Patents

Literature

89results about How to "Reduce dead area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

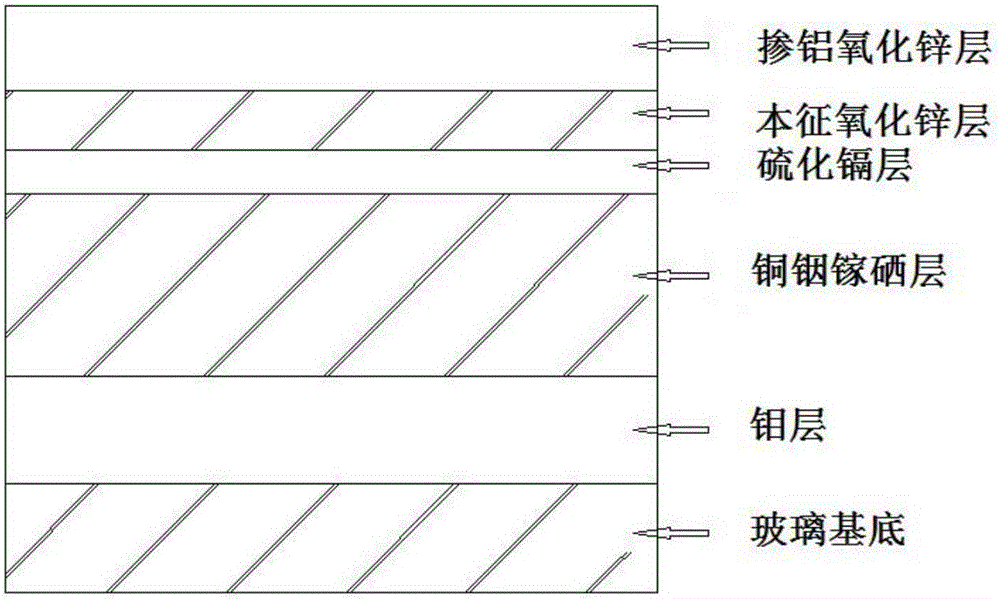

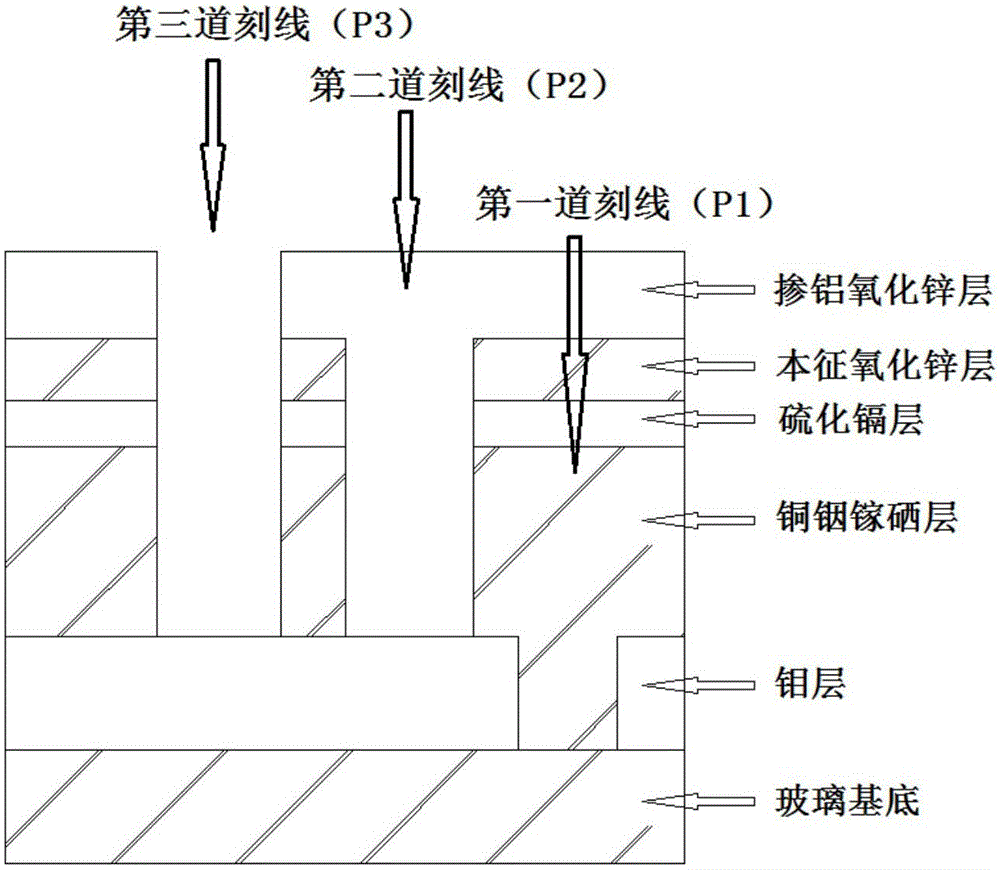

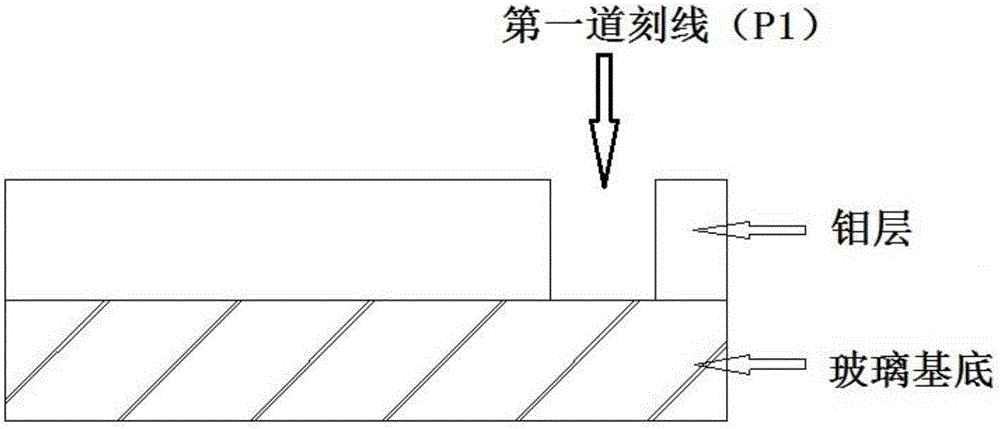

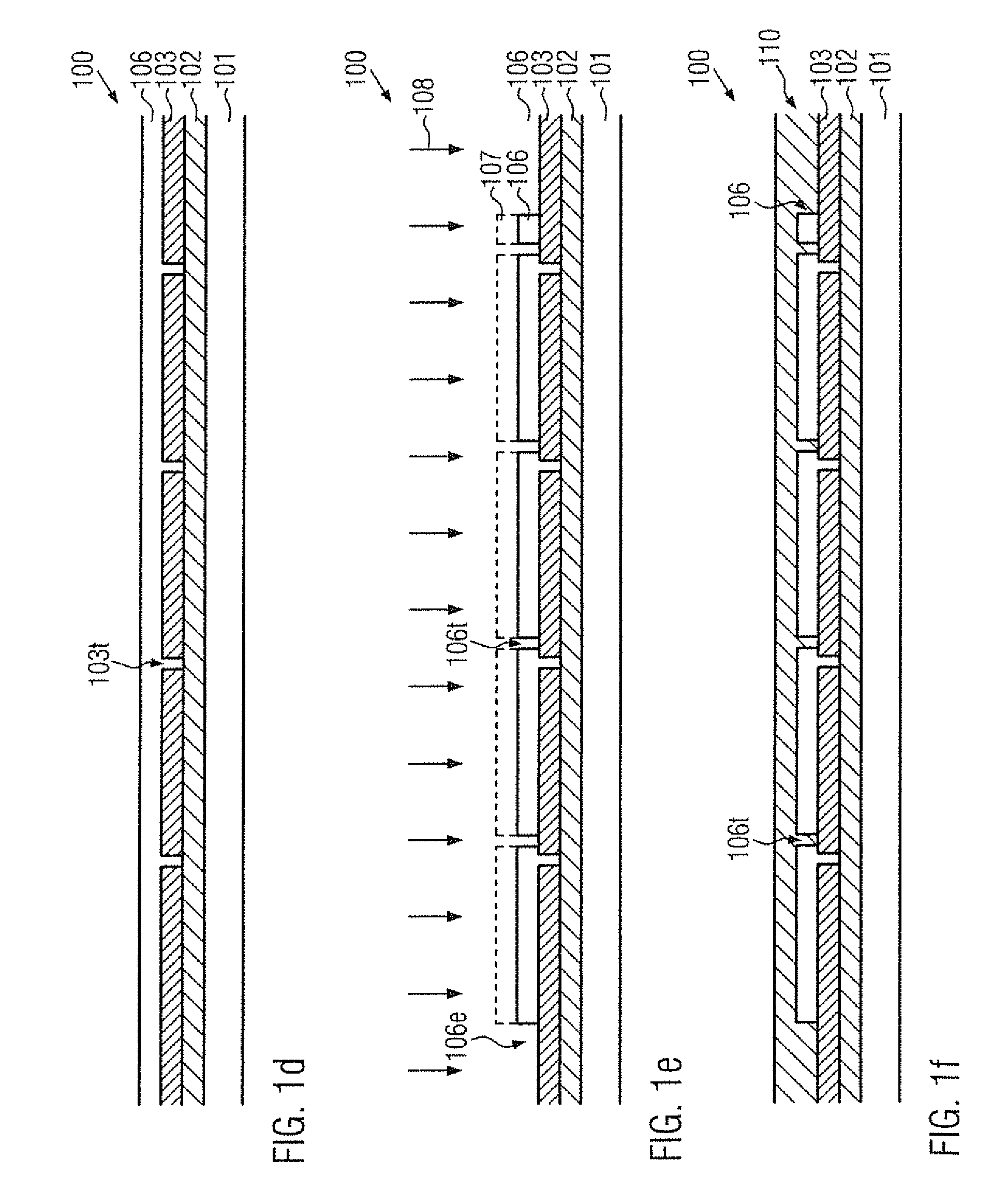

Full-laser grooving and scribing method of large-area copper indium gallium selenide (CIGS) thin-film solar cell assembly

ActiveCN104993013AIncrease component powerReduce dead areaFinal product manufactureSemiconductor/solid-state device manufacturingIndiumAluminum doped zinc oxide

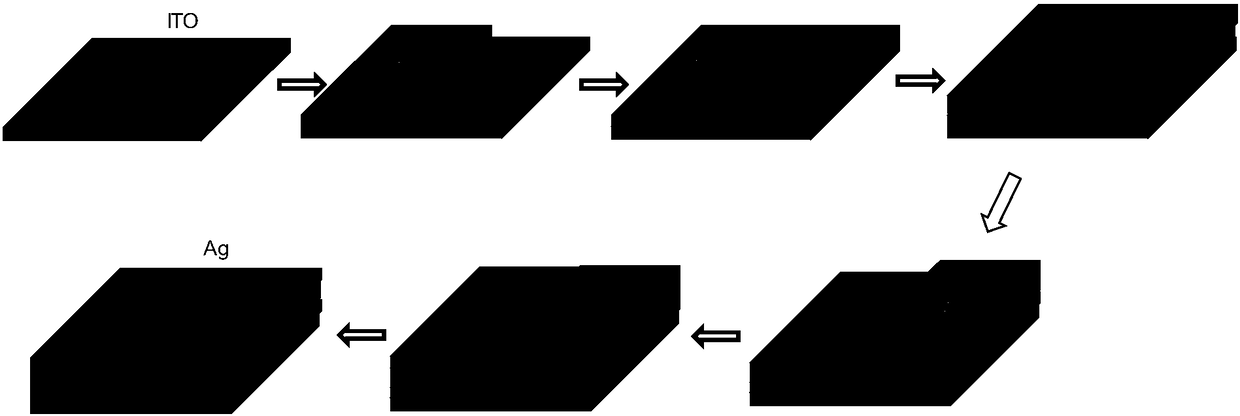

The invention provides a full-laser grooving and scribing method of a large-area copper indium gallium selenide (CIGS) thin-film solar cell assembly. The method comprises steps of using a laser to groove and scribe a molybdenum thin film prepared on soda-lime glass so as to form a first scribed line (P1); successively preparing a CIGS layer, a cadmium sulfide layer and an intrinsic zinc oxide layer on the molybdenum layer where the P1 has been grooved and scribed; after finishing the above film layer preparation, using a laser to perform grooving and scribing so as to form a second scribed line (P2) which is parallel to the P1; and after preparing an aluminum-doped zinc oxide layer on the intrinsic zinc oxide layer where the P2 has been grooved and scribed, using a laser to perform grooving and scribing so as to form a third scribed line (P3) which is parallel to the P1. According to the invention, inner join is performed for the CIGS thin-film solar cell assembly by the laser grooving and scribing method, so defects of large area of dead zones and frequency change of machinery needles in traditional machinery grooving and scribing technology can be overcome, thereby increasing efficiency of the assembly, improving stability of the grooving and scribing device and achieving objectives to reduce production cost and improve production efficiency.

Owner:BEIJING SIFANG JIBAO AUTOMATION

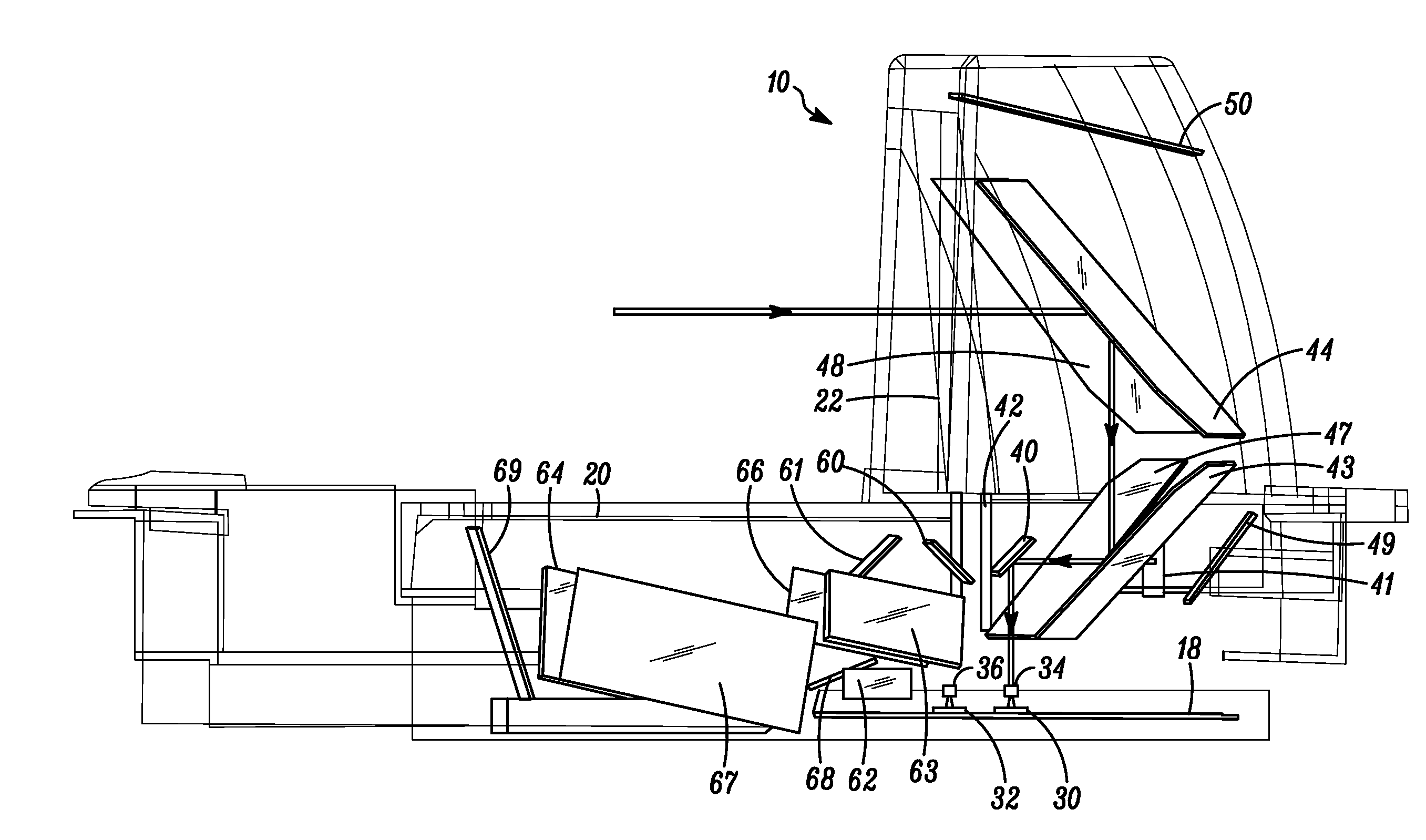

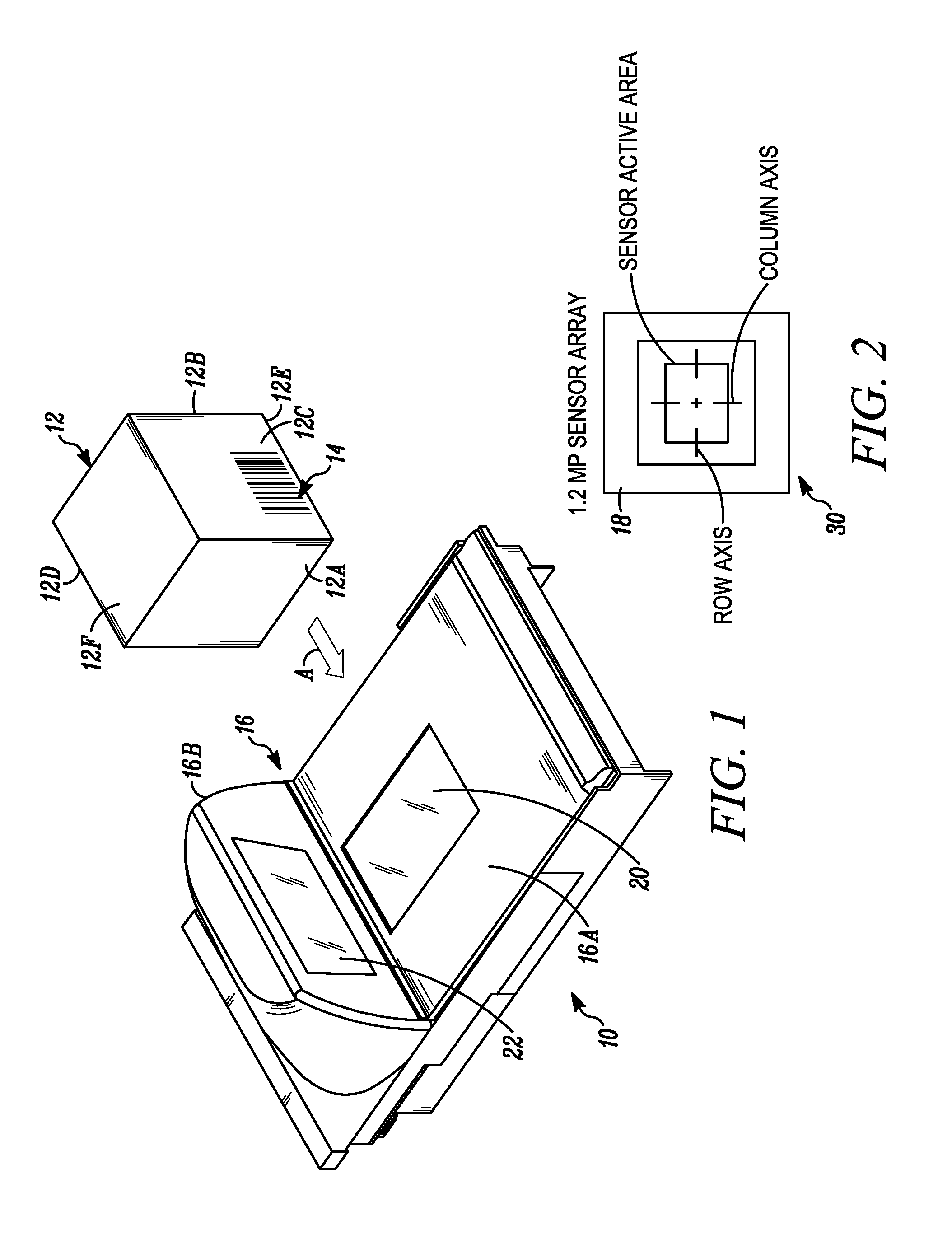

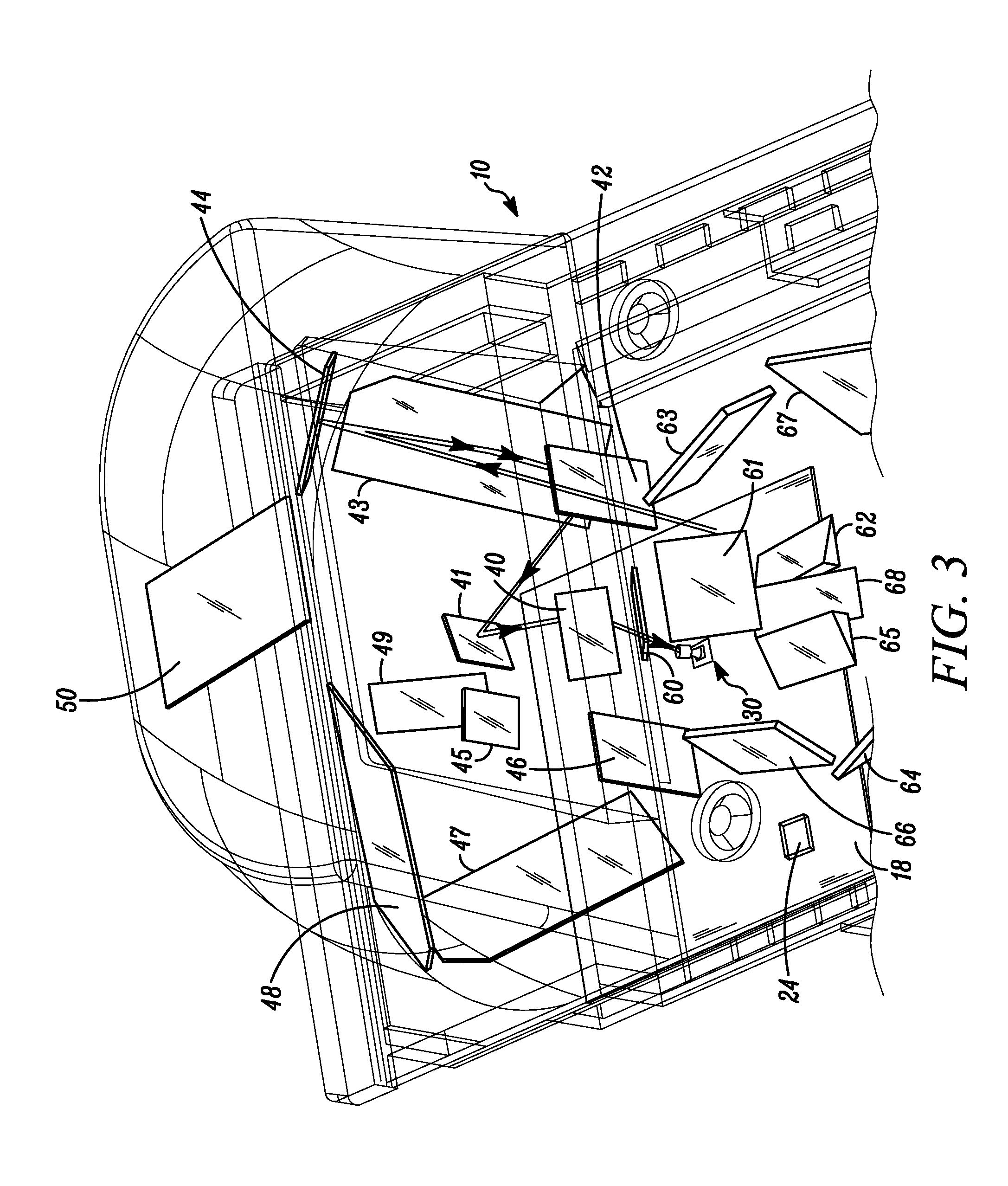

Imager exposure, illumination and saturation controls in a point-of-transaction workstation

ActiveUS20130026233A1Adding additional complexityEasy to processSensing detailsVisual representatino by photographic printingLighting systemWorkstation

An illumination time of an illumination system and / or an exposure setting of an imaging system are adjusted by a proximity system operative for detecting a product entering a field of view in a bi-optical, dual window, point-of-transaction workstation. The proximity system includes an infrared emitter for emitting infrared light to the product, and an infrared sensor for sensing return infrared light from the product. Multiple predefined thresholds are stored for the sensed return infrared light, and a predefined illumination time and / or exposure setting are stored and assigned to each predefined threshold. Adjustment of the illumination time and / or of the exposure setting is performed by comparing the sensed return infrared light from the product in real time operation with the stored predefined thresholds.

Owner:SYMBOL TECH LLC

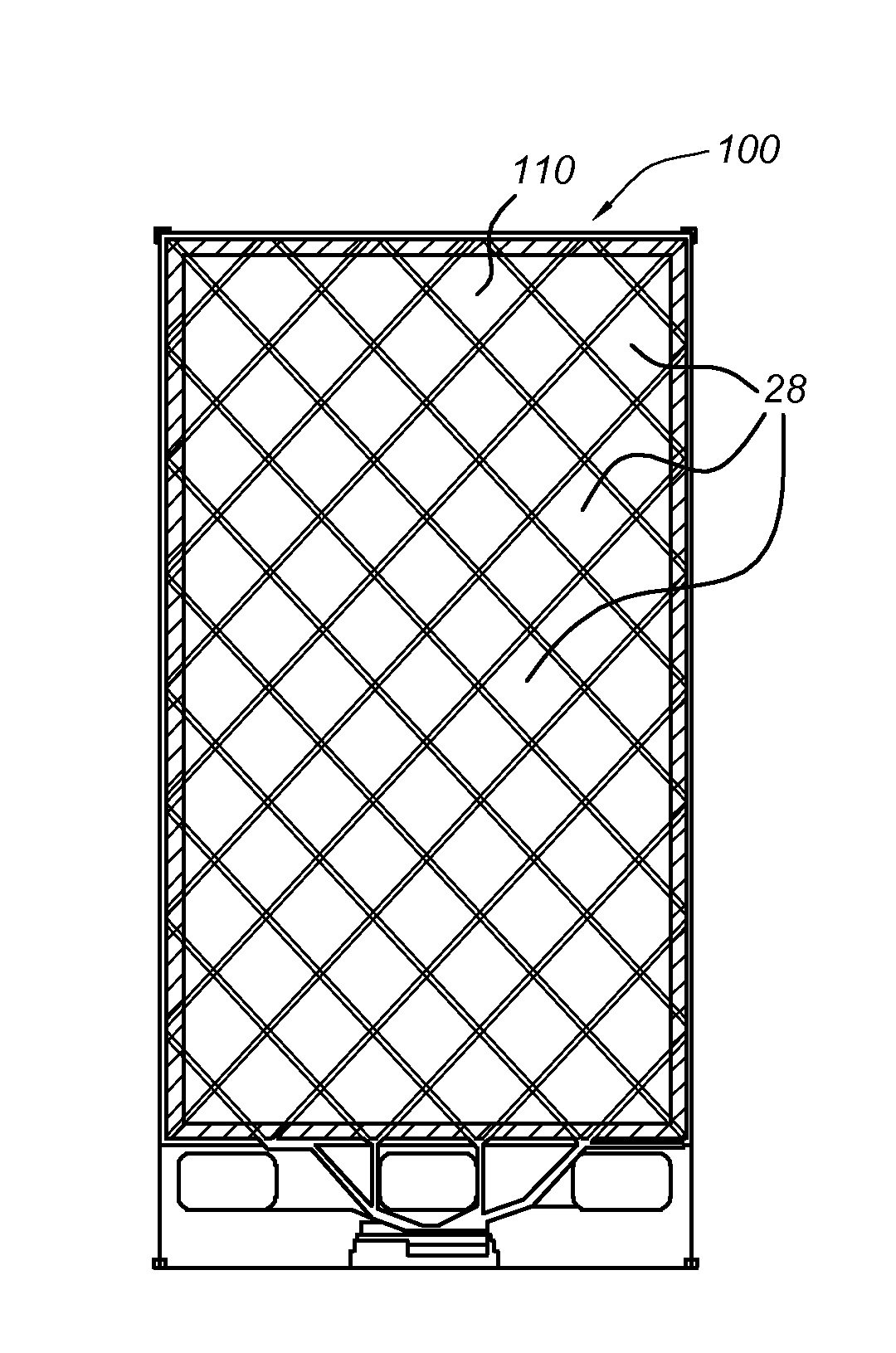

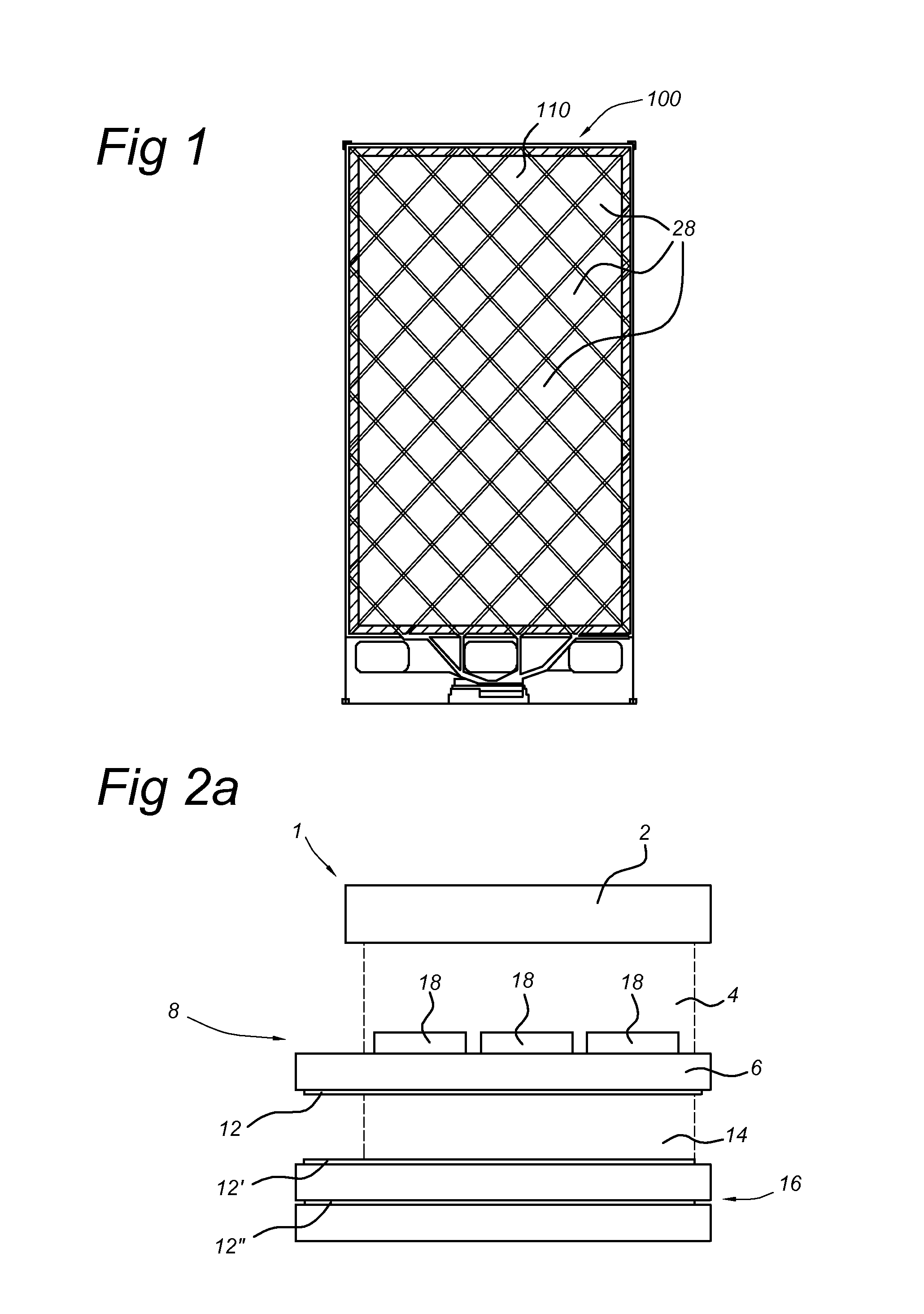

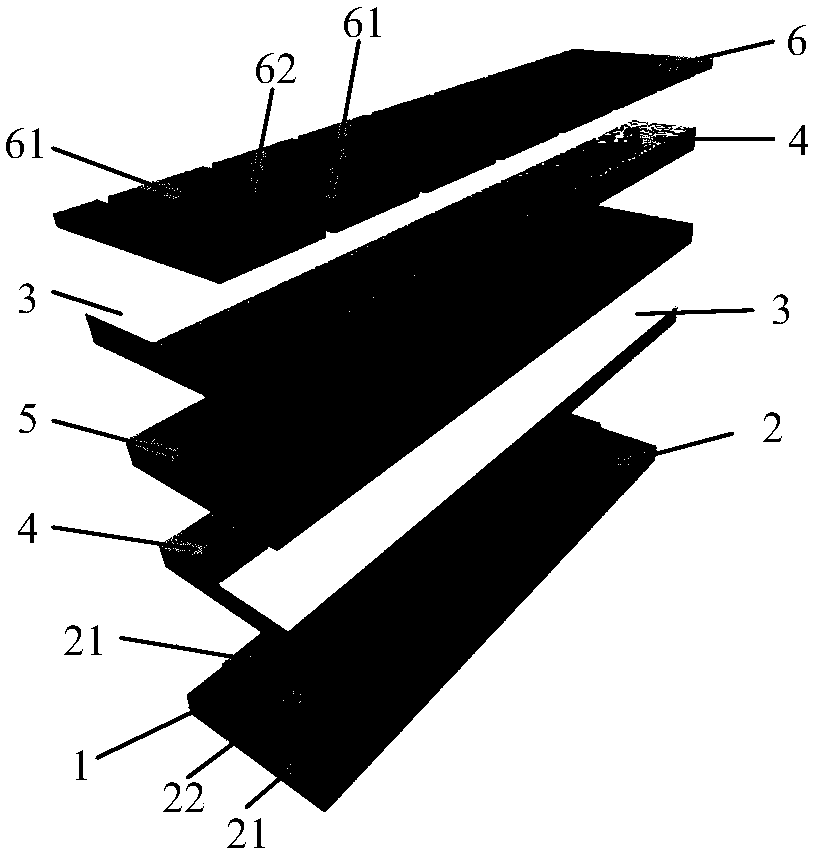

Capacitive touch panel device

InactiveUS20130307810A1Improve accuracyIncrease the number ofTransmission systemsInput/output processes for data processingElectrical resistance and conductanceCapacitance

The invention provides a touch panel device comprising, and arranged above each other in a downward direction, a cover layer for use as a touch surface, a sensor layer comprising a plurality of sensing elements, the sensing elements being arranged to register capacitance, characterized in that between the cover layer and the sensor layer is an electrically-resistive layer, electrically resistive layer being a electrically non-insulating layer and having an electrical resistance is provided, wherein the electrical resistance of the electrically-resistive layer is lower than the electrical resistance of the cover layer and higher than the electrical resistance of the sensing elements. The electrically-resistive layer can have a resistance suitable for causing, in response to a touch event above a center of a central sensing element, a detectable change in the capacitance as measured by at least two sensing elements adjacent to the central sensing element.

