Solar cell module and manufacturing method thereof

A technology of solar cells and modules, applied in the field of solar cells, which can solve the problems of extremely high requirements for instruments and equipment, reduction of the effective active area of photoelectric generation, and occupied effective area, so as to reduce the ineffective area, high space utilization rate, and save space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a solar cell module, comprising the following steps:

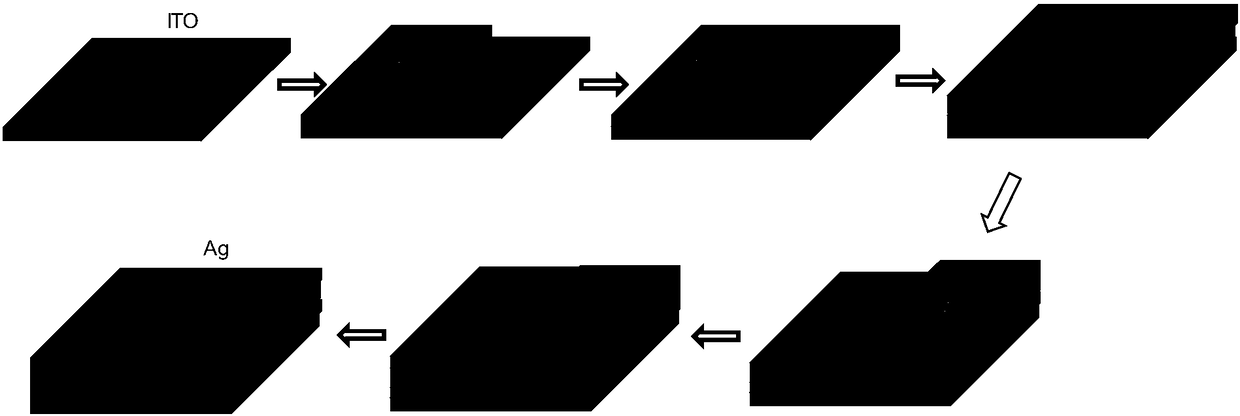

[0040] (1) Prepare a patterned bottom electrode on the substrate; the patterned bottom electrode includes several closely spaced bottom electrode units, and the bottom electrode unit includes two bottom electrode blocks, and the two bottom electrode blocks pass through the first A connection block is connected to form the first Z-shaped bottom electrode unit, and several first Z-shaped bottom electrode units arranged at equal intervals are the patterned bottom electrodes. The material selected for the first connection block and the bottom electrode The selected materials are the same; the distance between the bottom electrode units is preferably not more than 1 mm; the substrate of the bottom electrode can be glass, polyethersulfone resin (PES), polyethylene terephthalate (PET) or polyethylene For ethylene naphthalate (PEN), the bottom electrode can be conductive glass (...

