Patents

Literature

56 results about "Membrane mirror" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membrane mirrors are mirrors made on thin films of material, such as metallized PET film. They can be used as components in adaptive optics systems.

Tunable dispersion compensator

An optical dispersion compensator including: a spacer element having a top surface and a bottom surface; a thin film, multi-layer mirror formed on the top surface of the spacer element, the thin film mirror having a thermally tunable reflectivity; a highly reflective mirror element formed on the bottom surface of the spacer element; and a heater element for controlling a temperature of the thermally tunable thin film mirror.

Owner:AEGIS SEMICON

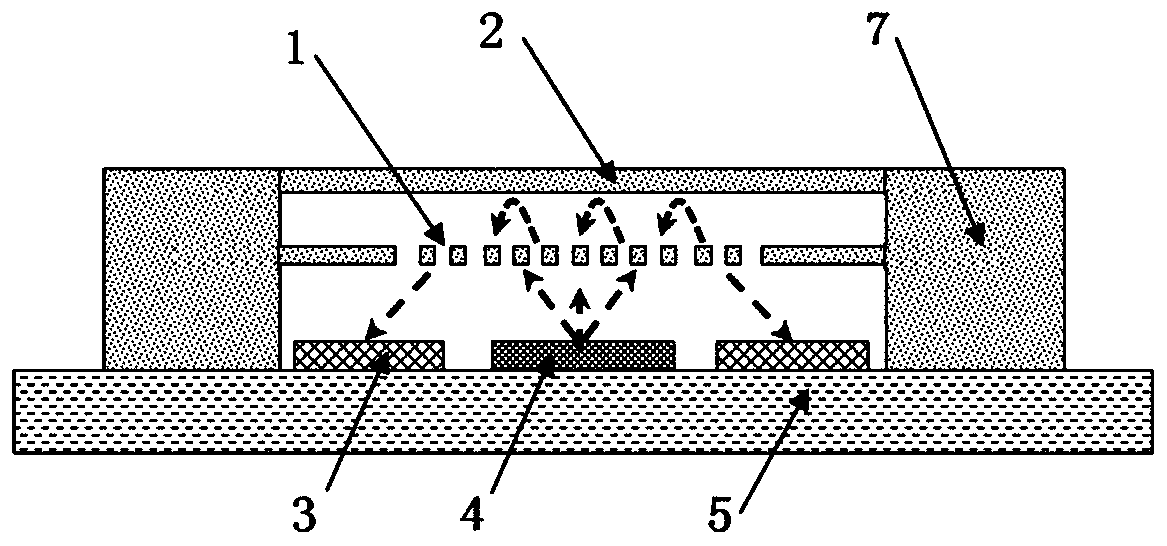

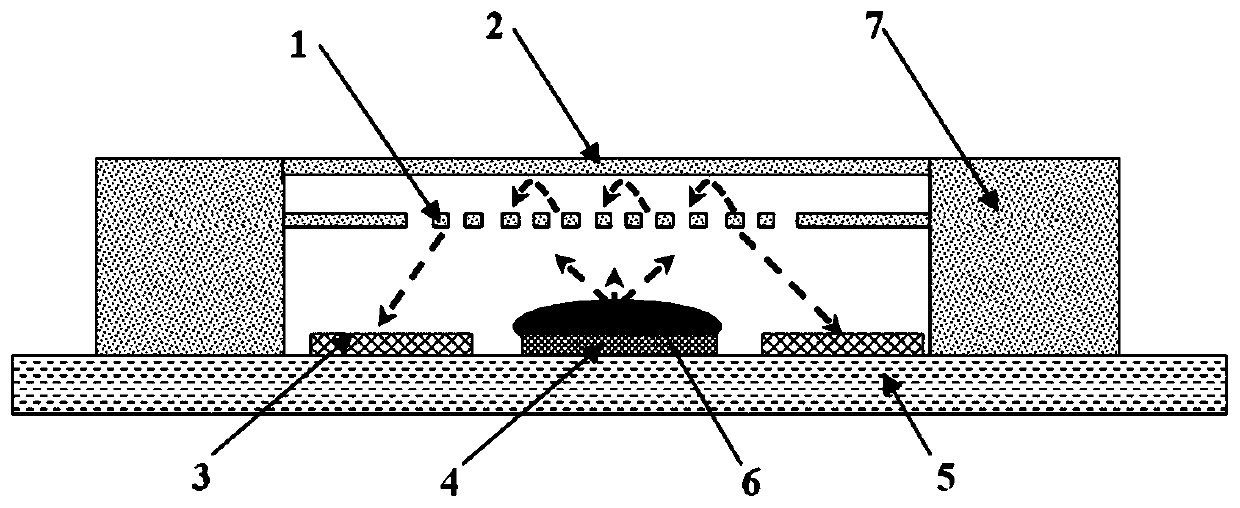

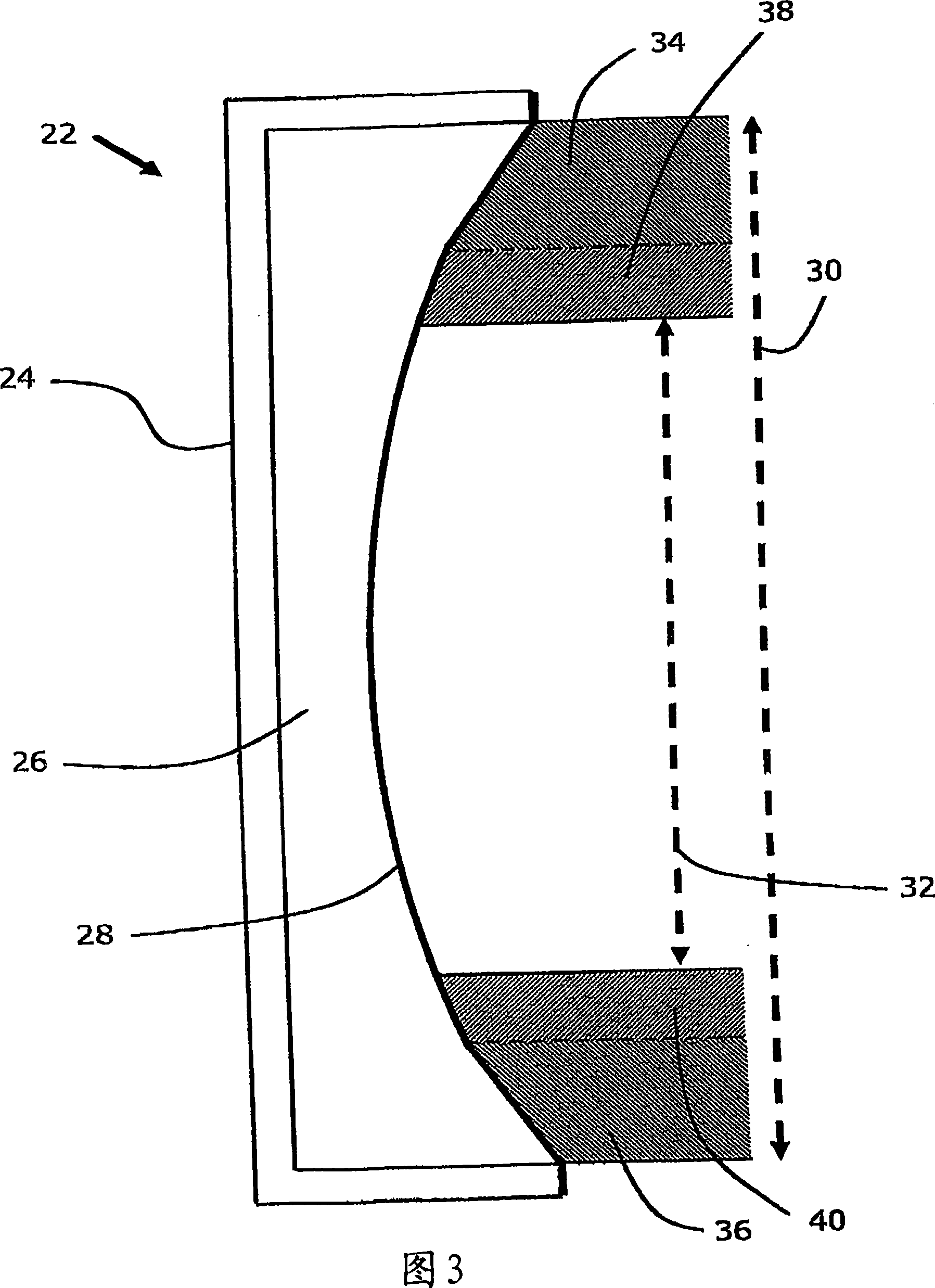

Bi-directionally actuated thin membrane mirror

A deformable membrane mirror and a related method for its use, the mirror including a deformable membrane having a reflective front face and a back face, and further including electrodes located on both sides of the membrane, to provide a desired surface contour without imparting a concave bias to the membrane. The electrodes include a first set of electrodes spaced from the back face of the membrane, and at least one additional electrode spaced from the front face of the membrane.

Owner:NORTHROP GRUMMAN SYST CORP

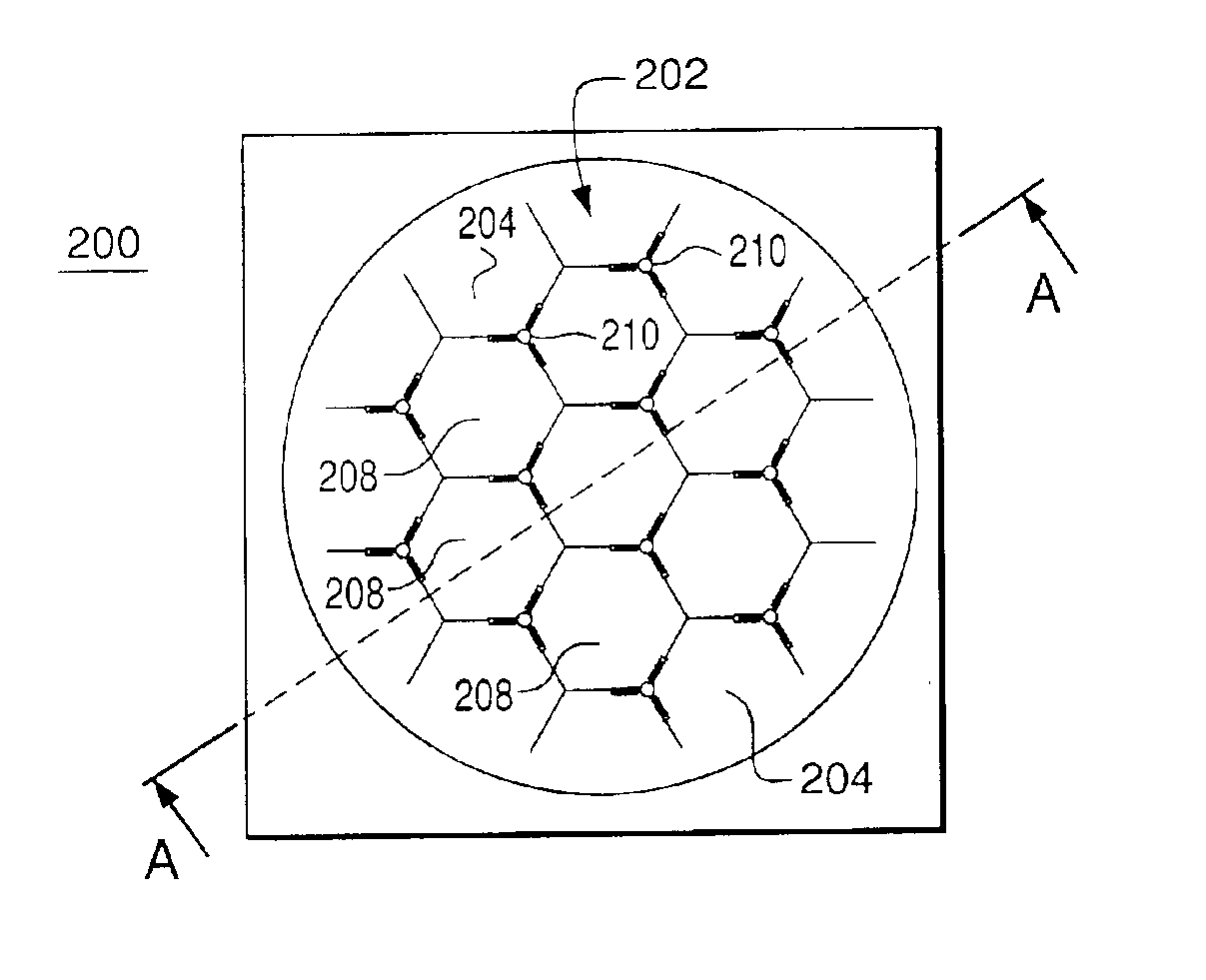

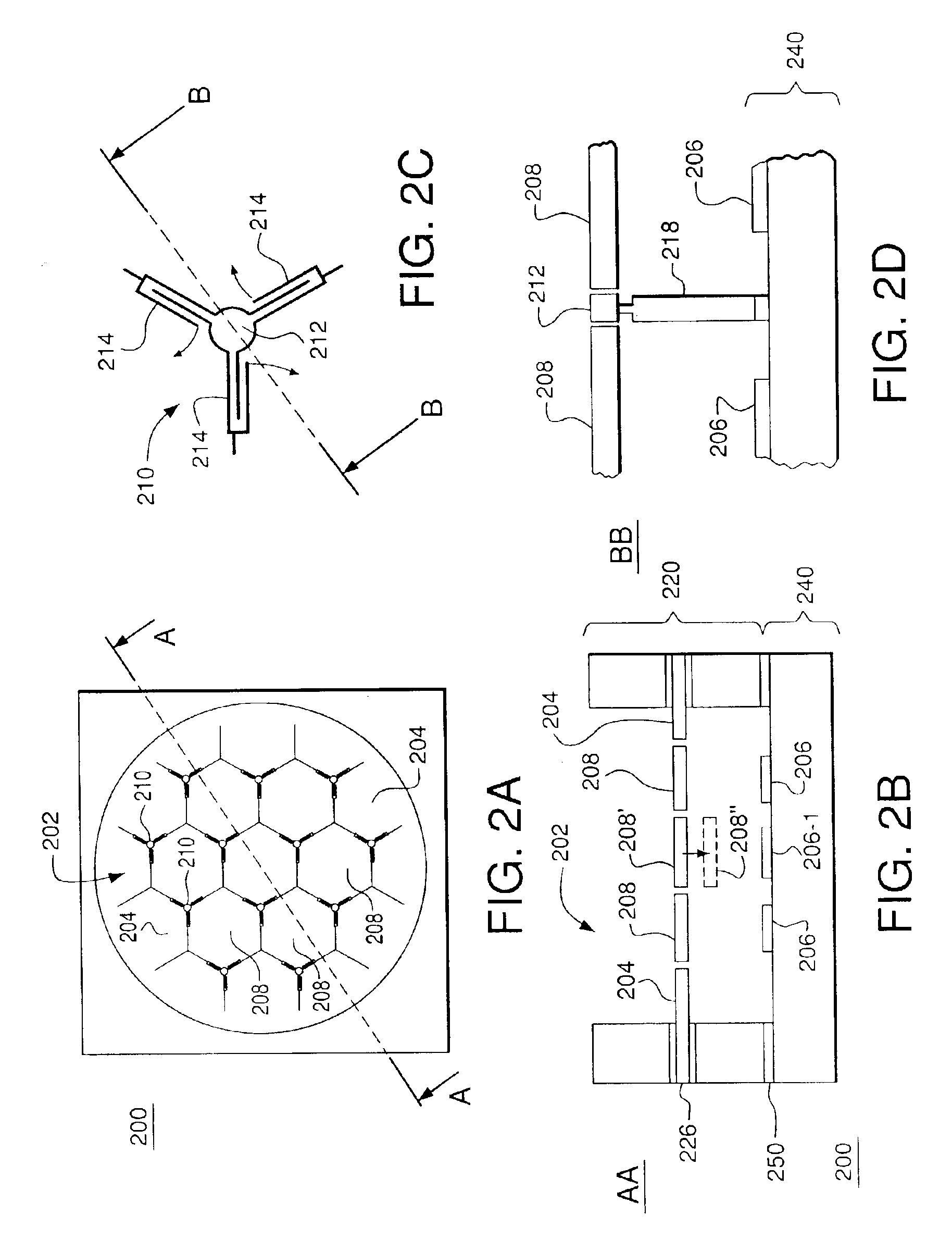

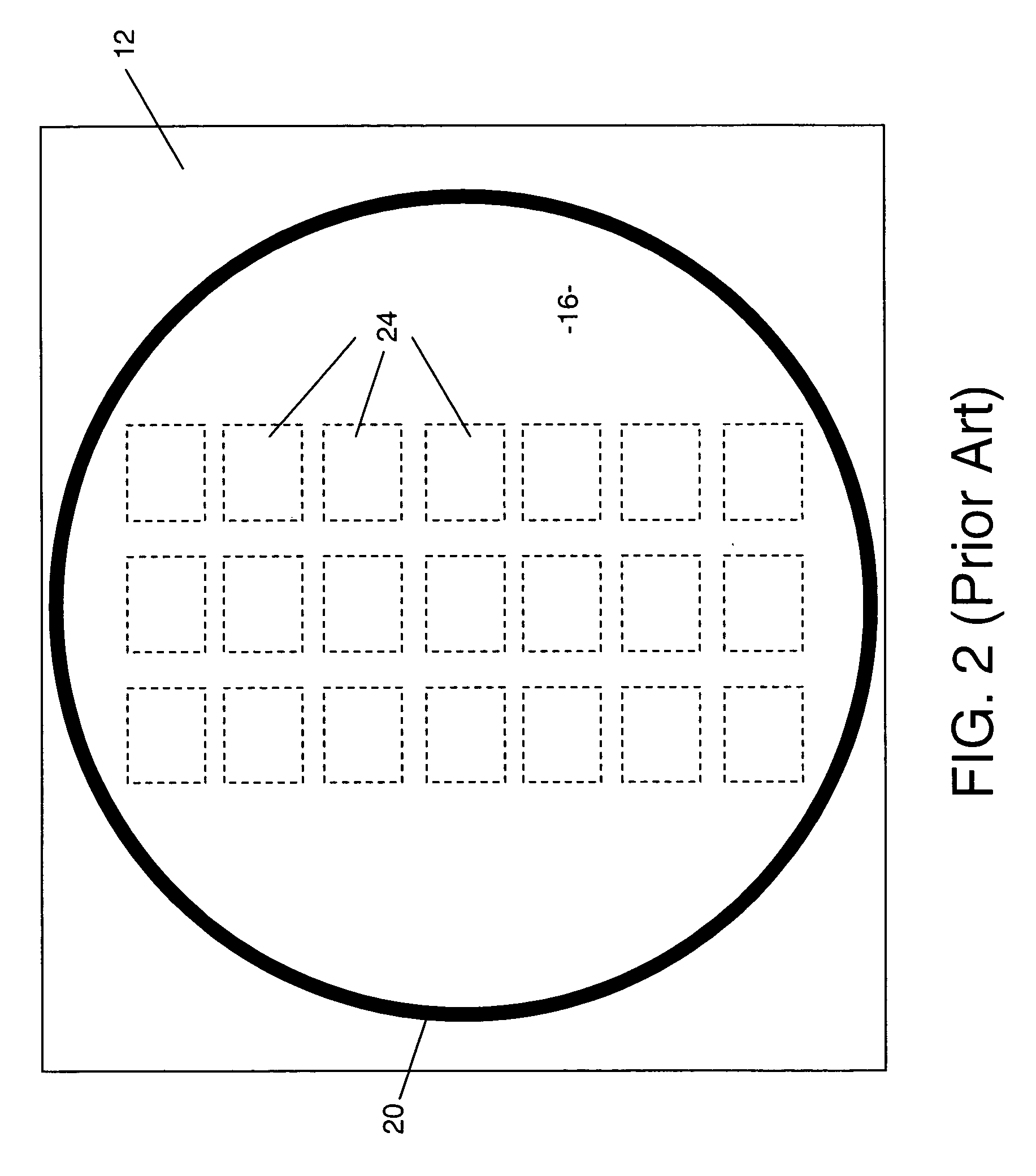

Deformable segmented MEMS mirror

A MEMS device having a deformable segmented mirror. The mirror includes a plurality of movable segments supported on a substrate using spring vertices, each vertex having a fixed plate and one or more springs. In a representative embodiment, three springs support each movable segment, where each spring connects the movable segment to a different spring vertex. The MEMS device also has a plurality of electrodes, each of which can be individually biased. A movable segment moves in response to a voltage applied to an electrode located beneath that segment while the deformed springs attached to the segment provide a restoring force. Due to the fixed plates, motion of each movable segment is substantially decoupled from that of the adjacent segments, which makes the shape of the segmented mirror relatively easy to control. In addition, segments in a deformable mirror of the invention can be displaced by a distance that is significantly larger than the maximum deformation amplitude for a membrane mirror of the prior art. The MEMS device can be fabricated using two silicon-on-insulator (SOI) wafers and an etch fabrication technique.

Owner:LUCENT TECH INC

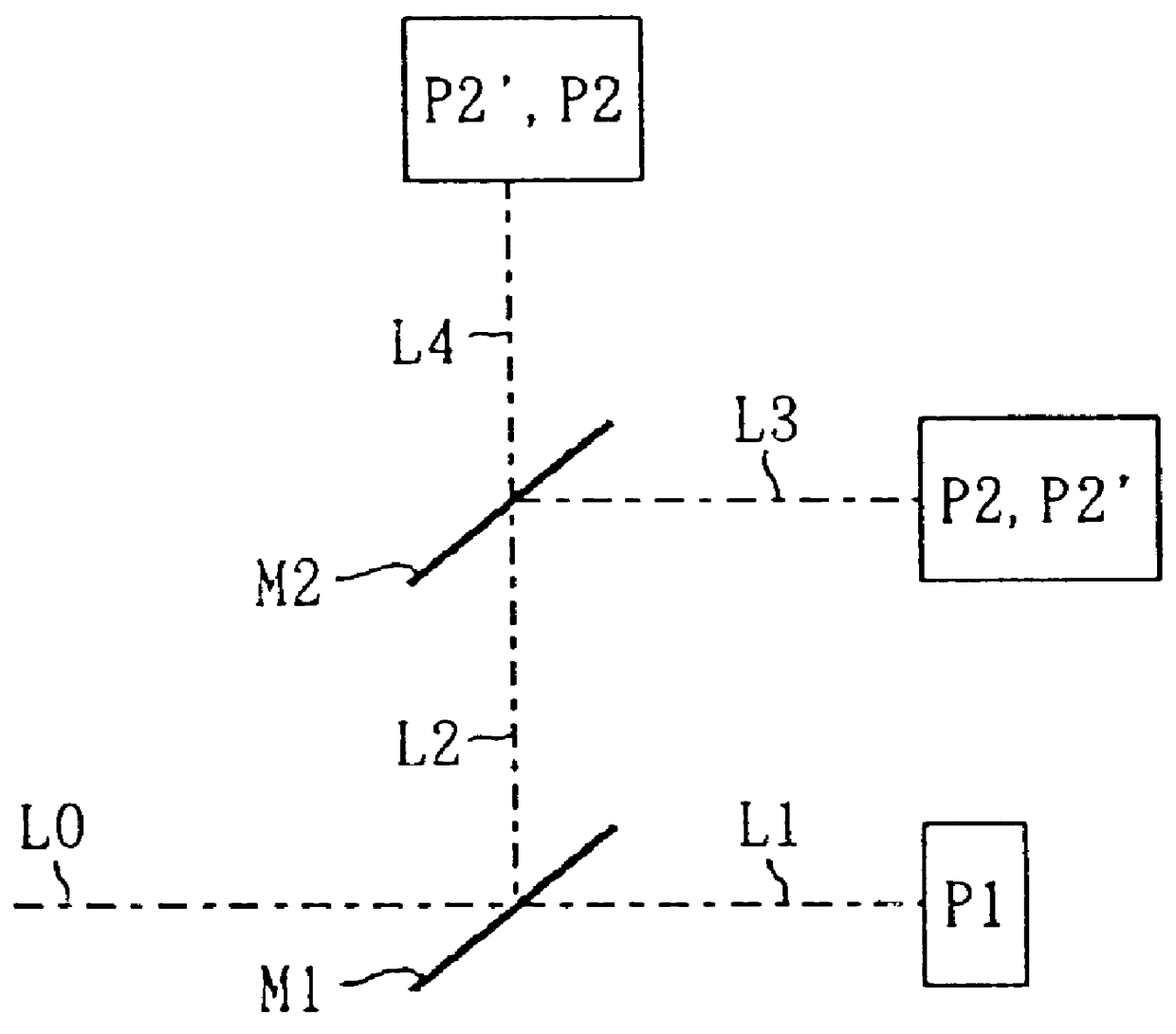

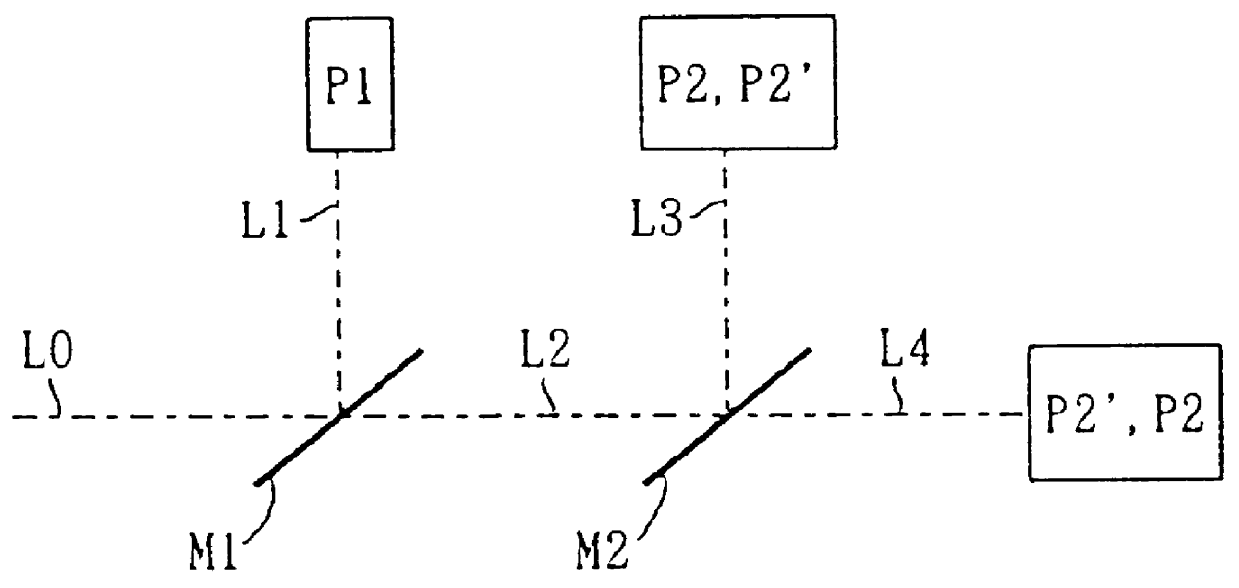

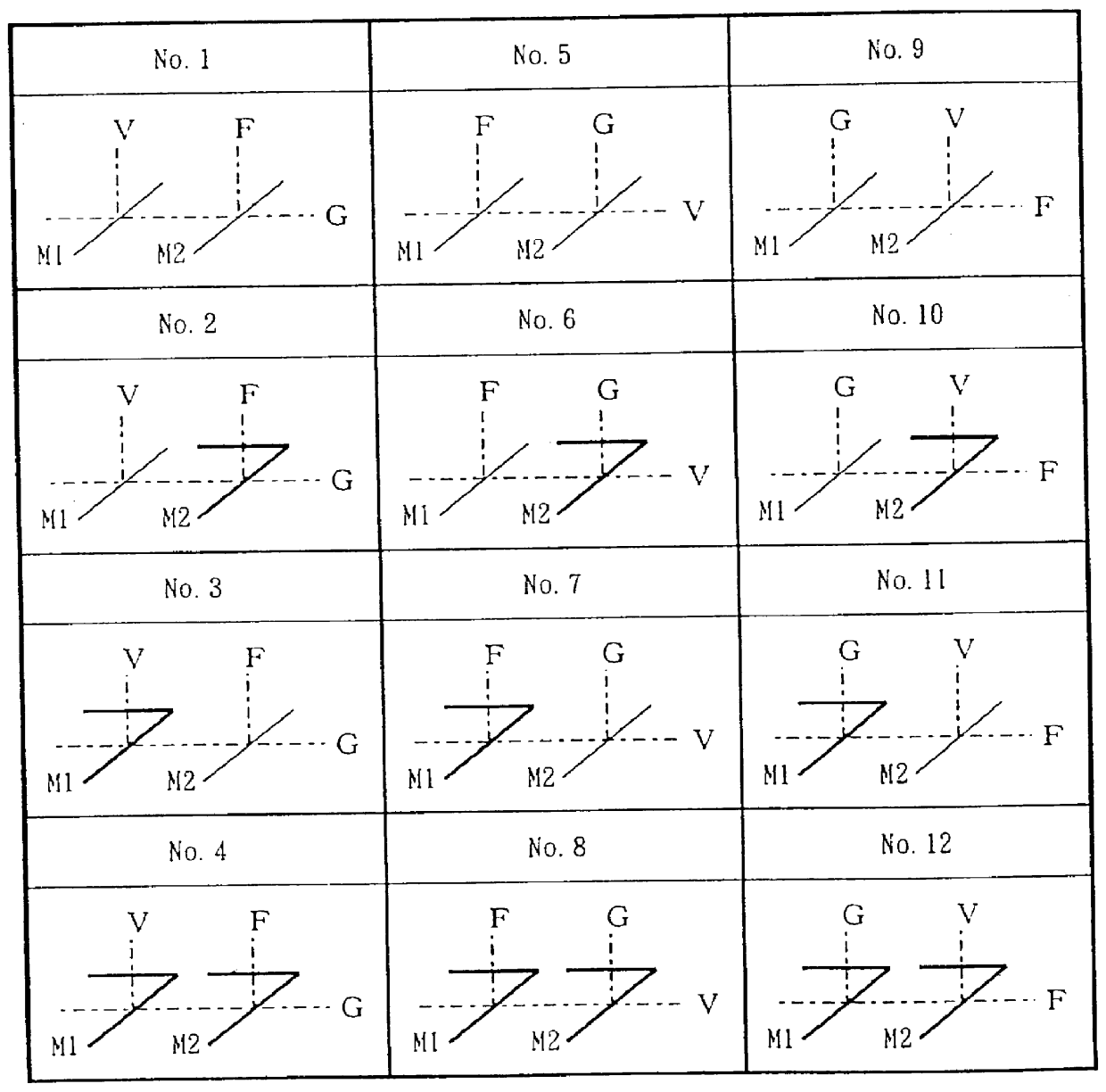

Camera capable of video and film shooting having optical viewfinder

A camera is capable of both silver-halide shooting, through which object images are recorded on silver-halide film, and video shooting, although its distance measurement device is placed substantially in the same way and its mirror box has substantially the same size as in ordinary single-lens reflex cameras. In this camera, a pellicle mirror splits the light flux having passed through a taking lens into a first light flux and a second light flux, and a rotatable mirror switches the subsequent path of the second light flux between the optical path for a third light flux and the optical path for a fourth light flux. The pellicle mirror, through its light flux splitting function, directs the first light flux to a silver-halide shooting system, and directs the second light flux to the rotatable mirror. The rotatable mirror, through its optical path switching function, either directs the third light flux to an optical viewfinder system, or directs the fourth light flux to a video shooting system.

Owner:MINOLTA CO LTD

High barrier metallized film with mirror-like appearance

InactiveUS6844077B2Improved gas propertyImproved moisture barrier propertyFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

A metallized, multi-layer film is disclosed that comprises at least a polyolefin layer, a tie layer, and a metallized lactic acid polymer layer to yield a final film having improved moisture and gas barrier, optical, and mechanical properties.