Owner:INNOCOM TECH SHENZHEN +1

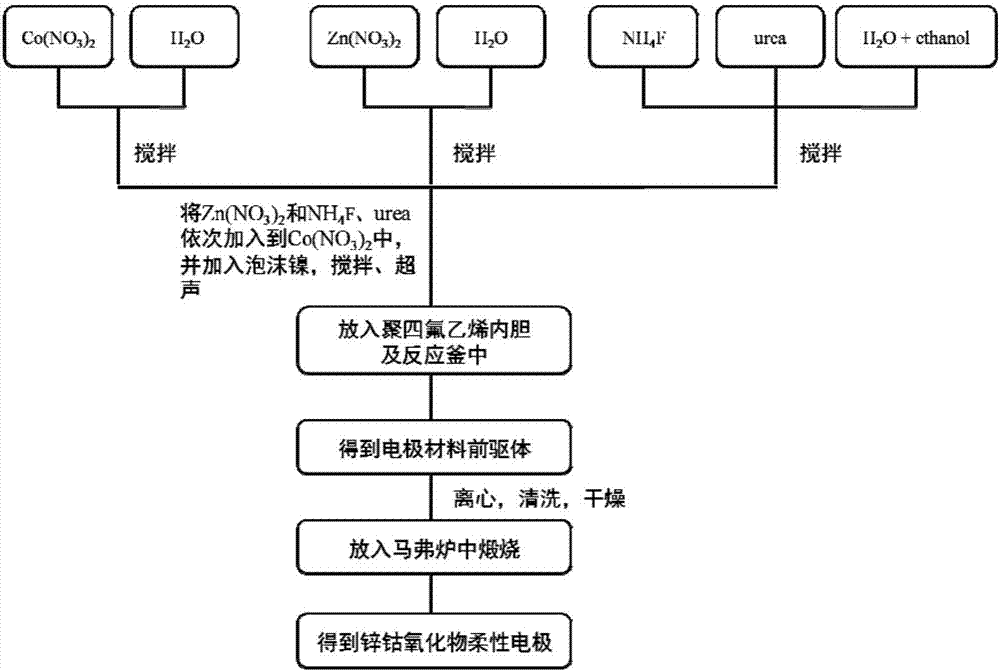

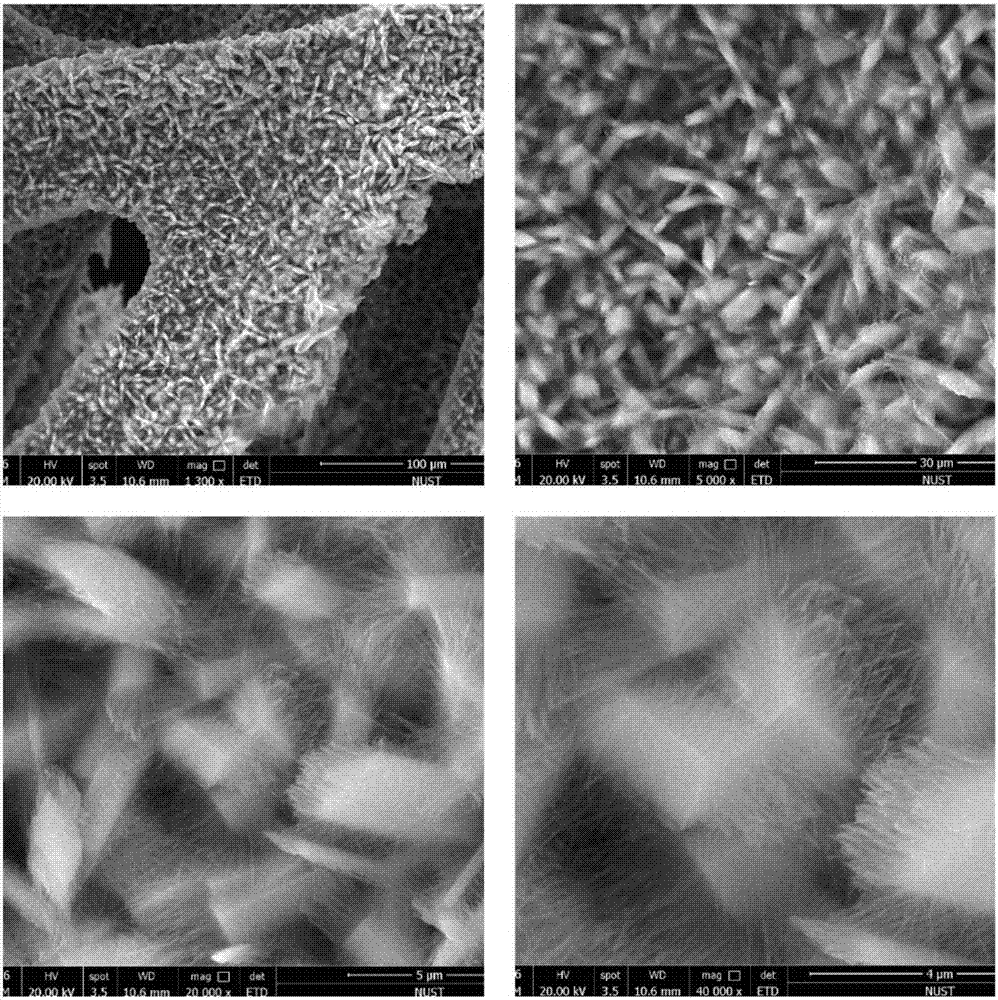

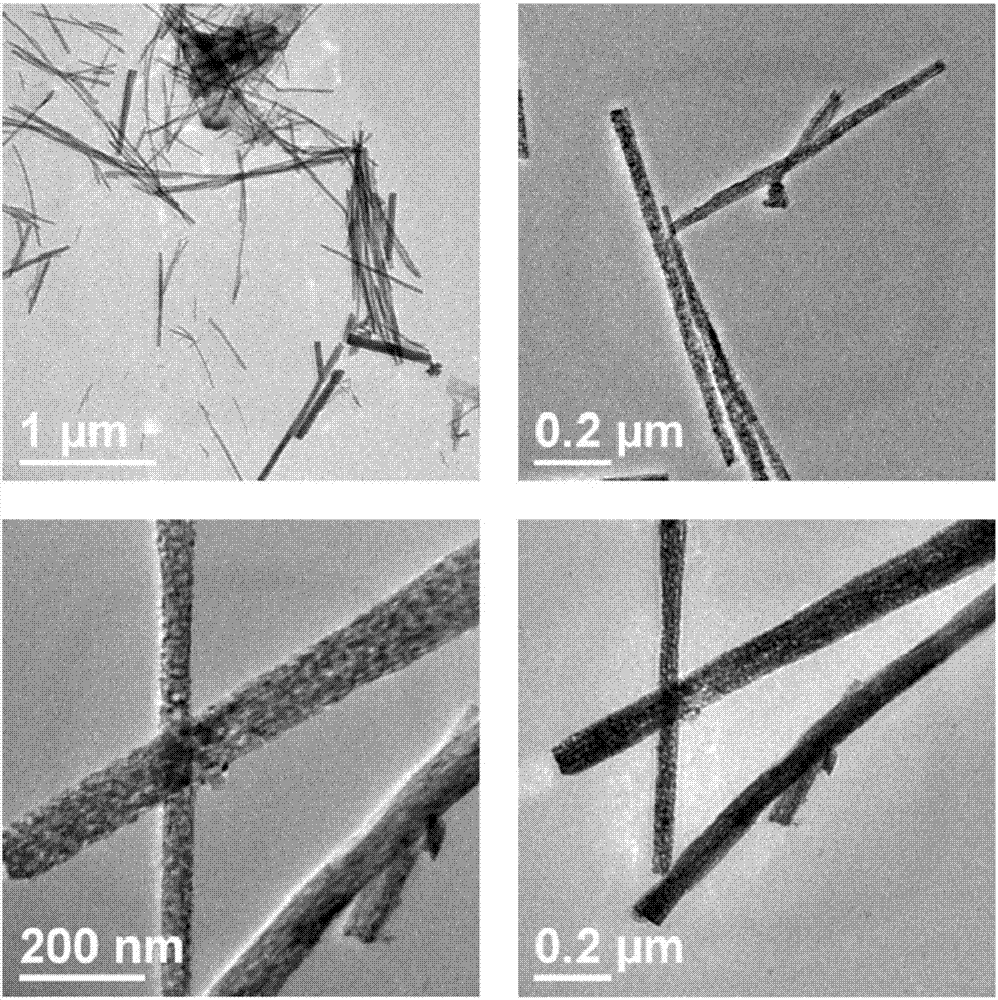

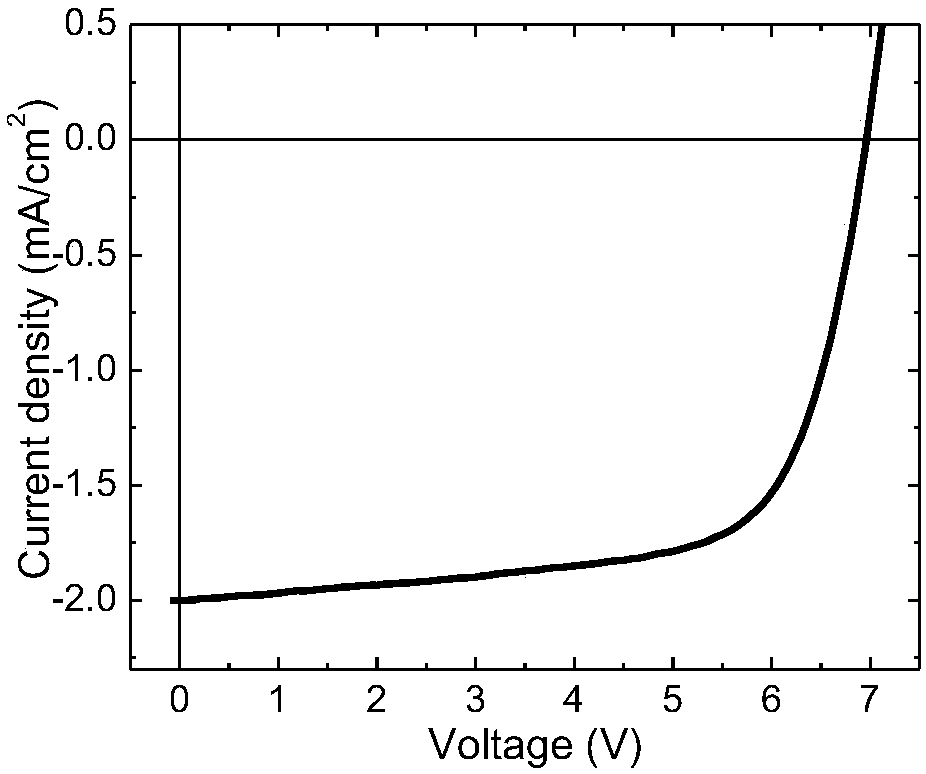

Super capacitor electrode material and preparation method thereof

InactiveCN107275105ALower internal resistanceReduce dead areaHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorElectrode impedance

The invention discloses a super capacitor electrode material and a preparation method thereof. According to the electrode material, a conductive agent and a binder are not used, a hydrothermal method is used to directly attach an active material to a surface of a flexible conductive substrate, and then the material is subjected to high temperature calcination in a muffle furnace to obtain a final electrode material. Since the conductive agent and the binder are not used, the fast transfer of ions is facilitated by a growth method, for an electrode with a blocked mass transfer process, the electrode impedance is effectively reduced by the growth method, the electrode specific capacity is improved, through a test, the specific capacity can reach 1590.4F / G in current density of 1 A / g, the electrode still can maintain 102% capacity after 10000 cycles under the current density of 10 A / g, and the electrode material has an industrialization prospect.

Owner:NANJING UNIV OF SCI & TECH

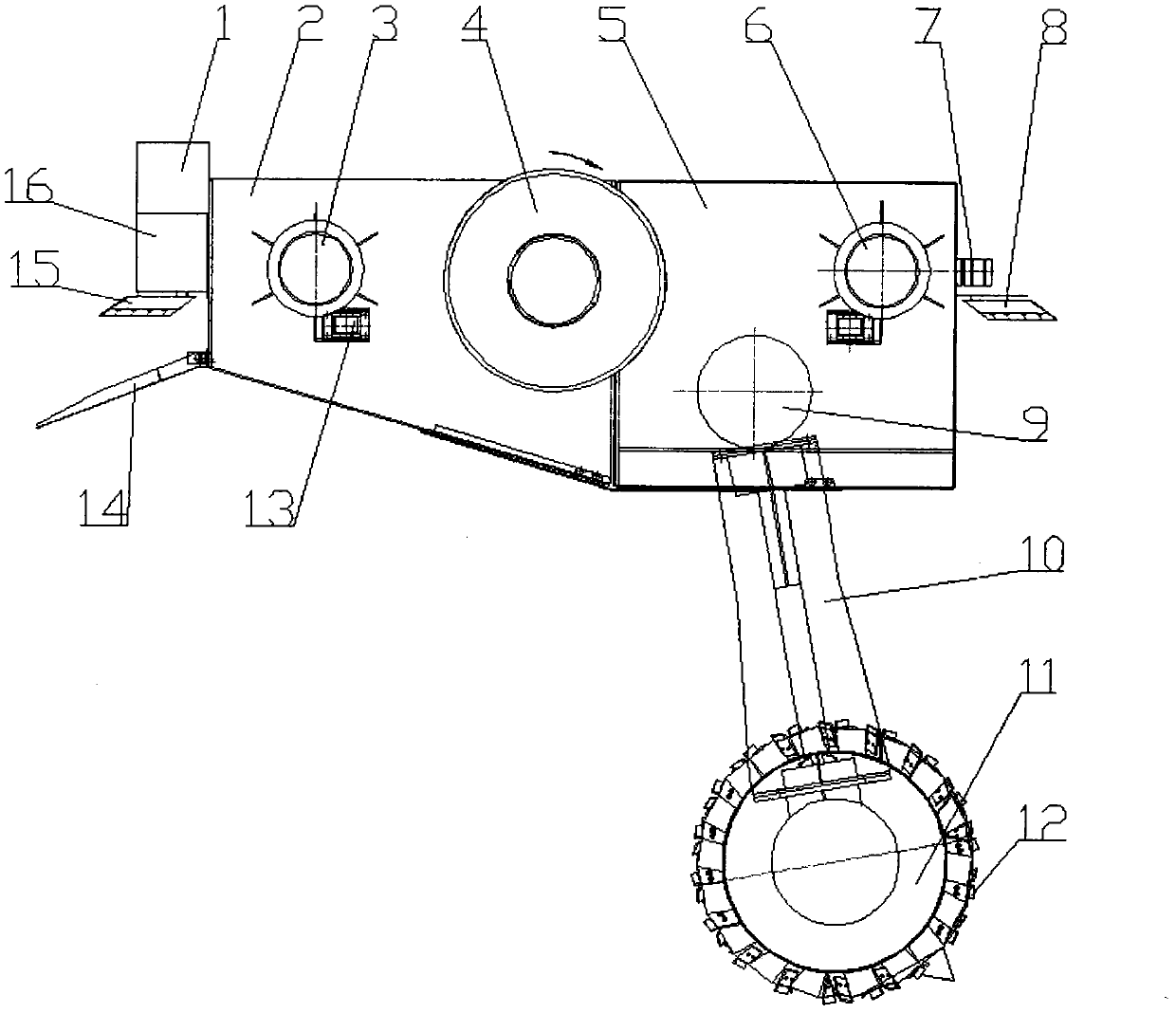

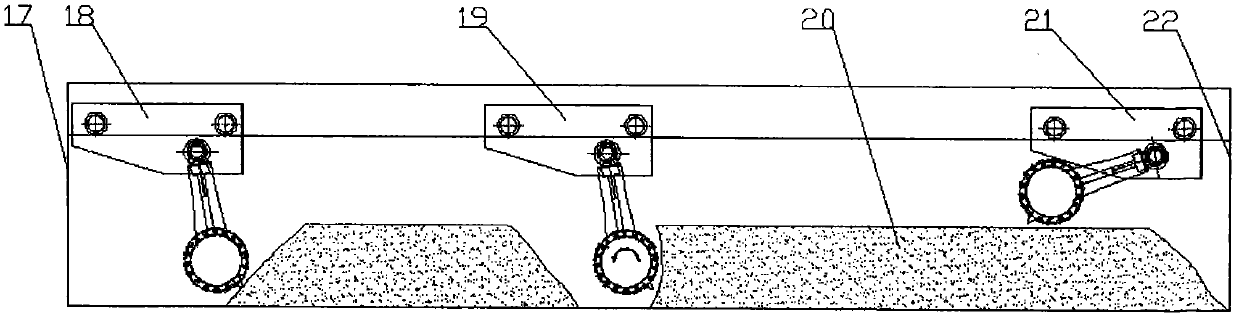

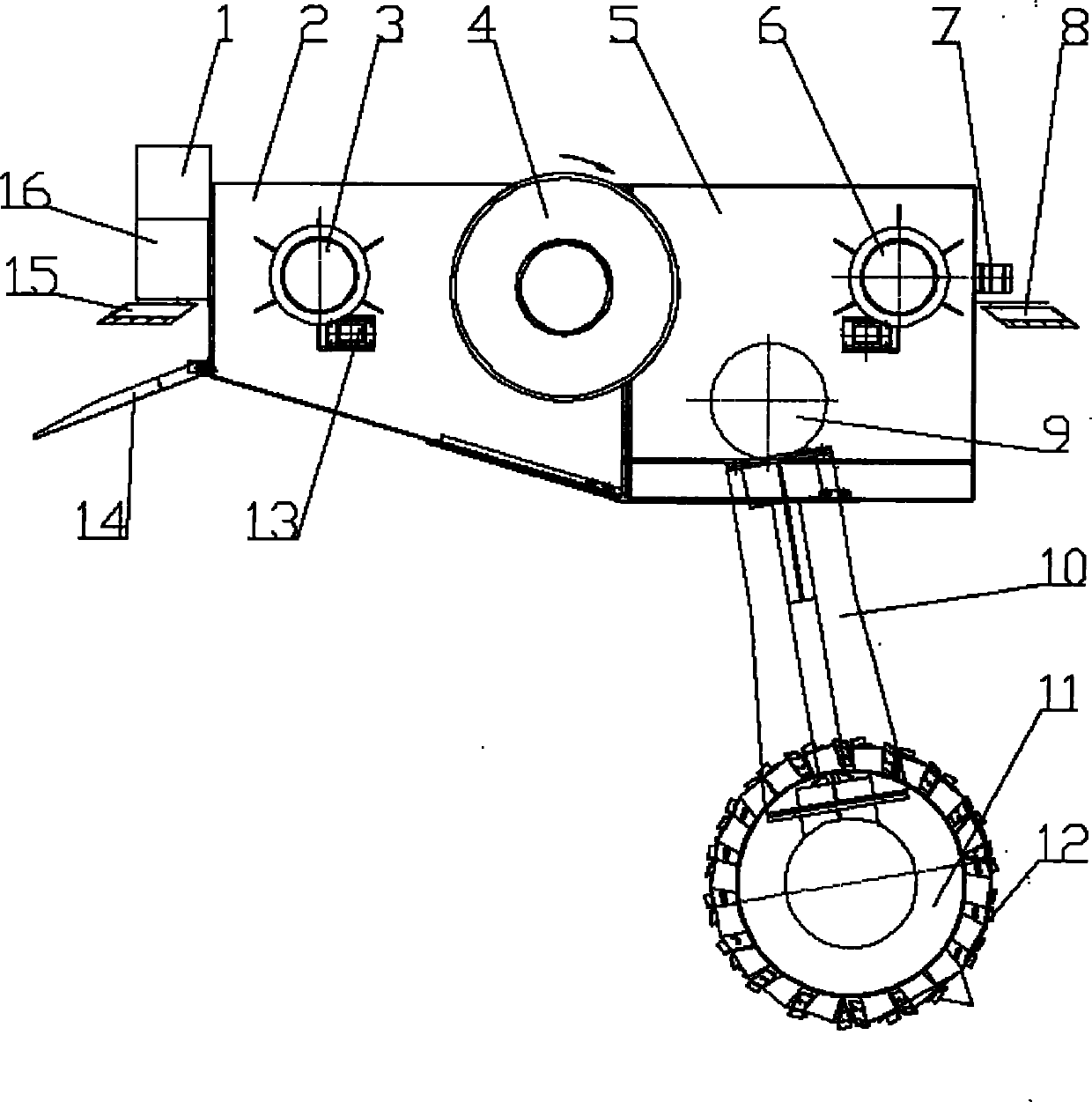

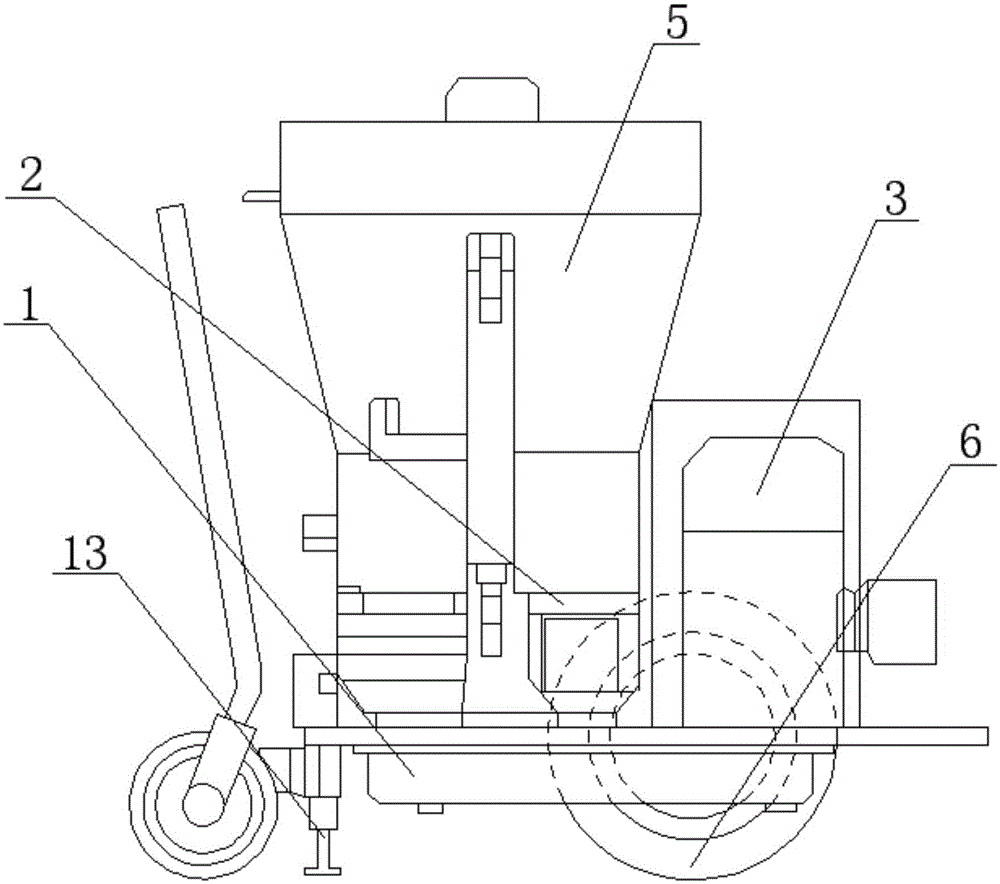

Drum-type sludge turning machine and turning method thereof

InactiveCN102557770AEasy to handleIncrease rotation speedBio-organic fraction processingClimate change adaptationAutomatic controlSludge

The invention relates to a drum-type type sludge turning machine and a turning method of the turning machine, wherein the drum-type type sludge turning machine comprises a frame, a drum mechanism, a travelling mechanism, a lifting mechanism, a cable pulling-pushing mechanism, a wheel-leaning mechanism, a sludge-blocking mechanism and an automatic control system; the drum mechanism comprises a rotary drum and a turning cutter, which is driven by a motor to rotate; the lifting mechanism is of a steeple shape and is driven hydraulically; the wheel-leaning mechanism is arranged outside the frame and contacts the rail surface; the sludge-blocking mechanism is divided into a front sludge-blocking plate, a side sludge-blocking plate, a bottom sludge-blocking plate and a back sludge-blocking plate, which are connected with the frame by bolts; an automatic control cabinet is located at rear of the drum-type sludge turning machine, is connected with the back frame by the bolt and is connected with each action device of the drum-type sludge turning machine by a cable; the method for turning the sludge uses high-speed rotation of the cutter driven by the drum to stir and crush materials and throws the materials to back of the drum-type sludge turning machine.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

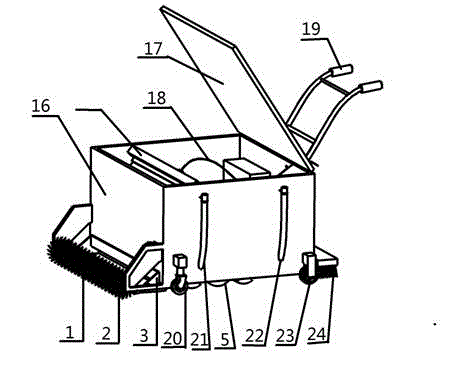

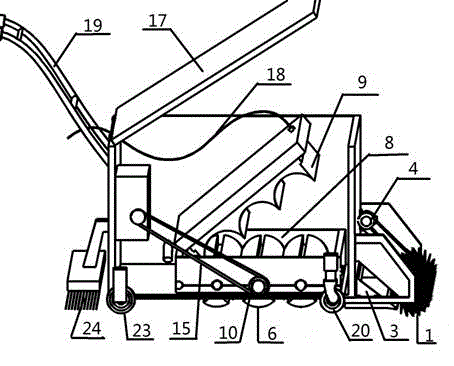

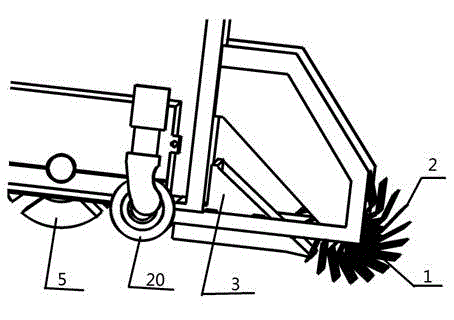

Simple self-cleaning mopping cart

InactiveCN103142193APrevent seepageImprove work efficiencyMachine detailsFloor sweeping machinesGeneral familyEngineering

The invention relates to a simple self-cleaning mopping device, which mainly comprises a sweeping roller, a garbage can, mopping rollers, a water tank, a drying roller, a sealing box, a handlebar, a battery, a motor and a variable gear. When the mopping cart is pushed by a person to advance, the front sweeping roller can sweep garbage into the garbage can; the mopping rollers in the middle of the mopping cart are driven by the motor to rotate forward; when the ground is cleaned, the mopping rollers are also cleaned, so that the trouble of removing the mopping rollers for cleaning is avoided; and a drying mop at the rear part of the mopping cart can dry the ground timely to prevent the ground from being dirty again. The device is simple in structure and low in cost, can operate continuously for a long time, and is applicable to cleaning work of the ground of a large-area location. The mopping cart is also applicable to the cleaning work of the general family ground after being miniaturized.

