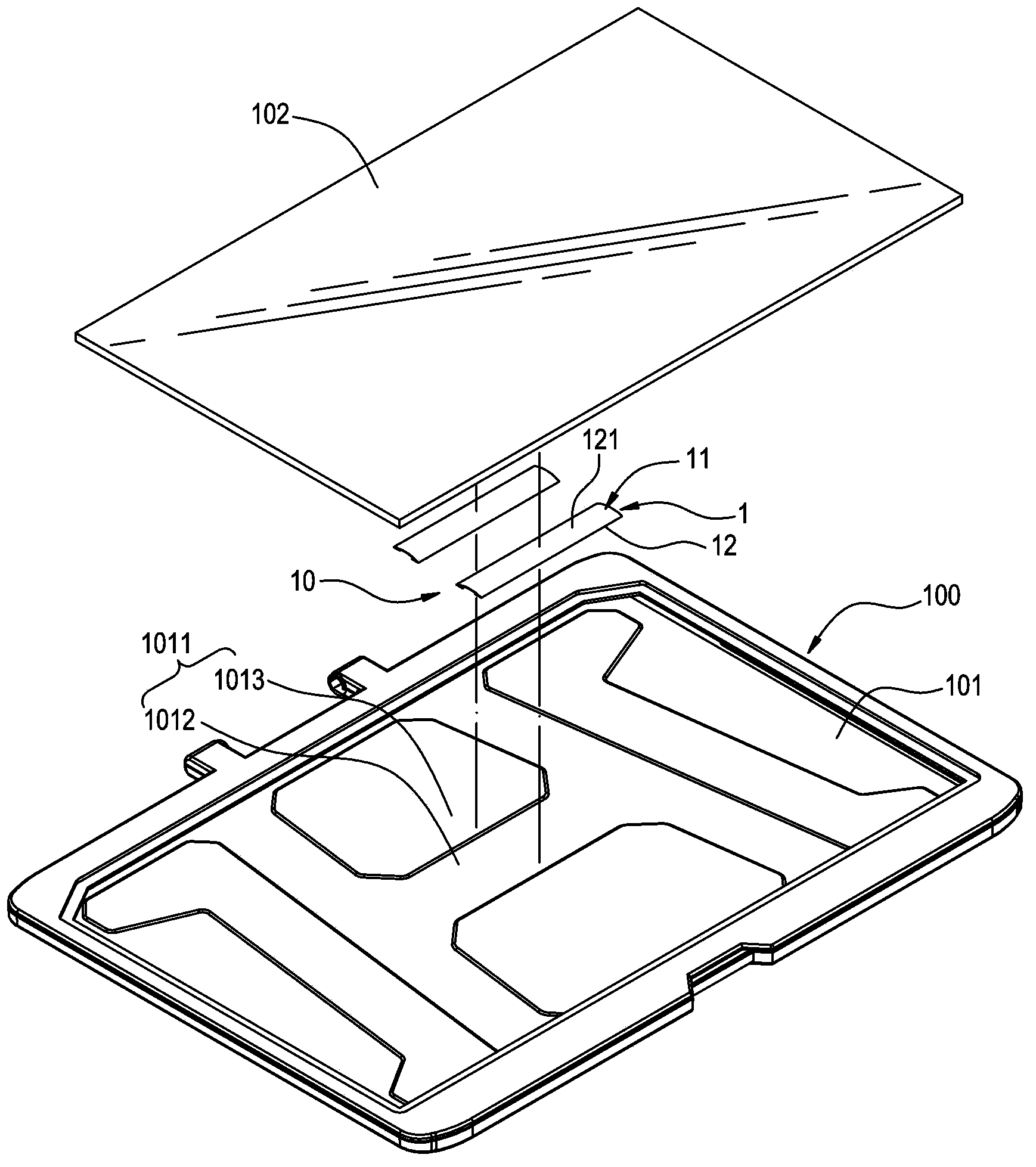

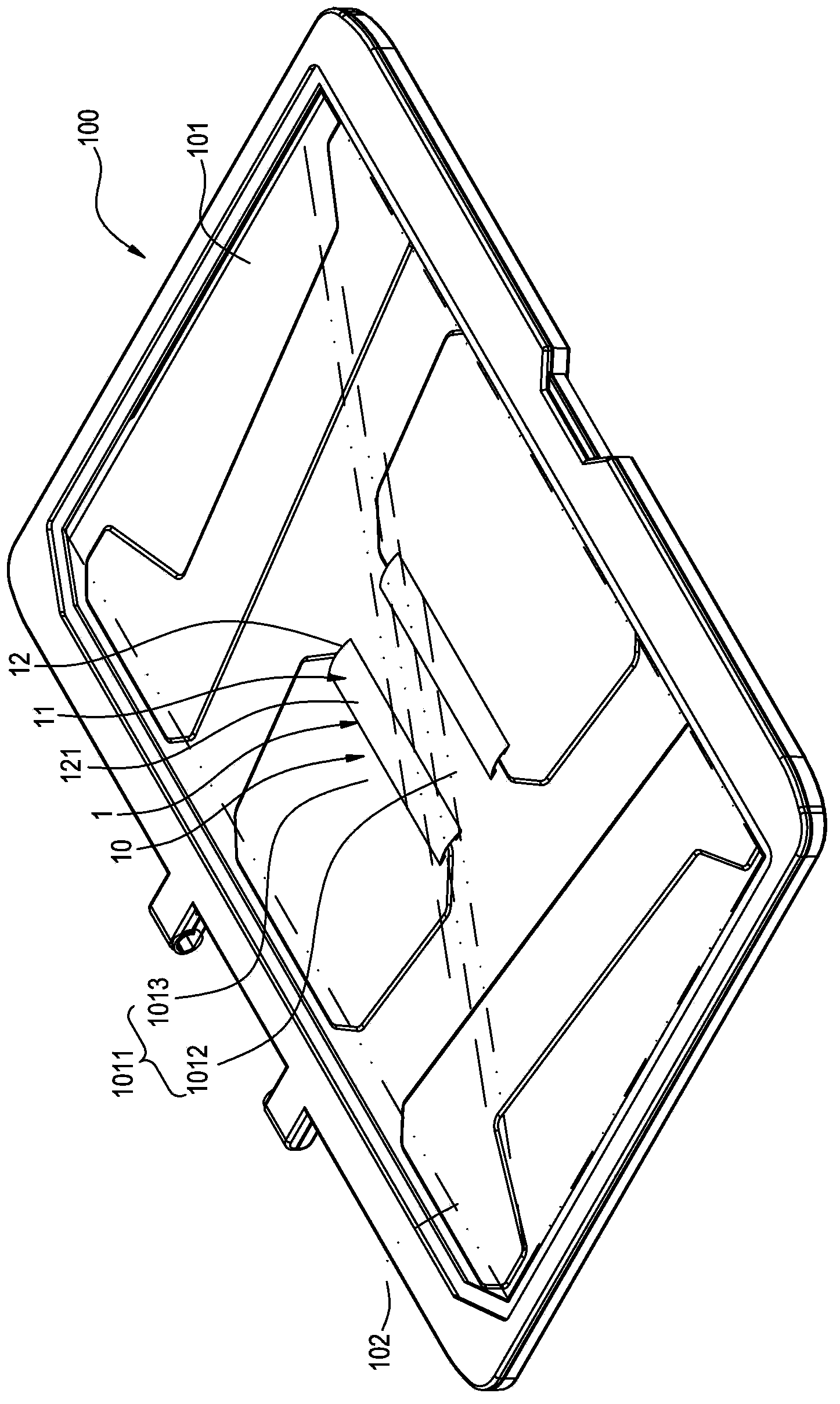

Pressure-resistance structure of electronic device

ActiveCN104284540AAvoid stress concentrationAffect operational efficiencyCasings/cabinets/drawers detailsElectrical apparatus contructional detailsStress concentrationEngineering

The invention provides a pressure-resistance structure of an electronic device. The electronic device is provided with a case and an electronic assembly contained in the case, a protrusion portion is formed on the case in the direction facing the electronic assembly, the pressure-resistance structure comprises a buffer body, the buffer body is fixed to the protrusion portion or the periphery of the protrusion portion, the buffer body is provided with at least one deformable convex face arranged in the direction of the electronic assembly, when the case is under pressure and the protrusion portion approaches the electronic assembly, and the deformable convex face makes contact with the electronic assembly and deforms so as to perform a pressure sharing function. Accordingly, when the protrusion portion approaches the electronic assembly, the deformable convex face will make contact with the electronic assembly first and deforms so as to provide a pressure sharing function, and then the situation that stress concentration occurs in the local position of the electronic assembly is avoided.