Embodiment 1

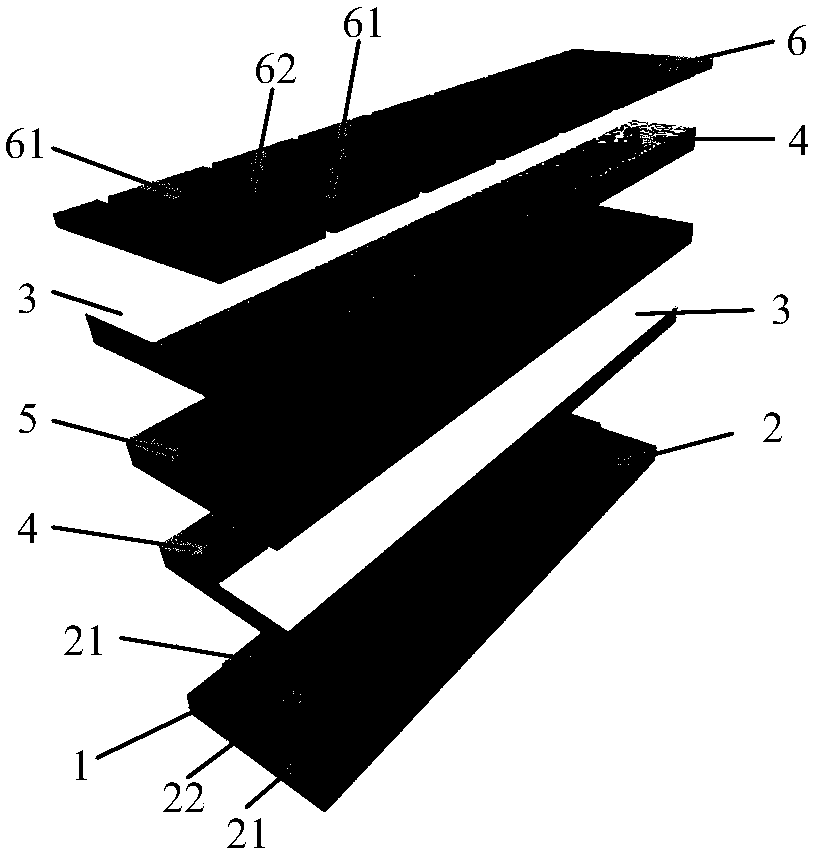

[0049] The solar cell module provided in this embodiment, the schematic diagram of its internal structure, such as figure 1 As shown, 1-substrate; 2-patterned bottom electrode; 21-bottom electrode block; 22-first connection block; 3-electron transport layer; 4-hole transport layer; 5-photoactive layer; 6- Patterned top electrode, 61-top electrode block; 62-second connection block; from bottom to top:

[0050] Patterned bottom electrode: the first Z-shaped bottom electrode unit arranged closely at equal intervals on the substrate, each bottom electrode unit consists of two bottom electrode blocks and a first connection block connecting the two electrode blocks Composition, the two bottom electrode blocks are connected and form the first zigzag;

[0051] The first interface layer: including a hole transport layer and an electron transport layer, the electron transport layer and the hole transport layer are in direct contact and respectively cover both sides of the first connect...

Embodiment 2

[0065] In this embodiment, the bottom electrodes are etched from ITO glass, and the patterns are arranged in a "Z" shape.

[0066] In the solar cell module, the hole transport layer below adopts a spin-coating process, and a strip of nickel oxide precursor solution is coated on the substrate, and then placed on a hot stage to sinter to form a dense nickel oxide film. This film is used to block electrons and collect holes.

[0067] In the solar cell module, the electron transport layer below adopts the spin-coating process. First, a layer of PEIE aqueous solution is spin-coated, and then a layer of CTAB:PCBM chloroform solution is spin-coated to form a two-layer film for collecting electrons and blocking holes.

[0068] In the solar cell module, the photoactive layer is spin-coated perovskite solution, and then sintered at 100°C to form a light-absorbing layer of about 200nm.

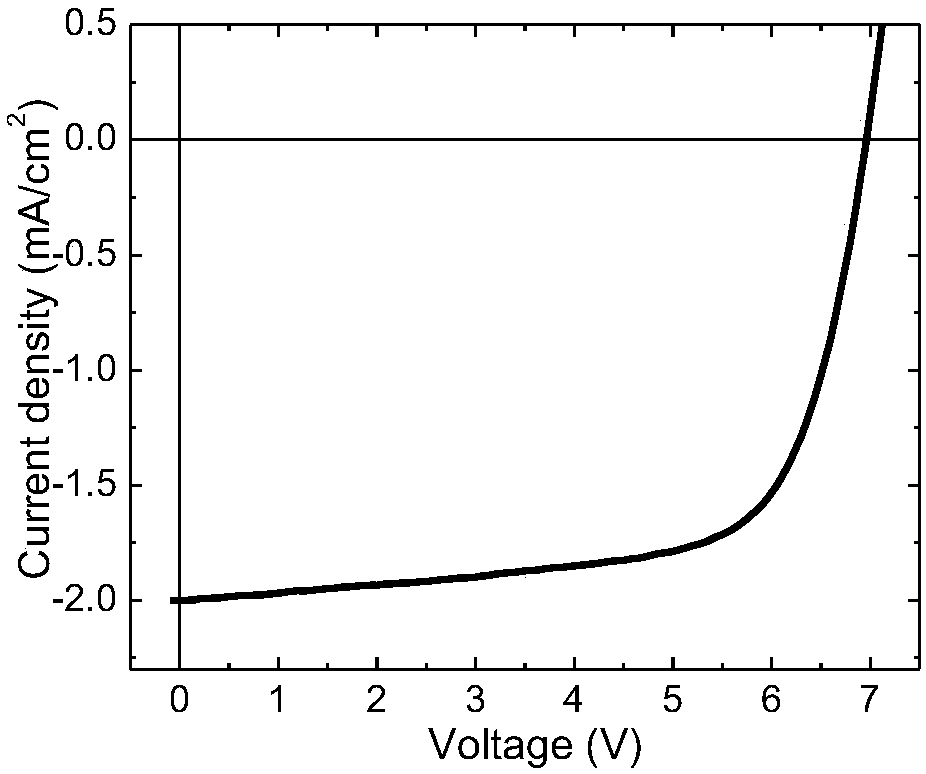

[0069] The upper hole transport layer and electron transport layer are also spin-coated, and Spiro a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com