Owner:曹林冲 +2

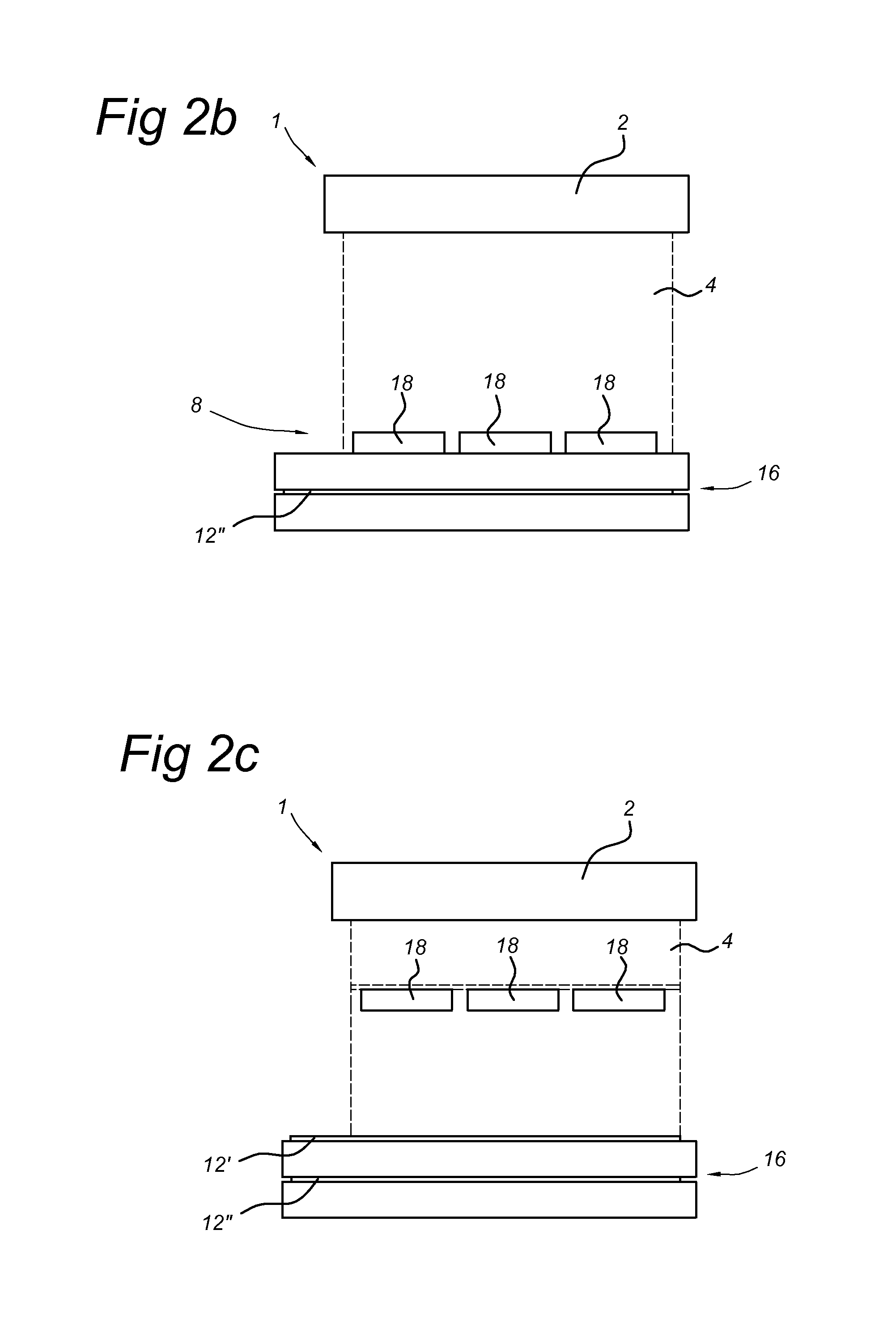

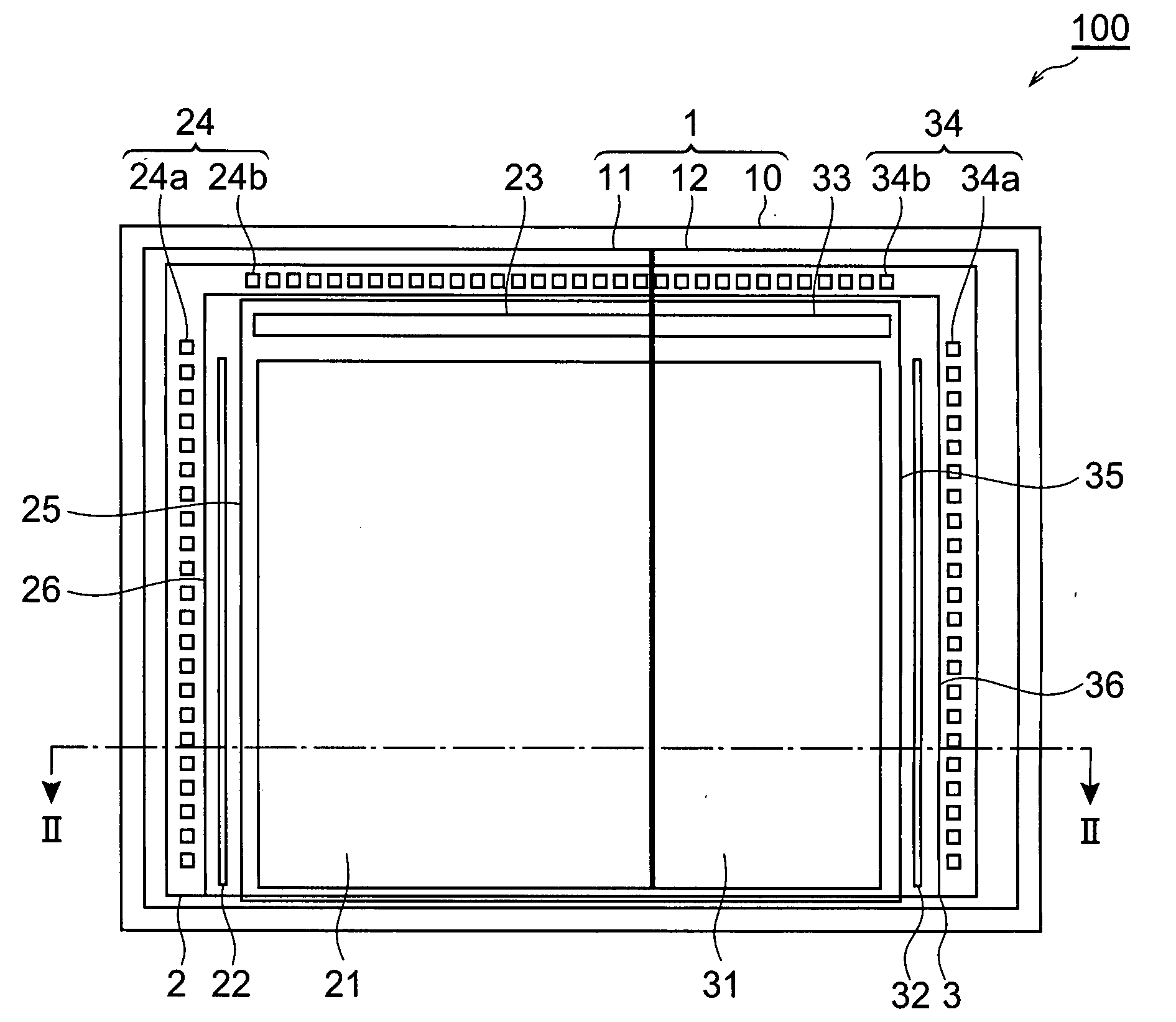

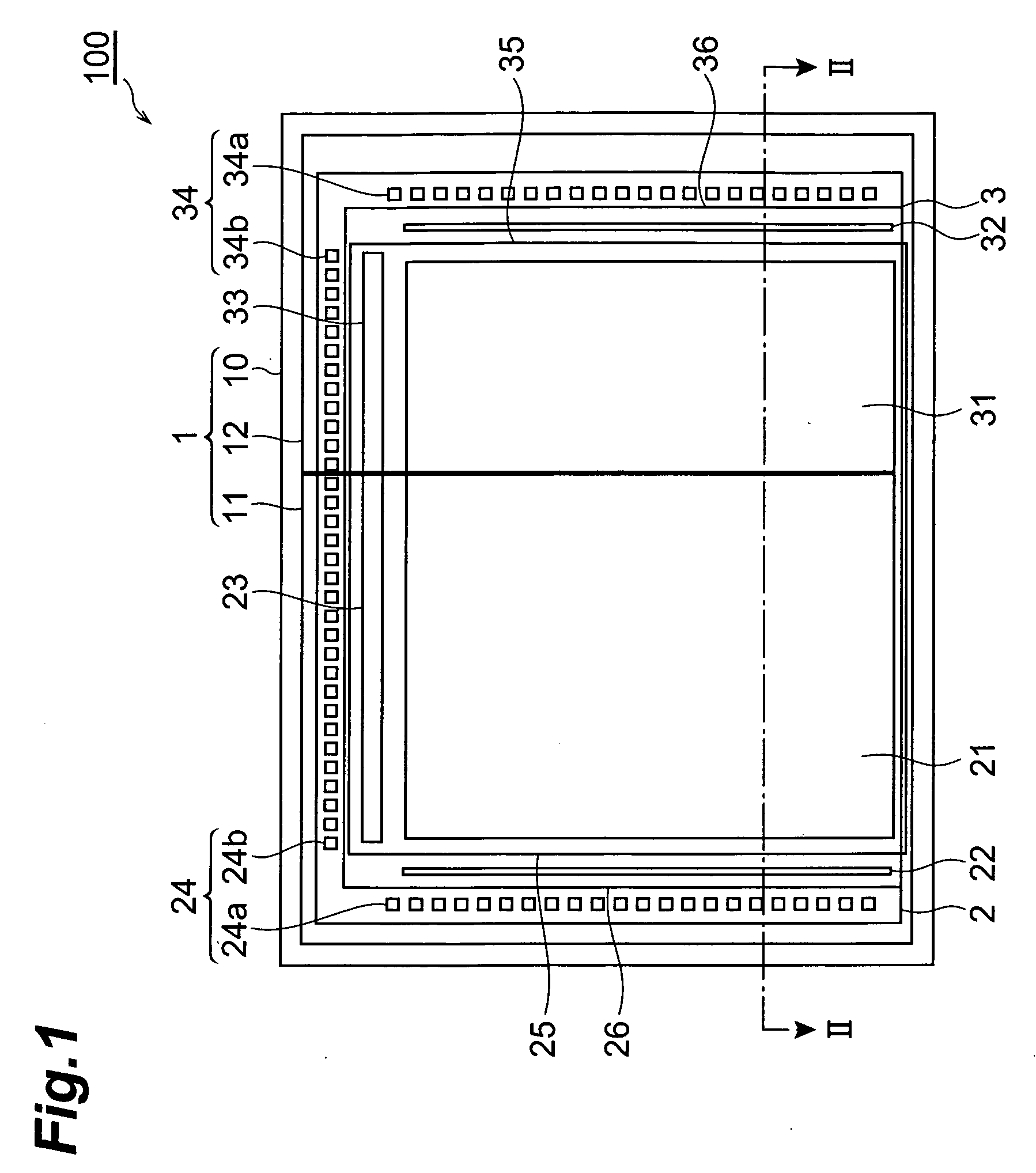

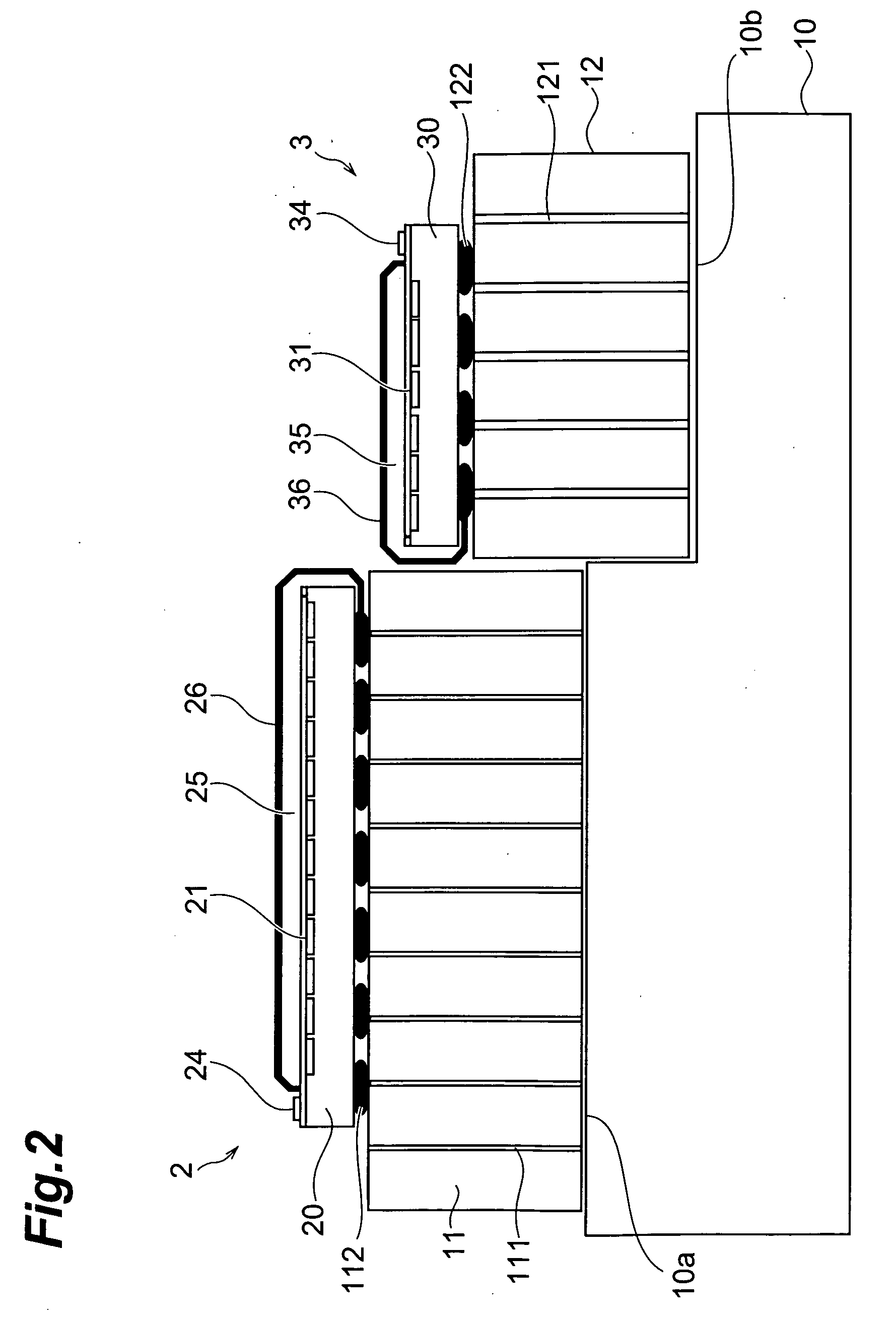

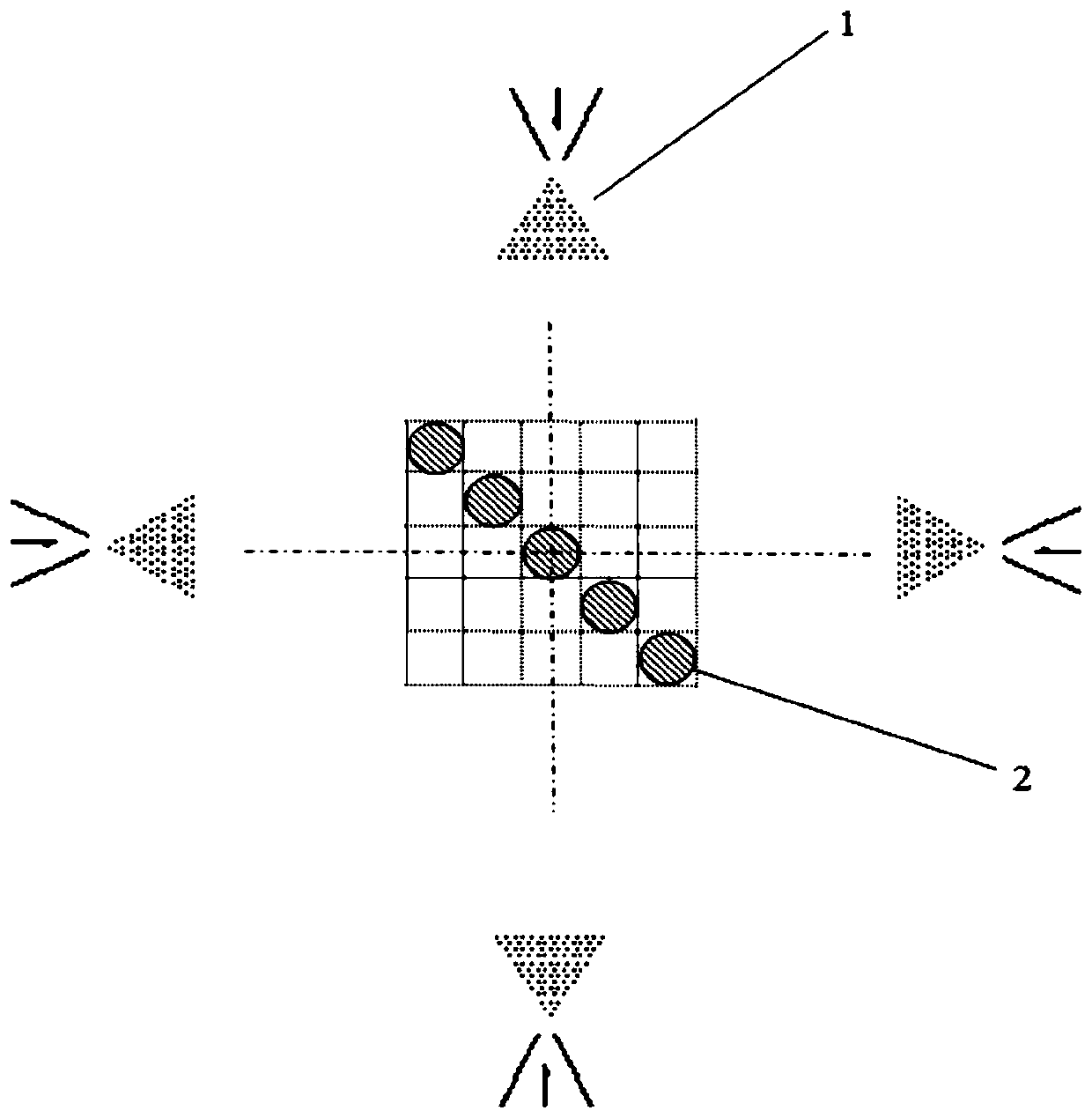

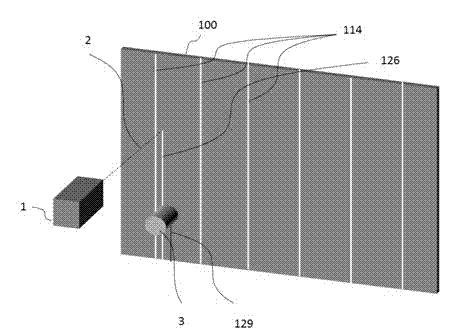

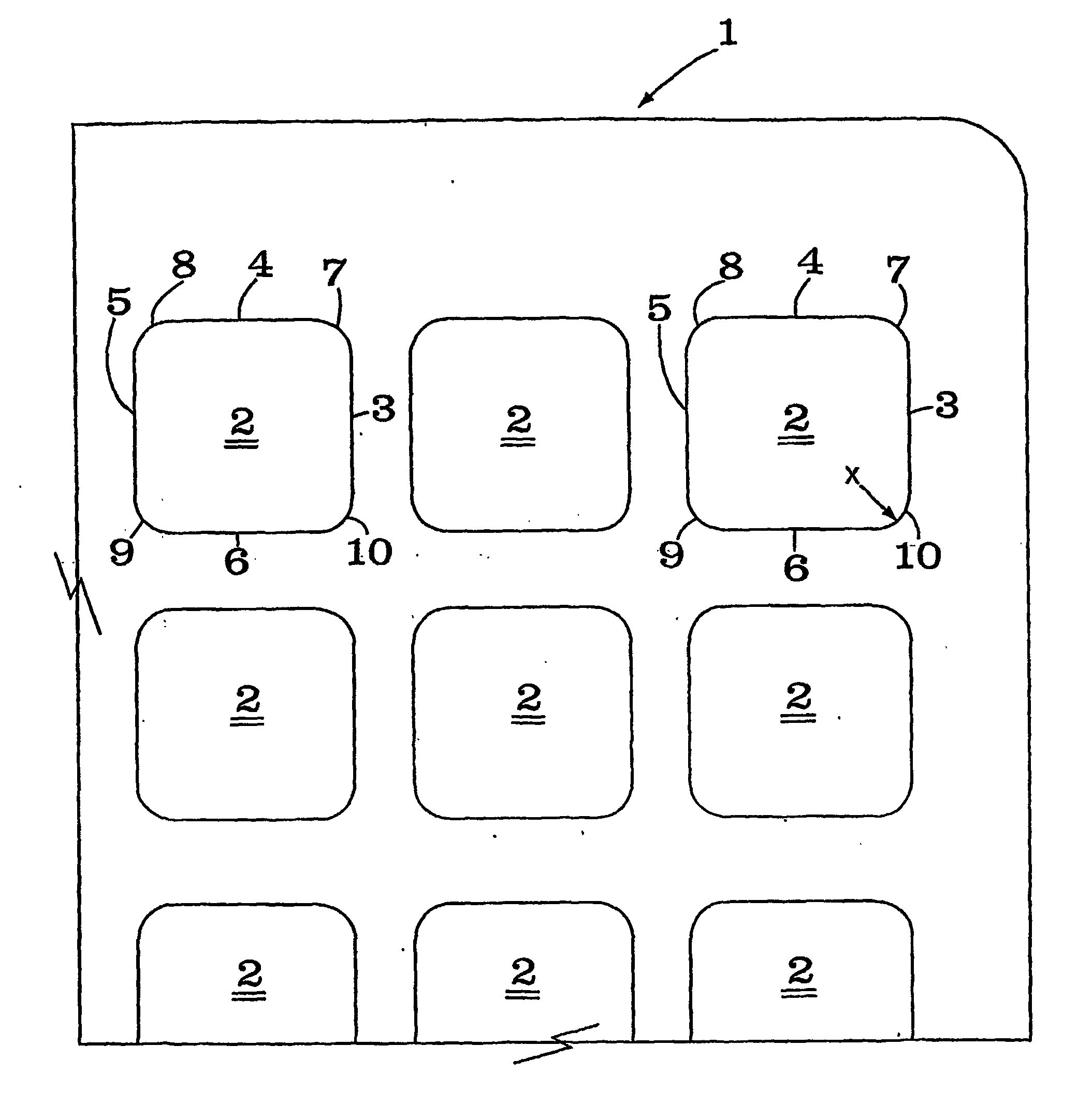

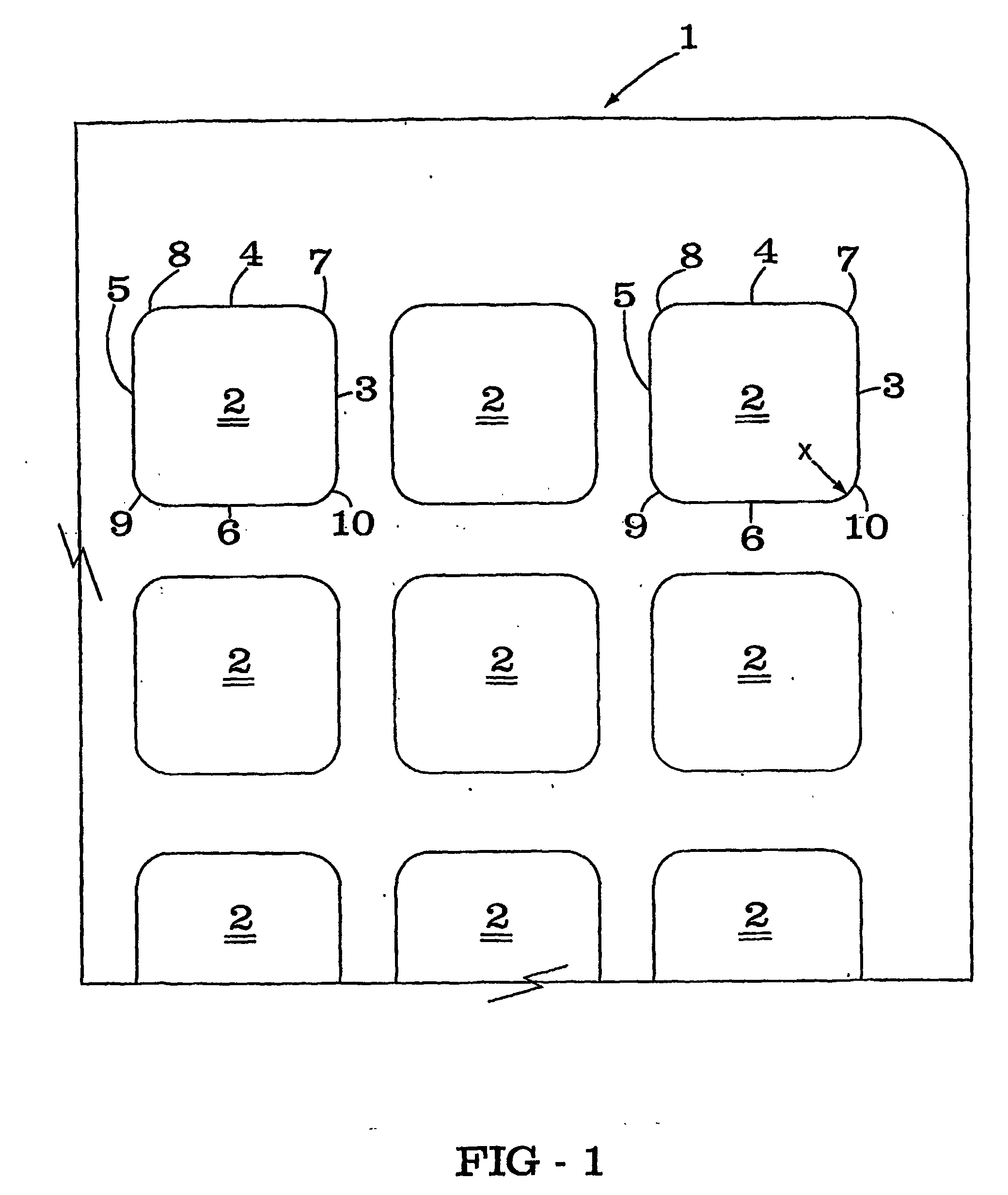

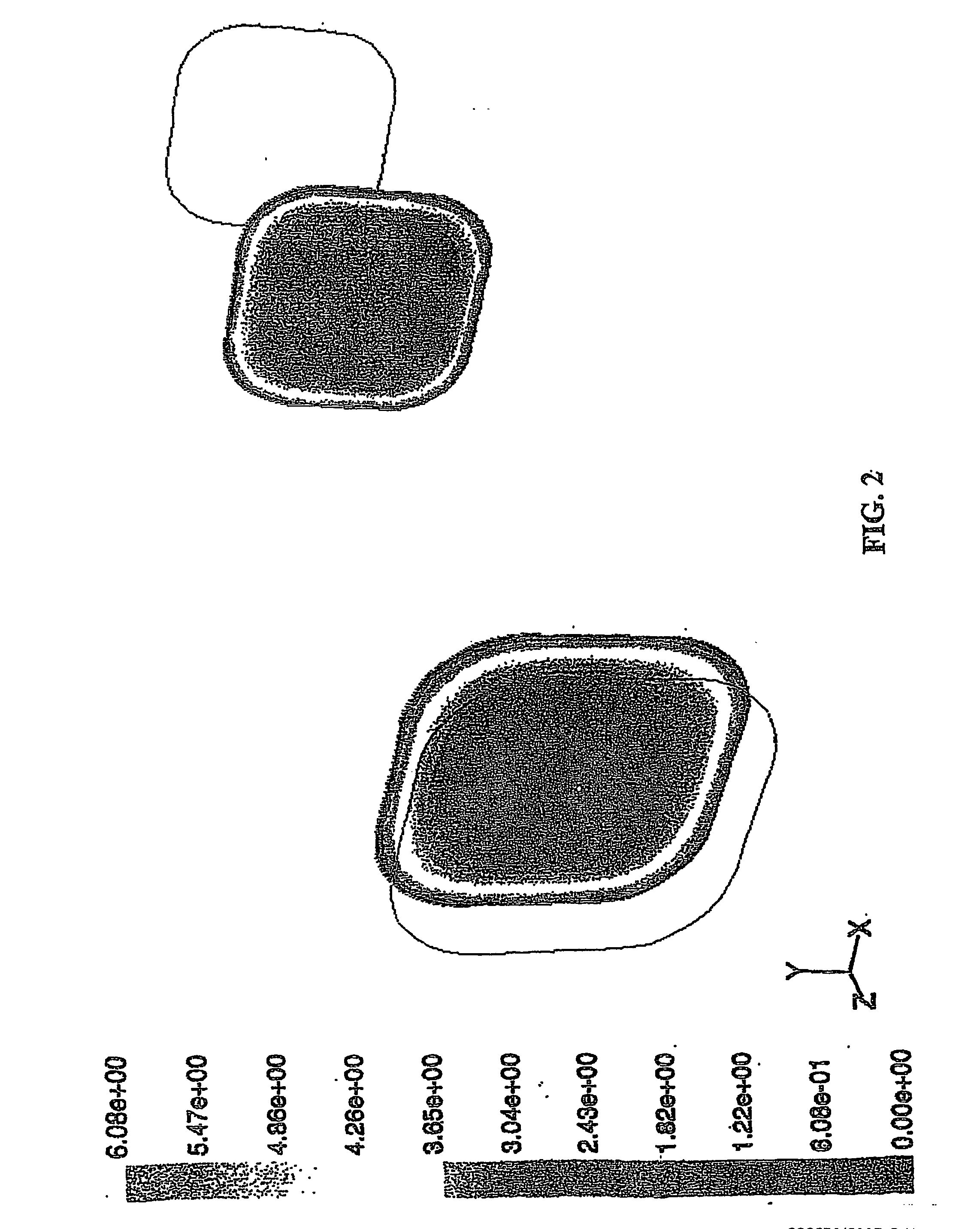

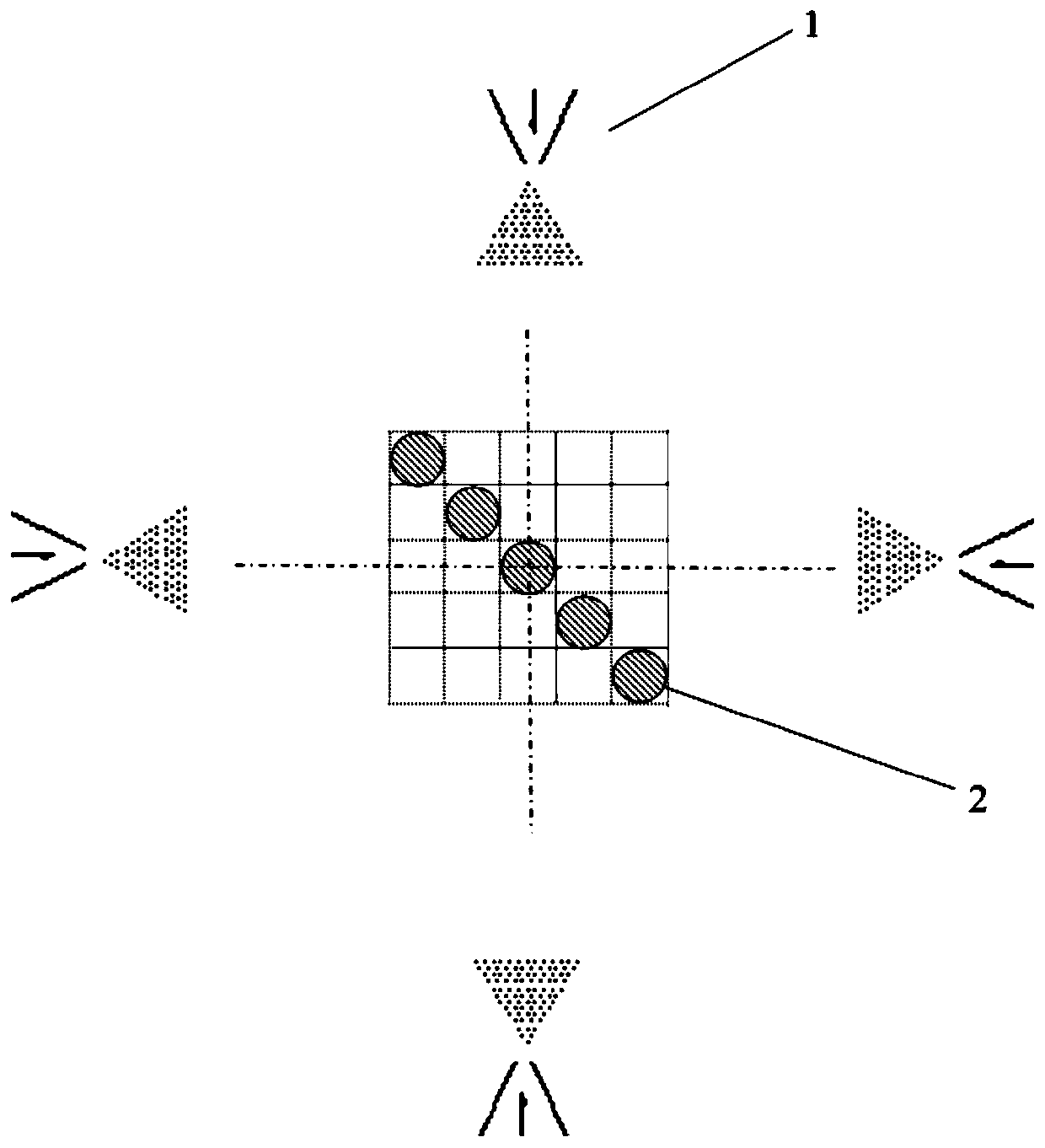

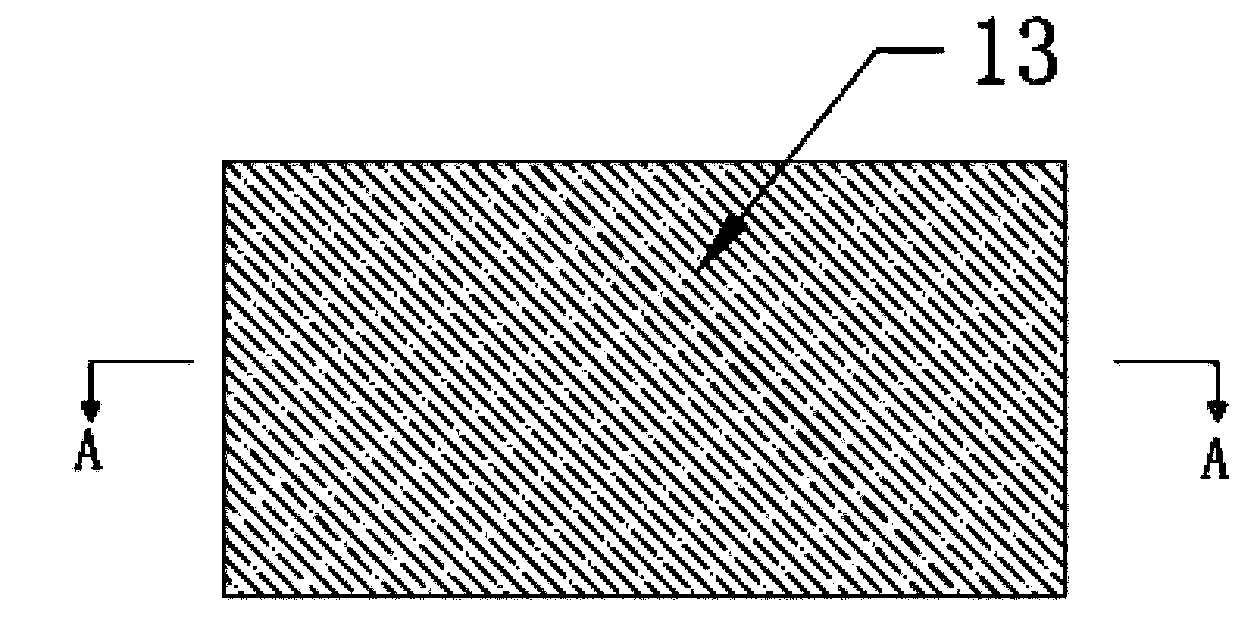

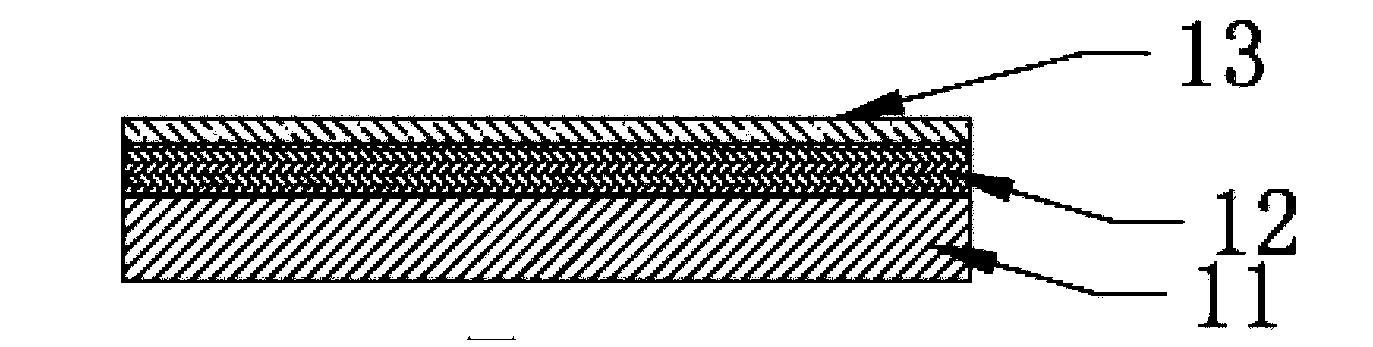

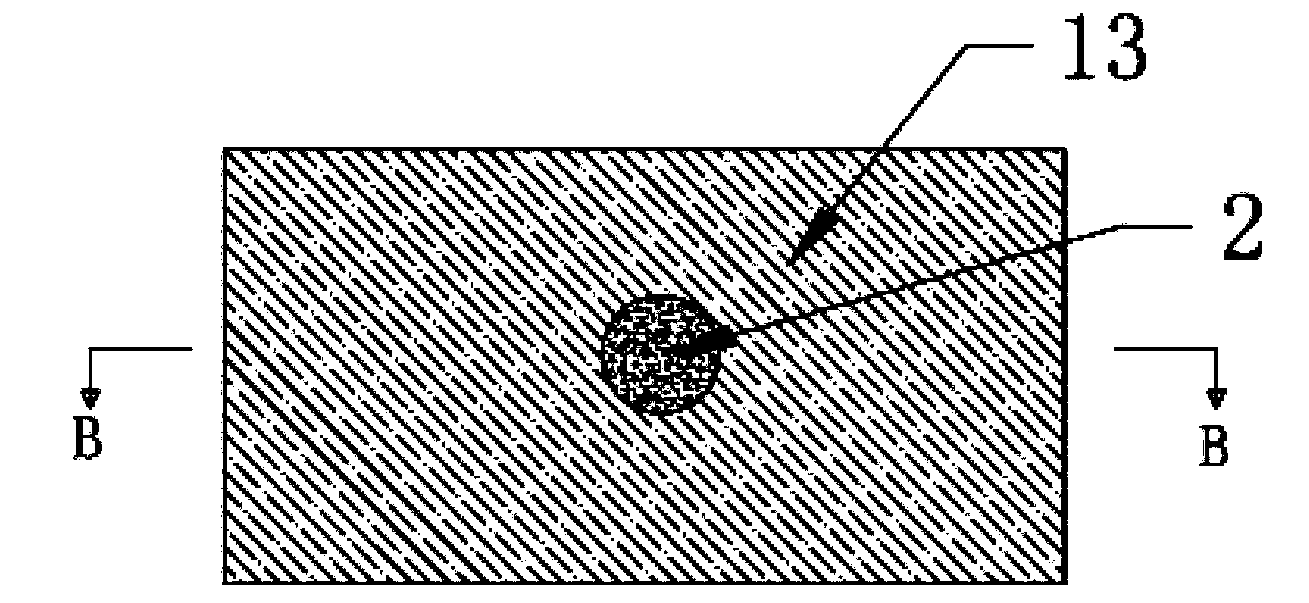

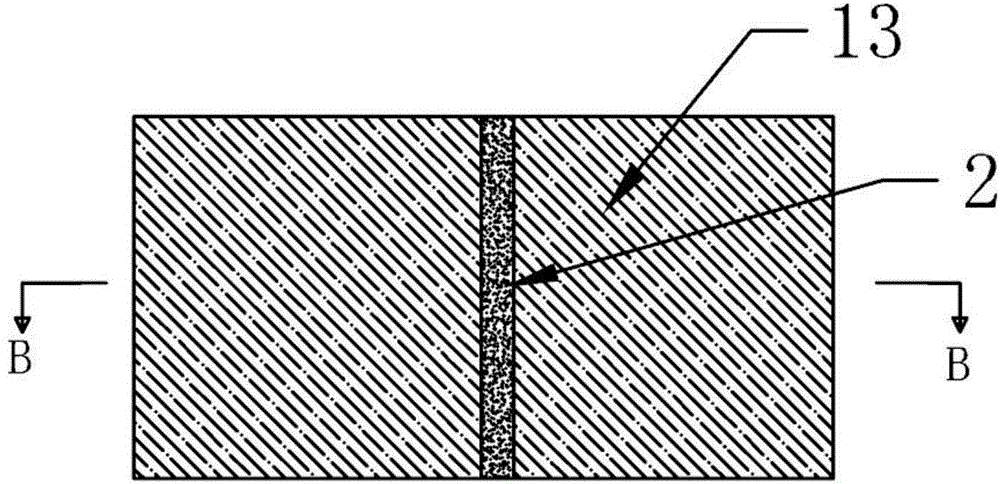

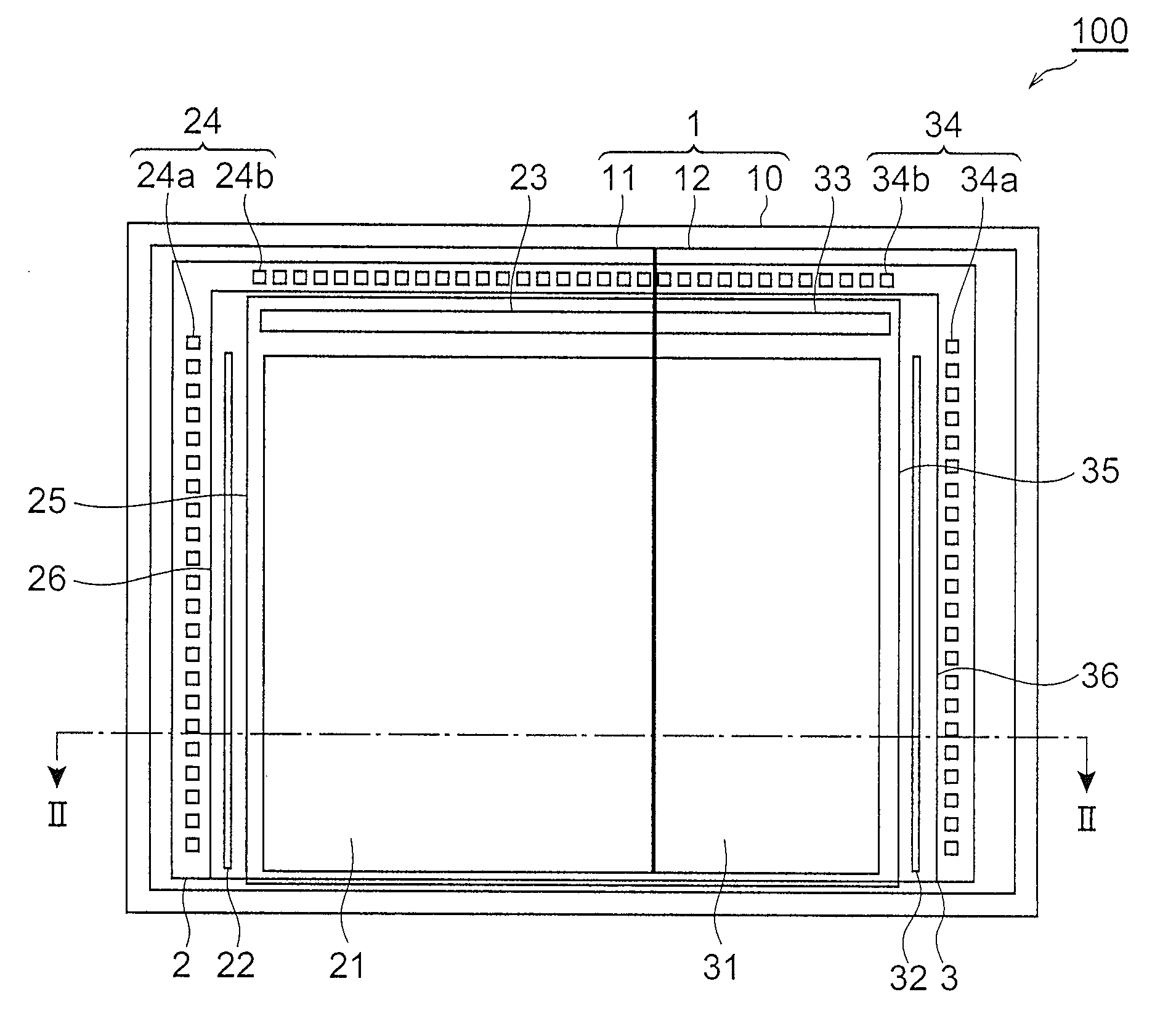

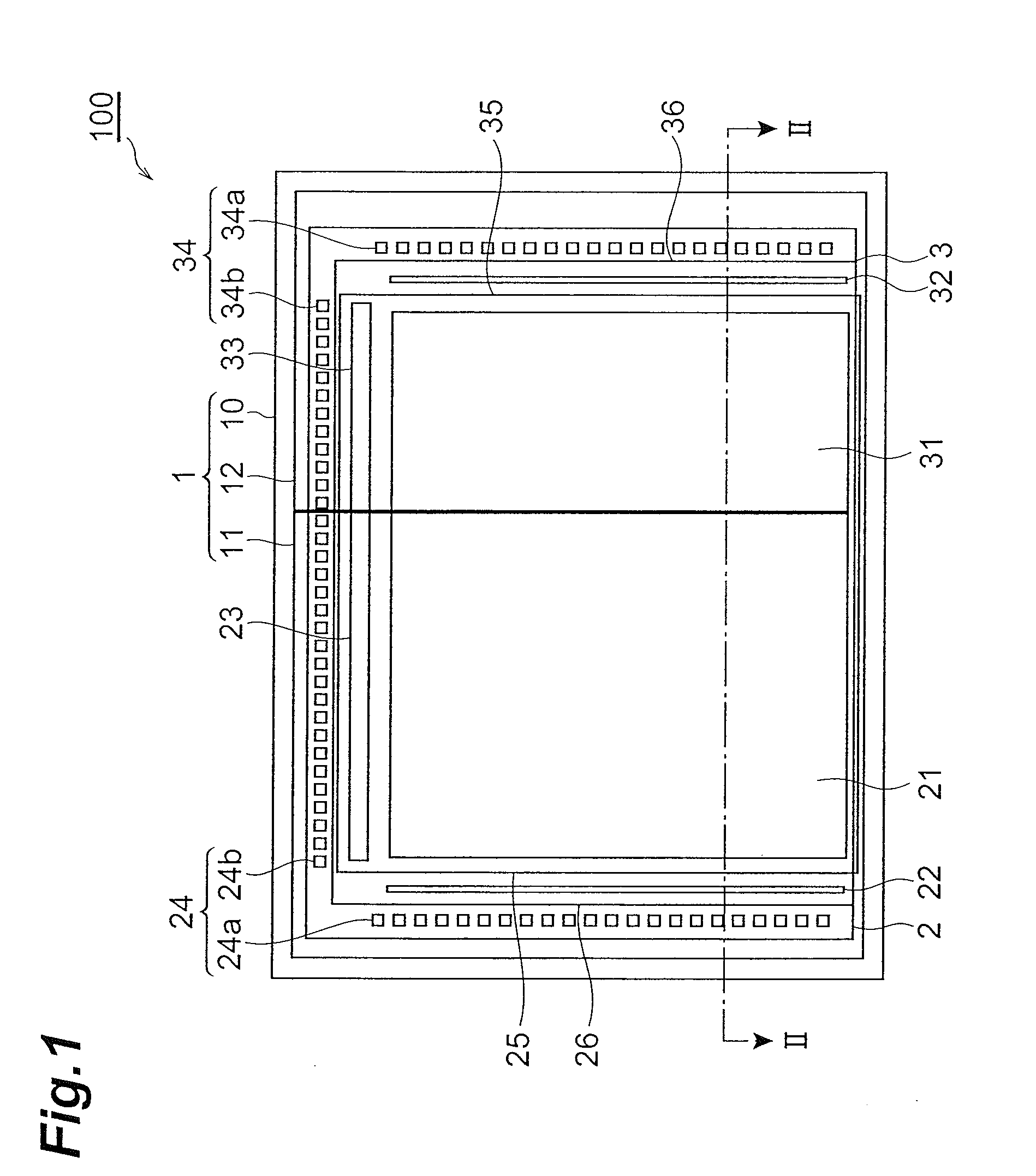

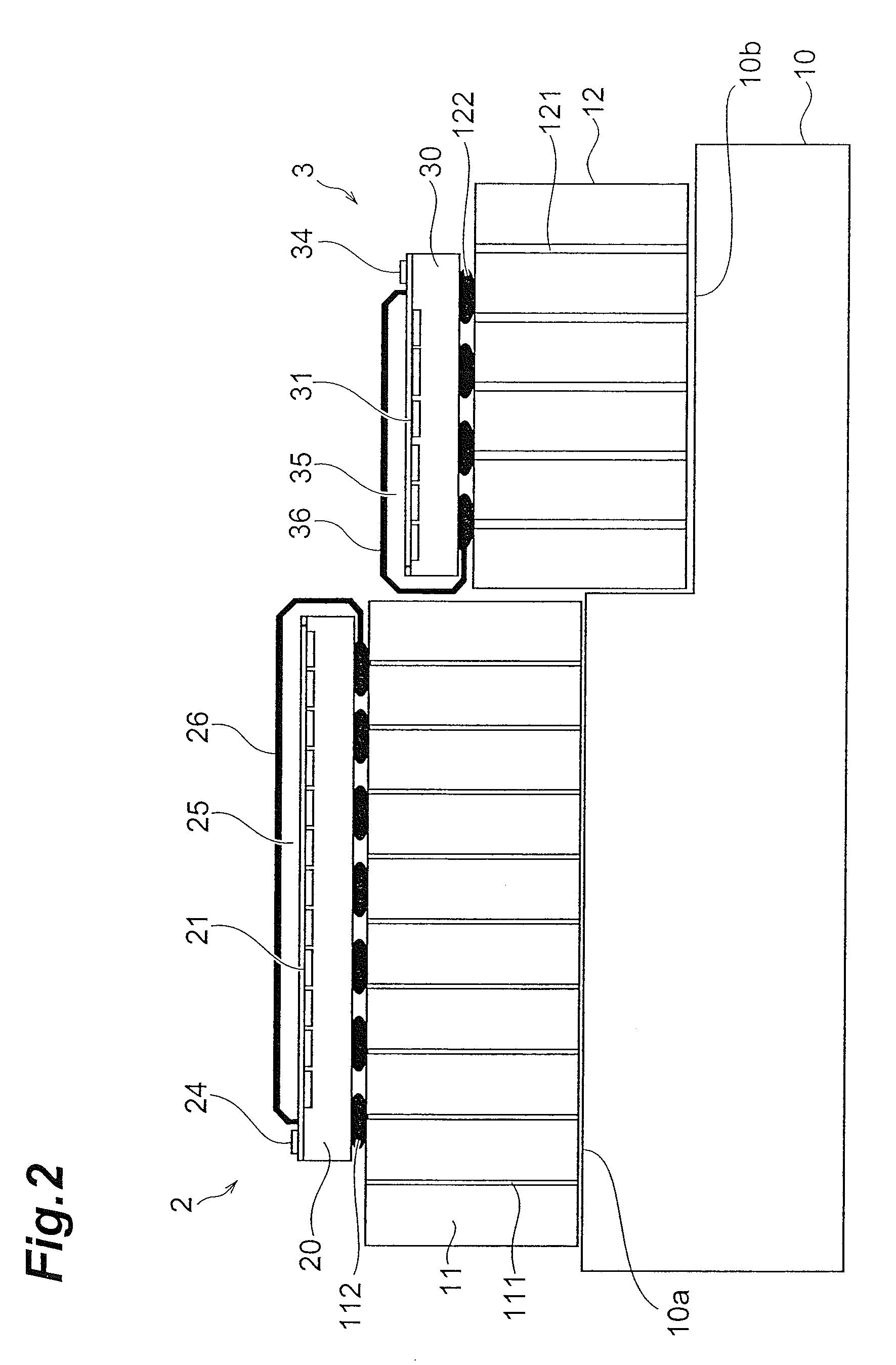

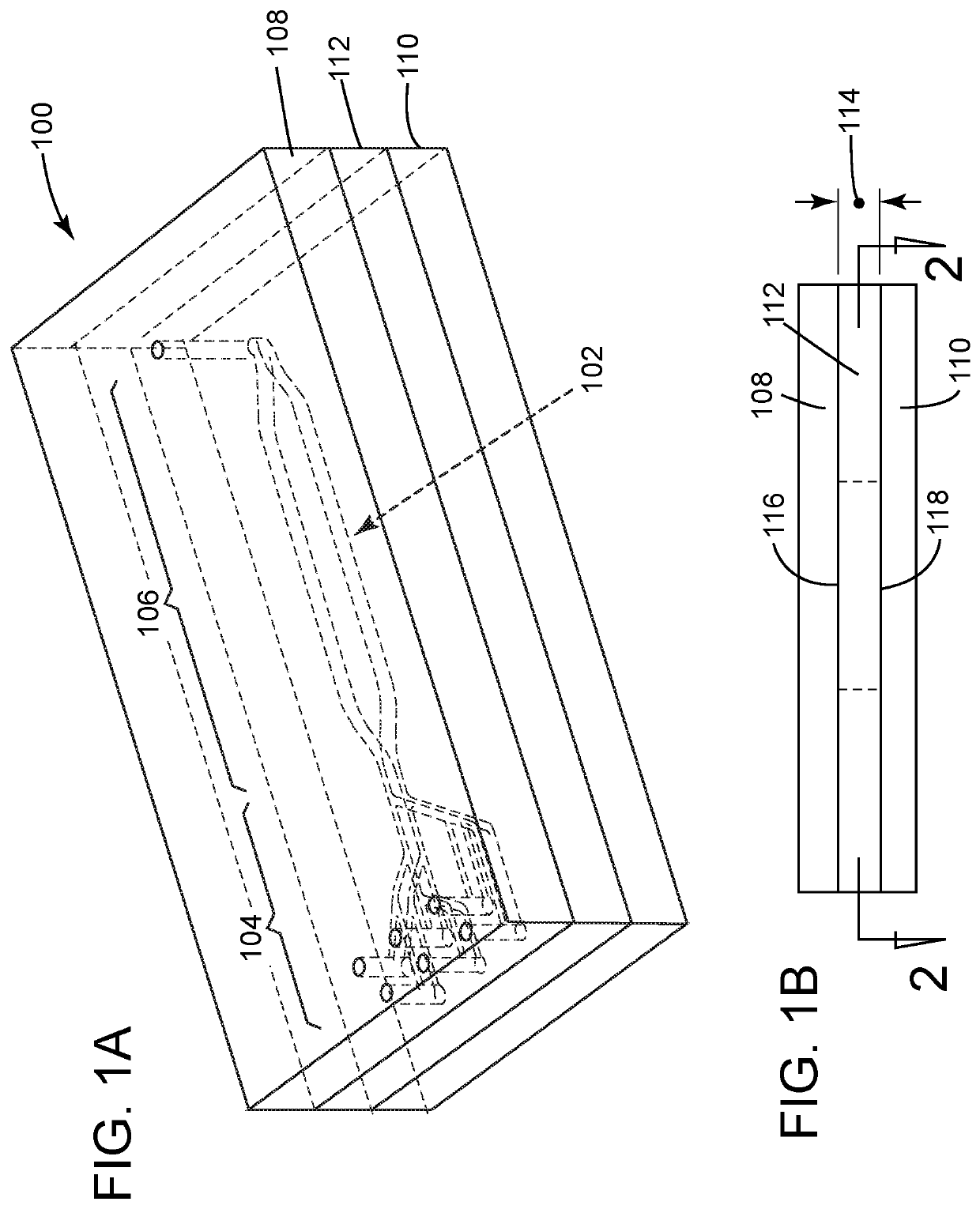

Radiation Imaging Device

ActiveUS20080192891A1Suppressing forming of dead areaHigh sensitivityTelevision system detailsSolid-state devicesRadiation imagingScintillator

Wiring substrates 11 and 12 are positioned on a fixed base 10 in a manner such that there is a step between the wiring substrates, and radiation imaging elements 2 and 3, respectively having scintillators 25 and 35 deposited on photosensitive portions 21 and 31, are respectively mounted on the wiring substrates 11 and 12. The radiation imaging element 2 is positioned so that its setting surface protrudes beyond a radiation incident surface of the radiation imaging element 3, and the photosensitive portion 21 of the radiation imaging element 2 and the photosensitive portion 31 of the radiation imaging element 3 are juxtaposed to a degree to which the portions do not overlap. The photosensitive portion 21 of the radiation imaging element 2 extends close to an edge at the radiation imaging element 3 side and the scintillator 25 of substantially uniform thickness is formed up to this position.