Owner:EXXONMOBIL CORP (US)

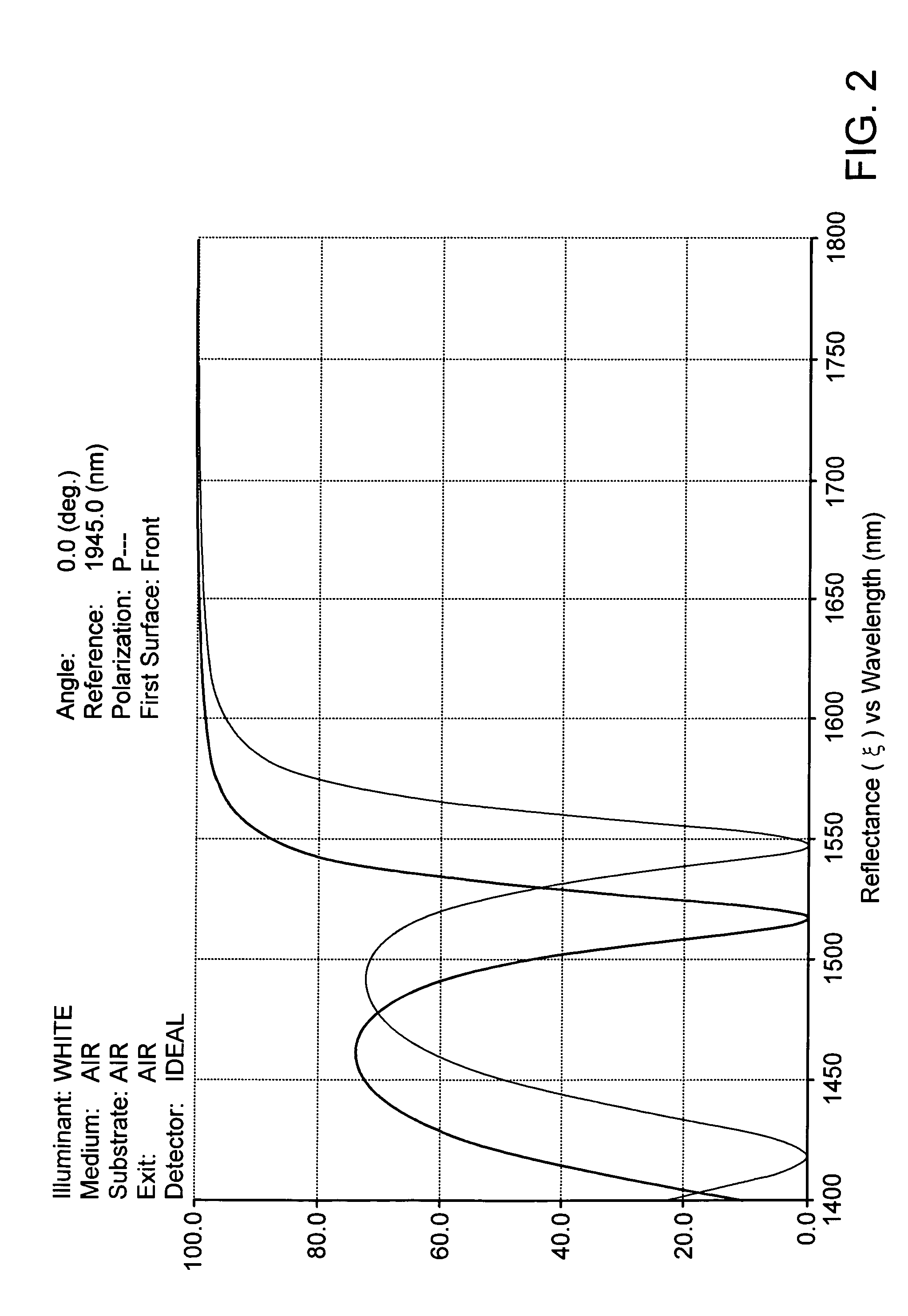

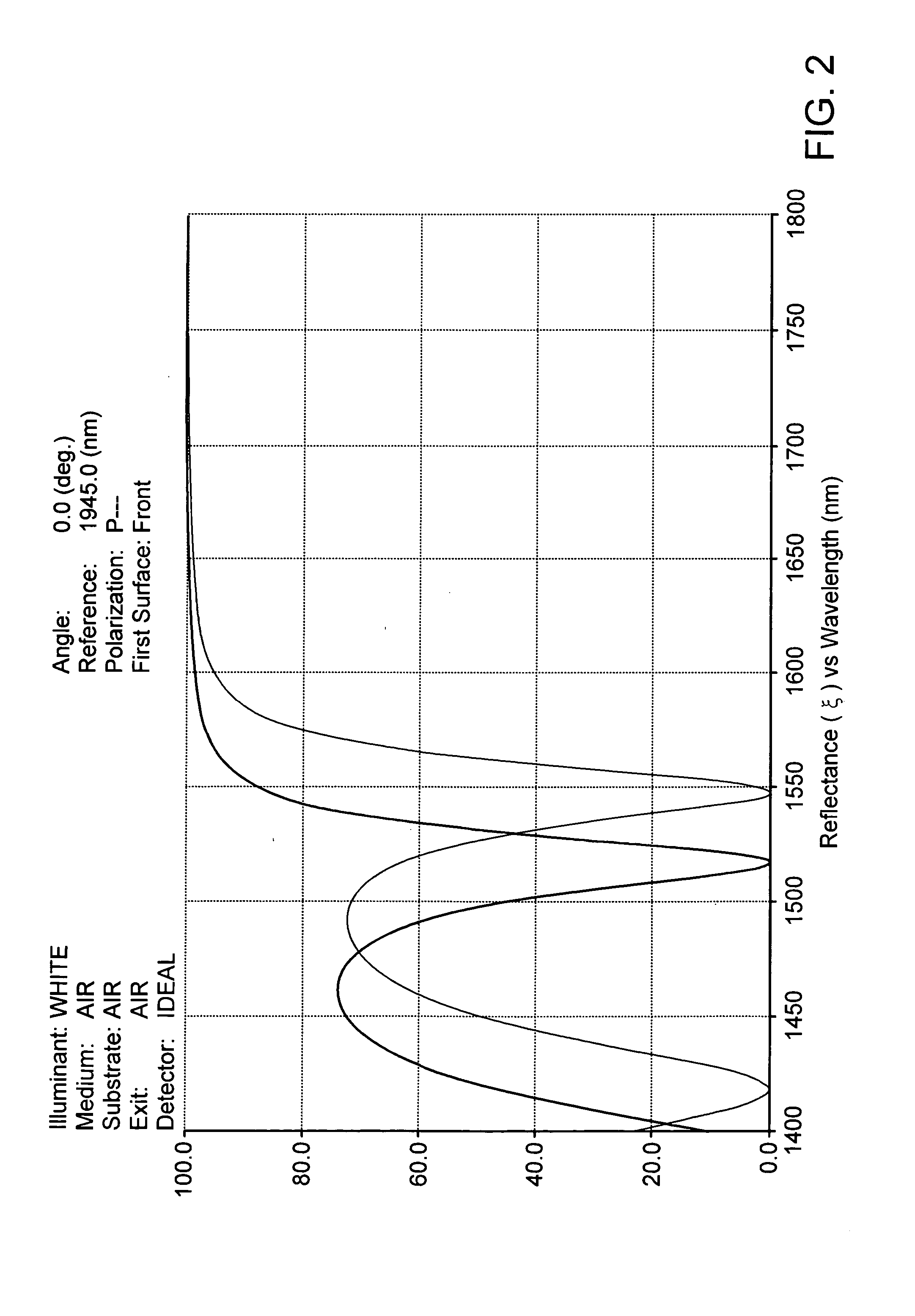

Tunable dispersion compensator

An optical dispersion compensator including: a spacer element having a top surface and a bottom surface; a thin film, multi-layer mirror formed on the top surface of the spacer element, the thin film mirror having a thermally tunable reflectivity; a highly reflective mirror element formed on the bottom surface of the spacer element; and a heater element for controlling a temperature of the thermally tunable thin film mirror.

Owner:AEGIS SEMICON

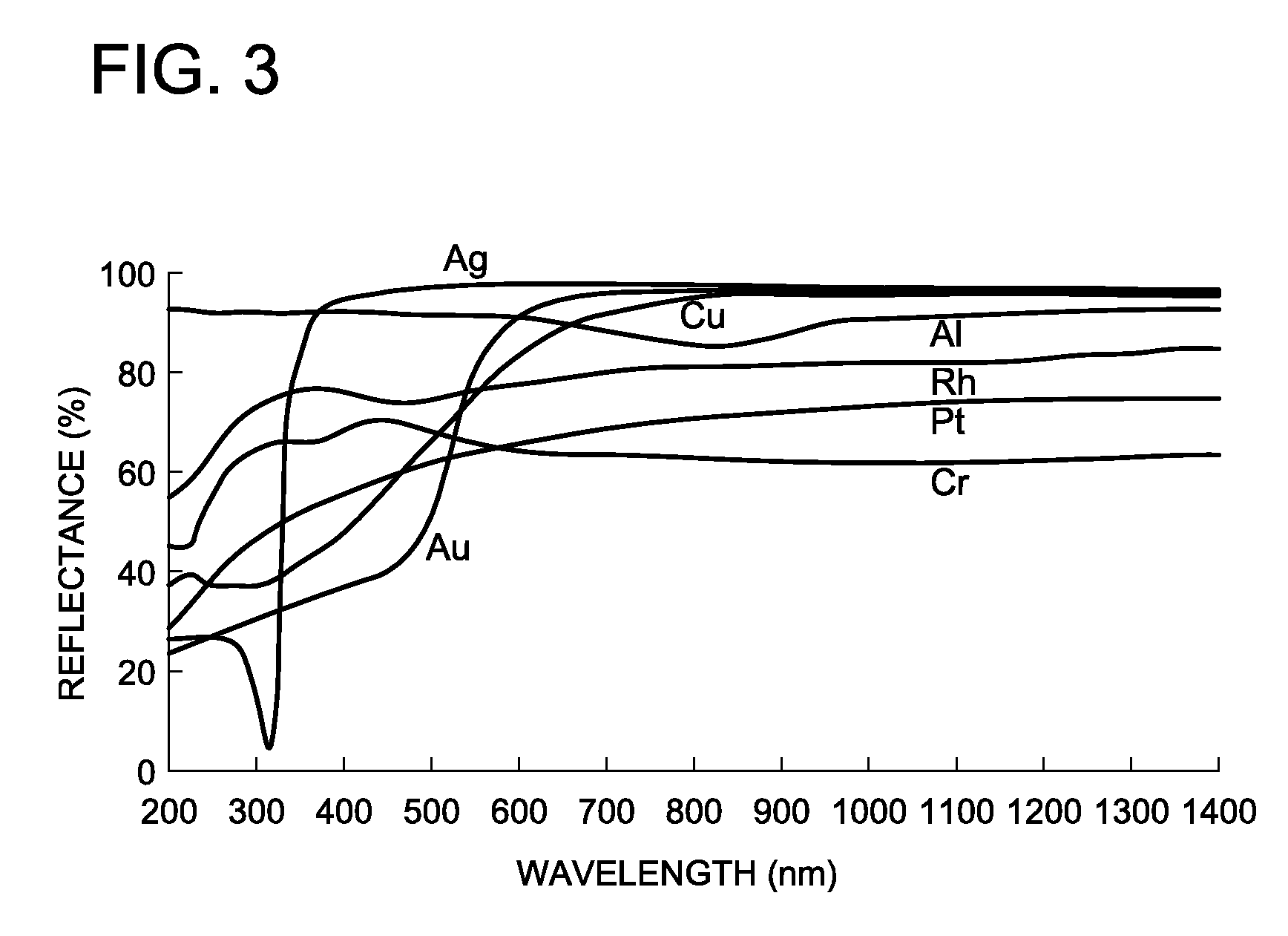

Composite film and film mirror for solar light reflection

An object of the invention is to provide a composite film and a film mirror for solar light reflection, to which dust and the like is not likely to adhere, of which resistance to scratch due to dust and the like is excellent, and in which cleaning properties of adhered dust and the like are excellent. The composite film according to the invention includes a composite film having a support and a surface covering layer, in which an elastic recovery rate of the surface covering layer is 60% or greater, a surface hardness thereof is 100 N / mm2 or less, and a water contact angle of a surface thereof is 40° or less.

Owner:FUJIFILM CORP

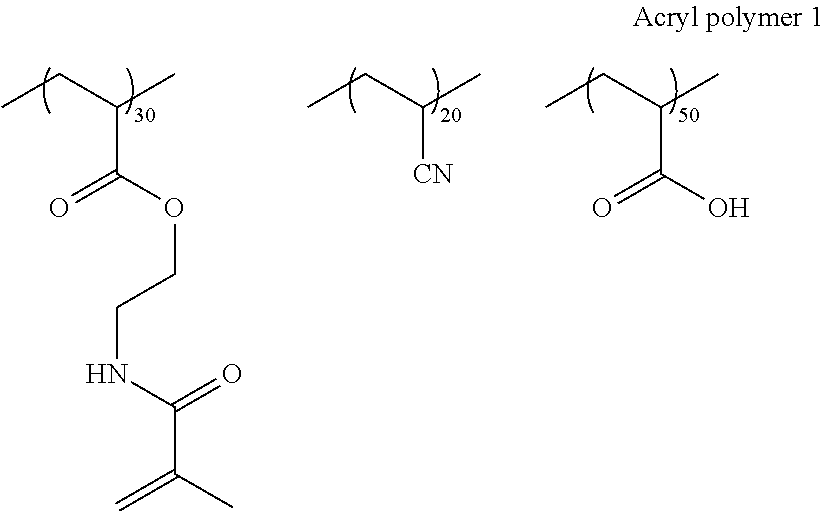

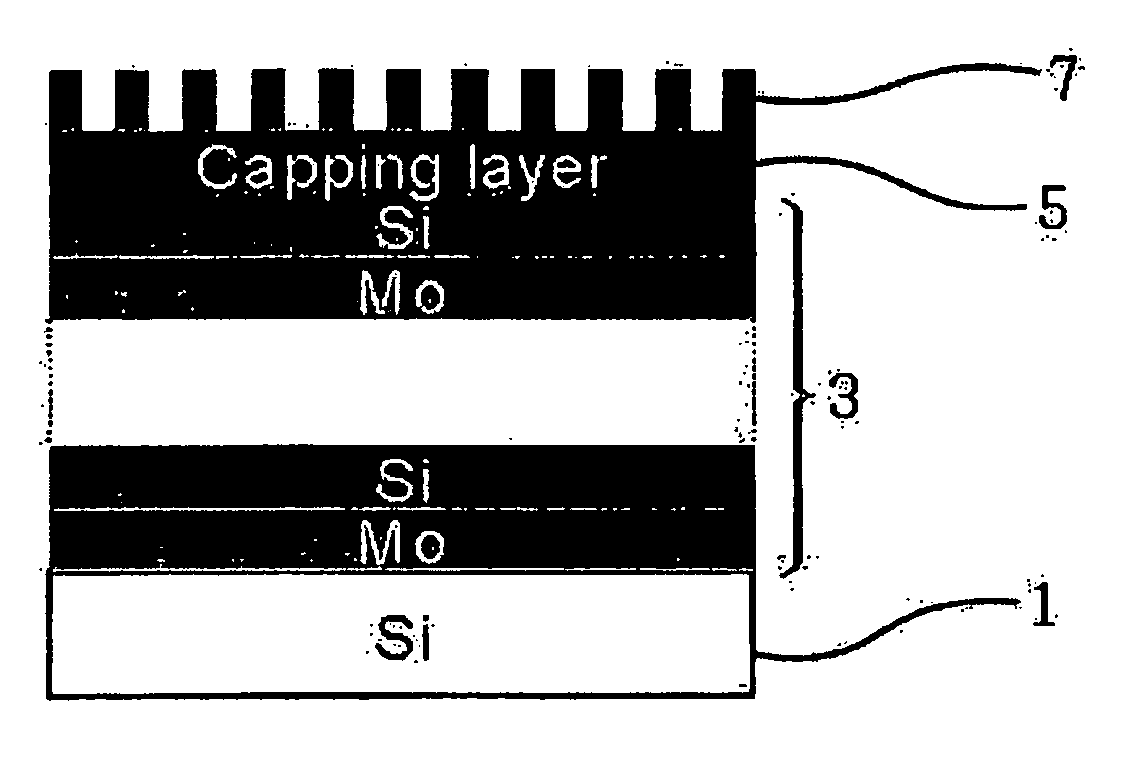

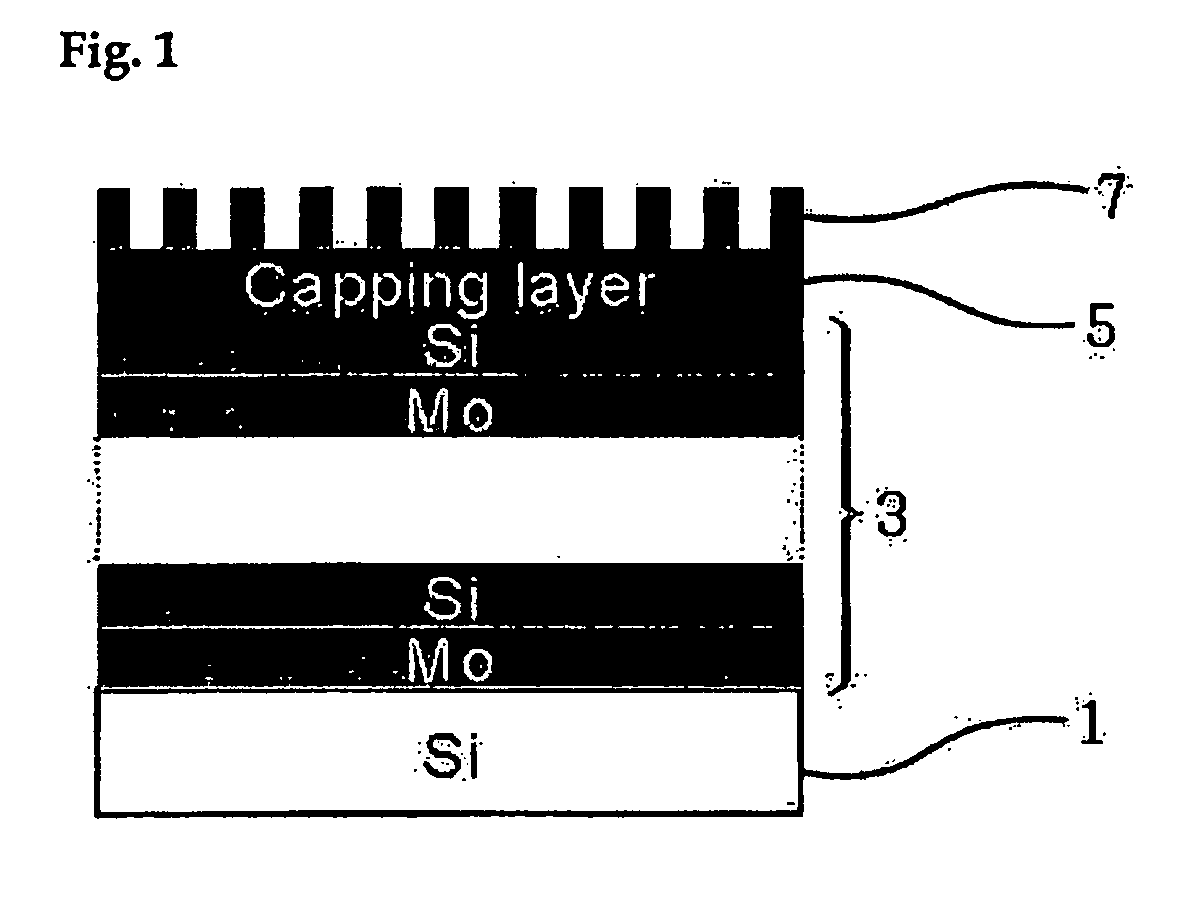

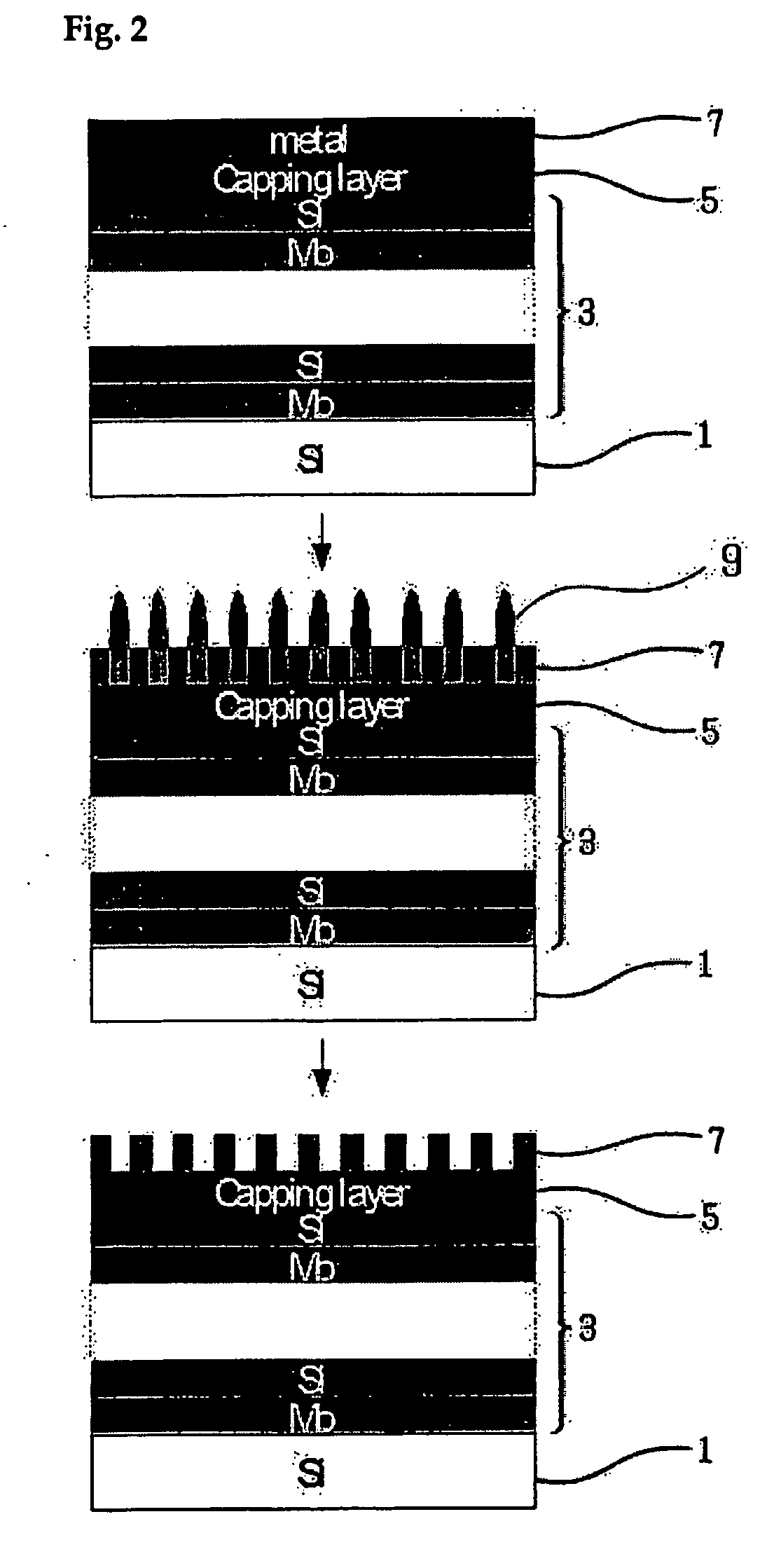

Fabrication method of extreme ultraviolet radiation mask mirror using atomic force microscope lithography

InactiveUS20070054196A1Reduce pollutionReduce surface roughnessMaterial nanotechnologyNanoinformaticsExtreme ultravioletRadiation exposure

The present invention relates to a method for manufacturing a reflective multi-layered thin film mirror for an extreme ultraviolet radiation (EUV) exposure process that is one of the next generation exposure process masks using an atomic force microscope (AFM). This reflective multi-layered thin film mirror for extreme ultraviolet radiation (EUV) exposure process allows metal oxide structures with fixed height and width to be obtained using anodic oxidization phenomenon between the cantilever tip of a atomic force microscope and an absorber material during the patterning of an absorber layer on a multi-layered thin film of a substrate, followed by forming the ultra-fine line width absorber patterns via etching of the metal oxide structure. Use of the manufacturing process of this invention is advantageous in manufacturing of extreme ultraviolet radiation exposure mask mirrors with high resolution and in manufacturing of reflective multi-layered thin film mirrors with minute absorber pattern sizes (less than 20 nm line width) compared to traditional manufacturing methods.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Deployable telescope having a thin-film mirror and metering structure

A deployable thin-film mirror telescope comprises a base structure and a metering structure. The base structure houses a thin-film mirror, which can be rolled for stowage and unrolled for deployment. The metering structure is coupled to the base structure and can be folded for stowage and unfolded for deployment. In the deployed state, the unrolled thin-film mirror forms a primary minor for the telescope and the unfolded metering structure positions a secondary minor for the telescope.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

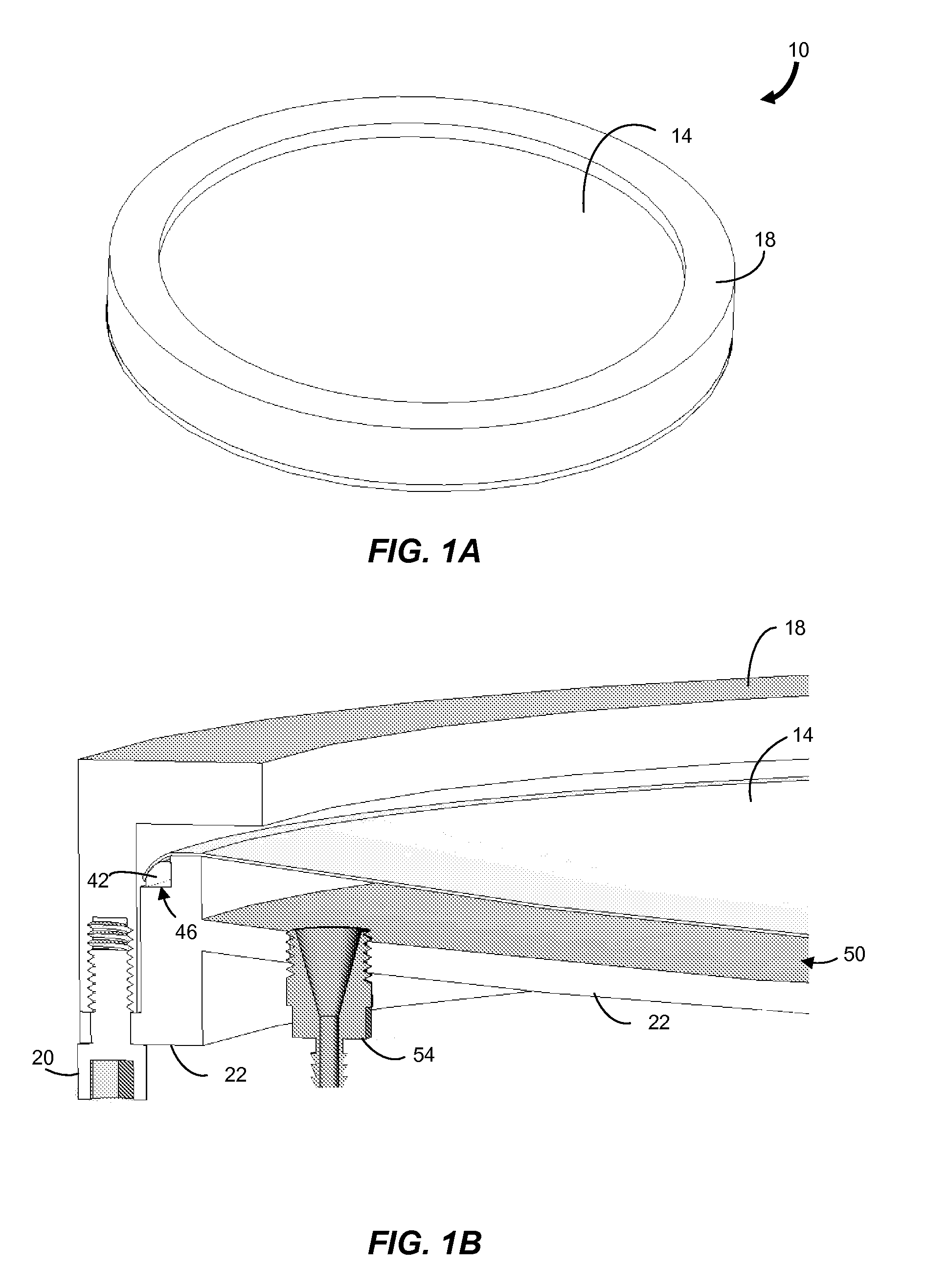

Magnetic membrane mirror

Described is a magnetic membrane mirror having a flexible membrane comprising a magnetic material and having a high reflectance. The flexible membrane is secured over a frame to enclose a volume between the frame and membrane. A transmembrane pressure is established to achieve a desired mirror shape or curvature. Curvature can be changed by modifying the transmembrane pressure by increasing or decreasing the pressure in the enclosed volume. An array of electromagnetic actuators generates individually-controlled magnetic fields to cause localized displacements of the mirror surface. The magnetic membrane mirror can be constructed with inexpensive components and can be used as a dynamic component in an adaptive optical system.

Owner:MASSACHUSETTS INST OF TECH

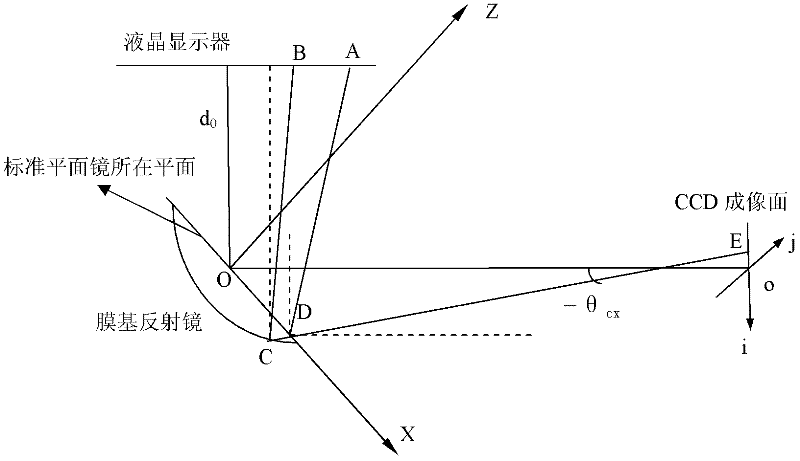

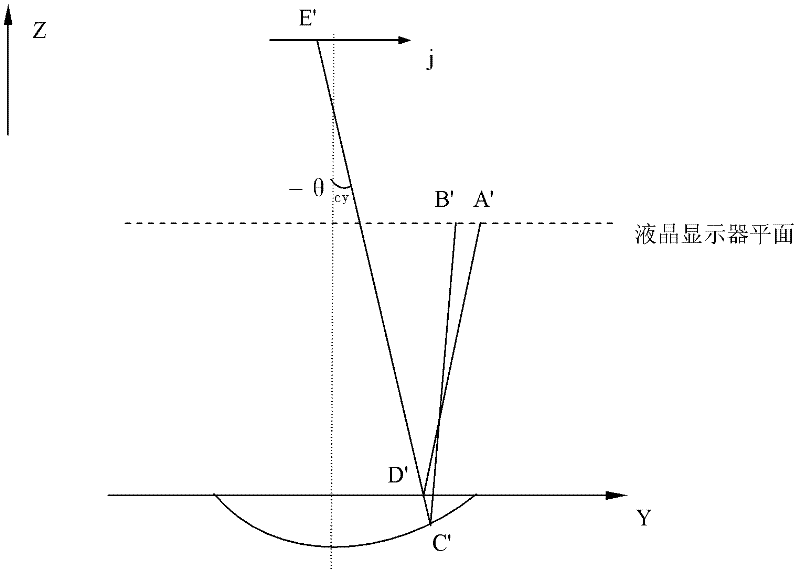

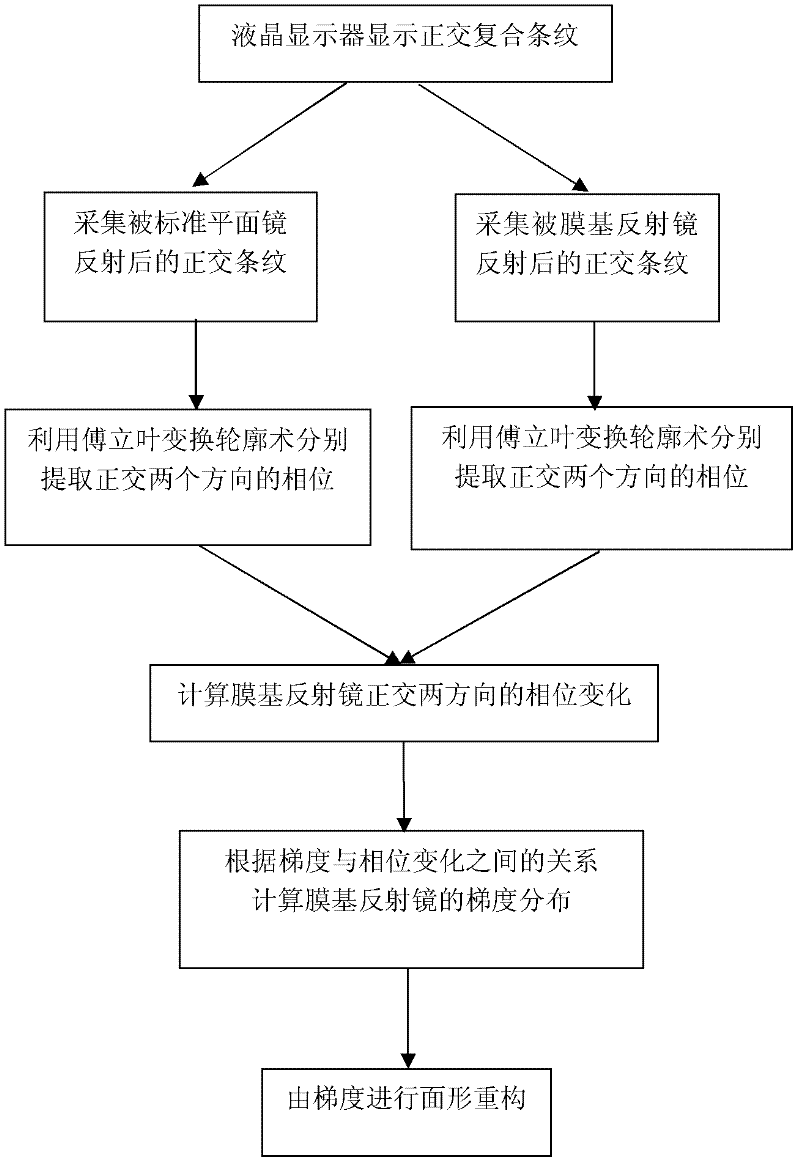

Method for measuring three-dimensional surface shape of membrane mirror

InactiveCN102410819AImprove real-time performanceImprove accuracyUsing optical meansMeasurement deviceFourier transform on finite groups

The invention discloses a method for measuring a three-dimensional surface shape of a membrane mirror. A measuring system comprises a liquid crystal display, a standard planar mirror, a charge coupled device (CCD), an image acquisition card, a computer and the like, wherein the liquid crystal display displays orthogonal sine stripes input through the computer; the CCD acquires compound stripes which are reflected by the standard planar mirror and the membrane mirror; and the system extracts phases in two orthogonal directions by using Fourier transformation profilometry, calculates phase changes in the two orthogonal directions caused by the membrane mirror, calculates gradient distribution of the membrane mirror according to a relation between gradient and the phase changes, and reconfigures the surface shape according to the gradient. By adopting an orthogonal sine stripe reflection technology, measurement of the surface shape of the membrane mirror can be realized only by acquiringa frame of bar graph reflected by the standard planar mirror and the membrane mirror respectively. A measuring device is simple, low in cost and high in instantaneity; and the problem that the three-dimensional surface shape of the membrane mirror is difficult to measure can be solved effectively.