Owner:SHENXUN COMP KUNSHAN +1

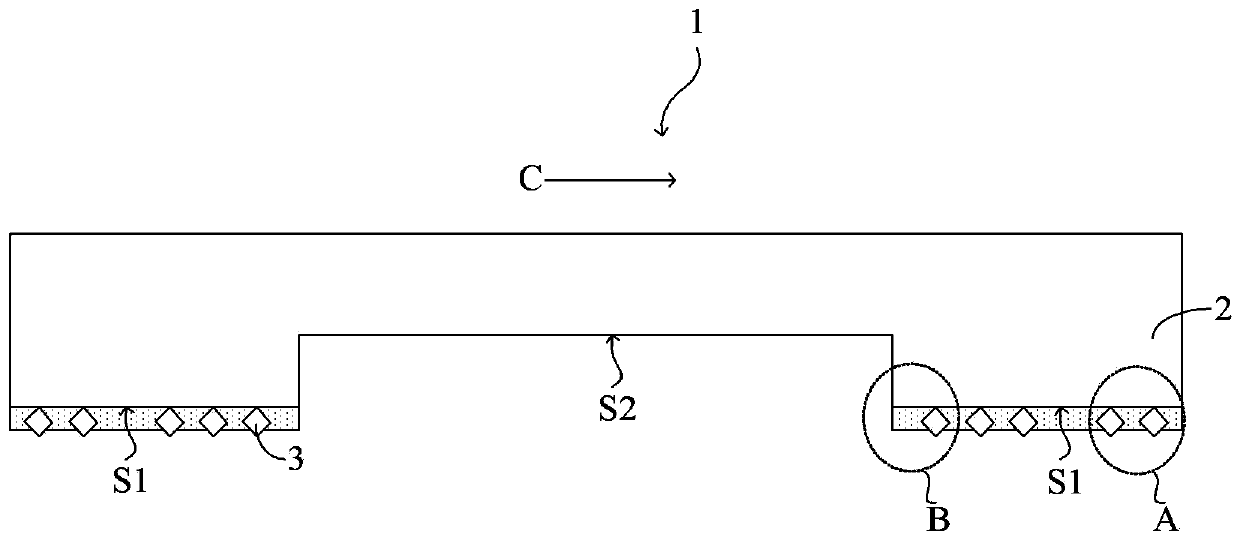

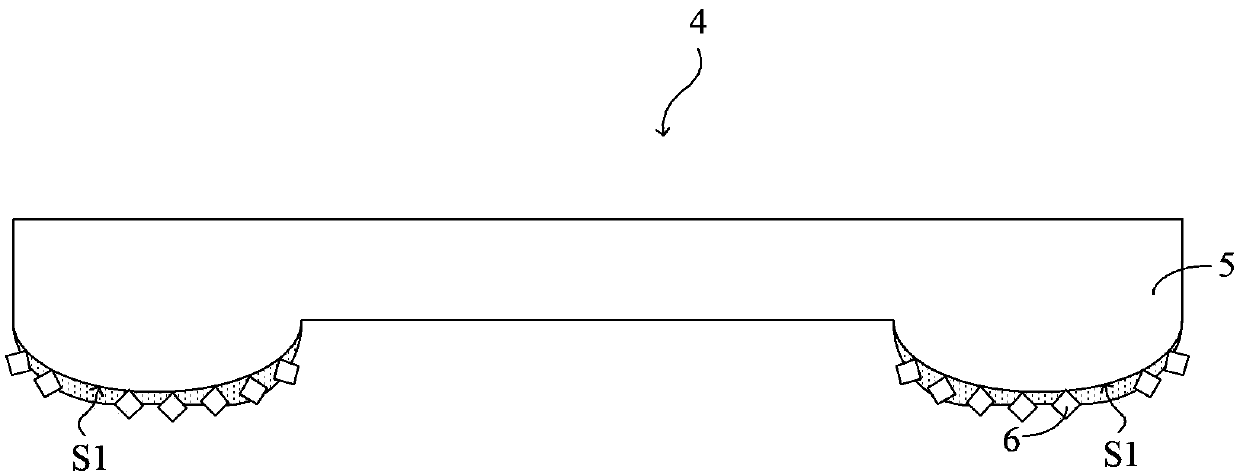

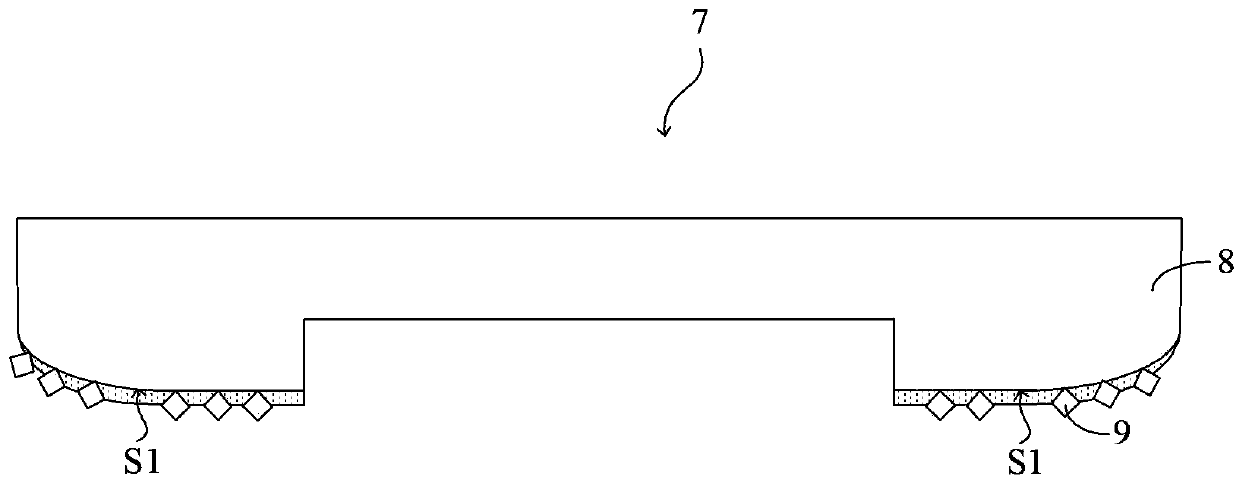

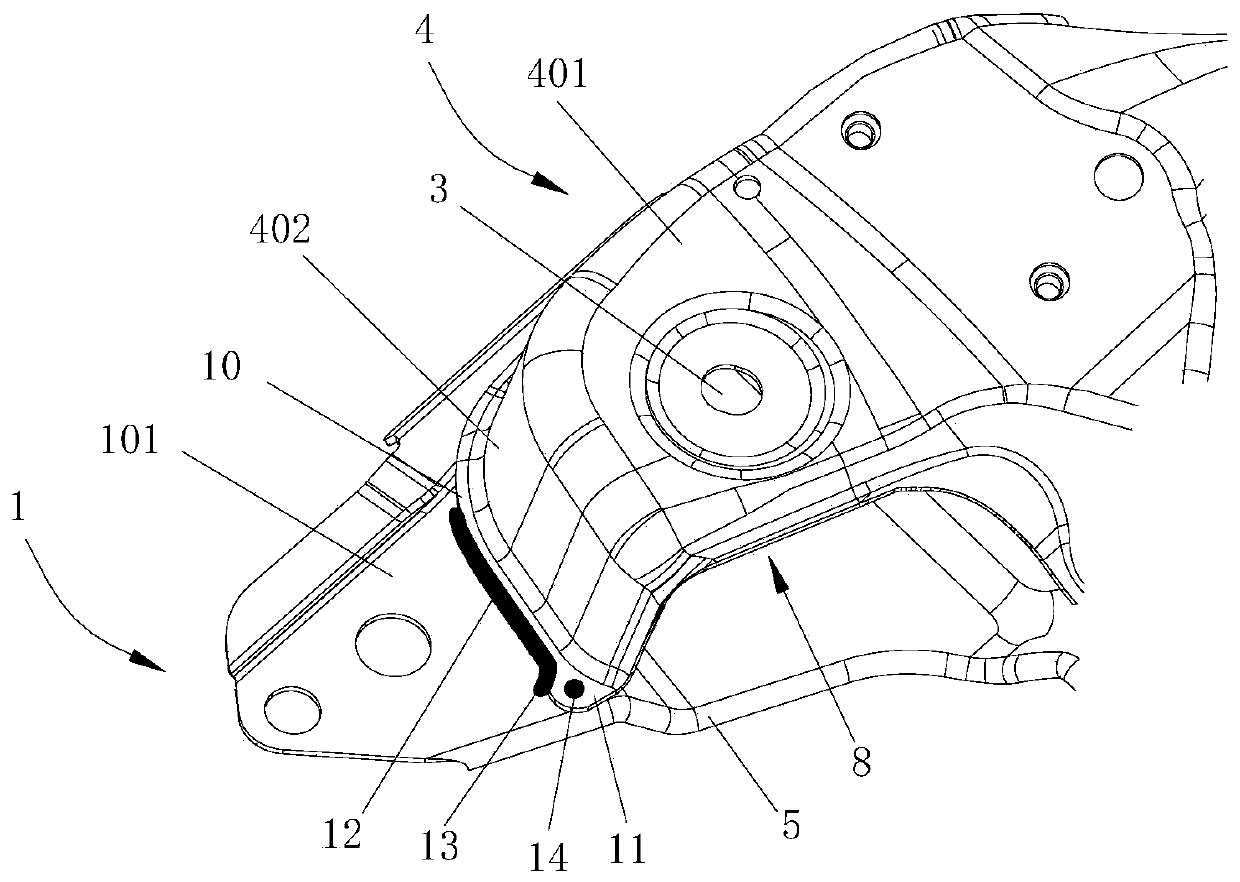

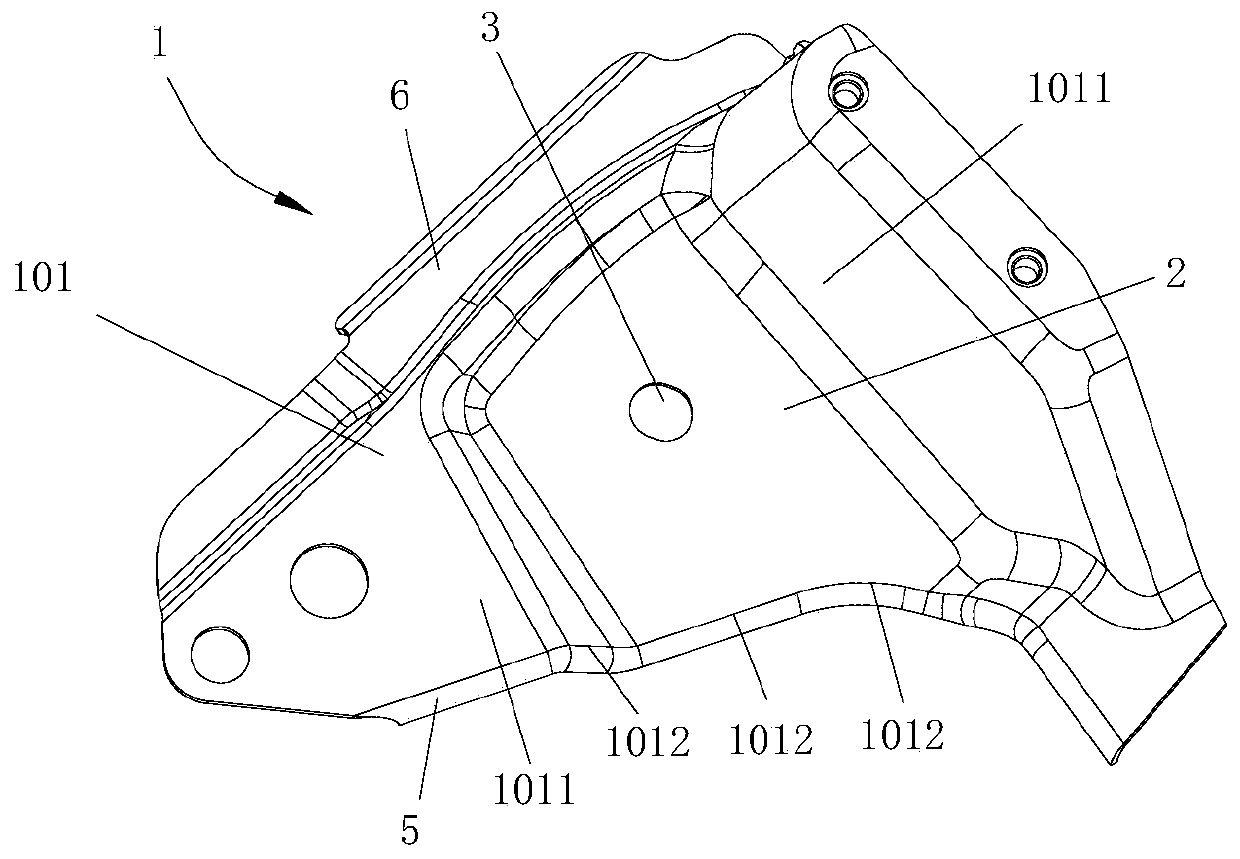

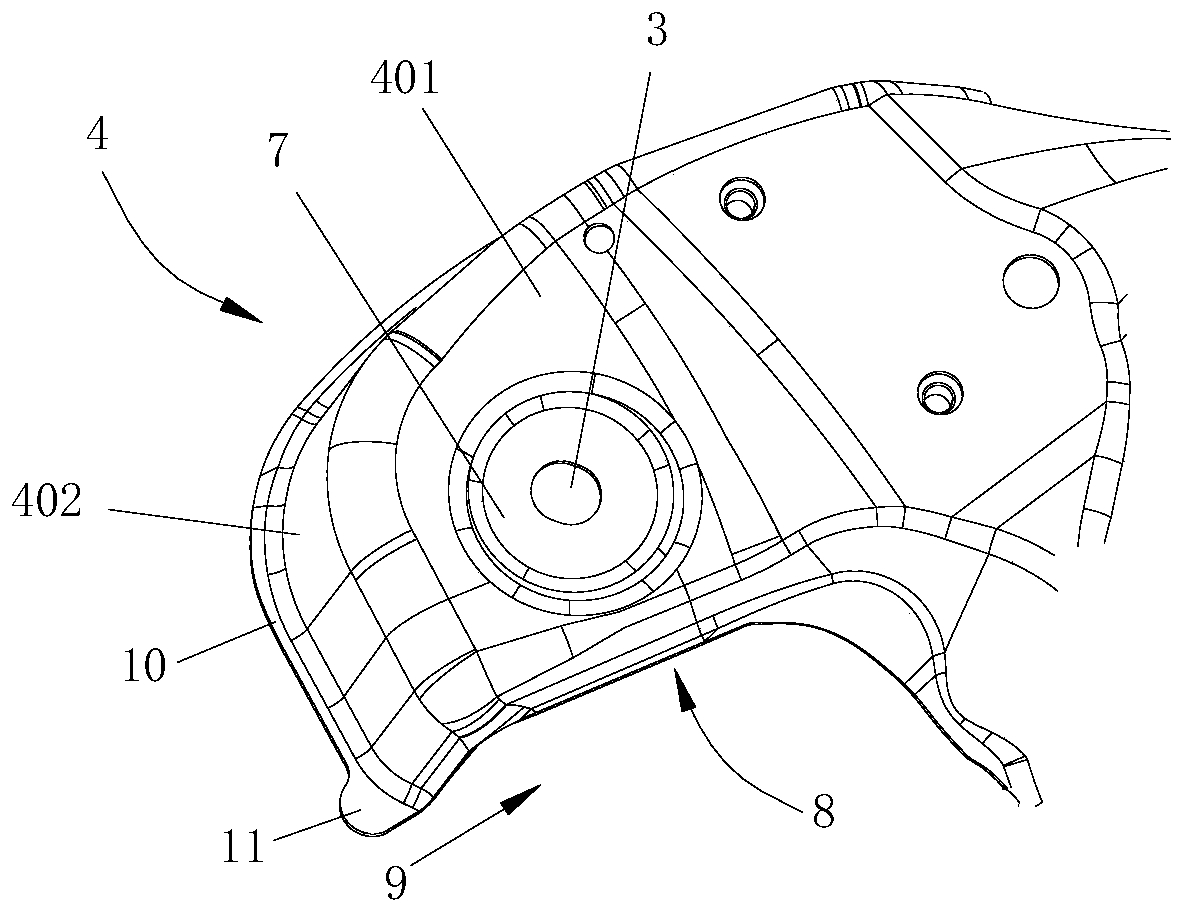

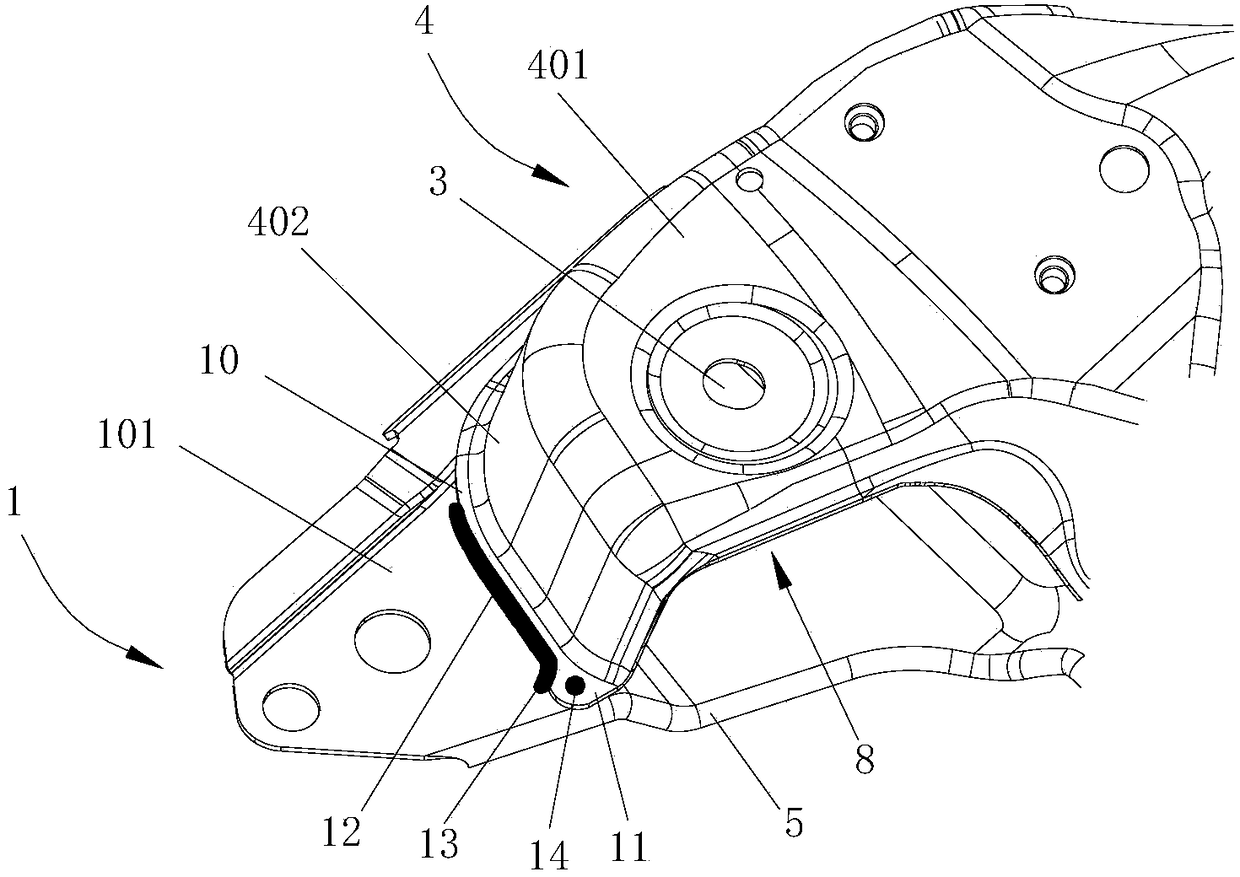

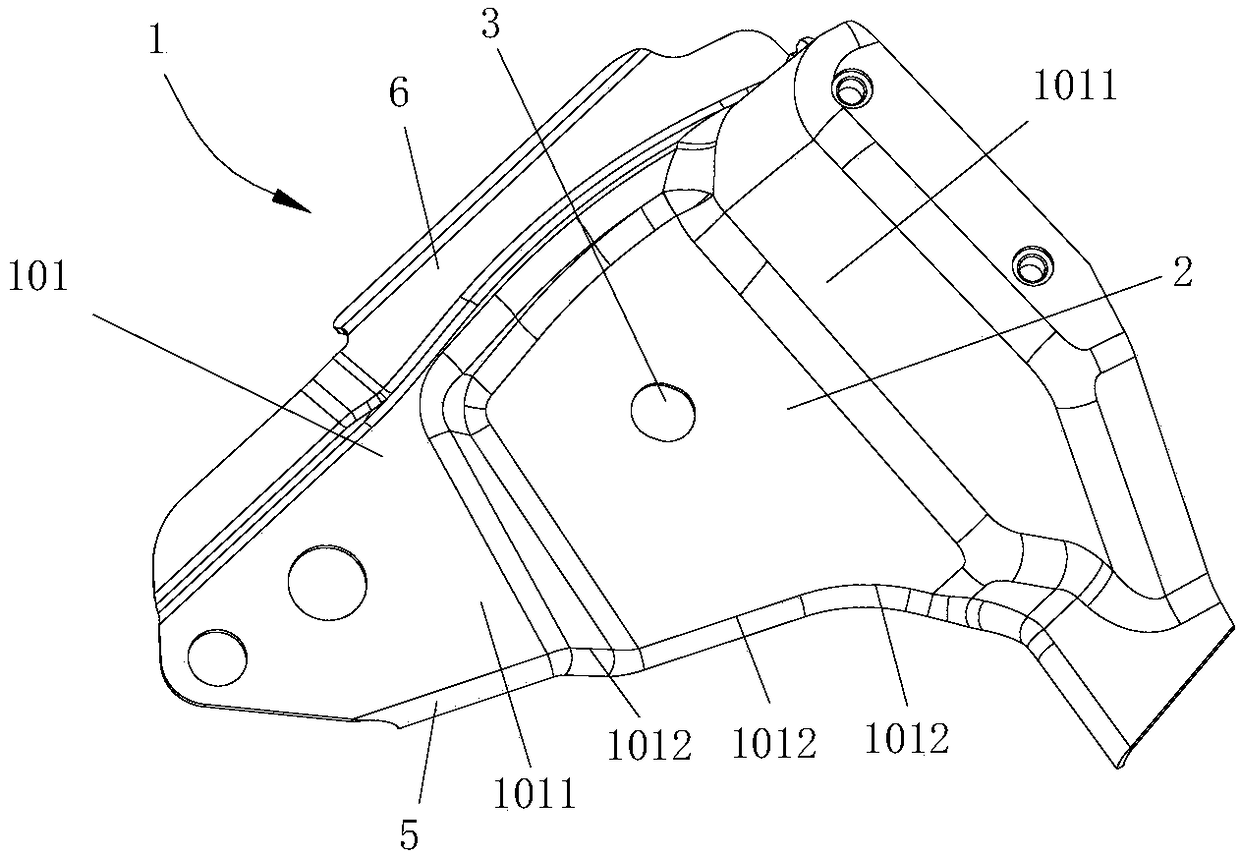

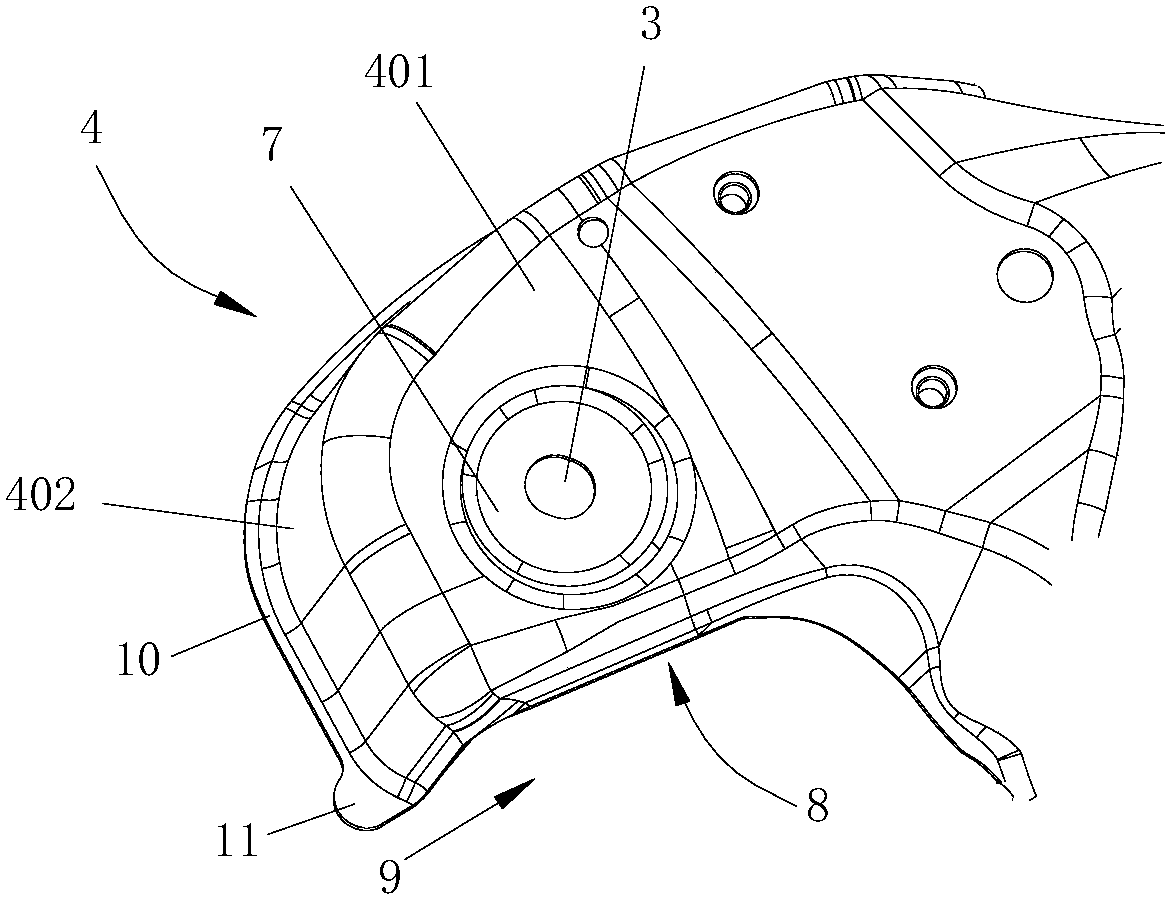

Vehicle sub-frame structure and installation method thereof

ActiveCN108263474BReduce crackingAvoid stress concentration situationsVehicle body-frame connectionsUnderstructuresVehicle frameWeld seam

The invention provides a vehicle auxiliary frame structure and a mounting method thereof. The vehicle auxiliary frame structure is provided with an upper edge plate, a lower edge plate and a connecting part, wherein the connecting part is integrally formed at the bottom of the upper edge plate, and the connecting part and the lower edge plate are arranged in an attached mode. The connecting part and the lower edge plate are connected in a welded mode to form a welded joint, the connecting part comprises a main connecting part body and an auxiliary connecting part body which is formed on at least one end portion of the main connecting part body, the welded joint comprises a main welded joint body following the main connecting part body in shape, and an auxiliary welded joint body, the auxiliary welded joint body follows the auxiliary connecting part body in shape due to guiding of the auxiliary connecting part body, and the auxiliary welded joint body and the main welded joint body forman inflection point at an intersection place. The vehicle auxiliary frame structure further comprises a point welding position located between the auxiliary connecting part body and the lower edge plate so as to form point welding connection between the auxiliary connecting part body and the lower edge plate, and the auxiliary welded joint body and point welding connection are simultaneously formed between the auxiliary connecting part body and the lower edge plate, so that welded joint connection and point welding connection jointly bear stress from the outside, the situation of stress concentration at the tail end of the welded joint can further be avoided, and the phenomenon of cracking of the welded joint is reduced.

