Super capacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, applied in the field of nanomaterials, can solve the problems of not forming nanorod arrays and unsatisfactory specific capacitance values, and achieve the effects of improving utilization, reducing electrode dead area, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

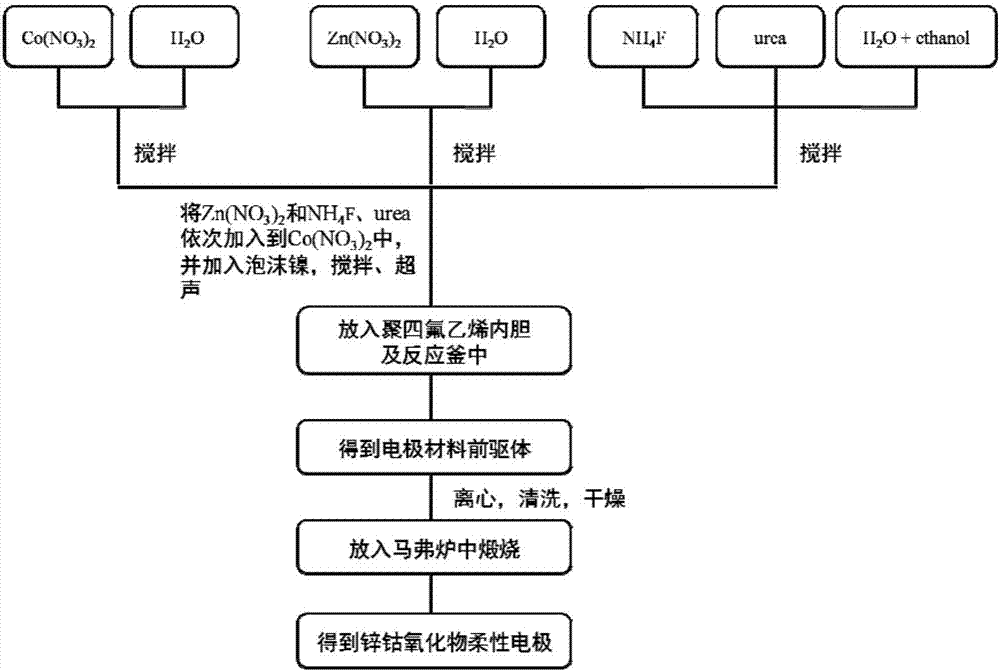

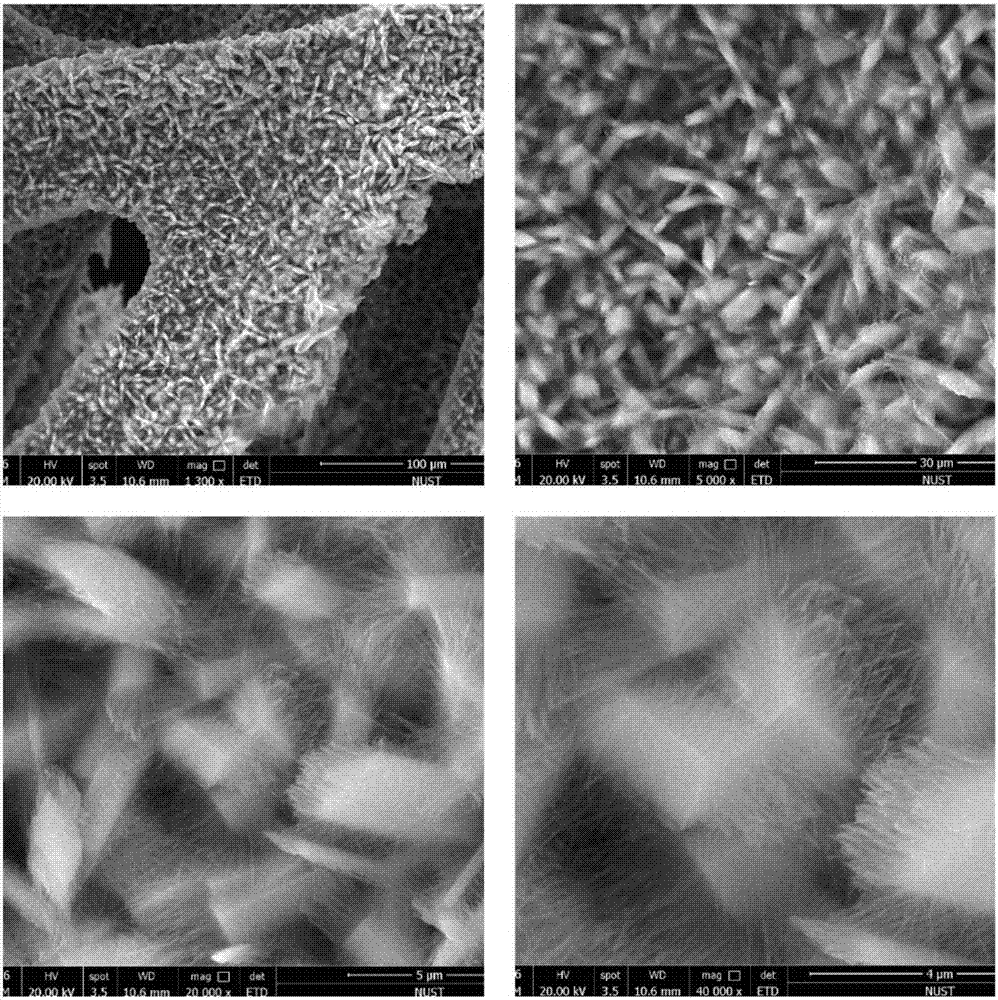

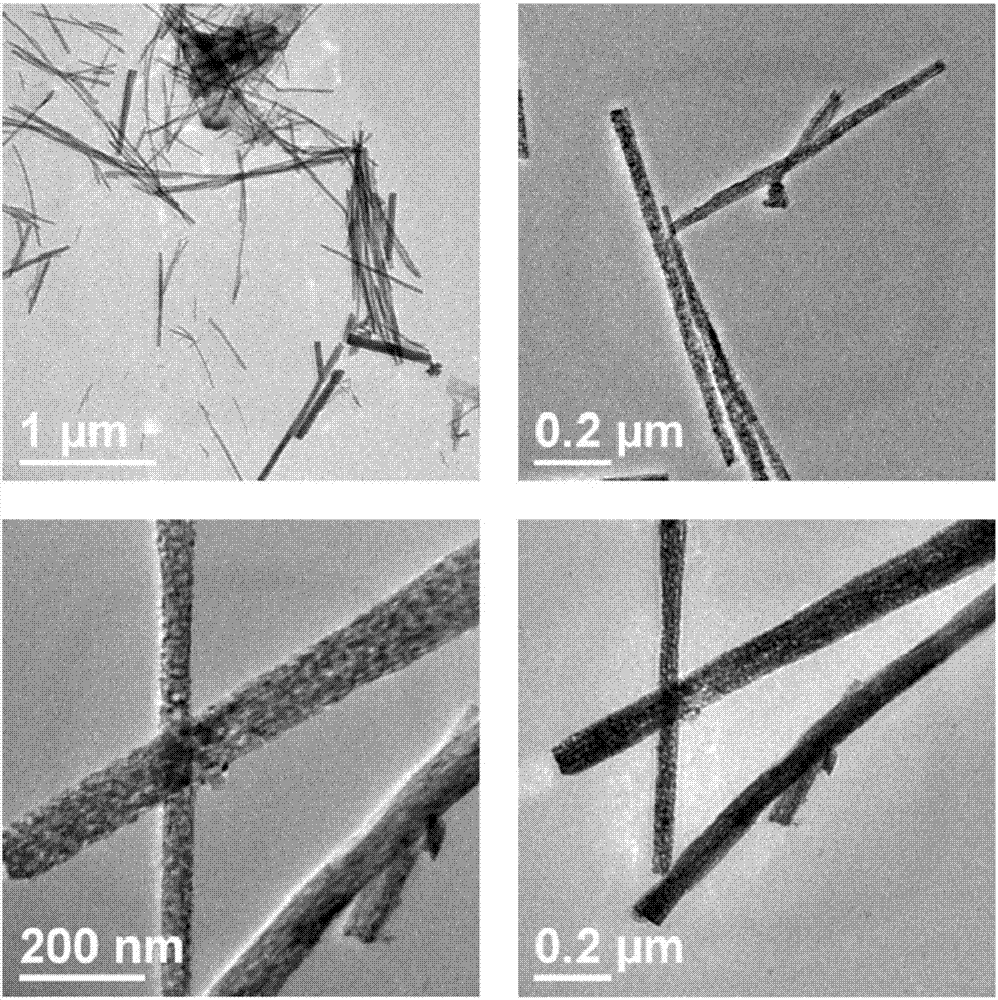

[0038]Step 1: Dissolve 1 mmol of zinc nitrate hexahydrate in 15 mL of deionized water and stir for 30 minutes; 2 mmol of cobalt nitrate hexahydrate in 15 mL of deionized water and stir for 30 minutes; 2 mmol of ammonium fluoride and Add 3 mL of deionized water to 5 mmol of urea to dissolve it, then add 37 mL of pure ethanol and stir for 30 minutes, then add zinc nitrate and ammonium fluoride-urea dropwise to zinc nitrate, and stir the mixed solution for 30 minutes minute;

[0039] Step 2: Pour the treated nickel foam and the prepared solution into the reaction kettle, and react at 150°C for 9 hours to obtain the electrode precursor;