Owner:HAMAMATSU PHOTONICS KK

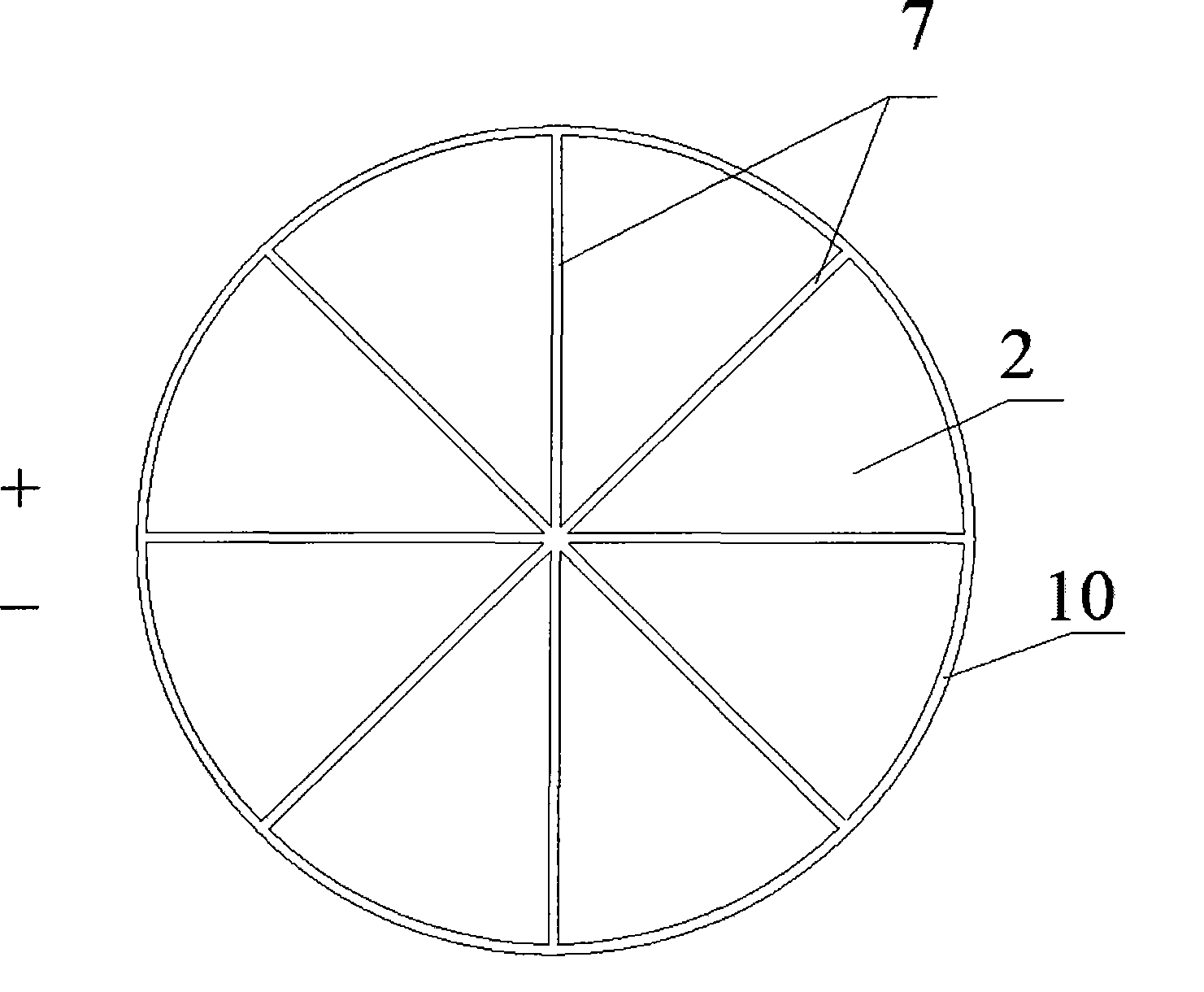

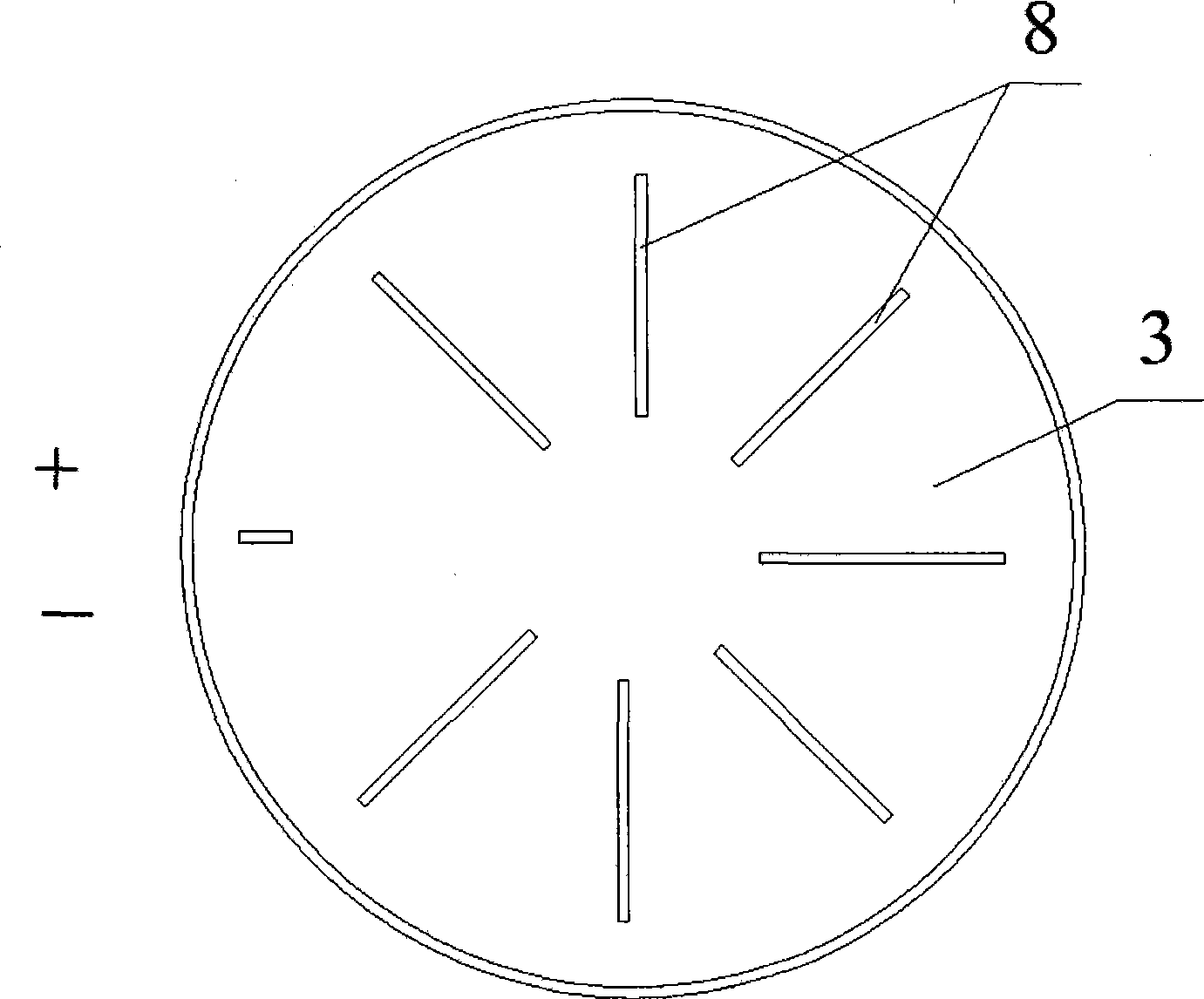

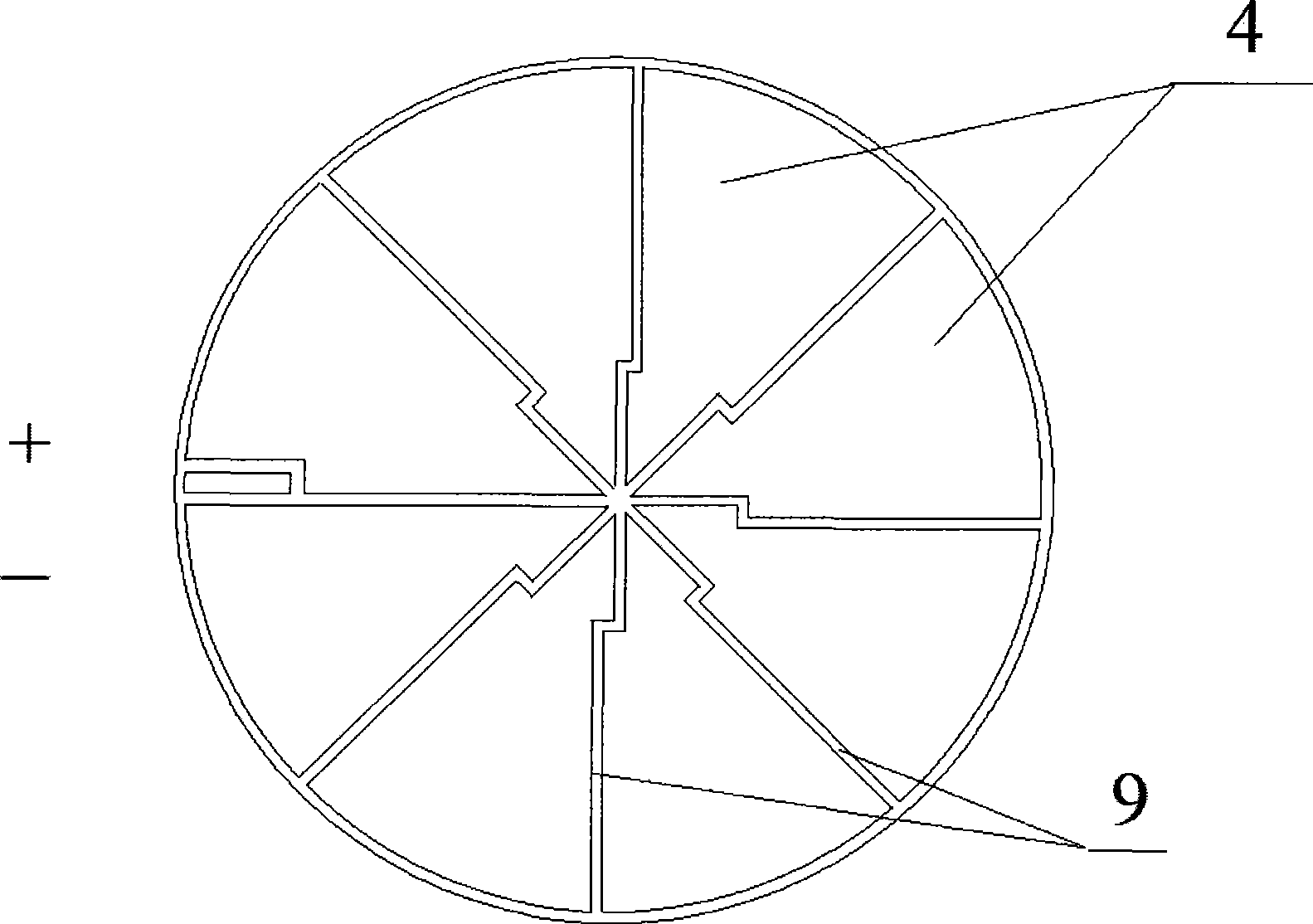

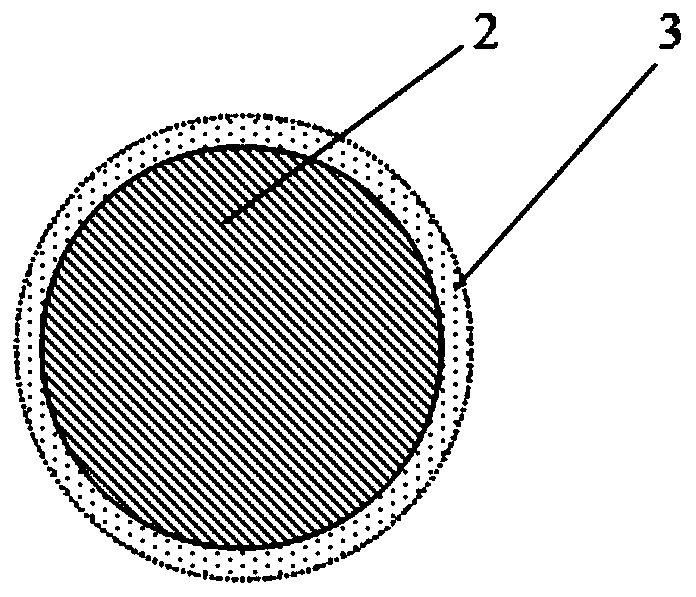

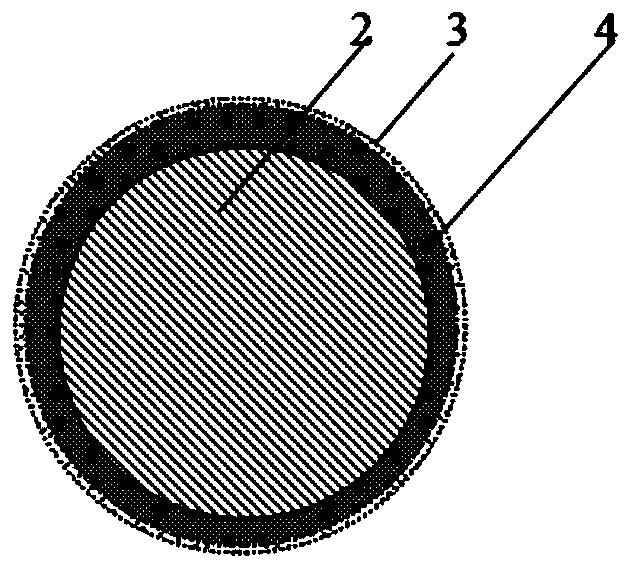

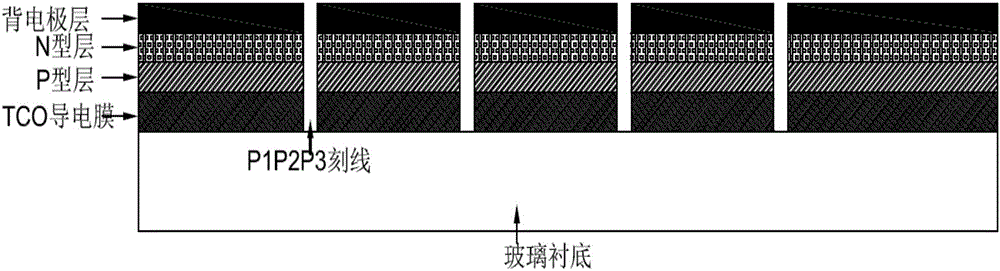

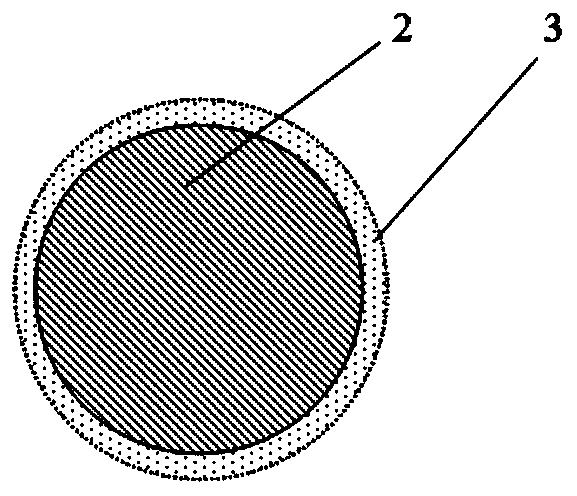

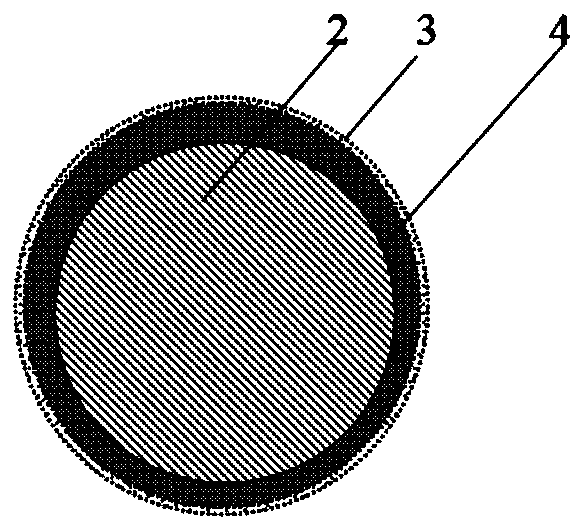

Circular silicon thin-film solar cell

ActiveCN101419989AIncrease the effective working areaGuaranteed electrical performancePhotovoltaic energy generationSemiconductor devicesLaser scribingSilicon thin film

The invention discloses a round silicon thin film solar cell and a fabrication method thereof. The cell is composed of cell units connected in series, and takes a transparent substrate as a substrate, comprises a front electrode layer, a silicon thin film layer, a back electrode layer and a back paint layer which are stacked up in sequence. The round silicon thin film solar cell is characterized in that working faces of the cell units are formed by laser scribing, an external envelope takes an arc shape, a working face inside the cell is composed of n serially connected cell units which have equal effective area, n is not less than 2, at least two shielding lines and a laser scribing line or a dot-and-dash line which connects a positive electrode and a negative electrode are arranged between the positive electrode and the negative electrode of the cell, and the width between the positive electrode and the negative electrode is 0.03-0.10mm. The fabrication method adopts advanced laser marking technology, can scribe the cell units with fan-shaped or irregular figures, has high precision, and causes the width of an invalid region inside the solar cell to decrease from 0.5-1.8mm to 0.03-0.20mm, thus enlarging the effective working area of the cell.

Owner:李毅

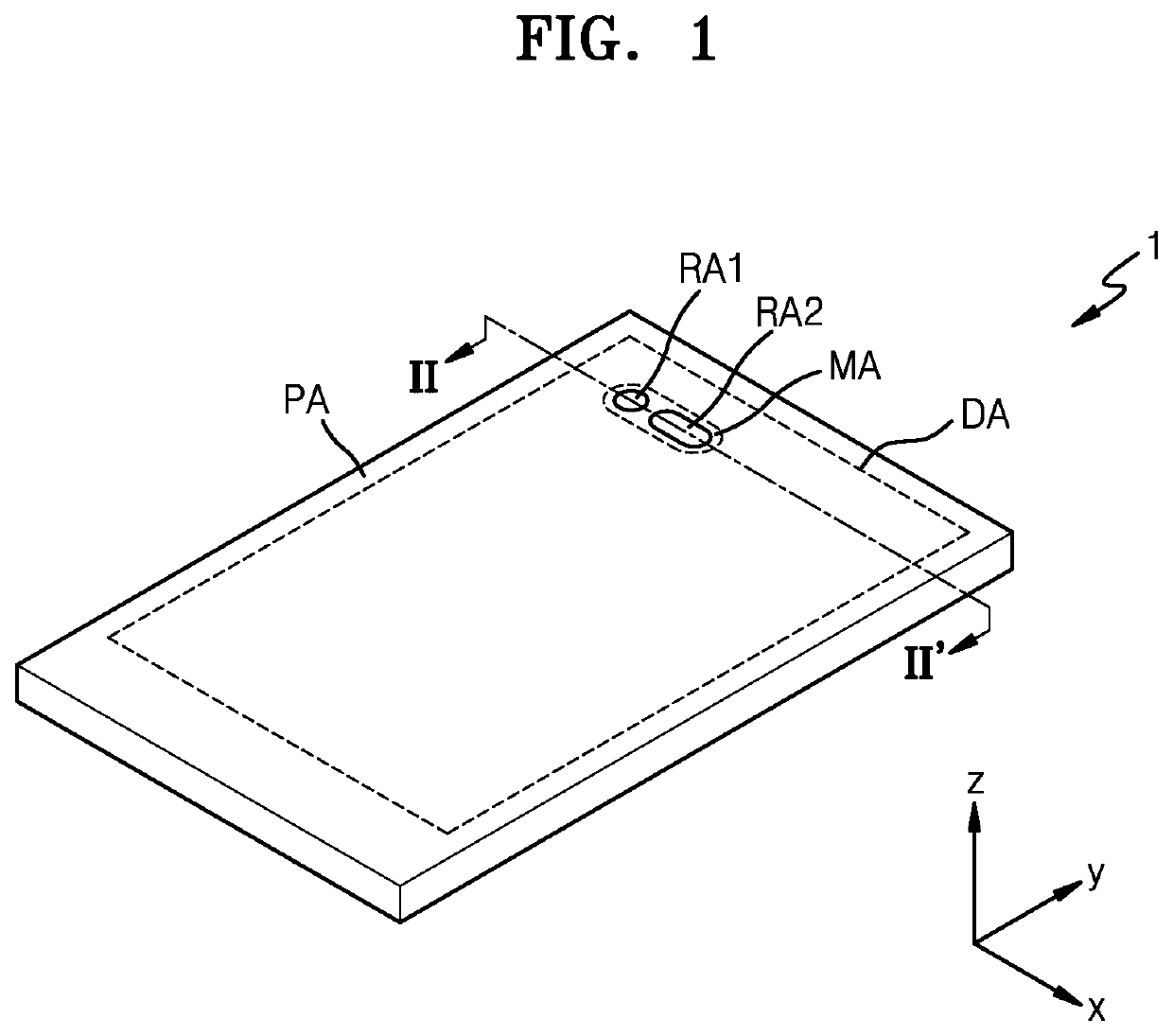

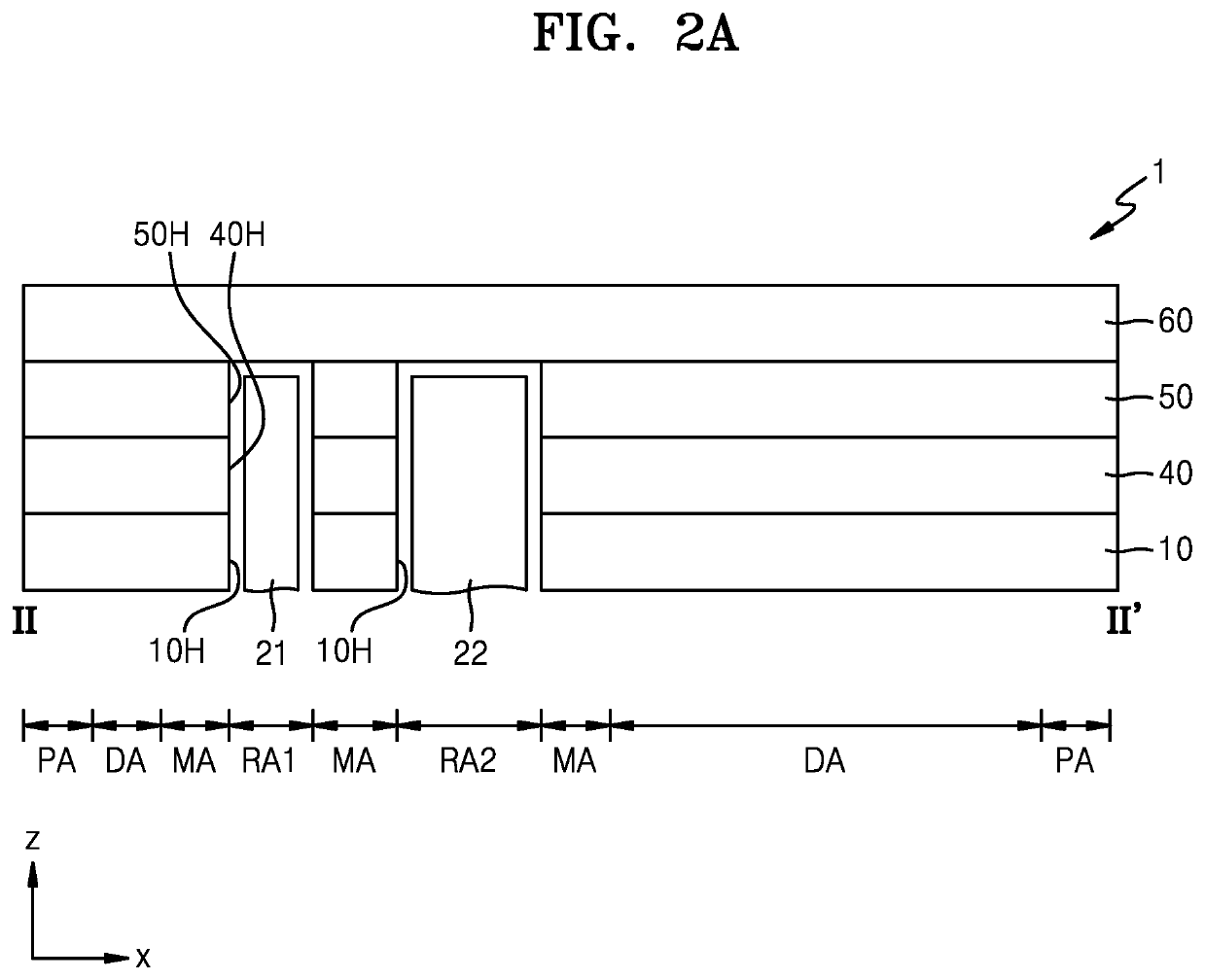

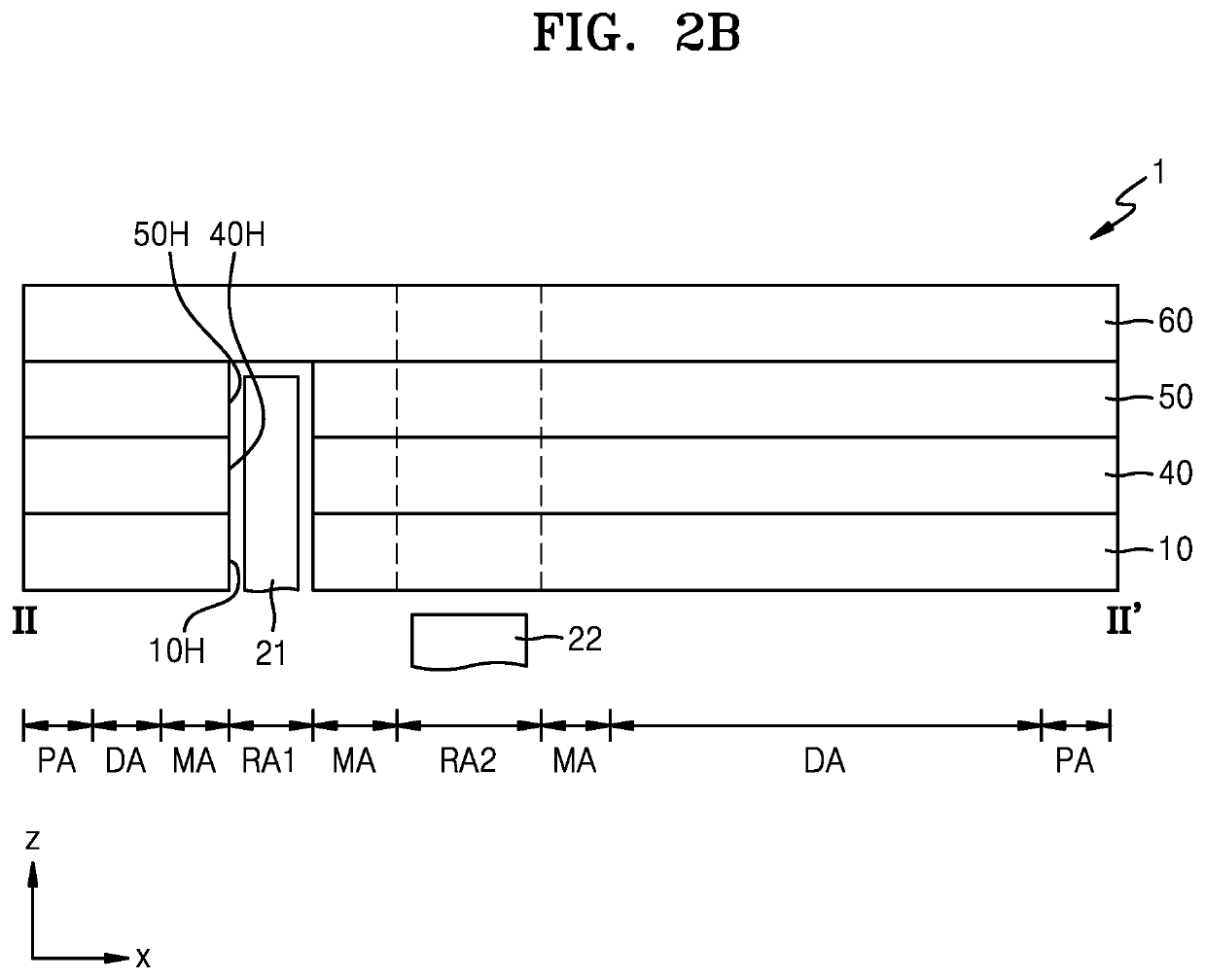

Display panel

ActiveUS20200168691A1Function increaseIncreasing dead areaStatic indicating devicesSolid-state devicesEngineeringComputer science