Owner:GREAT WALL MOTOR CO LTD

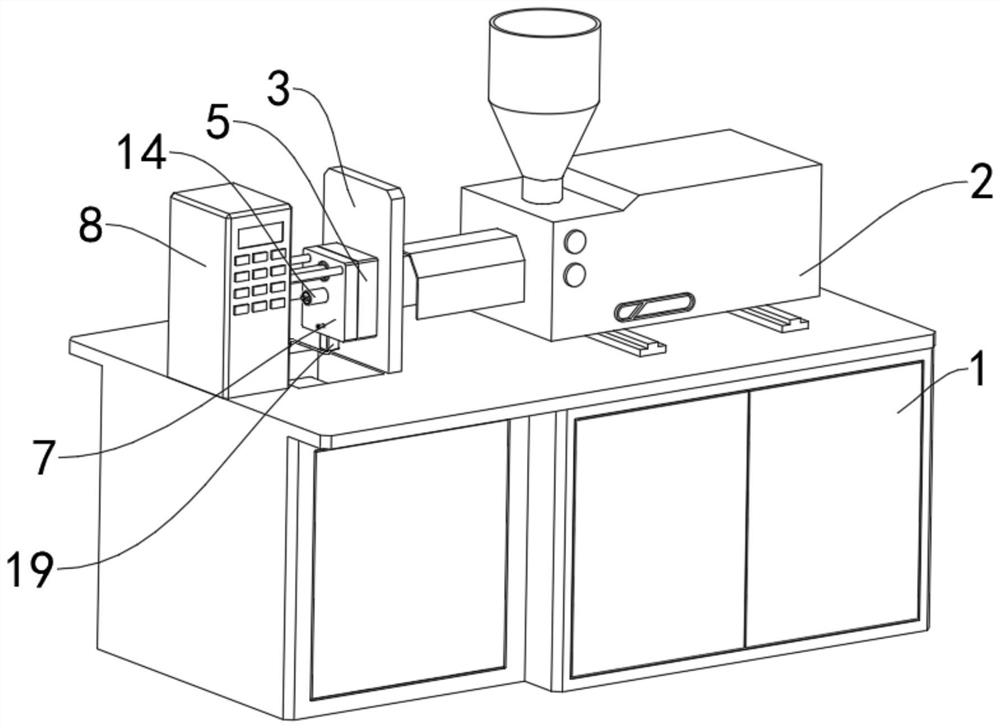

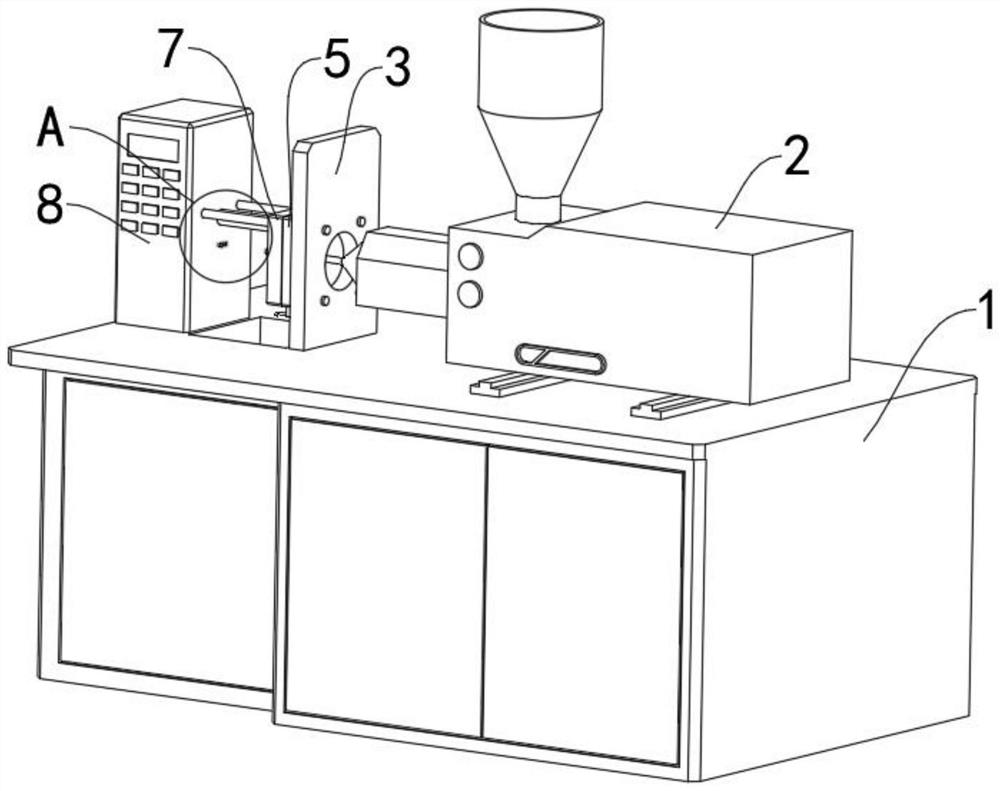

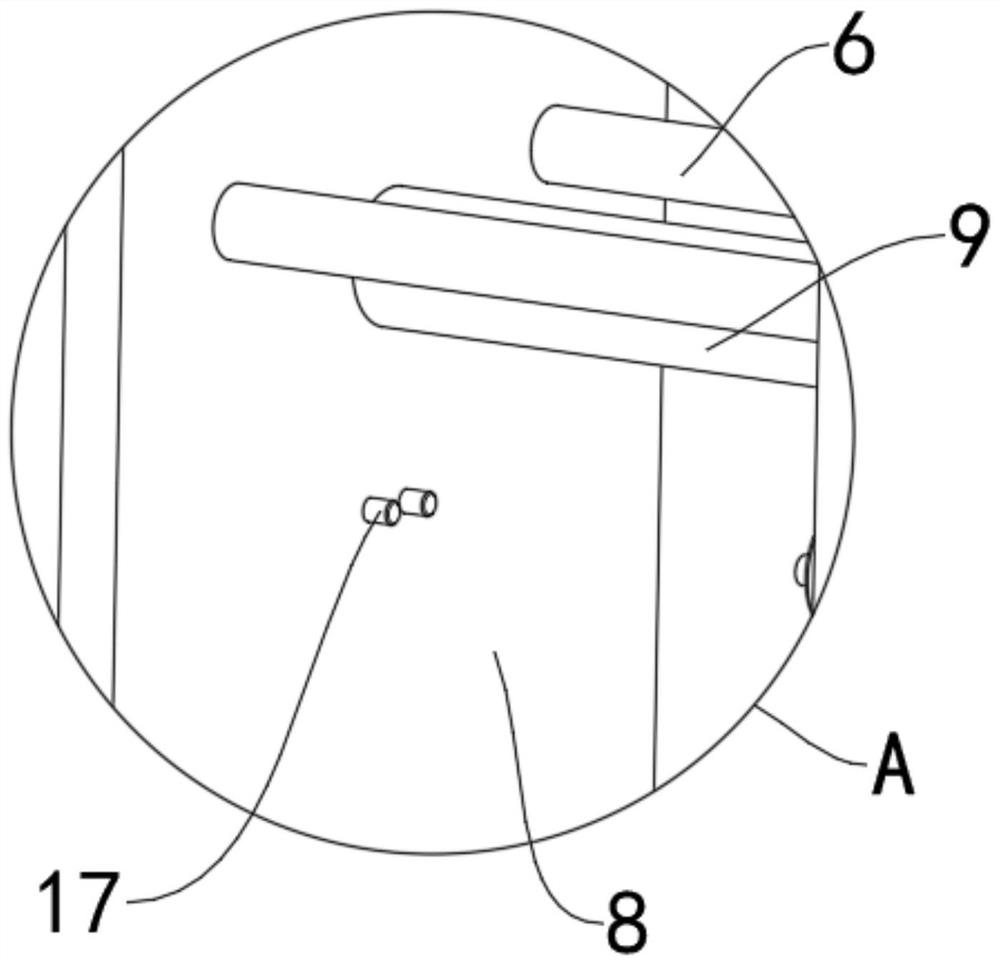

Auxiliary matched ejection device of injection molding machine for plastic part production

The invention belongs to the technical field of injection molding machines, and discloses an auxiliary matched ejection device of an injection molding machine for plastic part production, the auxiliary matched ejection device comprises a working platform and an injection molding assembly, a fixed plate is fixedly mounted on the top surface of the working platform, a fixed mold is fixedly mounted on the left side surface of the fixed plate, and a movable mold is inserted into the left end of the fixed mold; an electric control case is fixedly mounted at the left end of the top face of the working platform, and a connecting rod is in transmission connection with the middle of the right end of the electric control case. A power connection pipe makes contact with a power connection terminal to supply power to an electromagnet to generate magnetism, so that an electromagnet blocking shaft moves leftwards, the top end of a connecting air channel is opened, an air pump sucks air in an air bag into the connecting air channel, the air is blown to a plastic product on the right side of a movable mold through guiding of an air outlet pipe, and demolding of the plastic product is achieved; the plastic product is not in contact with the metal part, so that the surface of the plastic product is prevented from being scratched and abraded, and the plastic product is prevented from being damaged.

Owner:深圳市星凯科技有限公司

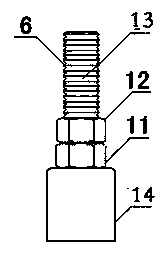

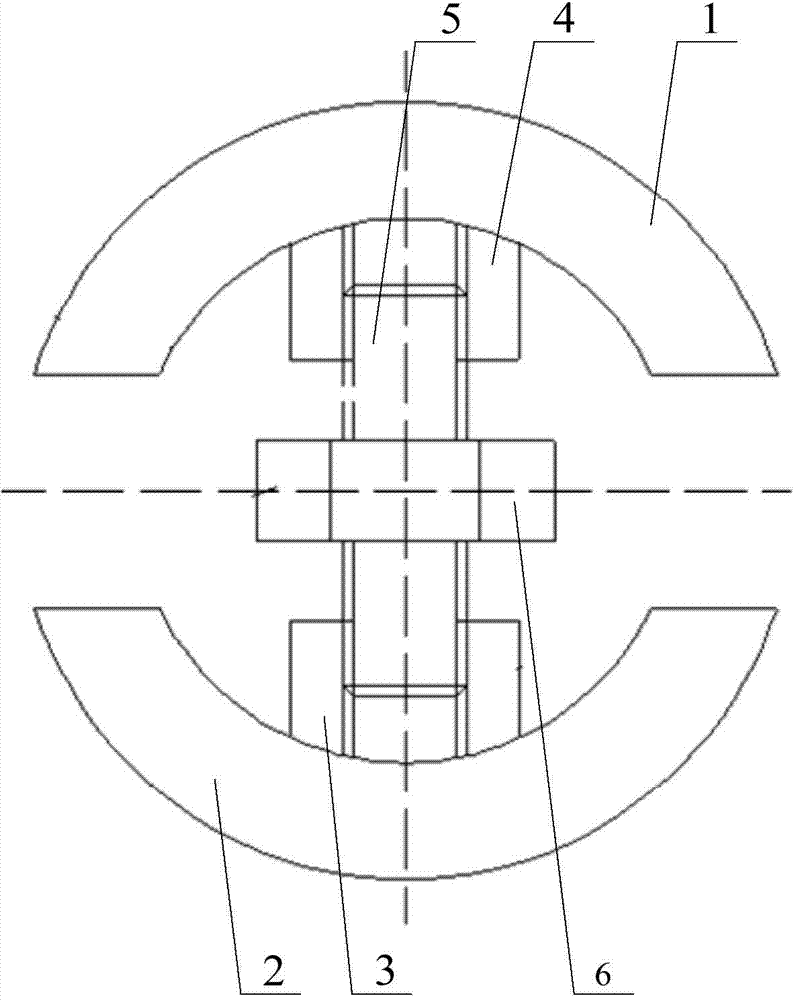

An induction furnace lining repair device

ActiveCN103629938BImprove rounding abilityAvoid damage to induction furnace liningsLinings repairScrew threadInduction furnace