Owner:SUZHOU UNIV

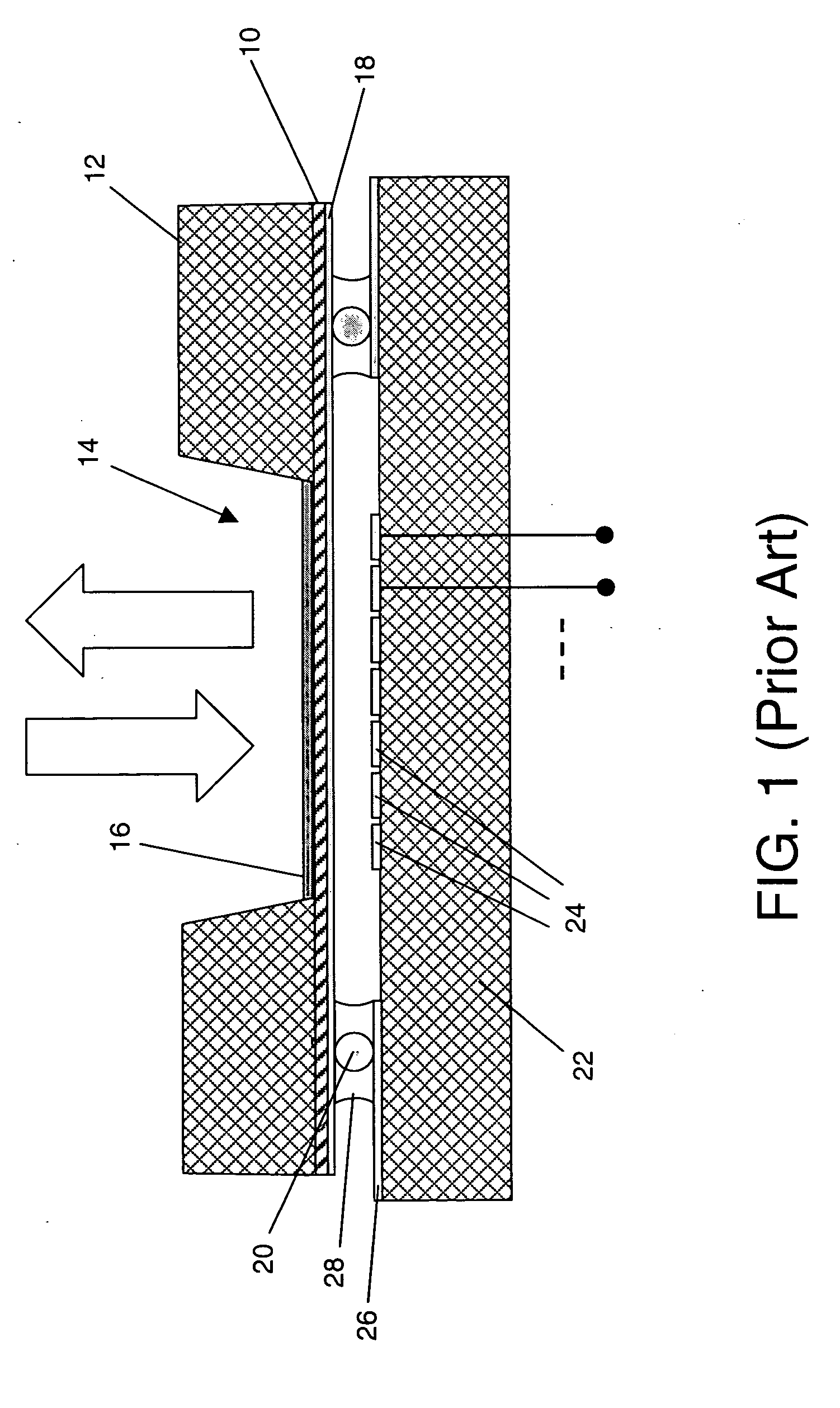

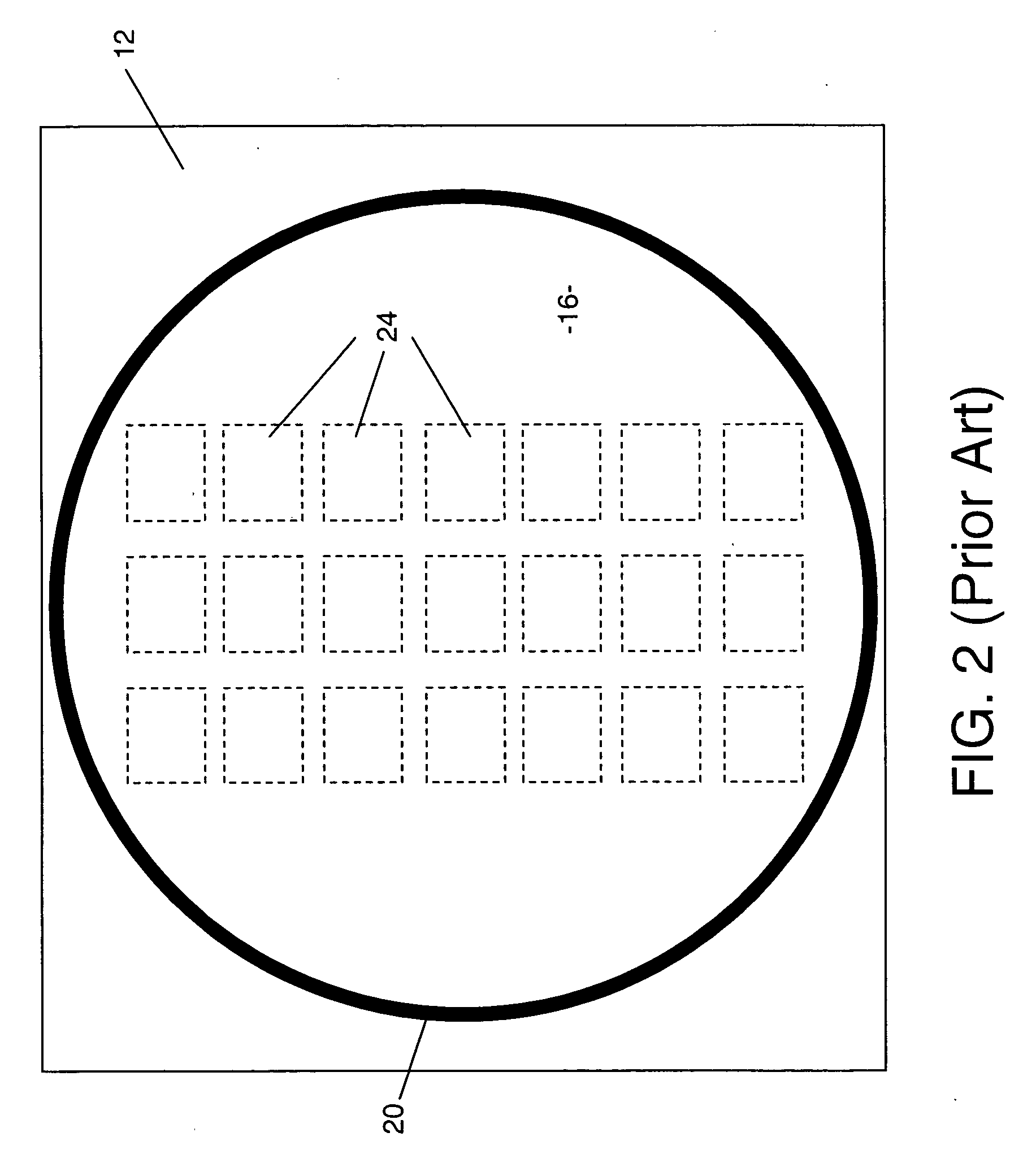

Wafer scale production of optical elements

InactiveUS6896949B1Small sizeGood optical performanceLayered productsSpectrum generation using multiple reflectionMembrane mirrorLength wave

Improved optical element wafers comprising stacked, optically coupled etalon wafers are disclosed. Each etalon wafer comprises a bulk optic wafer defining the optic cavity between selectively transparent thin film mirror coatings. The bulk optic wafer comprises an optically transparent body, such as a portion of a substrate wafer, along with a wedge correcting coating on at least one of the two surfaces of the optically transparent body and / or a thickness-adjustment layer on one or both surfaces. The bulk optic wafer is a solid, self-supporting body, optically transparent (at the wavelength or wavelengths of interest), whose thickness, i.e., the dimension between the selectively transparent surfaces, defines the cavity spacing of the bulk optic etalon wafer. Methods of making and using the optical element wafers are also disclosed.

