Drum-type sludge turning machine and turning method thereof

A stacker and drum-type technology, which is applied in the preparation of sewage/sludge fertilizer, organic fertilizer, organic fertilizer, etc., can solve the problems of large land occupation, insufficient capacity of stacker, low efficiency of stacker, etc. Achieve the effect of high rotation speed, improved breaking and throwing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

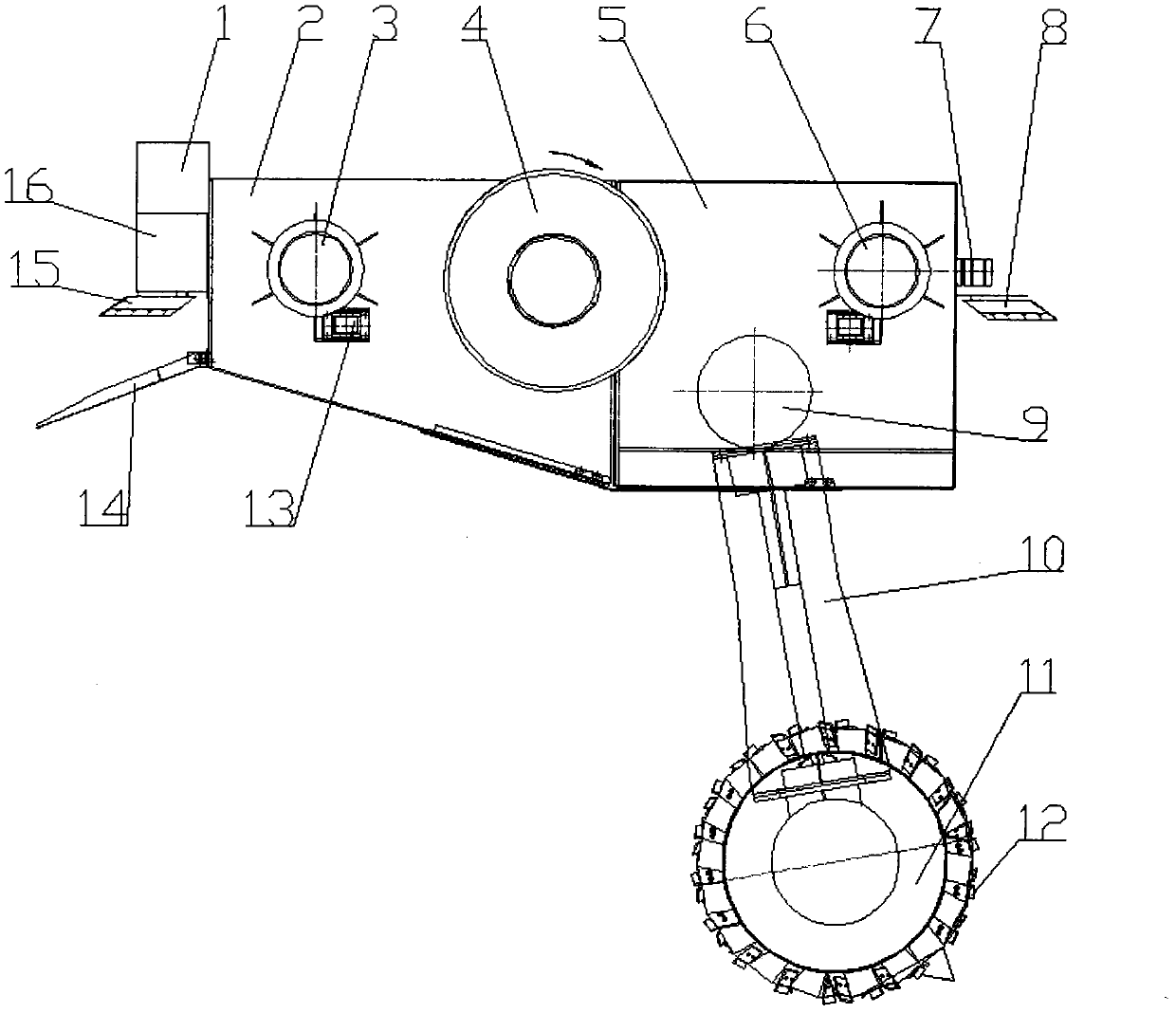

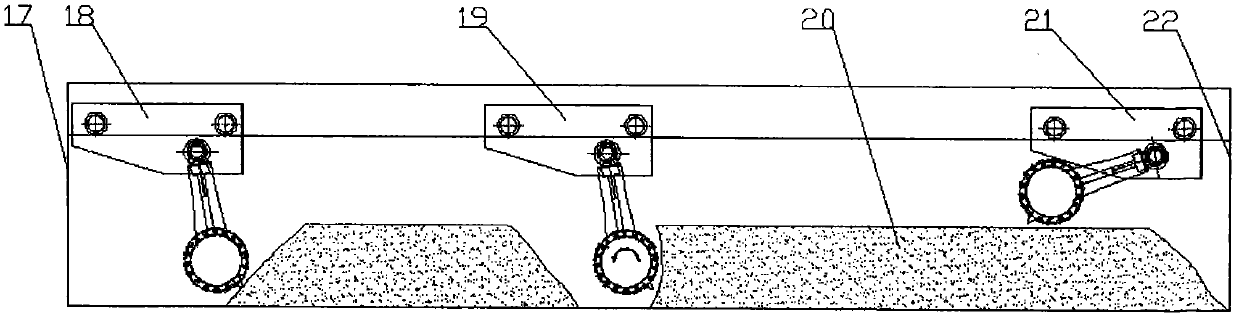

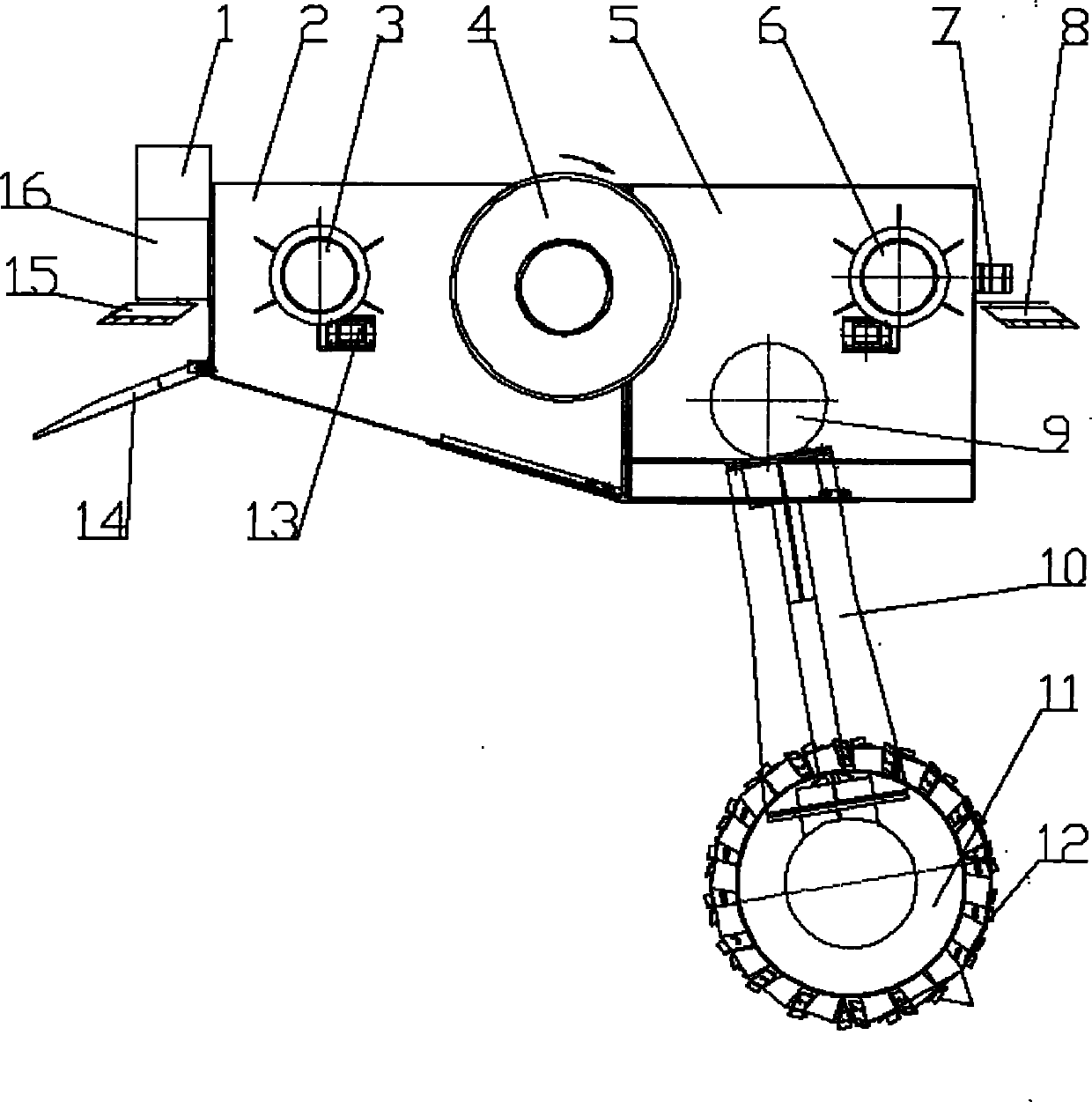

[0014] The structure, turning method and working process of the drum type compost turning machine of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] The overall frame of the drum type compost turner is formed by connecting the rear frame 2 and the front frame 5. The driving wheel 6 and the driven wheel 3 are located at the front and rear ends of the frame, which play a role in driving the compost turner to walk. When the compost turner is working, the drum 11 rotates counterclockwise, and the knives 12 on the drum 11 throw the material 20 backwards, so as to achieve the effect of overall compost turning and displacement.

[0016] When the compost turner starts to work, it is located at the initial working position 18. The driving wheel 6 drives the machine forward, and at the same time, the drum motor 9 drives the drum 11 to rotate, throwing the material 20 obliquely backward. During the turning process, the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com