The invention discloses a lining repairing device of an induction furnace. The lining repairing device of the induction furnace comprises an arc rounding press block, an arc supporting press block, a right-and-left threaded part, an arc rounding inner thread part and an arc supporting inner thread part, wherein the right-and-left threaded part comprises an arc rounding thread part and an arc supporting thread part which is fixed opposite to the arc rounding thread part; a thread rotation direction of the arc rounding thread part is opposite to that of the arc supporting thread part; one end of the arc rounding inner thread part is connected to the arc rounding press block fixedly, and the other end of the arc rounding inner thread part is in threaded connection with the arc rounding thread part; one end of the arc supporting inner thread part is connected to the arc supporting press block fixedly, and the other end of the arc supporting inner thread part is in threaded connection with the arc rounding inner thread part. Right-and-left threaded part rotation spaces are formed in the arc rounding inner thread part and the arc supporting inner thread part. Through the lining repairing device of the induction furnace, the rounding effect of a lining of the induction furnace can be improved.

Owner:SOUTHWEST ALUMINUM GRP

Vehicle auxiliary frame structure and mounting method thereof

ActiveCN108263474AReduce crackingAvoid stress concentration situationsVehicle body-frame connectionsUnderstructuresVehicle frameWelding joint

The invention provides a vehicle auxiliary frame structure and a mounting method thereof. The vehicle auxiliary frame structure is provided with an upper edge plate, a lower edge plate and a connecting part, wherein the connecting part is integrally formed at the bottom of the upper edge plate, and the connecting part and the lower edge plate are arranged in an attached mode. The connecting part and the lower edge plate are connected in a welded mode to form a welded joint, the connecting part comprises a main connecting part body and an auxiliary connecting part body which is formed on at least one end portion of the main connecting part body, the welded joint comprises a main welded joint body following the main connecting part body in shape, and an auxiliary welded joint body, the auxiliary welded joint body follows the auxiliary connecting part body in shape due to guiding of the auxiliary connecting part body, and the auxiliary welded joint body and the main welded joint body forman inflection point at an intersection place. The vehicle auxiliary frame structure further comprises a point welding position located between the auxiliary connecting part body and the lower edge plate so as to form point welding connection between the auxiliary connecting part body and the lower edge plate, and the auxiliary welded joint body and point welding connection are simultaneously formed between the auxiliary connecting part body and the lower edge plate, so that welded joint connection and point welding connection jointly bear stress from the outside, the situation of stress concentration at the tail end of the welded joint can further be avoided, and the phenomenon of cracking of the welded joint is reduced.

Owner:GREAT WALL MOTOR CO LTD

Motor package aluminum rotor structure

PendingCN107171467AGuaranteed inner circleGuarantee the concentricity of the outer circleMagnetic circuit rotating partsPump componentsInterference fitStress concentration

The invention discloses a motor package aluminum rotor structure which comprises a rotor body and a flange structure which is evenly symmetrically arranged on the outer circumferential side wall of the rotor body. The flange structure is used for disassembling and fixing fan blades. The rotor body, the steel ring and the flange structure are integrally die-casted. A number of positioning studs and threaded holes are arranged in the front of the flange structure to position and fix the fan blades. Reinforcing ribs are arranged on the back of the flange structure. The reinforcing ribs are arranged on the back of the flange structure, and a number of reinforcing ribs are arranged at the bottom of the casing body of the rotor body, so that air holes can be prevented in the formation of the flange structure and the casing body of the rotor body. Stress concentration caused by air holes during a working process can be prevented. The rotor structure is produced through an integral die-casting process, and the problem of beating caused by interference fit of the steel ring and the outer circle of the rotor body is reduced to the greatest extent.

Owner:FANS TECH ELECTRIC CO LTD

Circuit board bearing device and circuit board fixing method

InactiveCN101296607AIncrease contact surfaceAvoid stress concentrationPrinted circuit assemblingElectrical componentsBearing surfaceStress concentration

The invention provides a circuit board bearing device which is provided with a bearing surface used for bearing the circuit board. The bearing surface is provided with at least one groove which is provided with a groove bottom surface opposite to the bearing surface; the groove bottom surface is provided with a bonding layer. The technical proposal also provides a method for fixing the circuit board. In the technical proposal, the circuit board can be stably fixed on the circuit board bearing device, and the situation of stress concentration can not occur on electronic components adhered on the surface of the circuit board.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

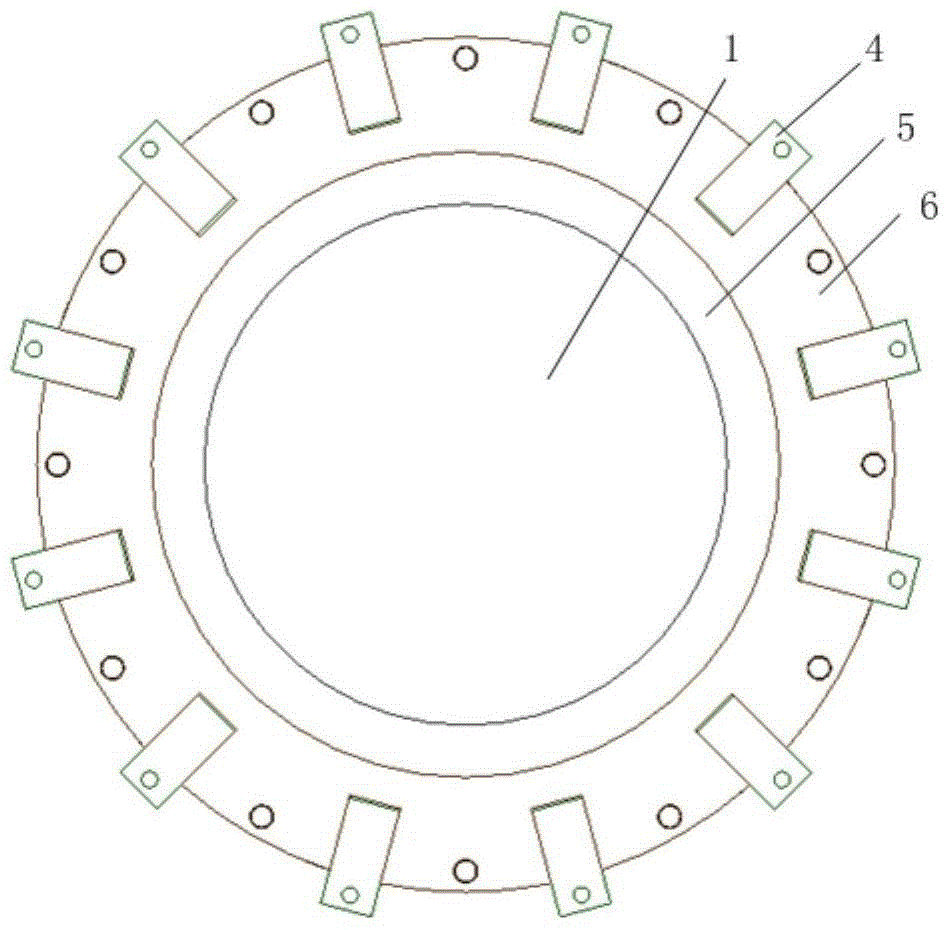

A method for installing a flat film mirror

ActiveCN104730681BImprove surface accuracyReduce the influence of low surface accuracyMountingsMembrane mirrorThin membrane

A method of installing a flat film mirror. First, the circular film mirror is unfolded into a flat state, and a rectangular thin gasket with holes is evenly and firmly bonded around the film mirror through a special tooling, and the two ends of N ropes are respectively connected to the rectangular gasket. and tension sensors, fix the tension sensors around so that each rope is on the same plane. Then, place the precision support ring under the film mirror, lightly top the film mirror with a side with a ring-shaped step surface, and then install the pressure ring above the support ring, pre-tighten the pressure ring with screws but ensure that the film mirror can Move between the pressure ring and the support ring, apply tension on the outermost end of the rope around the film mirror, and the tension sensor will display the tension value, adjust the tension value and detect the shape of the film mirror in real time, and repeatedly adjust each tension value according to the measured surface shape to make the film The mirror shape is optimal. The invention realizes the installation of the high-precision flat film mirror through the support of the support ring and the coplanar tension adjustment of the edge of the film mirror, and can meet the use requirements of the high-precision optical system.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Laser sealing method and system

InactiveCN103464900BSynchronous sealingAvoid Stress Concentration SituationsSemiconductor devicesLight beamLaser light

Owner:SHANGHAI UNIV +1

Lining repairing device of induction furnace

ActiveCN103629938AImprove rounding abilityAvoid damage to induction furnace liningsLinings repairScrew threadInduction furnace

The invention discloses a lining repairing device of an induction furnace. The lining repairing device of the induction furnace comprises an arc rounding press block, an arc supporting press block, a right-and-left threaded part, an arc rounding inner thread part and an arc supporting inner thread part, wherein the right-and-left threaded part comprises an arc rounding thread part and an arc supporting thread part which is fixed opposite to the arc rounding thread part; a thread rotation direction of the arc rounding thread part is opposite to that of the arc supporting thread part; one end of the arc rounding inner thread part is connected to the arc rounding press block fixedly, and the other end of the arc rounding inner thread part is in threaded connection with the arc rounding thread part; one end of the arc supporting inner thread part is connected to the arc supporting press block fixedly, and the other end of the arc supporting inner thread part is in threaded connection with the arc rounding inner thread part. Right-and-left threaded part rotation spaces are formed in the arc rounding inner thread part and the arc supporting inner thread part. Through the lining repairing device of the induction furnace, the rounding effect of a lining of the induction furnace can be improved.