Owner:II VI DELAWARE INC

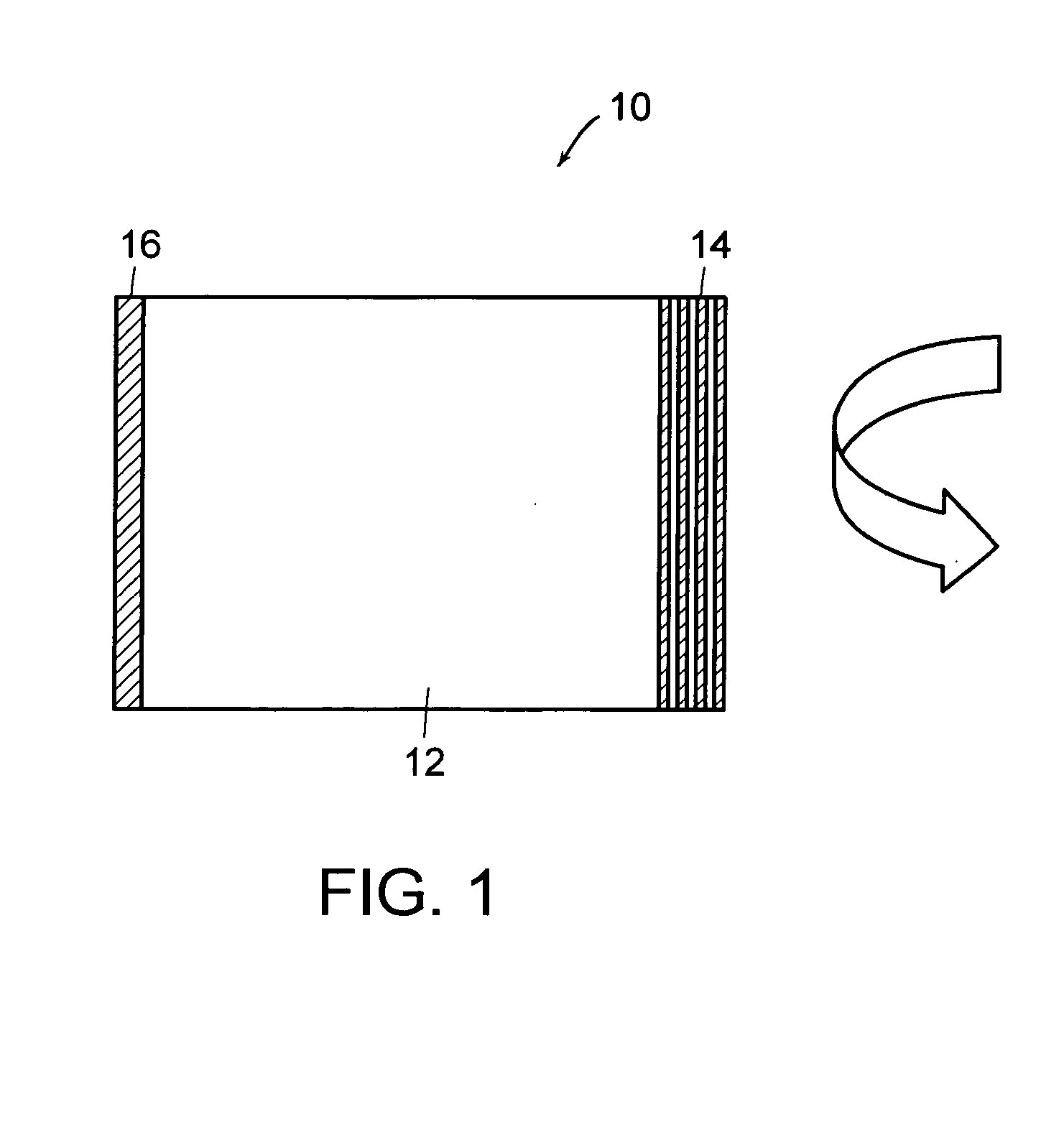

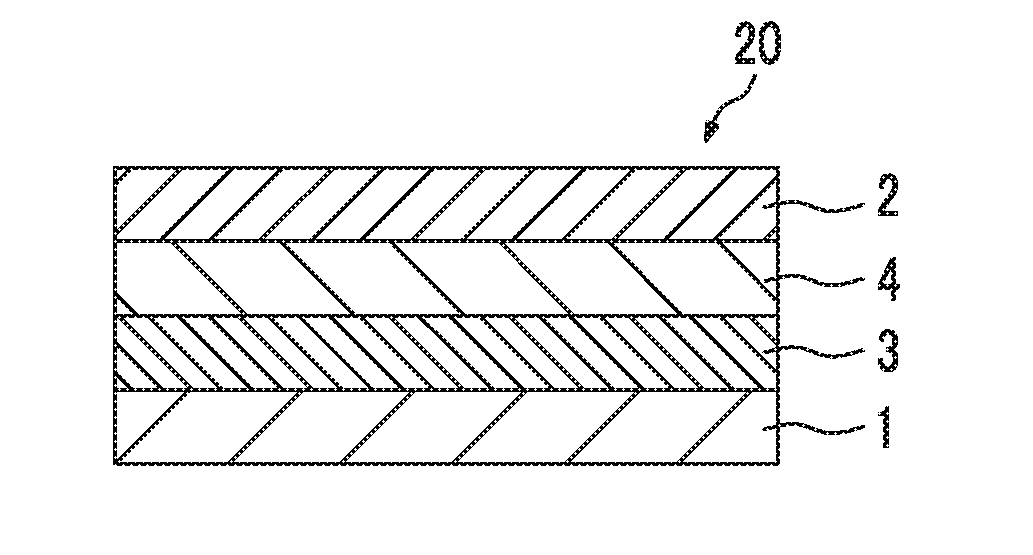

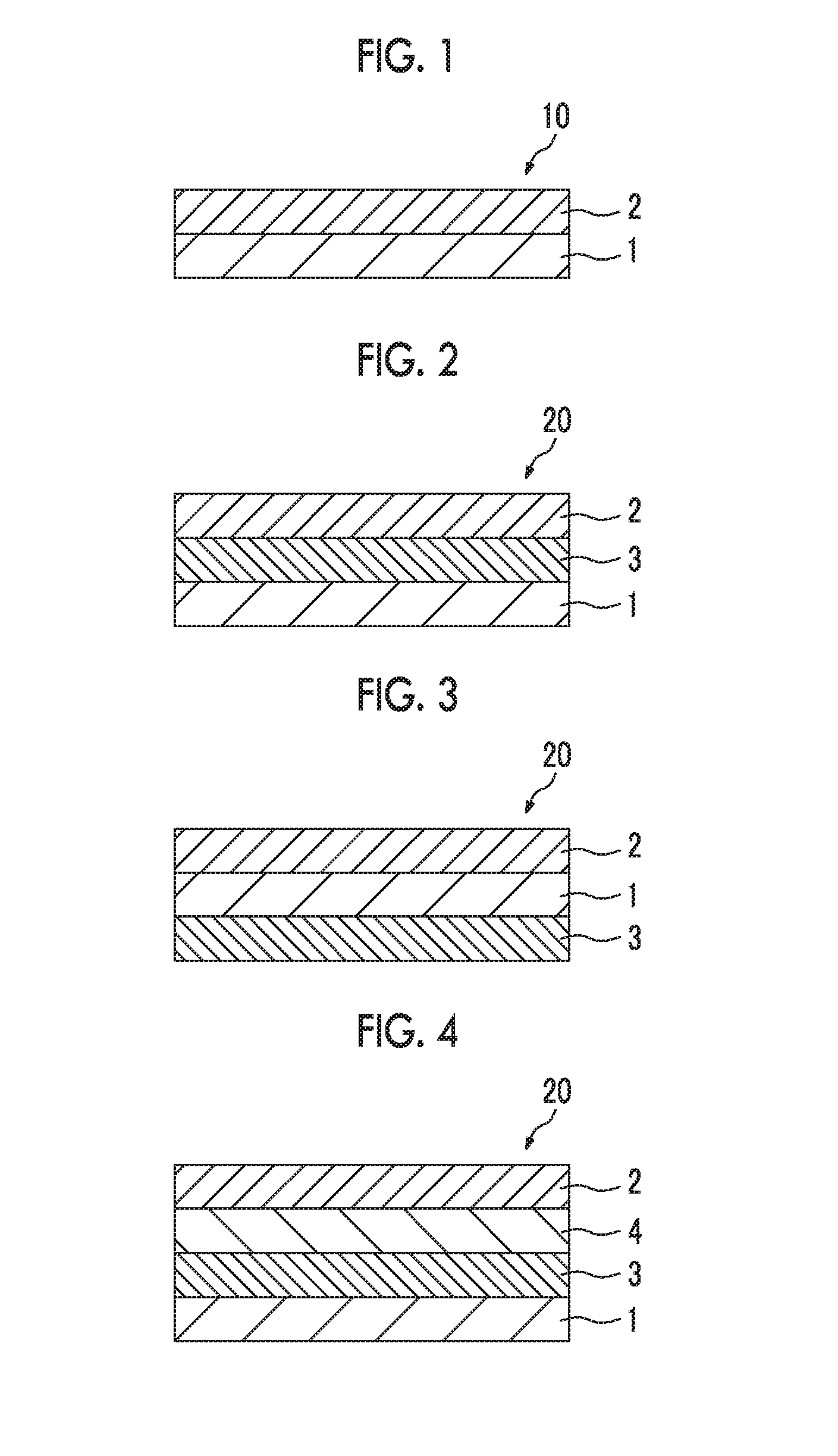

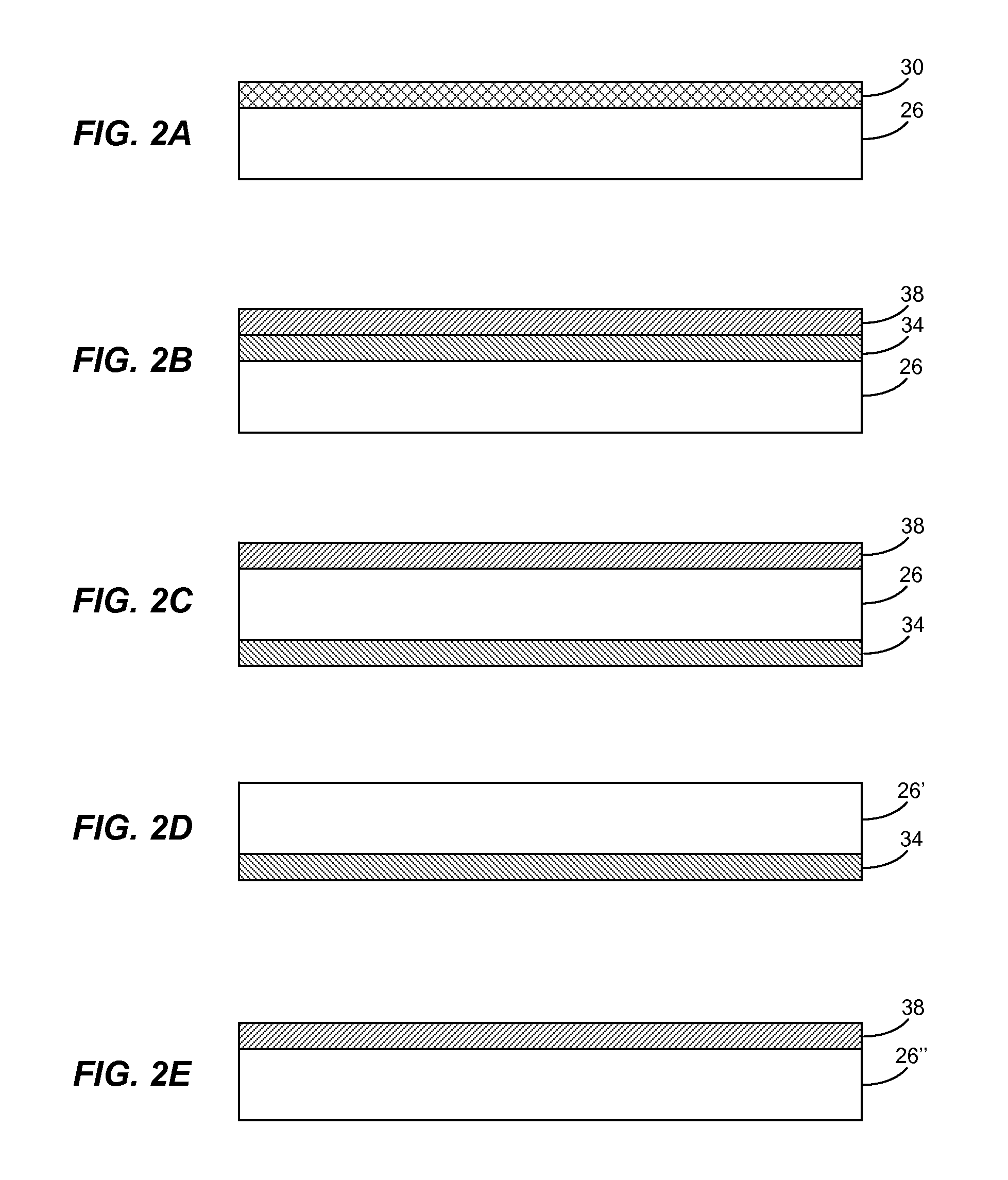

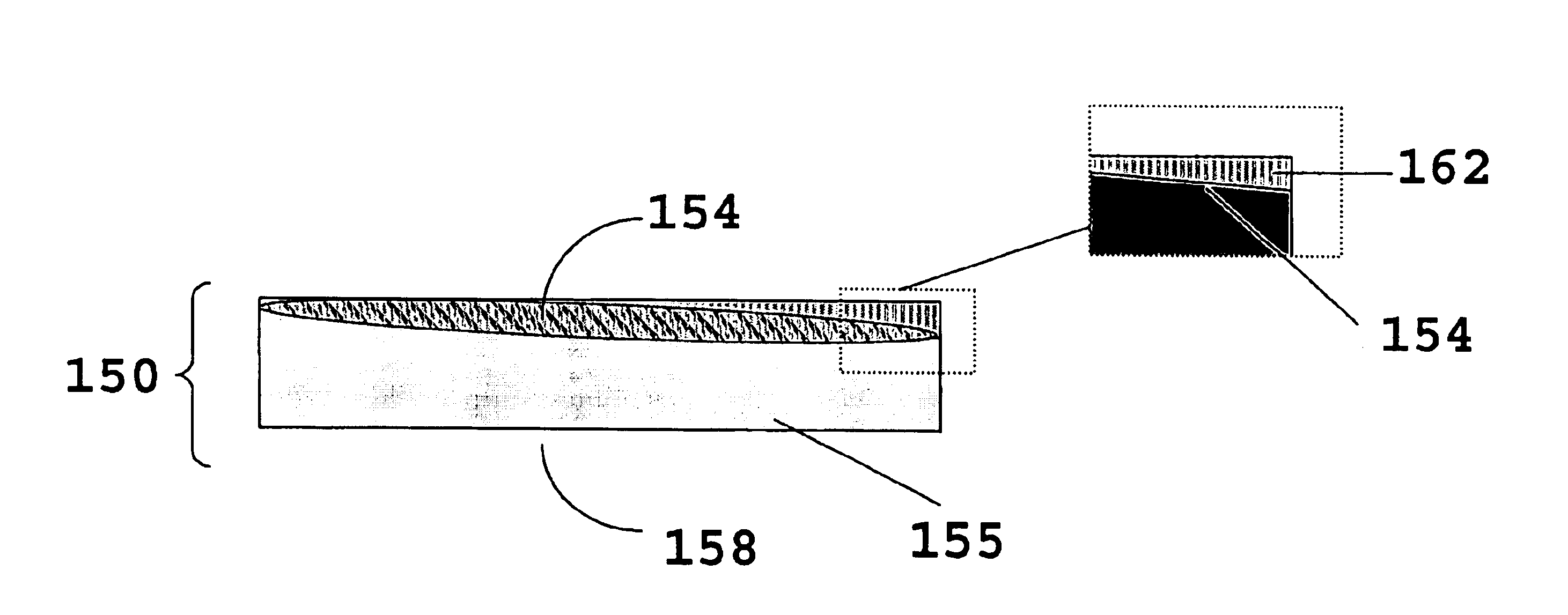

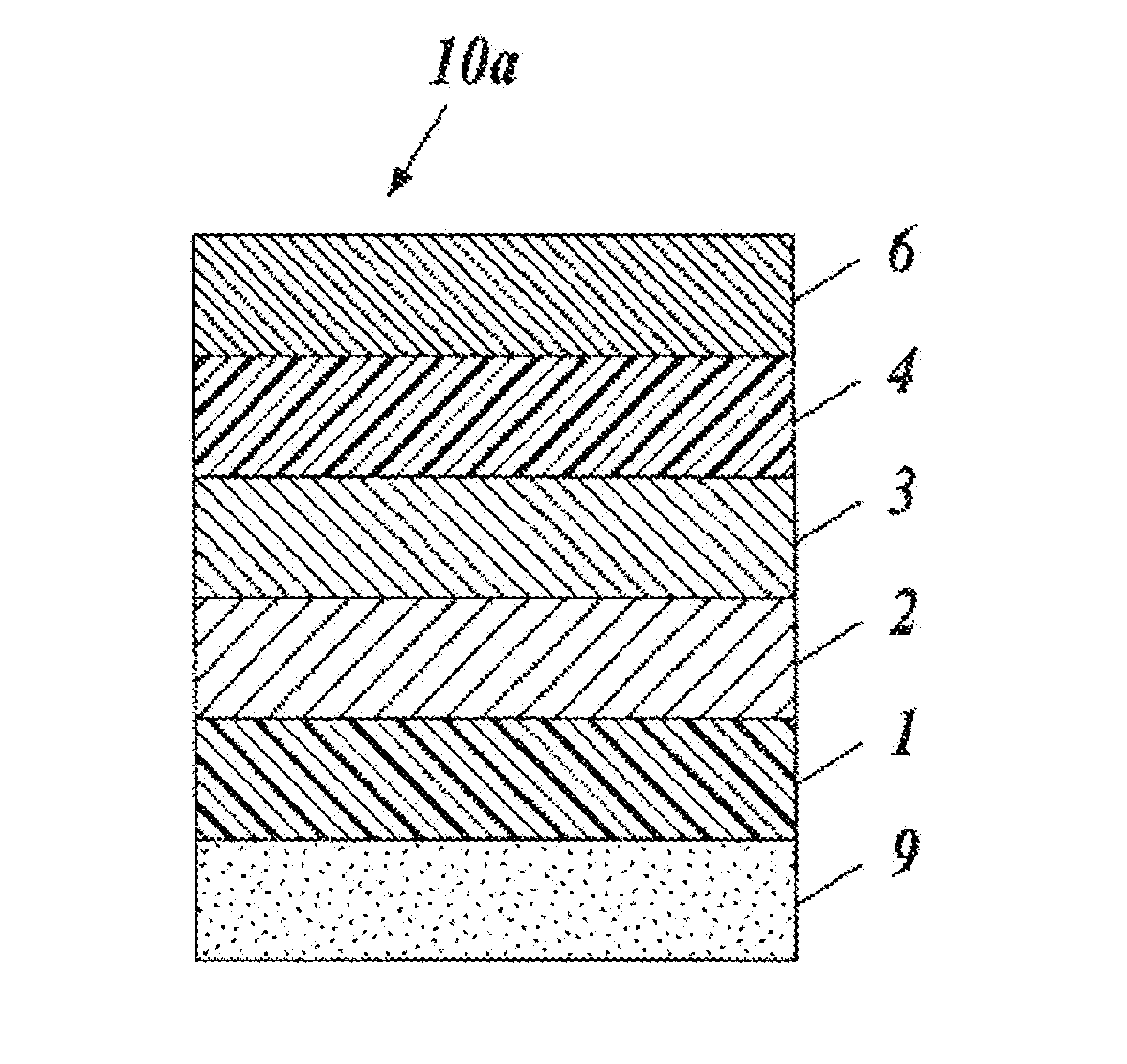

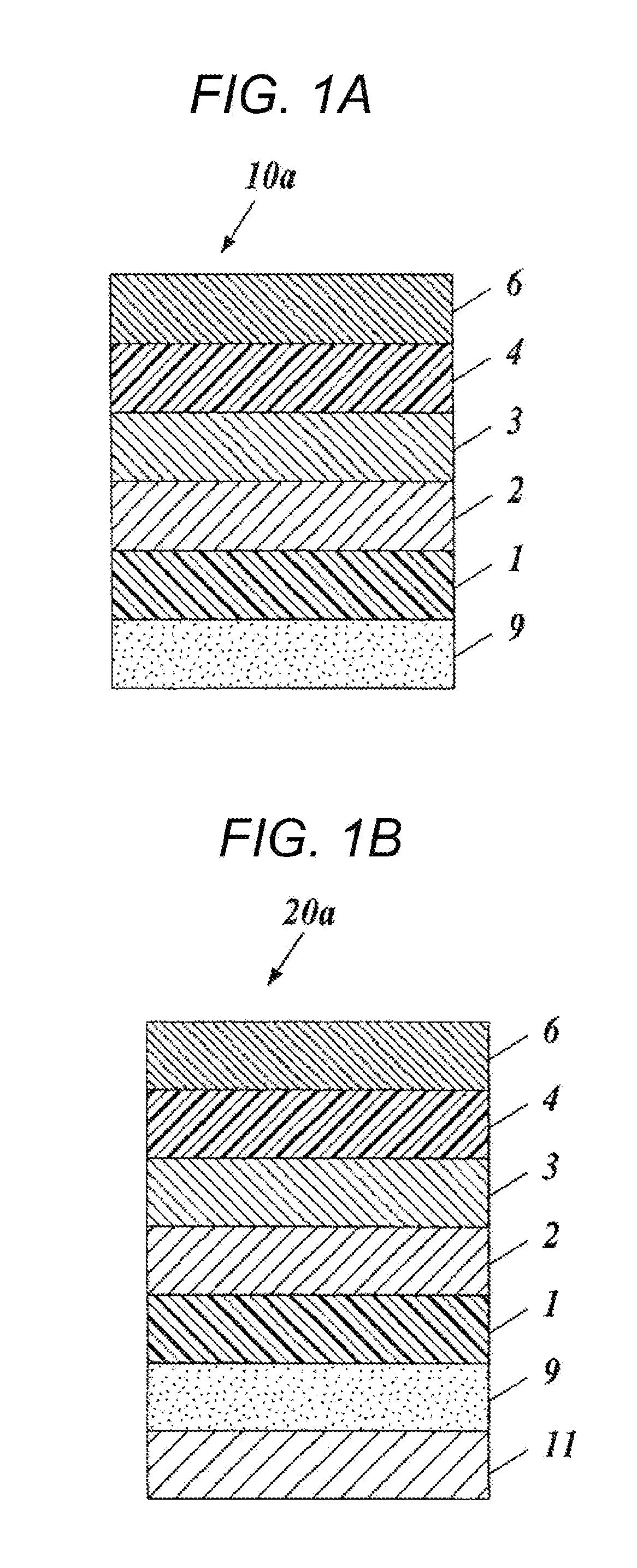

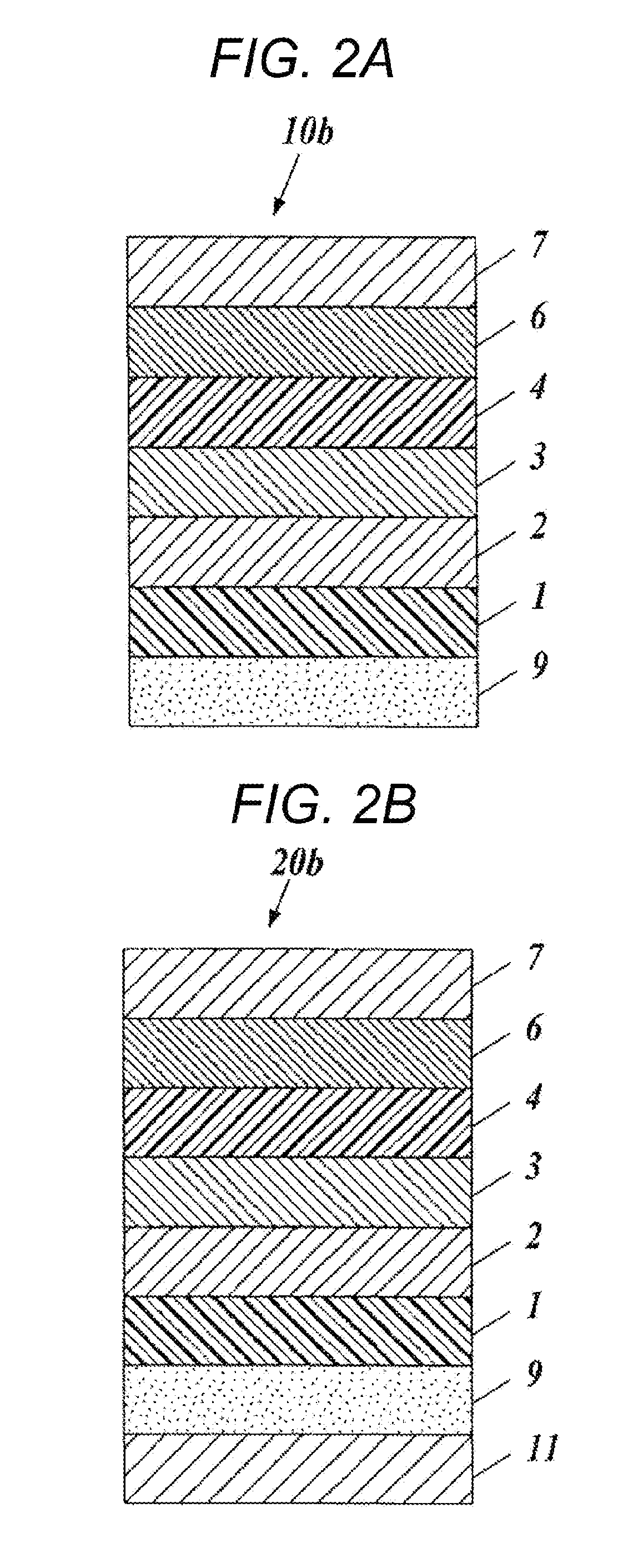

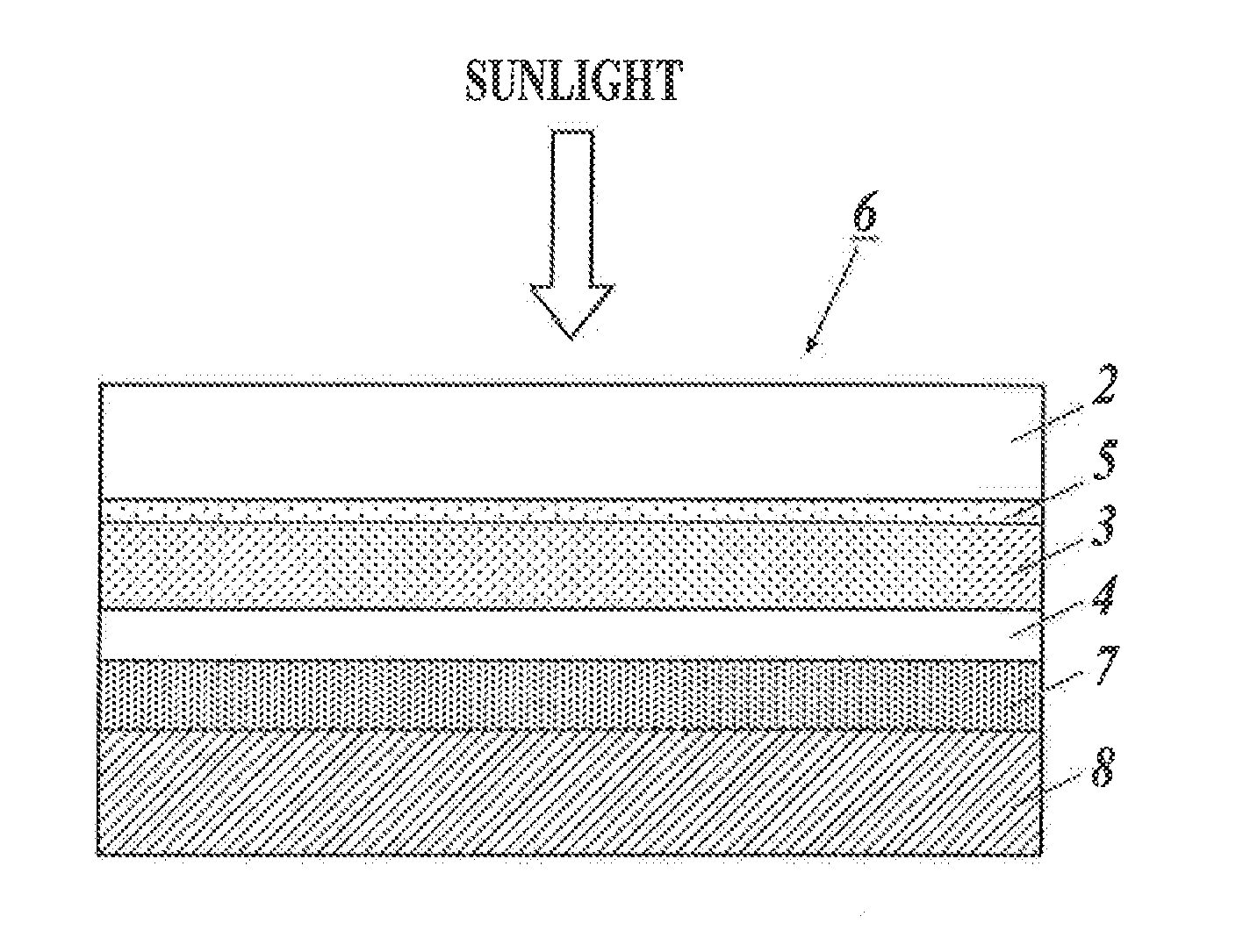

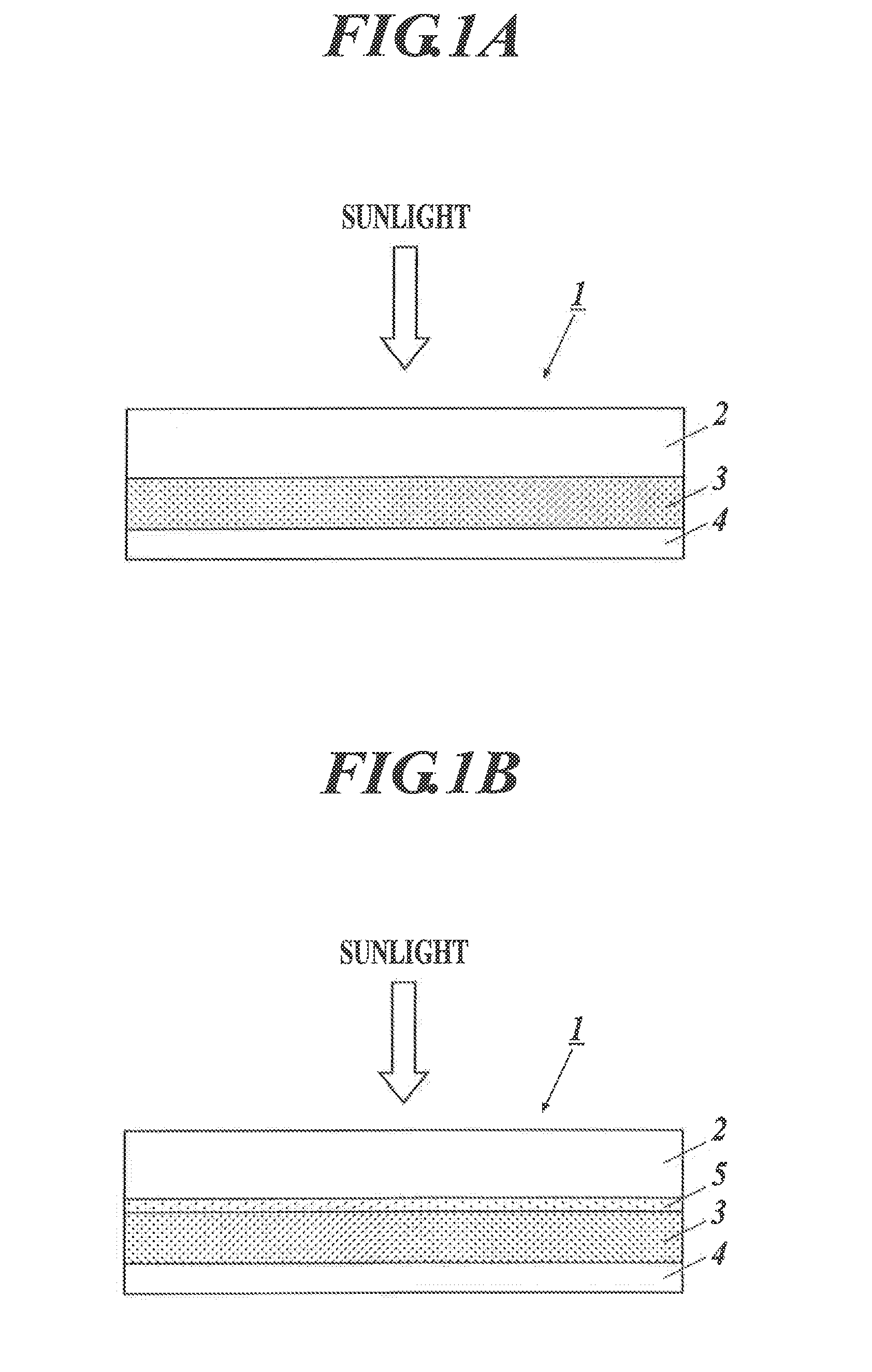

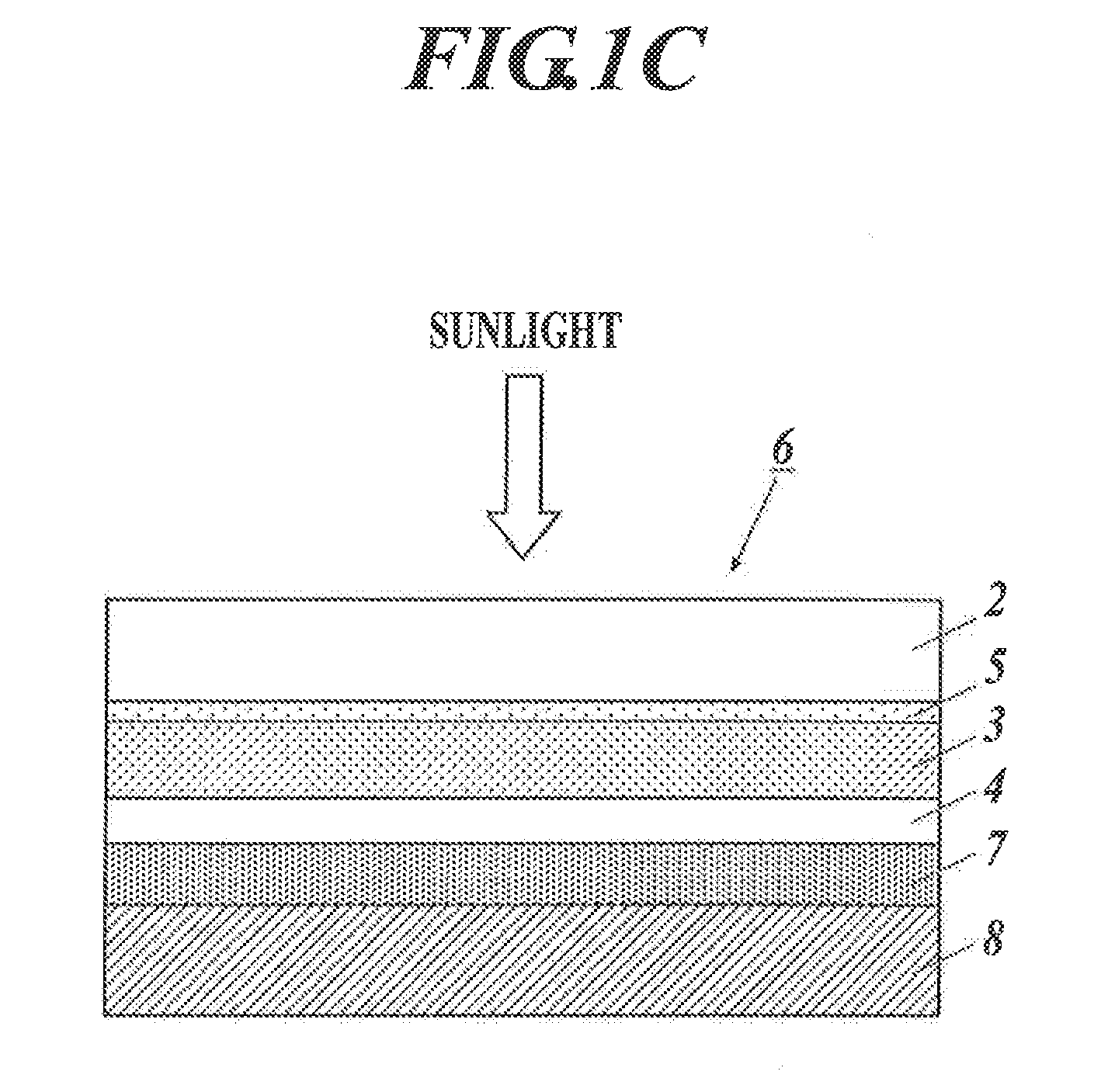

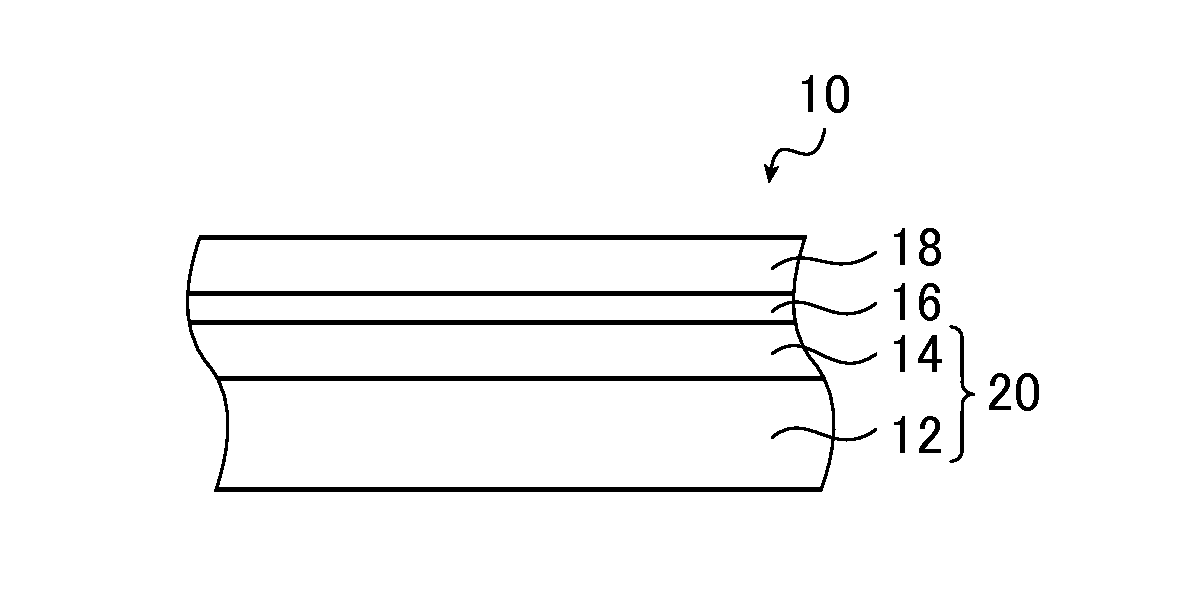

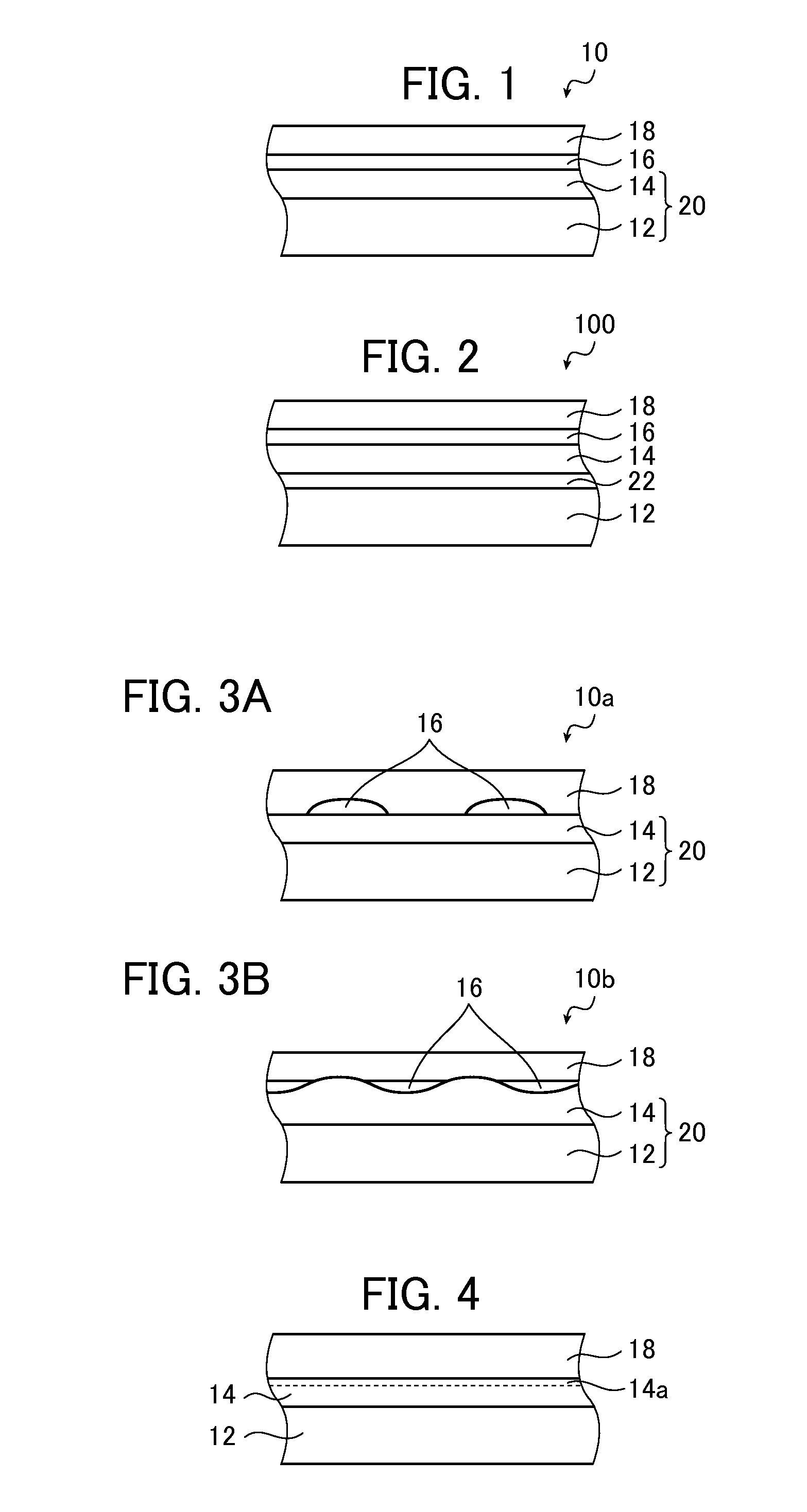

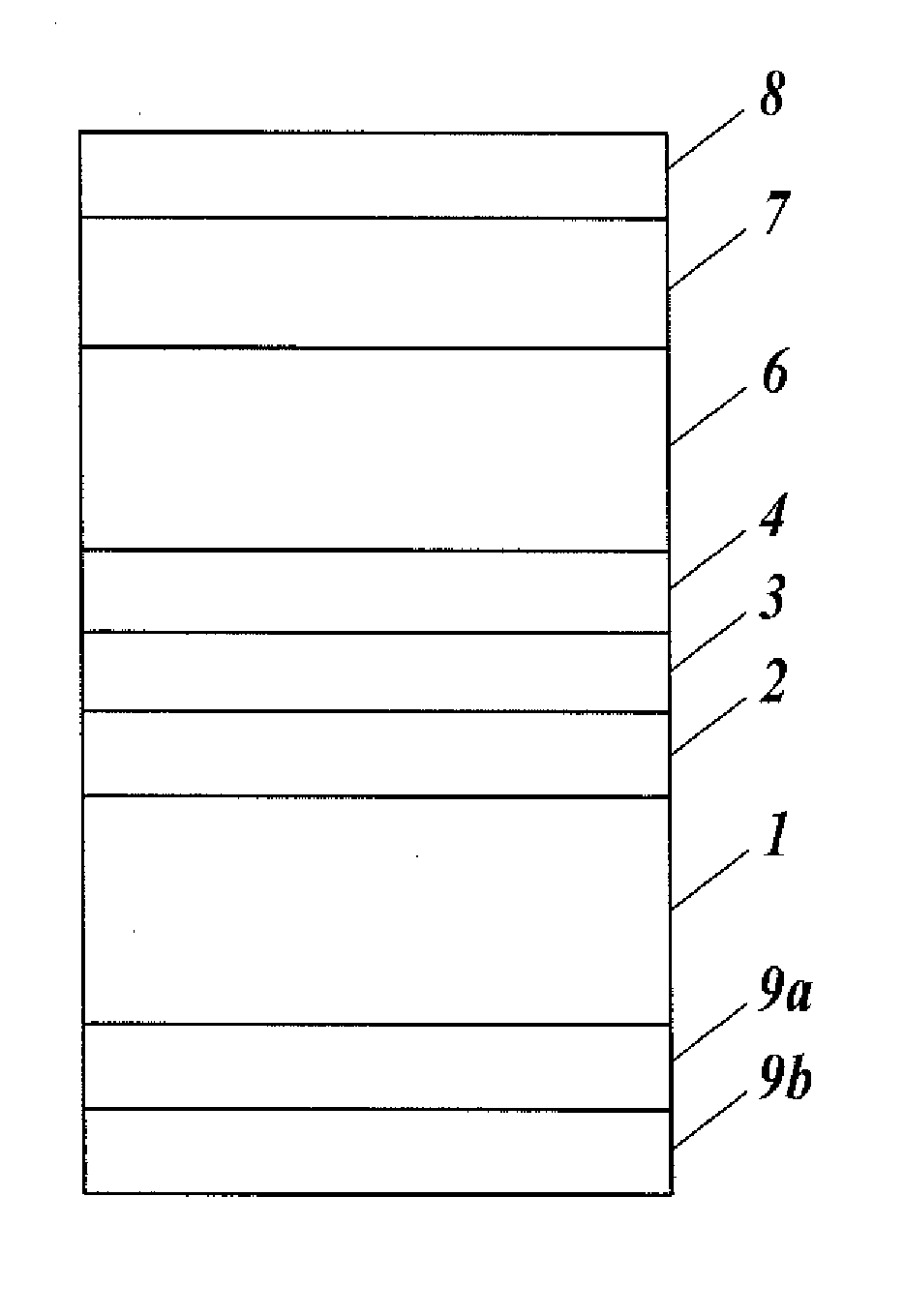

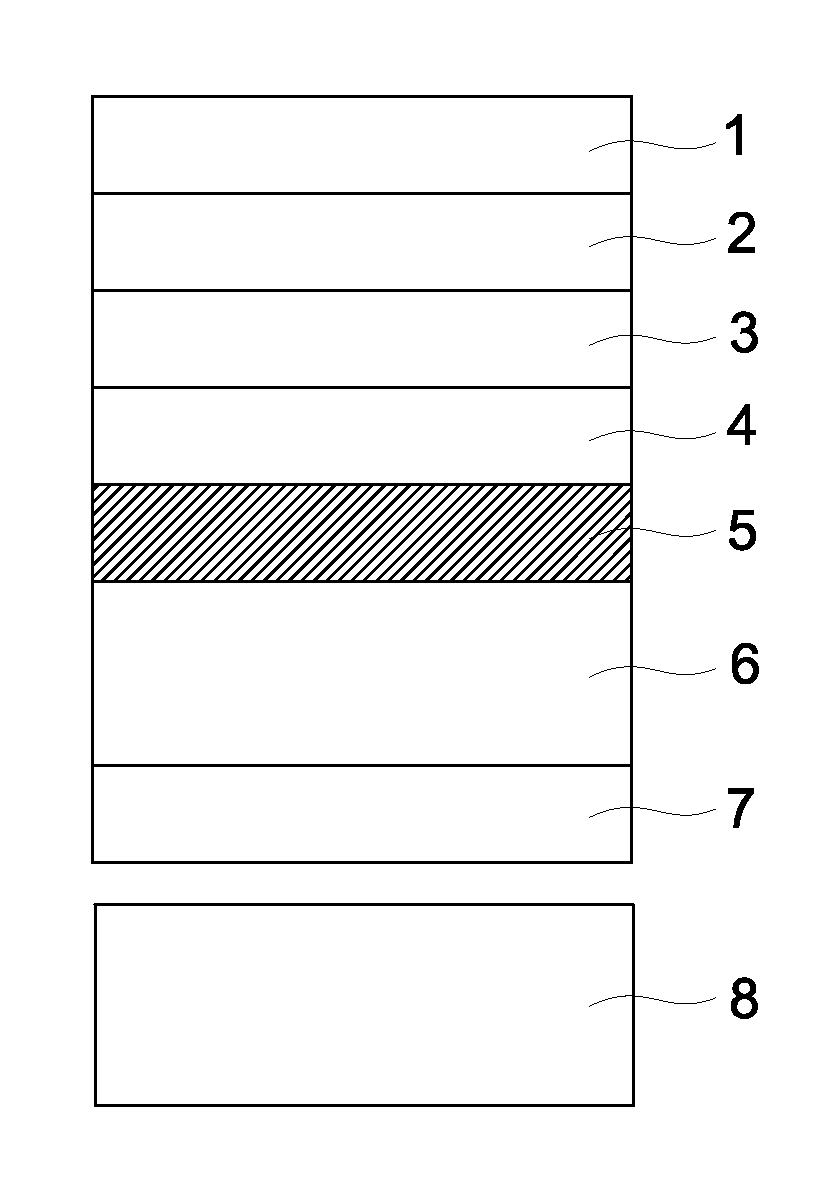

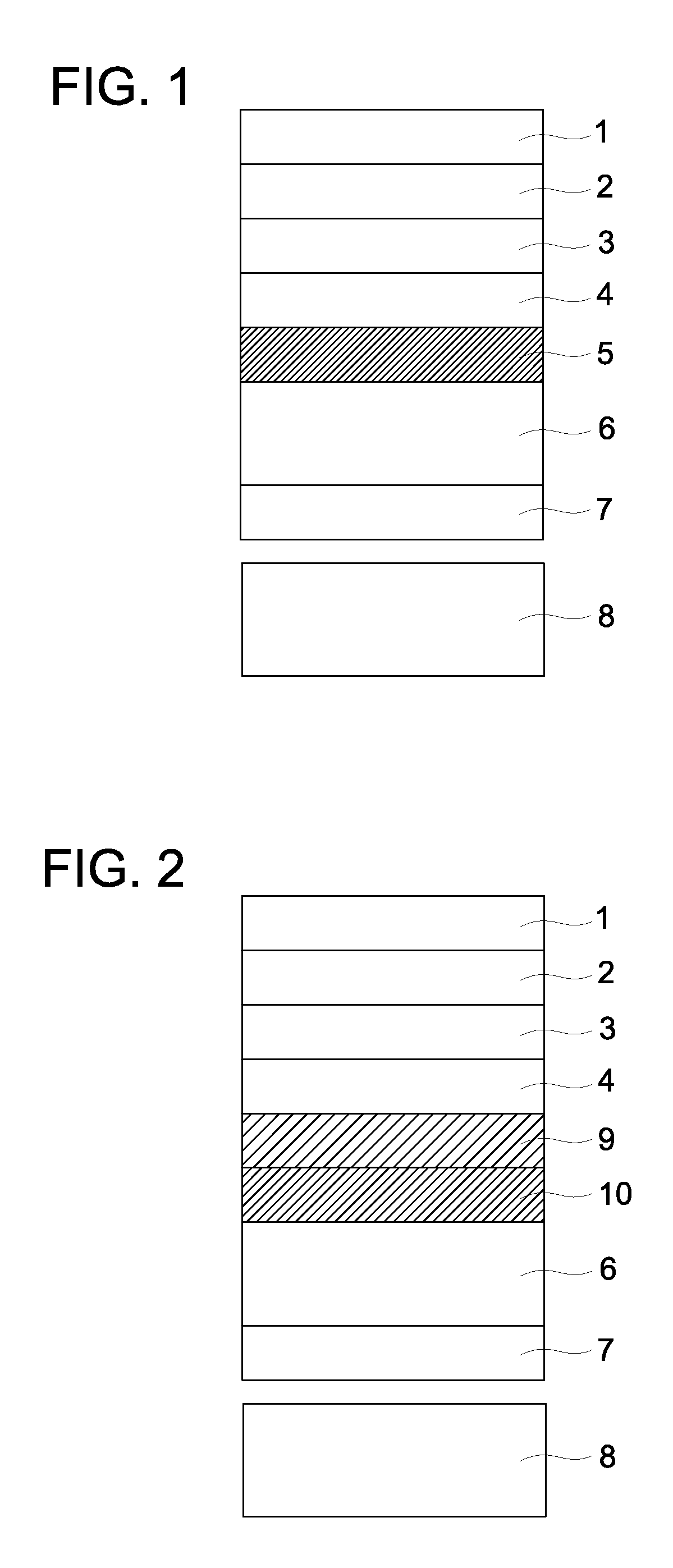

Film mirror, film mirror manufacturing method, film mirror for photovoltaic power generation, and reflection device for photovoltaic power generator

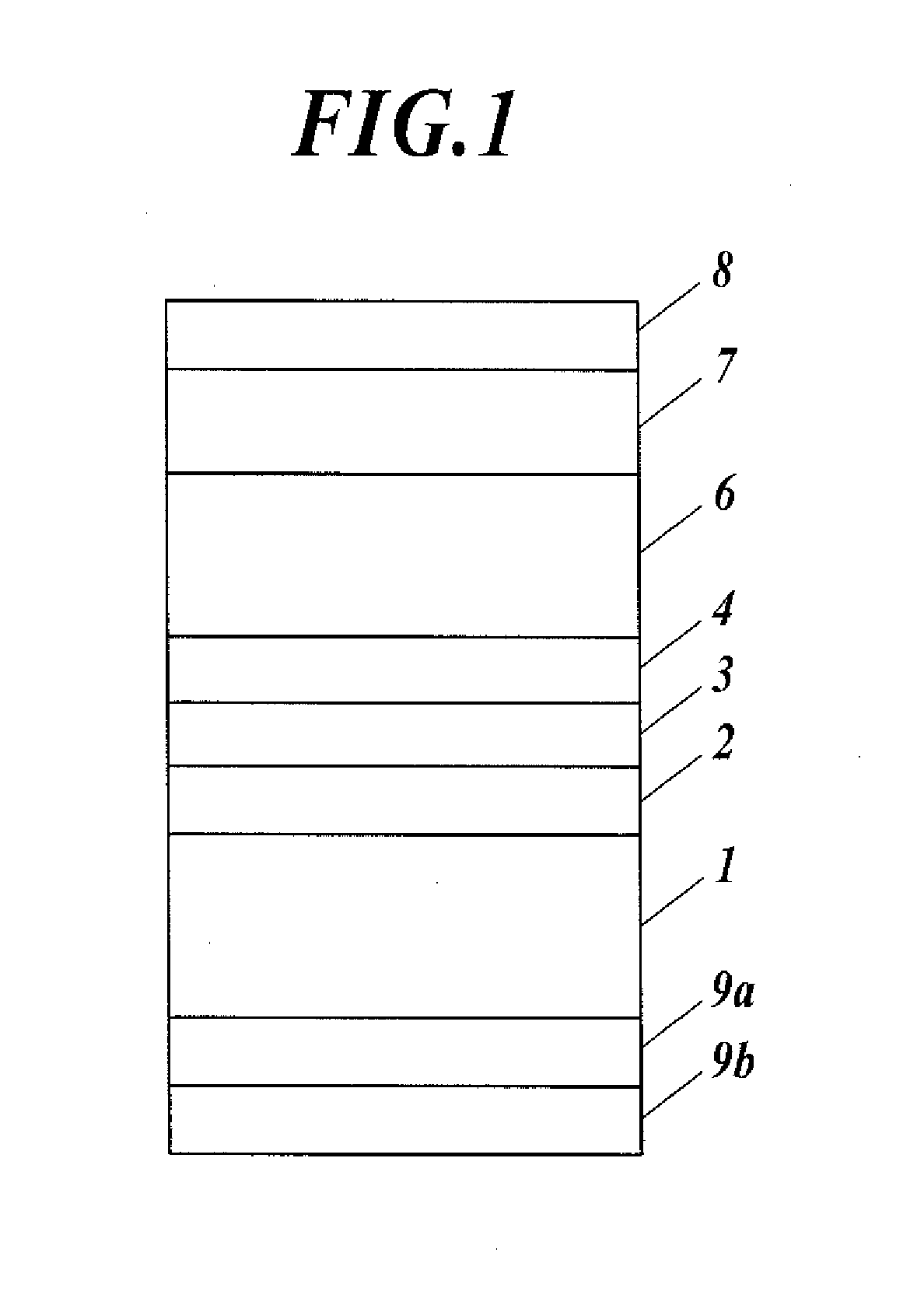

ActiveUS20140340741A1Improve reflectivityGood weather resistanceSolar heating energyMirrorsDielectricSolar light

The purpose of the present invention is to provide a film mirror having a high reflectivity for efficiently concentrating solar light and having excellent weather resistance, and to provide a method for manufacturing the film mirror, a film mirror for photovoltaic power generation, and a reflection device for photovoltaic power generation. This film mirror of the present invention is a film mirror 10a in which a metal reflective layer 3 is disposed above a resin substrate 1. The film mirror is characterized in that it is provided with, closer to the light incident side than the metal reflective layer 3, an interface reflective layer (dielectric reflective layer) 6 having at least one set of a high refractive index layer and a low refractive index layer that are adjacent to each other, and at least one of the high refractive index layer and the low refractive index layer contains a water soluble polymer and metal oxide particles.

