Powder resistivity testing device

A powder and test fixture technology, applied in measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve the problems of limited measuring range, difficult to replace configuration volume, limited material quantity, etc., to achieve stable pressure and easy use. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

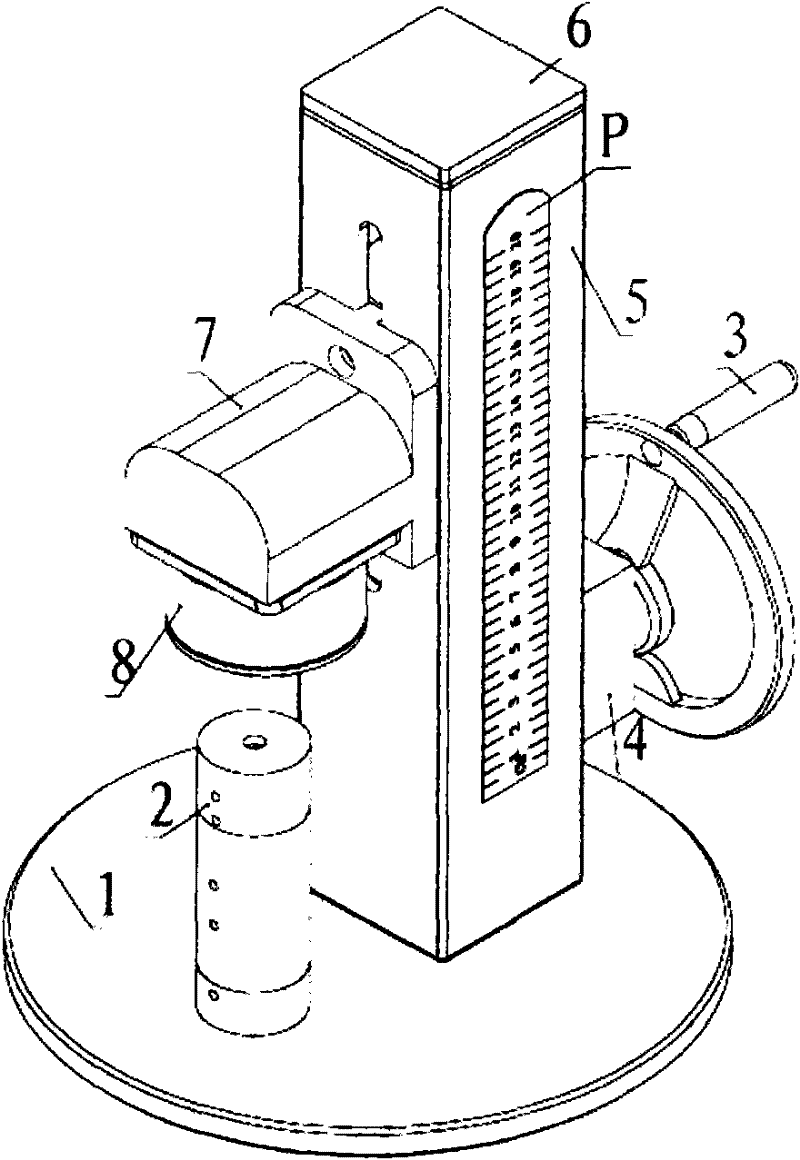

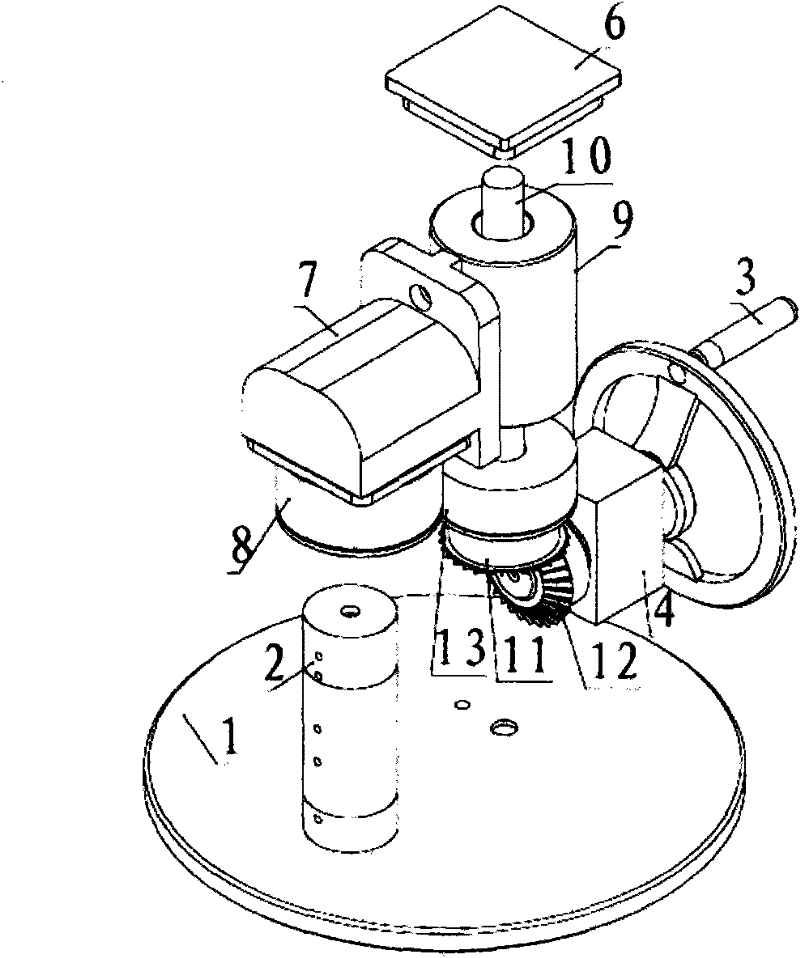

[0028] The test frame includes rack, pressure mechanism and powder standard container.

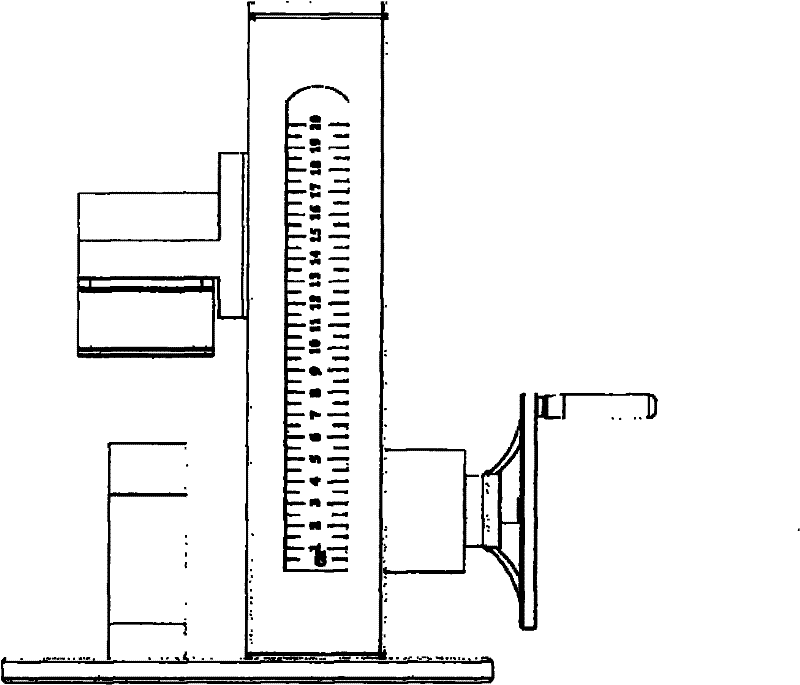

[0029] The frame includes a base 1 and a guide rail device 5 fixed on the base 1; a cover 6 is provided on the upper part of the guide rod device, and a vernier caliper P is provided on the side, which is characterized in that it can accurately display the capacity of powder in a standard container 1 . The interior is provided with a stud 9 and a screw screw 10, the stud 9 and the screw screw 10 are connected to the large gear 11 through the cam 13, and the large gear 11 is bonded to the pinion 12 while passing through the outer surface of the fixed seat 4. The power handle 3 reaches the gear transmission, and the purpose drives the pressurizing mechanism to pressurize.

[0030] The pressure mechanism includes a mobile frame 7 and a pressure sensor 8 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com