Owner:SOUTHWEST ALUMINUM GRP

Ink drying device applied to newspapers

InactiveCN108608729ASpeed up dryingNot limited by humidityPrinting press partsMechanical engineeringQuartz

The invention discloses an ink drying device applied to newspapers. The ink drying device applied to the newspapers comprises a supporting block, a supporting cover and guide parts; a strip-shaped hole is formed in the side wall of the supporting block; mounting holes are formed in the end, close to the ground, of the hole wall of the strip-shaped hole; the guide parts comprise elastic rubber strips, movable shafts, connection arms, supporting shafts and balls; the supporting shafts are sleeved with the balls; the two ends of the supporting shafts are connected with one ends of the movable shafts through the connection arms separately; the other ends of the movable shafts are each inserted into one corresponding mounting hole; the ends, away from the movable shafts, of the rubber strips are connected with the bottoms of the mounting holes; the supporting cover is located in the strip-shaped hole; the upper surface of the supporting cover is connected with the top of the hole wall of the strip-shaped hole through a magnet in an attraction mode; an opening of the supporting cover is downward; and a plurality of infrared quartz heating bulbs and a plurality of fans are arranged on thetop of an inner cavity of the supporting cover. The ink drying device applied to the newspapers accelerates drying of ink and facilitates smooth implementation of subsequent back face printing or cutting.

Owner:德阳日报印刷厂

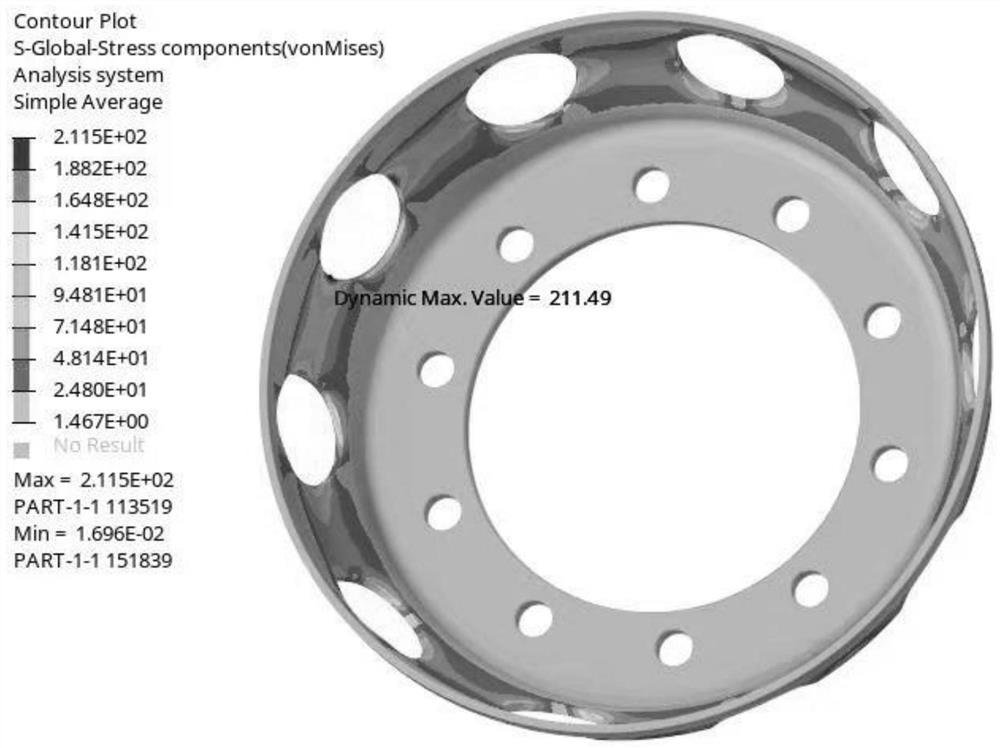

Wheel and vehicle with wheel

PendingCN112537166AImprove structural strengthSolve the problem of low structural strength at the position of the wind holeDisc wheelsEngineeringSpoke

The invention provides a wheel and a vehicle with the same. The wheel comprises a spoke, the spoke comprises an installation section, a transition section, a middle section and an end section which are connected in sequence, the middle section comprises a body section and a thickening section connected with the body section, and the thickening section is arranged between the body section and the end section. According to the technical scheme, the thickening section is arranged between the body section and the end section, so that the overall structural strength of the middle section is improved, the situation of stress concentration on the middle section is avoided, the overall structural strength of the spoke is improved, the service life of the spoke is prolonged, and the problem that the structural strength of the air hole position of the middle section is low in the prior art can be solved.