Owner:KONICA MINOLTA INC

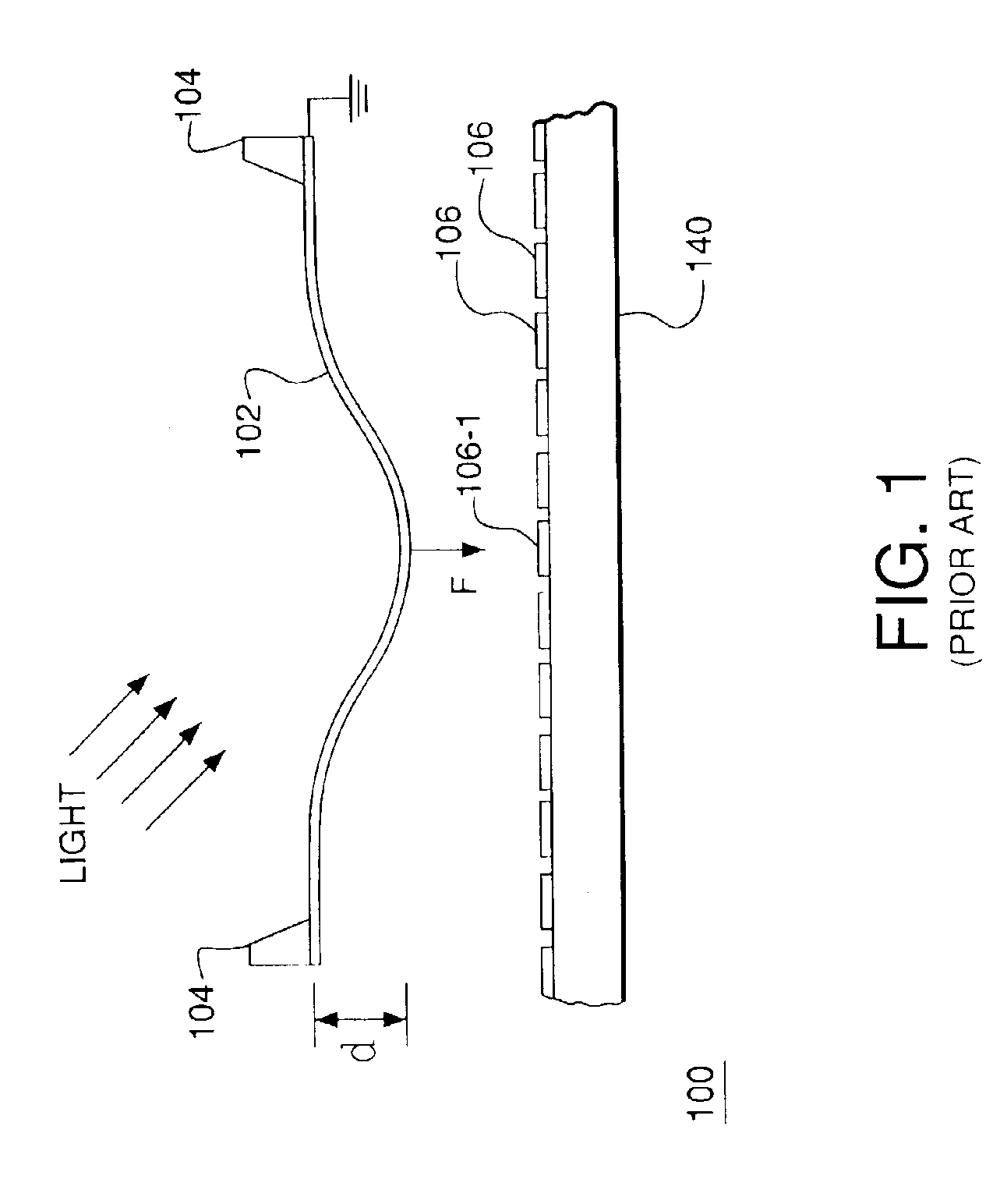

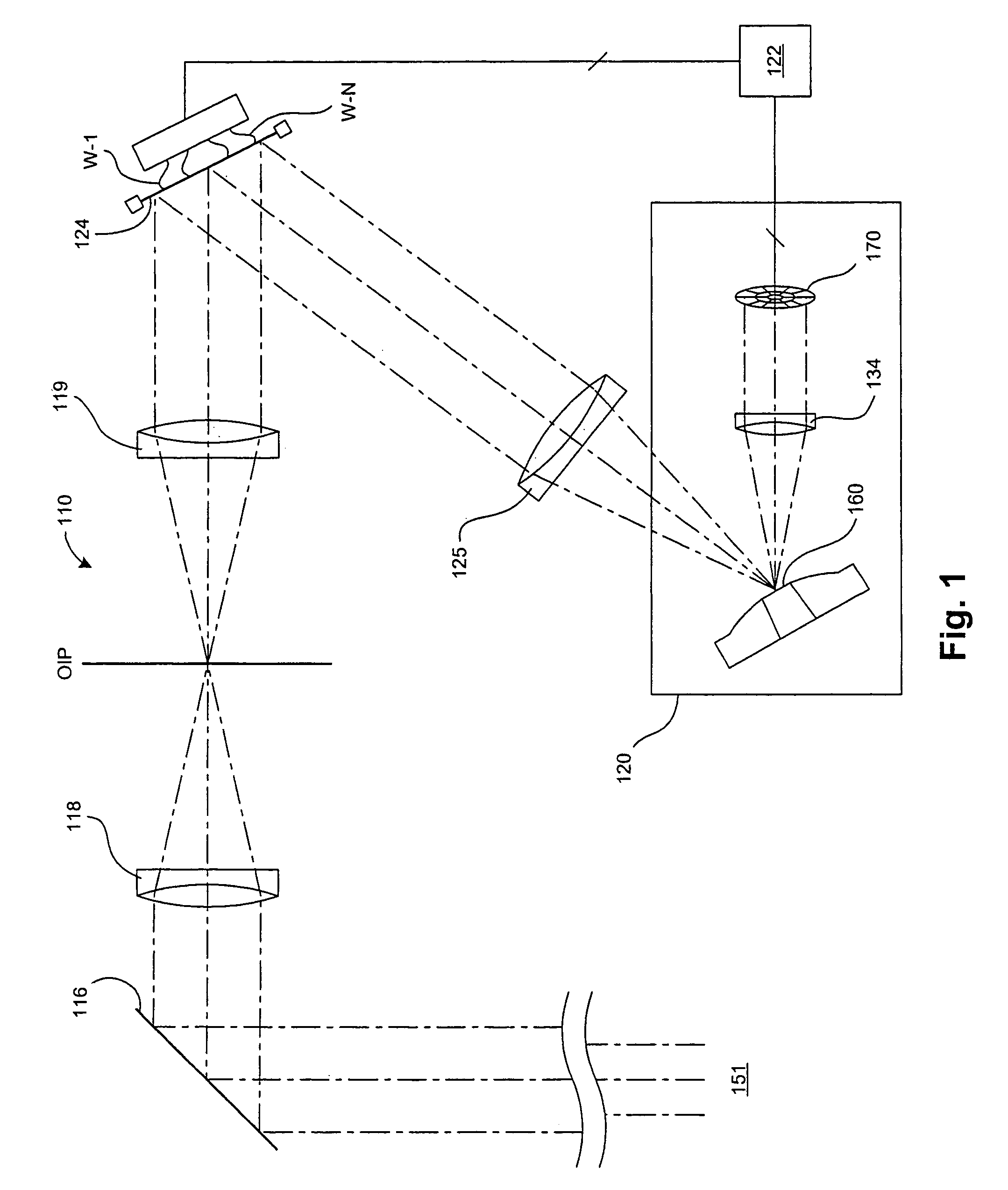

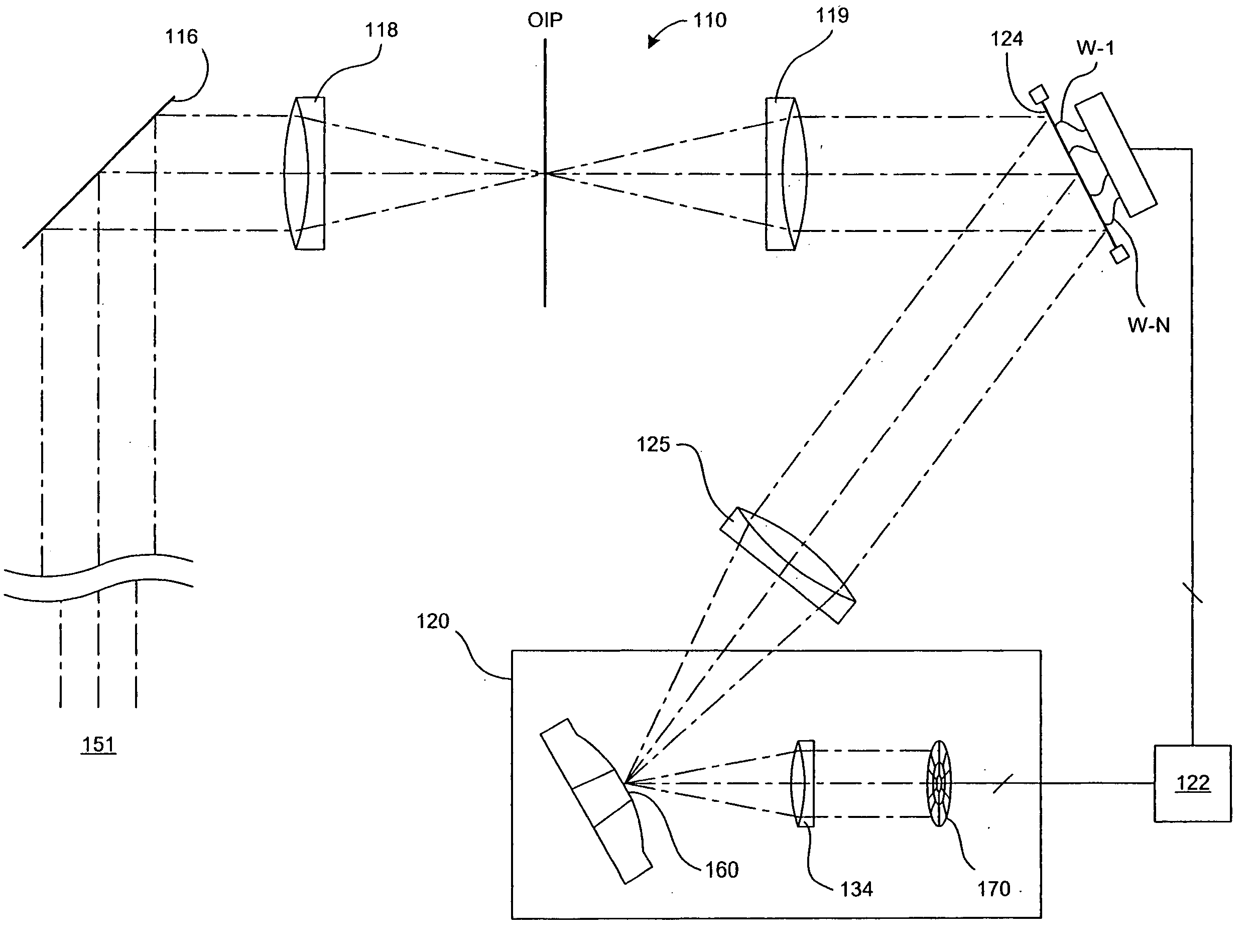

Speckle removal for a laser scanning projector

InactiveUS20120044464A1Improve visibilityShorten the lengthProjectorsOptical devices for laserVisibilityMembrane mirror

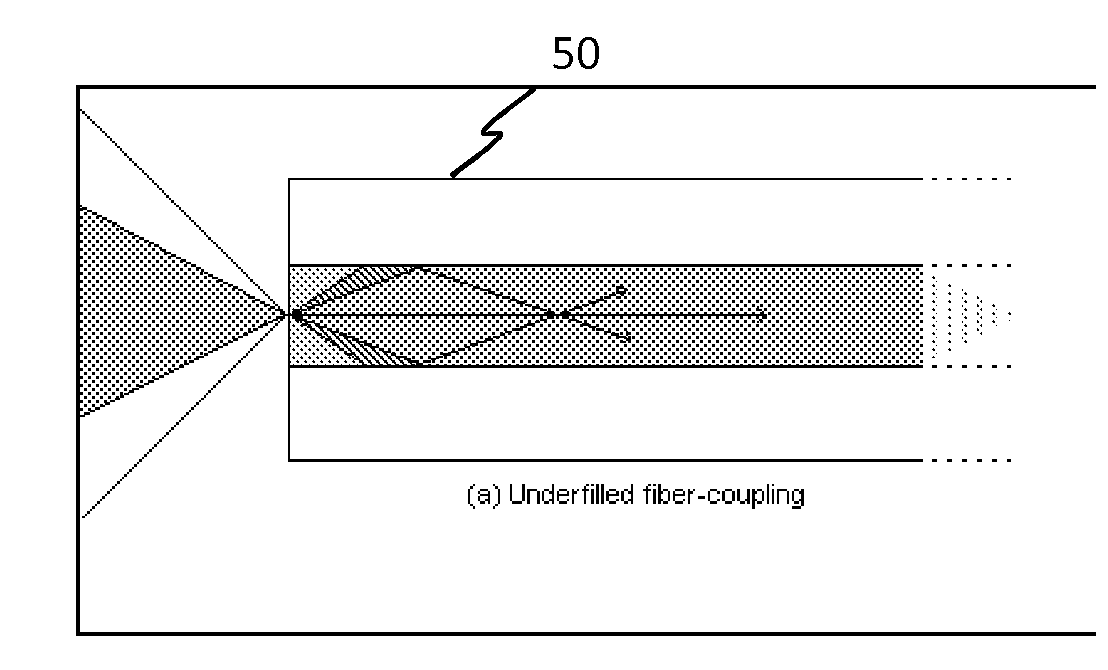

An apparatus and method for reducing the visibility of speckle in coherent light comprises propagating the coherent light through a multimode optical waveguide 106 to reduce a coherence length of the coherent light by intermodal dispersion. A vibratable membrane mirror 104 is arranged to reflect the coherent light either before or after passing through the multimode optical fibre further to reduce the coherence length by distributing wave packets across different propagating modes and to erase the modal structure by averaging the distribution of energy across the modes leading to a more uniform illumination. The invention may be used for speckle removal in a laser scanning projector.