Owner:SAMSUNG DISPLAY CO LTD

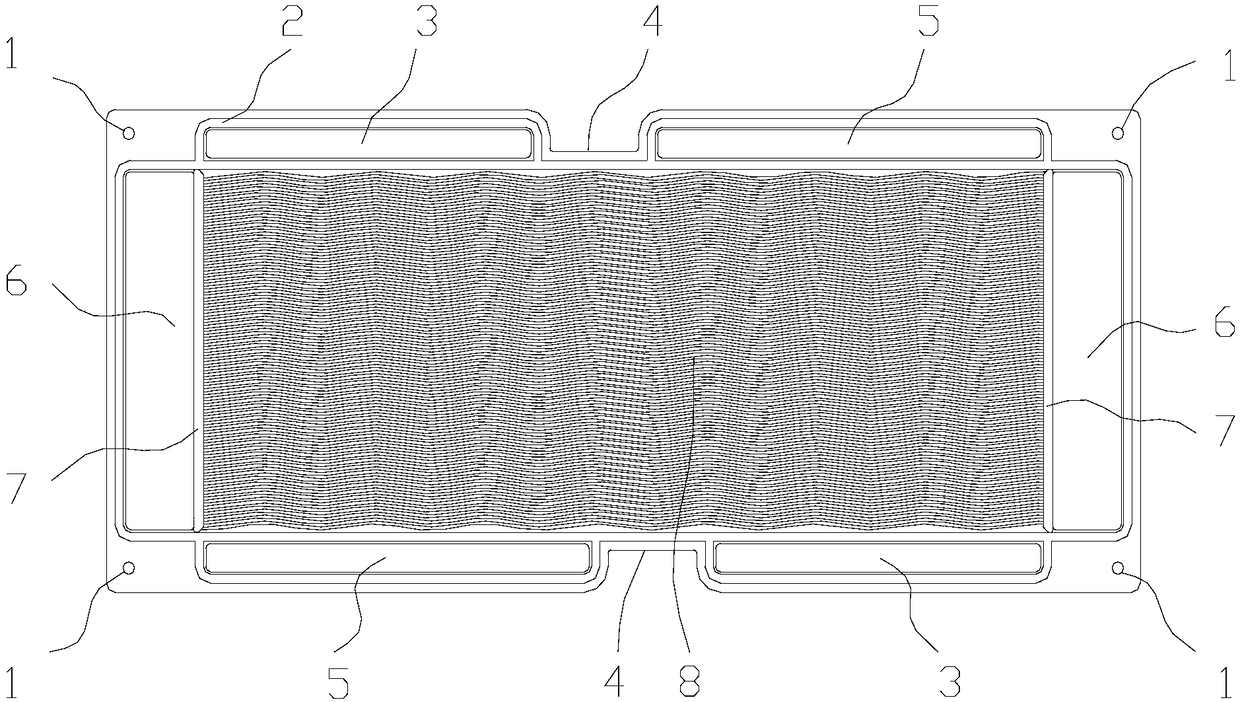

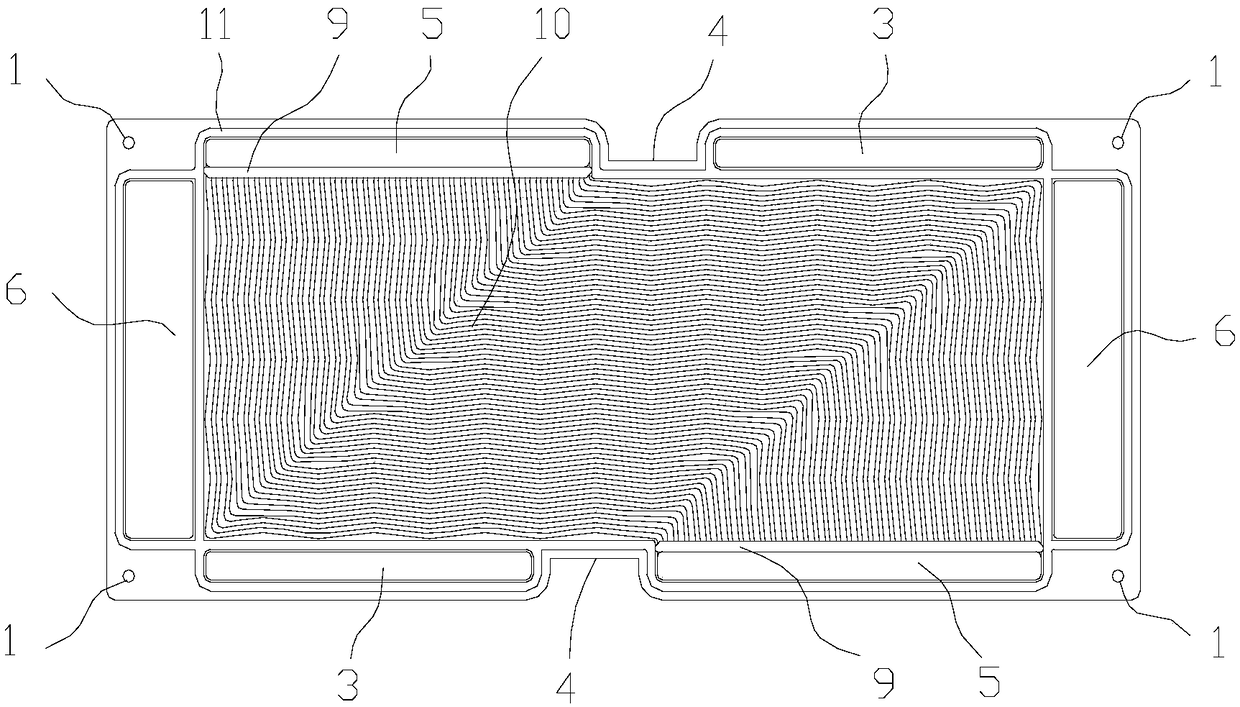

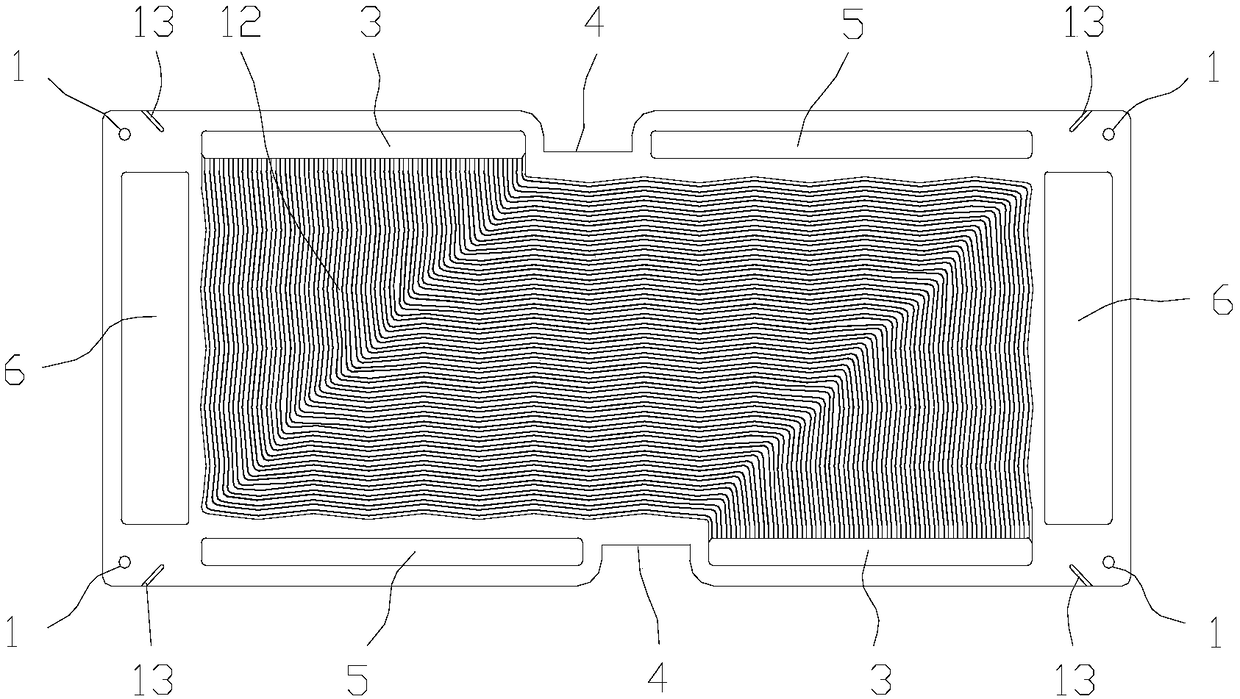

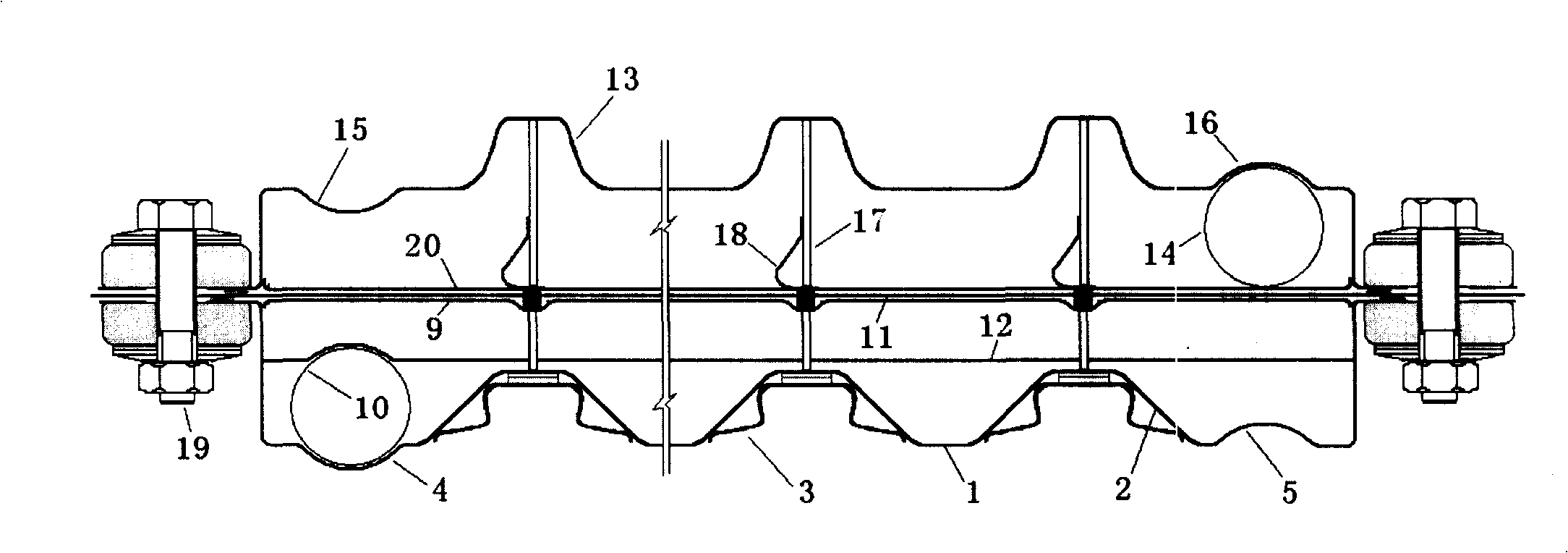

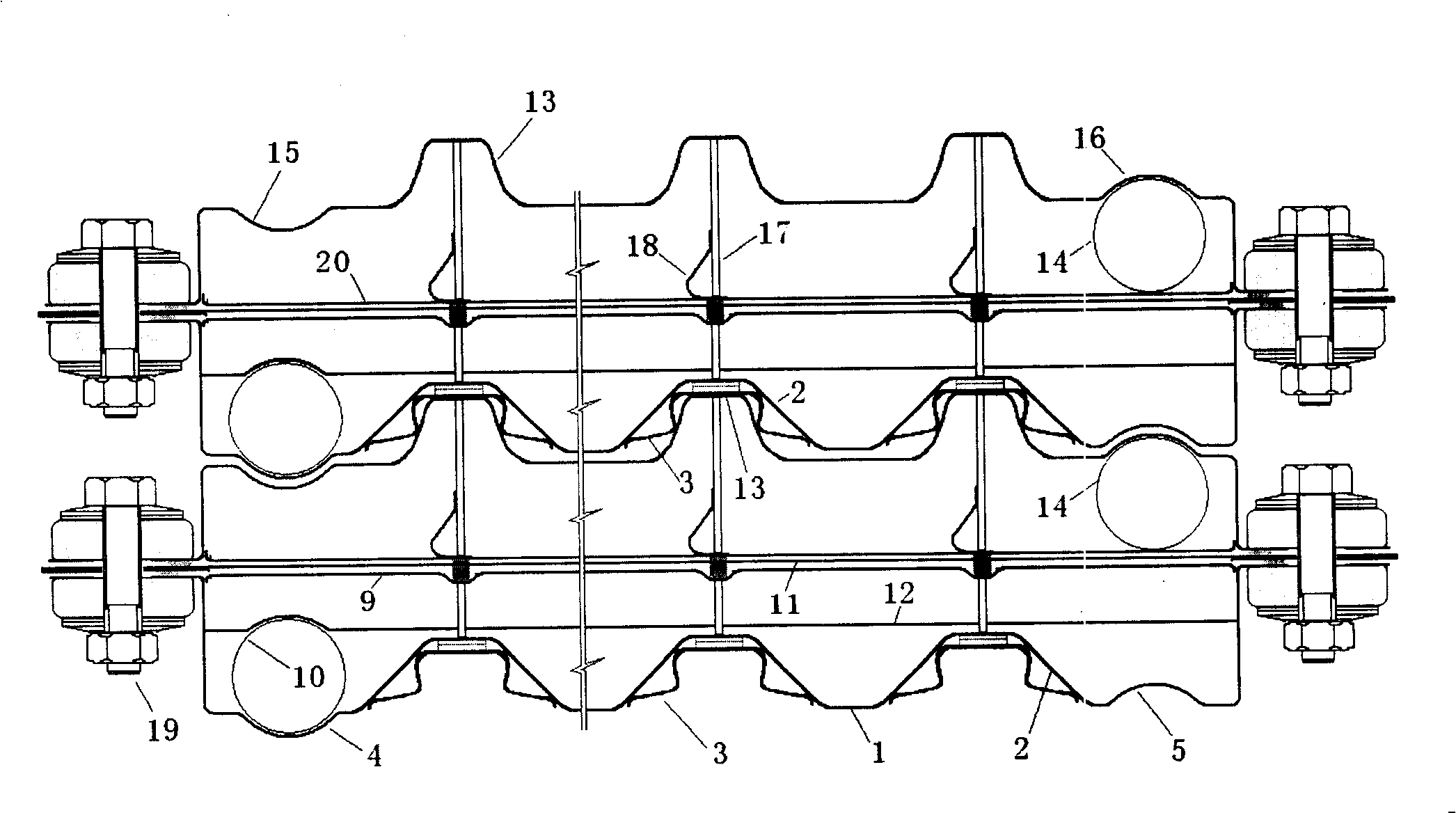

Fuel cell stack flow field plate capable of supporting high-current density discharging

ActiveCN108172857ASmall shape and position errorImprove consistencyCollectors/separatorsFluid fieldEngineering

The invention relates to a fuel cell stack flow field plate capable of supporting high-current density discharging. The fuel cell stack flow field plate comprises a negative flow field plate and a negative flow field plate, wherein back surfaces of the negative flow field plate and the negative flow field plate are oppositely connected, a water ripple-type air flow field passage and a water ripple-type hydrogen flow field passage are respectively processed in front surfaces of the negative flow field plate and the positive flow field plate, a cooling water flow field passage is processed between the back surfaces of the negative flow field plate and the positive flow field plate, a pair of common air passages, a pair of common hydrogen passages and a pair of common water passages are arranged on the negative flow field plate and the positive flow field plate and communicate with each other, and an air inlet / outlet, a hydrogen inlet / outlet and a cooling water inlet / outlet of an inlet port and an outlet port which are connected with the air flow field passage, the hydrogen flow field passage and the cooling water flow field passage are respectively formed. The flow field plate employs more optical runner design, more excellent material formula and more optimal assembly mode, so that the purposes of large-current discharging, temperature uniformity, low-temperature rapid startingsupporting, loading and rapid response to load change are achieved.

Owner:TONGJI UNIV

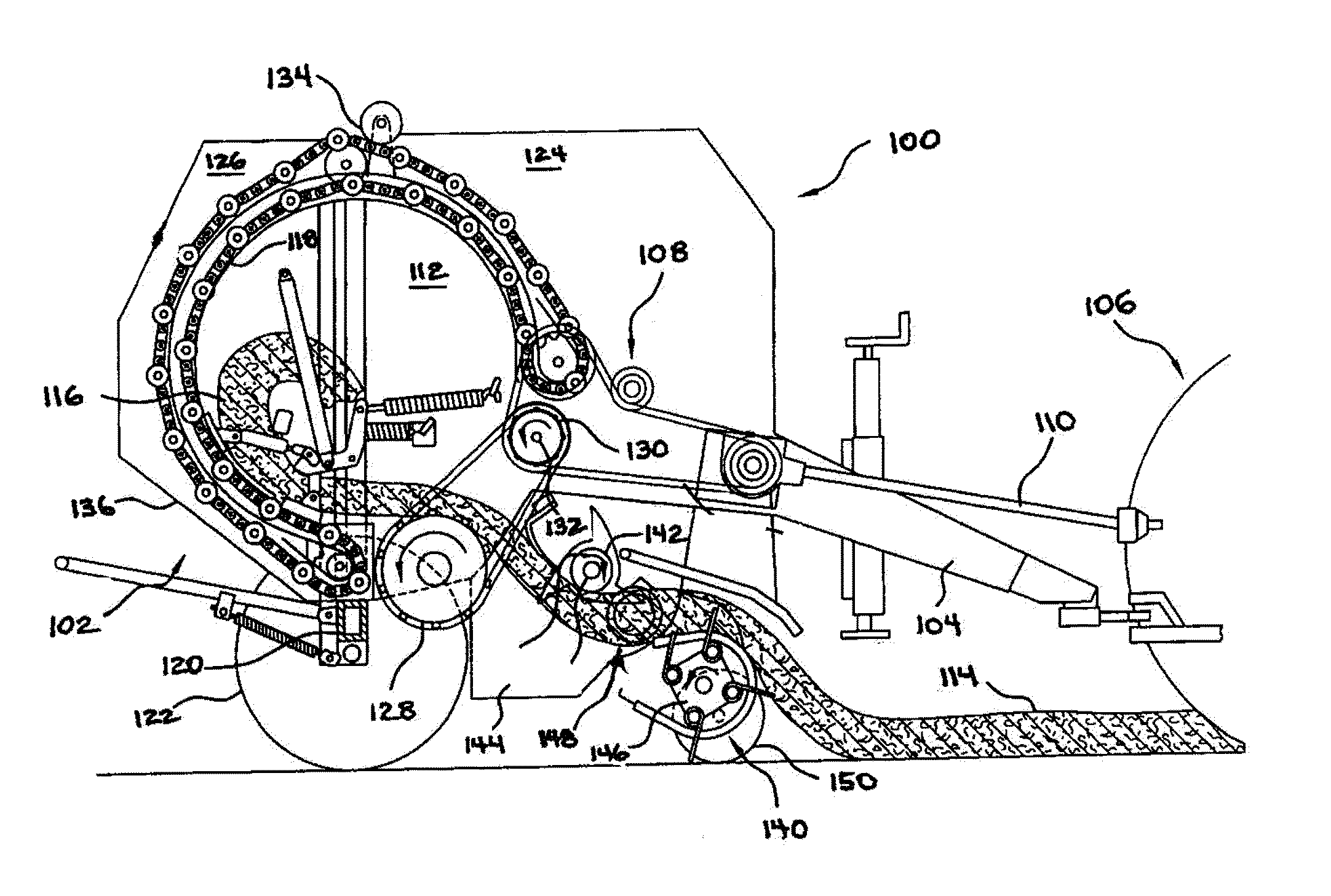

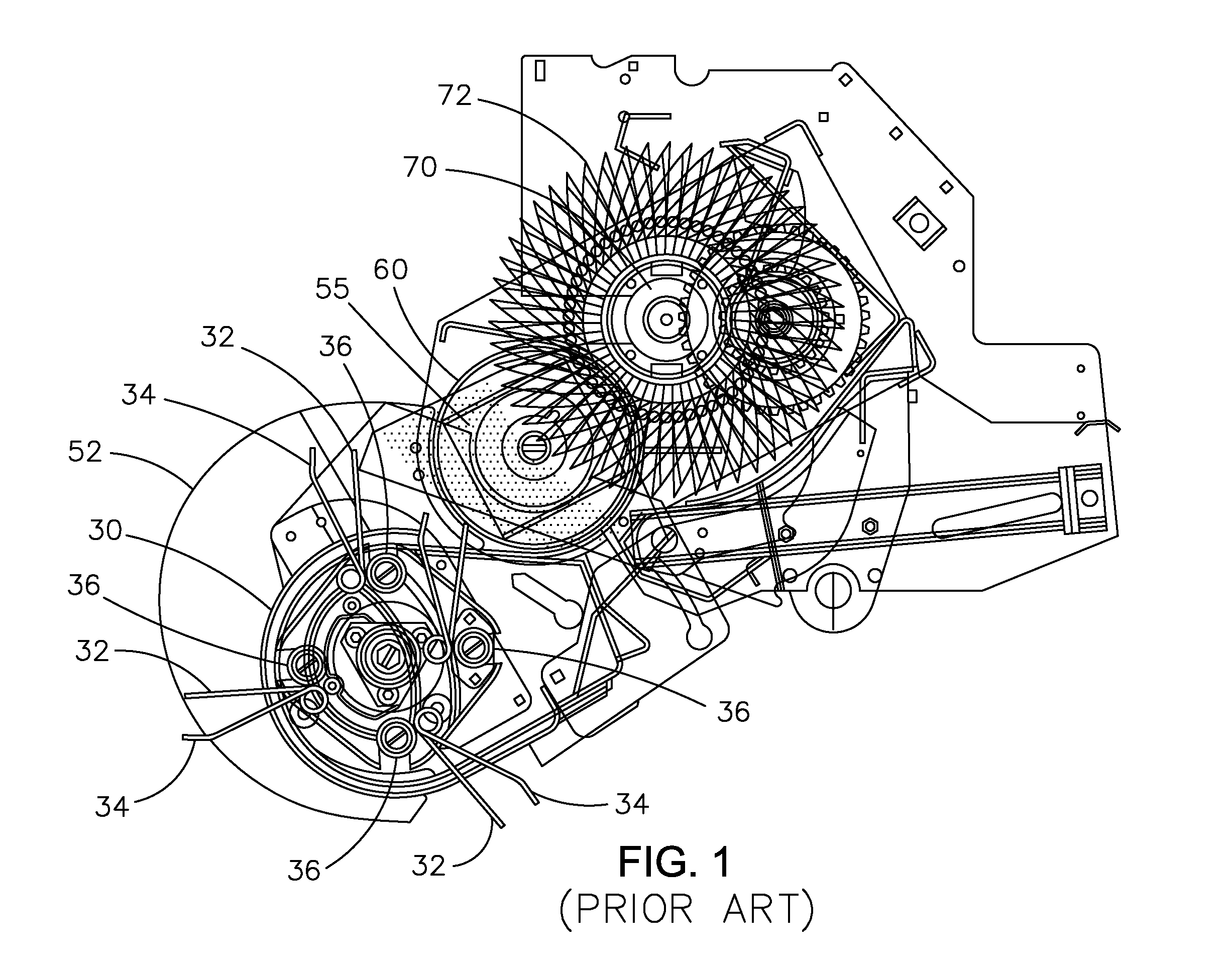

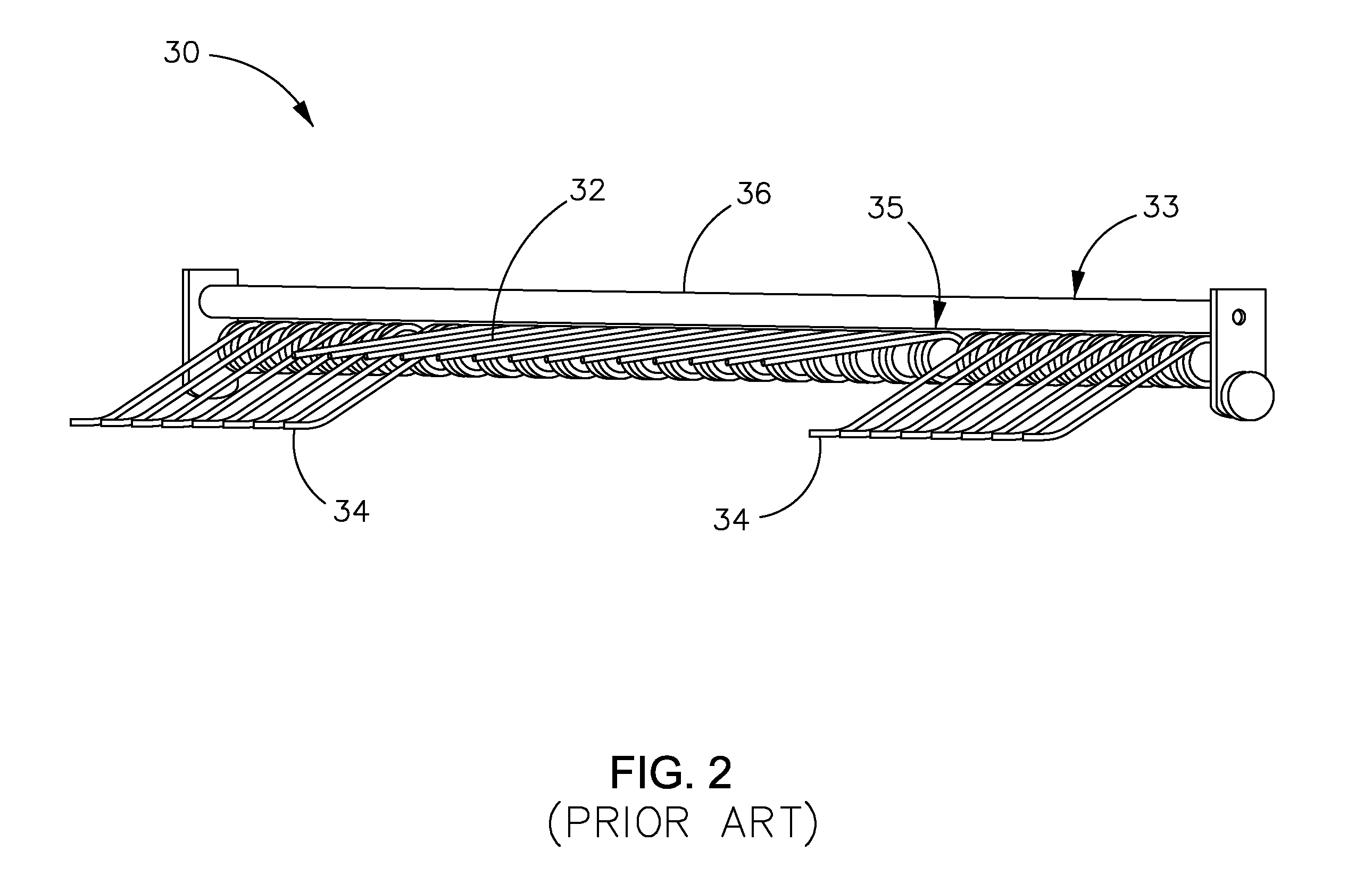

Offset pickup tines to improve feeding pick up

ActiveUS20110088365A1Reduce and substantially eliminate dead areaReduce dead areaLoadersMowersEngineeringMechanical engineering

An improved pickup comprising offset pickup tines for improved feeding of balers or harverters. The offset mounting of the rotor tines and auger tines of the pickup reduces and / or substantially eliminates the “dead area” between the pickup and the rotor during the handing off of crop from one feed mechanism to another feeding mechanism resulting in improved control of the crop as the crop travels through the machine. The rotor tines and the auger tines may comprise the same structure providing improved efficiencies in manufacturing, inventory and maintenance of the pickup equipment.

Owner:BLUE LEAF I P INC

Hot spraying rare earth aluminum alloy coating steel bar

ActiveCN110923616AImprove surface conditionImprove hardnessMolten spray coatingRebarBonding strength

The invention discloses a hot spraying rare earth aluminum alloy coating steel bar. A hot spraying manner is adopted, and the hot spraying rare earth aluminum alloy coating steel bar is prepared by spraying a rare earth aluminum alloy wire to the surface of a steel bar base body through mechanical rust removal, hot spraying, after treatment and other steps, wherein Si, Li, Ti, B, Mn, rare earth metal and the like can improve hardness, plasticity, tenacity, shielding performance and cathode protection capability of an aluminum alloy and a clad layer. A double-component waterborne polyurethane sealing agent and a finishing coat are adopted for treatment, cleanliness and environment friendliness are achieved, surface drying is rapid, and compatible bonding with concrete is easier due to the surface of the hot spraying rare earth aluminum alloy coating steel bar. According to the hot spraying rare earth aluminum alloy coating steel bar, the common technical problems that according to a current epoxy coating steel bar and a zinc-aluminum clad layer steel bar, the relative bonding strength with concrete is greatly reduced, the steel bar anchoring length is increased by 25%, anti-corrosion durability is insufficient, and notch and damaged positions are hard to repair on the site are solved, and good application prospects are achieved.

Owner:XUZHOU ZHONGKUANG ANFENG ENG TECH

Preparation method of series-parallel thin film battery assembly

ActiveCN106098809AIncrease power generationLower internal resistanceFinal product manufactureSemiconductor/solid-state device manufacturingLaser etchingPower station

The invention discloses a preparation method of a series-parallel thin film battery assembly. The method is mainly characterized in that a piece of TCO conductive glass is equally divided into two parts, which are the same in area, through a laser etching line, wherein the two parts are a series conductive portion and a parallel conductive portion, the series conductive portion is used for carrying out laser scribing on series sub-batteries, the parallel conductive portion is used for carrying out laser scribing on parallel sub-batteries, the series sub-batteries and the parallel sub-batteries are respectively connected by using a drainage strip and a bus bar, and then the series conductive portion and the parallel conductive portion are connected so as to manufacture the required series-parallel thin film battery assembly. According to the preparation method disclosed by the invention, a defect that the film uniformity is poor after large-area film plating is considered, characteristics of a series circuit and a parallel circuit are combined, and problems brought about by film difference and series connection of the sub-batteries are solved. Optimization for electrical parameters is carried out in allusion to a characteristic of high voltage or high current in the electrical parameters of a thin film battery, thereby avoiding influences imposed on such factors as inverter model selection and power station design in power station construction in a later period.

Owner:ZHONGSHAN RUIKE NEW ENERGY CO LTD

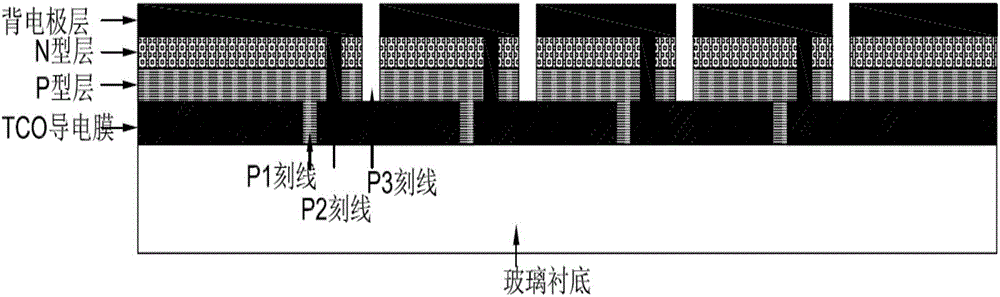

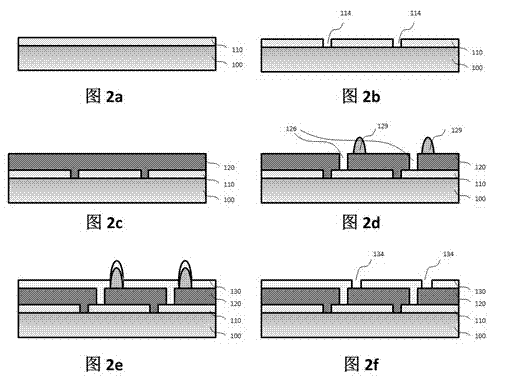

Drawing method of thin film solar cell and thin film solar cell device

ActiveCN102544197ASimple production methodThere is no positioning accuracy problemFinal product manufactureLaser beam welding apparatusEngineeringSemiconductor

The invention relates to a drawing method, especially relates to a drawing method of a thin film solar cell and a thin film solar cell device. The drawing method comprises three drawing lines (P2, P3, P1). According to traditional technology, drawing is conducted on a transparent conductive oxide film layer by means of laser. The drawing line (P1) penetrates through the transparent conductive oxide film layer, forming a first groove, and the drawing of drawing lines (P2, P3) is conducted after a semiconductor is coated with a film and before a back electrode is coated with a film. The drawing line (P2) penetrates through the semiconductor film layer, forming a second groove, in parallel with the first groove. The drawing line (P3) is provided with a soluble line which is disposed on the semiconductor film layer and in parallel with the second groove by means of soluble materials, and the soluble line is used as a preparation layer. The drawing device of the thin film solar cell combines a laser drawing device and a soluble line forming device on the same mechanical platform. The drawing device of the thin film solar cell has simple producing technology, low cost and can better cell performance and have long-term stability.

Owner:ZHEJIANG SHANGFANG ELECTRONICS EQUIP

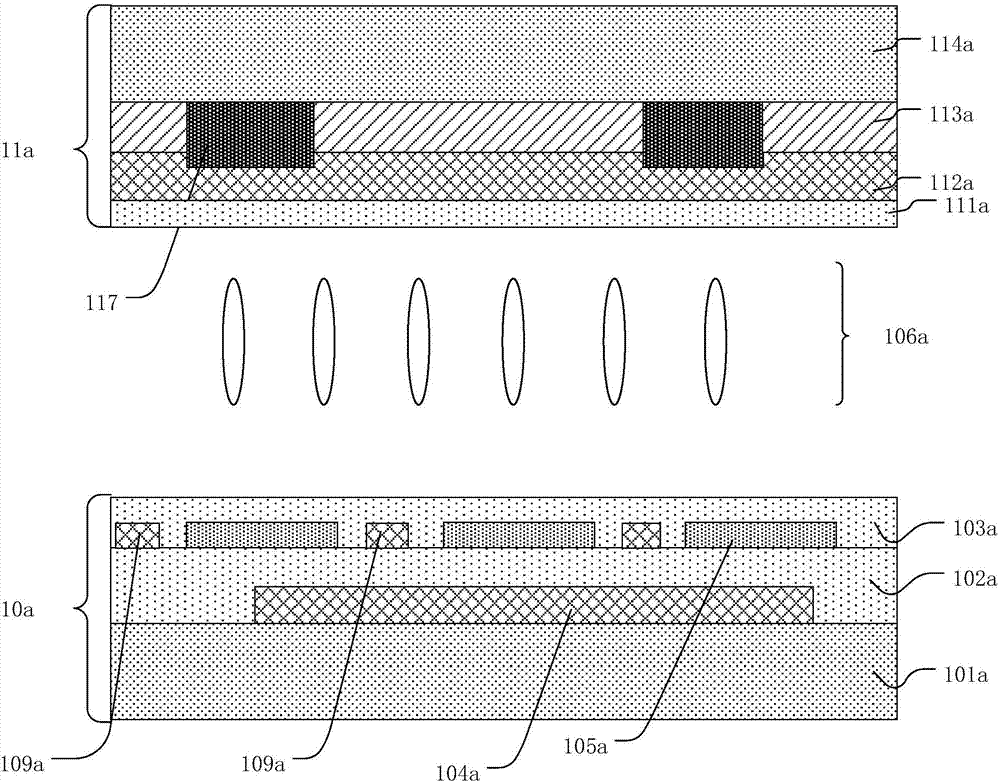

Touch display device

ActiveCN107422910AImprove experienceReduce dead areaNon-linear opticsInput/output processes for data processingDisplay deviceComputer science

The present invention relates to the technical field of touch control, and in particular, to a touch display device. The touch display device comprises: a color filter substrate; an array substrate opposite to the color filter substrate; a liquid crystal layer arranged between the color filter substrate and the array substrate; and a touch layer including a plurality of electrode groups for detecting touch. The plurality of electrode groups are arranged on the color filter substrate or the array substrate; each of the electrode groups comprises a plurality of electrodes; each electrode in the plurality of electrode groups comprises a grid structure and electrode leads connected with the grid structure; and in each of the electrode groups, the electrode size gradually decreases in at least one direction, so that the space for electrode lead extension is provided. The design can effectively reduce the dead zone area, and change the dead zone shape, so that the user experience is improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

Monolith for use in regenerative oxidizer systems

InactiveUS20070160943A1Reduce dead areaIncrease the lengthCombination devicesBurnersEngineeringMechanical engineering

A ceramic packing element comprising a monolith structure having a generally block shape and having plurality of equally spaced parallel openings therein extending the length of the block where the openings have generally straight sides and corners which are rounded. The corners are substantially radiused to produce the rounded corners. For example, where the openings in the element are between 1.8 and 6.5 mm, the radius will be between 0.3 and 1.8 mm. The block element will have between 20 to 60 cells by 20 to 60 cells totaling between 400 to 3600 cell elements.

Owner:LEXCO

Thermal spraying rare earth alloy coated rebar

ActiveCN111020447AImprove surface conditionTightly bondedMolten spray coatingAnti-corrosive paintsAlloyRebar

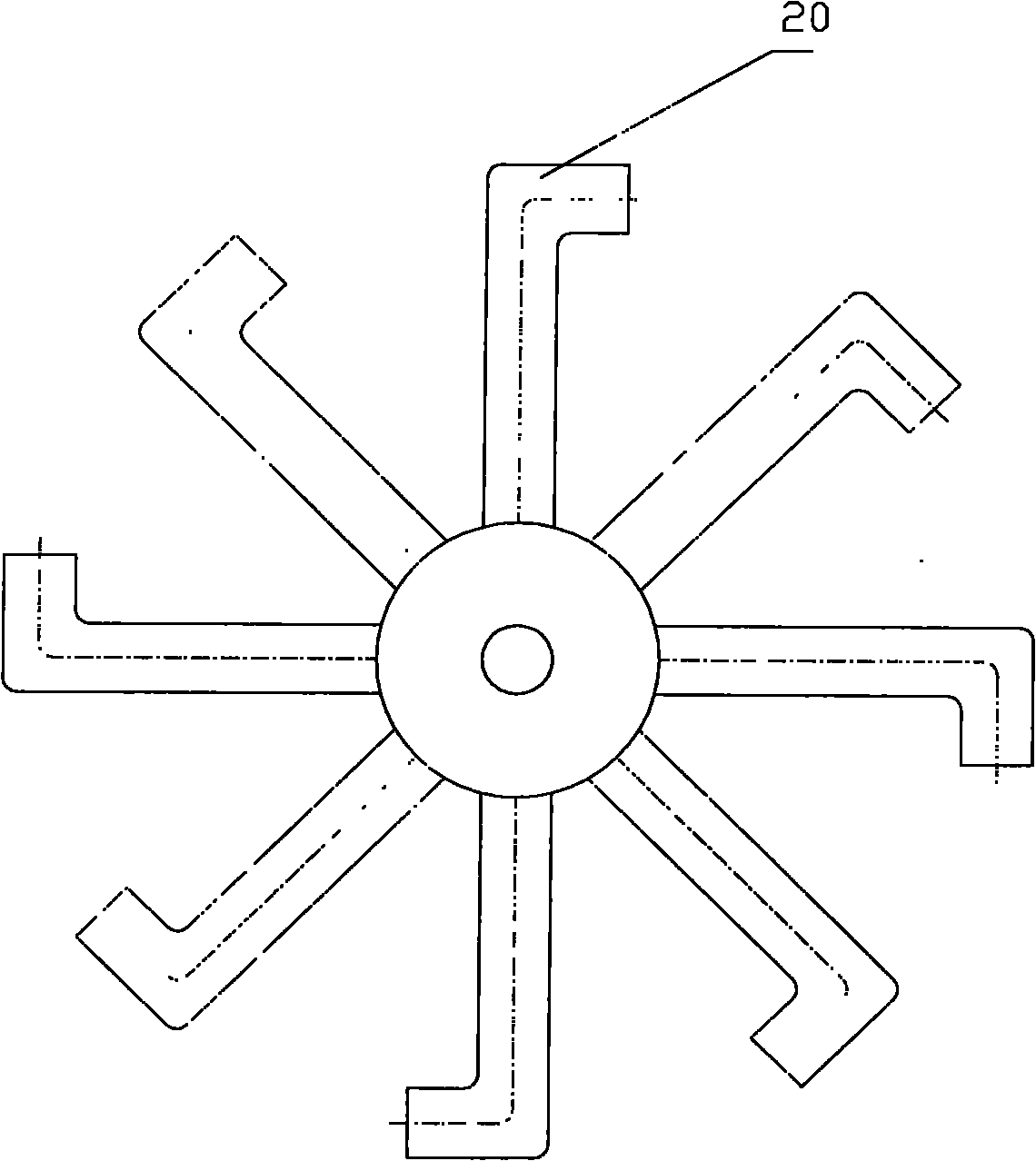

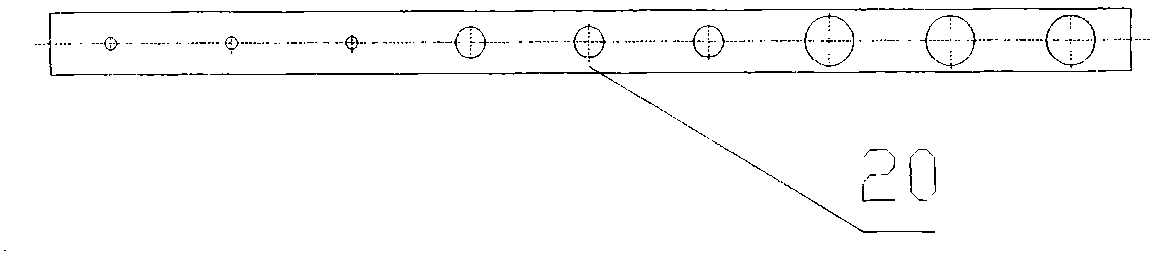

The invention discloses a thermal spraying rare earth alloy coated rebar. A thermal spraying mode is adopted, through the steps of mechanical derusting, thermal spraying, post-processing and the like,a rare earth alloy wire is sprayed onto the surface of a rebar substrate to prepare the thermal spraying rare earth alloy coated rebar, the rare earth alloy wire is mainly composed of Zn and Al and evenly added with Si, Li, Cu, Zr, V, Ti, B, Mn, rare earth metals and the like, and the hardness, plasticity and toughness of alloy and a coating as well as the shielding performance and cathode protection performance of a metal thermal spraying coating are improved; a two-component water-based polyurethane sealing agent and finish paint are adopted for processing, and the surface of the rebar canbe compatible with and adhere to concrete more easily; and the production effect is improved by adopting production lines of a structure in a cross shape, in a shape like the symbol '*', in a shape like the Chinese character 'mi' and the like. According to the thermal spraying rare earth alloy coated rebar, the common technical problems that at present, the relative adhesion strength between epoxycoated rebars and concrete as well as between zinc-aluminum coated rebars and concrete is substantially reduced, the anchorage length of the rebars is increased by 25%, the corrosion resistance and the durability are poor, and notches and damaged positions are difficult to repair on site are solved, and the good application prospect is achieved.

