Integrated fuel cell unit cell and fuel cell stack

A fuel cell and single cell technology, which is applied to fuel cells, fuel cell components, circuits, etc., can solve the problems such as the failure of the stack performance to meet the design requirements, the difference in the contact resistance of the battery cells, and the difficulty in guaranteeing the performance consistency. Achieve the effect of improved power generation performance, high structural stability and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

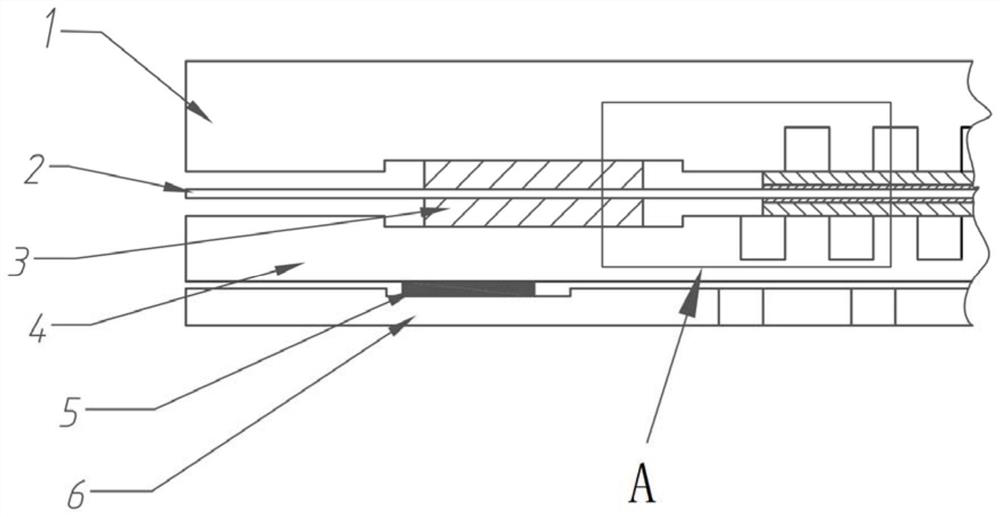

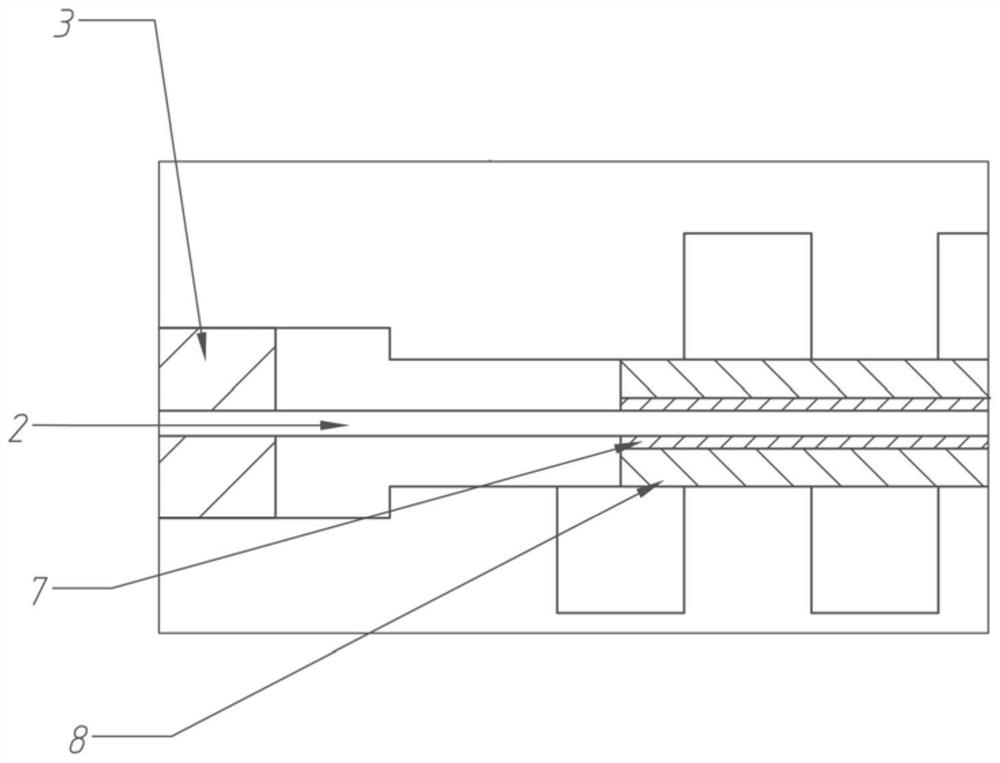

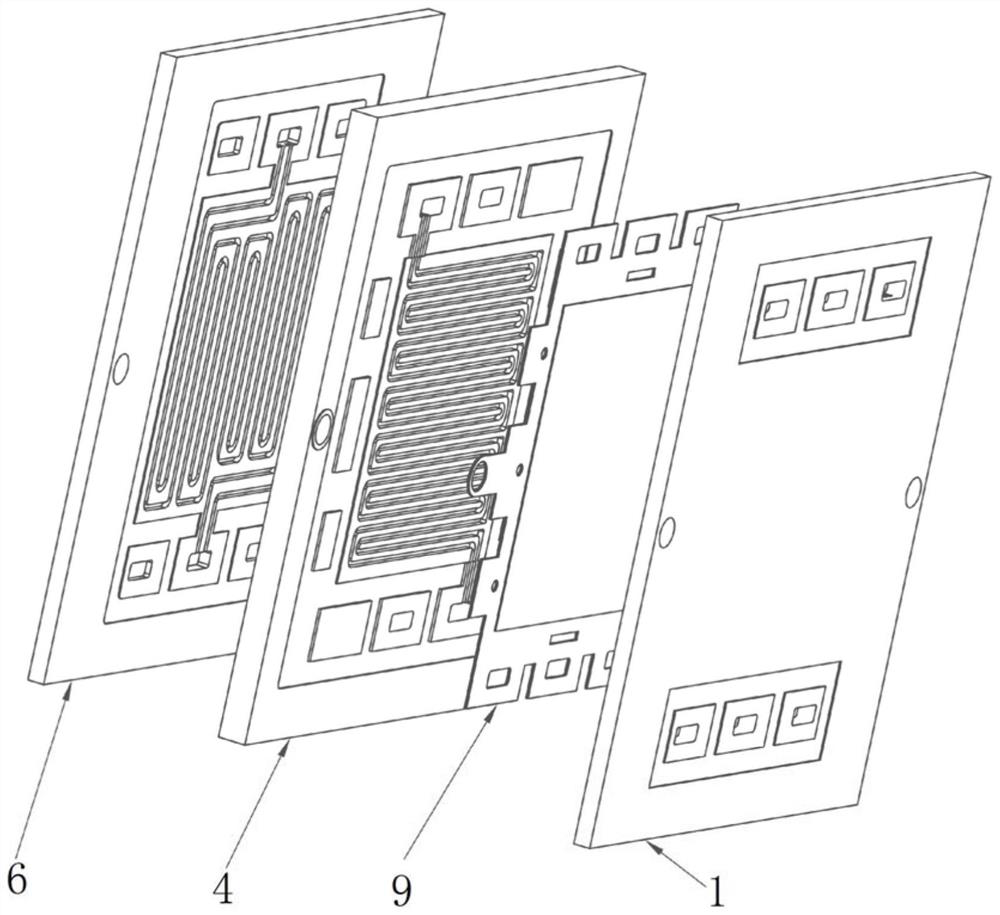

[0037] Such as Figure 3 ~ Figure 5 As shown, an integrated fuel cell unit includes a cathode plate 1 , a membrane electrode assembly 9 , an anode plate 4 and a water plate 6 stacked in sequence. The anode plate 4 forms a fuel channel, the cathode plate 1 forms an air channel, and then forms a flow field between the anode plate 4 and the cathode plate 1. The membrane electrode assembly 9 is used as a carrier for electrochemical reactions to generate electric energy, and the water plate 6 is used to form a Cooling water channel. Membrane electrode assembly 9 includes a proton exchange membrane 2, and the proton exchange membrane 2 is stacked with a catalyst layer 7 and a gas diffusion layer 8 at the flow field position of the cathode plate 1 and the anode plate 4. The single cell also includes a membrane electrode support body 11, the proton exchange membrane 2 peripheral sides are fixed in the membrane electrode support body 11 and form a complete plane with the membrane elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com