Owner:OPTYKA

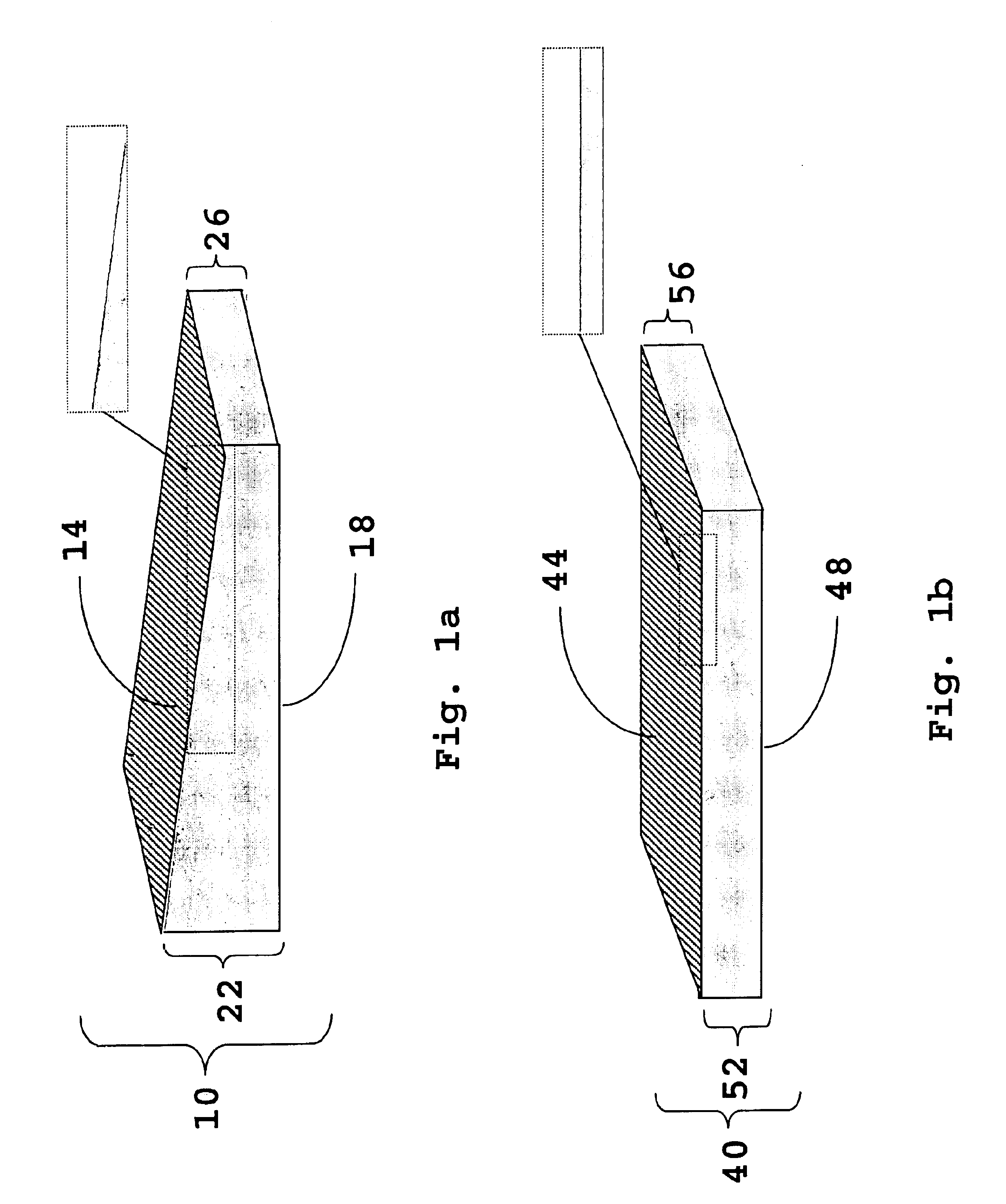

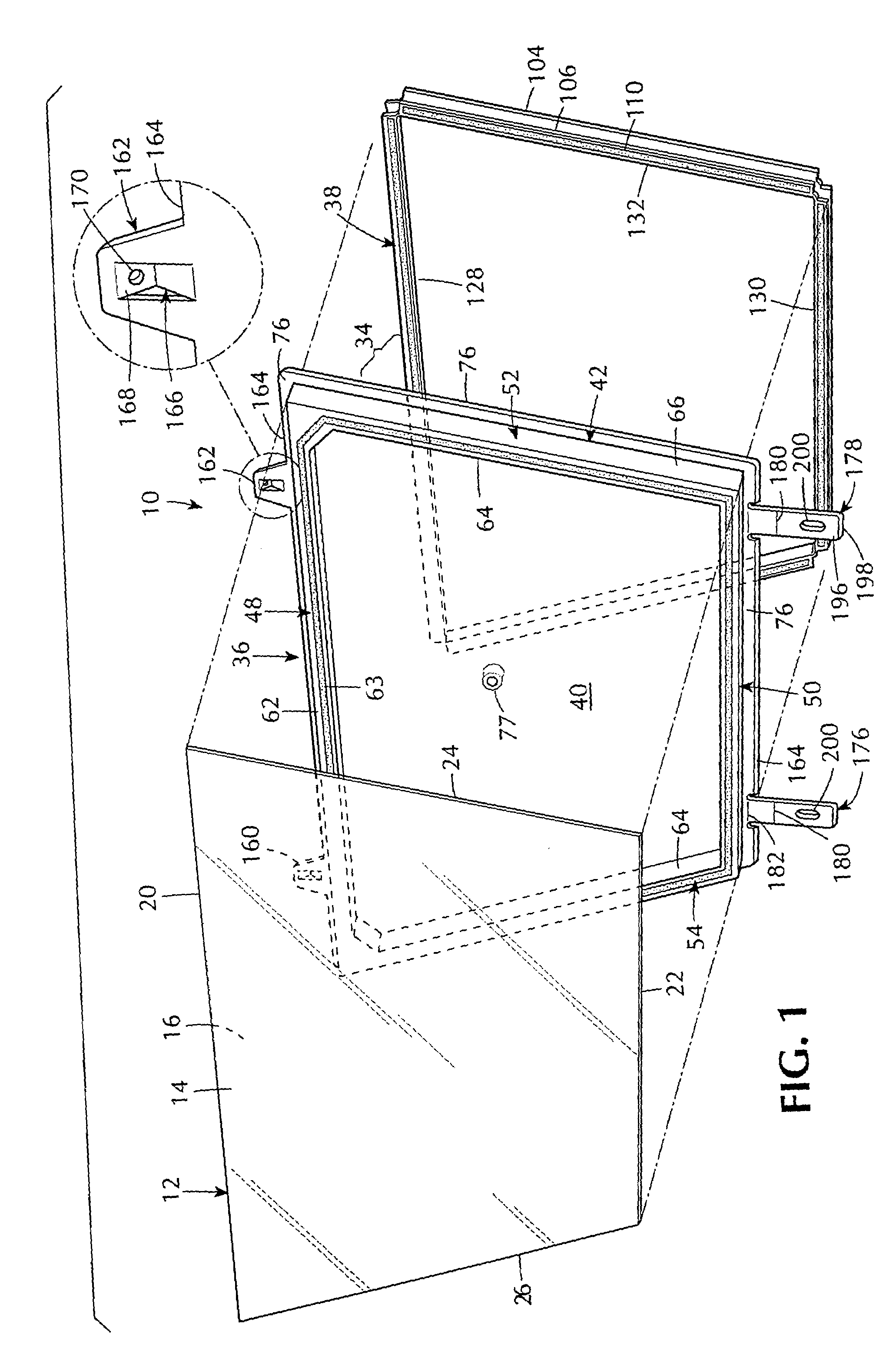

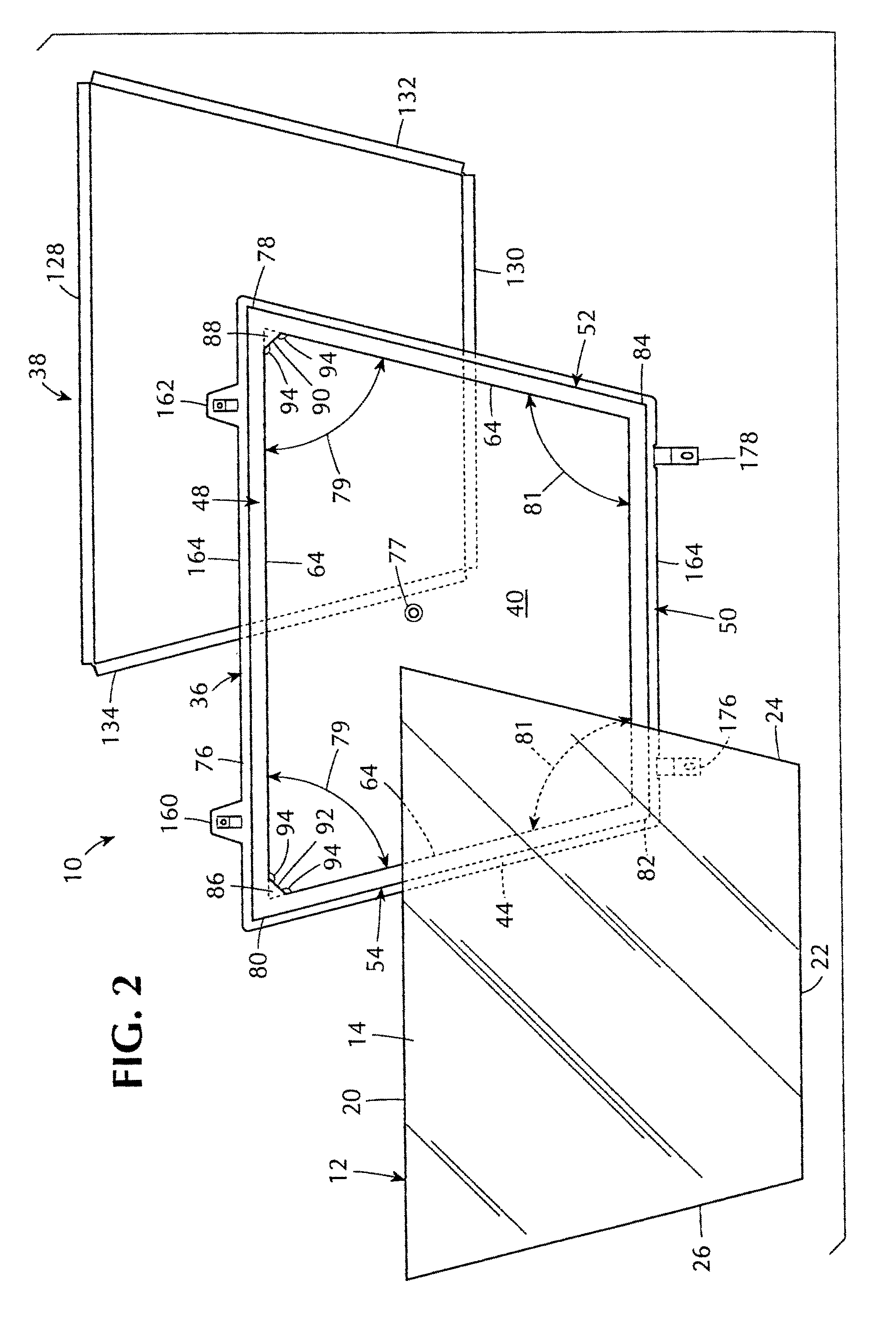

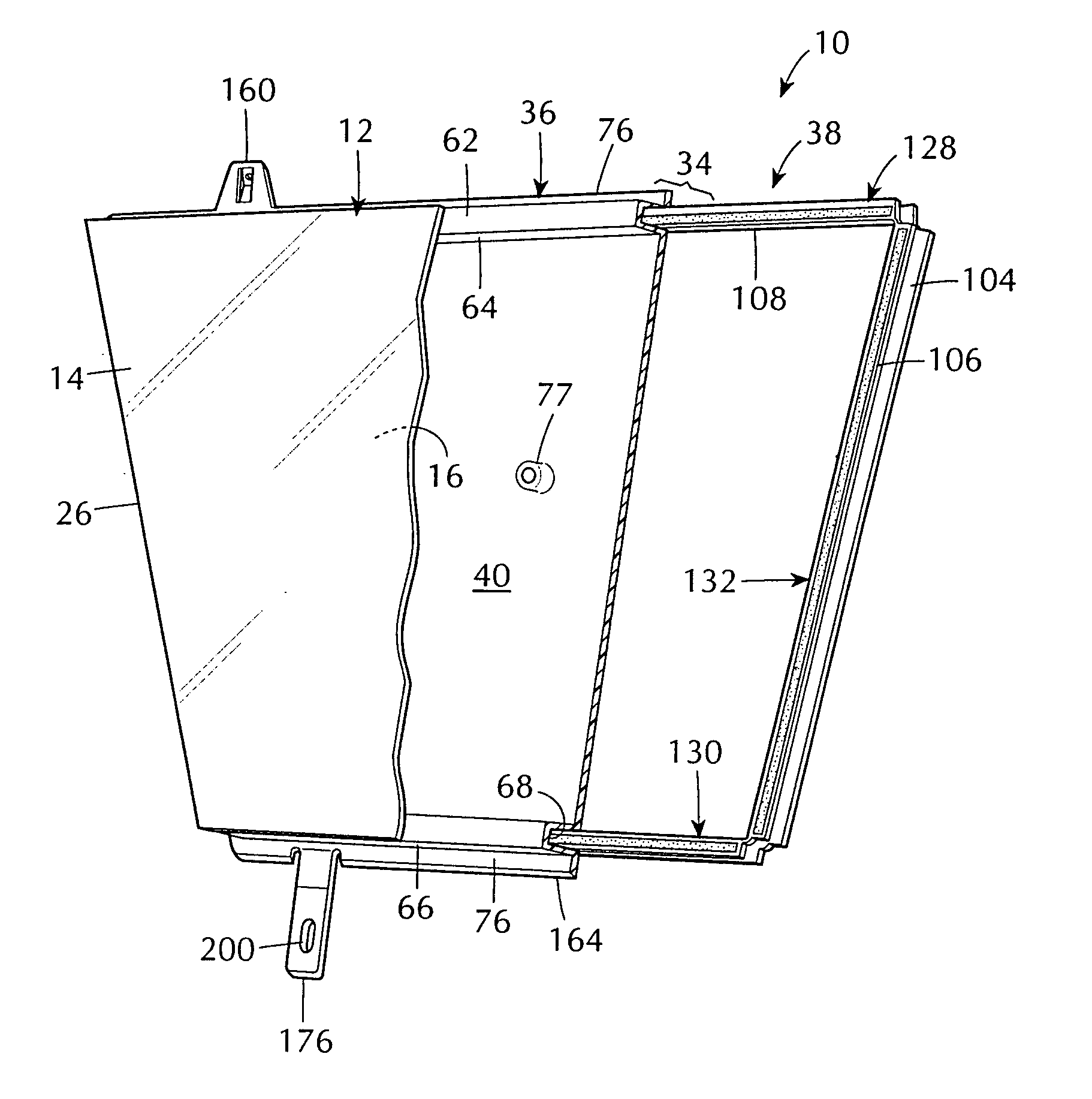

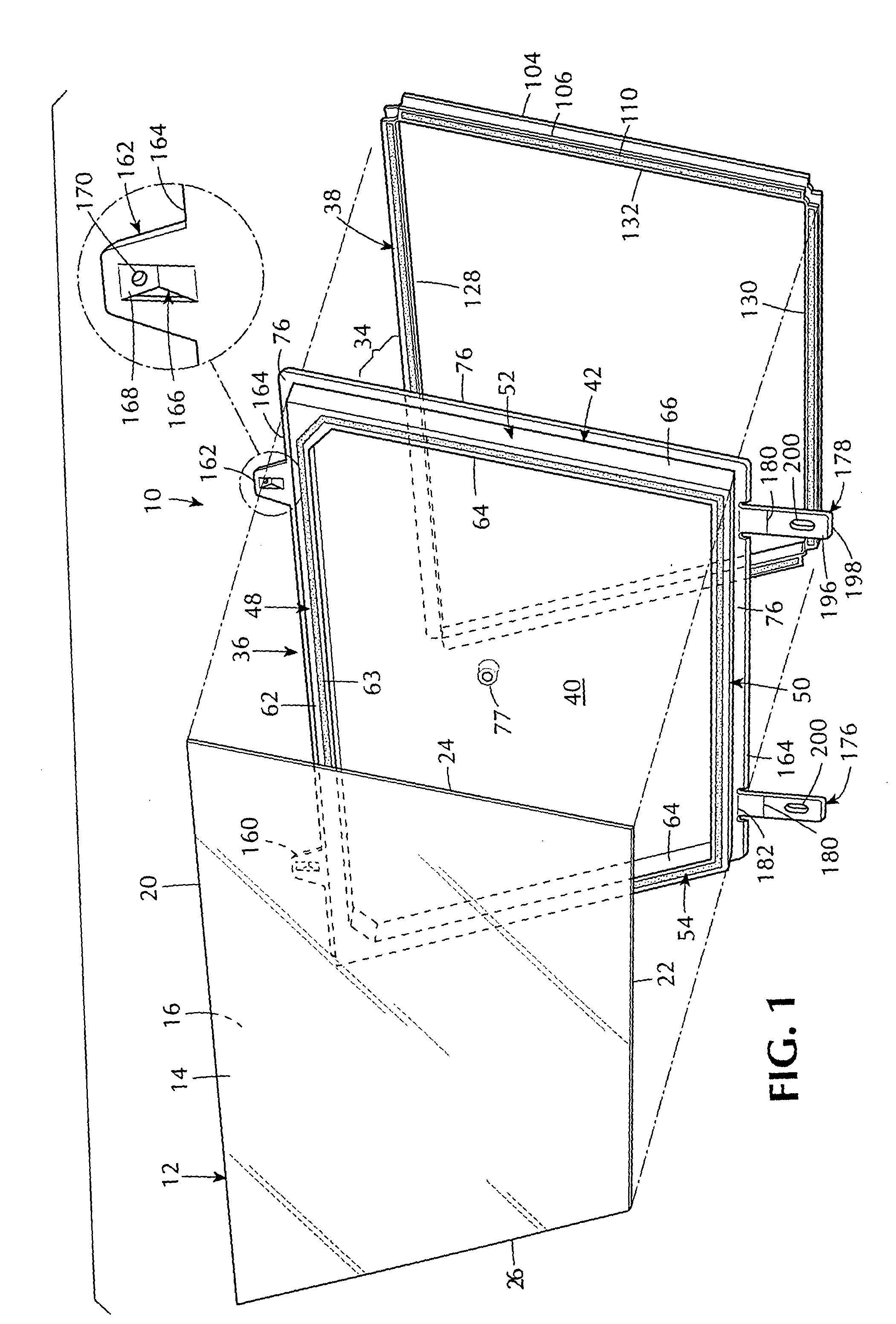

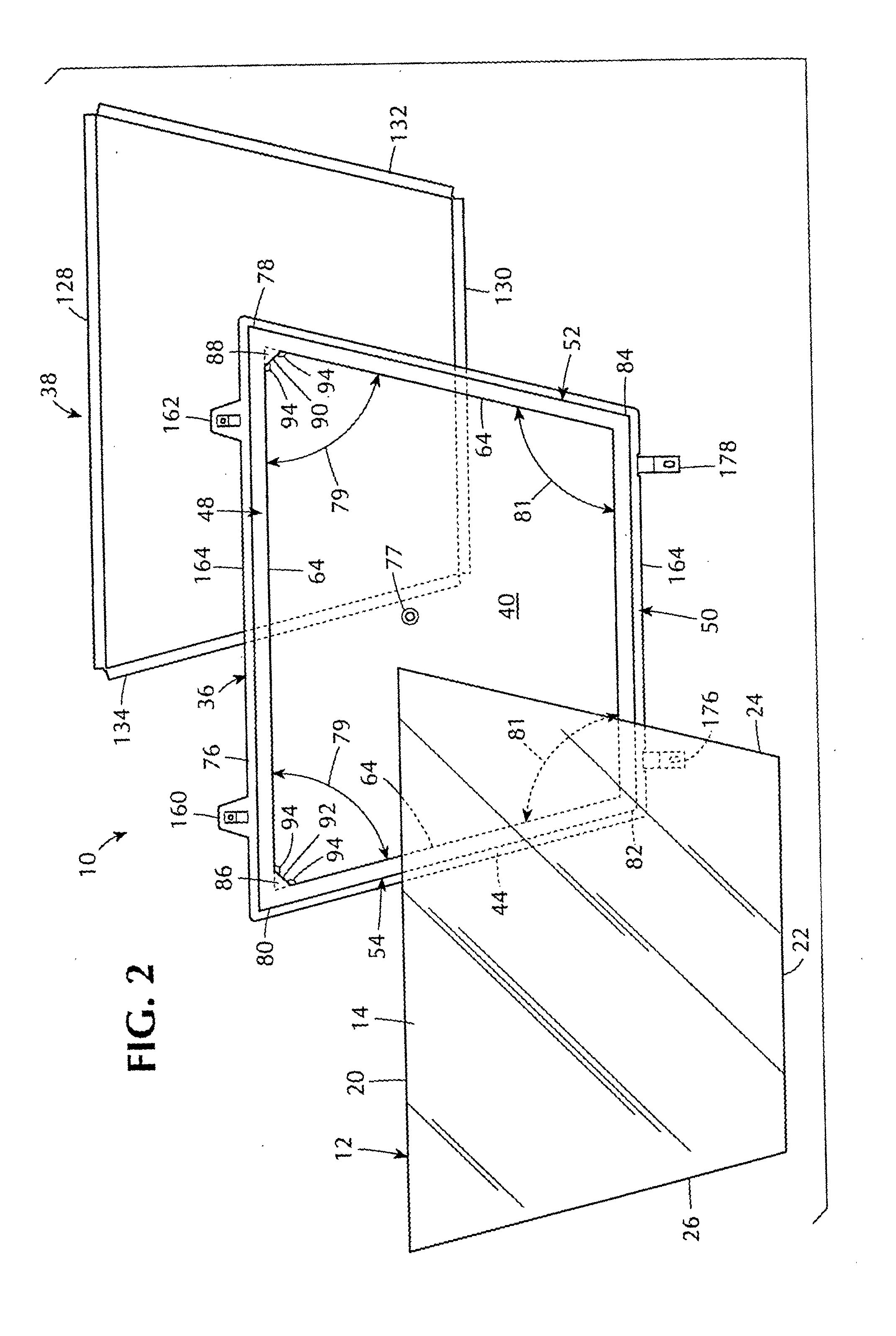

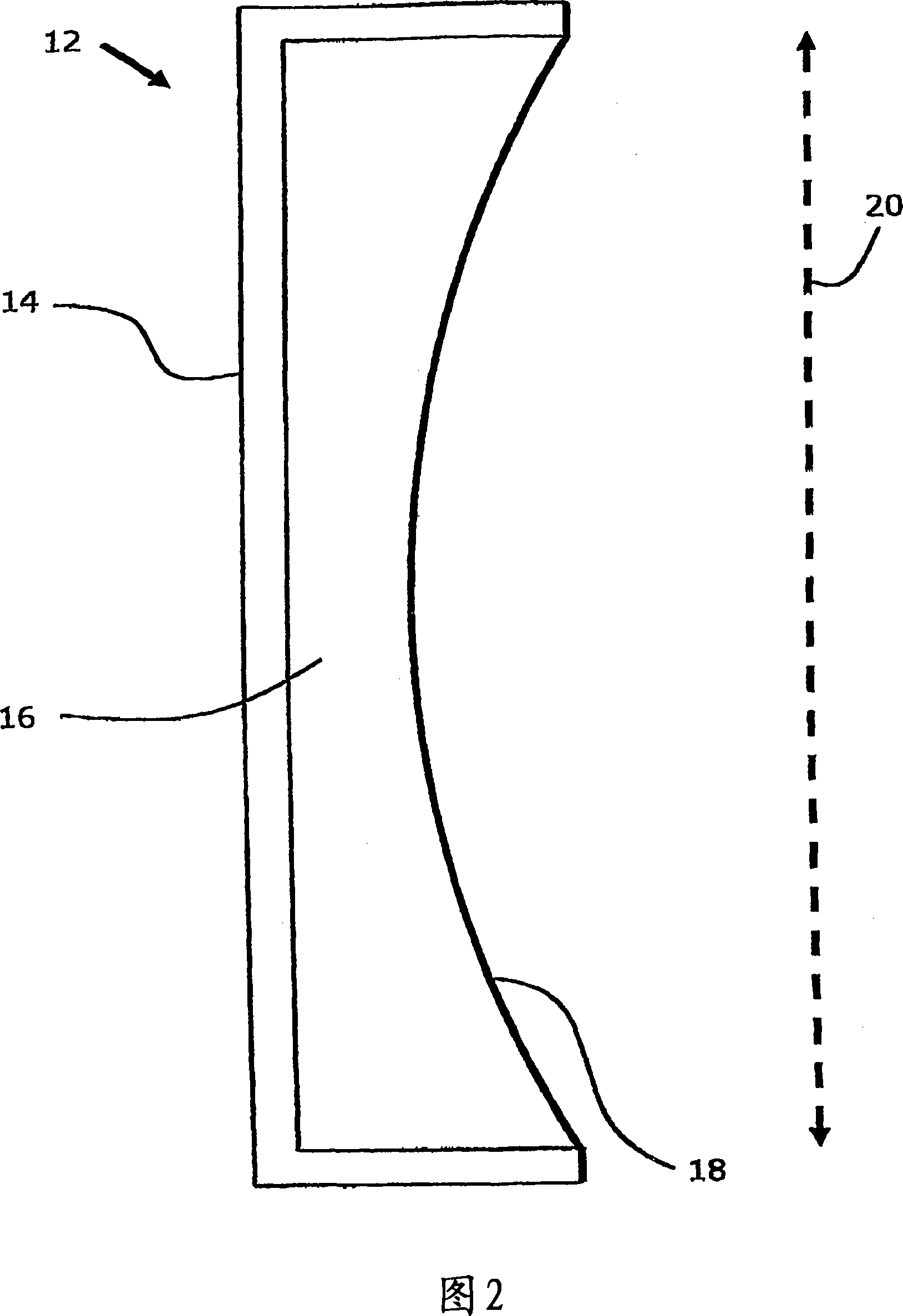

Thin film mirror

The thin-film mirror includes a pan-shaped housing having a pan surface and a hollow wall bordering the pan surface. The hollow wall has a mounting surface for thin reflecting film, which mounting surface is stepped above the pan surface. The hollow wall has an open portion opposite the mounting surface and accommodates a reinforcing member that rigidities the pan-shaped housing. A thin reflecting film that spans the pan surface is secured to the film mounting surface. The pan-shaped housing is a miterless one-piece structure which can be in the form of a trapezoid. Hollow fillets can be provided at the acute angle corners of the trapezoid. The fillets constitute an additional mounting surface portion for the thin reflecting film and are formed such that no corner of the mounting surface has an acute angle.

Owner:MARTINEZ SR EUGENE

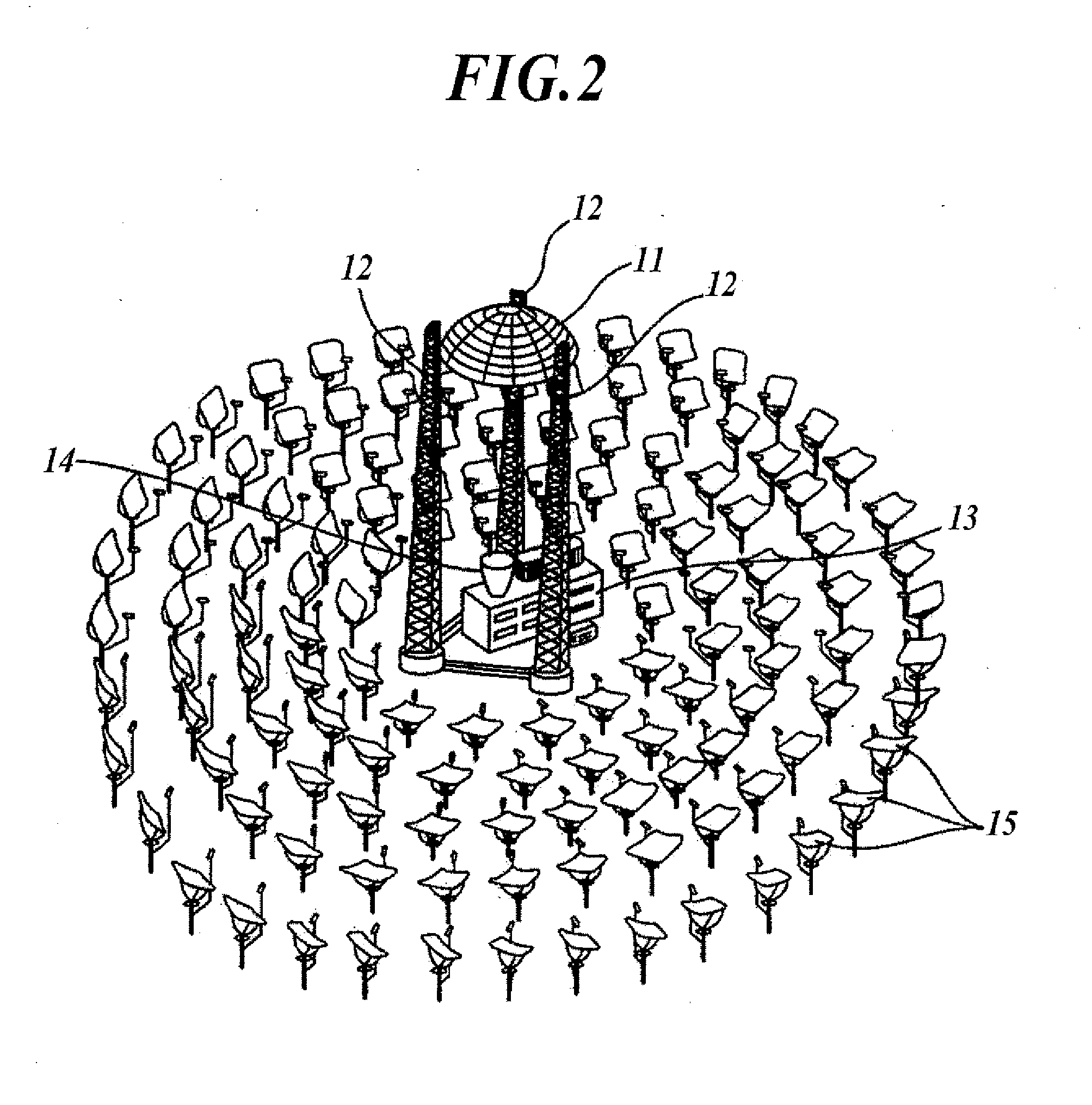

Film mirror for reflecting sunlight and reflective device for solar thermal power generation

InactiveUS20130081612A1Easy to manufactureImprove reflectivitySolar heating energyMirrorsMembrane mirrorReflective layer

A film mirror for reflecting sunlight includes a polymer film substrate, a reflective layer including silver coating, and a protective coating layer in sequence from the incident side of sunlight. The reflective layer is formed by coating and calcining (firing) a coating liquid containing a silver complex compound.

Owner:KONICA MINOLTA OPTO

Fabrication method for hydrogel/macromolecule polymer film muscular tissue support

ActiveCN103976805AHigh strengthImplement fixed functionLigamentsMusclesMembrane mirrorNetwork structure

The invention discloses a fabrication method for a hydrogel / macromolecule polymer film muscular tissue support. The method comprises obtaining a three-dimensional support structure through a layer-upon-layer stacking mode; designing and fabricating a blood vessel network structure mold and a directional flow passage mold according to muscle structural characteristics; fabricating polymer directional film through an electro-spinning technology, fabricating a support single-layer plane structure, stacking other layers of supports on the three-dimensional support structure, and performing covering with the macromolecule polymer film support bonded on the outermost layer to obtain the hydrogel / macromolecule polymer film support. According to the method, the blood vessel network and the directional flow passage are fabricated on hydrogel, directional growth of cells can be achieved through the directional flow passage, nutrition and oxygen supply can be achieved through blood vessel network pipes, the polymer film covered on the periphery has a directional structure, and accordingly, directional growth of peripheral cells can be achieved, stretched film is bound and sewn, and fixation of the support is achieved.

Owner:XI AN JIAOTONG UNIV

Film mirror for solar radiation collection and method for producing same

InactiveUS20150369974A1StructuredGood light fastnessSolar heating energyMirrorsMembrane mirrorThin membrane

A film mirror for solar radiation collection includes at least a protective layer, a silver reflective layer and a resin substrate in this order from a light incident side and has a corrosion inhibitor present at either or both of a surface and a surface layer of the silver reflective layer on the protective layer side, with the content of the corrosion inhibitor being 0.1 to 10 mg / m2. The film mirror for solar radiation collection is excellent in adhesion of the protective layer and in lightfastness as well.