Owner:XUZHOU ZHONGKUANG ANFENG ENG TECH

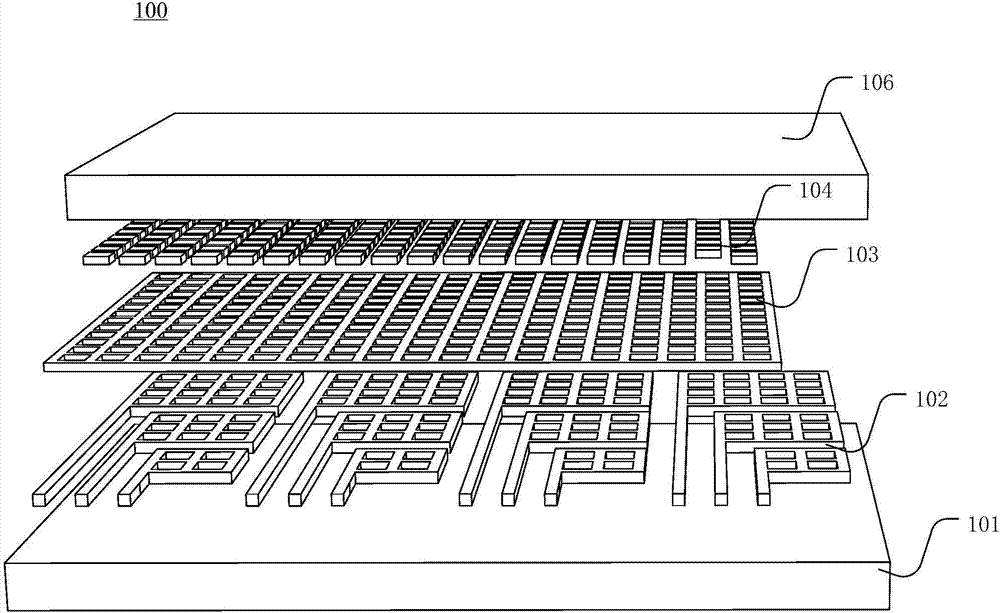

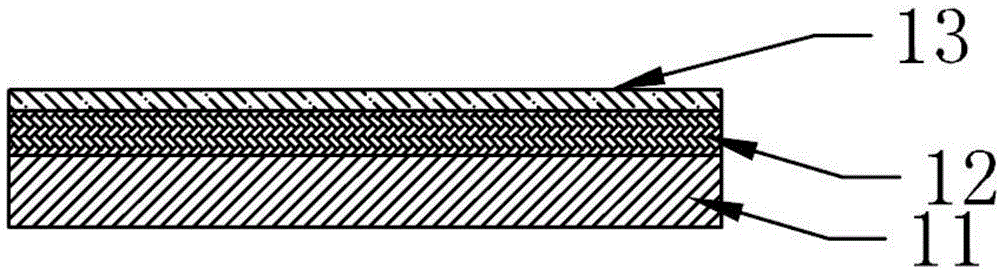

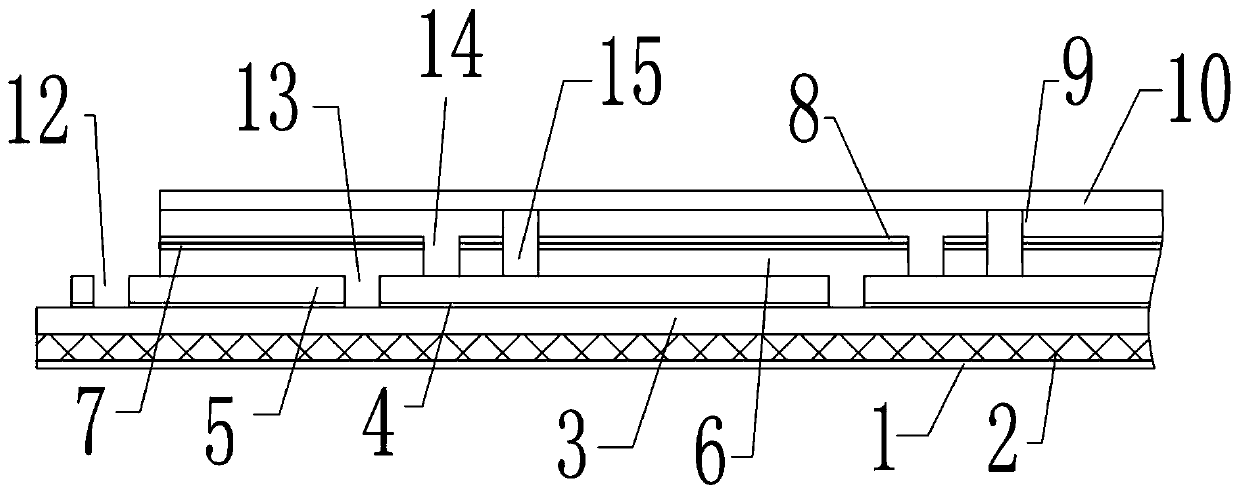

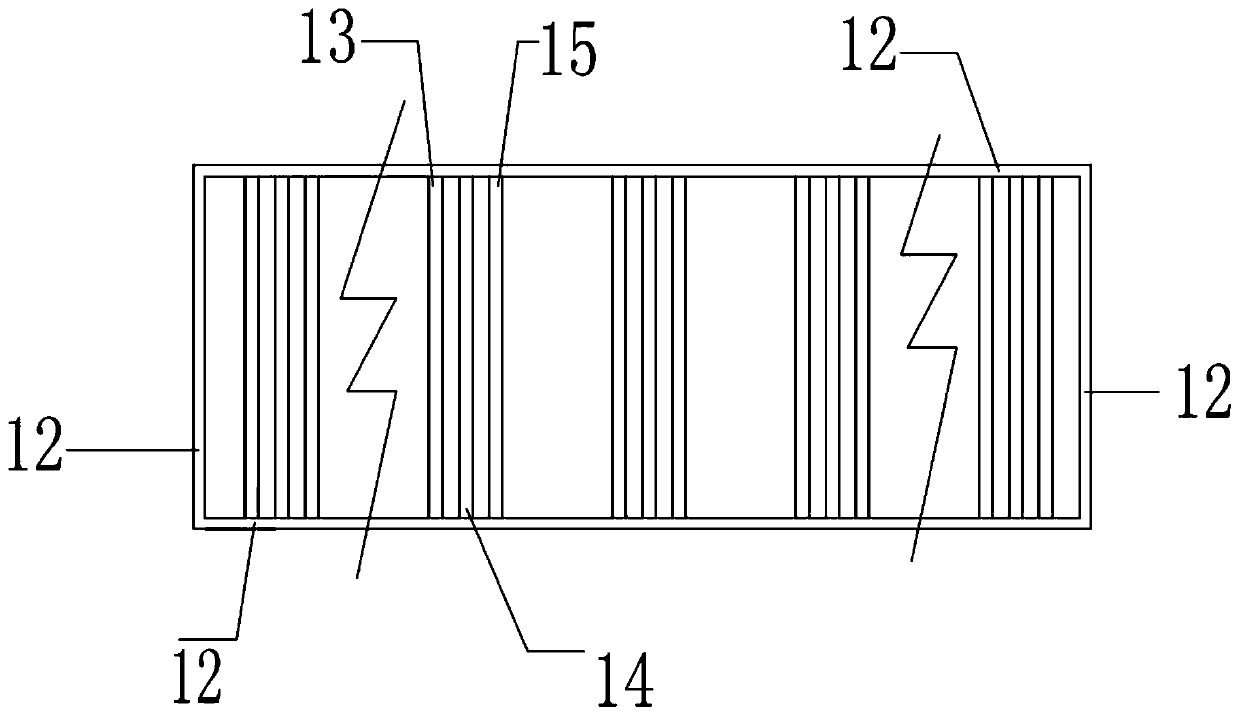

Solar cell module and manufacturing method thereof

ActiveCN108550647AEliminate contact resistanceReduce dead areaFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention belongs to the field of solar cells, and particularly relates to a solar cell module and a manufacturing method thereof. The solar cell module comprises multiple serially connected sub-cells. Each sub-cell comprises a base electrode, an electronic transmission layer, an optical active layer, a hole transmission layer and a top electrode successively from the bottom to the top. The polarities of any two adjacent sub-cells are opposite to each other on the serial connection circuit of the solar cell module. The base electrodes of any two adjacent sub-cells on the serial connectioncircuit are directly connected with each other or directly connected with the top electrodes. According to the invention, middle ineffective area used for connecting the sub-cells can be effectively reduced; space filling factors of the module are improved; meanwhile, contact resistance of upper and lower electrodes is eliminated; and performance of the cell is further improved. According to the invention, it is potentially possible to achieve highly-efficient large-area solar cells.

Owner:HUAZHONG UNIV OF SCI & TECH +1

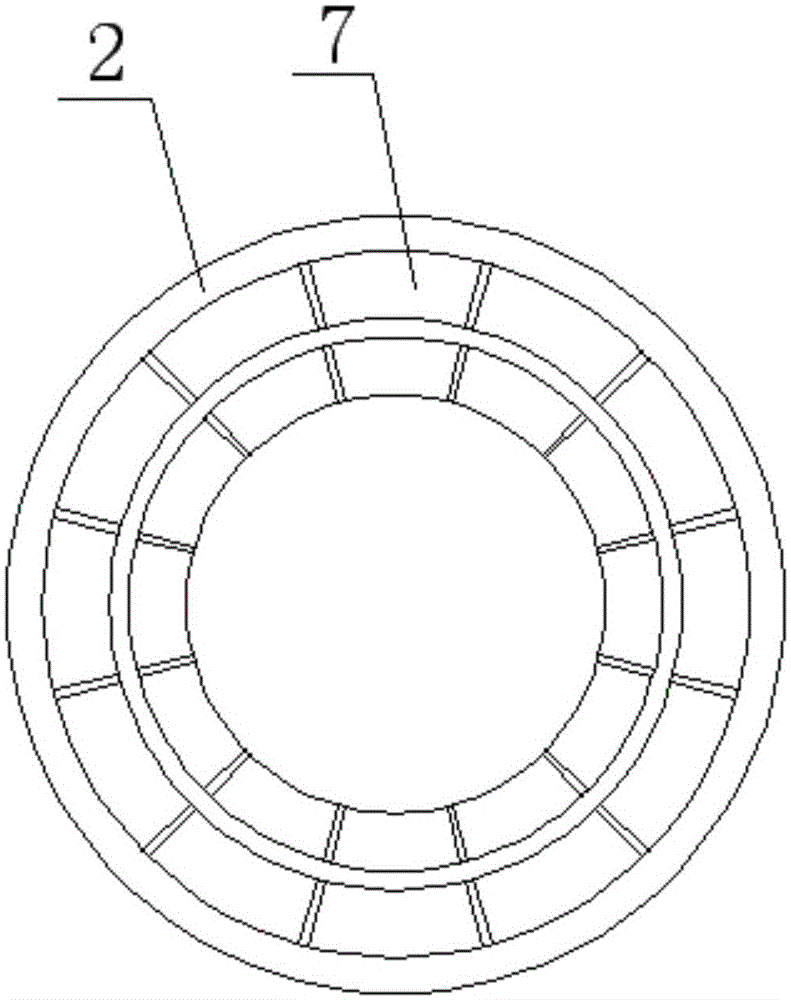

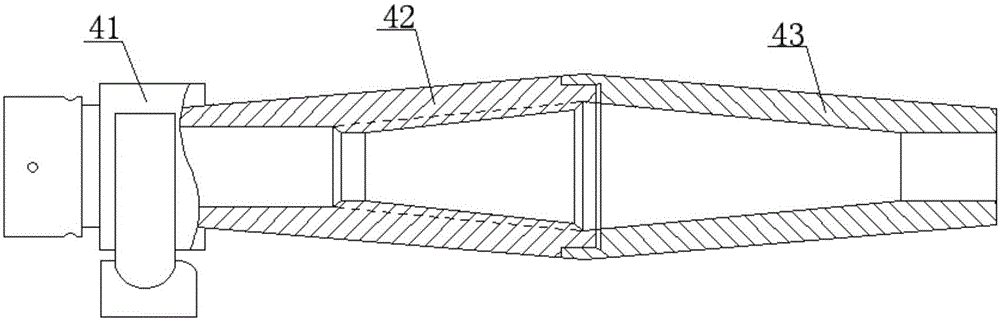

Mining rotor type variable shotcrete machine

InactiveCN105019921AVolumetric Efficiency MaximizationImprove Section UtilizationUnderground chambersTunnel liningShotcreteDrive motor

The invention discloses a mining rotor type variable shotcrete machine. The mining rotor type variable shotcrete machine comprises a frame, a rotor block, a drive motor, a gun head injection pipe and a hopper, wherein a plurality of U-shaped cavities penetrating through the rotor block and having fan-shaped sections are distributed in the rotor block in the circumferential direction; the gun head injection pipe comprises a conical spiral feeding pipe and a conical discharging pipe, one end, with smaller diameter, of the conical spiral feeding pipe is connected with an injection pipe base, and the other end is connected with one end, with larger diameter, of the conical discharging pipe; with the adoption of the U-shaped cavity structures, the fan-shaped cavities replace cylindrical cavities, so that the volume efficiency of the cavities realizes maximum, the section utilization rate of the rotor block is increased, air feeding and material discharging are more continuous and more uniform, the pulse phenomenon of material discharging is greatly reduced, and resilience and dust are reduced. Meanwhile, the gun head injection pipe is spliced by two sections of conical pipes, so that an injection material and water are mixed sufficiently and uniformly, the injection quality is improved, the injection layer is more compact, and homogeneity and strength are improved.

Owner:淮南久辉工贸有限责任公司

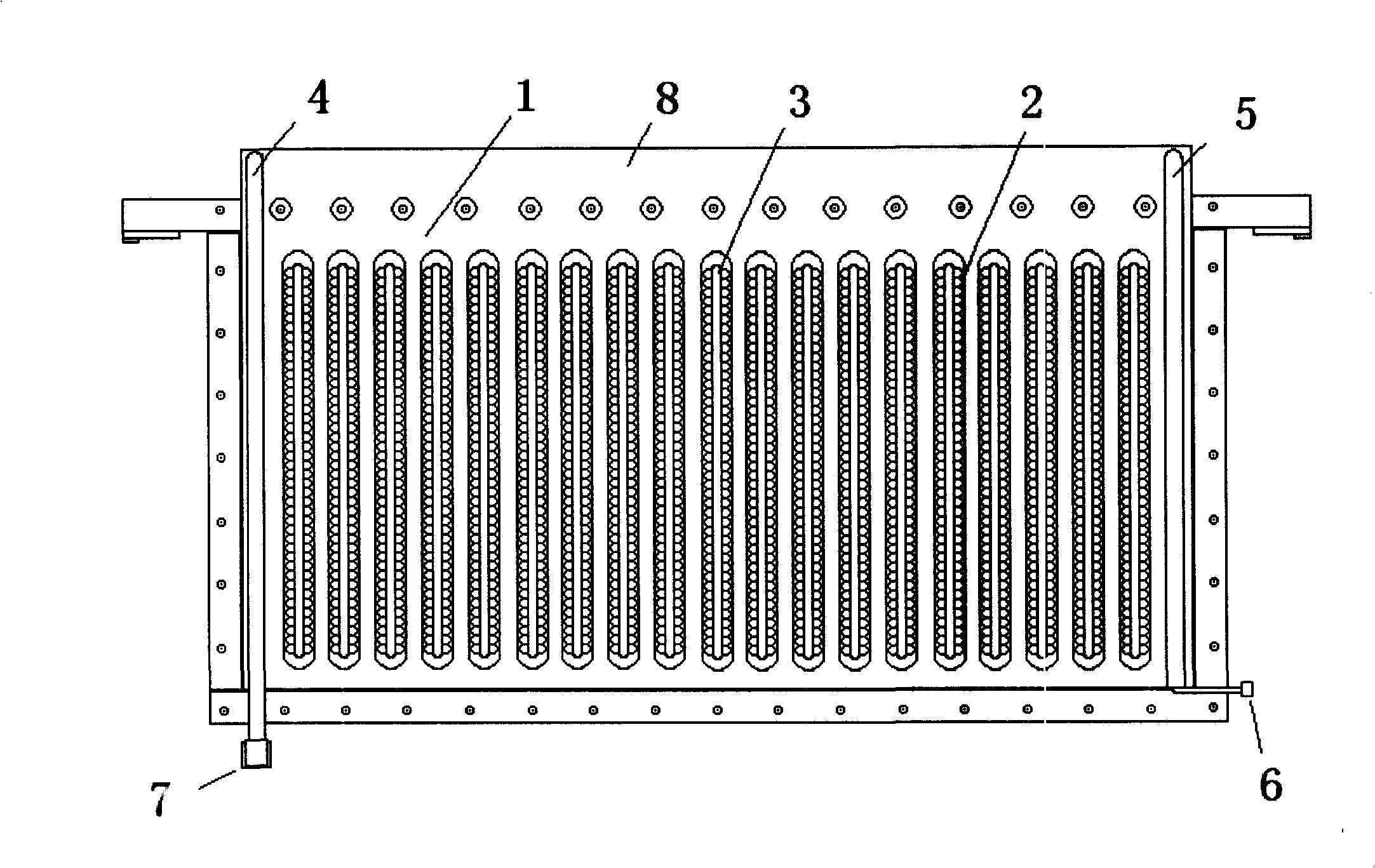

Electrode structure for electrochemical device

InactiveCN101265587AIncrease the conductive contact areaReduce contact currentCellsElectrode shape/formsEngineeringChemical property

An electrode component used for an electrochemical appliance comprises a tray-shaped trough main body; a sealing edge extending outwards on the periphery of the tray; a porous electrode covering the tray surface and on the same level as the periphery; and an electric supporting element for connecting the electrode with the back wall of the tray. The technical points are as follows: as an anode component, the anode tray is provided with leading grooves protruding inwards, the leading grooves are provided with electric springs on the inner walls, the two ends of the anode tray are respectively provided with a guide slot equipped with a communicating tube; as a cathode component, the cathode tray is provided with tongues protruding outwards, the two ends of the cathode tray corresponding to the anode tray are respectively provided with a guide slot equipped with a communicating tube, each tongue of the cathode tray are corresponding to the leading grooves on the anode component side; the communicating tubes arranged in the guide slots on the two sides of the trays are connected with a gas-liquid separation chamber on the upper part of the tray, the lower parts of the communicating tubes are connected with an outlet at the bottom of the tray. The structure can protect physical and chemical properties of the film to a greatest extent and prolong the service life of the film and the trough.

Owner:刘国桢

Thin film solar cell production method and electrodeposition device thereof

ActiveCN104091854AIncrease contact areaReduce contact resistanceFinal product manufacturePhotovoltaic energy generationElectricityContact electrode

The invention provides a thin film solar cell production method and an electrodeposition device thereof. The method comprises the steps that a transparent conductive layer is deposited on a glass substrate; a window layer is formed on the transparent conductive layer; an absorption layer is electrodeposited on the window layer; a contact electrode is removed, and a contact electrode gap is produced at the position of the original contact electrode; a first trench is drawn; the first trench and the remaining contact electrode gap are filled; a second trench is drawn; a back contact layer and a back electrode are deposited; a third trench is drawn; and the position of the contact electrode gap and the position of the first trench and / or the second trench and / or the third trench partially or completely overlap. According to a solar cell production device and method in the existing technology, the photoelectric conversion effective area in the unit area of a solar cell is small. According to the thin film solar cell production method and the electrodeposition device thereof, the photoelectric conversion effective area in the unit area is large.

Owner:北京恒昀动力科技有限公司

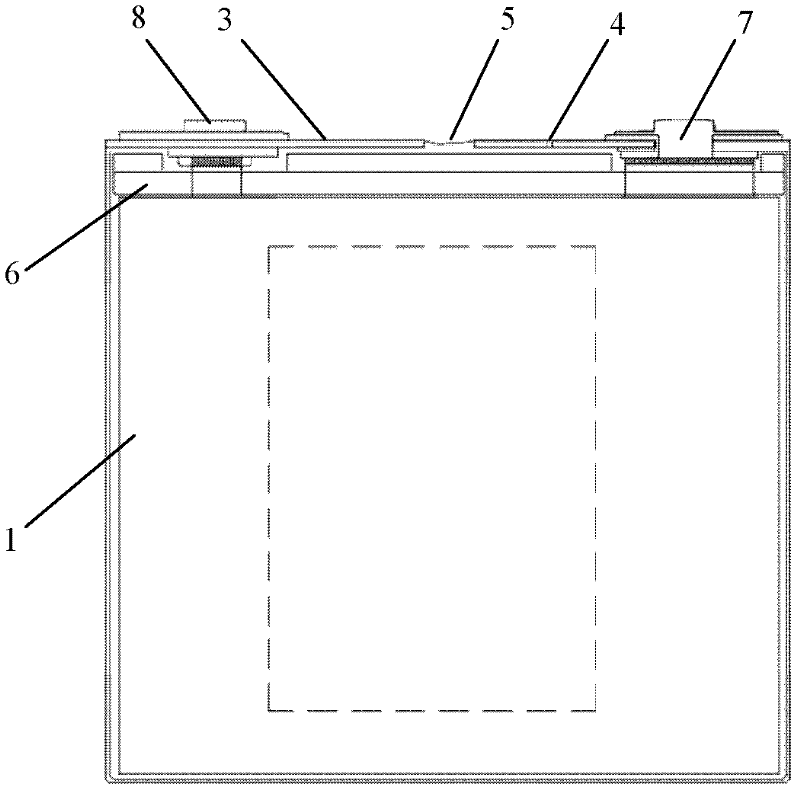

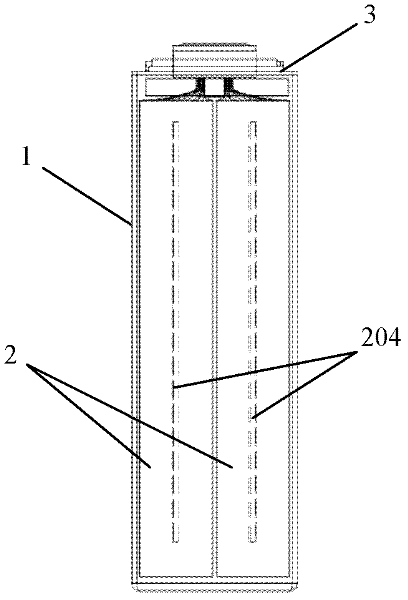

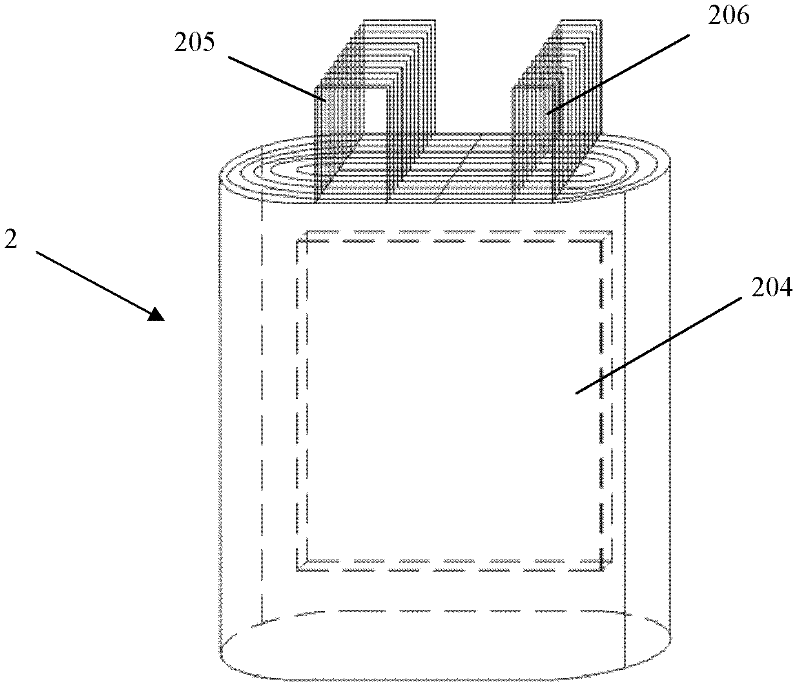

High-capacity lithium ion battery

InactiveCN102340036AUniform responseImprove electrical performanceFinal product manufactureSecondary cellsElectrical batteryLithium-ion battery

The invention discloses a high-capacity lithium ion battery, which comprises a shell. Battery core pole groups are arranged in the battery shell. The tops of the battery core pole groups are provided with a battery cover on which a filling port is formed. A safety valve is welded at the central position of the battery cover. The battery core pole group comprises a positive plate, a diaphragm, a negative plate and an elastic core plate. The positive and negative plates are wound on the elastic core plate. The diaphragm is arranged between the positive and negative plates to separate the positive and negative plates. A positive tab and a negative tab are positioned at the top ends of left and right sides of the pole group respectively, and are correspondingly connected with a cathode and an anode on the battery cover by a positive wire and a negative wire on the two sides of the battery cover respectively. By the high-capacity lithium ion battery with such a structure, the dead zone area of the battery plate is decreased, the electrical properties and safety performance of the battery are improved, and the high capacity and high-current output of the battery can be ensured.

Owner:LISHEN POWER BATTERY SYST CO LTD

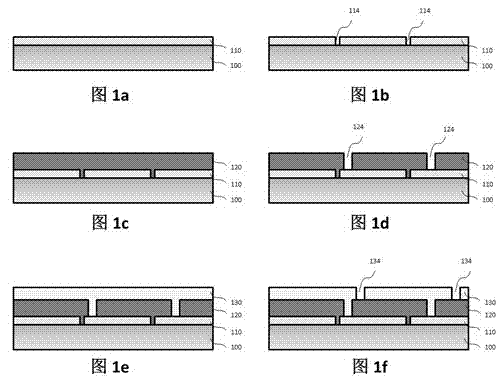

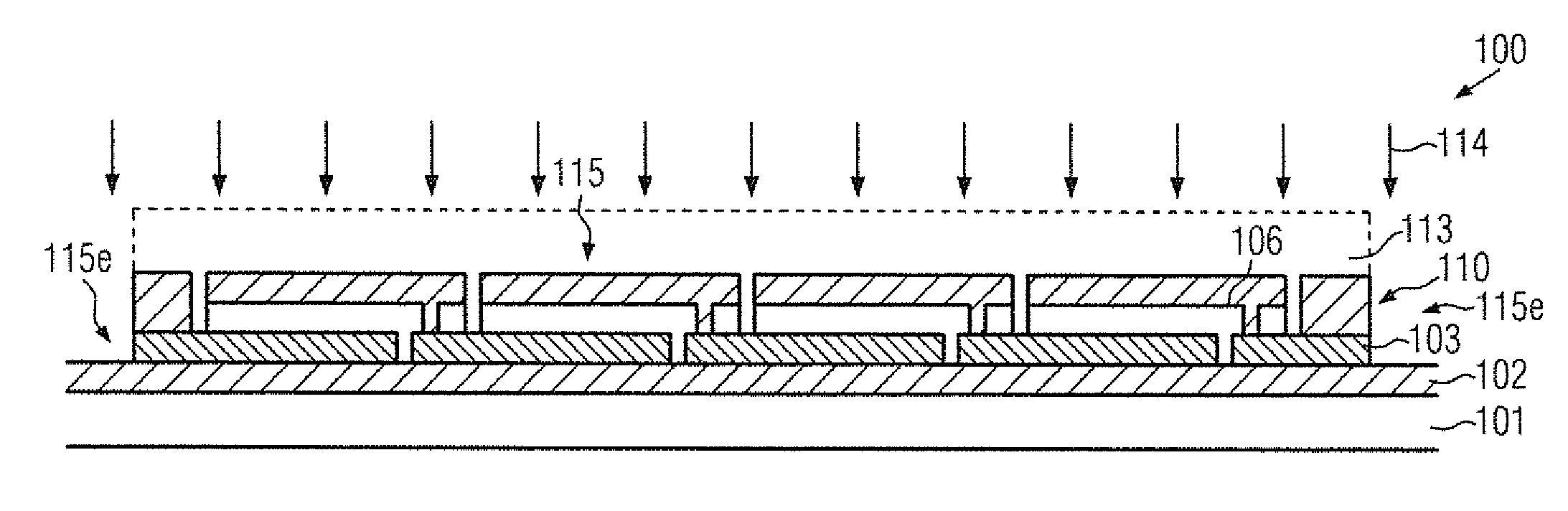

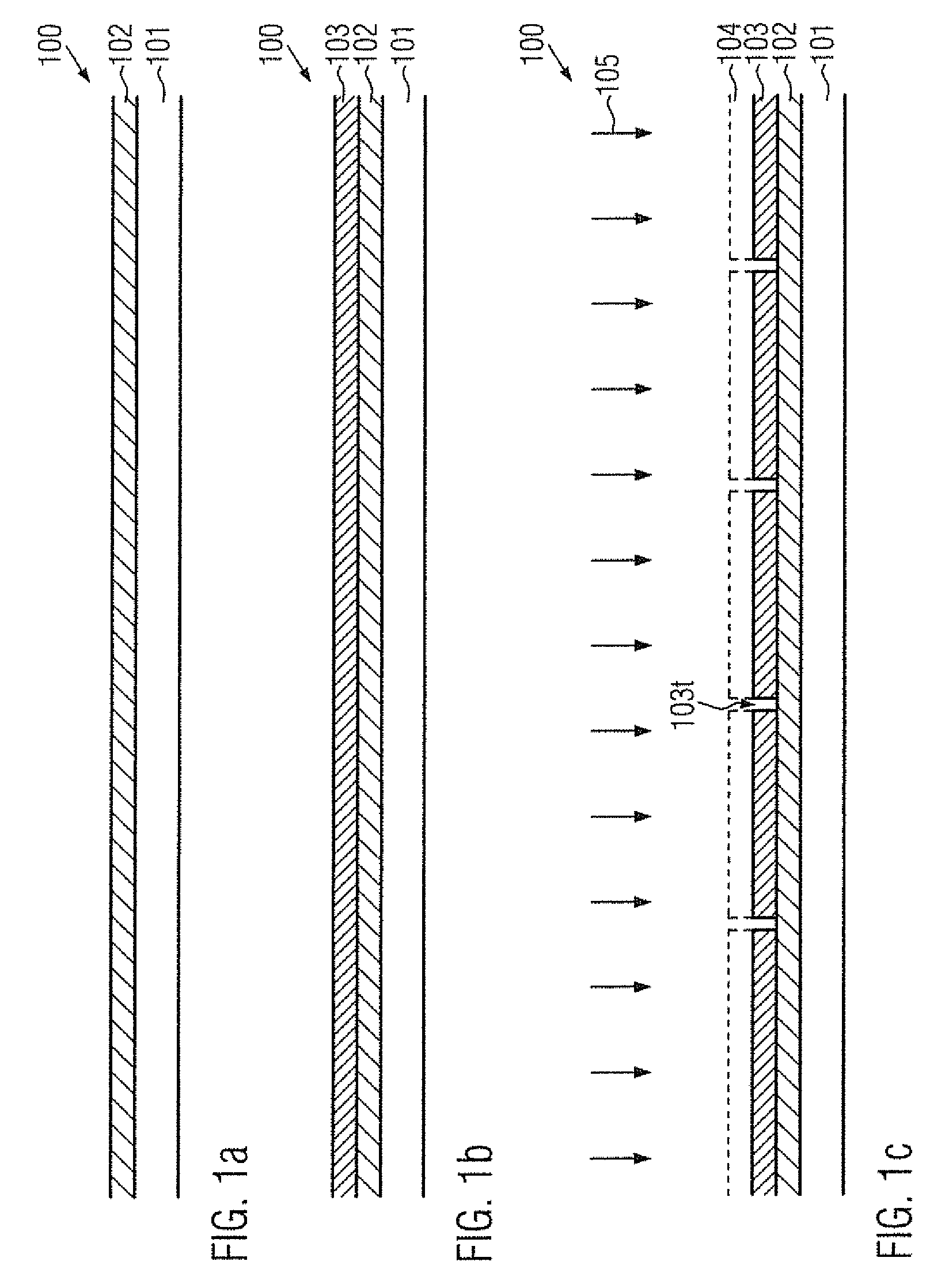

Thin film solar cell module including series-connected cells formed on a flexible substrate by using lithography

ActiveUS20130032197A1Reduce dead areaReduce probabilityPV power plantsSemiconductor/solid-state device manufacturingLithographic artistEngineering

Solar thin film modules are provided with reduced lateral dimensions of isolation trenches and contact trenches, which provide for a series connection of the individual solar cells. To this end lithography and etch techniques are applied to pattern the individual material layers, thereby reducing parasitic shunt leakages compared to conventional laser scribing techniques. In particular, there may be series connected solar cells formed on a flexible substrate material that are highly efficient in indoor applications.