[0040] Step 3: After the reaction, cool the reactor to room temperature naturally, take out the electrode precursor, wash it with deionized water and ethanol, and dry it after ultrasonic

[0041] Step 4: Put the dried electrode into a tube furnace, calcinate it under a nitrogen atmosphere, set the temperature rise gradient to 2 °C / min, keep it a...

Embodiment 2

[0045] Step 1: Dissolve 1 mmol of zinc nitrate hexahydrate in 15 mL of deionized water and stir for 30 minutes; 2 mmol of cobalt nitrate hexahydrate in 15 mL of deionized water and stir for 30 minutes; 2 mmol of ammonium fluoride and Add 5 mmol of urea to 3 mL of deionized water to dissolve it, then add 37 mL of ethanol and stir for 30 minutes, then add zinc nitrate and ammonium fluoride-urea dropwise to zinc nitrate, and stir the mixed solution for 30 minutes;

[0046] Step 2: Pour the treated nickel foam and the prepared solution into the reaction kettle, and react at 160 ° C for 8 hours to obtain the electrode precursor;

[0047] Step 3: After the reaction, cool the reactor to room temperature naturally, take out the electrode precursor, wash it with deionized water and ethanol, and dry it after ultrasonic

[0048] Step 4: Put the dried electrode into a tube furnace, calcinate it under a nitrogen atmosphere, set the temperature rise gradient to 5 °C / min, keep it at 400 °C f...

Embodiment 3

[0051] Step 1: Dissolve 1 mmol of zinc nitrate hexahydrate in 15 mL of deionized water and stir for 30 minutes; 2 mmol of cobalt nitrate hexahydrate in 15 mL of deionized water and stir for 30 minutes; 2 mmol of ammonium fluoride and Add 5 mmol of urea to 3 mL of deionized water to dissolve it, then add 37 mL of ethanol and stir for 30 minutes, then add zinc nitrate and ammonium fluoride-urea dropwise to zinc nitrate, and stir the mixed solution for 30 minutes ;

[0052] Step 2: Pour the treated nickel foam and the prepared solution into the reaction kettle, and react at 140 ° C for 10 hours to obtain the electrode precursor;

[0053] Step 3: After the reaction, cool the reactor to room temperature naturally, take out the electrode precursor, wash it with deionized water and ethanol, and dry it after ultrasonic

[0054] Step 4: Put the dried electrode into a muffle furnace, calcinate it under a nitrogen atmosphere, set the temperature rise gradient to 5 °C / min, keep it at 450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com