Owner:FUJIFILM CORP

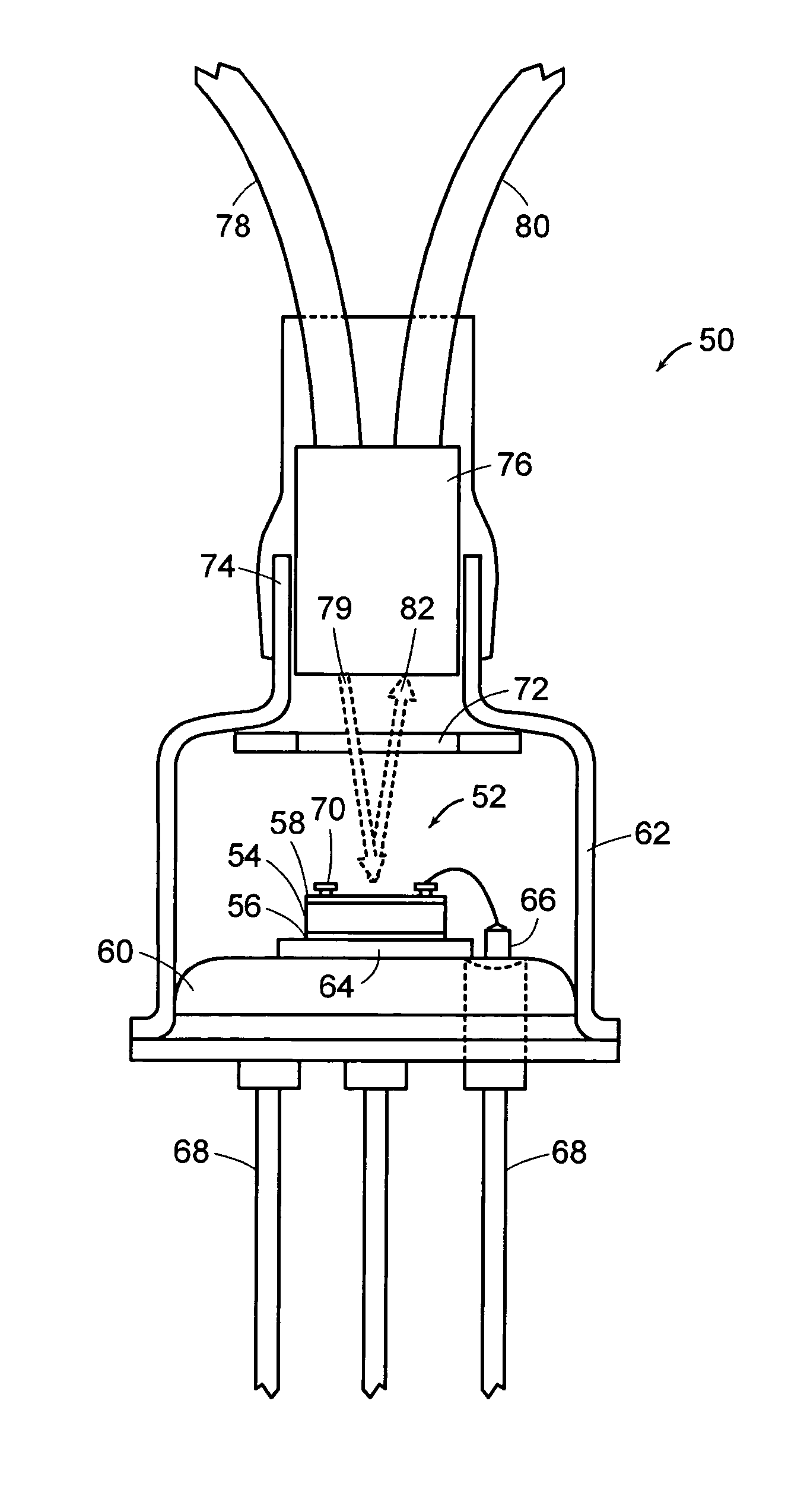

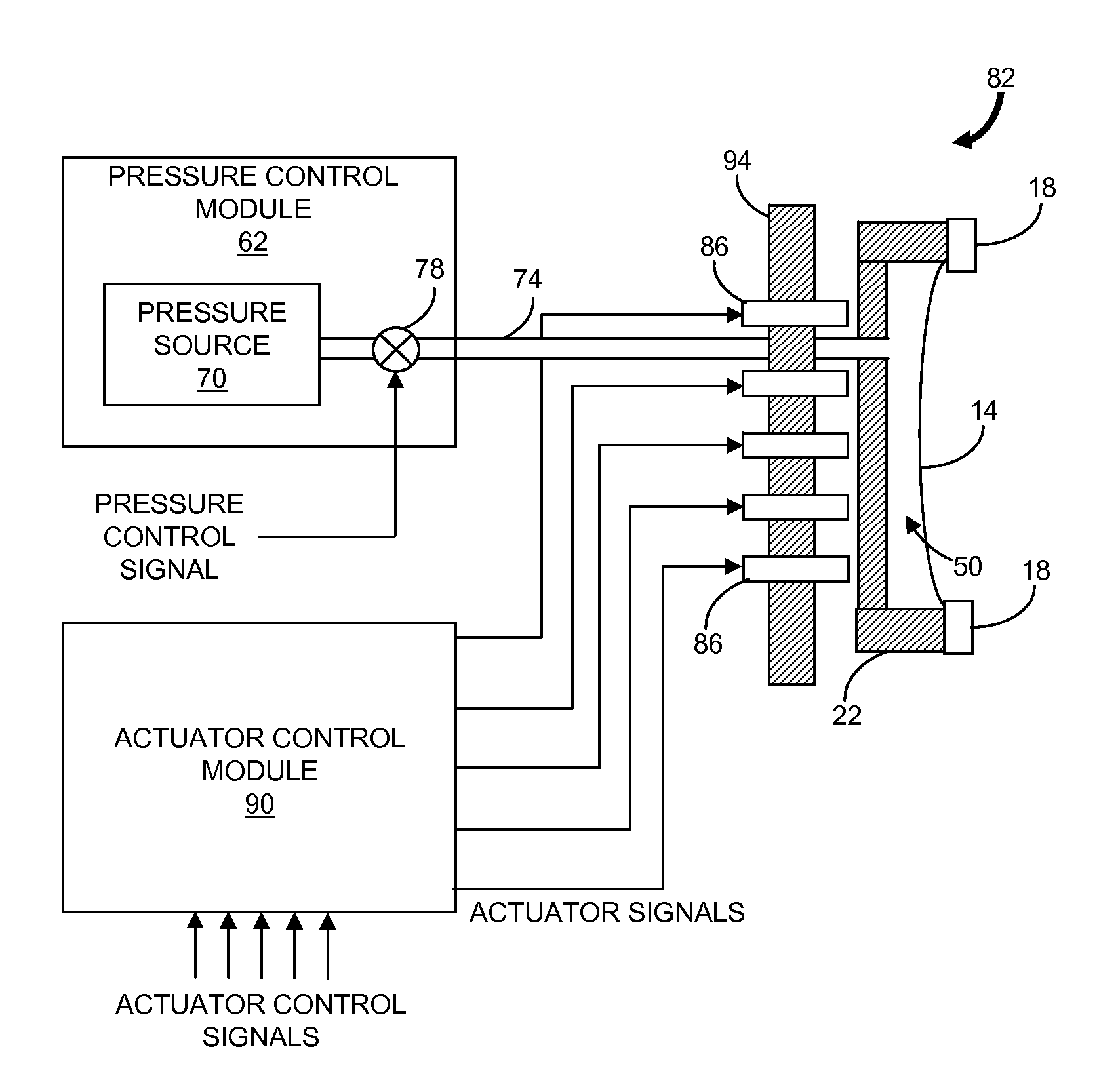

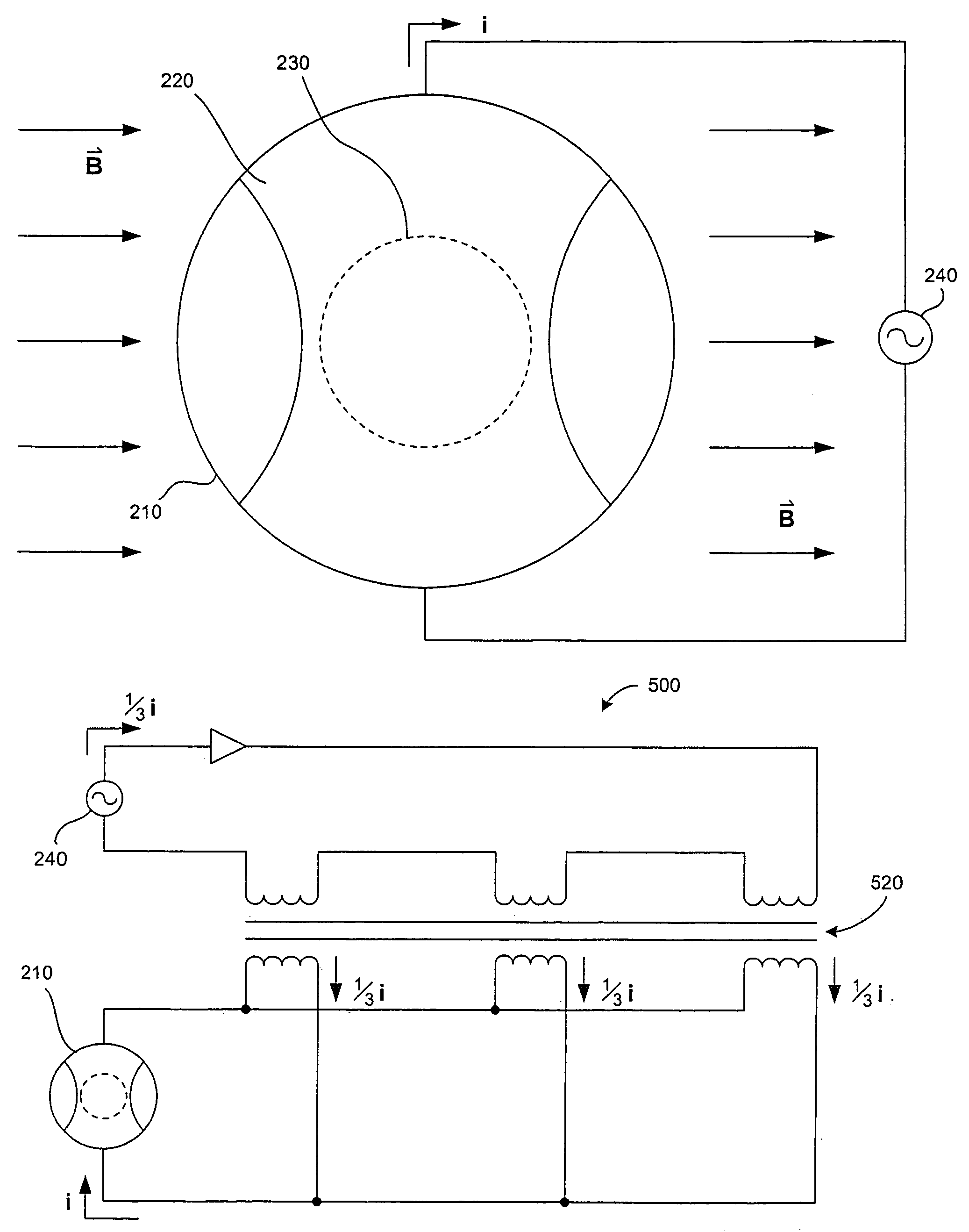

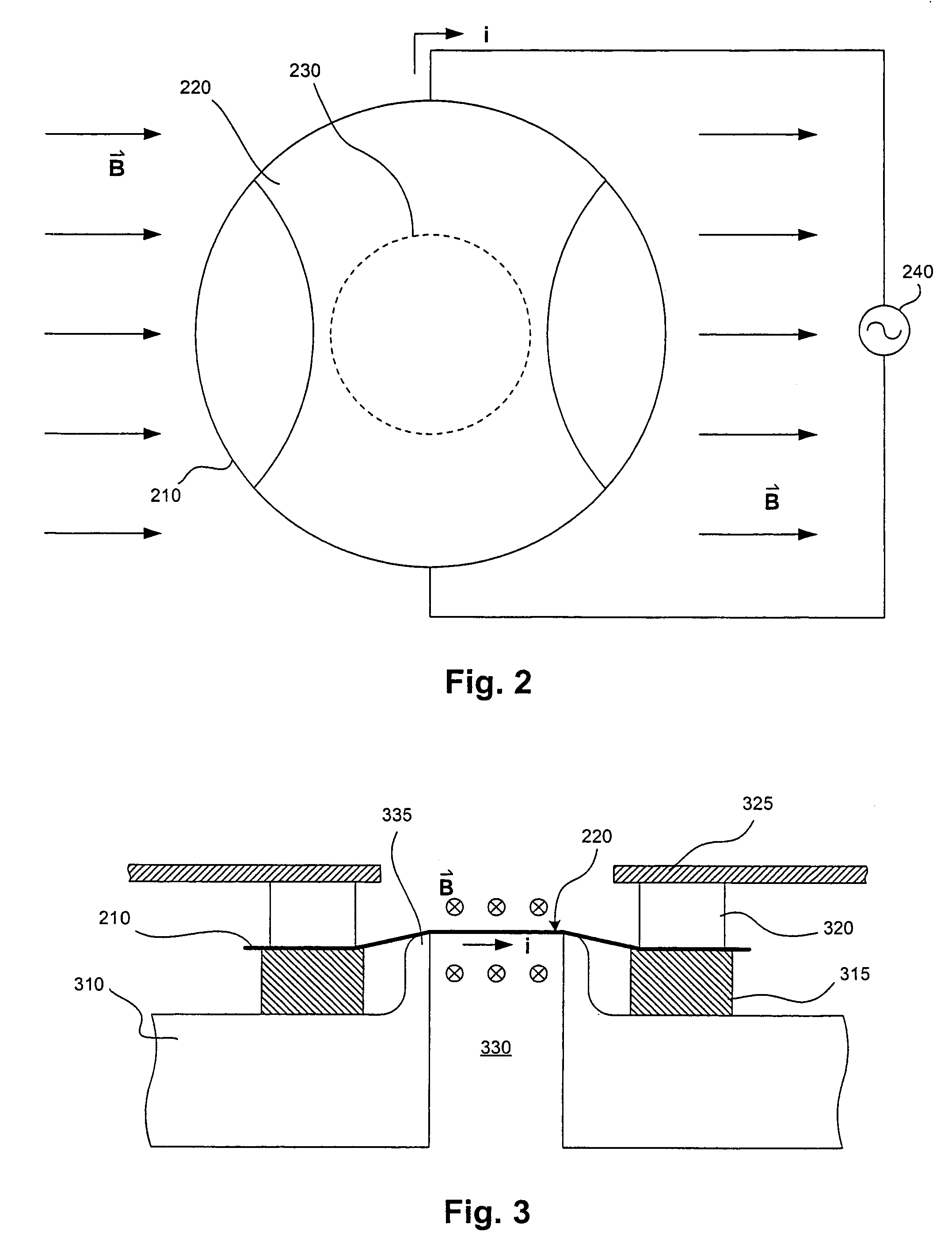

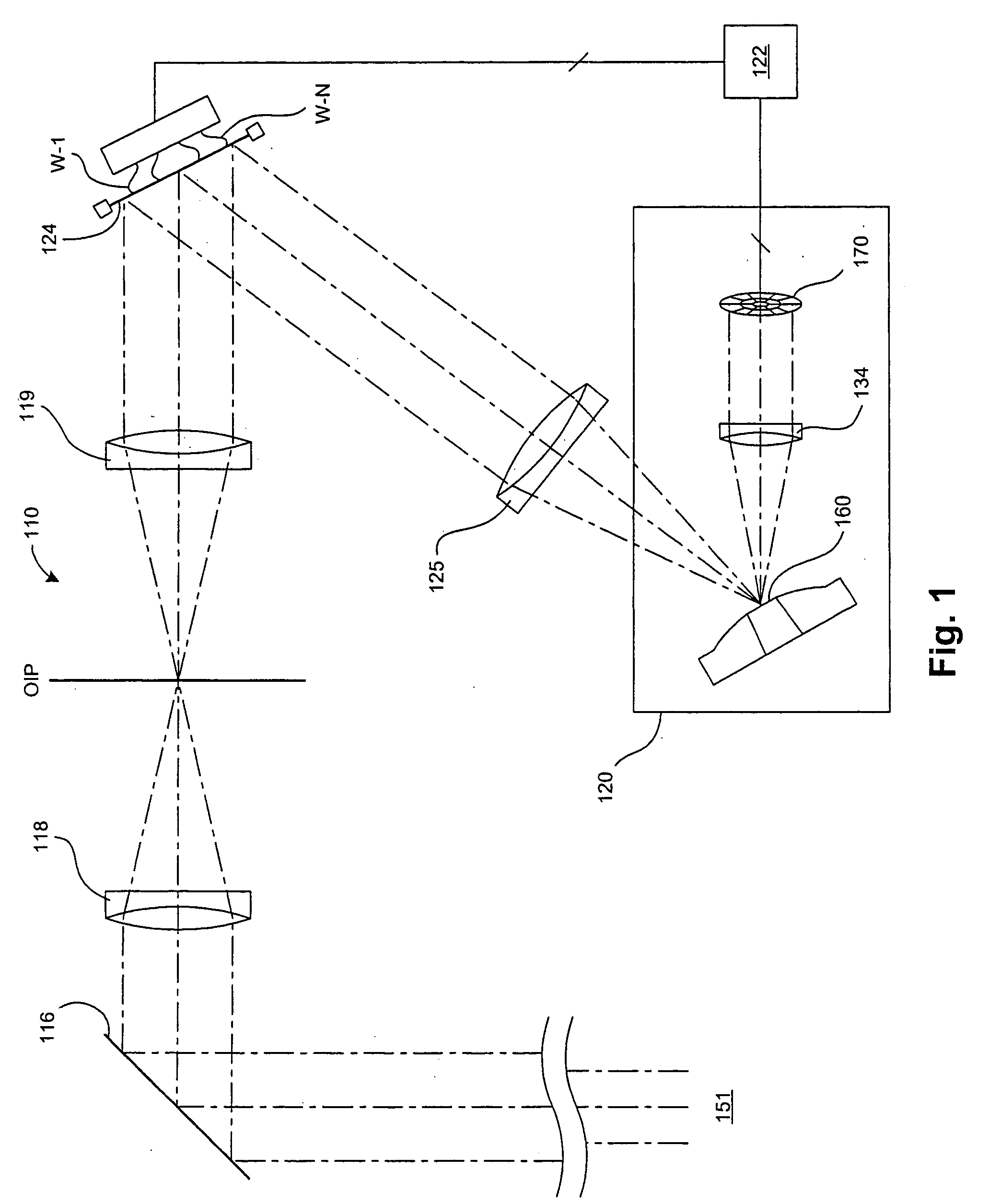

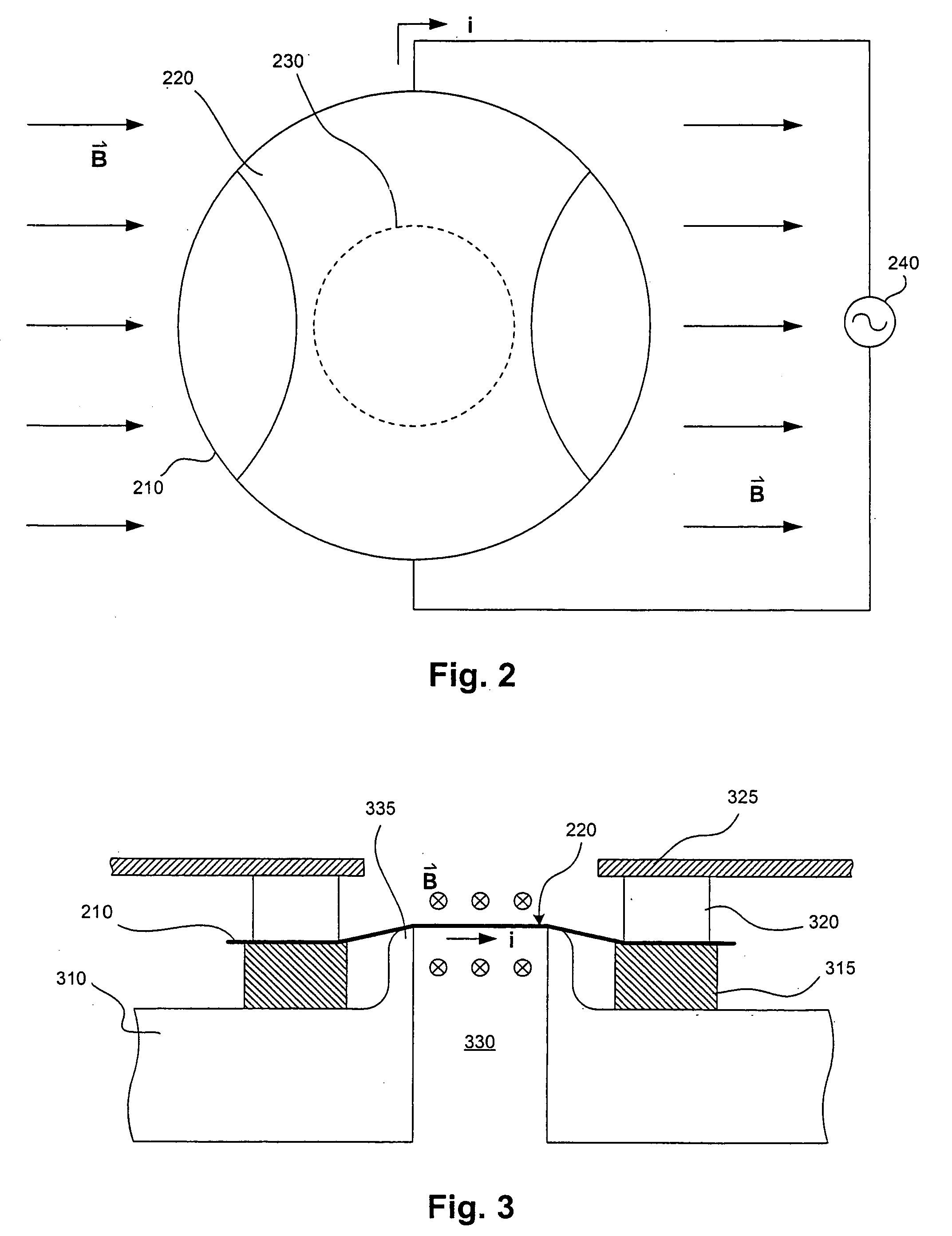

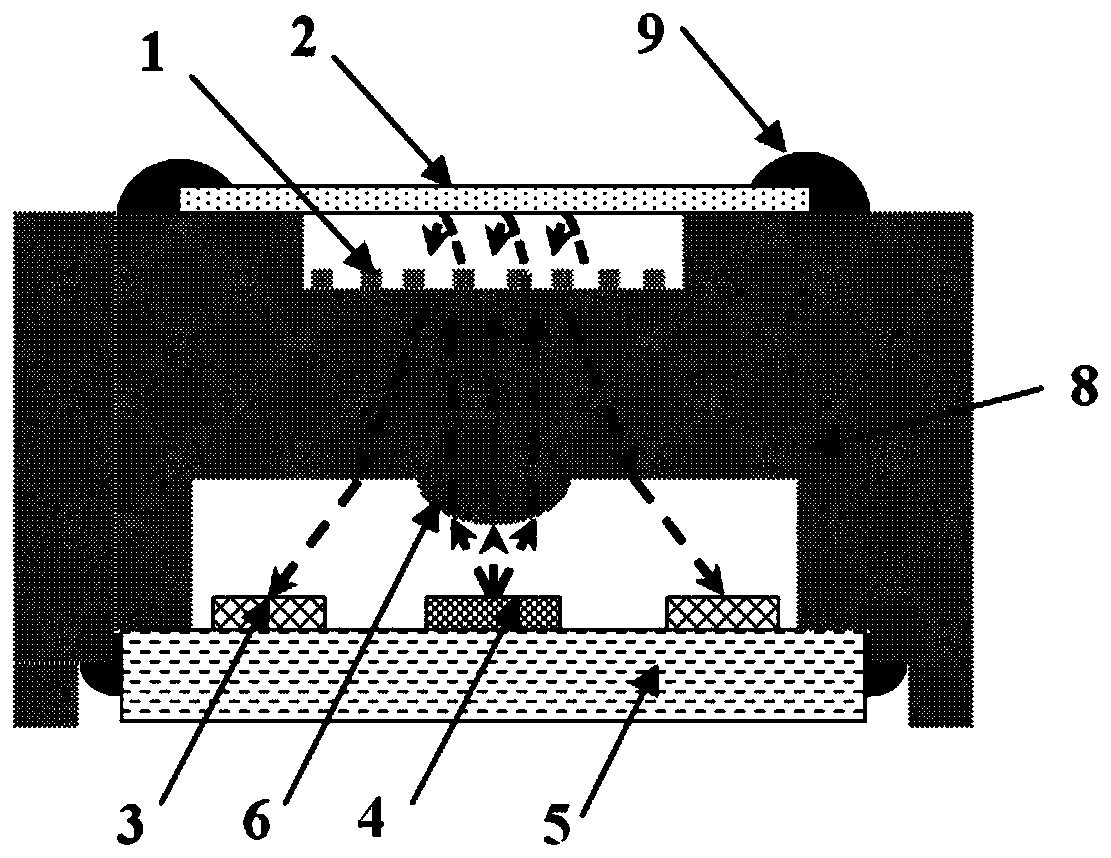

Electromagnetically driven membrane mirror assembly

ActiveUS7102114B2Avoid defectsCorrection of deformationOptical measurementsPhotometry using reference valueMembrane mirrorWavefront sensor

Owner:EOS DEFENSE SYST USA INC

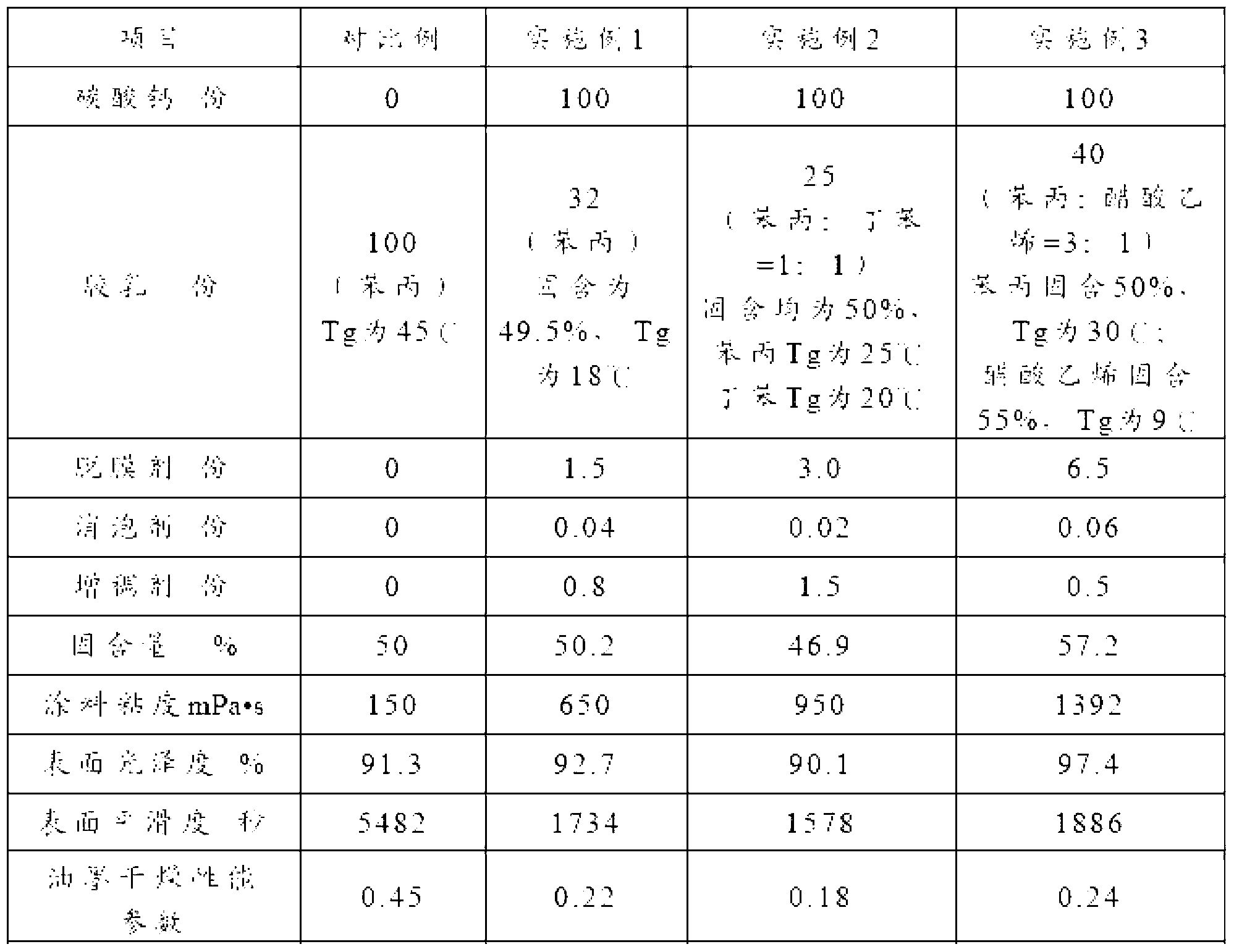

Transfer membrane mirror copper coating and coated paper using same

InactiveCN103306160AFirmly attachedGood effectCoatings with pigmentsCoatingsMembrane mirrorCopper coating

The invention discloses a transfer membrane mirror copper coating, comprising the components in parts by weight: 100 parts of pigment, 25-40 parts of latex, and 1.5-6.5 parts of a release agent, wherein the pigment is calcium carbonate or silica; the mean particle size of the calcium carbonate is 0.2-0.7 microns; the glass transition temperature of the latex is 8-35 DEG C. The invention also provides a coated paper prepared by using the transfer membrane mirror copper coating. The transfer membrane mirror copper coating disclosed by the invention can be suitable for various printing modes of a relief block, a soft block, a gravure, an offset plate, UV (ultraviolet) ink printing and the like, and is bright in printing color, fast to dry the ink, firm to stick the ink, and good in effect. The surface gloss of the coated paper coated by the transfer membrane mirror copper coating is greater than 90%; the surface smoothness is greater than 1000 seconds.

Owner:GOLD EAST PAPER JIANGSU

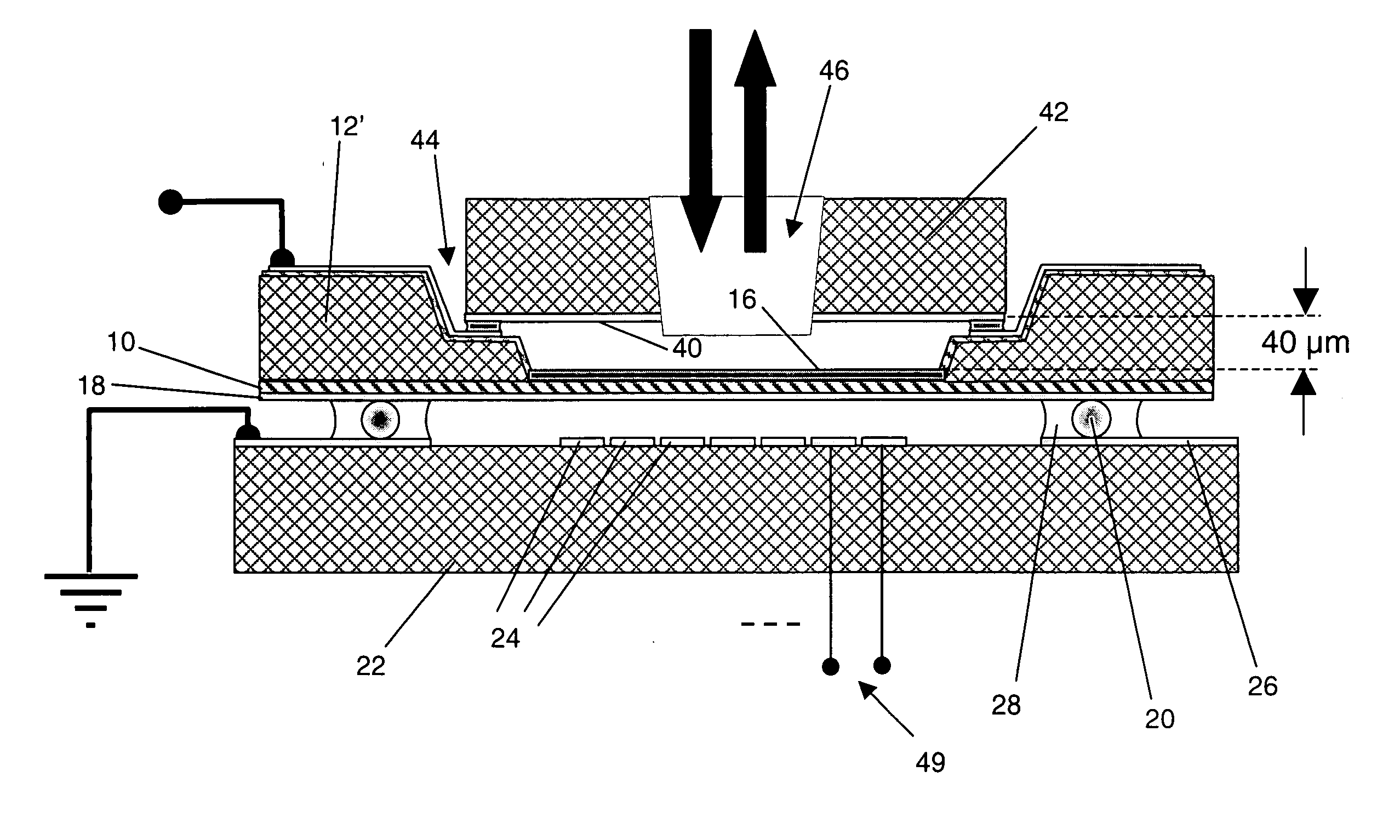

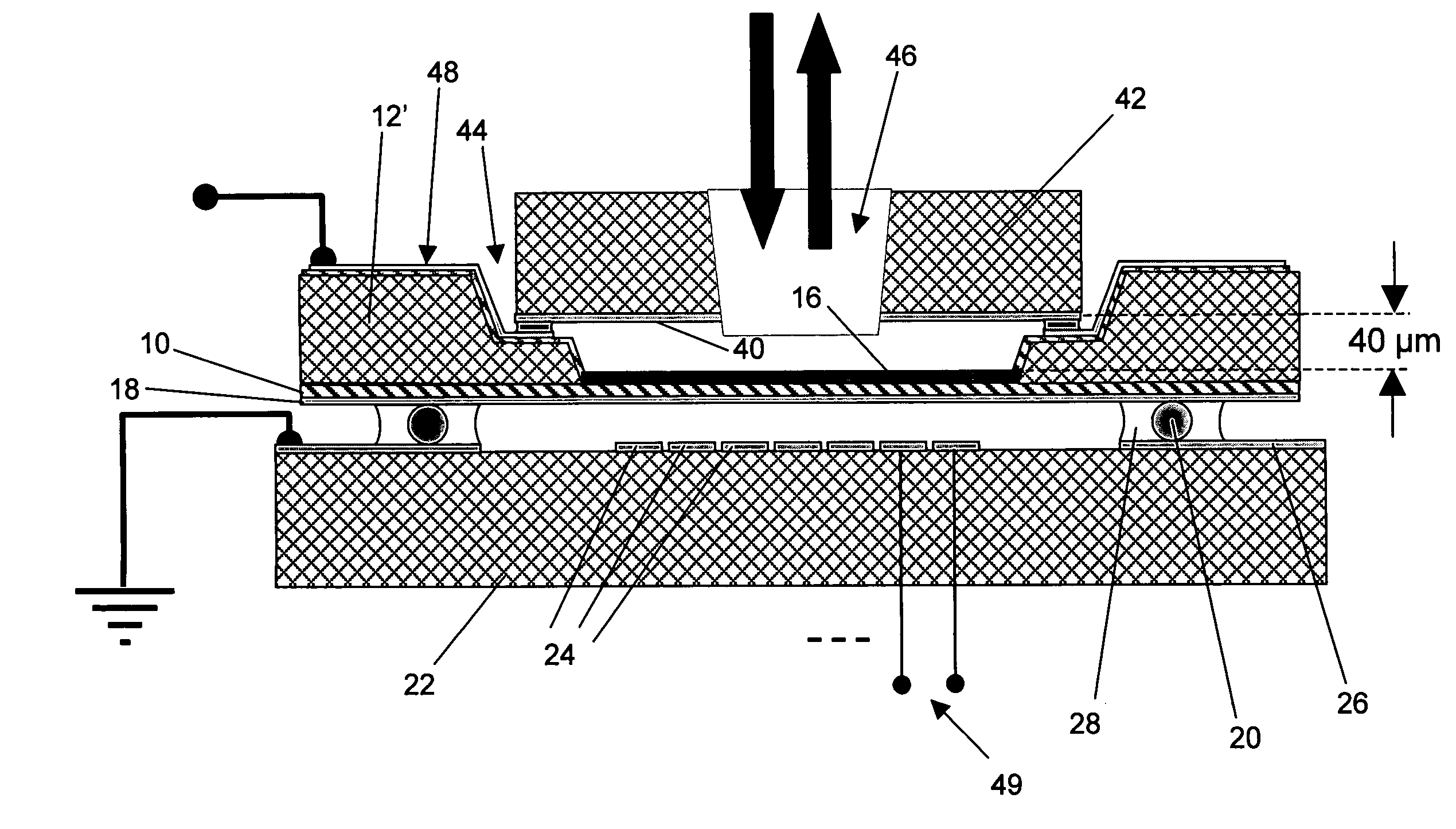

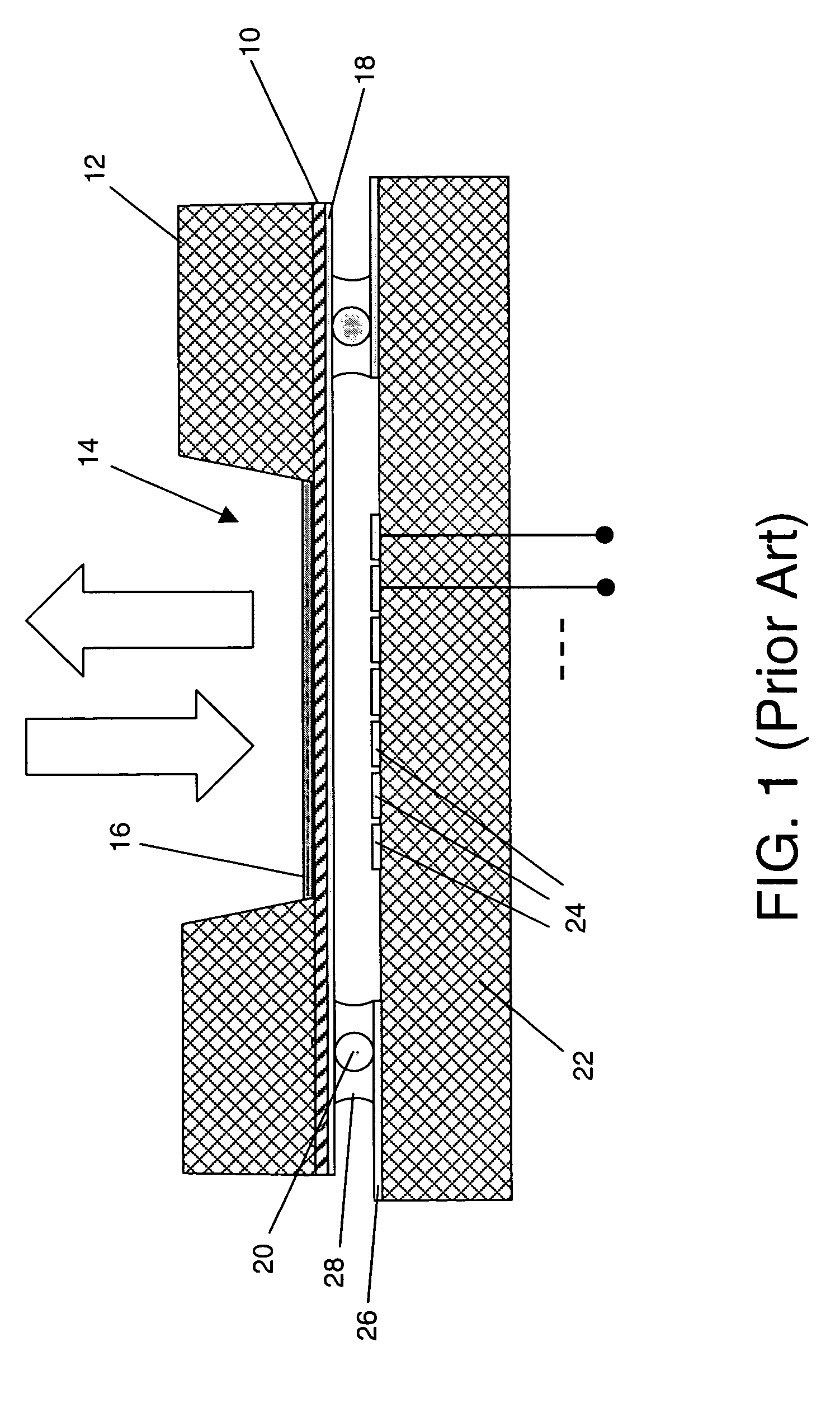

Electromagnetically driven membrane mirror assembly

ActiveUS20050194513A1Avoid defectsCorrection of deformationPhotometry using reference valueOptical measurementsElectrical conductorMembrane mirror

In an optics system, a flexible mirror is deformed with an electromagnetic force. In one embodiment, an electrical current is directed through the mirror, or a conductor attached to the mirror, in the presence of a magnetic field. In one application in an adaptive optics system, the membrane mirror is used in a wavefront sensor. Deformed to oscillate between convex and concave positions, the mirror is used to alternately defocus a received light signal for determining aberrations in the light signal. By detecting aberrations in the light signal, the adaptive optics system can correct for those aberrations.

Owner:EOS DEFENSE SYST USA INC

Micro acoustic sensor based on diffraction grating structure

InactiveCN110388980ASolve the noiseSNRSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansThin film sensorPhotovoltaic detectors

The invention relates to a micro acoustic sensor based on a diffraction grating structure. The micro acoustic sensor comprises a MEMS chip, a VCSEL, a PD and a substrate, wherein the MEMS chip comprises a diffraction grating and a membrane mirror; the membrane mirror is located above the diffraction grating; an upper cavity is formed between the membrane mirror and the diffraction grating; and a lower cavity is formed between the diffraction grating and the substrate. The micro acoustic sensor, based on an optical principle, improves a capacitive sensor structure, optimizes the size and the structure of the diffraction grating, adjusts the distance between the diffraction grating and a thin film sensor, converts an acoustic signal into a light intensity change signal, and further convertsthe light intensity change signal into an electric signal to be output by an photoelectric detector. The diffraction grating reduces the noise of the structure. The optical principle improves the sensitivity of the sensor, solves the low sensitivity and large noise of a current MEMS acoustic sensor, and has the advantages of flexible structure design and low cost.

Owner:SHANDONG UNIV

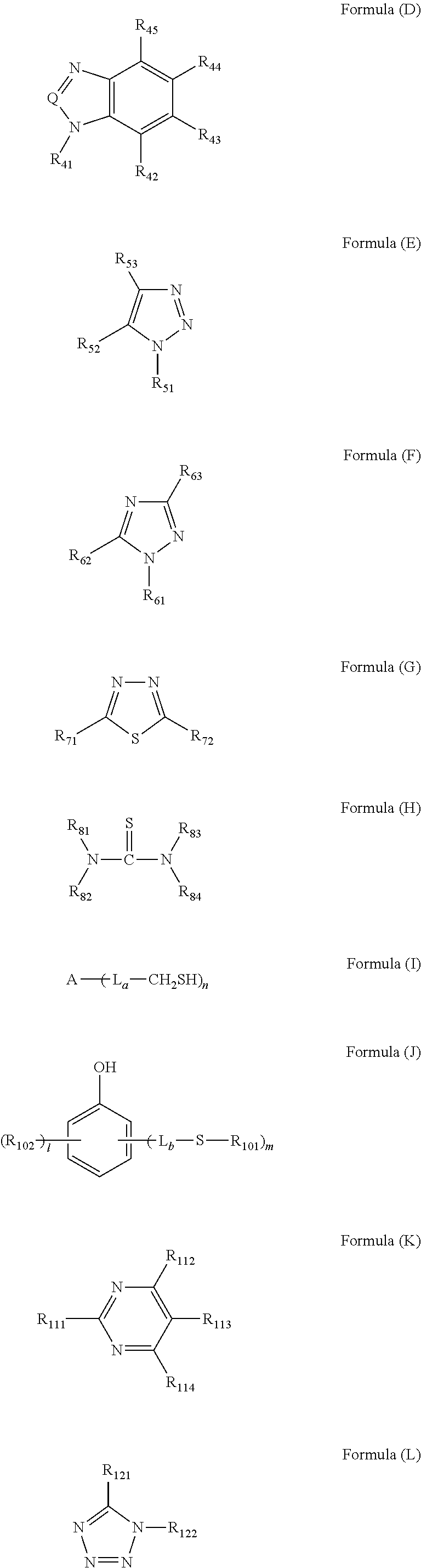

Film mirror for solar light reflection, and reflective device for solar power generation

InactiveUS20150116820A1Reduce bleedingImprove compatibilitySolar heating energyMirrorsMembrane mirrorSolar light

Provided is a film mirror for solar light reflection, which is so adapted that a protective layer containing a resin is arranged on the solar light incident side relative to a resin-film-like support and a silver reflective layer. The resin has a benzotriazole-type ultraviolet-ray-absorbing group and / or a triazine-type ultraviolet-ray-absorbing group.

