Polishing pad finisher, polishing pad finishing device and polishing system

A dressing device and polishing pad technology, applied in the field of chemical mechanical polishing (CMP), can solve the problems of reducing the service life of the dresser 1, scratching silicon wafers, easy peeling, etc., and achieving the effect of reducing the possibility of peeling and reducing the frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

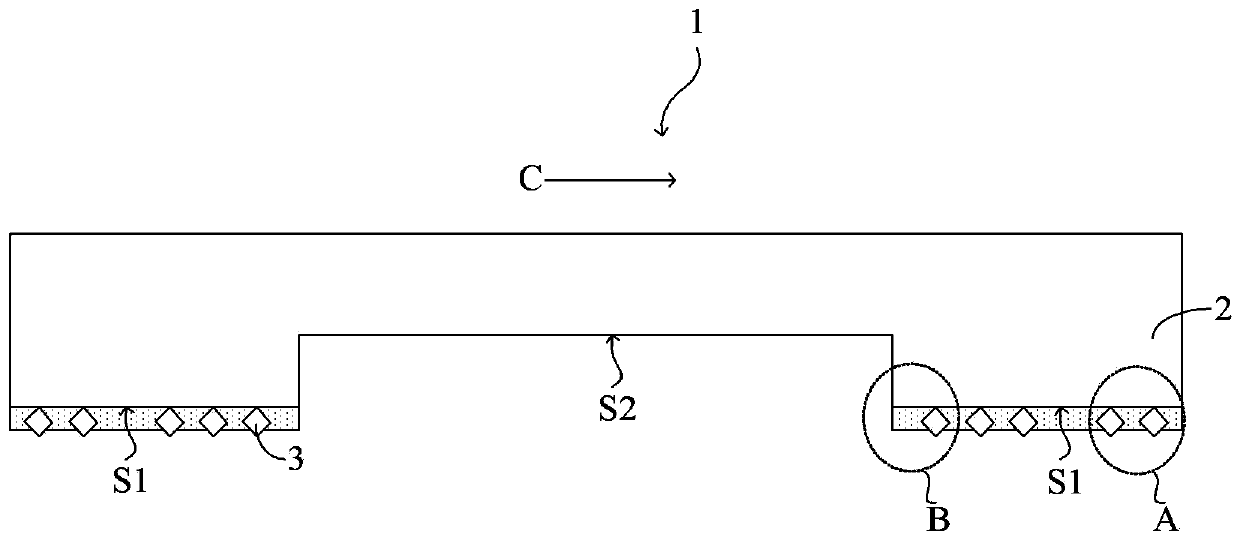

[0037] The inventor has found through research that one of the reasons why the diamond abrasive grains at the edge position are easy to peel off is: as figure 1 As shown, in the process of using the dresser 1 to dress the polishing pad, the outer edge position ( figure 1 The diamond abrasive grains 3 at the position indicated by the dotted line circle A) have a relatively large linear velocity, so they are easily subjected to a large shear force; , therefore, when using the dresser 1 to dress the polishing pad, no matter how much the indentation depth of the dresser 1 into the polishing pad is, all the diamond abrasive particles 3 on the grinding surface S1 will grind the polishing pad, increasing the outer edge position The frequency of use of the diamond abrasive grains 3 causes the diamond abrasive grains 3 at the outer edge to peel off easily.

[0038] The second reason why the diamond abrasive particles at the edge are easy to peel off is: continue to refer to figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com