Owner:STMICROELECTRONICS SRL

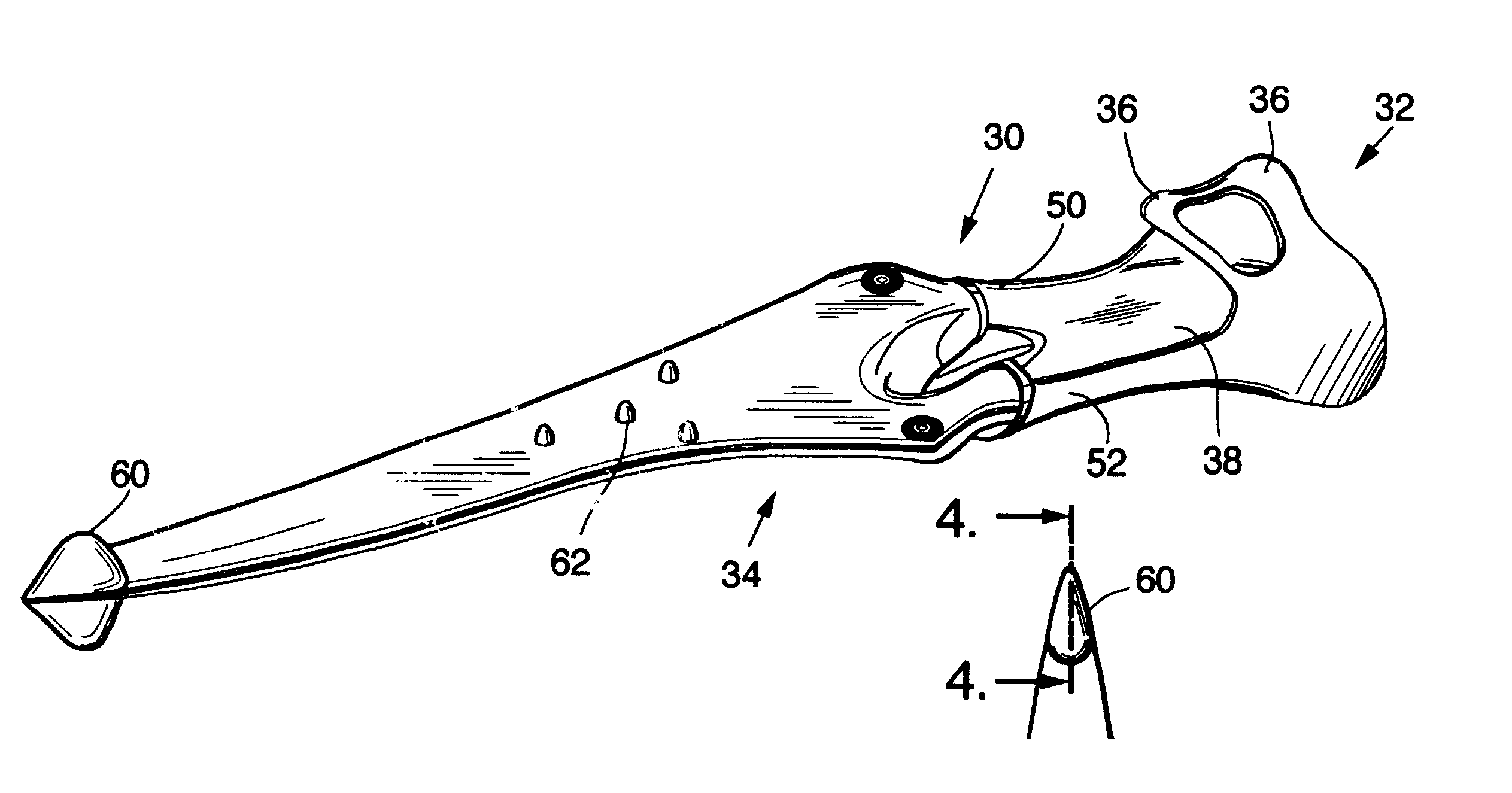

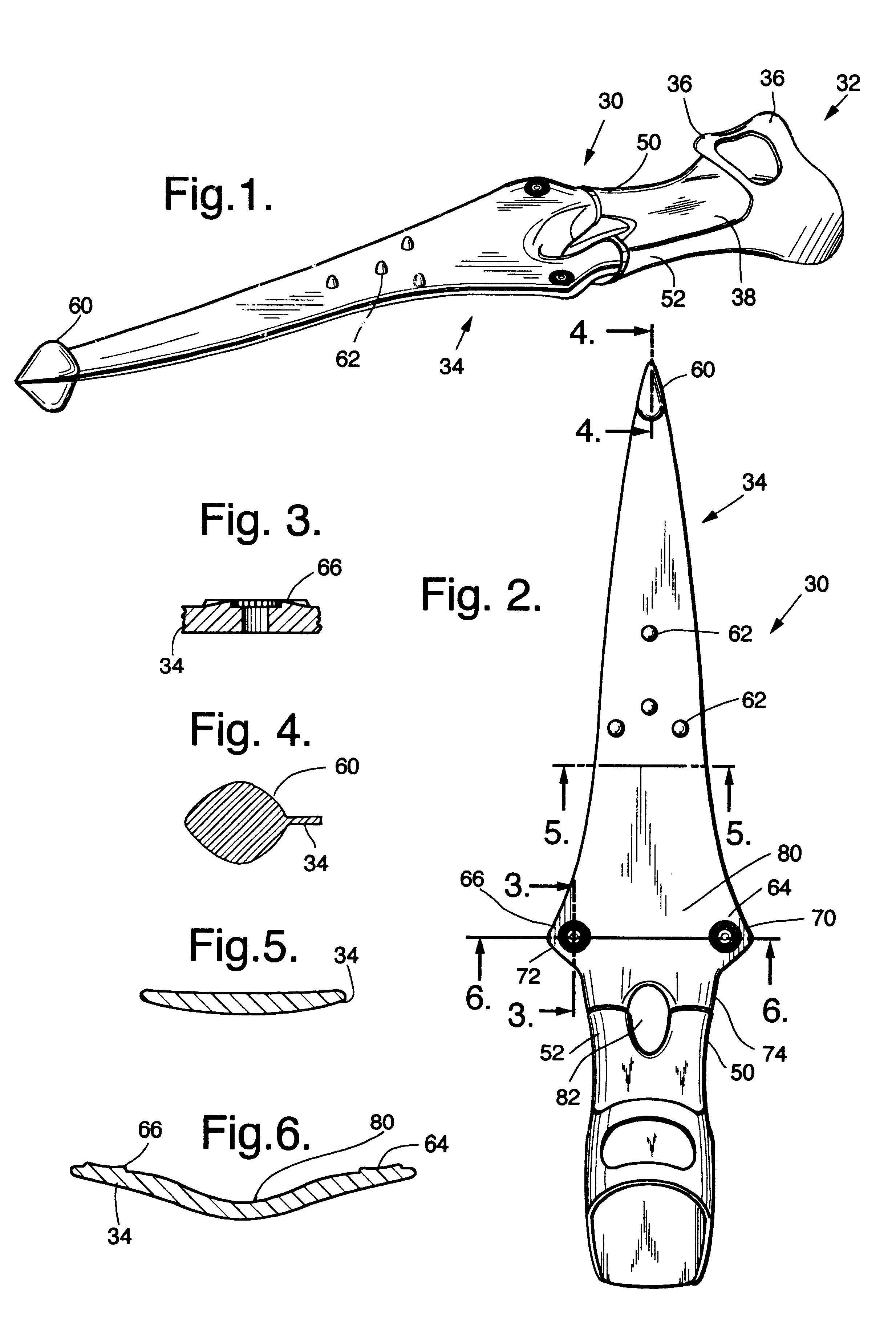

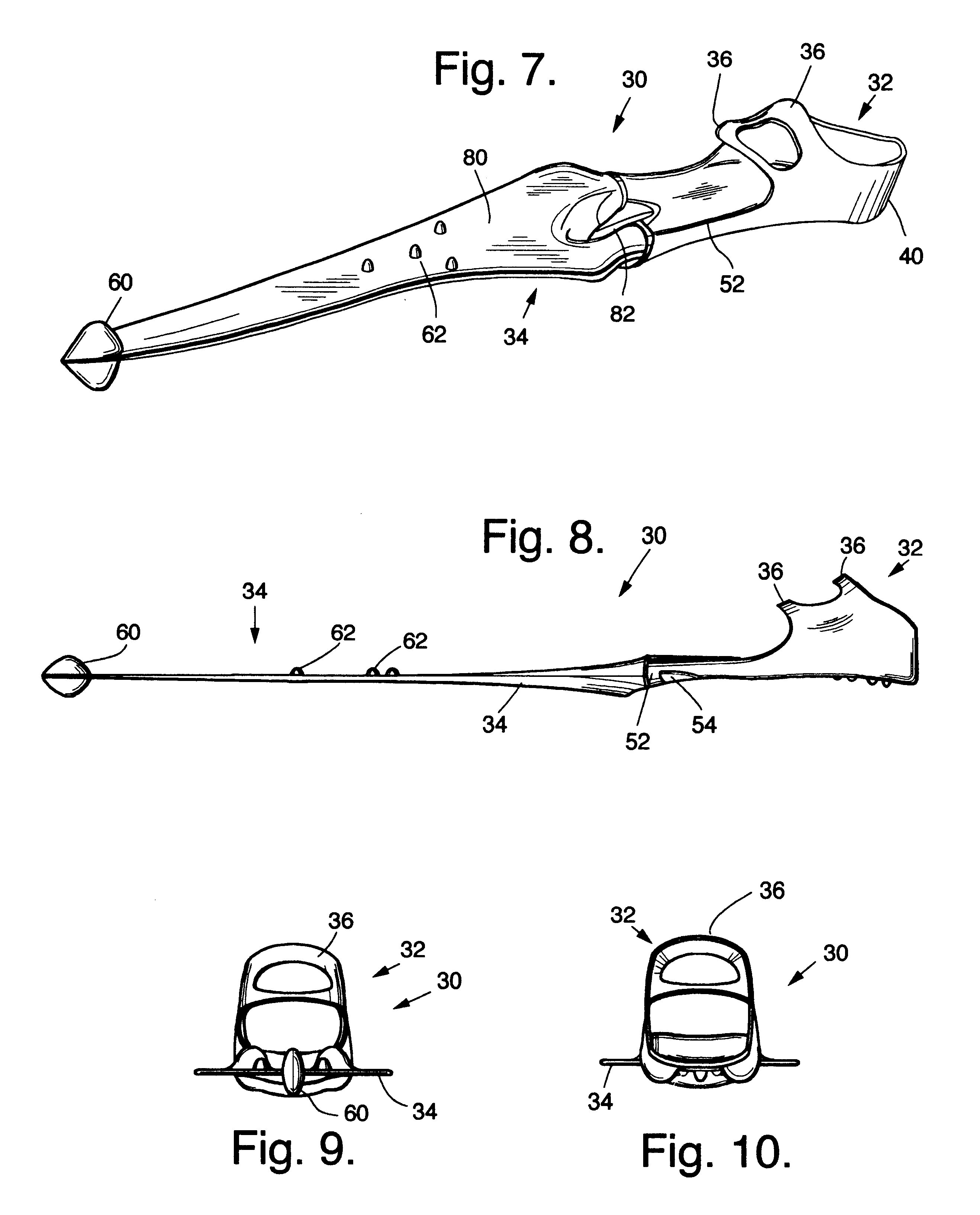

Spear-blade swim fin

Spear-bladed swim fins provide new means by which divers may propel themselves through the water. Spear-bladed swim fins generally provide a lower surface area to a higher perimeter edge length. By reducing the effective surface area of the swim fin, more propulsive force is delivered by the fin for each kick of the diver. Such dispersion of the diver's energy may be particularly advantageous where stationery swimming is required, as for underwater photography. Additionally, vortices generated during swim kicks may advantageously complement the operation of the swim fin. In the first embodiment, the spear blade is narrow. In a second embodiment, the spear blade is wider but has a larger channel through which water can flow to eliminate dead spots on the lee side of the fin. Fork extension stubs present with the foot pocket of the swim fin provide an adjustable means by which the flexing, bowing, and / or geometry of the swim fin blade may be adjusted according to the preferences and / or demands of the diver.

Owner:EVANS ROBERT B

Preparation method of flexible supercapacitor positive electrode material

ActiveCN110739162ALower internal resistanceReduce dead areaMaterial nanotechnologyElectrolytic inorganic material coatingElectrolytic agentIonic conductivity

The invention discloses a preparation method of a flexible supercapacitor positive electrode material. The preparation method comprises the following steps: firstly, nickel ions and cobalt ions are co-deposited on the surface of three-dimensional graphene foam by electrochemical method to obtain supercapacitor positive electrode material, and the morphology and the properties of the material are modified with different electrochemical deposition time to improve the conductivity, the ionic conductivity and the electron mobility of the material. The prepared positive electrode material has petalshape, and its nano sheets are formed by stacking 3-5 nanometer grains which are evenly distributed and have a larger reaction interface area with the electrolyte so that more electrochemical redox reaction charges can be generated and significant improvement of the material performance can be realized. The test results of the electrochemical energy storage performance of the material show that the material has excellent electrochemical energy storage performance and cycle stability. The material also has quite good flexibility based on the graphene foam.

Owner:CHINA-SINGAPORE INT JOINT RES INST

Production method of film solar cell and electro-deposition device thereof

ActiveCN105206703AReduce dead areaAvoid occupyingFinal product manufactureSemiconductor devicesElectrical isolationElectricity

The invention provides a production method of a film solar cell. A first groove is filled with a substance identical with an absorption layer, and the substance of the absorption layer is a semiconductor; the vacancy of a long-strip-shaped contact electrode is directly filled with a substance identical with a back electrode, and the direct contact resistance between the back electrode and the absorption layer is very large, so that no influenced are caused to serial connection of solar cell units; and that is to say, the film solar cell does not need to be filled by an electrical-isolation substance, the electrical-isolation substance does not participate in photoelectric conversion, and the area of a dead area is reduced, so that the occupation of the solar cell by the electrical-isolation substance is avoided, and the photoelectric conversion area of the solar cell is increased. In addition, when the used contact electrode is the long-strip-shaped contact electrode, the long-strip-shaped contact electrode is removed after electro-deposition, then a long-strip-shaped contact electrode vacancy is obtained, and the original groove etching process is omitted, so that the wastes of production materials are reduced, the processes are saved, and the production cost is further lowered.

Owner:BEIJING HI TECH WEALTH INVESTMENT DEV

Radiation image device

ActiveUS20090224166A1Suppressing forming of dead areaImaging characteristicTelevision system detailsLayered productsRadiation imagingScintillator

Wiring substrates 11 and 12 are positioned on a fixed base 10 in a manner such that there is a step between the wiring substrates, and radiation imaging elements 2 and 3, respectively having scintillators 25 and 35 deposited on photosensitive portions 21 and 31, are respectively mounted on the wiring substrates 11 and 12. The radiation imaging element 2 is positioned so that its setting surface protrudes beyond a radiation incident surface of the radiation imaging element 3, and the photosensitive portion 21 of the radiation imaging element 2 and the photosensitive portion 31 of the radiation imaging element 3 are juxtaposed to a degree to which the portions do not overlap. The photosensitive portion 21 of the radiation imaging element 2 extends close to an edge at the radiation imaging element 3 side and the scintillator 25 of substantially uniform thickness is formed up to this position.

Owner:HAMAMATSU PHOTONICS KK

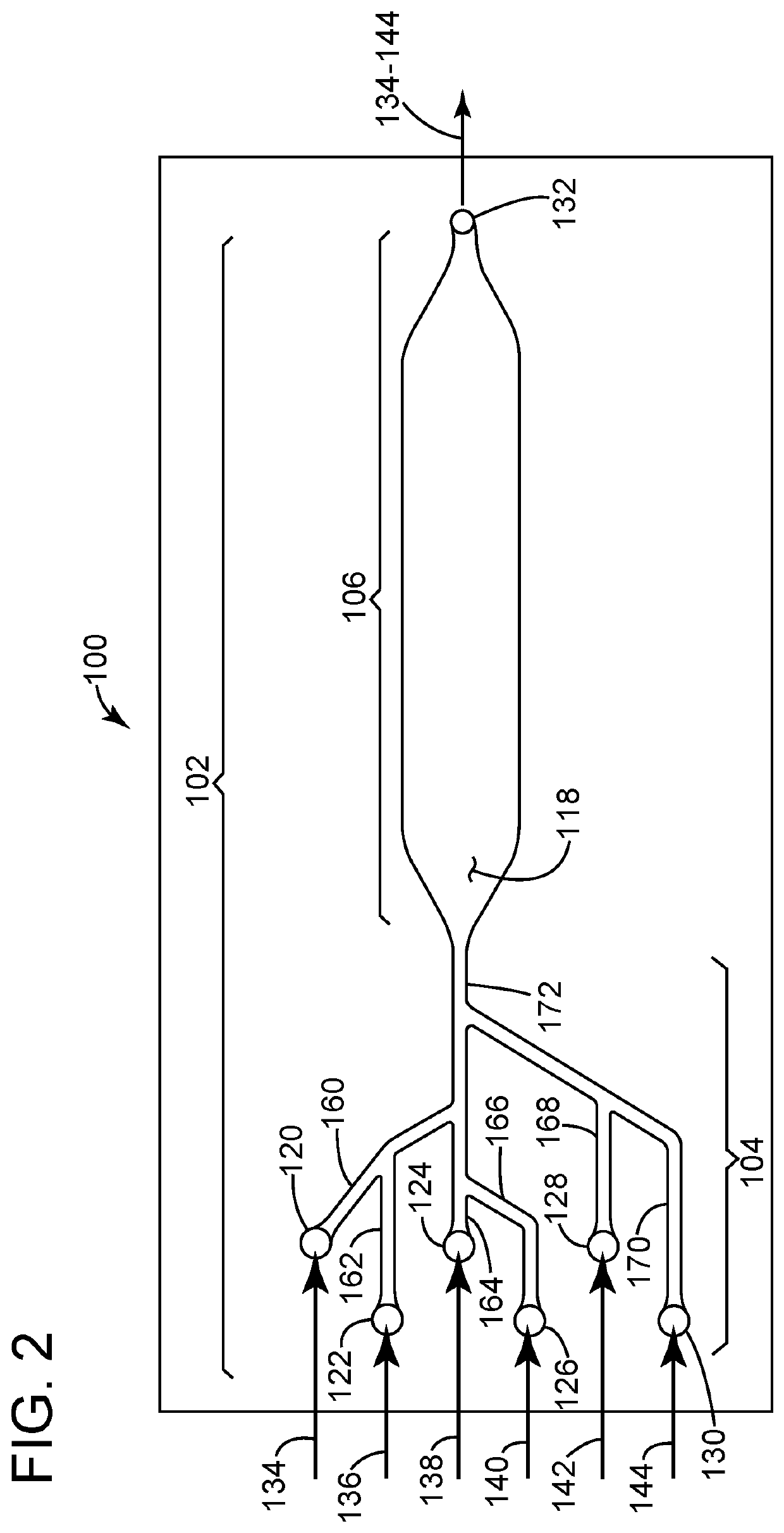

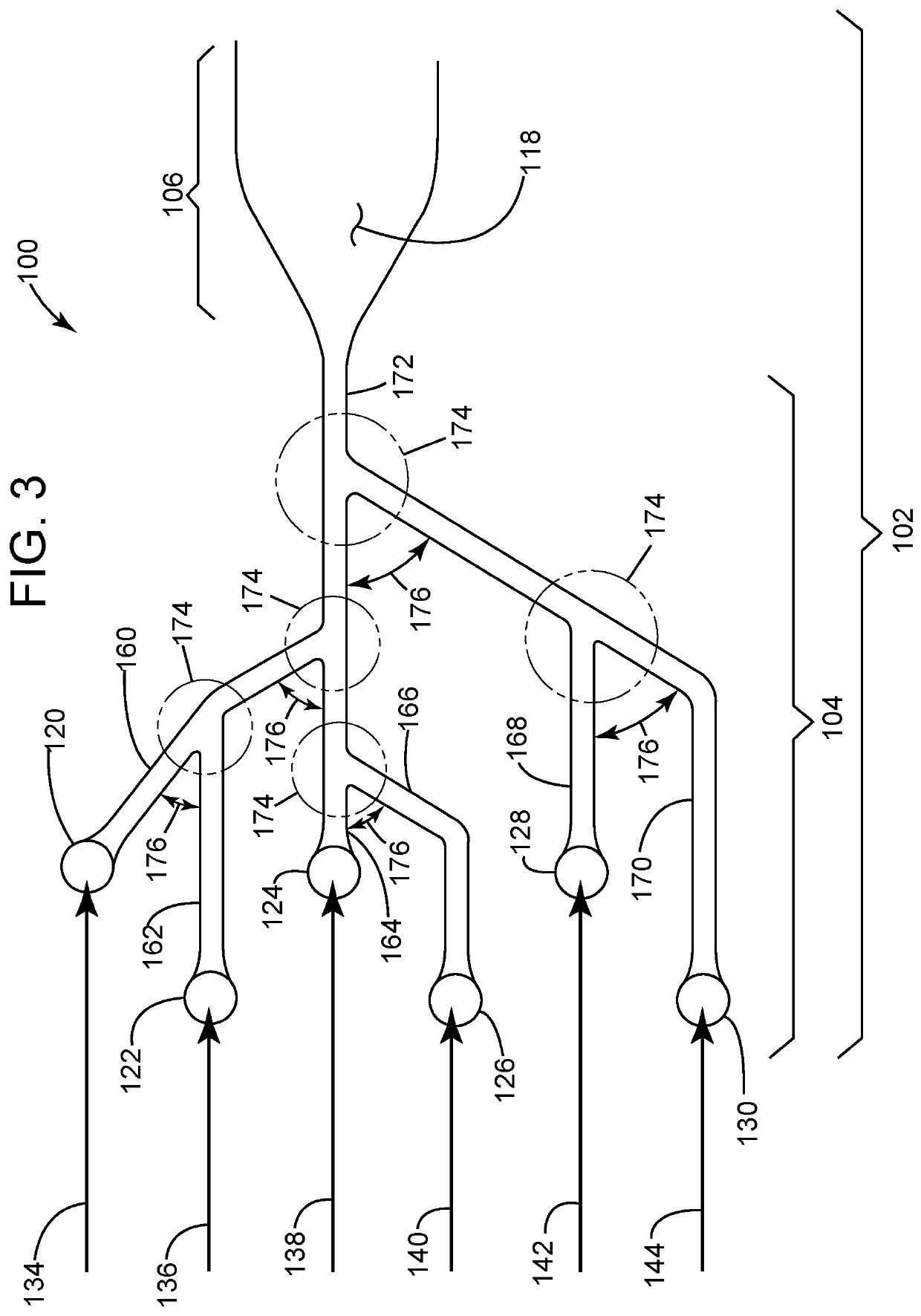

Flow cell with integrated manifold

ActiveUS20190336970A1Reduce dead areaMaterial analysis by optical meansLaboratory glasswaresAnalyteFlow cell

In one example, a flow cell includes a plurality of inlet ports sized to receive a flow of reagent from one of a plurality of reagents into the flow cell. An outlet port of the flow cell is sized to pass each flow of reagent out of the flow cell. A flow channel of the flow cell is positioned between, and in fluid communication with, each inlet port and the outlet port. The flow channel includes a manifold section and a detection section. The manifold section has a plurality of manifold branches in fluid communication with a common line, wherein each branch is connected to one of each inlet port. The detection section is in fluid communication with the common line and the outlet port. The detection section is operable to perform a plurality of different chemical reactions between the plurality of reagents and analytes positioned in the detection section.

Owner:ILLUMINA INC

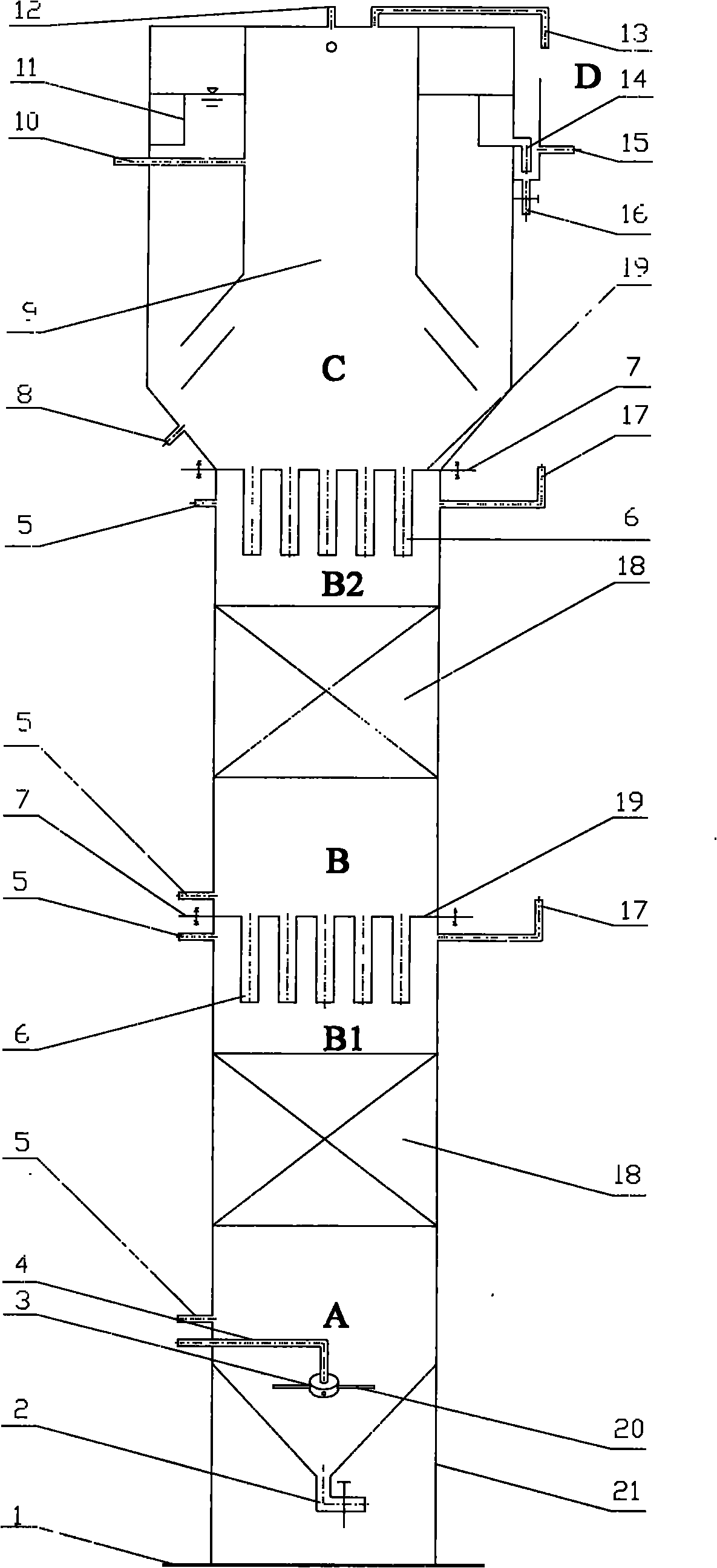

Augmentin strain enrichment expanding culture reactor

ActiveCN101948742AImprove mass transfer effectReduce dead areaBioreactor/fermenter combinationsBiological substance pretreatmentsDistribution systemMass transfer

The invention discloses an Augmentin strain enrichment expanding culture reactor. The main body of the reactor comprises a water distribution system, a reaction system, a isolation system and a liquid seal system from the bottom up, wherein the water distribution system comprises a water inlet pipe and a rotational flow water distributor; the reaction system comprises a main reaction zone and an auxiliary reaction zone; and the isolation system comprises a three-phase isolator and a sedimentation zone. The invention has the main advantages that (1) the unique rotational flow water distributorensures even water inflow; (2) caged floating ball stuffing is beneficial to retaining sludge and accelerating the start of the reactor; (3) a five-pipe baffle enhances the mass transfer effect and reduces the area of a dead zone; (4) sectional gas collection eliminates the gaskick phenomenon and promotes the sludge to be granulated; (5) a dual-efficiency three-phase isolator effectively isolatesgas, liquid and solid; and (6) two stages of reaction zones are connected in series, and thereby, matrix backmixing can be restrained and the treatment efficiency is improved.

Owner:ZHEJIANG UNIV

High-water-resistance flexible internal-series-connection CIGS solar cell and preparation method thereof

PendingCN110265508AHigh water resistance and oxygen resistanceReduce packaging costsFinal product manufacturePhotovoltaic energy generationProduction lineHigh resistance

The invention discloses a high-water-resistance flexible internal-series-connection CIGS solar cell and a preparation method thereof. The high-water-resistance flexible internal-series-connection CIGS solar cell comprises a flexible substrate; a back protection layer for preventing selenium steam from corroding the flexible substrate; an internal-series-connection CIGS solar cell assembly; an organic-inorganic-alternate multilayer composite water-resistant insulation layer, which is prepared on the bottom portion of the internal-series-connection CIGS solar cell assembly, and comprises a high-density insulation inorganic water-resistant film, an organic acrylate layer I and an inorganic water-resistant film; and an organic-inorganic-alternate multilayer composite water-resistant insulation anti-reflection layer, which is prepared on the top portion of the internal-series-connection CIGS solar cell assembly ,and comprises a high-density high-resistance inorganic water-resistant anti-reflection film, an organic acrylate layer II and an inorganic water-resistant anti-reflection film. The high-water-resistance flexible internal-series-connection CIGS solar cell and the preparation method thereof realize formation of an internal-series-connection cell chip and meanwhile, finish water-resistant oxygen-resistant light-receiving surface anti-reflection package of the device; and the water-resistant oxygen-resistant package film can be deposited in a large area on the same production line with a cell device, thereby reducing water-resistant oxygen-resistant package process difficulty of the flexible cell, and facilitating large-area commercial production.

Owner:绵阳皓华光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com