Method for measuring three-dimensional surface shape of membrane mirror

A technology of three-dimensional surface shape and mirror surface, which is applied to measuring devices, instruments, and optical devices, etc., can solve problems such as poor real-time performance, and achieve good real-time performance, improved accuracy, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

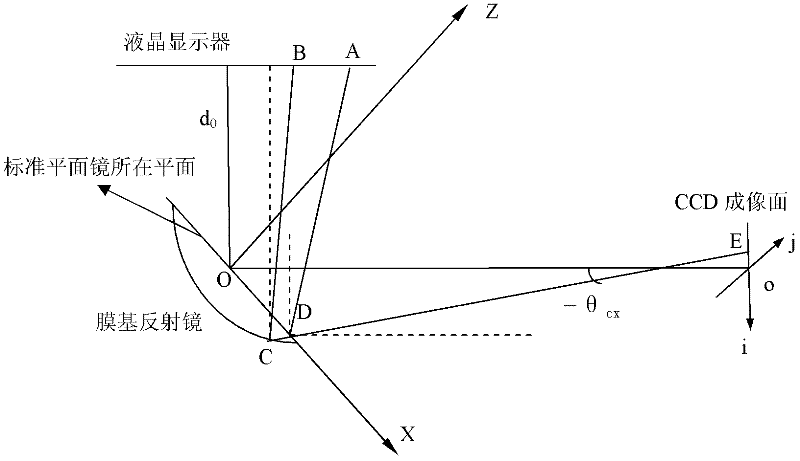

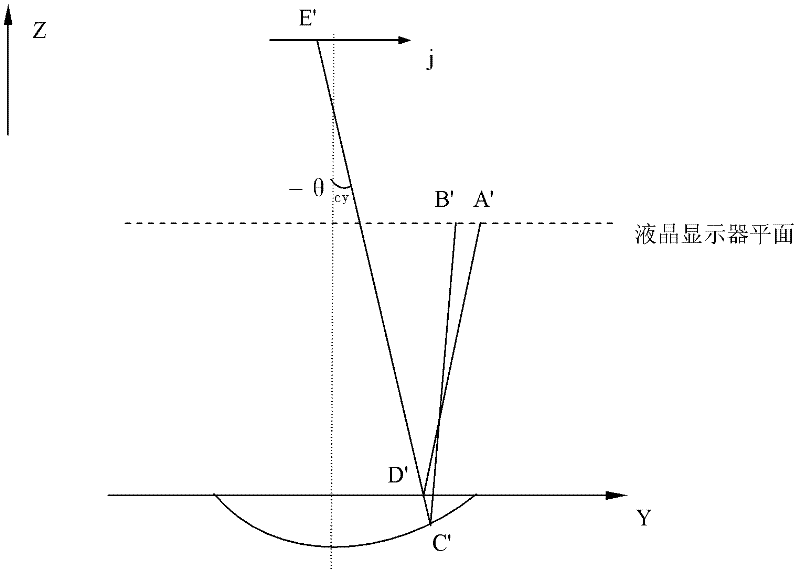

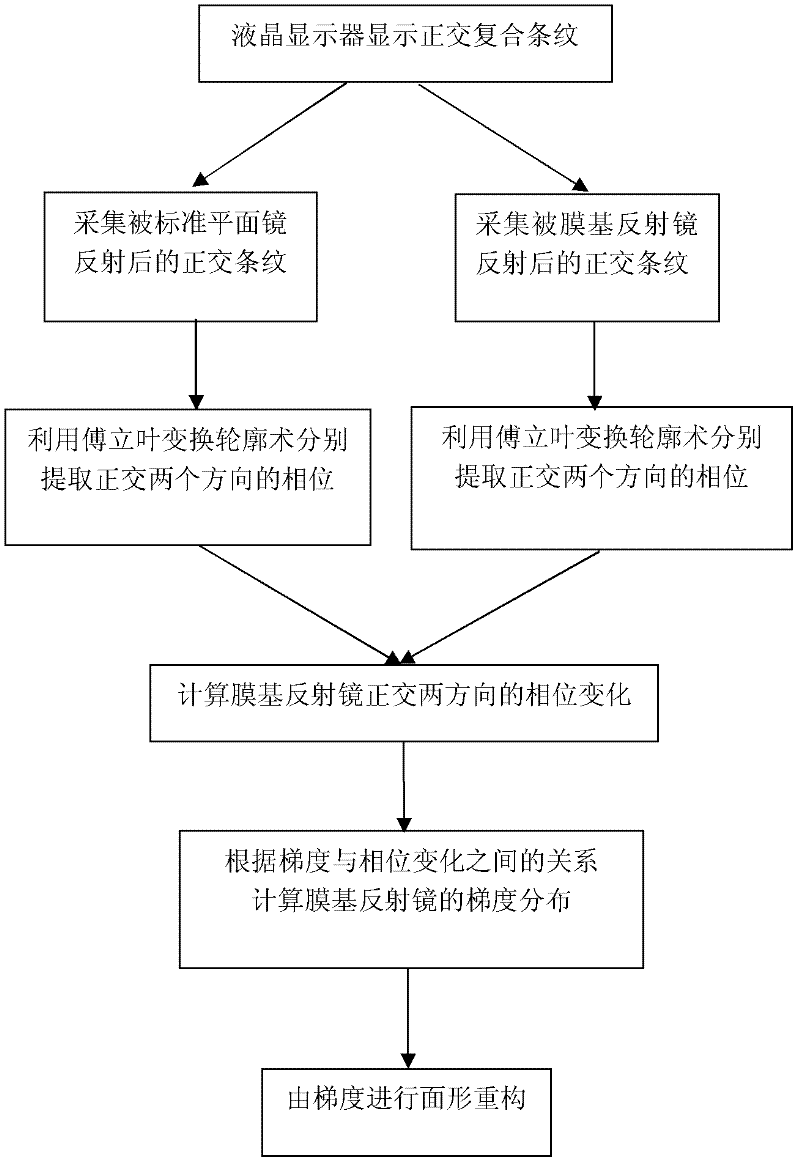

[0024] See attached figure 1 , which is a top view of the structure schematic diagram of the three-dimensional surface shape measurement device of the film-based mirror provided by the invention, reflecting the deflection of the light in the horizontal direction (in the coordinate system XOZ); refer to the attached figure 2 , it is the deflection of the light of the measuring device provided by the invention in the vertical direction (in the coordinate system XOZ); by figure 1 and 2 It can be seen that the measurement device includes a liquid crystal display, a standard flat mirror, a CCD, an image acquisition card, a computer, etc., and the base surface of the liquid crystal display plane and the standard flat mirror (ie figure 1 In the XOY plane), the imaging surface of CCD is perpendicular to the horizontal plane; the plane of liquid cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com