Owner:KONICA MINOLTA INC

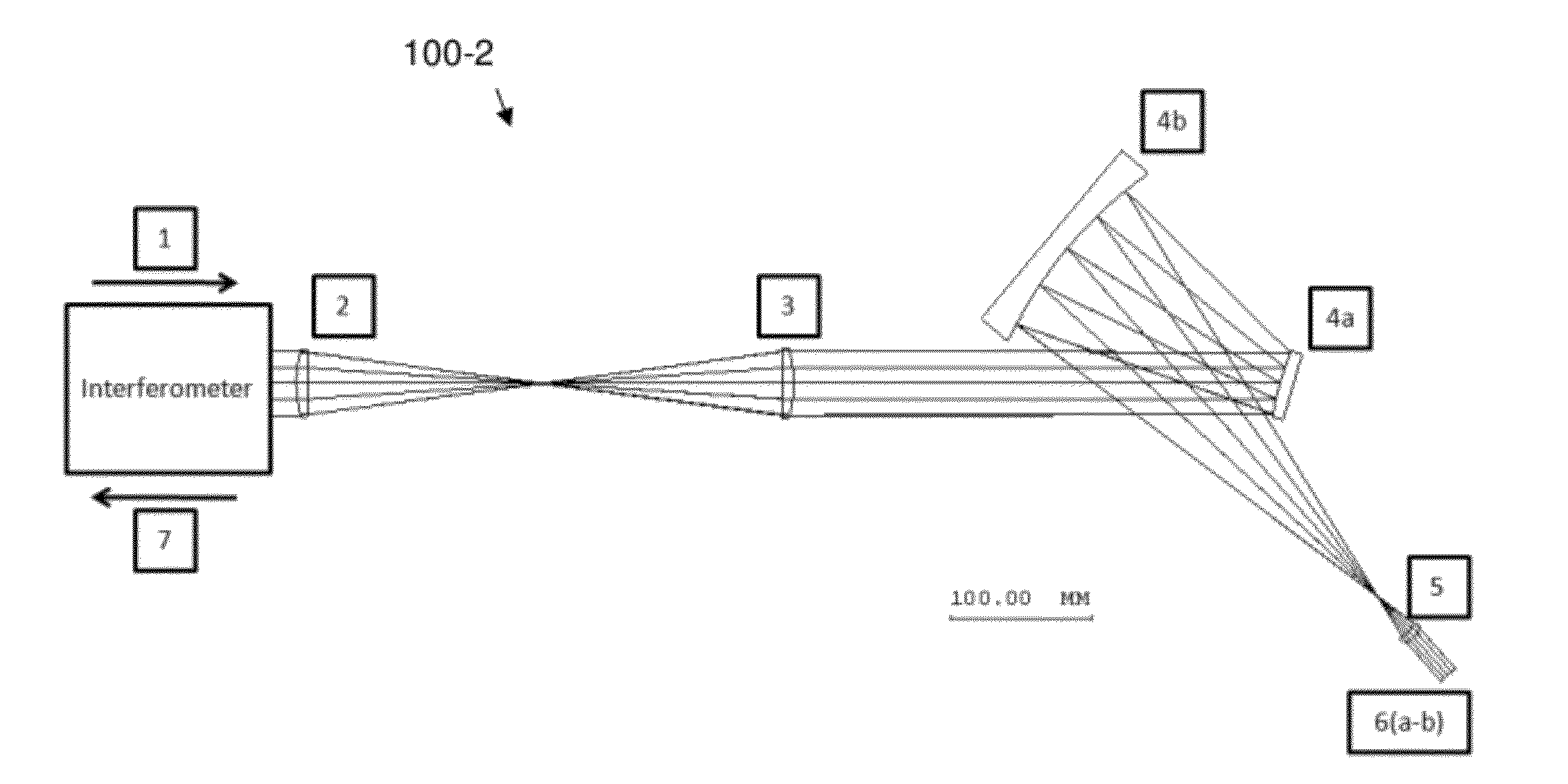

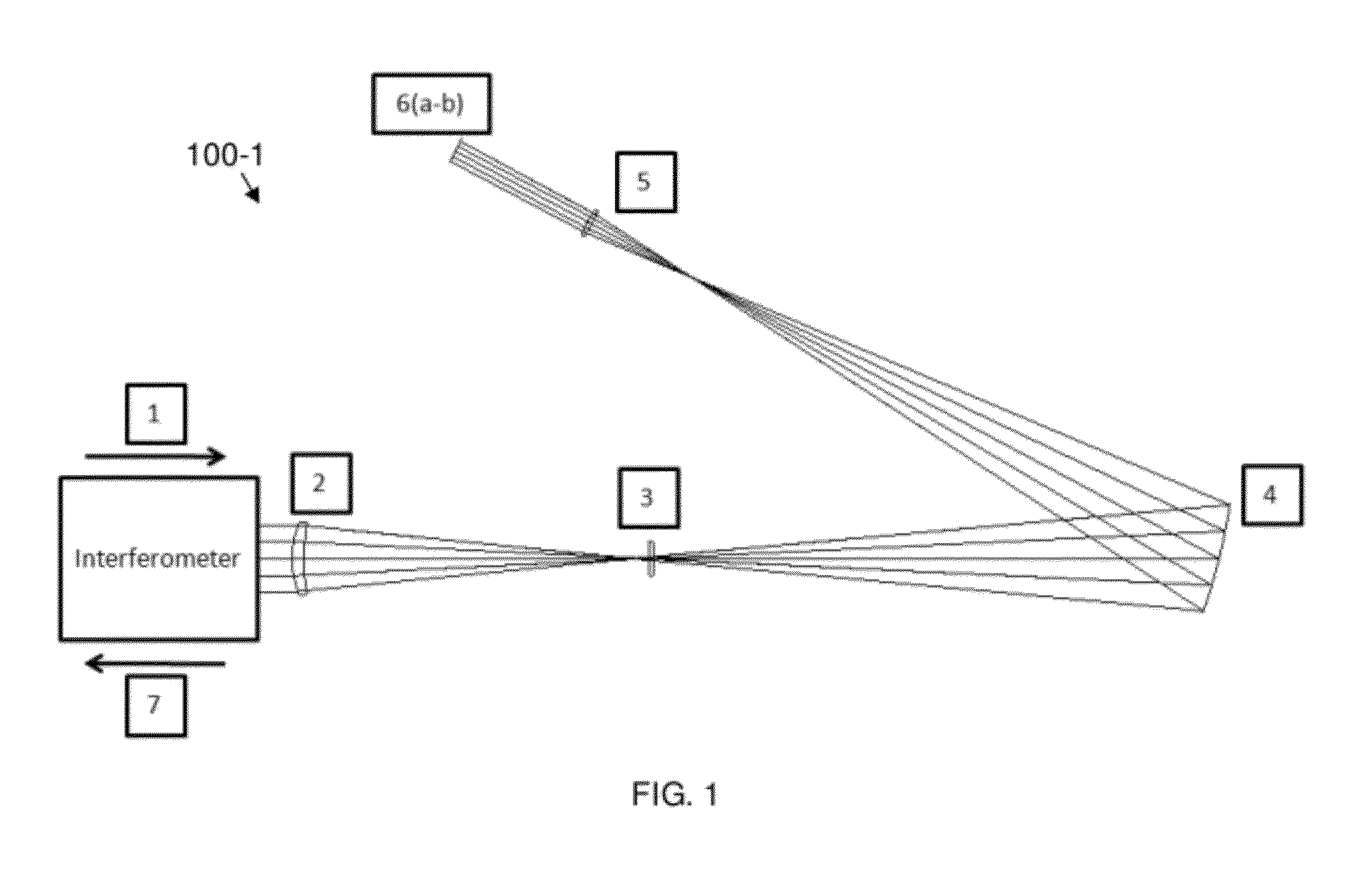

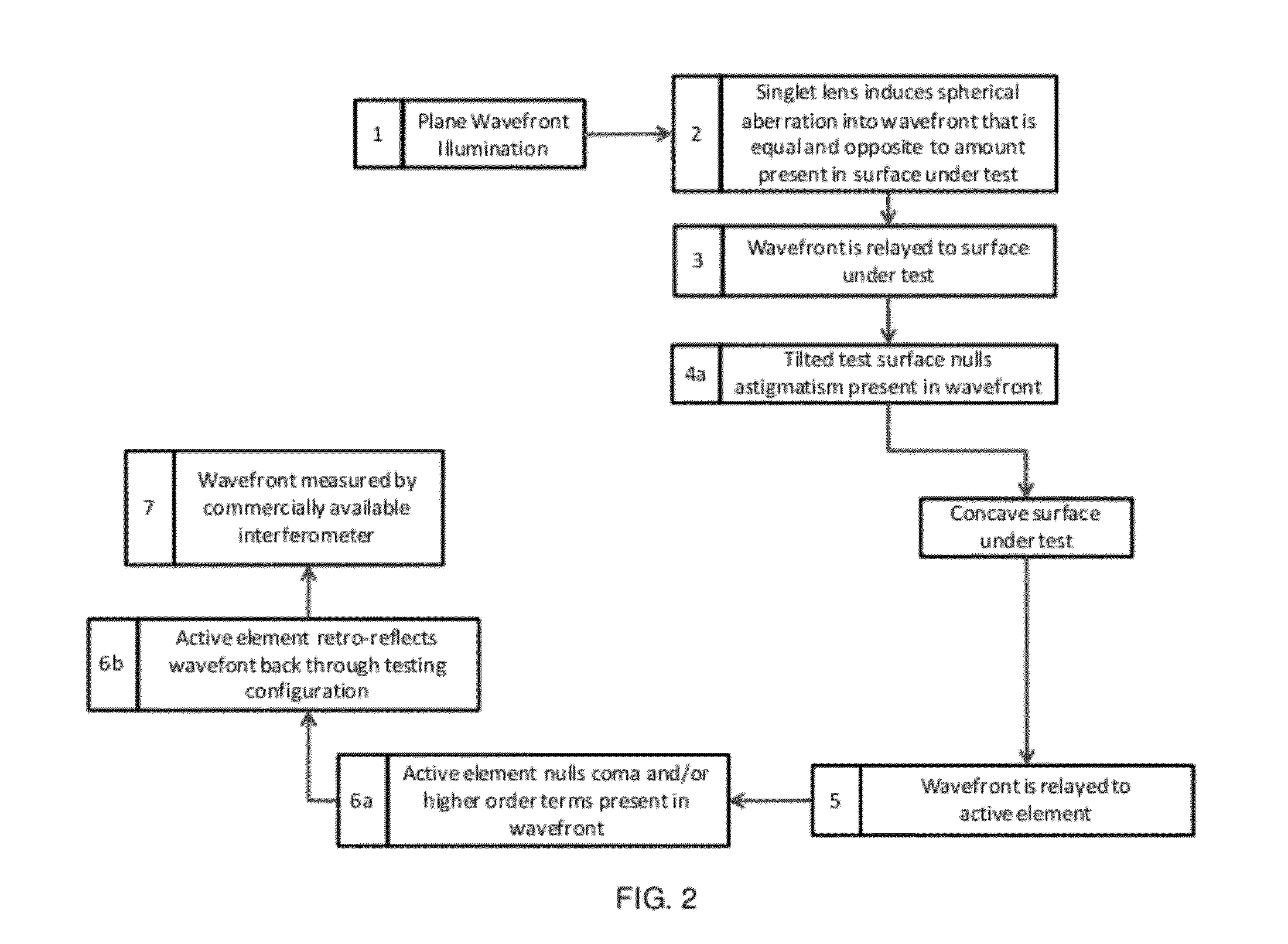

Optical testing apparatus and methods

An apparatus and associated method for testing a non-symmetric (e.g., phi-polynomial) surface. The apparatus uses several simple (singlet) optical elements (e.g., an Offner null configuration) and a tilted optic under test in combination with an active optical element (e.g., actuated, deformable membrane mirror, optical phase modulator, etc.) that together form a null or quasi-null that allows for conventional null-based interferometry. This solution solves the problem of exceeding the dynamic range of a conventional interferometer when trying to test non-symmetric optical surfaces.

Owner:UNIVERSITY OF ROCHESTER

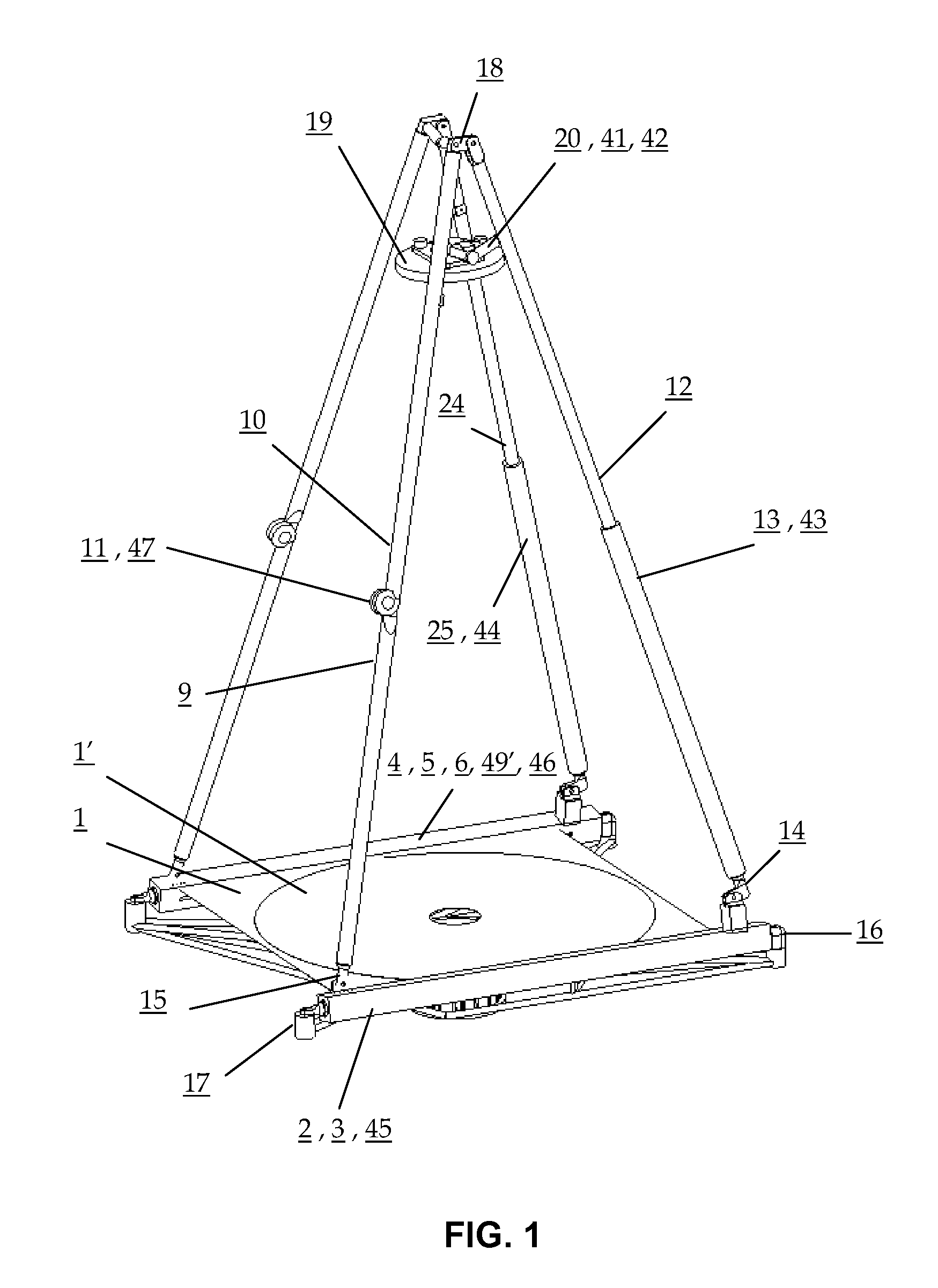

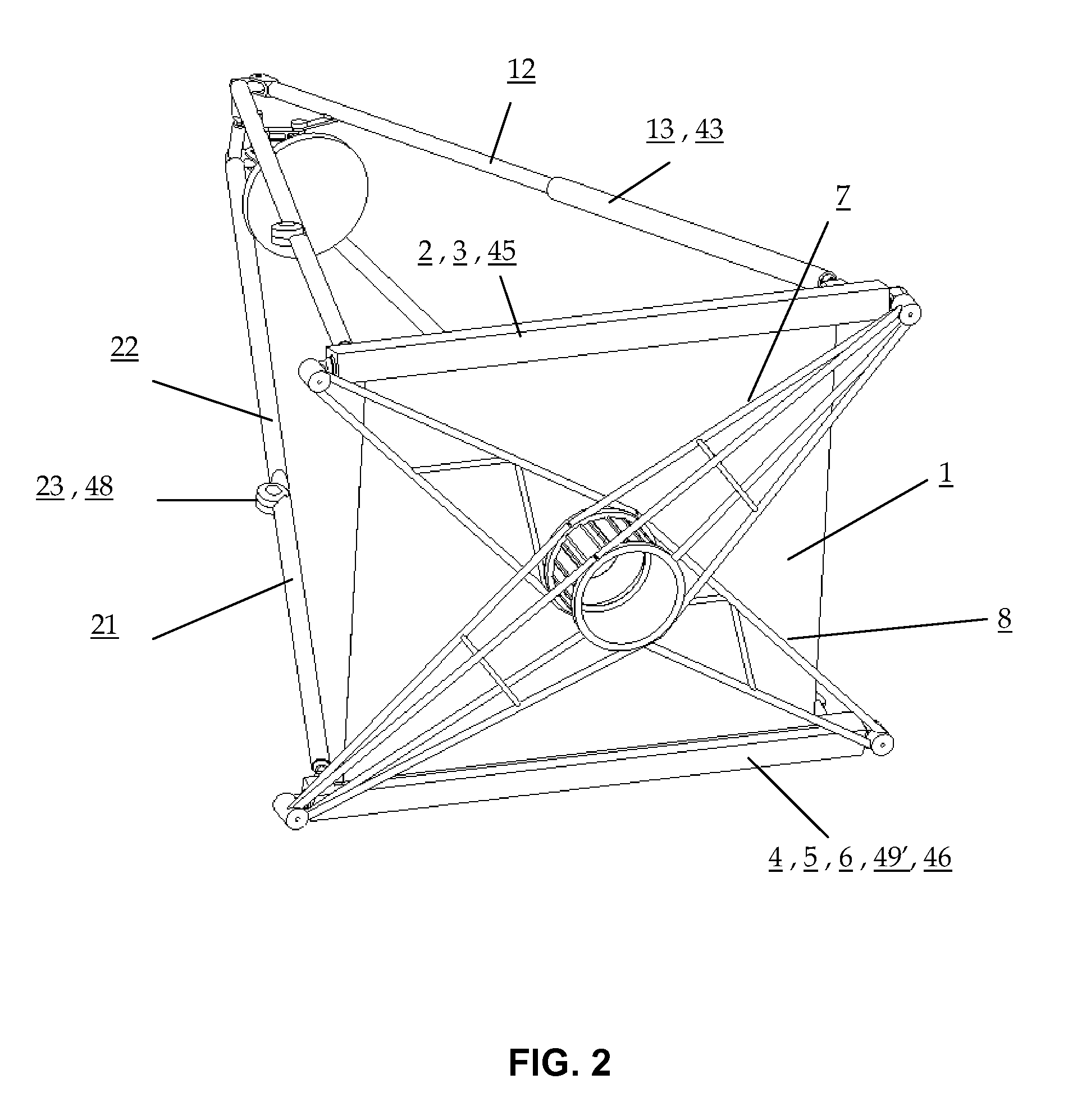

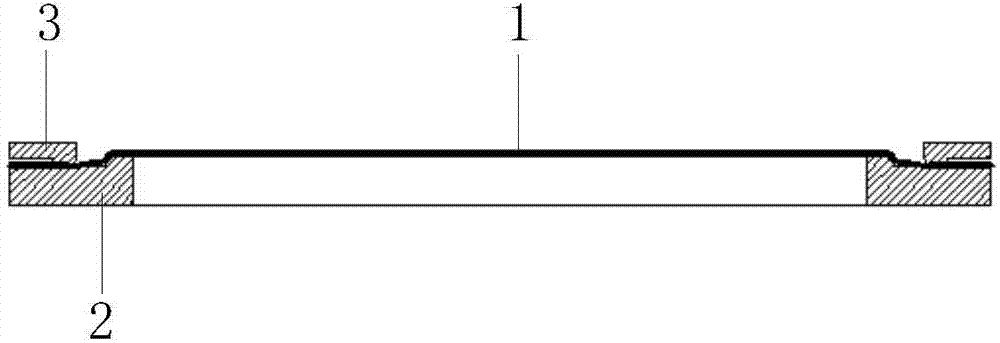

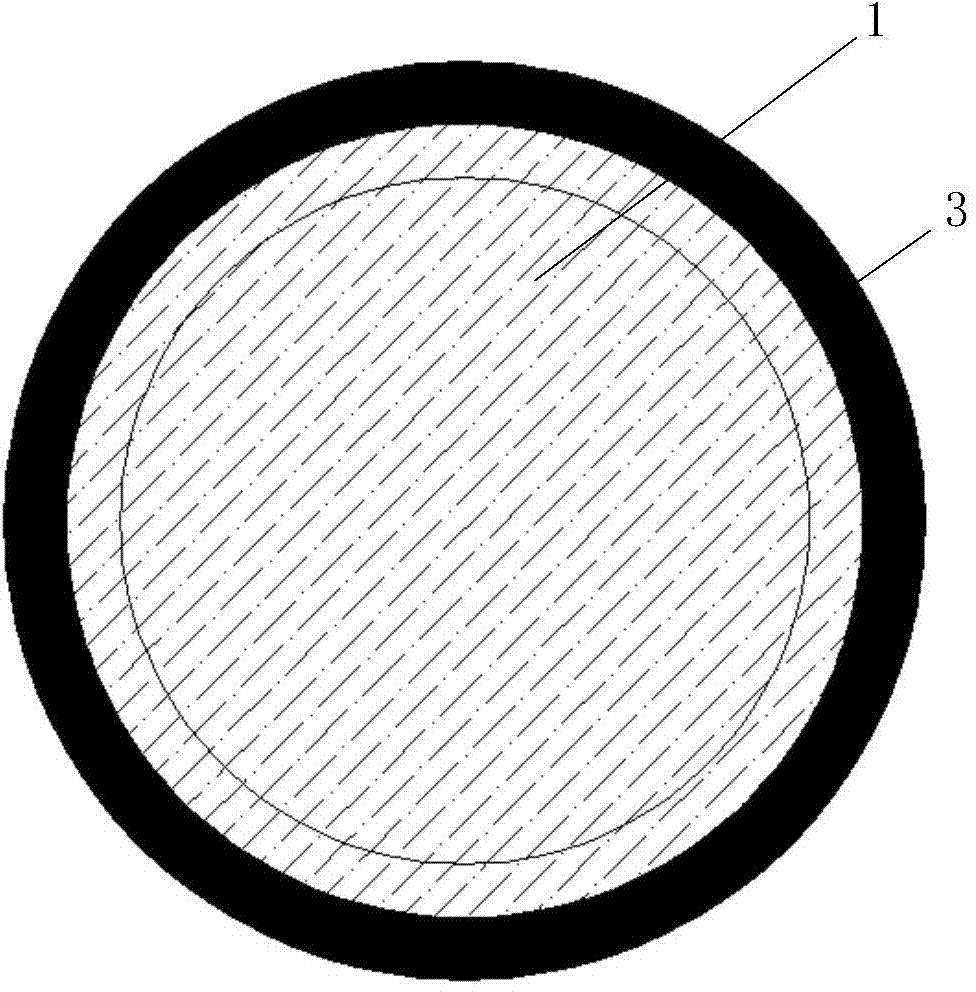

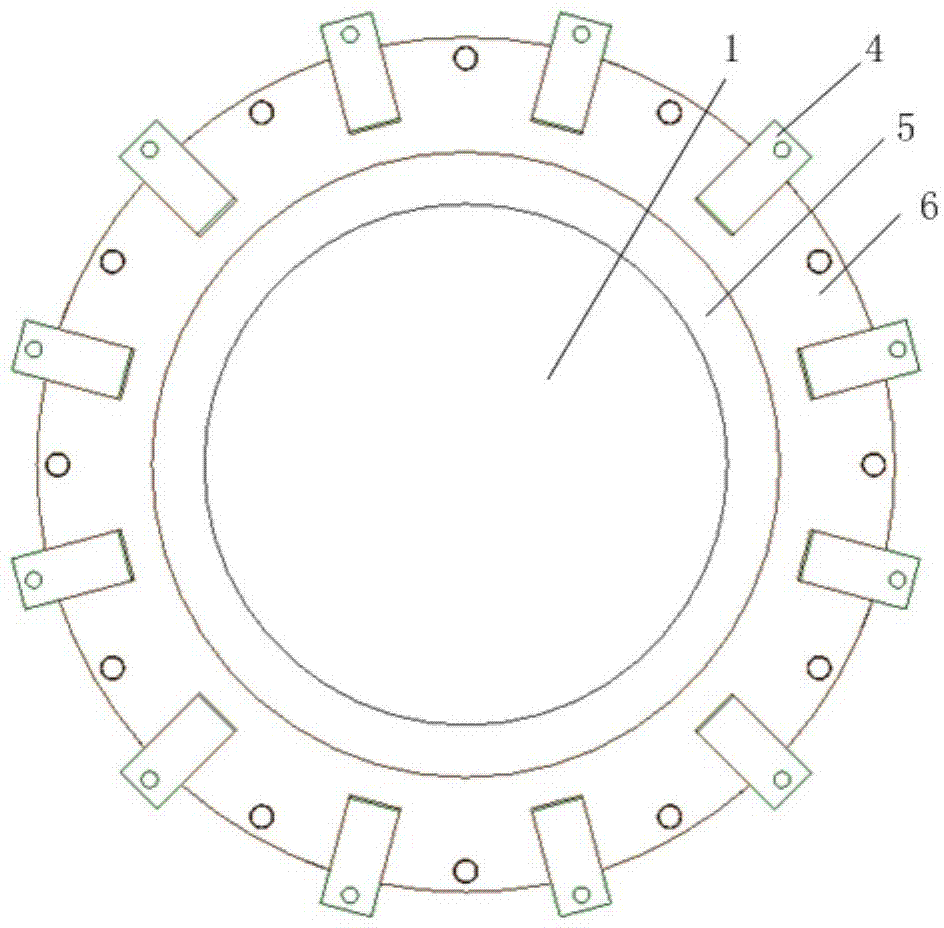

Planar film mirror installing method

ActiveCN104730681AImprove surface accuracyReduce the influence of low surface accuracyMountingsMechanical engineeringMembrane mirror

Provided is a planar film mirror installing method. Firstly, a round film mirror is expanded to be in a planar state, rectangular thin gaskets with holes evenly and firmly adhere to the periphery of the film mirror through a special tool, the two ends of N ropes are connected with the rectangular gaskets and tension sensors respectively, and the tension sensors on the periphery are fixed so that the ropes can be located on the same plane. Then, a precise supporting ring is placed below the film mirror which is slightly ejected through the side with an annular step face, a pressing ring is installed above the supporting ring, the pressing ring is pre-tightened through a screw, but it is guaranteed that the film mirror can move between the pressing ring and the supporting ring, tension is applied to the outermost ends of the ropes on the periphery of the film mirror, tension values are displayed through the tension sensors, the tension values are adjusted, deformation of the film mirror is detected in real time, and the tension values are repeatedly adjusted according to actually measured deformation so that the film mirror face can be optimal. According to the method, supporting is performed through the supporting ring, installation of the high-precision planar film mirror is achieved in a coplane tension adjustment mode on the edge of the film mirror, and the using requirement of a high-precision optical system can be met.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

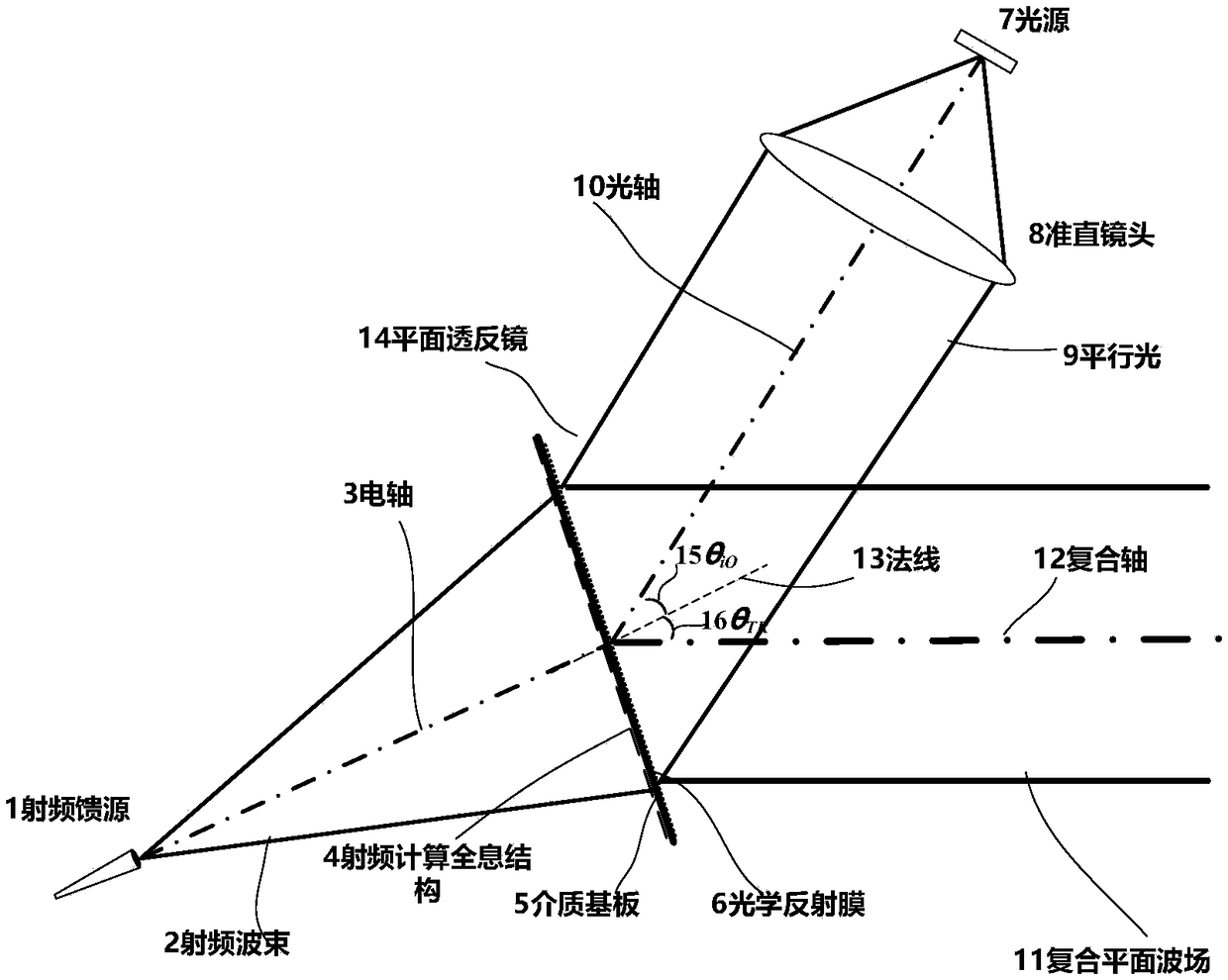

Radio-frequency holographic transmission/light reflection type common-caliber composite plane wave field simulation device

InactiveCN108693653ASimple structureCompact structureOptical elementsOptical reflectionMembrane mirror

The invention discloses a radio-frequency holographic transmission / light reflection type common-caliber composite plane wave field simulation device comprising a radio frequency feed source, a plane transflective mirror, a light source and a collimating lens. The phase center of the radio frequency feed source is arranged at the focal point of the plane transflective mirror. The light source is arranged at the focal plane of the collimating lens. A radio-frequency beam emitted by the radio frequency feed source is irradiated on the plane transflective mirror; the beam enters the plane transflective mirror and then is transformed into a plane wave based on a radio frequency calculation holographic structure; the light source is collimated into parallel light by the collimating lens; the parallel light is reflected by an optical reflection membrane mirror surface of the surface of the plane transflective mirror; and the reflected light and the transmitted radio-frequency beam form a composite plane wave field. According to the invention, the advantage of composite plane wave field forming by the traditional beam combiner and structure is absorbed. The simulation device has advantagesof simple and compact structure and high integration degree.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

Bi-directionally actuated thin membrane mirror

A deformable membrane mirror and a related method for its use, the mirror including a deformable membrane having a reflective front face and a back face, and further including electrodes located on both sides of the membrane, to provide a desired surface contour without imparting a concave bias to the membrane. The electrodes include a first set of electrodes spaced from the back face of the membrane, and at least one additional electrode spaced from the front face of the membrane.

Owner:NORTHROP GRUMMAN SYST CORP

Film mirror for solar heat power generation, method of manufacturing film mirror for solar hear generation, and reflection device for solar heat power generation

InactiveUS20130011666A1High regular reflectanceImprove light resistanceSolar heating energySolar heat devicesWeather resistanceMembrane mirror

A film mirror for solar heat power generation suppresses decline of regular reflectance caused by degradation of a sticky adhesive layer provided on the side opposite to the light incidence side of a reflection layer; is lightweight and flexible; exhibits excellent light resistance and weather resistance; and has excellent regular reflectance to sunlight; and others. The film mirror has a silver alloy reflection layer including a main group metal element or transition metal element; or a reflection layer including a silver layer and laminated on a side opposite to an incident light side of the silver layer, a thick layer, the film mirror having a structure in which a support is attached onto a sticky adhesive layer provided on a side opposite to the incident light side of the silver alloy reflection layer or the reflection layer.

Owner:KONICA MINOLTA OPTO

Thin film mirror

The thin-film mirror includes a pan-shaped housing having a pan surface and a hollow wall bordering the pan surface. The hollow wall has a mounting surface for thin reflecting film, which mounting surface is stepped above the pan surface. The hollow wall has an open portion opposite the mounting surface and accommodates a reinforcing member that rigidities the pan-shaped housing. A thin reflecting film that spans the pan surface is secured to the film mounting surface. The pan-shaped housing is a miterless one-piece structure which can be in the form of a trapezoid. Hollow fillets can be provided at the acute angle corners of the trapezoid. The fillets constitute an additional mounting surface portion for the thin reflecting film and are formed such that no corner of the mounting surface has an acute angle.

Owner:MARTINEZ SR EUGENE

Method of constructing a thin film mirror

Owner:ROCKWELL COLLINS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com