Owner:ZHEJIANG JINGU CO LTD

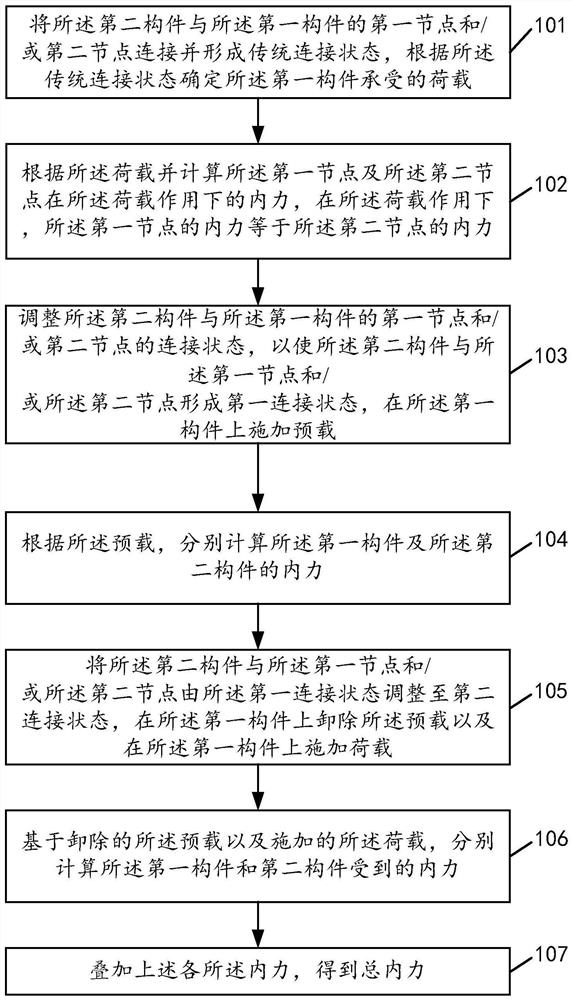

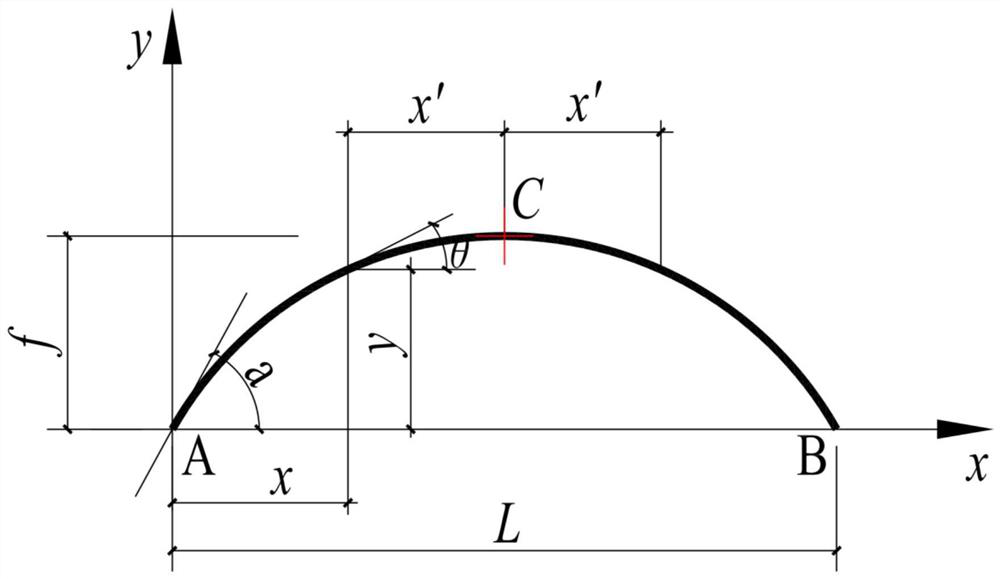

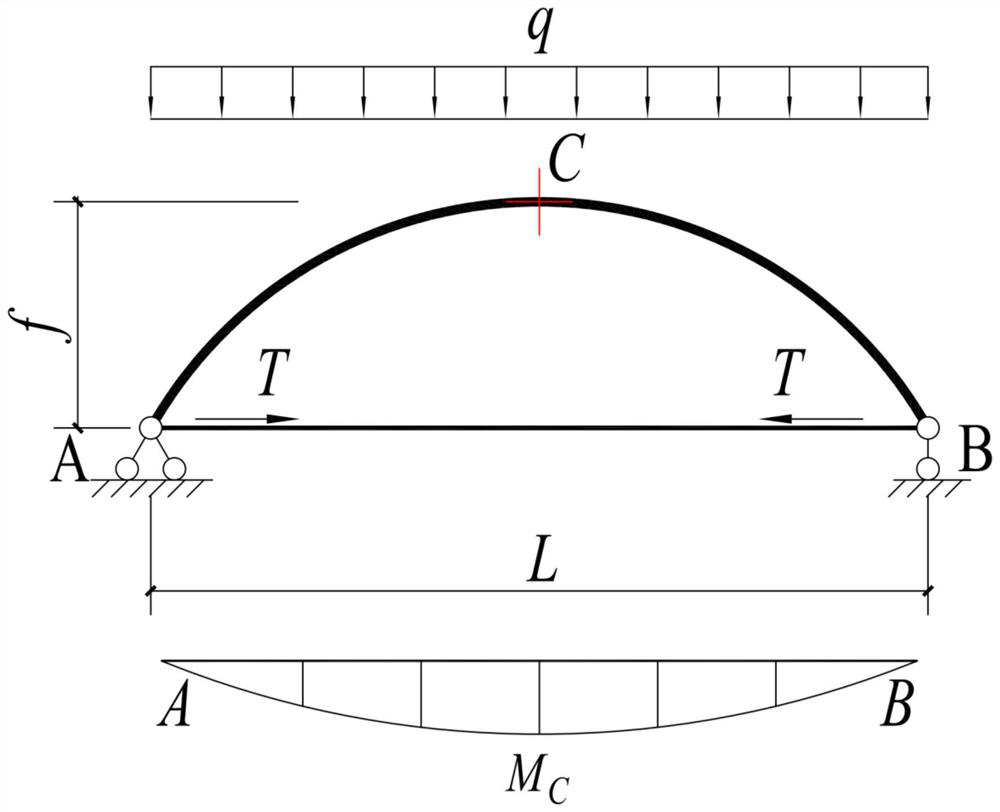

Pre-internal force of secondary internal force structure and calculation method thereof

PendingCN112446070AMain controlling internal force distribution equalizationEqualization of controlled internal force distributionGeometric CADConstraint-based CADControl theoryMechanical engineering

The invention discloses a pre-internal force of a secondary internal force structure and a calculation method thereof. The secondary internal force structure comprises a first component and a second component, the first component comprises a first joint and a second joint, and the method comprises the steps that the connection state of the second component and the first joint and / or the second joint of the first component is adjusted, so that the second component and the first node and / or the second node form a first connection state, and a preload is applied to the first component; internal force of each node of the first component is calculated according to the applied preload; the method also includes adjusting the connection state of the second component and the first node and / or the second node of the first component to be a second connection state, removing the preload on the first component, and applying a load on the first component; based on the unloading preload and the applied load, respectively calculating the internal force of each node of the first component; performing superposition of the internal forces. By the adoption of the method, secondary internal force generated by the first component can be effectively reduced, and meanwhile distribution of main control internal force of the first component is homogenized.

Owner:SHENZHEN GENERAL INST OF ARCHITECTURAL DESIGN & RES

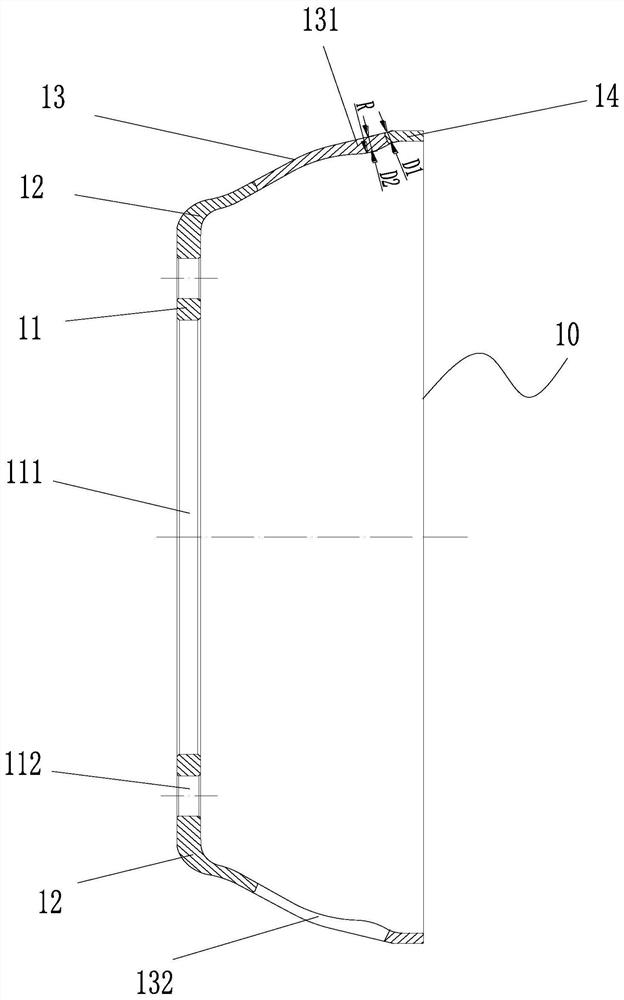

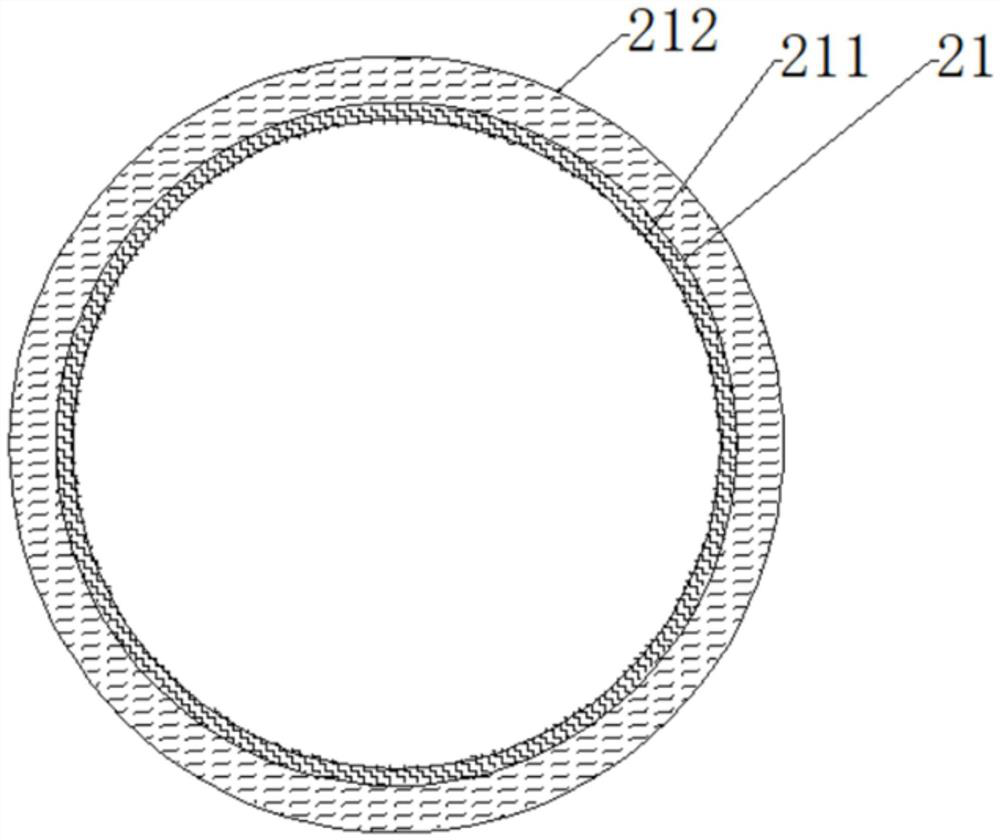

A kind of in-situ thermoplastic forming lining pipe and its construction technology

ActiveCN110094596BUniform prestressAvoid Stress Concentration SituationsPipe elementsPolymer sciencePolymer chemistry

The invention discloses an in-situ thermoplastic forming lining pipe and a construction process. The in-situ thermoplastic forming lining pipe comprises an outer pipe. The outer pipe comprises a blocking layer and a supporting layer. The blocking layer is located on the outer side of the supporting layer and used for water prevention and corrosion prevention. The supporting layer comprises a fiberreinforced layer. A fiber network and thermosetting resin are included in the fiber reinforced layer. The fiber network is located in the thermosetting resin. A secondary curing layer is fixed to theinner side face of the supporting layer and comprises a light-cured resin layer and a thermoset resin layer, the thickness of the light-cured resin layer ranges from 0.2 mm to 1 mm, and the thicknessof the thermoset resin layer ranges from 0.5 mm to 2 mm. After the light-cured resin layer is hardened due to UV-irradiation, the round pipe form of the outer pipe can be supported. An inner pipe isfurther included and is made of a thermoset PVC or resin material, the outer diameter of the inner pipe is larger than the inner diameter of the inner pipe and the inner diameter of the outer pipe, and the difference value is 1 / 10-1 / 8 of the diameter of the outer pipe. The lining pipe can effectively support a pipeline and bear stress, and stress concentration can be avoided.

Owner:上海乐通管道工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com